Multifunctional colored concrete structure and preparation process

A color concrete, multi-functional technology, applied in the direction of adhesive type, adhesive additive, construction, etc., can solve the problem that concrete cannot meet the diversified needs of roads or ground, and achieve the effect of increasing strength and improving functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

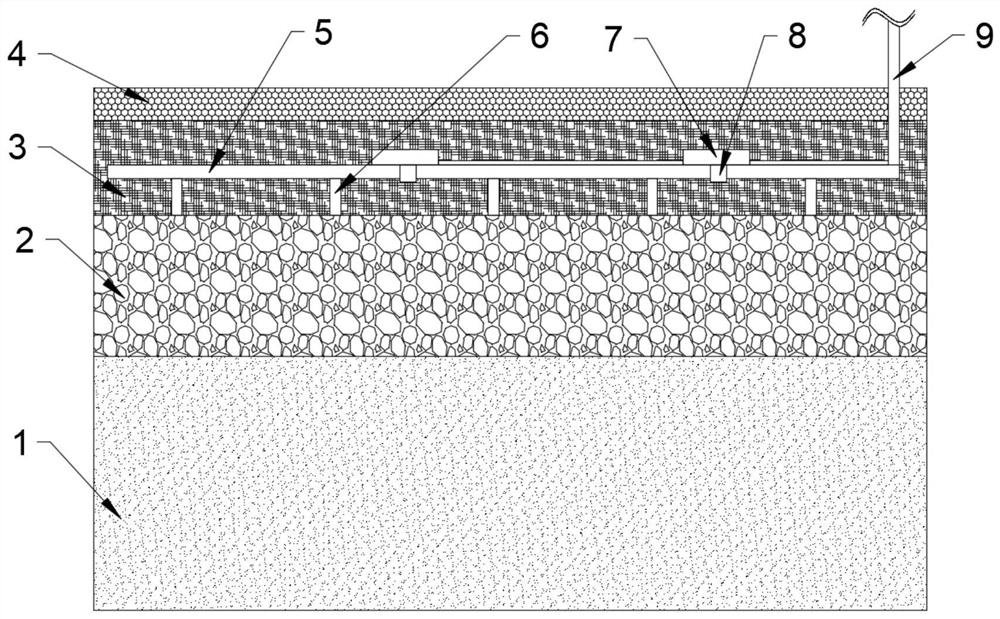

[0032] The present invention also provides a preparation process for a multifunctional colored concrete structure, comprising the following steps:

[0033] Step 1: Spread the base soil layer 1 and tamp it with a 500kg road roller; then lay the gravel layer 2 and level it mechanically, and finally use a small excavator for preliminary tamping;

