Patents

Literature

503results about How to "Smooth exhaust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

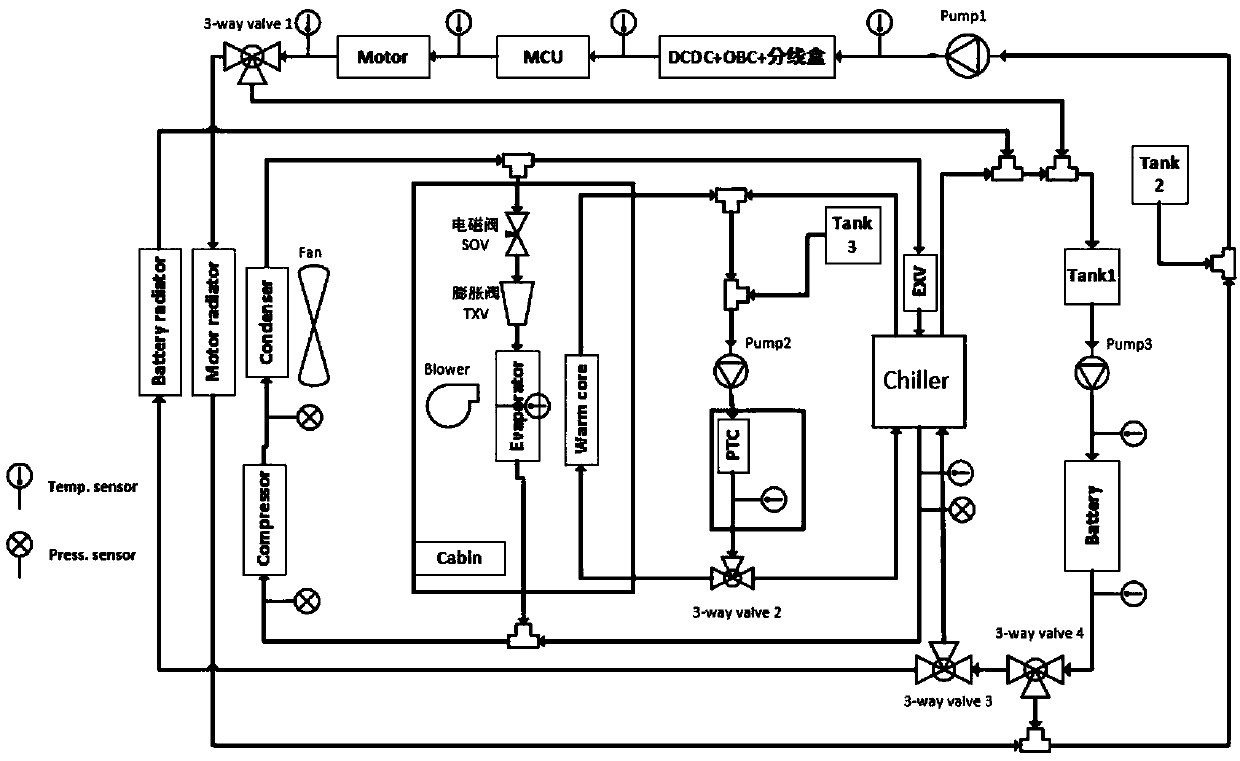

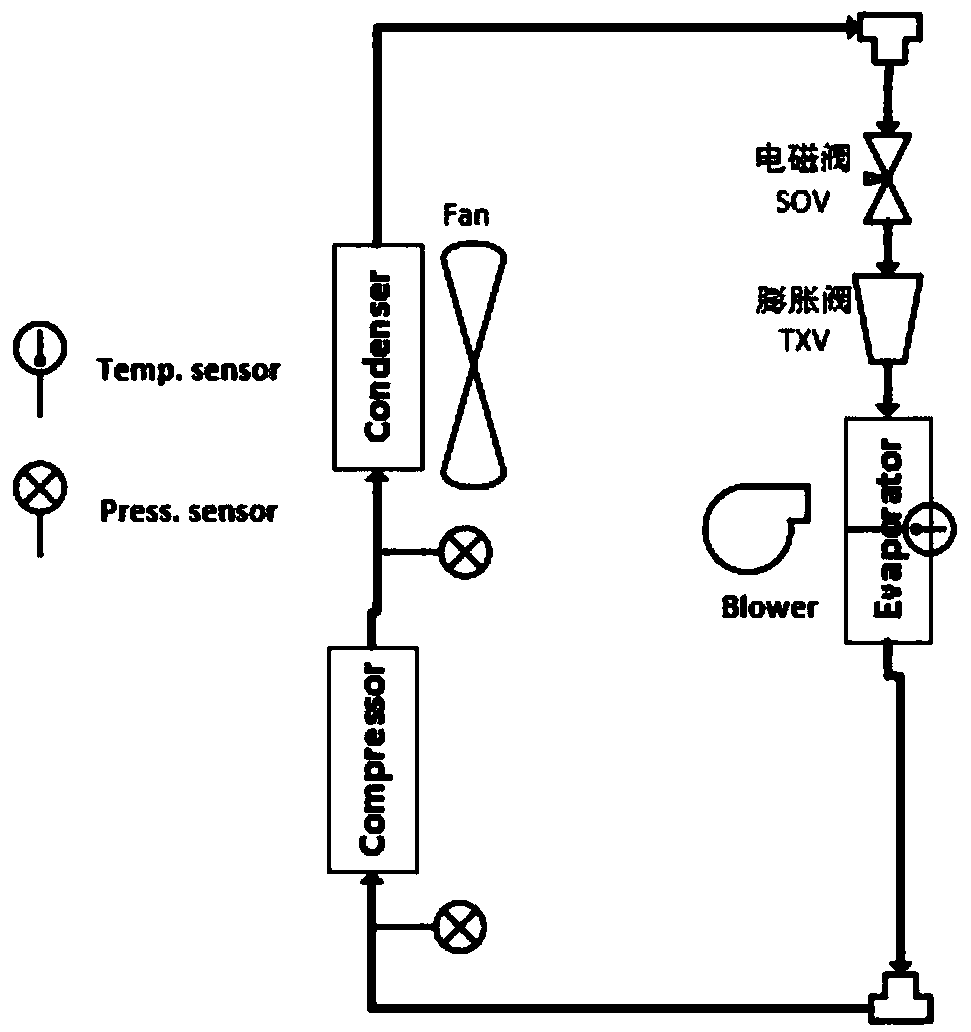

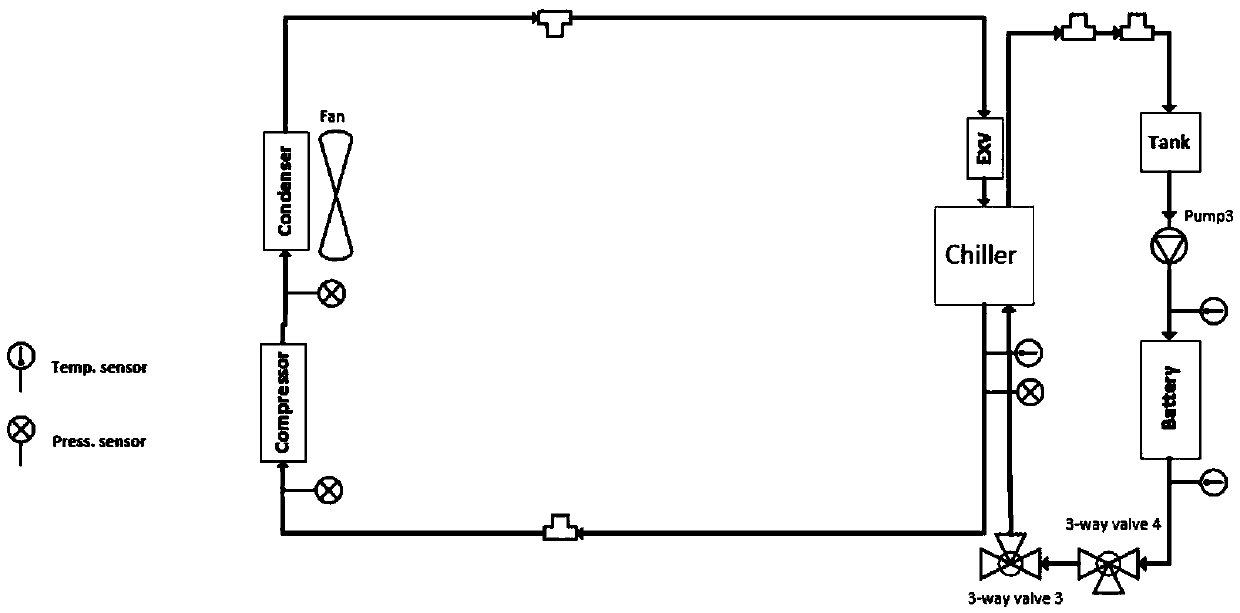

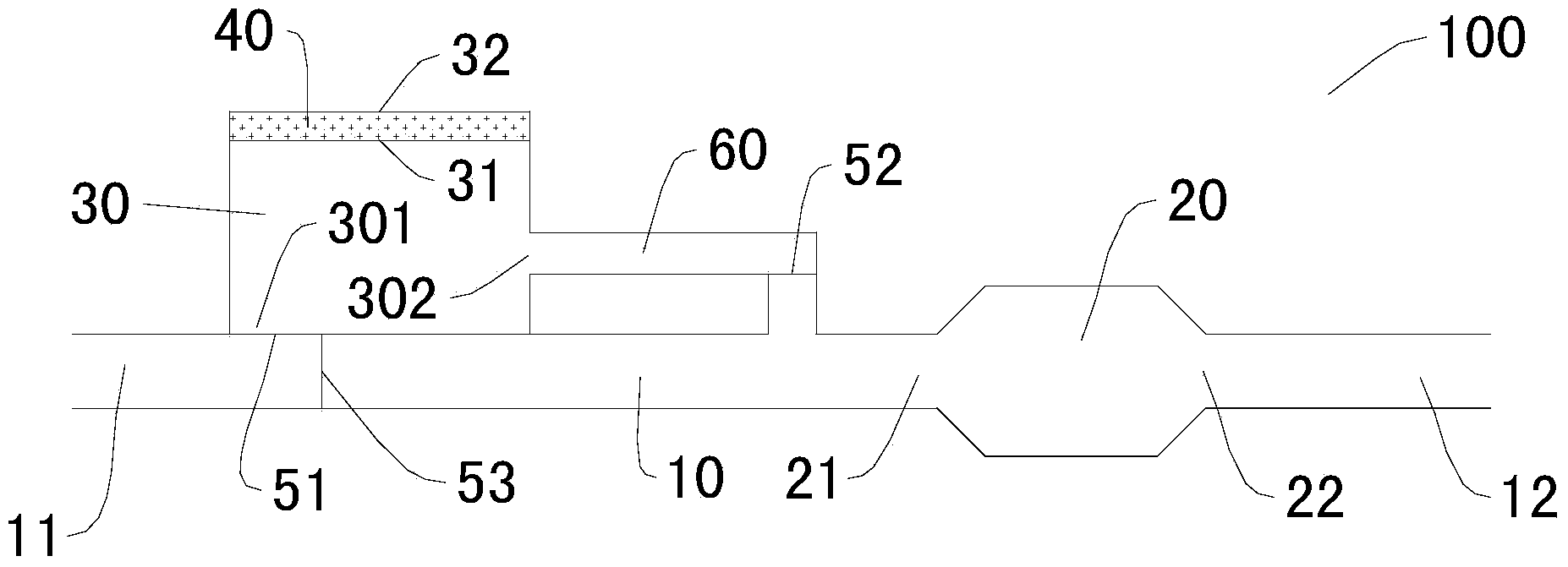

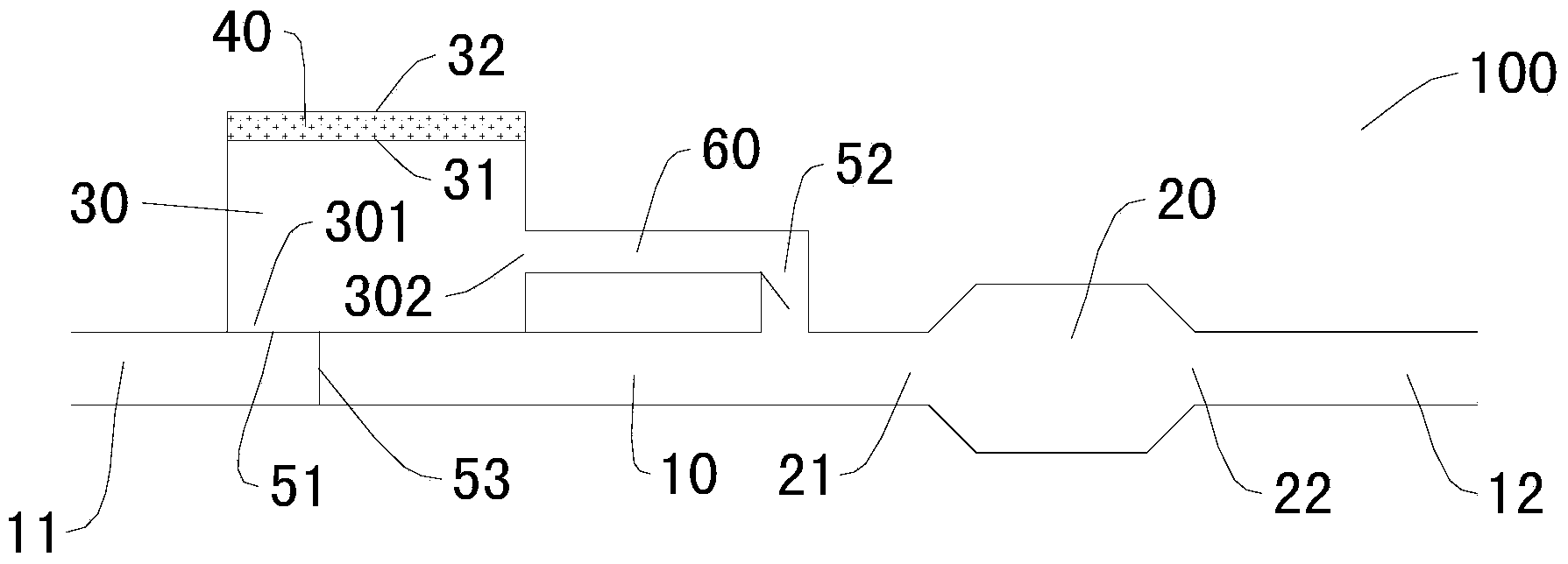

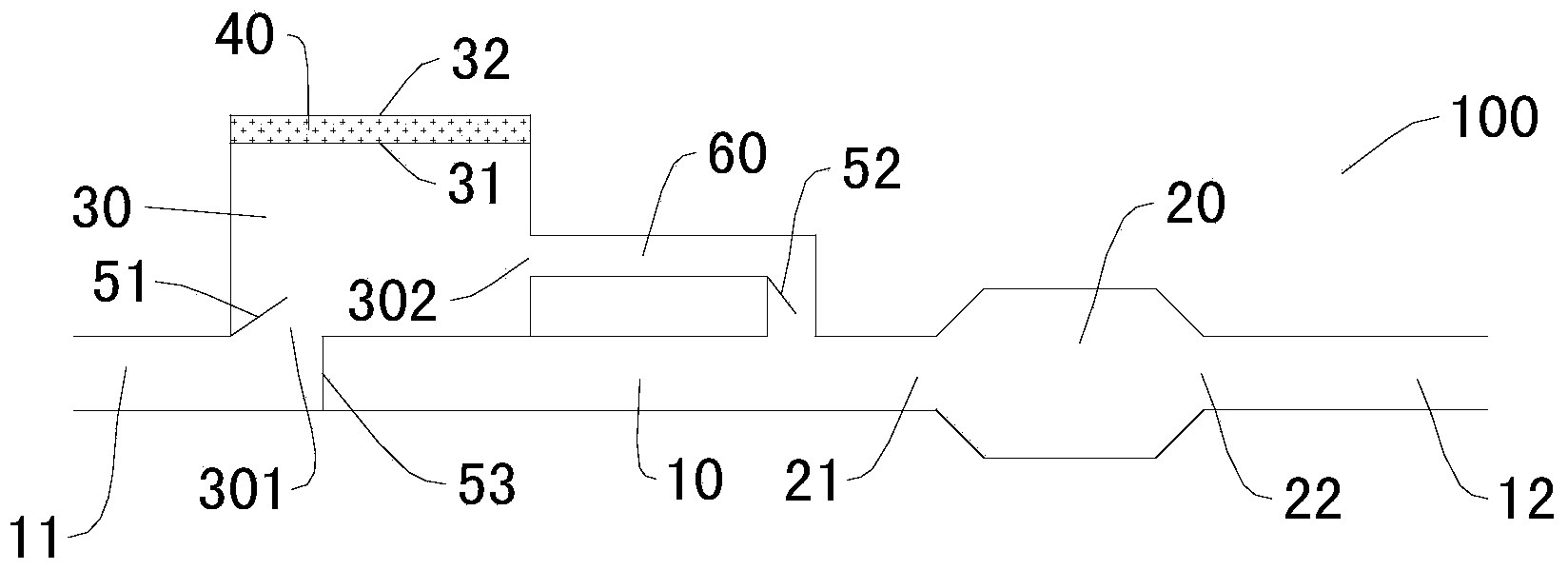

Low-power-consumption heat management system of electric car

InactiveCN109532563AReduce heating effectReduce cooling effectAir-treating devicesSecondary cellsElectrical batterySolenoid valve

The invention relates to an electric car heat management system, in particular to a low-power-consumption heat management system of an electric car. The low-power-consumption heat management system comprises an electric compressor, a condenser, a refrigerant solenoid valve, a thermostatic expansion valve, an HVAC assembly, an electronic expansion valve, a cooler, a first expansion kettle, a thirdelectronic water pump, a fourth three-way valve and a third three-way valve. After the components are combined, a passenger compartment refrigerating cycle loop, a battery forced cooling cycle loop, abattery low-temperature heat radiation cycle loop, a passenger compartment heating cycle loop, a battery forced heating cycle loop, a battery waste heat utilization cycle loop, a battery temperatureequalization cycle loop and a motor cooling cycle loop are formed. According to the low-power-consumption heat management system, the situation that a PTC and the electric compressor are utilized forheating and cooling a battery can be effectively reduced, and therefore the whole car power consumption is reduced, and the driving mileage is increased.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

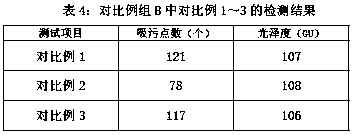

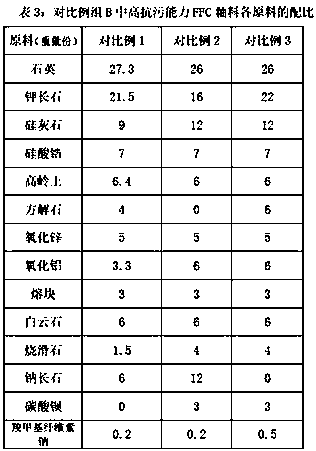

FFC glaze with high stain resistance, FFC sanitary ceramic and preparation method of FFC sanitary ceramic

ActiveCN111253071AExtended firing temperature rangeReduce glaze porosityPotassium feldsparSodium carboxymethylcellulose

The invention discloses an FFC glaze with high stain resistance, an FFC sanitary ceramic and a preparation method of the FFC sanitary ceramic. The FFC glaze with high stain resistance comprises the following raw materials in parts by weight: 22-29 parts of quartz, 24-28 parts of potassium feldspar, 6-10 parts of wollastonite, 7-8 parts of zirconium silicate, 5-10 parts of kaolin, 0-5 parts of calcite, 5-7 parts of zinc oxide, 5-7 parts of aluminum oxide, 2-3 parts of frit, 4-8 parts of dolomite, 5-8 parts of calcined talc, 1-4 parts of barium carbonate and 0.2-0.5 part of sodium carboxymethylcellulose. According to the FFC glaze with high stain resistance, multi-alkali effect is utilized, barium carbonate is introduced, the use amount of calcined talc is increased, and the use amount of albite is reduced, so venting of a green body is more smooth, the porosity of a glaze surface is reduced, and microcracks of the glaze surface are reduced. Besides, the FFC glaze with high stain resistance also utilizes the principle of like dissolves like to increase the consumption of aluminum oxide and quartz, improve the bonding property of the blank and a glaze, and further reduce the microcracks on the glaze surface of the sanitary ceramic correspondingly.

