Ceramic micro-powder master batch, polymer composite material with ceramic texture and preparation methods of ceramic micro-powder master batch and polymer composite material

A technology of ceramic micropowder and composite materials, which is applied in the field of modified polymer resins. It can solve the problems of affecting the mechanical properties of composite materials, affecting the production and manufacturing of composite materials, and reducing the physical properties of polymers, so as to avoid delamination and difficult cutting. Problems, thick texture and appearance, and improvement effect of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

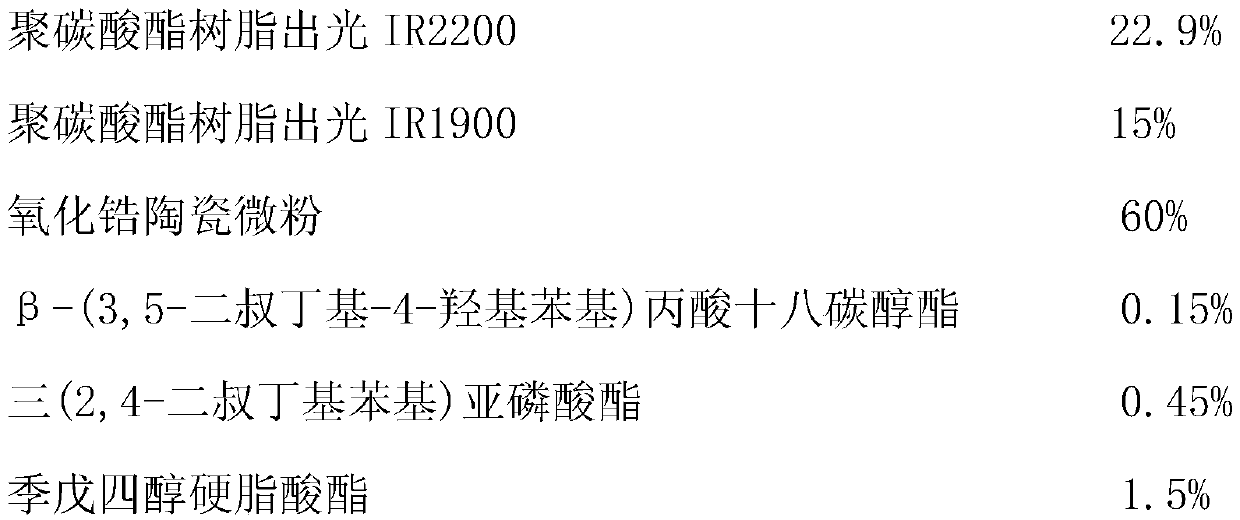

[0038] The formula for making ceramic micropowder masterbatch, raw materials and weight fractions are as follows:

[0039]

[0040] The formula for making a polymer composite material with a ceramic texture, the raw materials and weight fractions are as follows:

[0041]

[0042] The preparation method of ceramic micropowder masterbatch, steps and conditions include: according to the formula of ceramic micropowder masterbatch, weigh 22.9 parts of polycarbonate resin Idemitsu IR2200, 15 parts of polycarbonate resin Idemitsu IR1900, 60 parts of zirconia ceramic micropowder, 0.15 parts β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 0.45 parts of tris(2,4-di-tert-butylphenyl) phosphite, 1.5 parts of pentaerythritol stearyl acid ester; put the above-mentioned other formula components except zirconia ceramic powder into the high-speed mixer and mix evenly; evenly sprinkle 50% of the above-mentioned zirconia ceramic powder components into the high-speed mixer and m...

Embodiment 2

[0046] The formula for making ceramic micropowder masterbatch, raw materials and weight fractions are as follows:

[0047]

