PBT (polybutylene terephthalate) zipper material with high modulus and washability and application of PBT zipper material

A water-washable, high-modulus technology, applied in the field of zipper preparation, can solve the problems of unfavorable processing technology, instability, and very high requirements for blending technology, and achieve the advantages of improving deformation resistance, increasing adhesion, and reducing agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

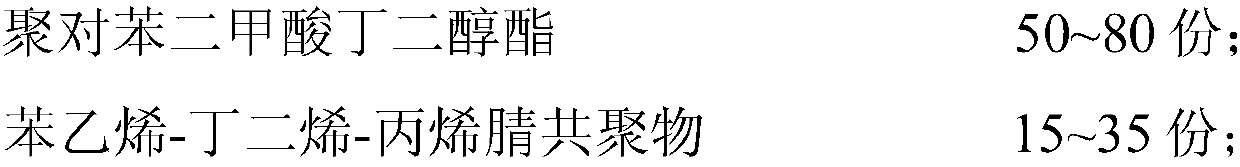

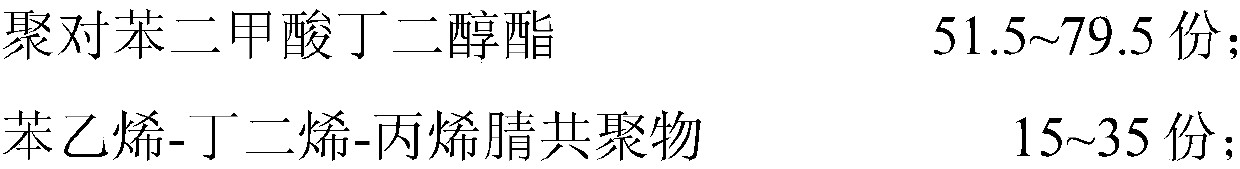

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of modified nucleating agent comprises the steps:

[0048] Gradually add 50 parts by weight of mineral powder to 50 parts by weight of water, then add 1% acetylacetone of the total weight of the solution, stir until uniform, and slowly add 10 parts by weight of butyl titanate and each Mineral and water weight 1% polycarboxylate sodium salt and titanate coupling agent, after the dropwise addition, continue to stir for 0.5 hours, under the action of acetylacetone, butyl titanate is hydrolyzed to generate titanium dioxide particles, and coated on On the surface of mineral particles, polycarboxylate sodium salt is added as a dispersant, and the surface is modified with a water-based titanate coupling agent. The coated titanium dioxide particles are filtered, dried and pulverized to prepare a modified nucleating agent, which is taken out for use.

[0049] The material performance test method is as follows:

[0050] 1. Material bronzing quality: under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com