Owner:江门市东鹏智能家居有限公司

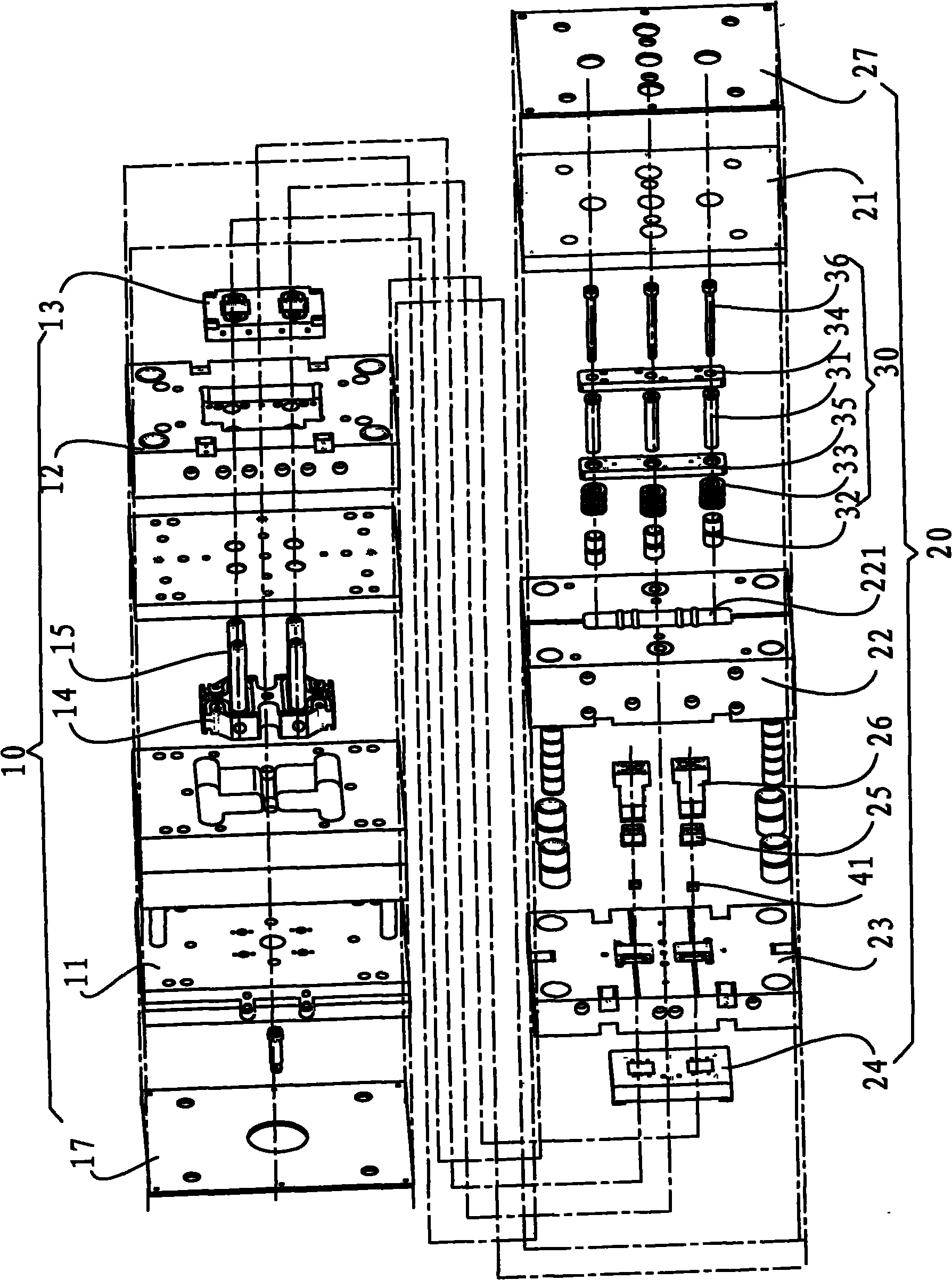

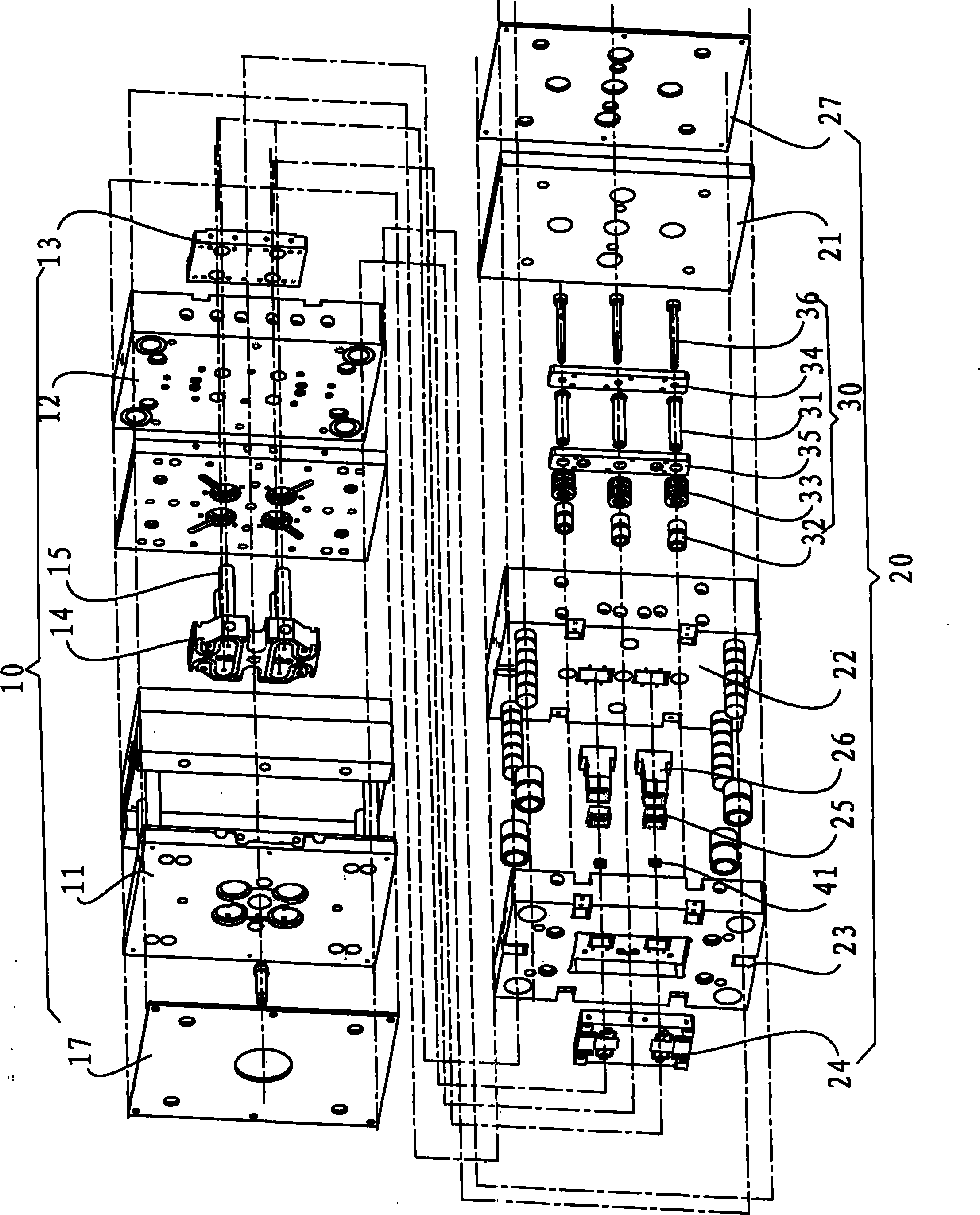

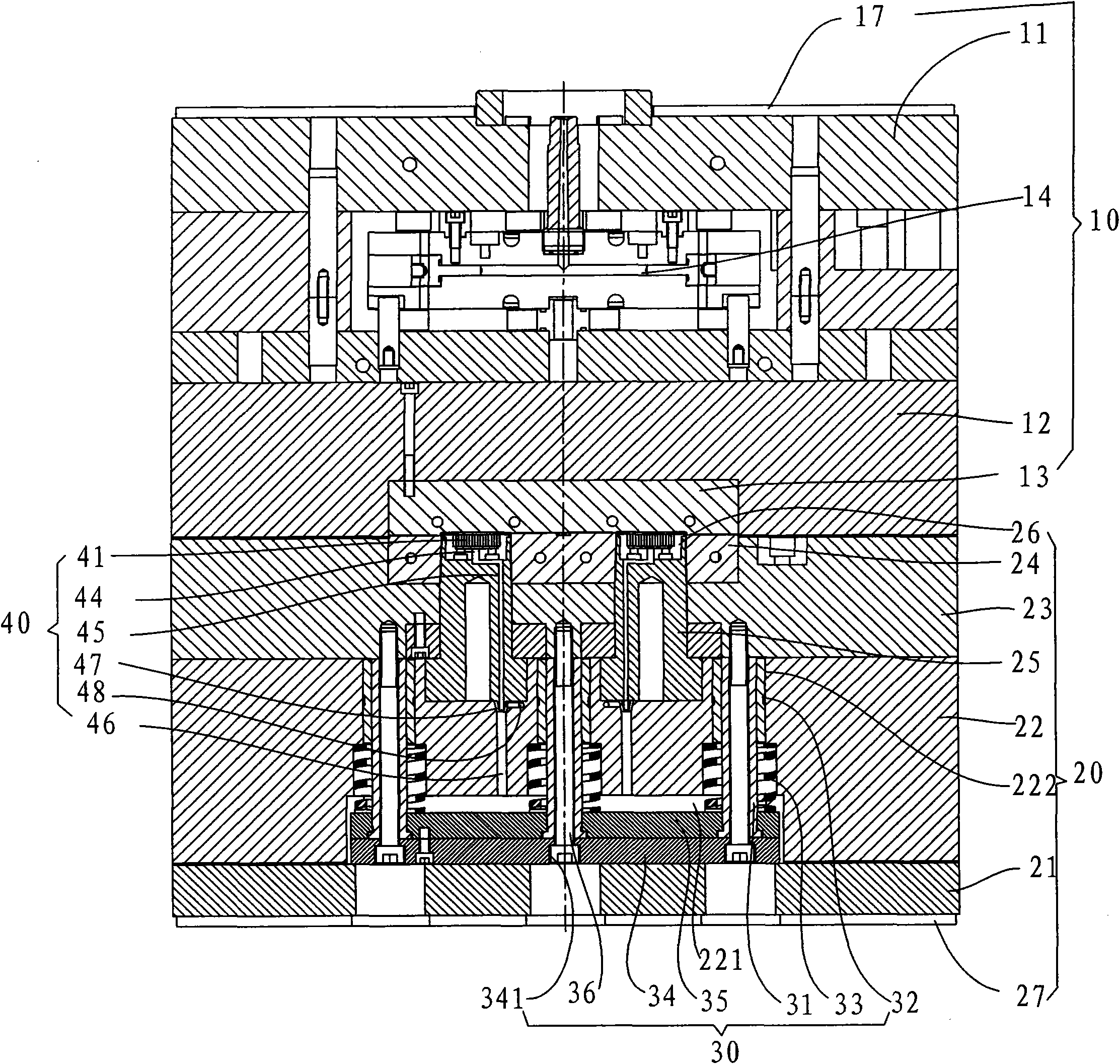

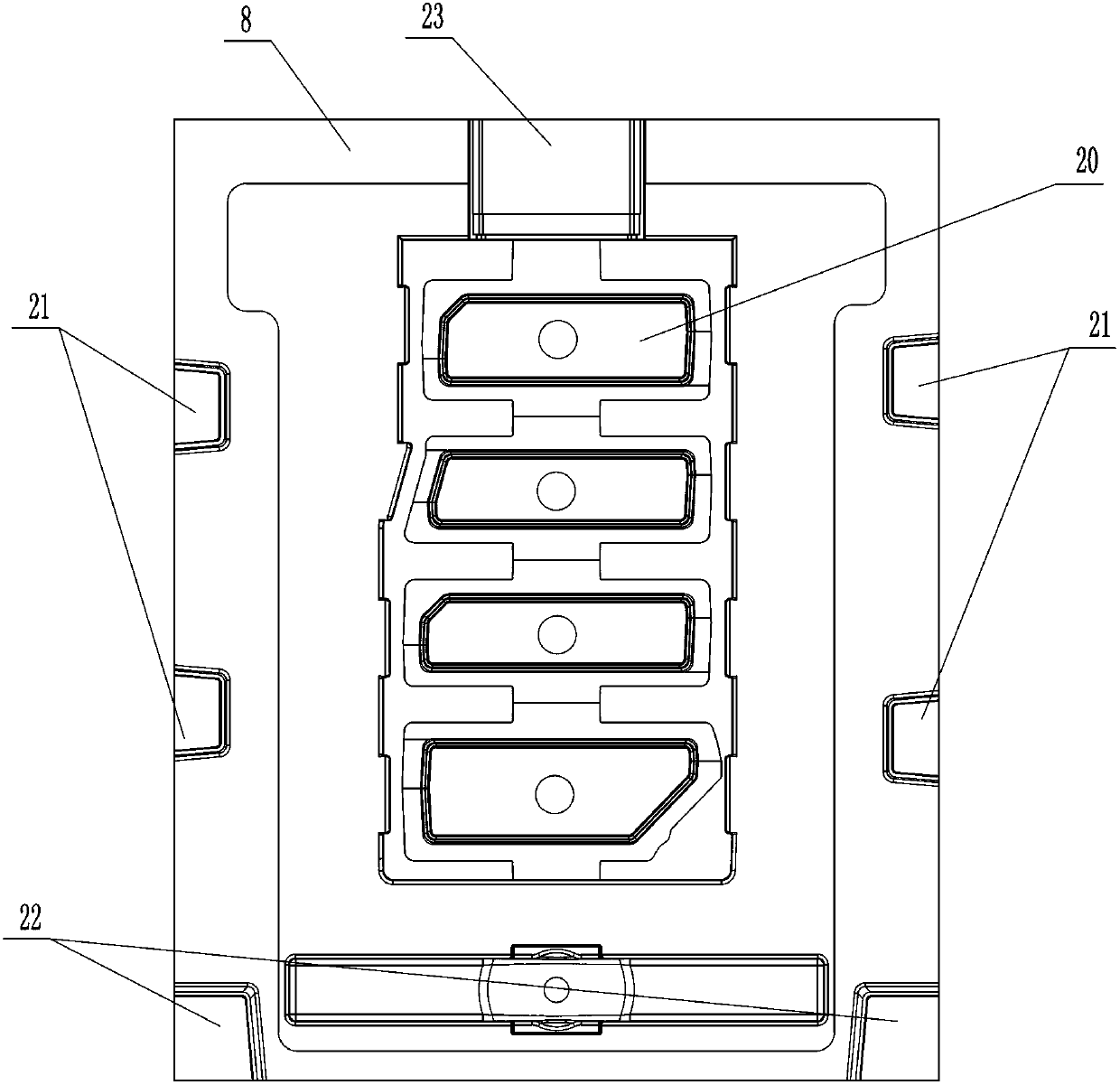

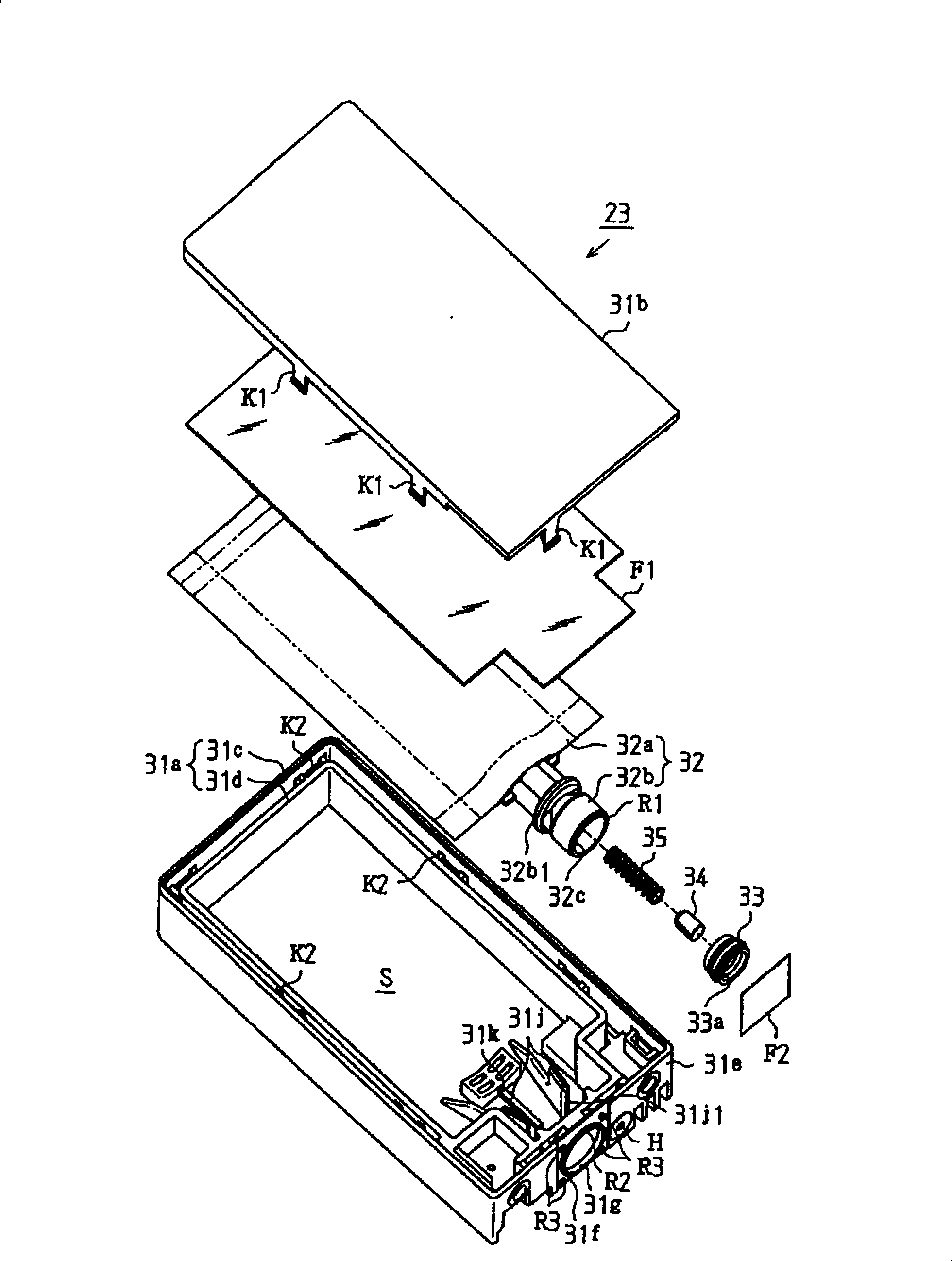

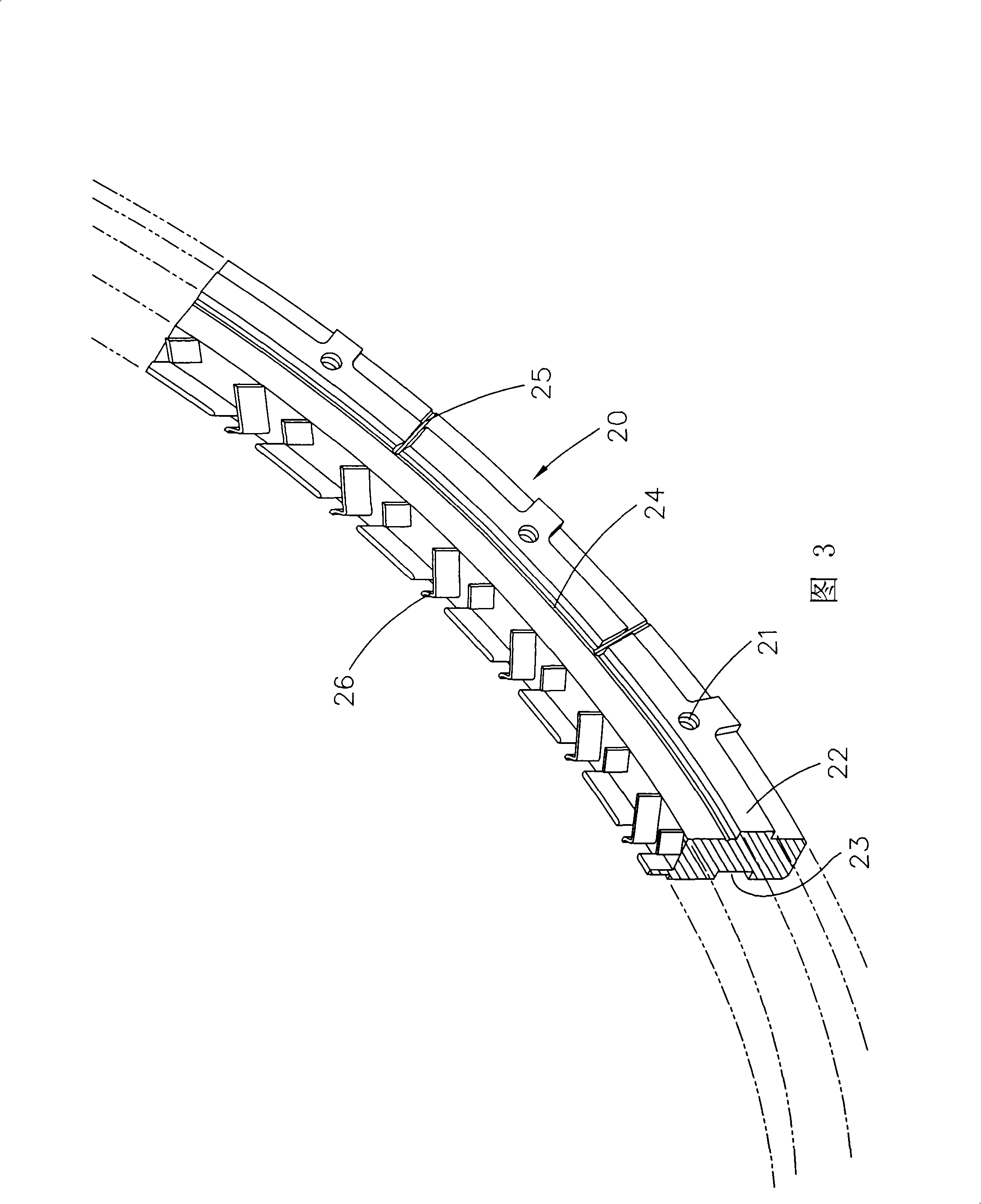

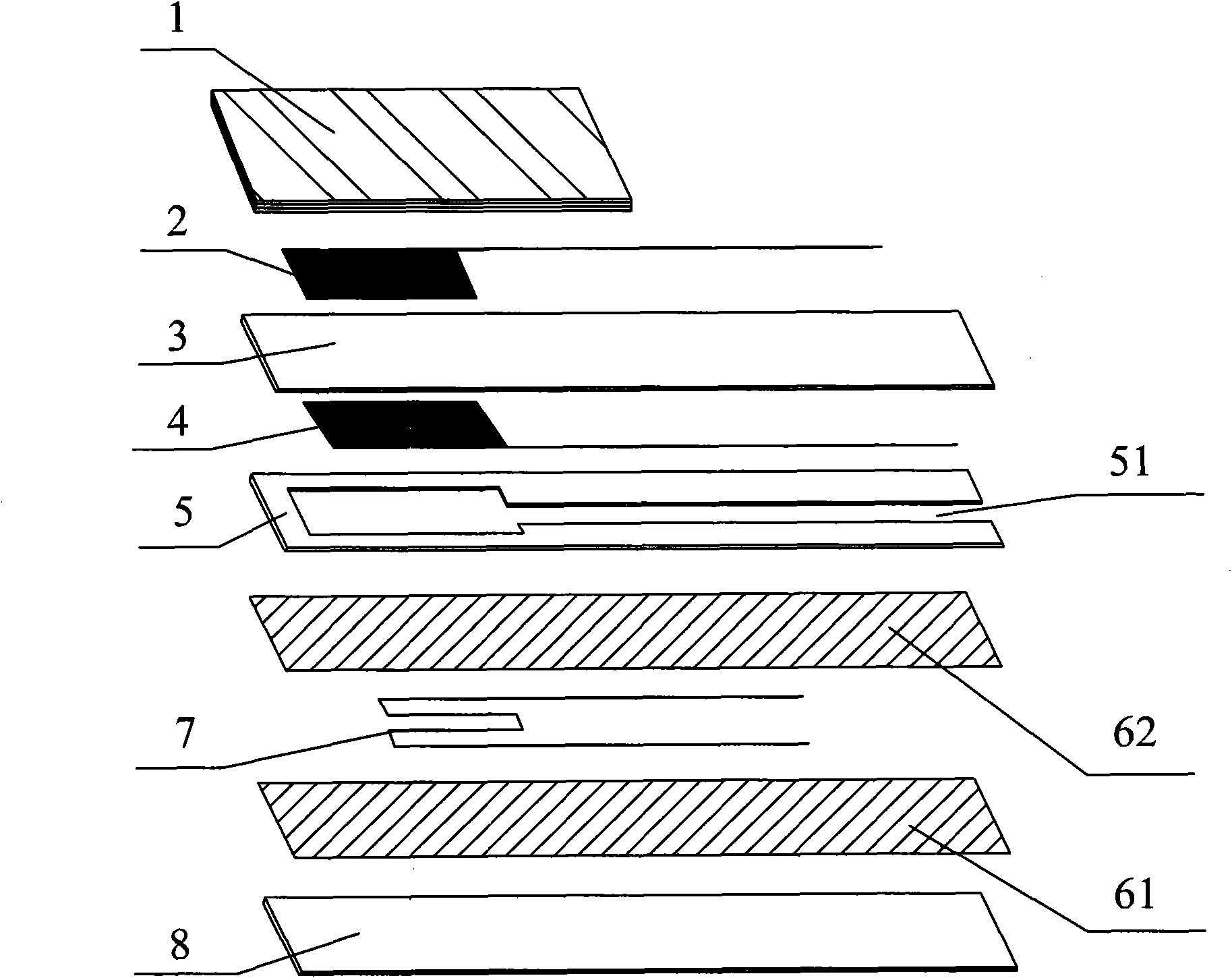

Large-area ultrathin plastic part injection mould

ActiveCN102120357AImprove pressure bearing capacityExtend your lifeAir trappingPlastic injection molding

The invention relates to the field of plastic injection molding moulds, and particularly relates to a large-area ultrathin plastic part injection mould. The mould comprises a static mould and a movable mould, wherein the static mould is composed of a static mould fixing plate, and the static template and a static mould core, a movable mould composed of a movable mould fixing plate, a pad, a movable template and a movable template core; the static template is a thickened static template; the pad is a whole square thick steel block; an ejection device is a push board ejection device; an exhaustsystem comprises a group of exhaust plates at the bottom of a mould cavity, an exhaust groove at the periphery of the mould cavity and an exhaust channel connected with the exhaust plates and the exhaust groove; and a compressed air blow pipe leading the exhaust channel to generate negative pressure is arranged on the exhaust channel. The mould has high strength, the service life is up to 2 million times; the exhaust is smooth, and adverse phenomena, such as insufficient filling, burning, air trapping, heavy fused connecting wire and the like, are prevented, so that the purpose of large area of 1,429mm<2> and ultrathin of 0.18mm molding is achieved; and the extrusion or deformation of a product is effectively avoided by adopting the push board ejection device.