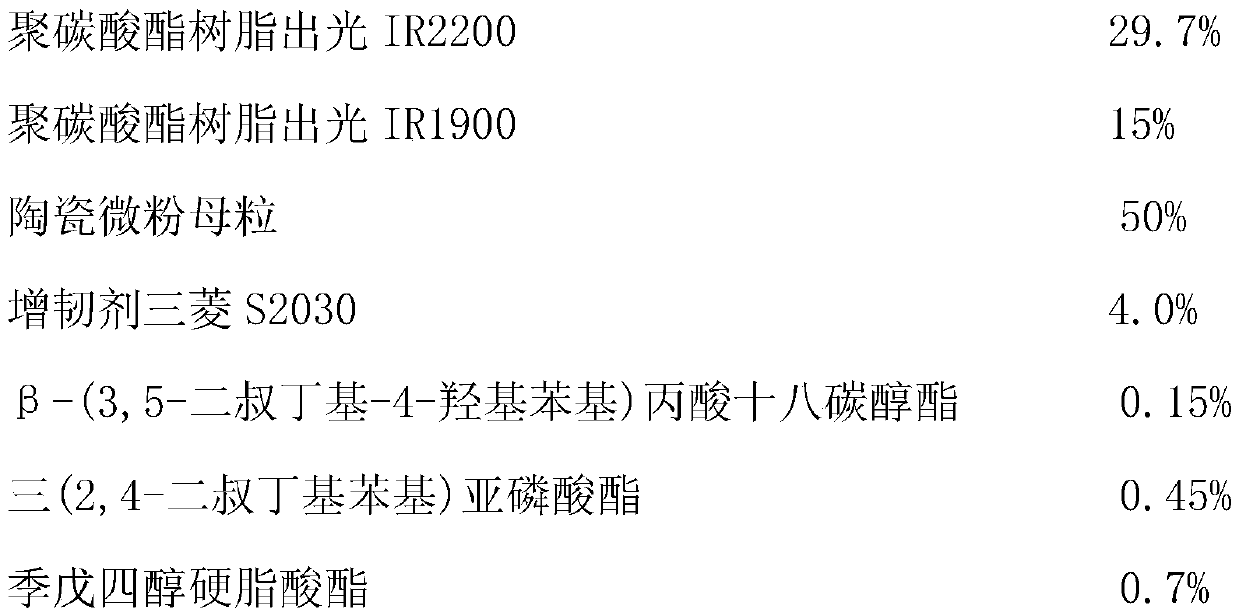

[0048] The formula for making a polymer composite material with a ceramic texture, the raw materials and weight fractions are as follows:

[0049]

[0050]

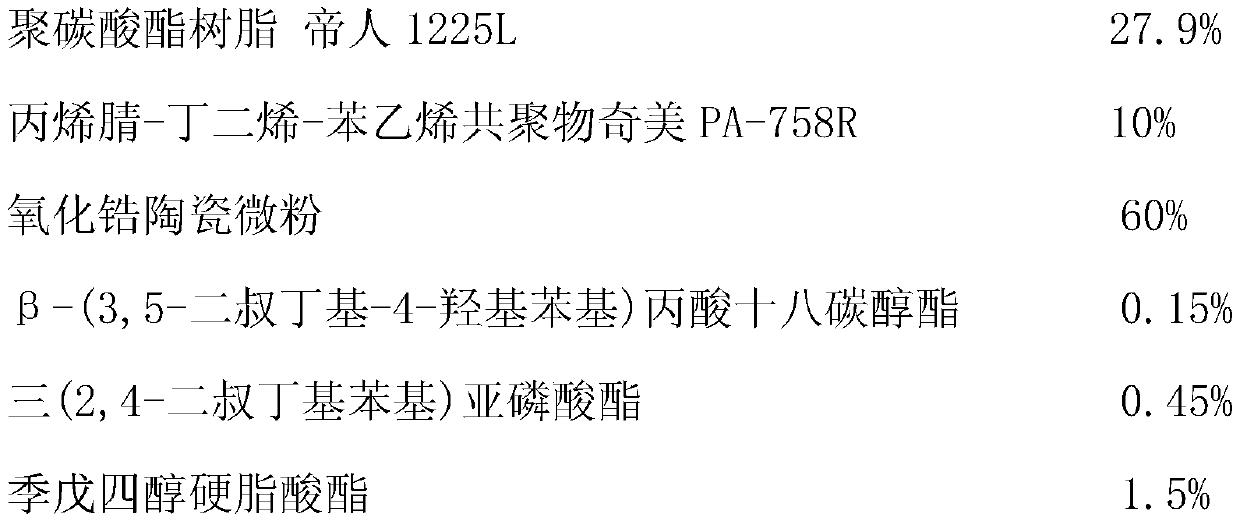

[0051] The preparation method of ceramic micropowder masterbatch, steps and conditions include: according to the formula of ceramic micropowder masterbatch, weigh 27.9 parts of polycarbonate resin Teijin 1225L, 10 parts of acrylonitrile-butadiene-styrene copolymer Chimei PA-758R, 60 parts of zirconia ceramic powder, 0.15 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 0.45 parts of tris(2,4-di-tert-butylphenyl) Phosphite, 1.5 parts of pentaerythritol stearate; put the above-mentioned other formula components except zirconia ceramic powder into the high-speed mixer and mix evenly; 50% of the above-mentioned zirconia ceramic powder components are evenly sprinkled into the...

Embodiment 3

[0055] The formula for making ceramic micropowder masterbatch, raw materials and weight fractions are as follows:

[0056]

[0057] The formula for making a polymer composite material with a ceramic texture, the raw materials and weight fractions are as follows:

[0058]

[0059] The preparation method of ceramic micropowder masterbatch, steps and conditions include: according to the formula of ceramic micropowder masterbatch, weigh 32.9 parts of polybutylene terephthalate Changchun Chemical Industry 1200-211M, 5.0 parts of polyethylene terephthalate Ester-1,4-cyclohexanedimethanol ester Eastman GN071, 60 parts of zirconia ceramic powder, 0.15 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecanol propionate ester, 0.45 parts of tris(2,4-di-tert-butylphenyl) phosphite, 1.5 parts of pentaerythritol stearate; put the above-mentioned other formula components except zirconia ceramic powder into a high-speed mixer and mix them evenly ; Evenly sprinkle 50% of the above zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com