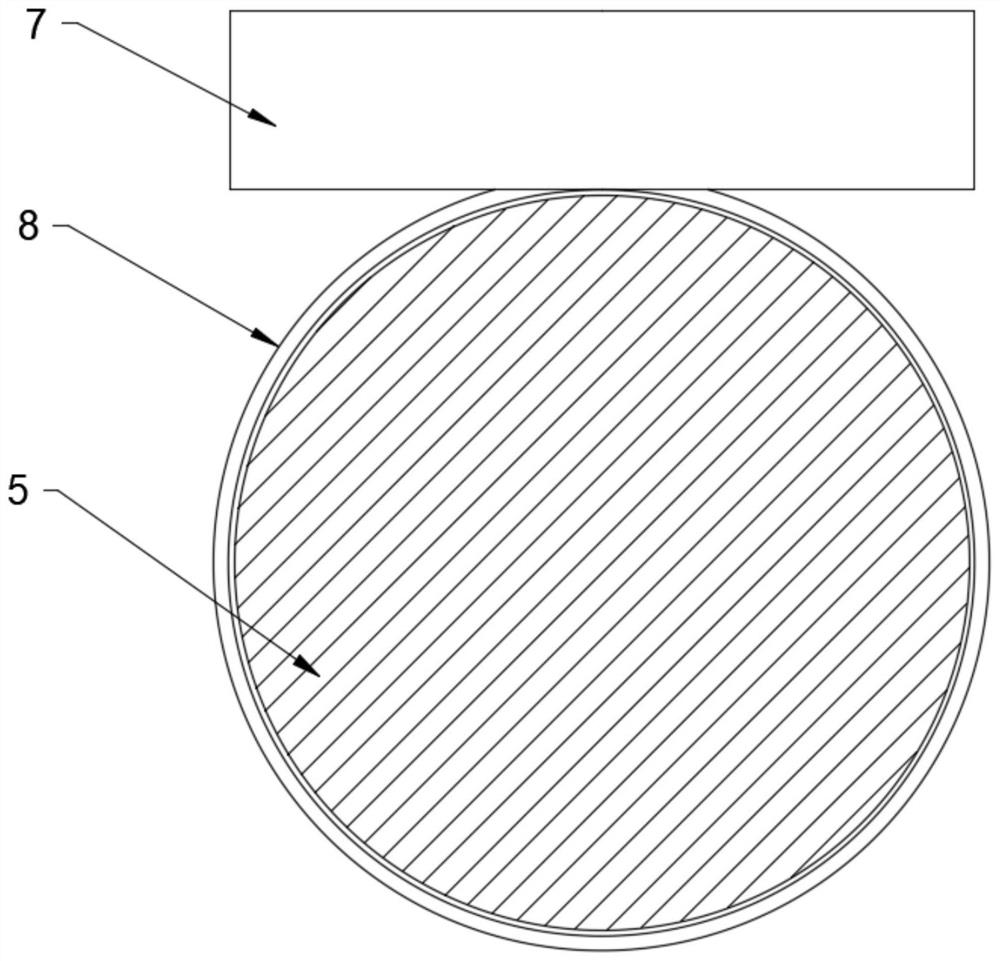

[0034] Step 2: Support the steel bar 5 on the gravel layer 2 through the steel bar support frame 6, and then install a plurality of detection elements 7 on the steel bar 5 at intervals;

[0035] Step 3: Mix and stir 80 parts of aggregate, 15 parts of cement, 15 parts of water and 8 parts of anti-cracking fiber to obtain concrete, pour concrete on the crushed stone layer 2 to be higher than the steel bar 5, and then obtain it by manual scraping or mechanical leveling The concrete layer 3 is finally covered with plastic film or other coverings and left to dry;

[0036] Step 4: After stirring 50 parts of styrene-butadiene rubber and 10 pa...

Embodiment 2

[0039] The present invention also provides a preparation process for a multifunctional colored concrete structure, comprising the following steps:

[0040] Step 1: Spread the base soil layer 1 and tamp it with a 500kg road roller; then lay the gravel layer 2 and level it mechanically, and finally use a small excavator for preliminary tamping;

[0041] Step 2: Support the steel bar 5 on the gravel layer 2 through the steel bar support frame 6, and then install a plurality of detection elements 7 on the steel bar 5 at intervals;

[0042] Step 3: Mix and stir 90 parts of aggregate, 17 parts of cement, 17 parts of water and 10 parts of anti-cracking fiber to obtain concrete, pour concrete on the gravel layer 2 to be higher than the steel bar 5, and then obtain it by manual scraping or mechanical leveling The concrete layer 3 is finally covered with plastic film or other coverings and left to dry;

[0043] Step 4: After stirring 65 parts of styrene-butadiene rubber and 12 parts of...

Embodiment 3

[0046] The present invention also provides a preparation process for a multifunctional colored concrete structure, comprising the following steps:

[0047]Step 1: Spread the base soil layer 1 and tamp it with a 500kg road roller; then lay the gravel layer 2 and level it mechanically, and finally use a small excavator for preliminary tamping;

[0048] Step 2: Support the steel bar 5 on the gravel layer 2 through the steel bar support frame 6, and then install a plurality of detection elements 7 on the steel bar 5 at intervals;

[0049] Step 3: Mix and stir 100 parts of aggregate, 20 parts of cement, 20 parts of water and 13 parts of anti-cracking fiber to obtain concrete, pour concrete on the crushed stone layer 2 to be higher than the steel bar 5, and then obtain it by manual scraping or mechanical leveling The concrete layer 3 is finally covered with plastic film or other coverings and left to dry;

[0050] Step 4: After stirring 80 parts of styrene-butadiene rubber and 15 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com