Owner:DONGMING XINGYE SCI TECH CO LTD

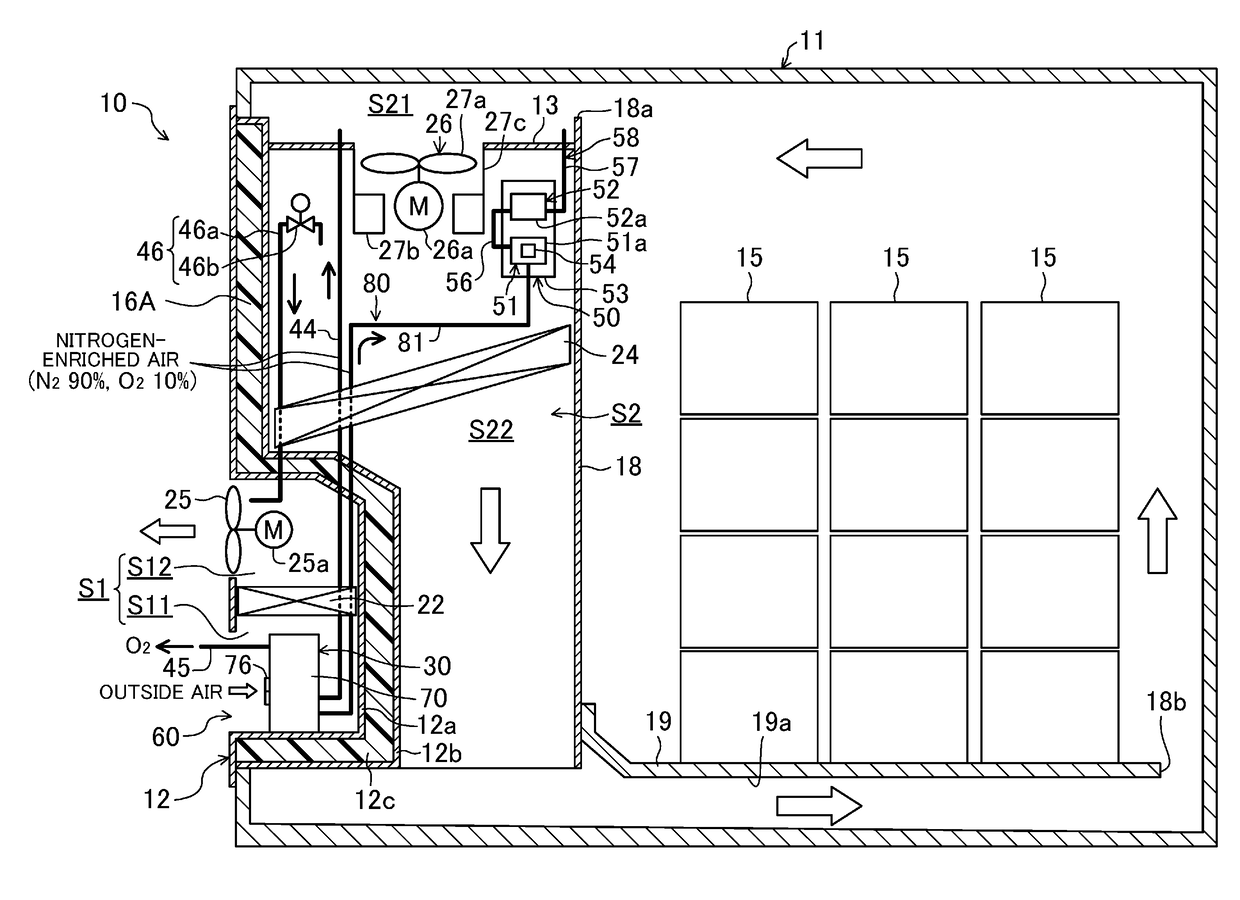

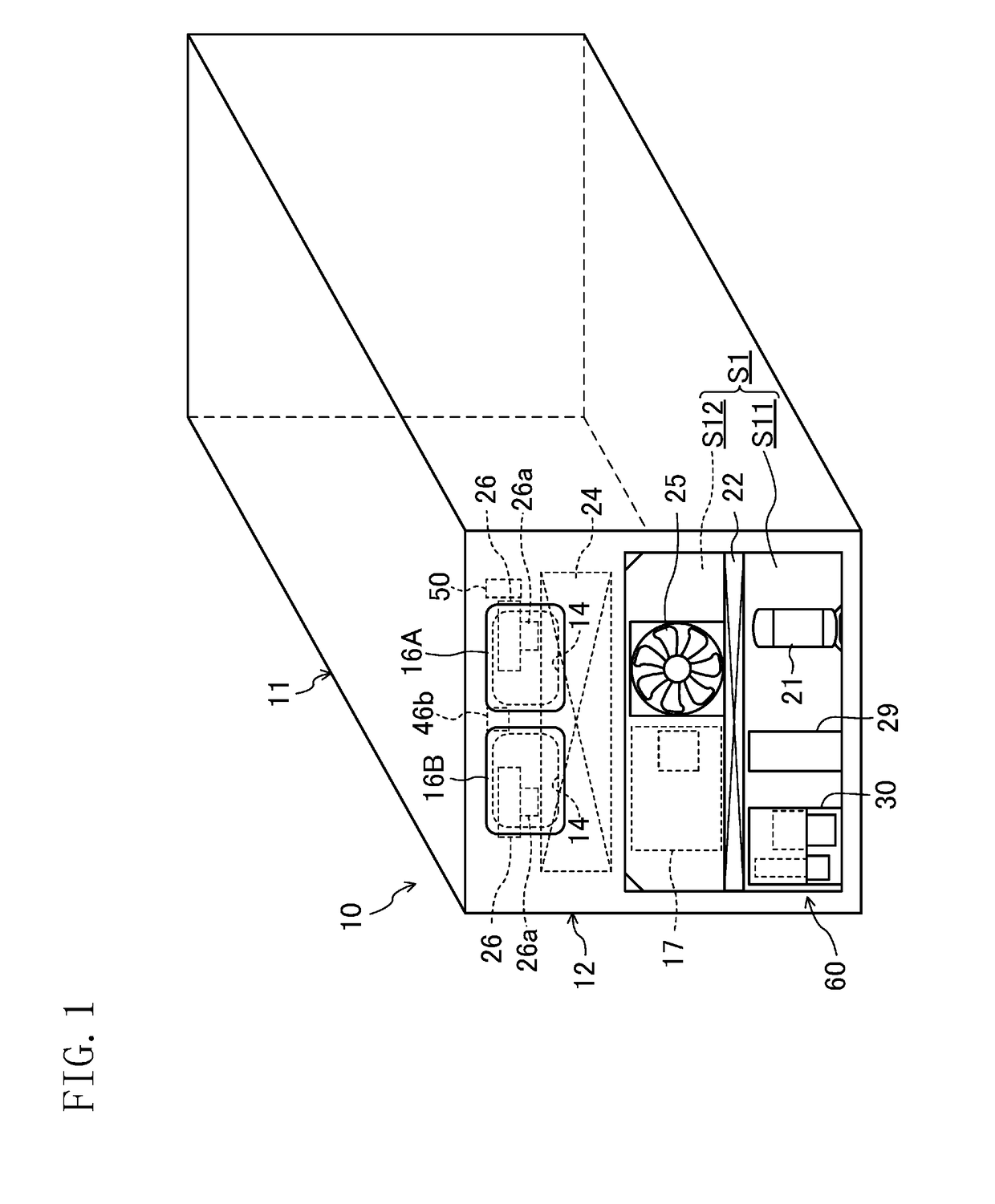

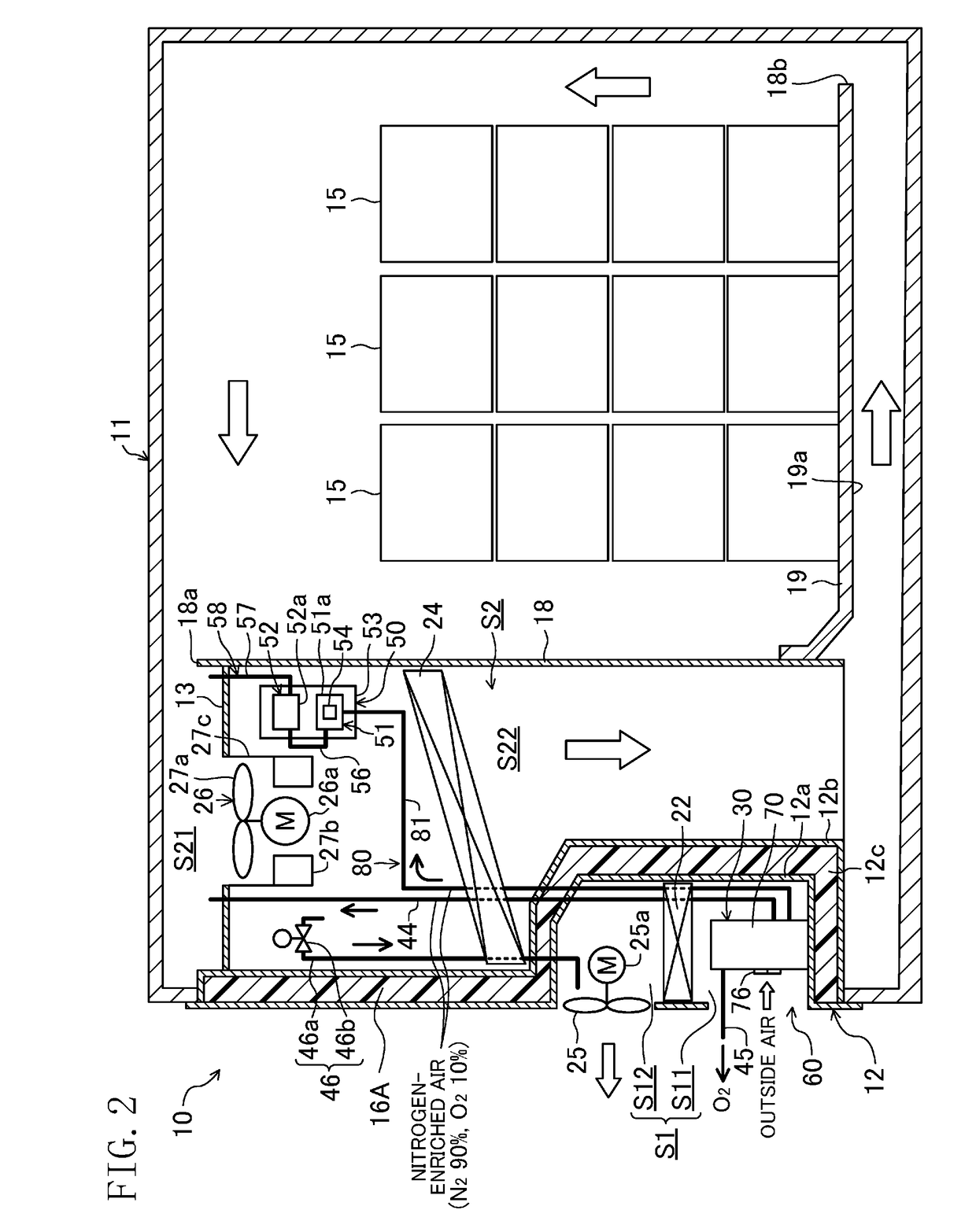

Refrigeration apparatus for containers

ActiveUS20180245835A1Quick and accurate controlReduce pressureLighting and heating apparatusDomestic refrigeratorsRefrigerantAerospace engineering

A container refrigeration apparatus includes: a casing which forms an external storage space communicating with the exterior of the container and an internal storage space communicating with the interior of the container; a refrigerant circuit; an external fan; an internal fan; and an inside air control system including an exhaust passage which allows a space on a blowout side of the internal fan in the internal storage space to communicate with the external storage space, and controls composition of the inside air in the container. An external end of the exhaust passage is open on a suction side of the external fan in the external storage space.

Owner:DAIKIN IND LTD

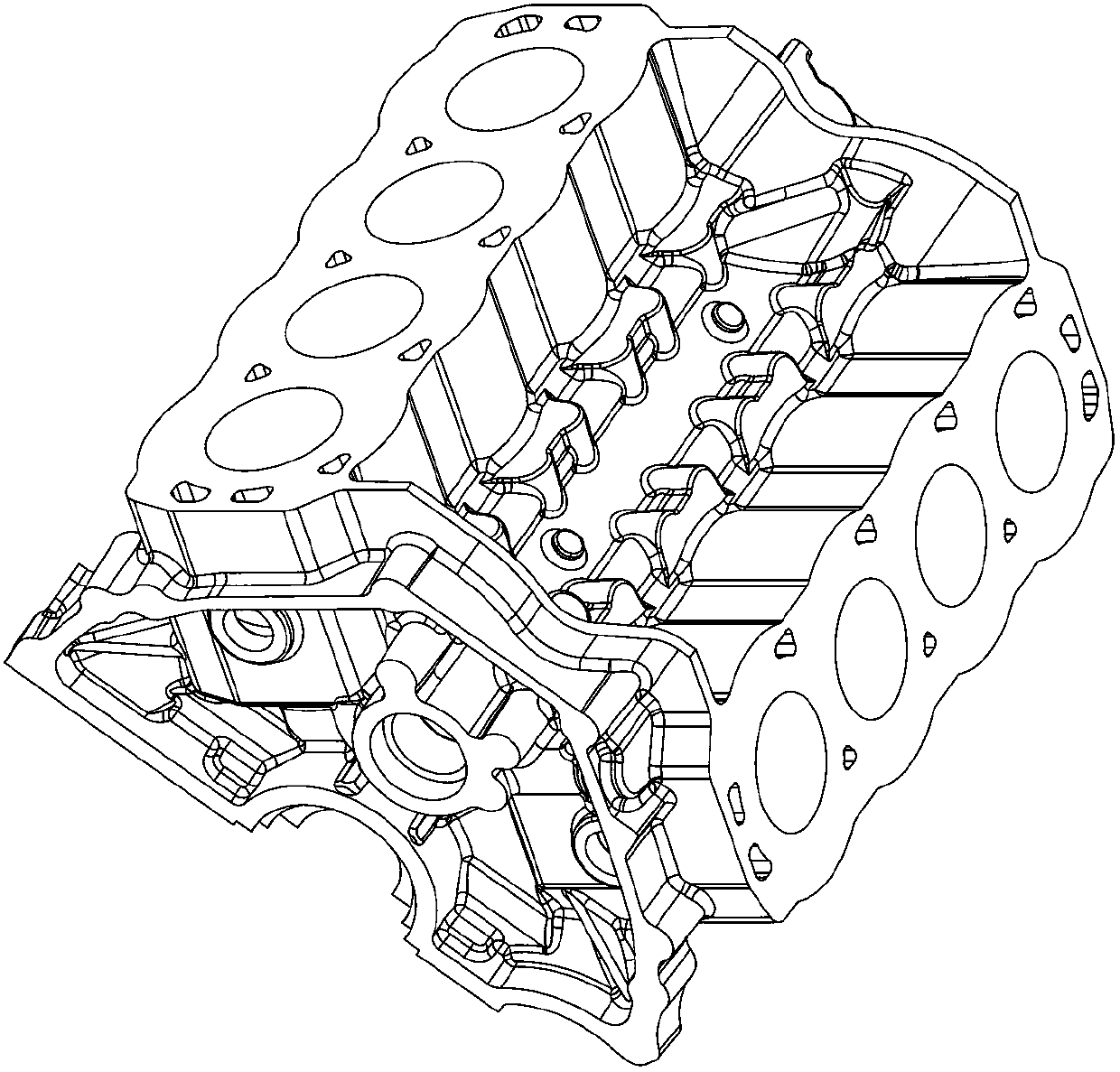

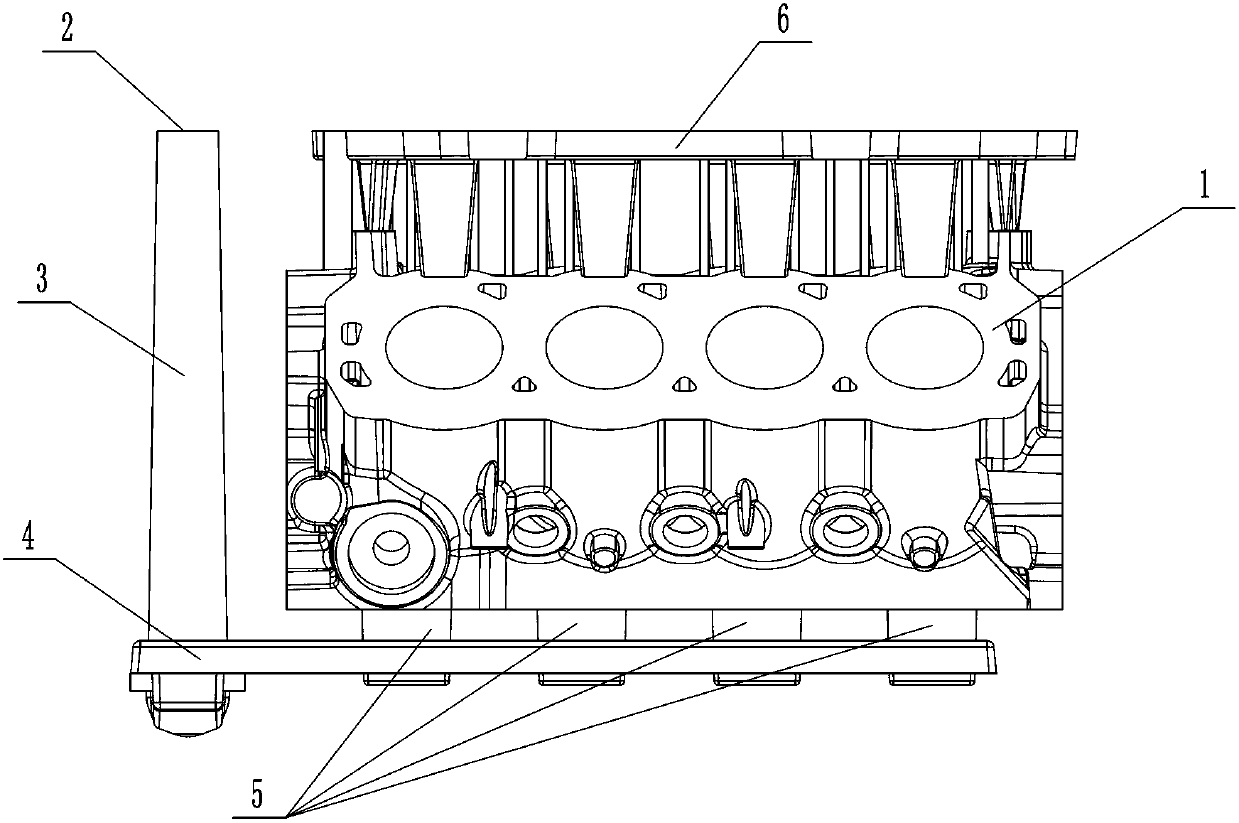

V8 type gray cast iron cylinder body casting pouring method

ActiveCN103121082AStable flow rateSmall structureFoundry mouldsFoundry coresAssembly structureMaterials science

The invention discloses a V8 type gray cast iron cylinder body casting pouring method which is carried out by adopting a core assembly pouring mode. The V8 type gray cast iron cylinder body casting pouring method comprises the following steps of: 1, setting a pouring position of a casting; 2, arranging a pouring system; 3, assembling a core assembly; and 4 pouring. Compared with the prior art, the V8 type gray cast iron cylinder body casting pouring method has the characteristics of relatively simple core assembly structure, high yield and low production cost.

Owner:宁波亿泰来模具有限公司

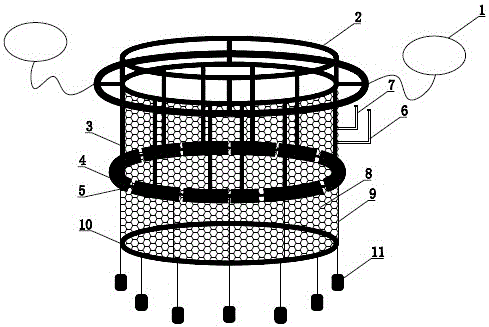

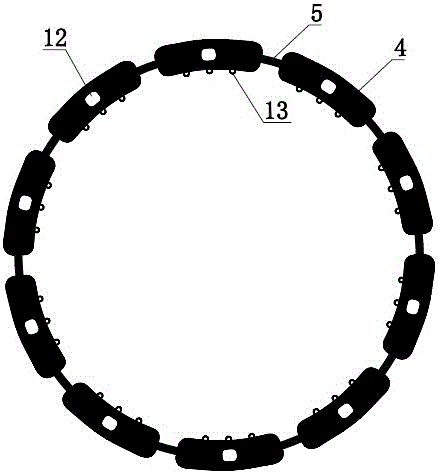

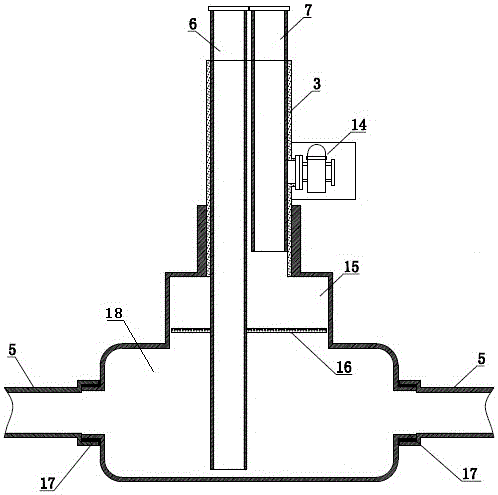

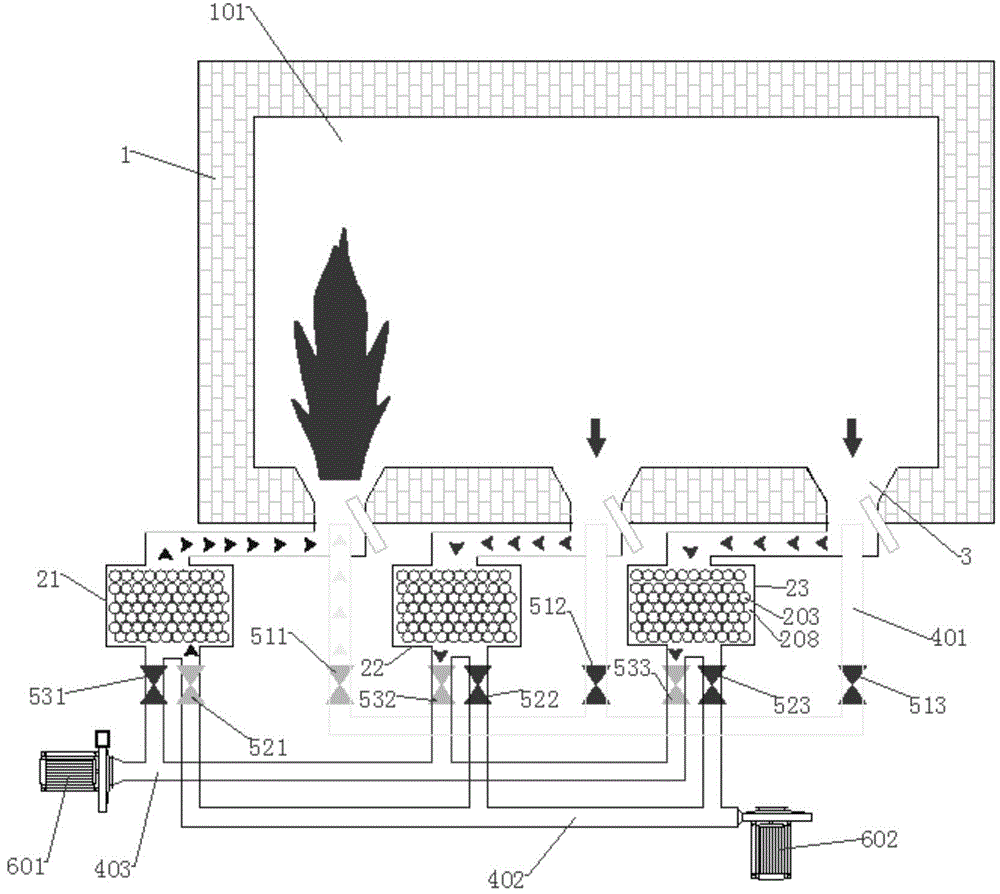

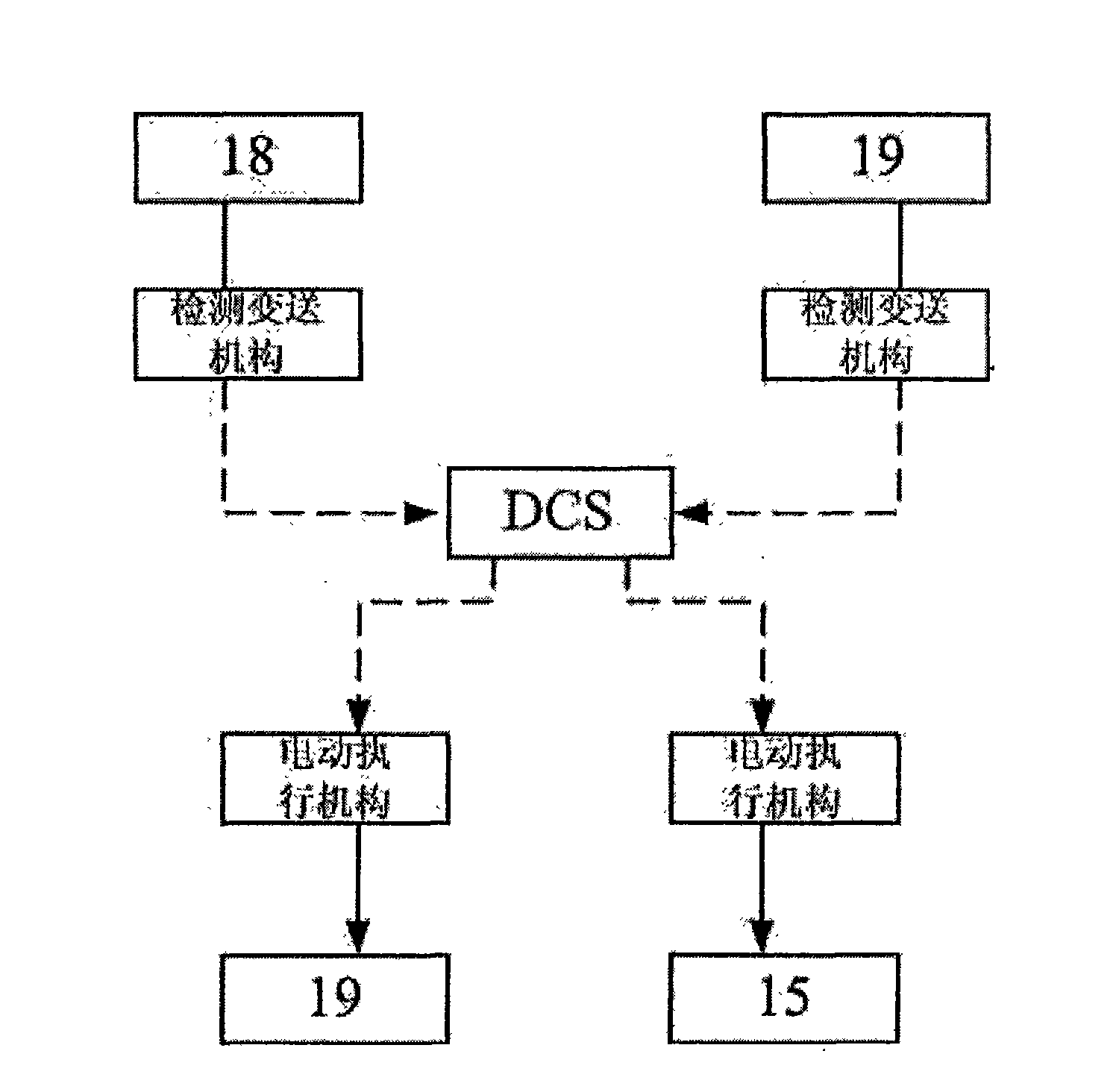

Floating and sinking type culturing net cage subjected to isobaric control and control method

ActiveCN106472379ASinking smoothlyLower center of gravityClimate change adaptationPisciculture and aquariaUnderwaterEngineering

