Toilet seat and preparation method thereof

A toilet and seat technology, applied in the field of sanitary ware, can solve the problems of potential safety hazards, non-conformity with long-term skin contact habits, etc., and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] see Figure 9 and Figure 10 , the seat ring of the present invention includes a urea-formaldehyde body and a heating component 3 embedded in the urea-formaldehyde body. Wherein, the urea-formaldehyde body includes a primary molding seat part 4 and a secondary molding seat part 7 .

[0039] see Figure 1 to Figure 8 , the production method of the seat ring of the present invention comprises the following steps

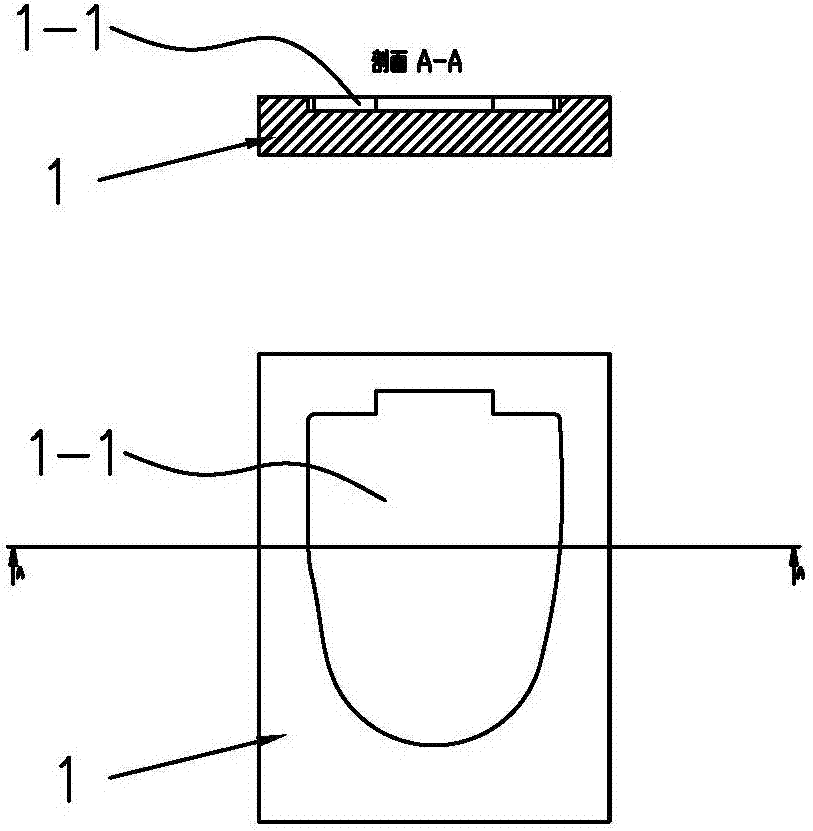

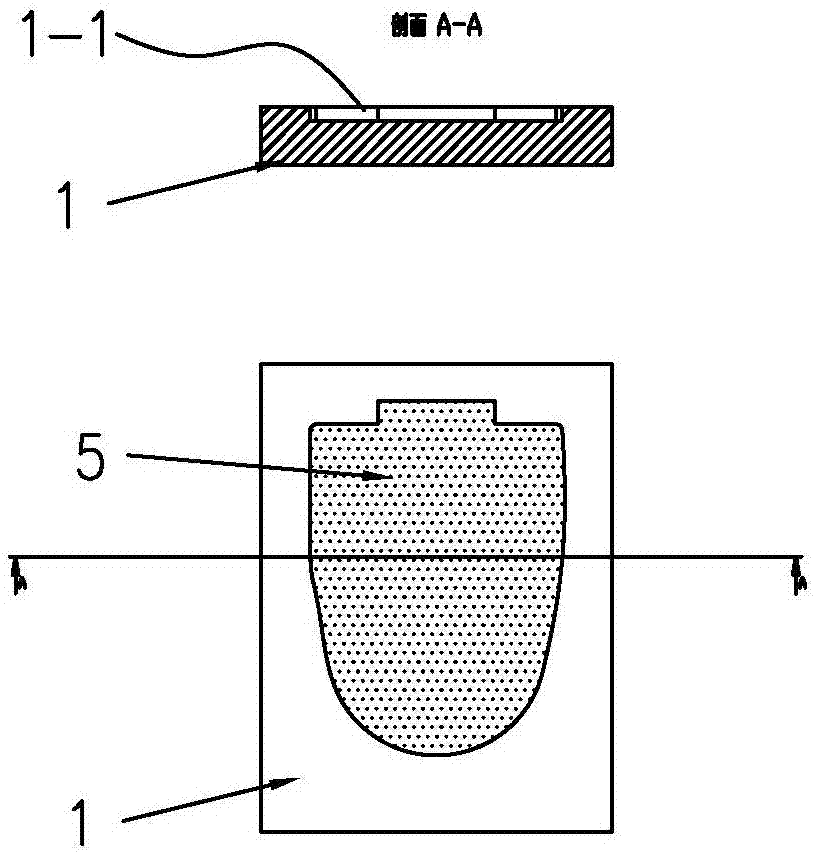

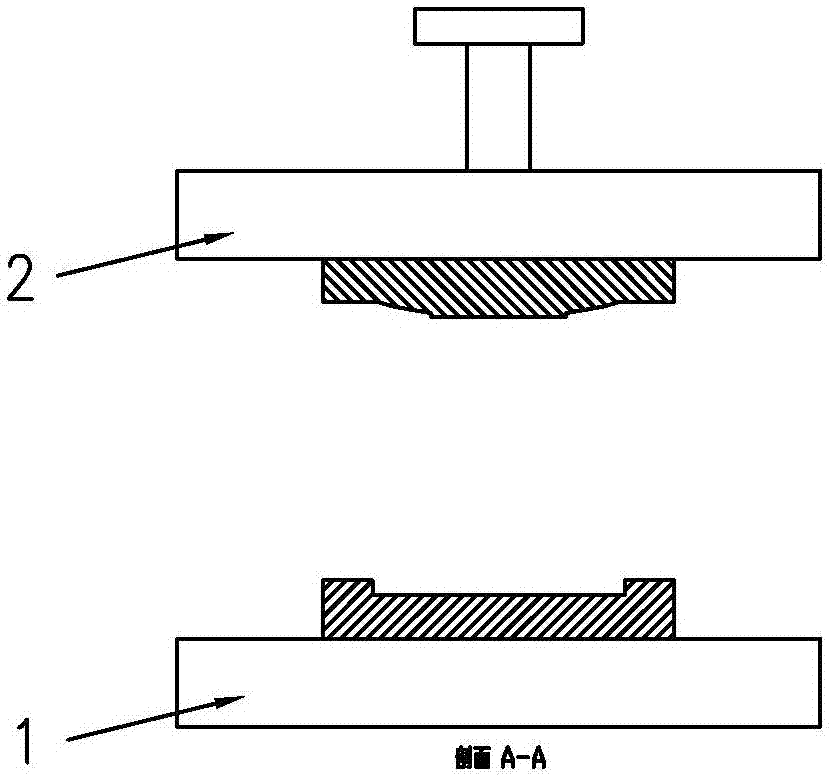

[0040] Provide urea-formaldehyde resin particles; And two sets of molds with upper and lower molds, wherein, the first set is a lower mold 1 and the first upper mold 2, and the second set is a lower mold 1 and a second upper mold 6, that is, the two sets The mold shares the lower mold 1.

[0041] see figure 1 and figure 2 , lay the first layer of urea-formaldehyde particles in the mold cavity 1-1 of the lower mold 1; see image 3 and Figure 4 , close the first upper mold 2 for molding, and form a molding seat ring 4 in the cavity 1-1; open and remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com