Anti-ageing PP/HDPE (Polypropylene/High-Density Polyethylene) plastic for automobile interior and preparation method thereof

An anti-aging technology for automotive interior parts, which is applied in the field of anti-aging PP/HDPE plastics for automotive interior parts and its preparation, and can solve problems such as poor anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] After weighing each raw material according to the data corresponding to Example 1 in Table 1, add it to a high-speed mixer for stirring, control the speed at 300-400r / min, stir at a temperature of 70-90°C, and stir for 2-4 minutes, and then extrude through a screw Machine extruding and granulating, the extrusion temperature is 170-210 DEG C, cooling and molding in cold water of 10-40 DEG C, and the anti-aging PP / HDPE plastics for automotive interior parts are obtained.

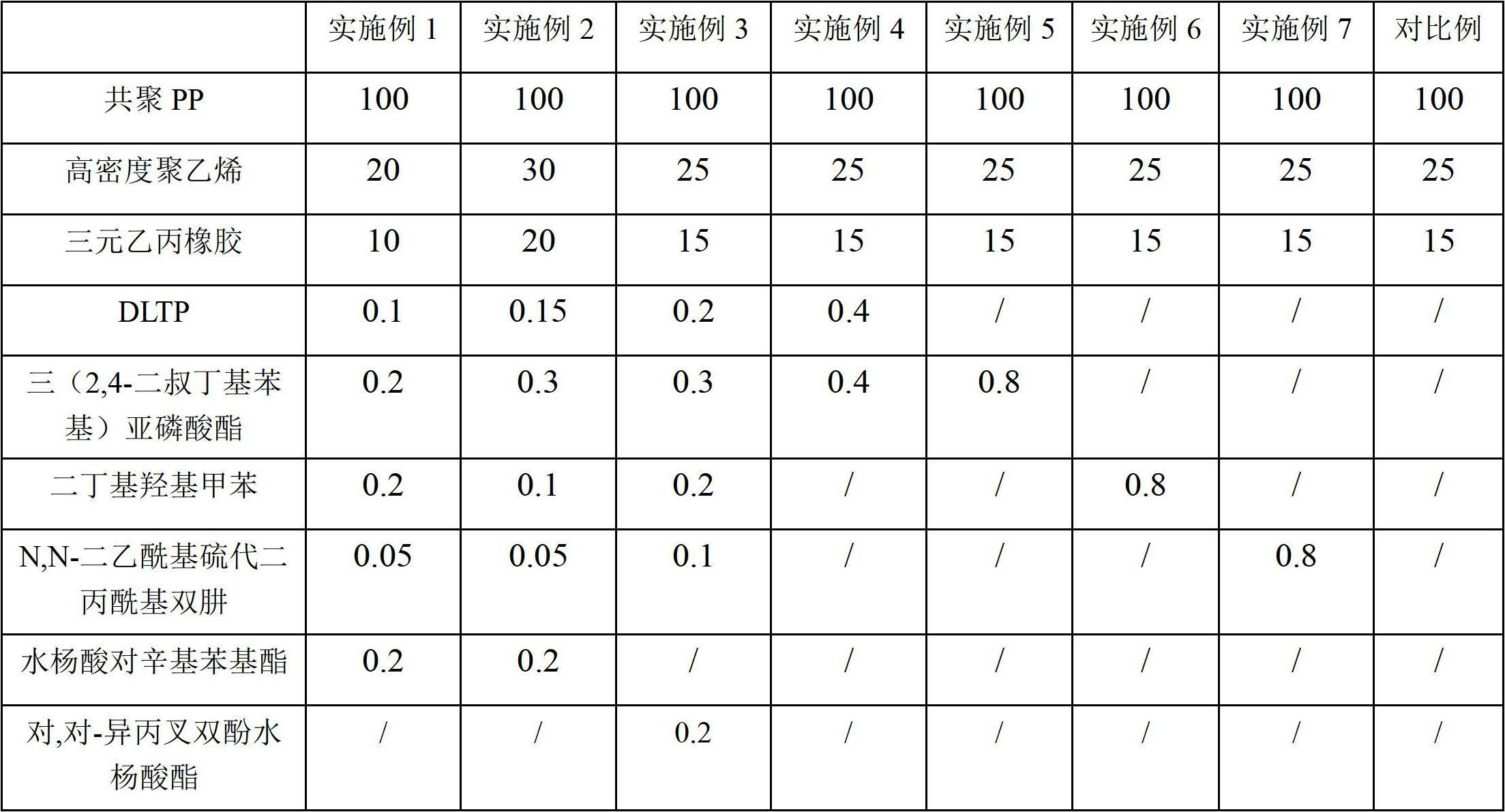

[0031] Table 1: Formula table of anti-aging PP / HDPE plastics for automotive interior parts Unit: kg

[0032]

Embodiment 2

[0034] Each raw material was weighed according to the data corresponding to Example 2 in Table 1. The method described in Example 1 was used to prepare the anti-aging PP / HDPE plastic for automotive interior parts.