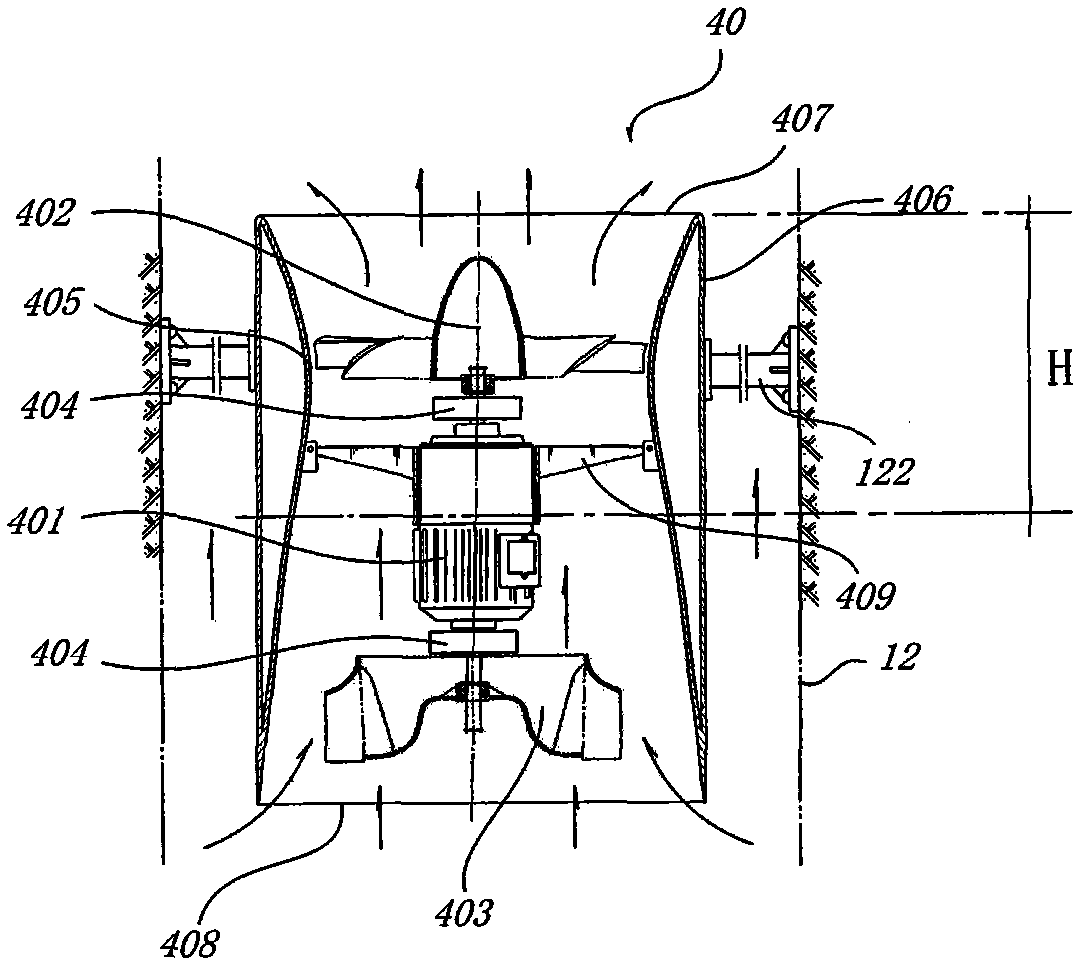

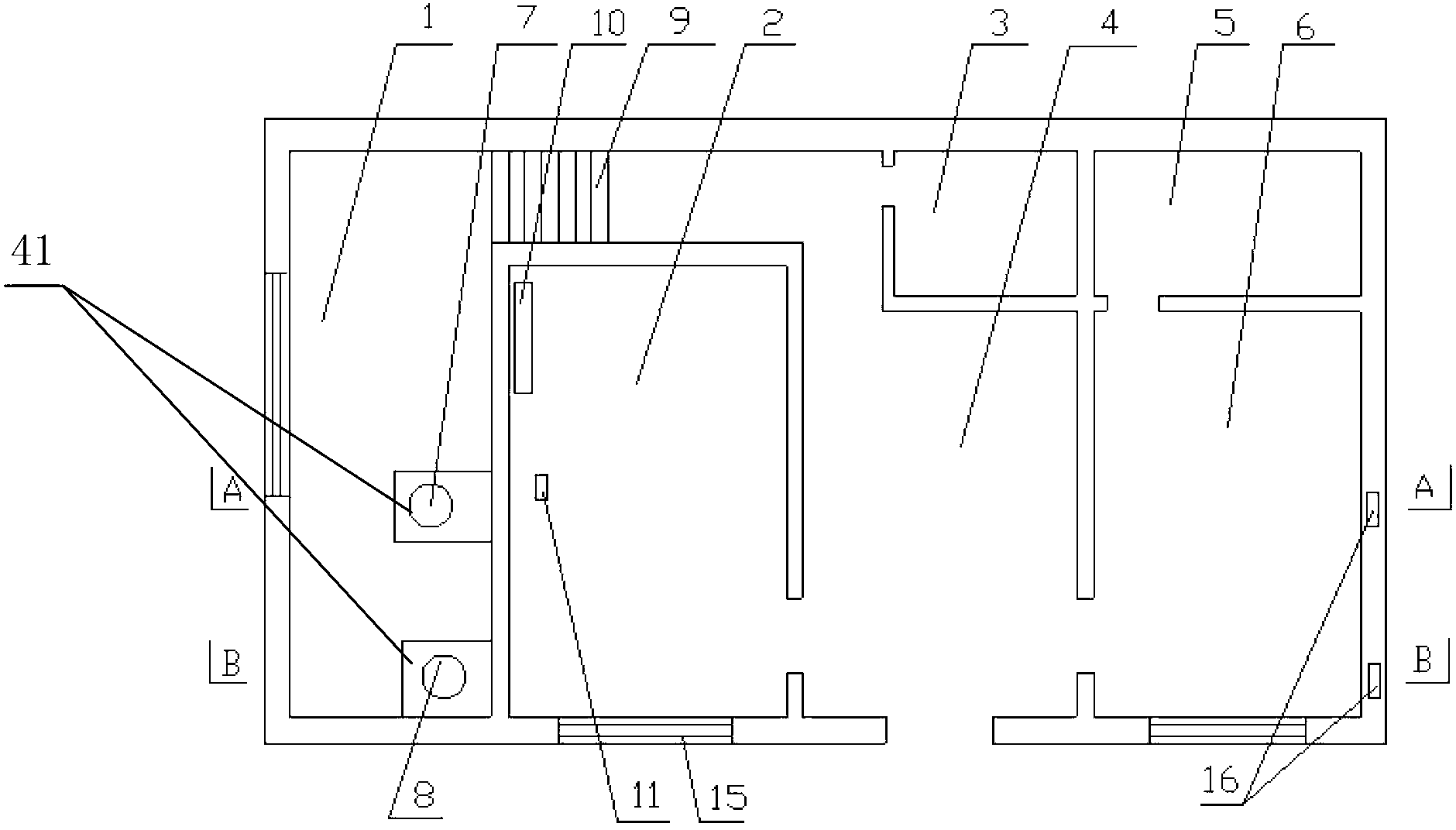

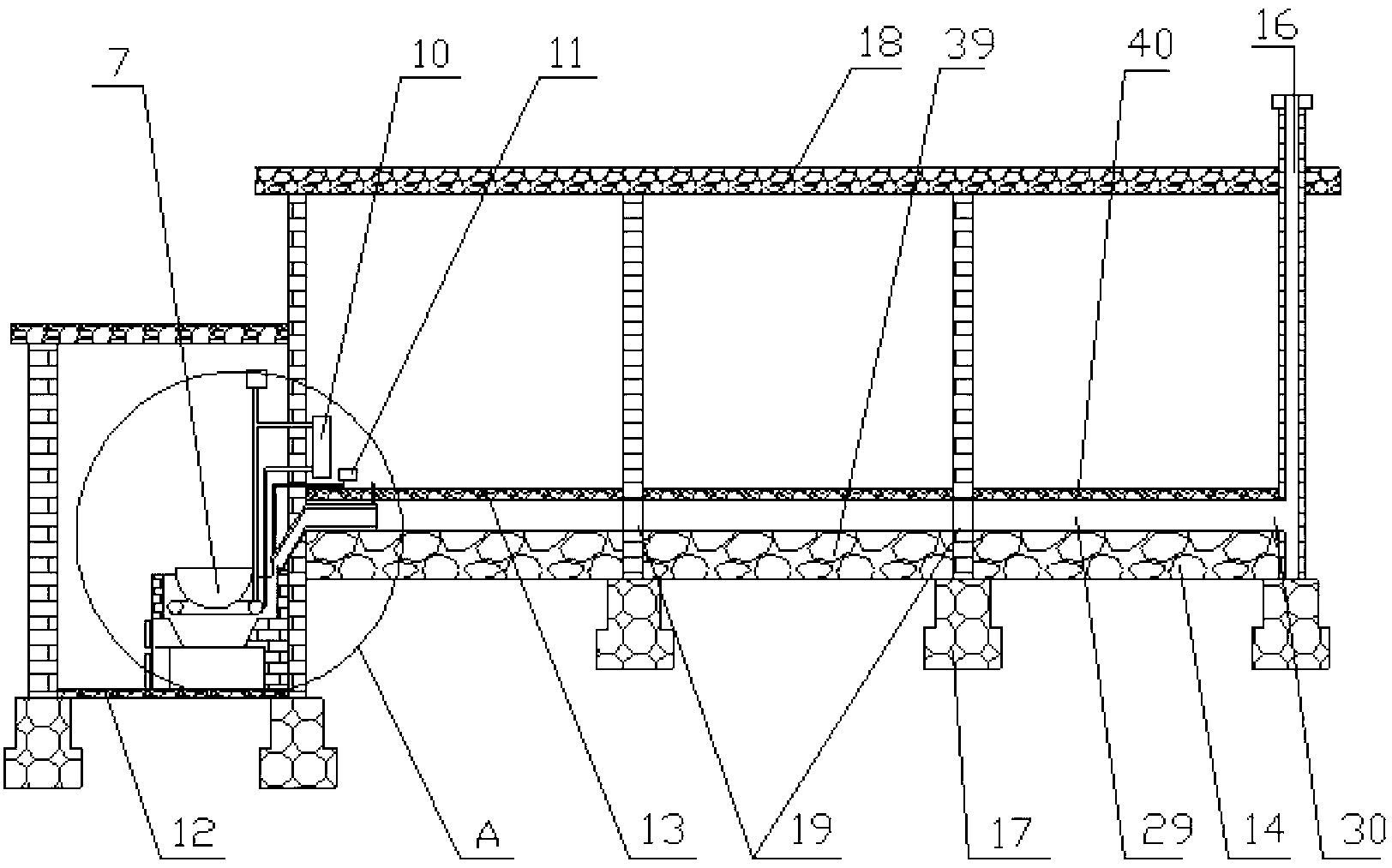

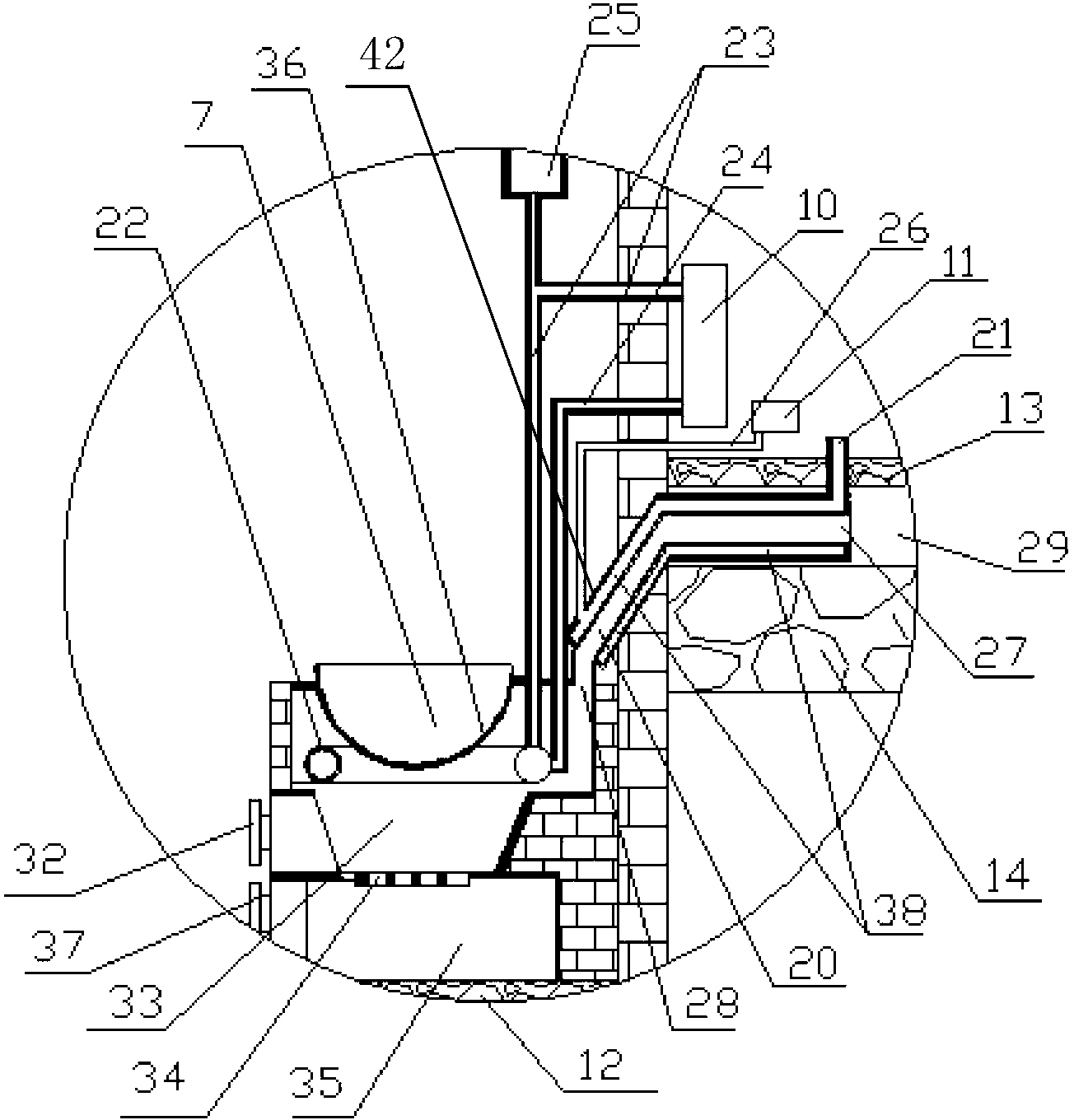

The invention discloses a floating and sinking type culturing net cage subjected to isobaric control and a control method. The floating and sinking type culturing net cage comprises floating balls, a main floating body frame, vertical supporting pipes, a sinking and floating control body, netting, a water inlet-discharge pipe and an air inlet-exhaust pipe, wherein the floating balls are fastened to the main floating body frame by flexible ropes; the main floating body frame, the vertical supporting pipes and the sinking and floating control body form one rigid whole; the sinking and floatation control body is of an annular structure which is formed by connecting multiple sinking and floatation cabins by communicating pipes, so as to form an isobaric cavity; the sinking and floating control body is located at the 1 / 2 position of a net cage, and is fastened to and connected with the vertical supporting pipes by the sinking and floating cabins and a buffering cabin. The sinking and floating control body of the floating and sinking type culturing net cage subjected to the isobaric control replaces a conventional integral separating sub-cabin; the whole sinking and floating control body is enabled to form the isobaric cavity underwater; the smooth and steady sinking of the net cage is realized; the main floating body frame, the vertical supporting pipes and the sinking and floating control body are enabled to form the rigid whole; the structural strength of the net cage is improved; deformation of the netting is avoided.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI +1

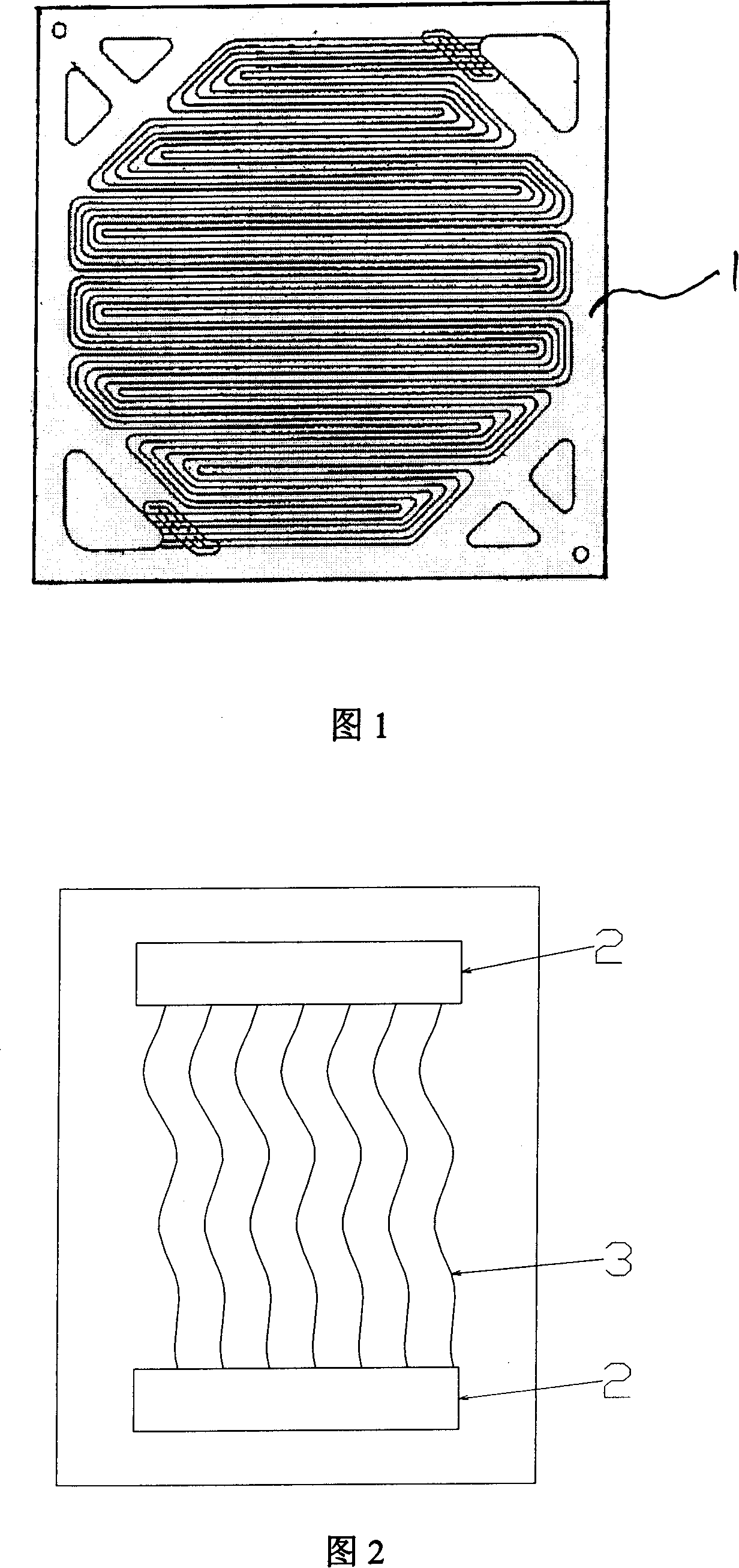

A fuel battery flow guiding polarized plate without water blockage

The invention relates to fuel battery guiding board which is not easy to stop water, the guiding board is guiding two-way board, said guiding two-way board comprises positive air guiding groove, negative hydrogen guiding groove, middle cooling flow interlayer, said flow hole which air or hydrogen in and out is single hole for in, two or more hole for out, guiding groove and connecting groove which connects guiding groove are set between flow hole for air or hydrogen, the guiding groove and connecting groove are all designed to direct flow groove or nearly direct flow groove; said flow hole for cooling liquid is single hole or double holes or more holes for in, two holes or more holes for out, guiding groove and connecting groove which connects guiding groove are set between flow hole for cooling liquid, the guiding groove and connecting groove are all designed to direct flow groove or nearly direct flow groove. Comparing with current technique, the invention can make liquid flow on liquid field evenly, freely; jam of guiding groove can be avoided.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

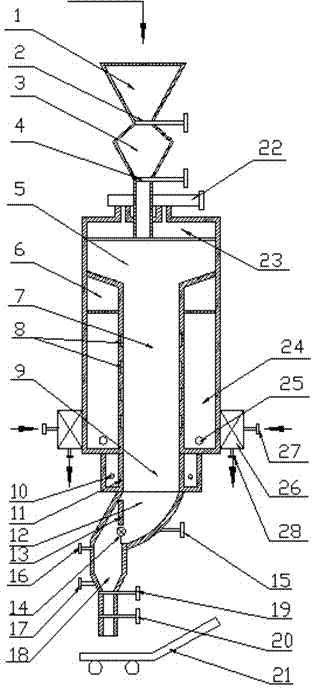

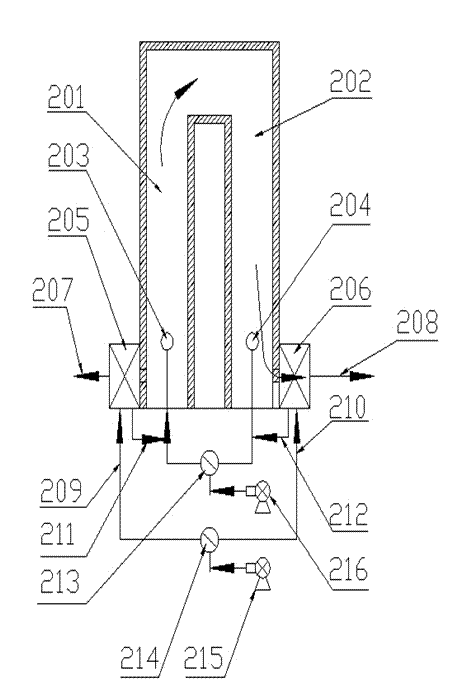

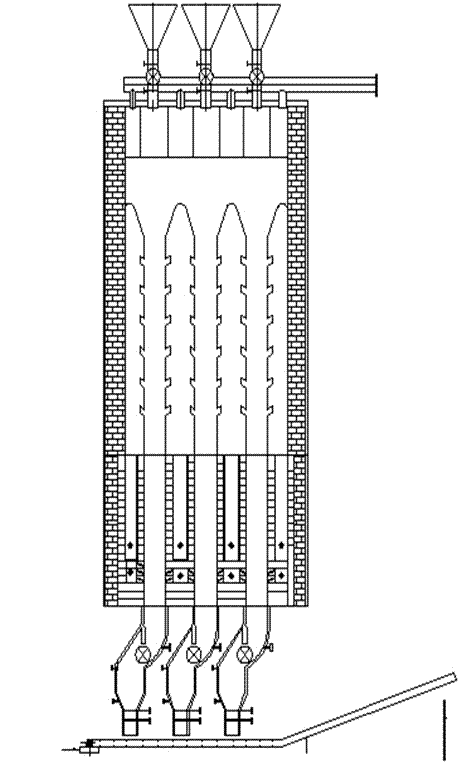

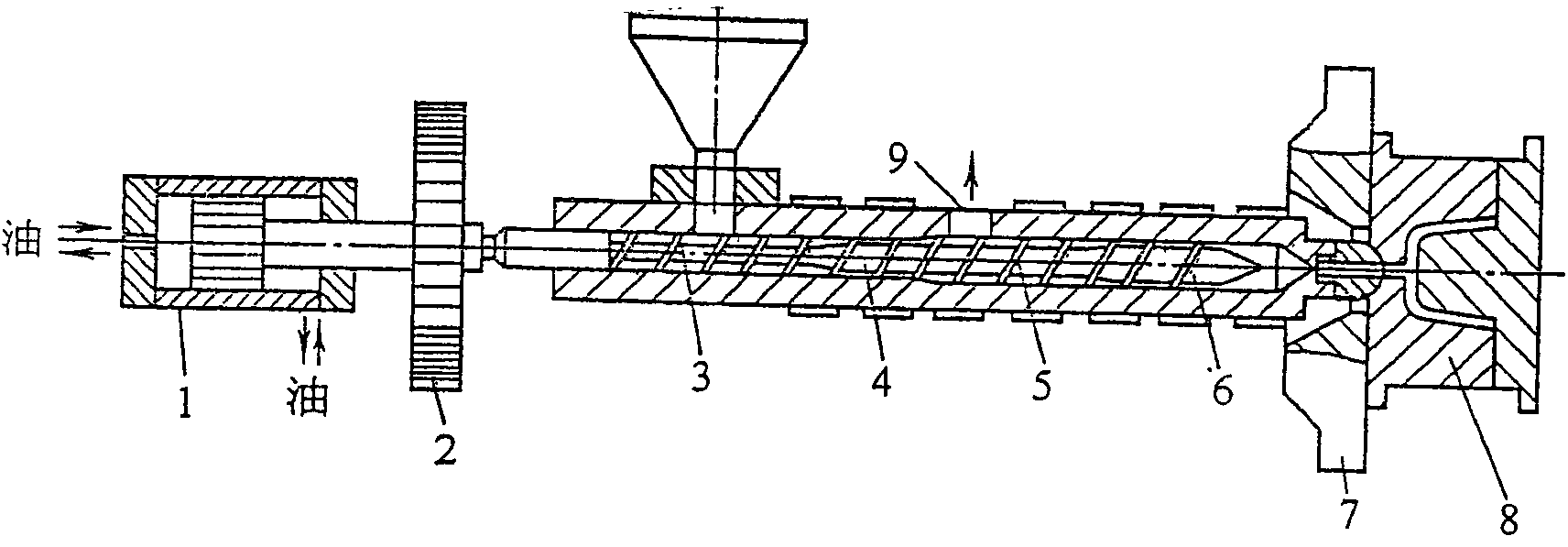

HY type dry distillation furnace

ActiveCN103923676ASolve the problem of low utilization efficiencyImprove utilization efficiencyIndirect and direct heating destructive distillationEnergy inputCombustion chamberHeat carrier

The invention discloses an HY type dry distillation furnace which is characterized by comprising a plurality of dry distillation subunits, wherein each dry distillation subunit comprises a charging device, an oil gas discharge device, a dry distillation device, a heating device and a coke discharge device; materials are subjected to dry distillation by using a combined radiation heat exchange and convection heat exchange mode in the furnace; gas generated in a dry distillation process is used as a dry distillation heat source, and the dry distillation heat can be self-balanced; the materials are directly heated by virtue of radiation of a furnace wall of a combustion chamber, and a heat carrier does not need to be subjected to secondary heating and long-distance conveying; a dry distillation gas outputting device is arranged in the furnace, so that the gas in the furnace flows smoothly; coke is discharged by a dry method. The dry distillation furnace is high in heat utilization efficiency, low in outlet gas quantity, low in water consumption, high in oil yield and large in daily treatment capacity capable of being more than 6,000 tons, and is suitable for low and medium-temperature dry distillation of the materials such as oil sand, oil shale, coal and the like, and suitable for oil refining and dry distillation of large particle materials and small particle materials of less than 15mm.

Owner:辽宁智越建设有限公司

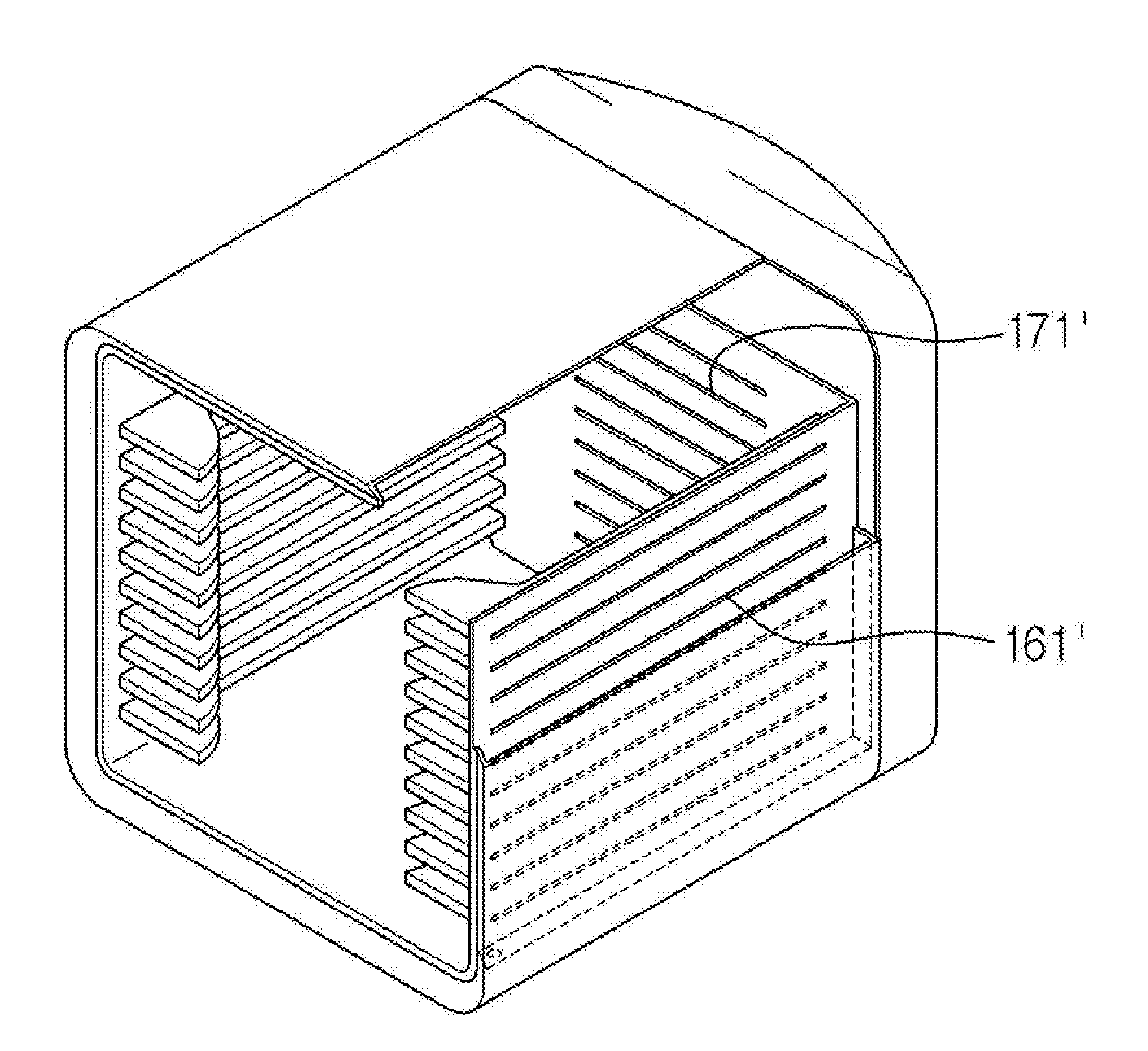

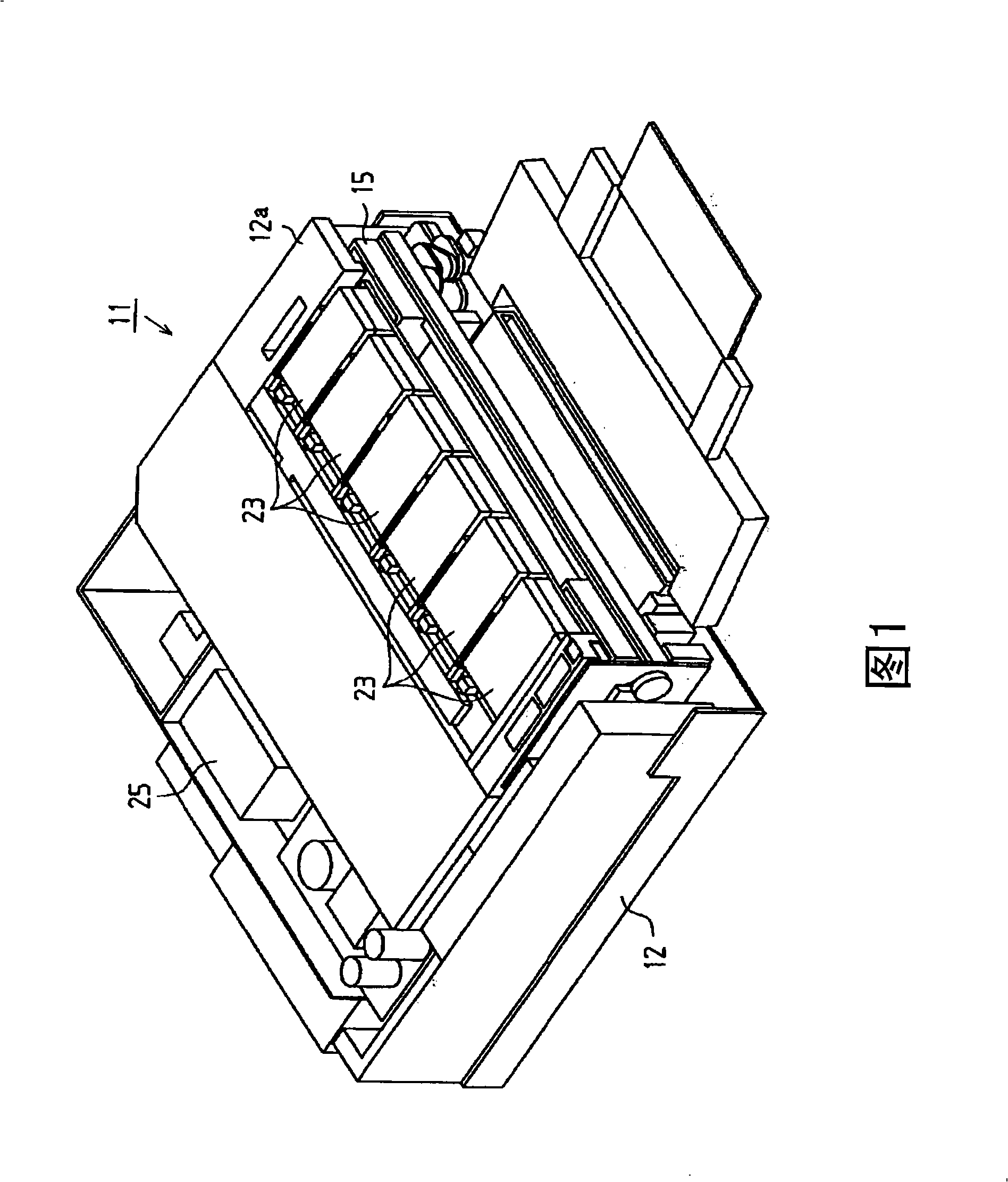

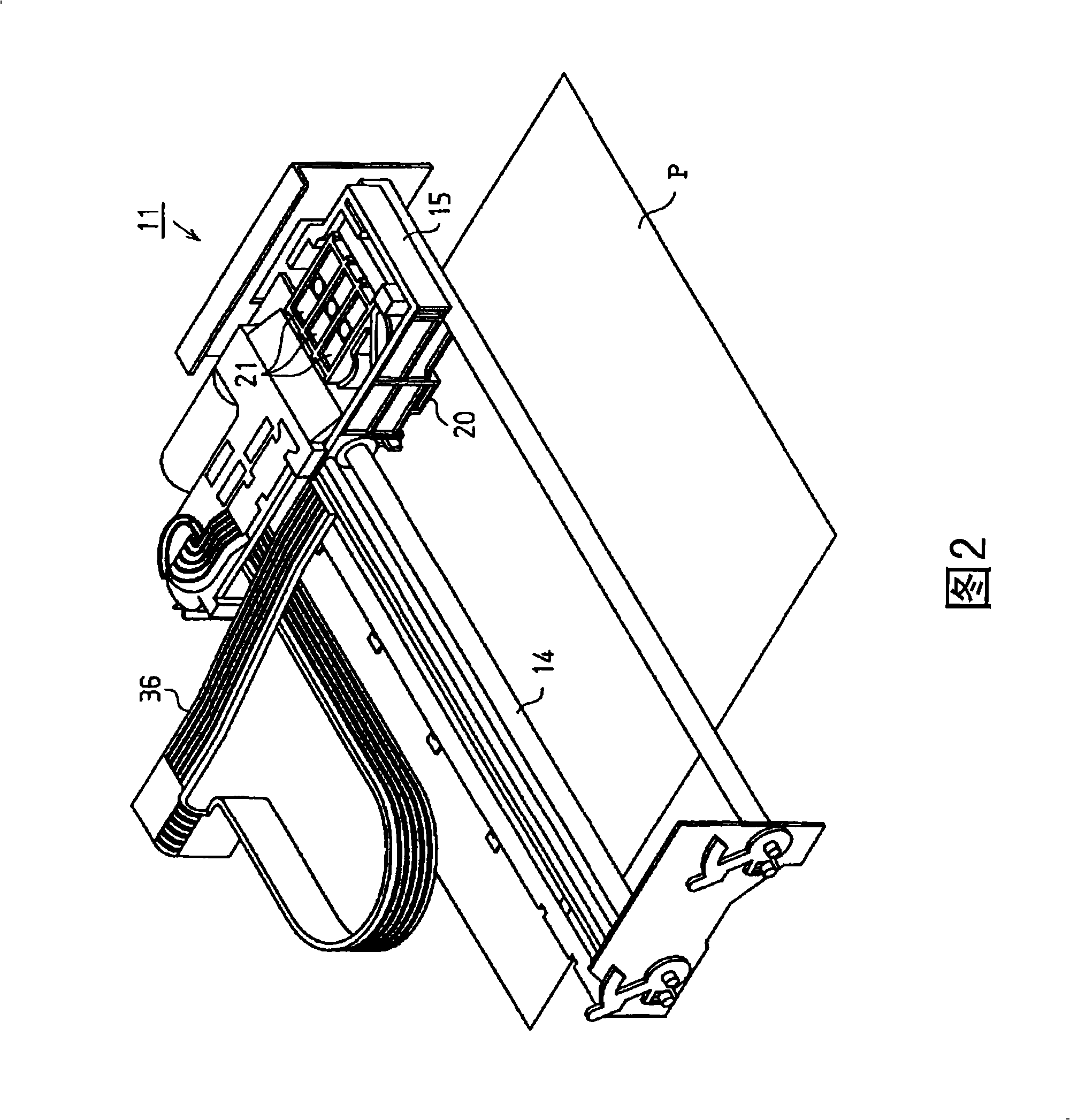

Wafer storage container

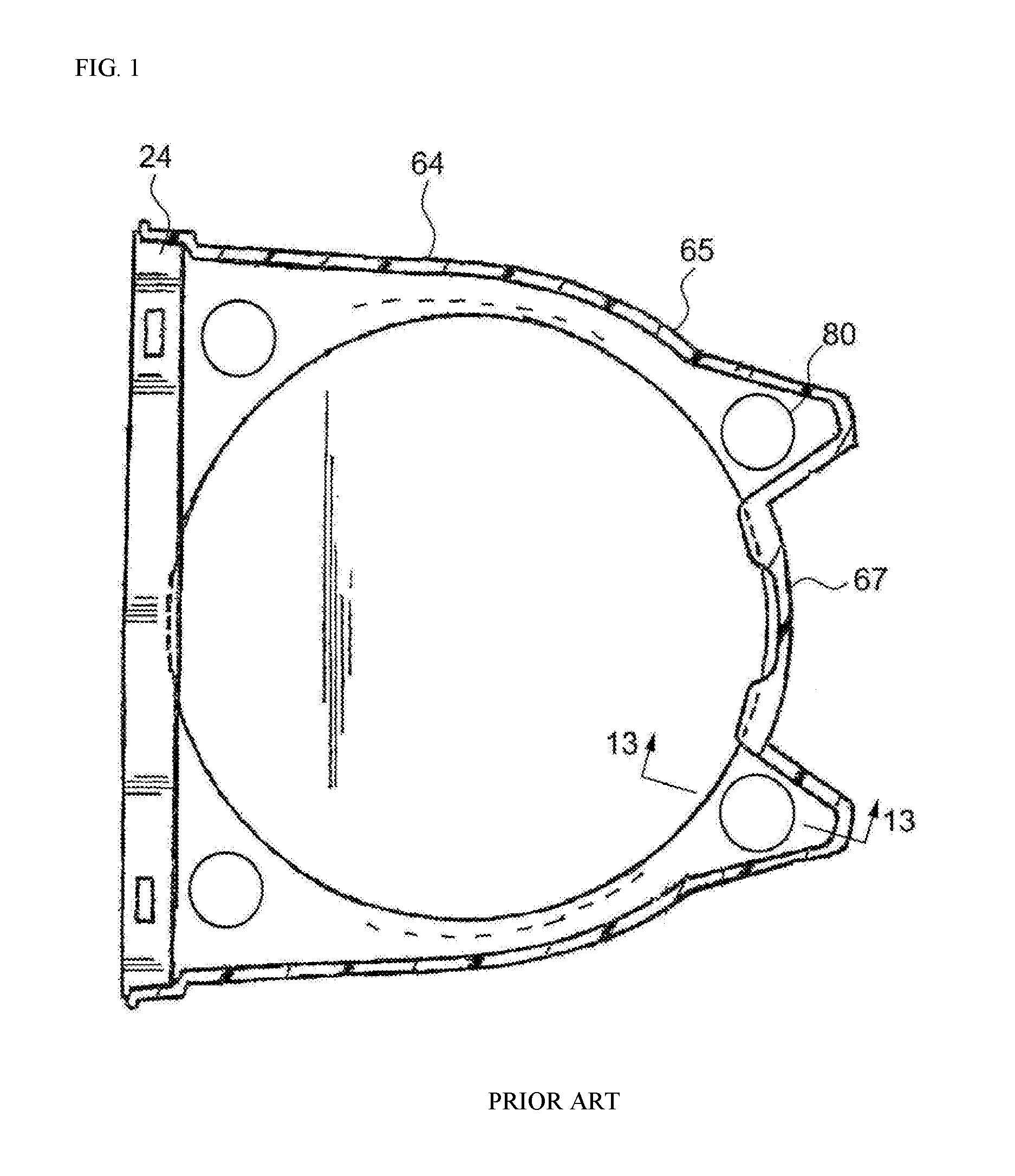

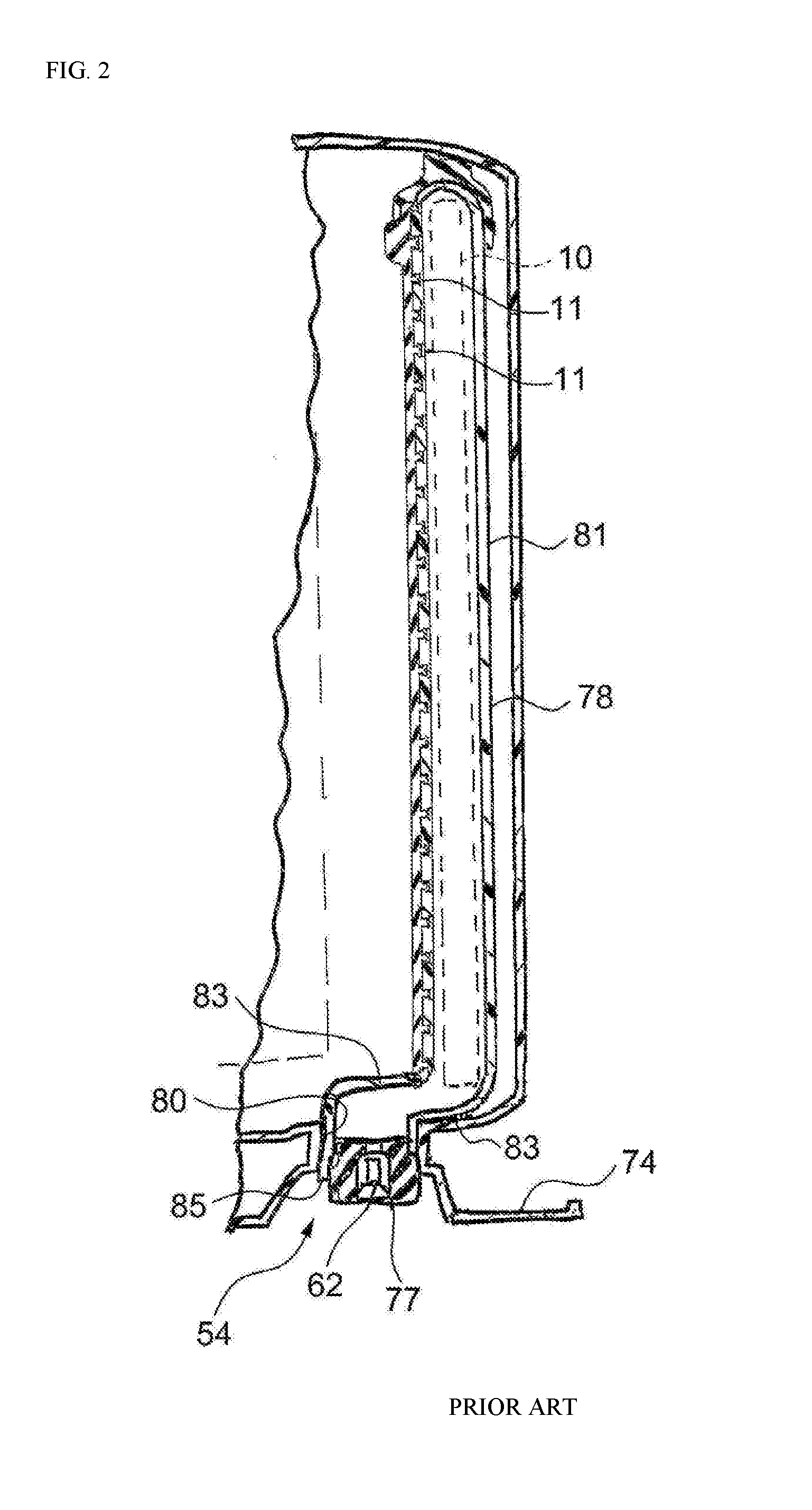

ActiveUS20160284580A1Efficient removalSmooth exhaustSemiconductor/solid-state device manufacturingEngineeringHolding room

The present invention relates to a wafer storage container, more particularly, relates to a wafer storage container wherein the space of the wafer storage container is divided into the spaces, namely a storage room, a gas injection room, and a gas exhausting room, which are independent and separate from each other, so when the wafer storage container is transported to the load port and being coupled therewith, the purge gas is injected / exhausted through the separating walls inside the storage room, thereby efficiently removing the remaining fumes on the surface of the wafer.