Embodiment 3

[0036] Each raw material was weighed according to the data corresponding to Example 3 in Table 1. The method described in Example 1 was used to prepare the anti-aging PP / HDPE plastic for automotive interior parts.

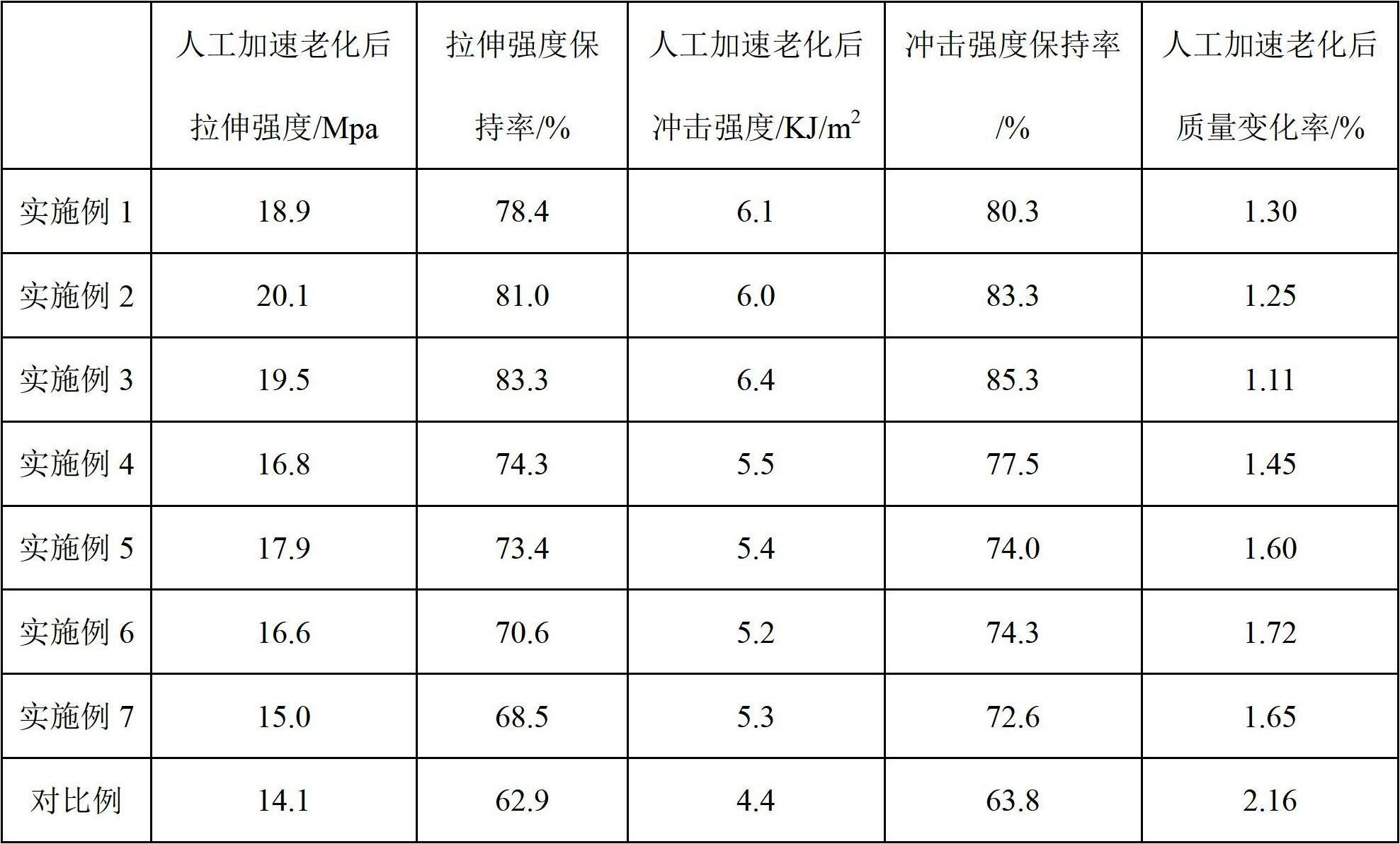

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com