Owner:PICO & TERA CO LTD +1

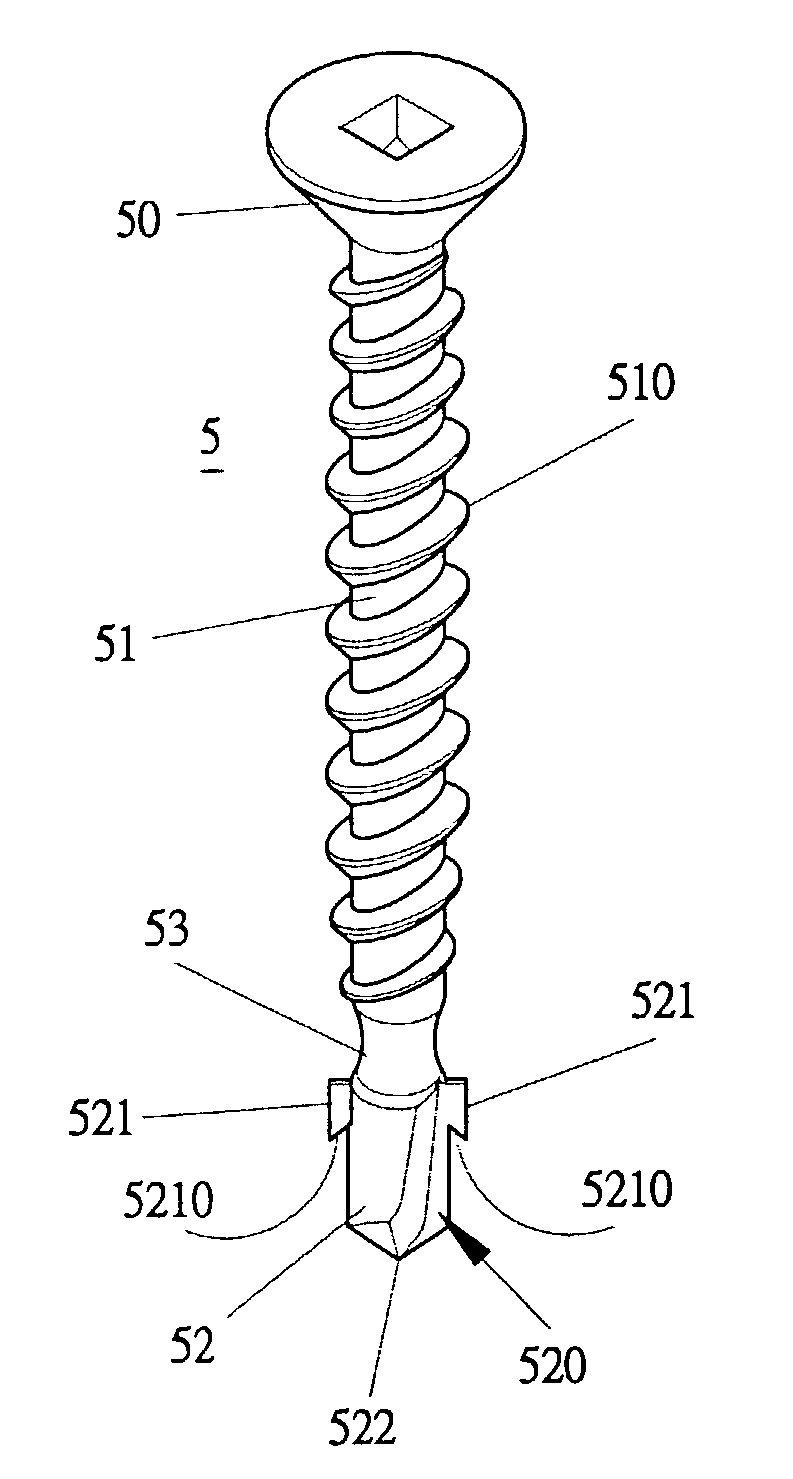

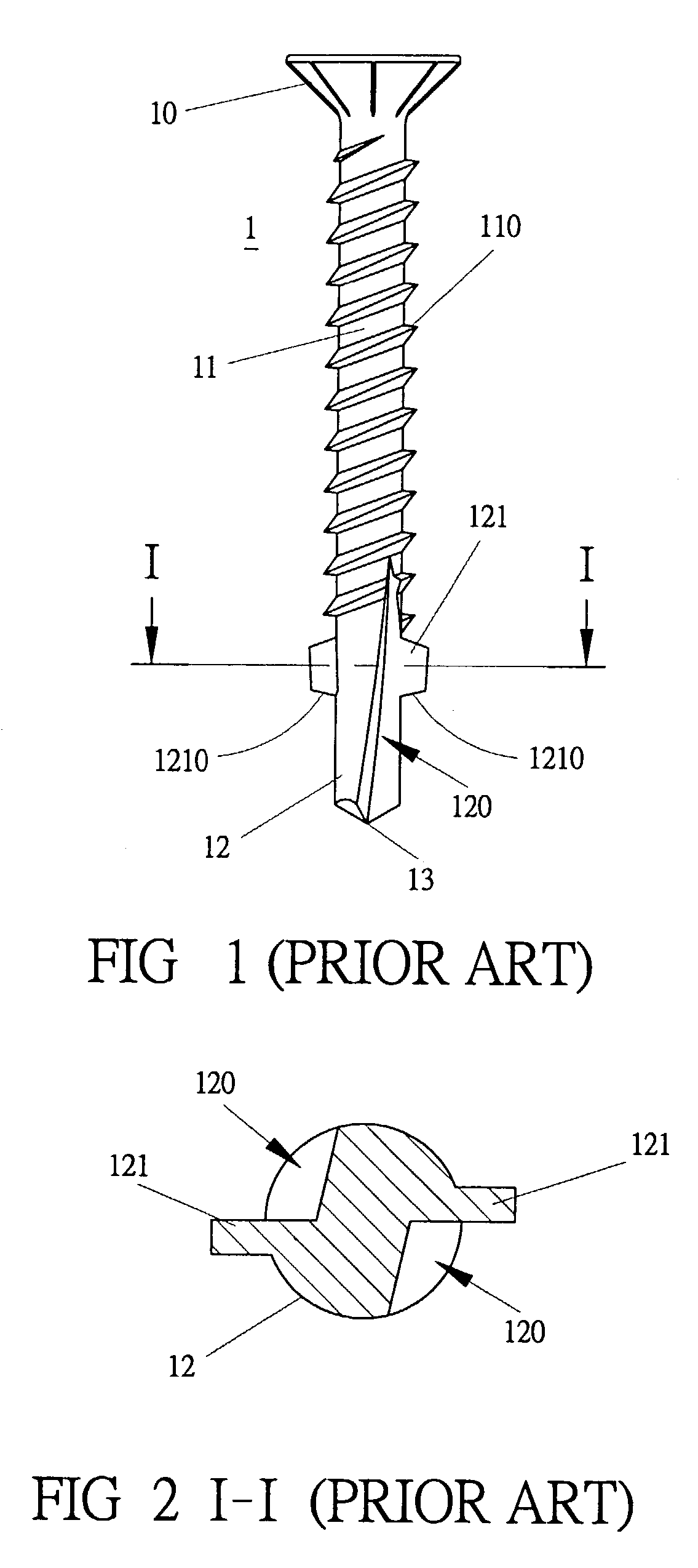

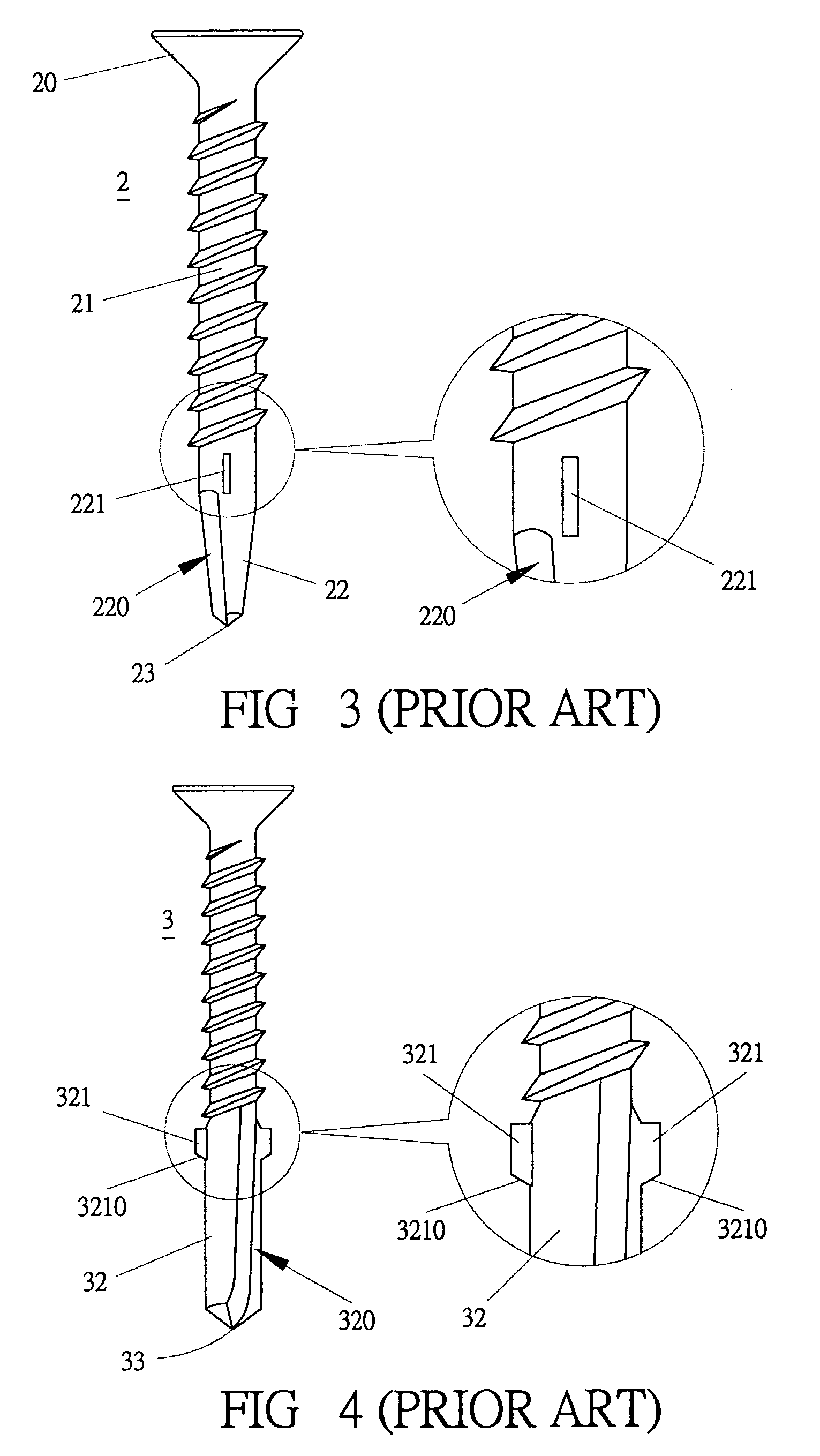

Tapping screw

A tapping screw includes a head, a shank and a cutting member, Said the shank has male threads, and the cutting member extends down from the shank and has a plurality of cutting grooves lengthwise formed and / or a plurality of wings also lengthwise formed; an annular groove is further provided between the shank and the cutting groove for wood waste cut out of a drilled hole of an object to move out smoothly and quickly, so the sharpness of the cutting member and the pointed end may be kept usual, and resistance against drilling and fixing of the screw may be reduced.

Owner:CHEN HO TIEN

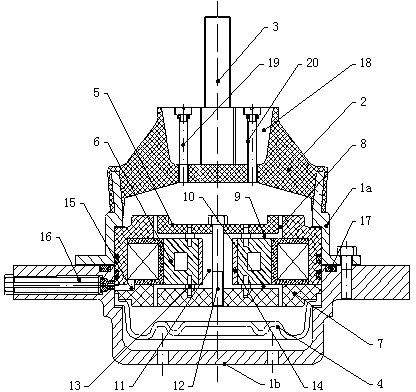

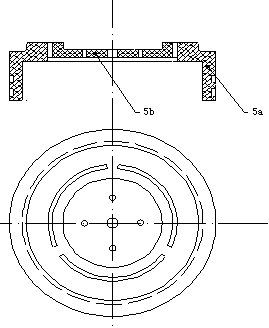

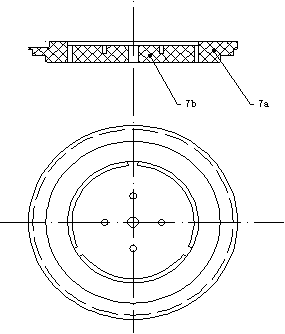

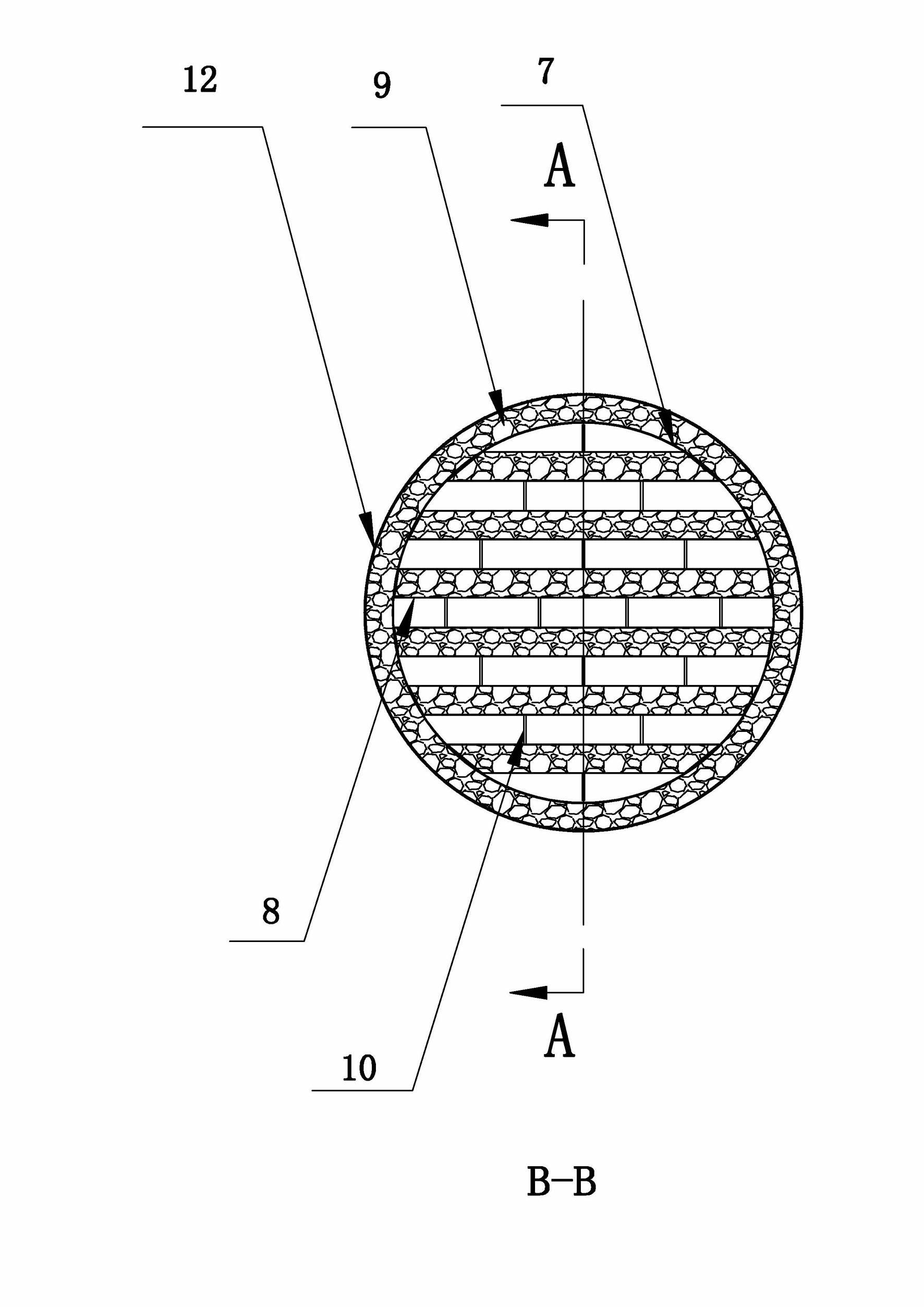

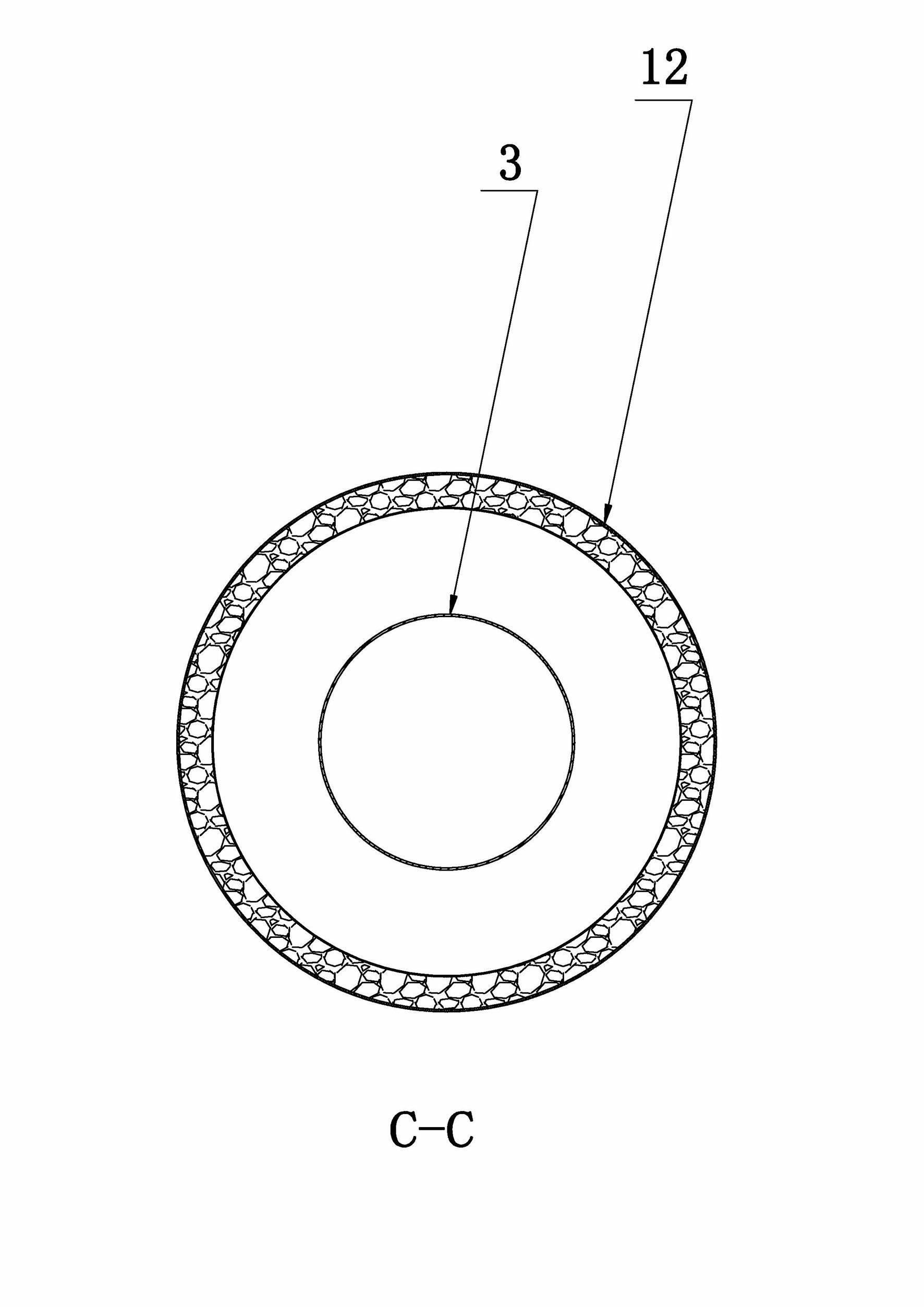

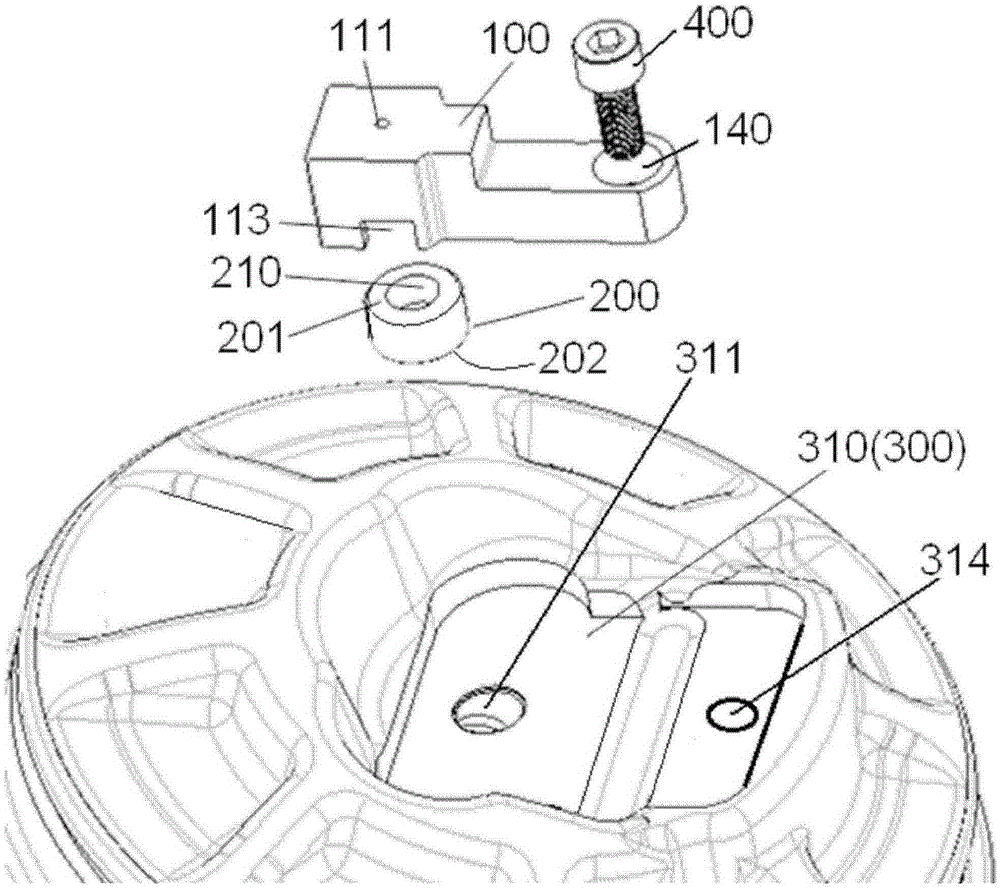

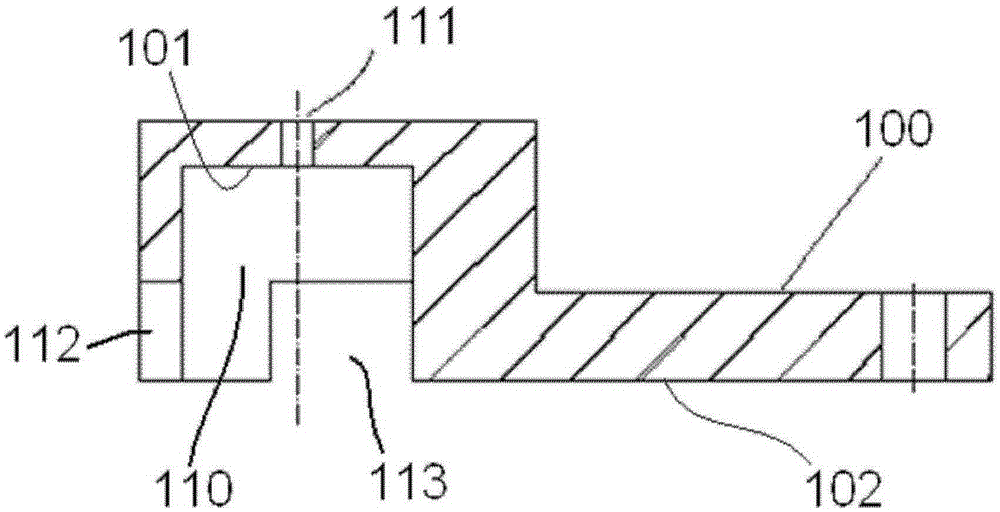

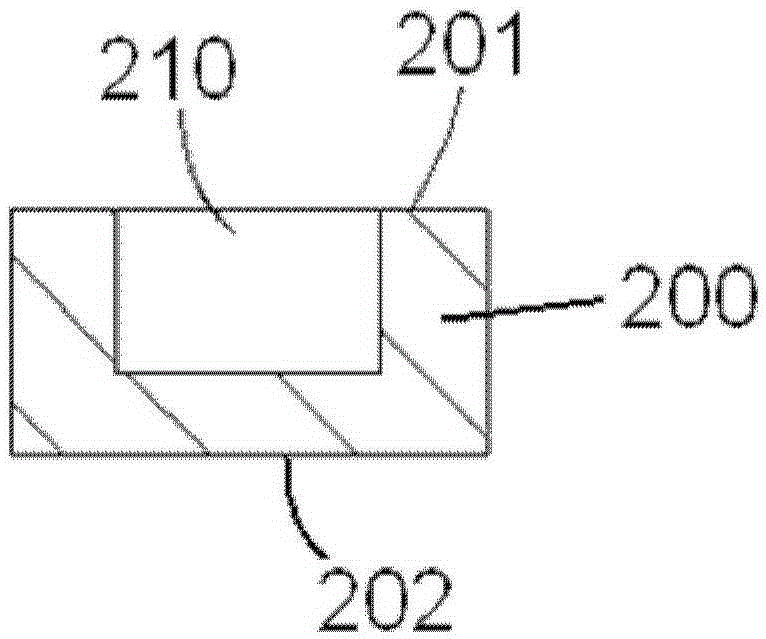

Engine magneto-rheological hydraulic mount method based on circumferential and radial flowing mode

InactiveCN104074919AIncrease the lengthLarge adjustment rangeSpringsJet propulsion mountingEngineeringAlloy

The invention discloses an engine magneto-rheological hydraulic mount method based on a circumferential and radial flowing mode. By means of the combination of a circumferential damping passageway and a radial damping passageway, the length of the damping passageways is increased in the limited structural size; the longer the damping passageways are, the larger the output damping force becomes; due to the fact that the amplitude of an engine is small, the maximum damping force can be increased by increasing the length of the damping passageways, and the adjustable range of the damping force can be widened; the width of the radial damping passageway is determined by the size of an insertion pin, and the width of the radial damping passageway can be changed by changing the size of the insertion pin; a liquid injection hole and an exhaust hole are formed in the middle of a reinforcing block, and therefore exhaust is more smooth in the liquid injection process, and liquid injection can be more convenient; a shell is made of magnetism isolation aluminum alloy material, and therefore magnetic flux leakage is weakened for a magnetic circuit when the engine works.

Owner:CHONGQING UNIV

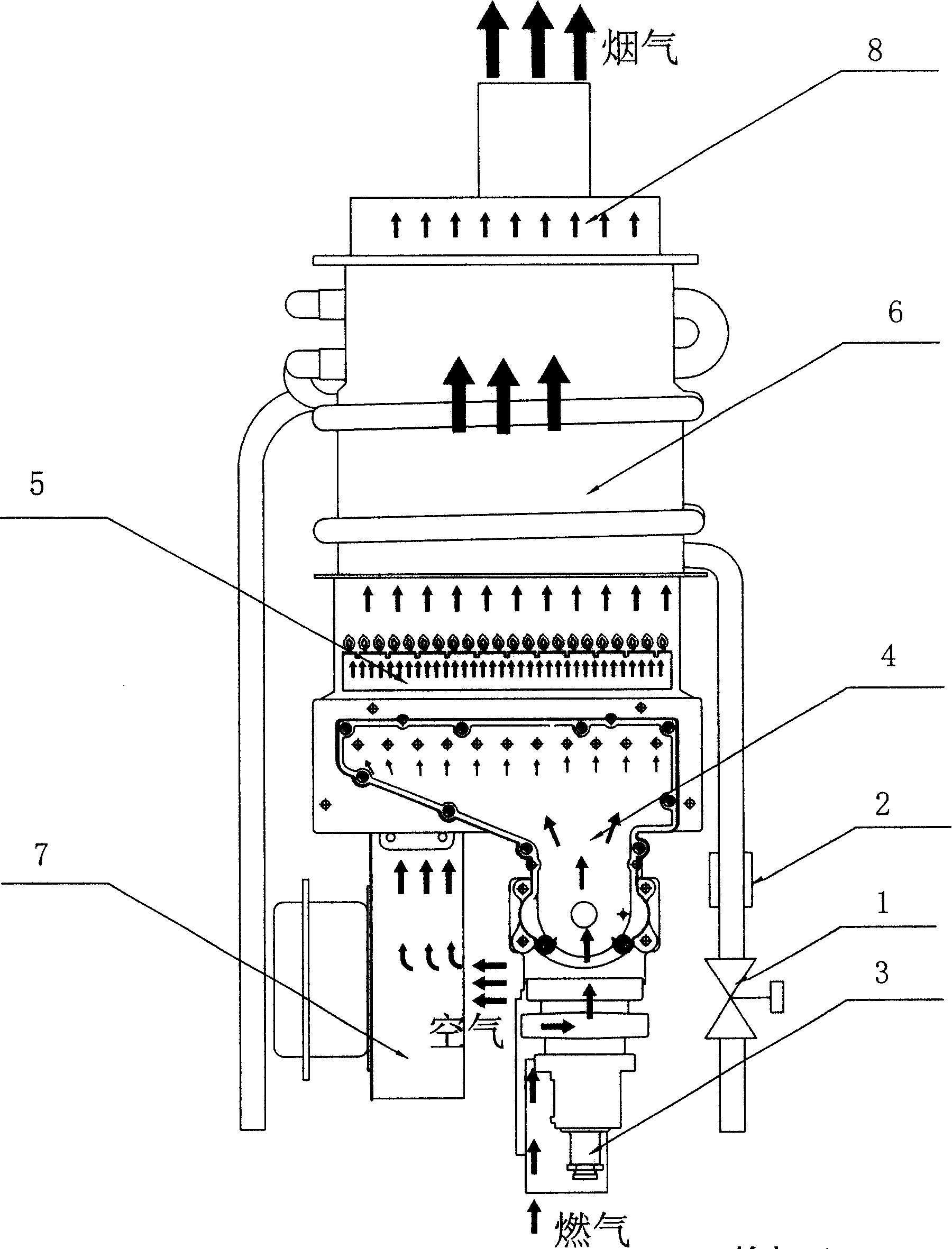

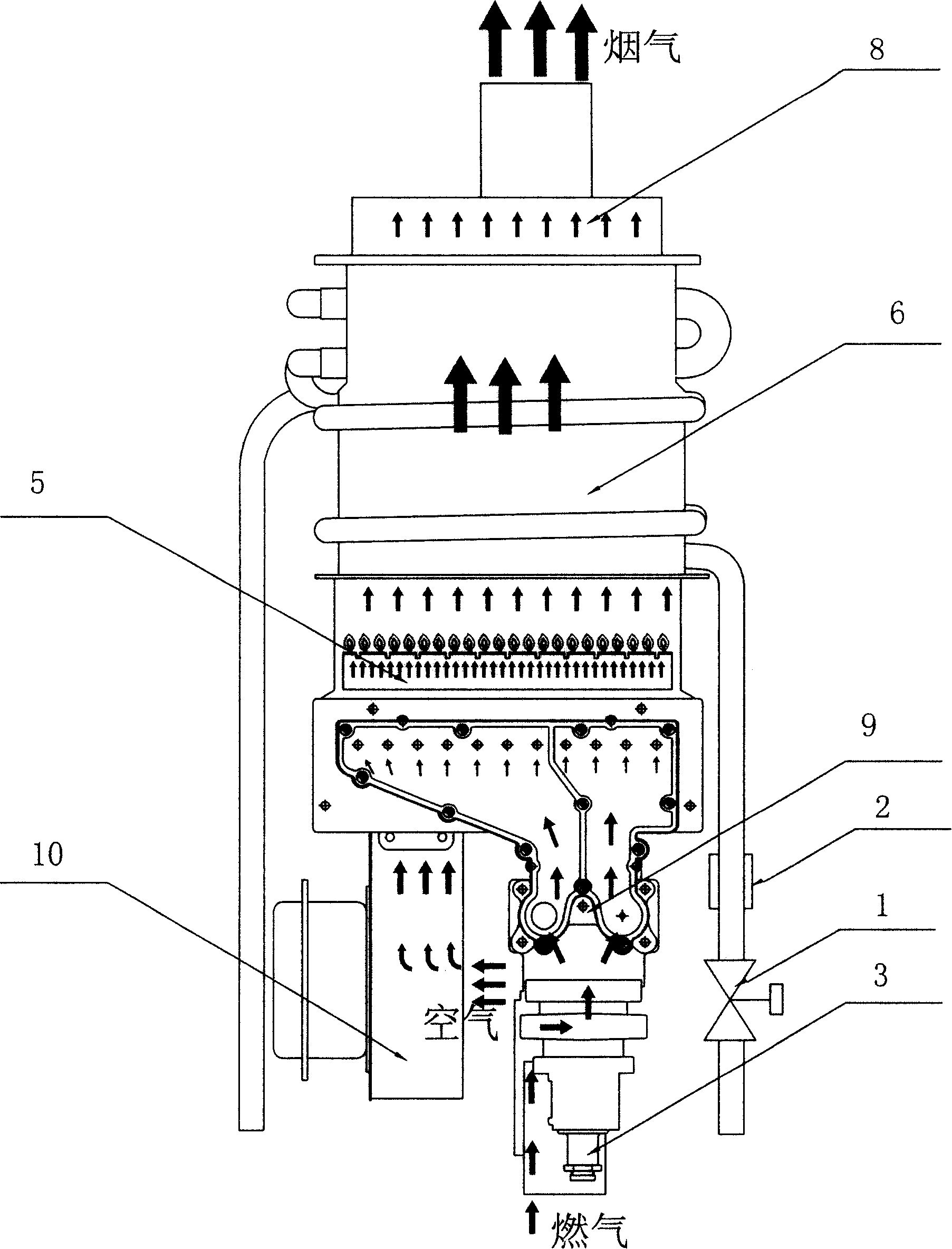

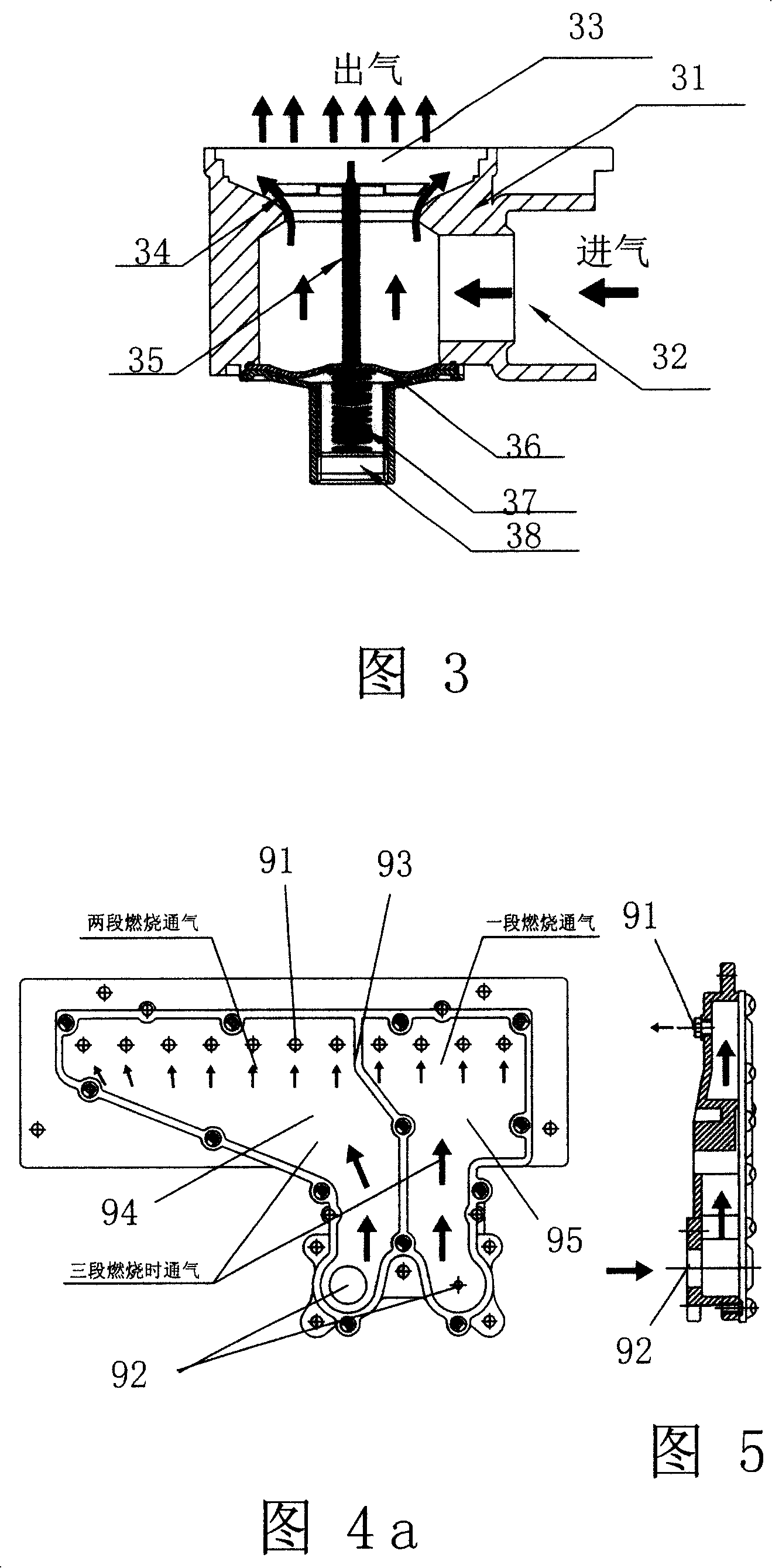

Blue flare subsection air feed gas water heater

The present invention relates to a water heater, in particular to a blue flame segmental air supply gas water heater, comprising: a water inlet valve, a water inlet flow sensor, a gas valve, a pulse igniter, a multi-column fire row burner, a heat exchanger and The fan is characterized in that it is provided with an n-way distributor, the gas valve is connected to the n-1 distributor through n-1 solenoid valves, and one of the n-way distributors is directly connected to the gas valve, Each distributor is provided with a plurality of gas nozzles, and each gas nozzle is directly facing the injection hole of a fire row burner; the fan is an n-speed fan. Divide the air intake channel into multi-stage control, combined with multi-speed variable speed fans to correspond to the low fire, medium fire, and high fire of the burner, so that the excess air coefficient α during combustion is always maintained within the range of 1.5, so that the burner burns in the best state , the content of CO in the flue gas is below 300PPm, and the thermal efficiency is higher than 88%.

Owner:HAIER GRP CORP +1

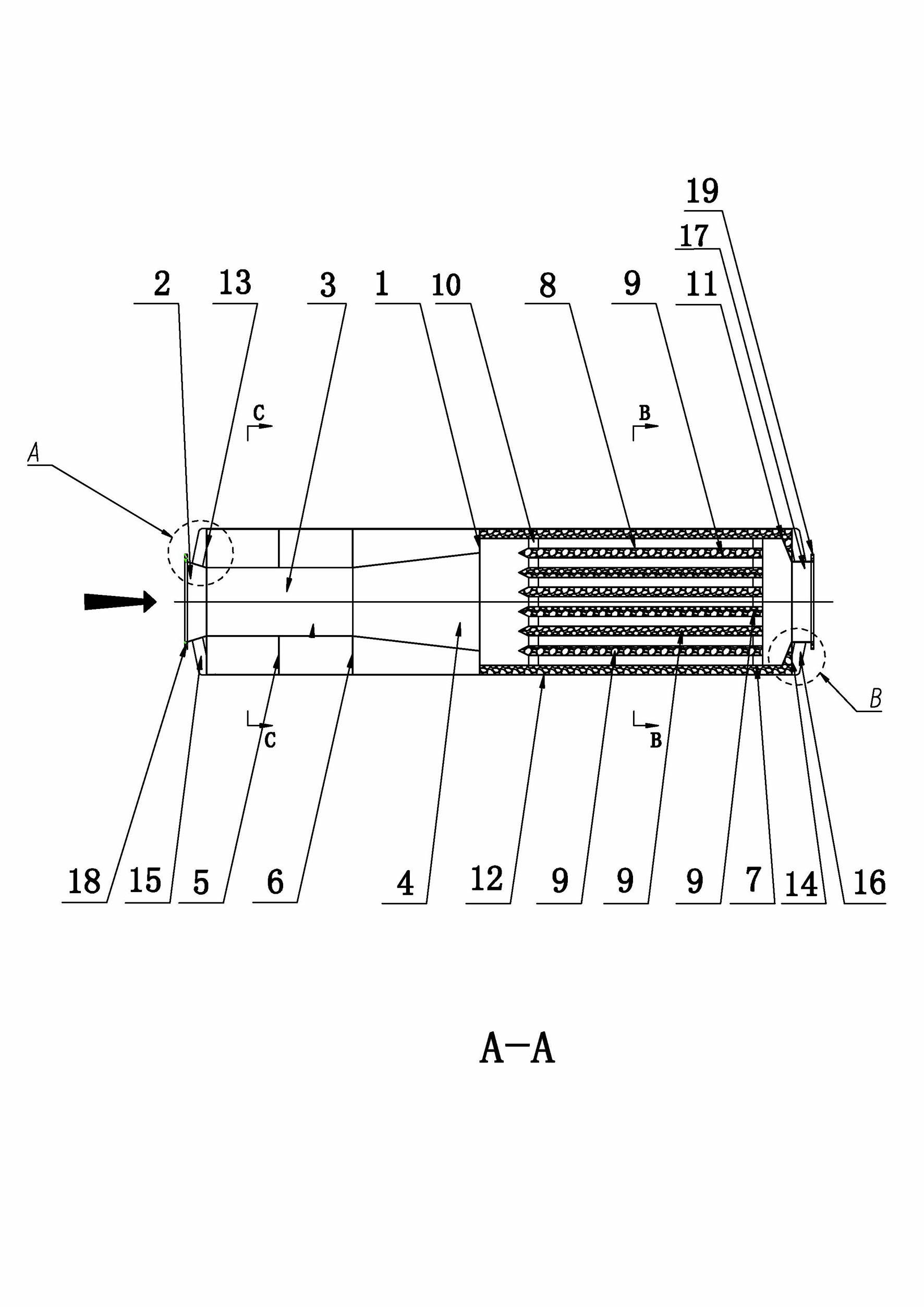

Resistance-and-reactance-compounded exhaust silencer

ActiveCN102230407AReduce high, medium and low frequency noiseKeep the exhaust smoothSilencing apparatusMachines/enginesPhysicsEngineering

The invention relates to the field of exhaust silencing equipment, in particular to a resistance-and-reactance-compounded exhaust silencer. The resistance-and-reactance-compounded exhaust silencer comprises a reactance silencer and a resistance silencer, wherein the reactance silencer consists of a first concentric reducer, a resonance tube, a second concentric reducer, a first fixing ring and a second fixing ring; the inner wall of the reactance silencer is provided with a high temperature-resisting material layer which is made of porous boiler steel; the resistance silencer comprises a lining tube, a silencing block shell, a silencer block which is made of a porous fireproof material prepared from an ultra-thin glass fiber and high temperature rock wool, a fixing plate and a third concentric reducer; and the silencing block is arranged inside the silencing block shell. Compared with the prior art, the resistance-and-reactance-compounded exhaust silencer is characterized in that: theresistance-and-reactance-compounded exhaust silencer can works in a high temperature environment, has a firm structure and is difficult to deform; high, intermediate and low frequency noise which is generated by an internal-combustion engine set can be effectively and greatly reduced; and the smooth exhaust of the internal-combustion engine set can be maintained, and the like.

Owner:湖南省力宇燃气动力有限公司

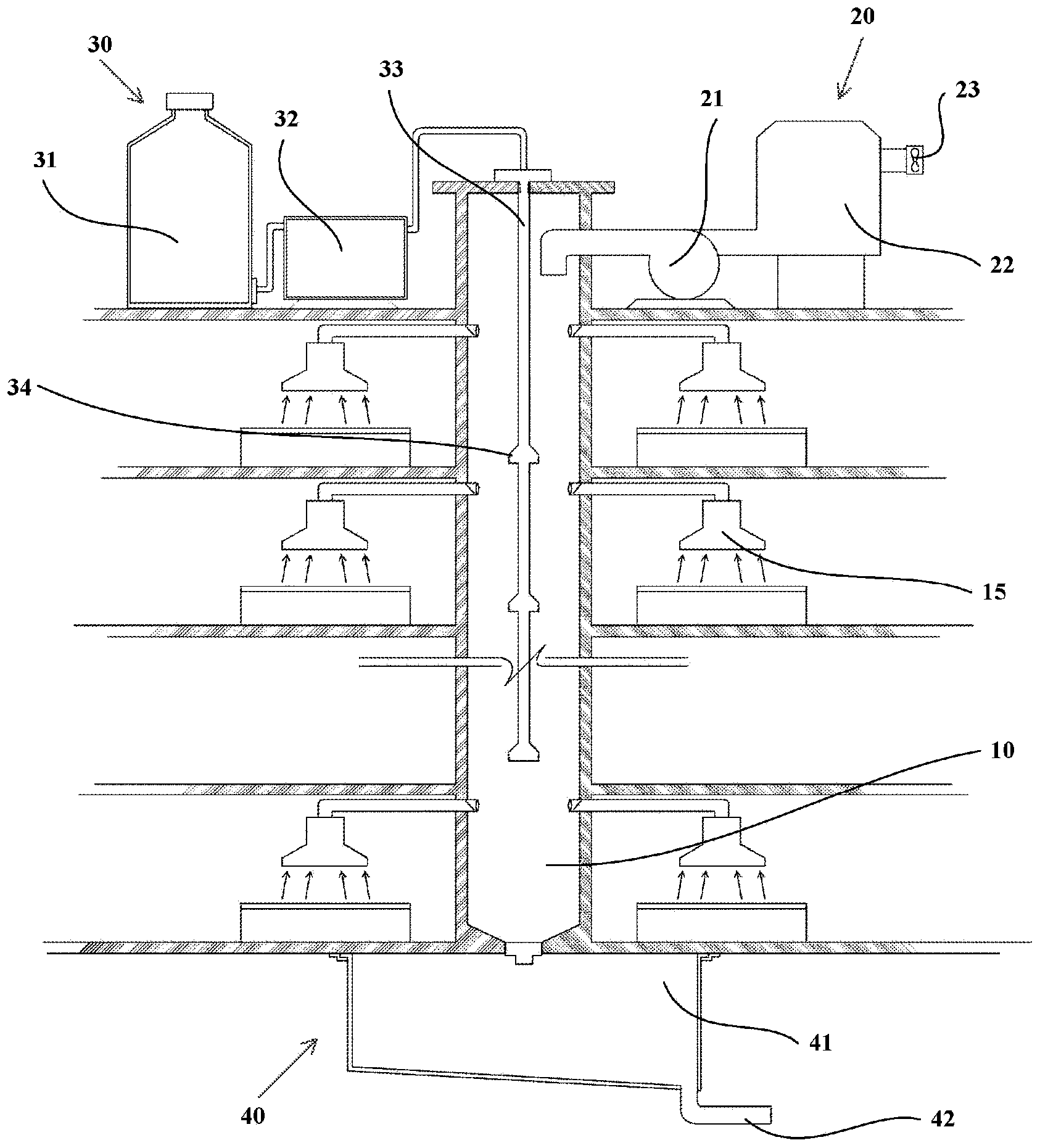

Amalgamated dwelling flue purifying and discharging system

The invention provides an amalgamated dwelling flue purifying and discharging system which comprises a vertically arranged centralized flue. The centralized flue is communicated with each smoke exhaust ventilator arranged at each storey. The amalgamated dwelling flue purifying and discharging system is characterized in that the amalgamated dwelling flue purification discharging system further comprises a cleaning device, an oil stain recovery device, a pumping and drainage type static oil fume purifying and discharging device and a control device; the cleaning device is used for cleaning the centralized flue; the oil stain recovery device is arranged below the centralized flue and used for recovering oil stains and / or liquid waste generated after the centralized flue is cleaned; the pumping and drainage type static oil fume purifying and discharging device is used for forming negative pressure in the centralized flue so as to purify and discharge oil fume in the centralized flue; the control device is used for controlling the pumping and drainage type static oil fume purifying and discharging device according to preset time or oil fume concentration in the centralized flue to form negative pressure in the centralized flue. The amalgamated dwelling flue purifying and discharging system can prevent oil fume in the smoke exhaust ventilators from flowing backwards and avoid unsmooth fume discharging, and discharged oil fume is clean; particularly, the amalgamated dwelling flue purifying and discharging system can lower potential fire hazards and keep the centralized flue clean.

Owner:华信恒基(北京)科技发展有限公司 +1

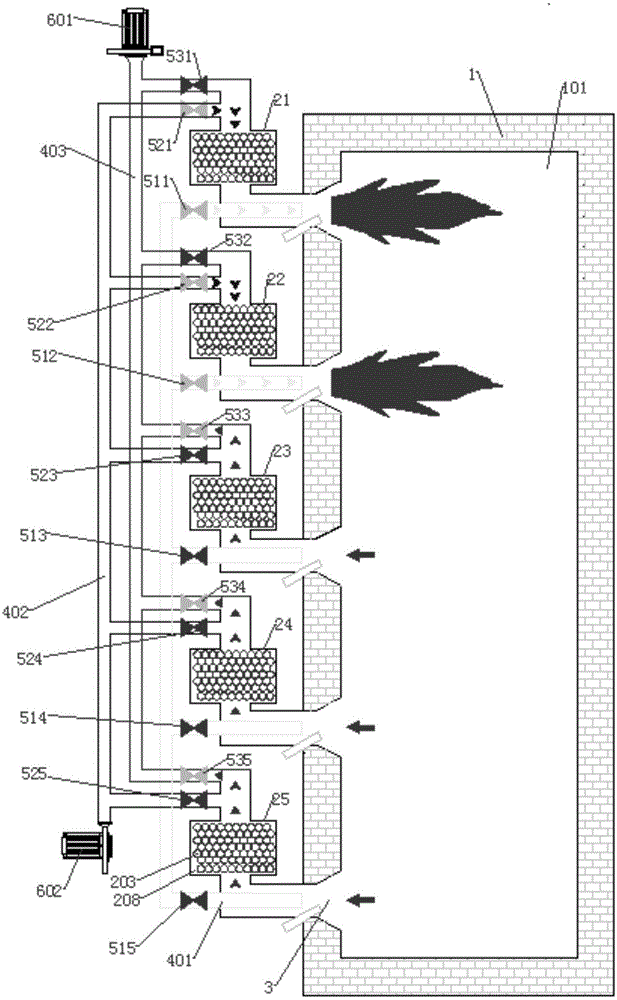

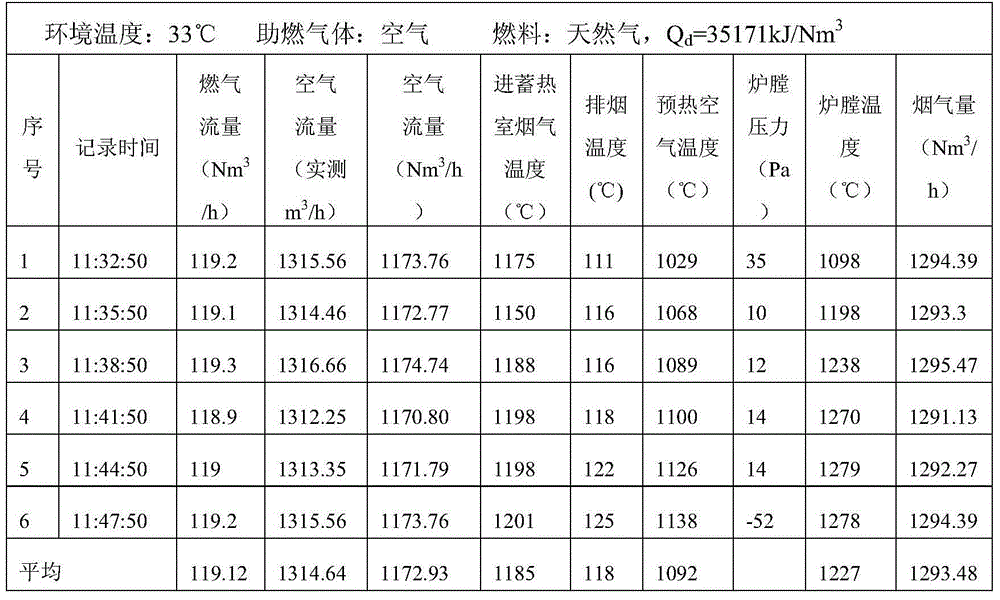

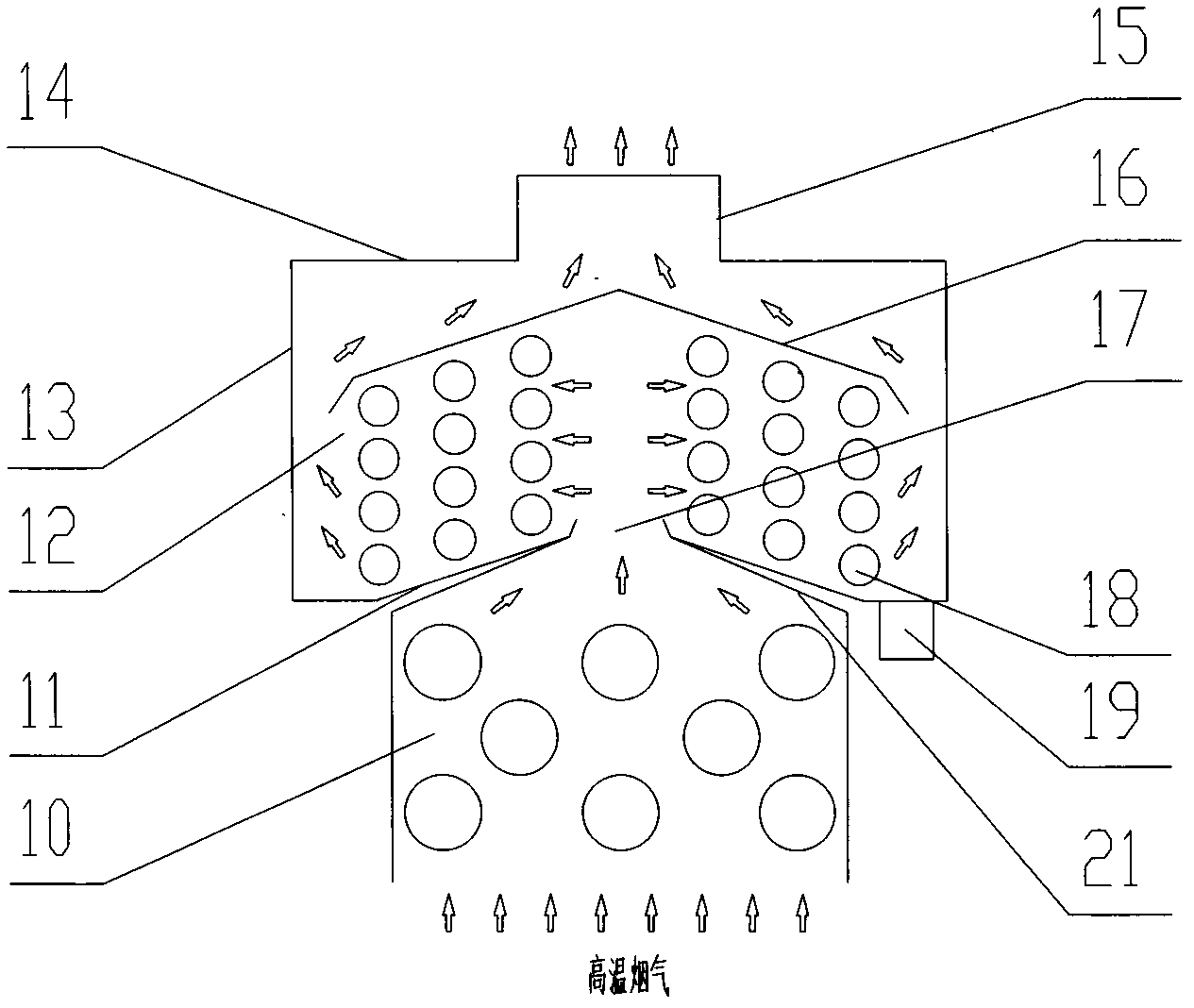

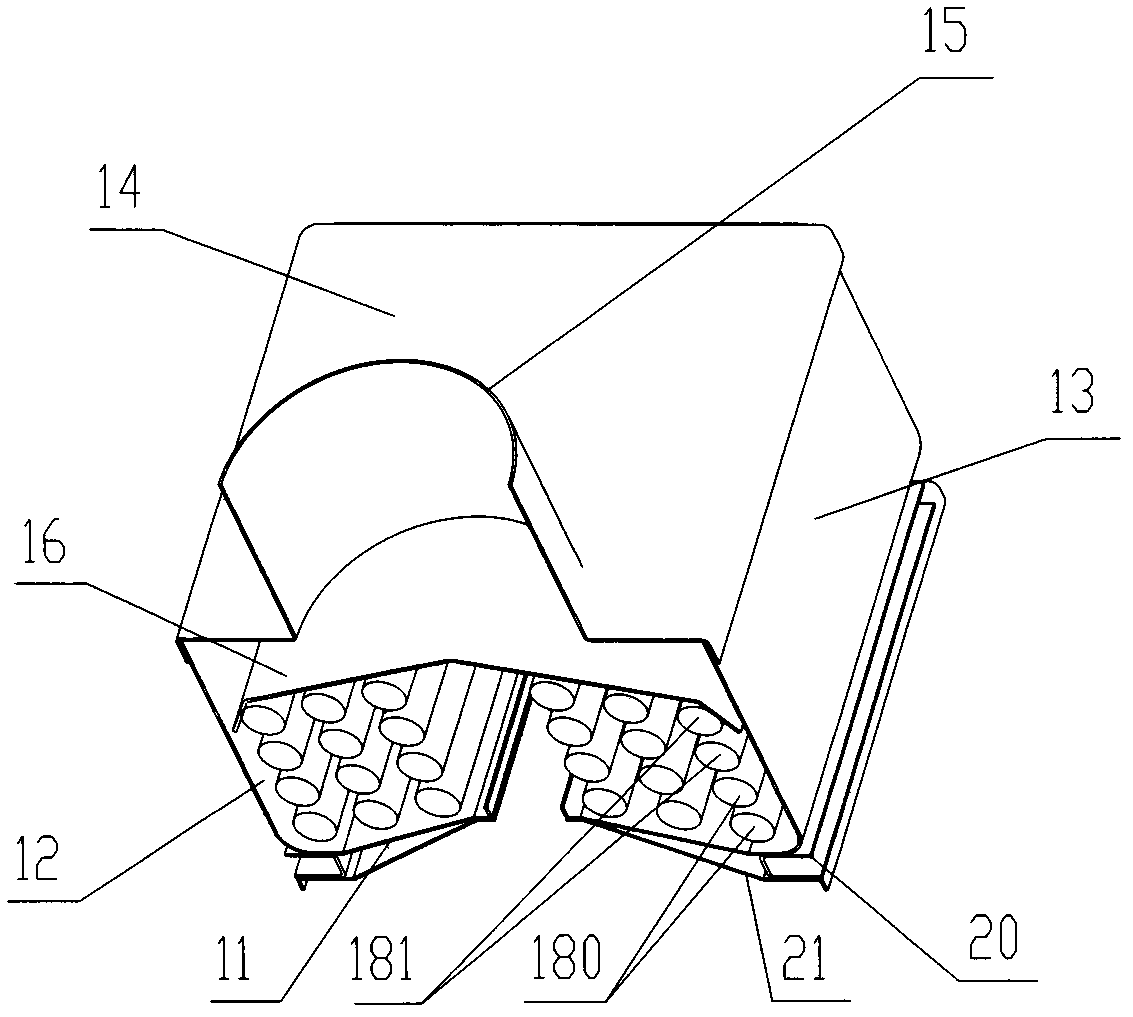

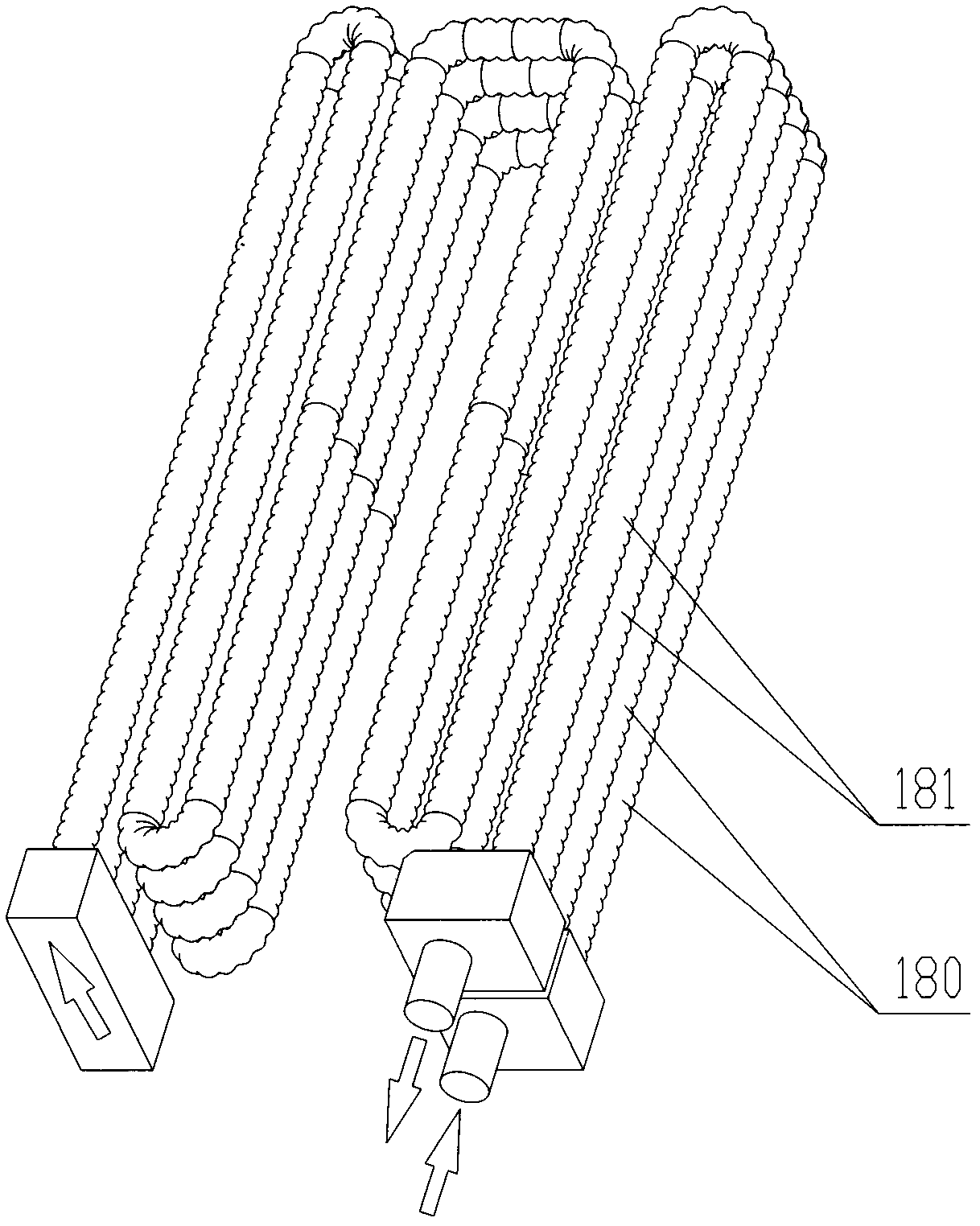

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

Liquid storage container and liquid filling method and liquid refilling method using the same

The present invention relates to a liquid storage container and a liquid filling method thereof and a liquid refilling method using the same, and thereby the lequid which causes poor quality ro faulty operation. The liquid storage container includes a liquid containing body that is formed of a flexible film and contains liquid therein; a liquid lead-out member connected to the liquid containing body; and a spacer member disposed in the liquid containing body. The liquid containing body deforms in a direction in which inner wall surfaces of the flexible film facing each other are brought into contact with each other at the time of reduction in the remaining amount of the liquid as the inside liquid is taken out through the liquid lead-out member, and the spacer member regulates contact between parts of the inner wall surfaces of the flexible film facing each other at the time of reduction in the remaining amount of the liquid to thereby form a remaining liquid space where liquid remains.

Owner:SEIKO EPSON CORP

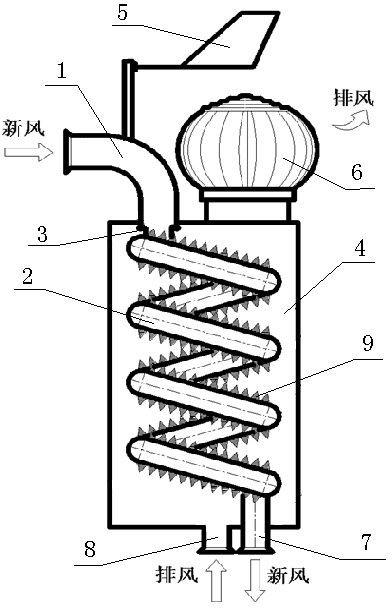

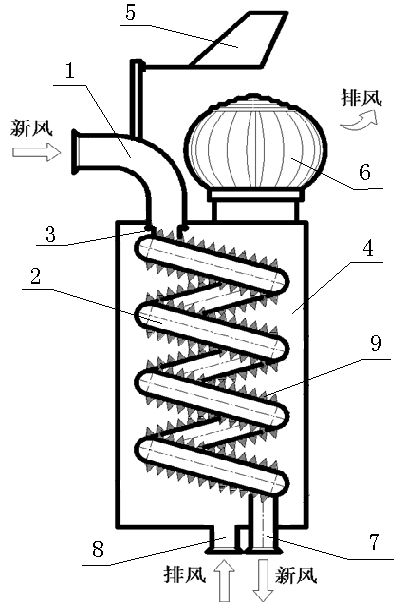

Energy-saving air inlet/exhaust combined air port

ActiveCN102162675ALow costIncrease the heat exchange areaAir-flow control membersMechanical engineeringExhaust heat

The invention relates to an air inlet / exhaust combined air port, and particularly discloses an energy-saving air inlet / exhaust combined air port. The combined air port comprises an air inlet entrance pipeline, an air inlet pipeline and an air exhaust pipeline, wherein the air inlet pipeline is located in the air exhaust pipeline; a connection groove is arranged at the end part of the entrance endof the air inlet pipeline; the bottom end of the air inlet entrance pipeline is arranged in the connection groove; a rotary blade is fixed on the air inlet entrance pipeline; and the orientation of the rotary blade is opposite to that of the entrance of the air inlet entrance pipeline. Due to the unique design of the air inlet / exhaust combined air port, the air inlet entrance always faces to the coming flow, and the air exhaust waste heat can be utilized to save energy; and moreover, the combined air port also adopts an unpowered air cap to perform air exhaust so that the air exhaust is smoother and energy loss is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Exhaust system applied to vehicle and vehicle provided with exhaust system

ActiveCN103835788APrecise temperature controlReduce contentExhaust apparatusSilencing apparatusHazardous substanceExhaust fumes

The invention discloses an exhaust system applied to a vehicle and the vehicle provided with the exhaust system. The exhaust system applied to the vehicle comprises an exhaust pipe, a catalytic converter, a heat-preserving gas storage tank and a temperature adjustment layer, wherein a gas inlet of the exhaust pipe is connected with an outlet of an exhaust pipeline of an engine of the vehicle; the catalytic converter is arranged on the exhaust pipe and located between the gas inlet of the exhaust pipe and a gas outlet of the exhaust pipe; the heat-preserving gas storage tank is connected with the exhaust pipe to collect waste gas in the exhaust pipe and store the waste gas, and the heat-preserving gas storage tank can selectively supply the stored waste gas to the catalytic converter; the temperature adjustment layer can melt to absorb heat and solidify to release heat and is arranged in the heat-preserving gas storage tank to adjust the temperature of the waste gas in the heat-preserving gas storage tank. According to the exhaust system applied to the vehicle, at the time of cold start of the engine, the ignition of a catalyst is accelerated, and the content of harmful substances in the waste gas of the exhaust system is effectively lowered; the temperature of the waste gas in the heat-preserving gas storage tank can be controlled accurately, and therefore the exhaust system saves more energy and is more efficient.

Owner:GREAT WALL MOTOR CO LTD

Mold releasing agent and preparation method thereof

InactiveCN104174812ADoes not affect normal useImprove stabilityFoundry mouldsFoundry coresPolyvinyl alcoholAdhesive

The invention discloses a mold releasing agent and a preparation method thereof. The mold releasing agent comprises the following raw materials by weight: 500 g of pure water, 6-9 g of adhesive, 1-3 g of stabilizing agent, and 15-35 g of cork powder, wherein the adhesive is bone glue; the stabilizing agent is polyvinyl alcohol; and the cork powder is mixed powder of cork powder of 200 mesh and cork powder of 600 mesh. The preparation method of preparing the mold releasing agent comprises the following steps: (1) pouring of a backing material: the pure water is poured in an aluminum pot; (2) adding of the adhesive and the stabilizing agent, heating and stirring: the adhesive and the stabilizing agent are added in the aluminum pot; the aluminum pot is heated to a boiling point; and the mixing is performed during heating; (3) adding of the cork powder: the cork powder is added in the aluminum pot, and the mixture is cooled to the room temperature; and (4) storage. The process is simple and the cost is low; the mold releasing agent has the advantages of easy coating, good adhesiveness, high-temperature resistance, high-pressure resistance and smooth exhaust; the number of mold spraying times in unit time is decreased; the production efficiency and the product quality are improved; and the economic benefit of enterprises is enhanced.

Owner:TIANNENG BATTERY WUHU

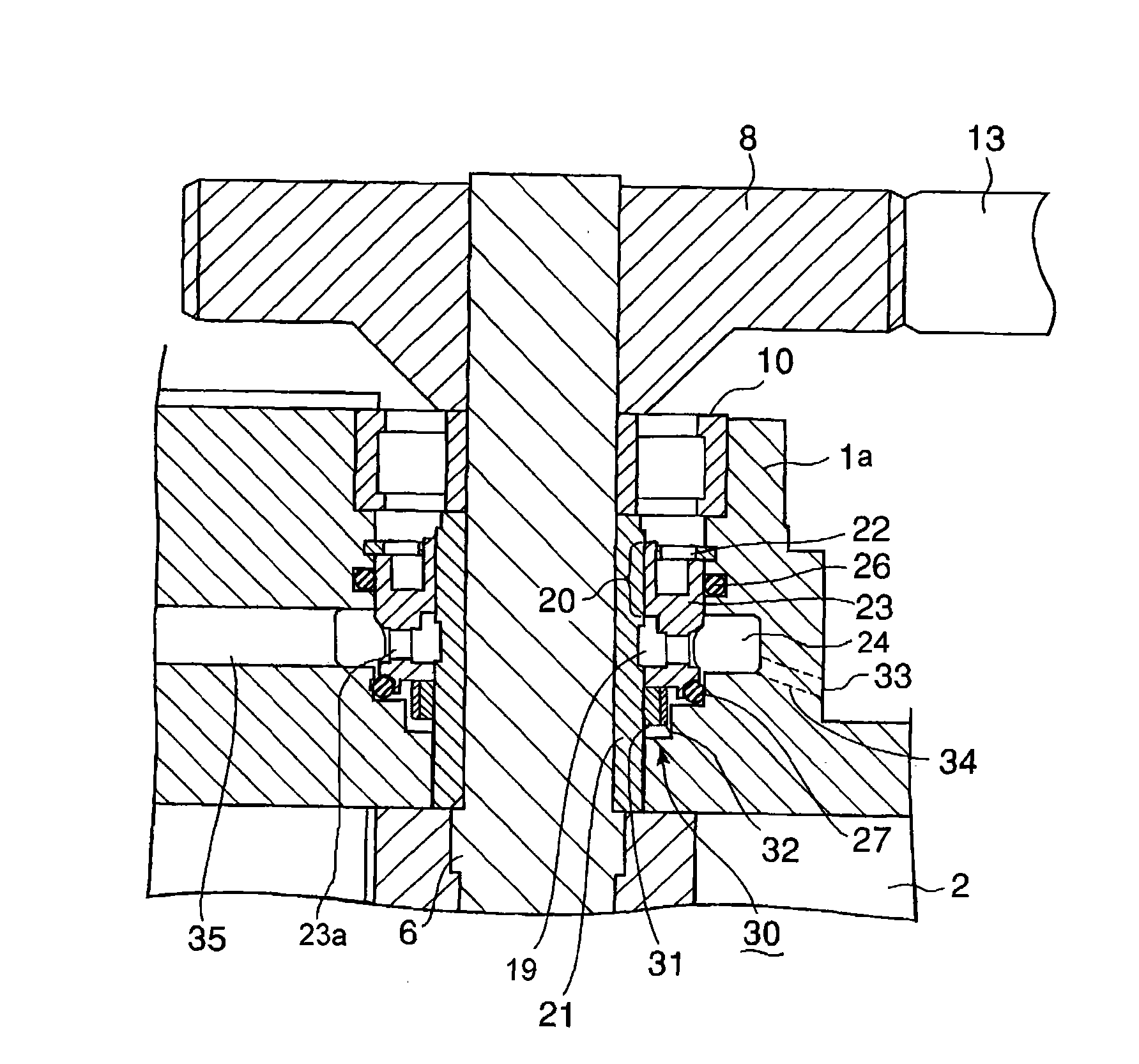

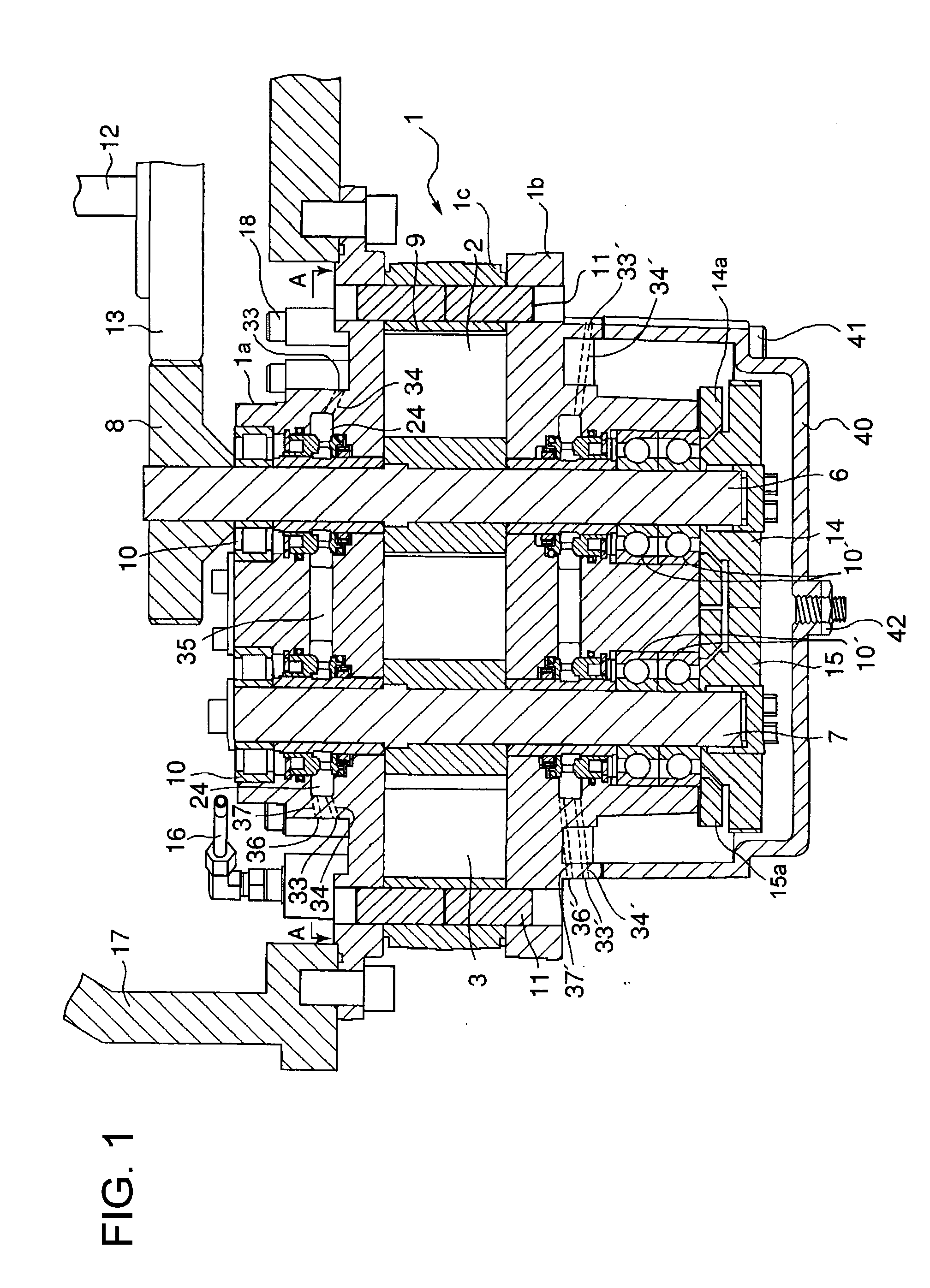

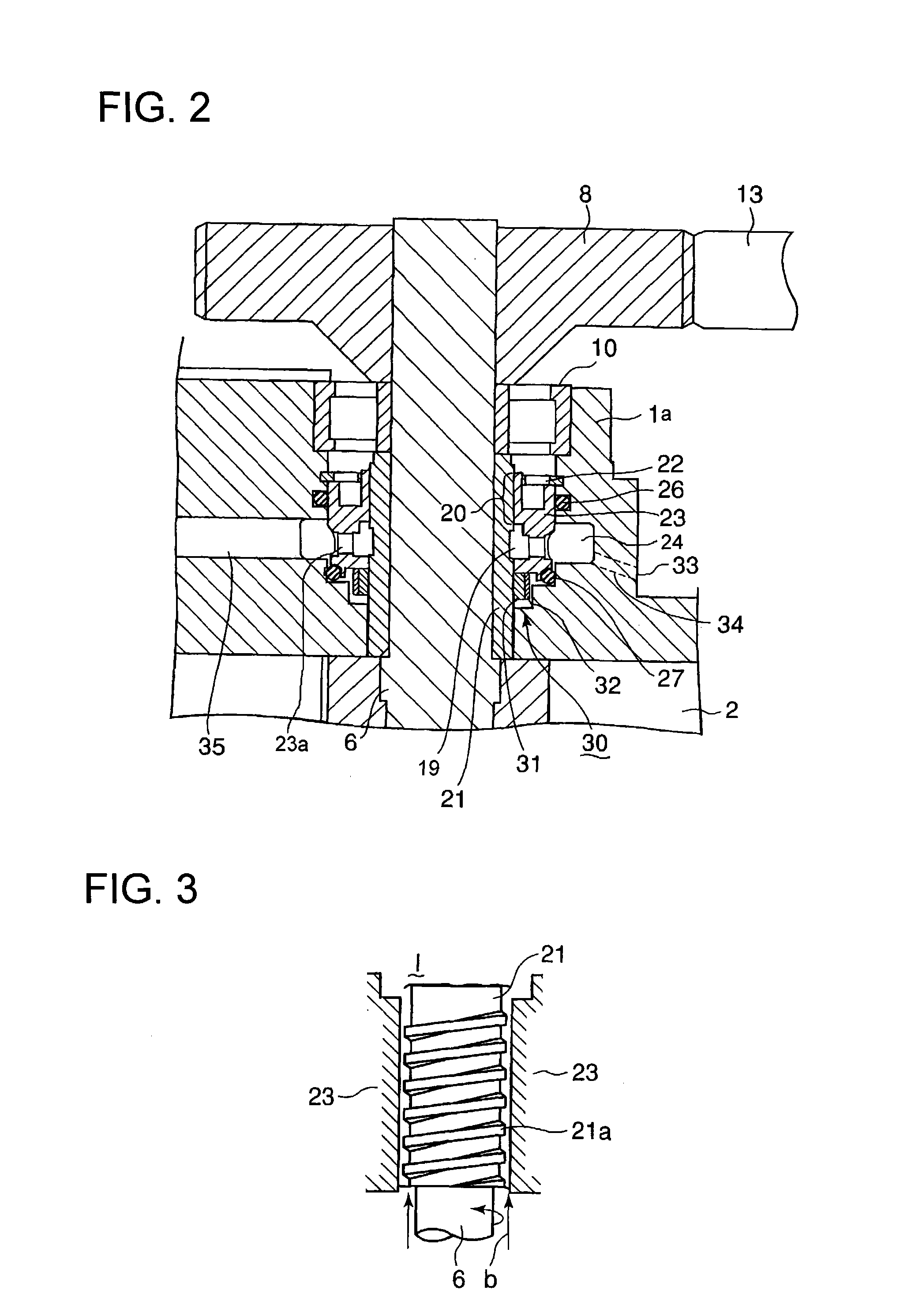

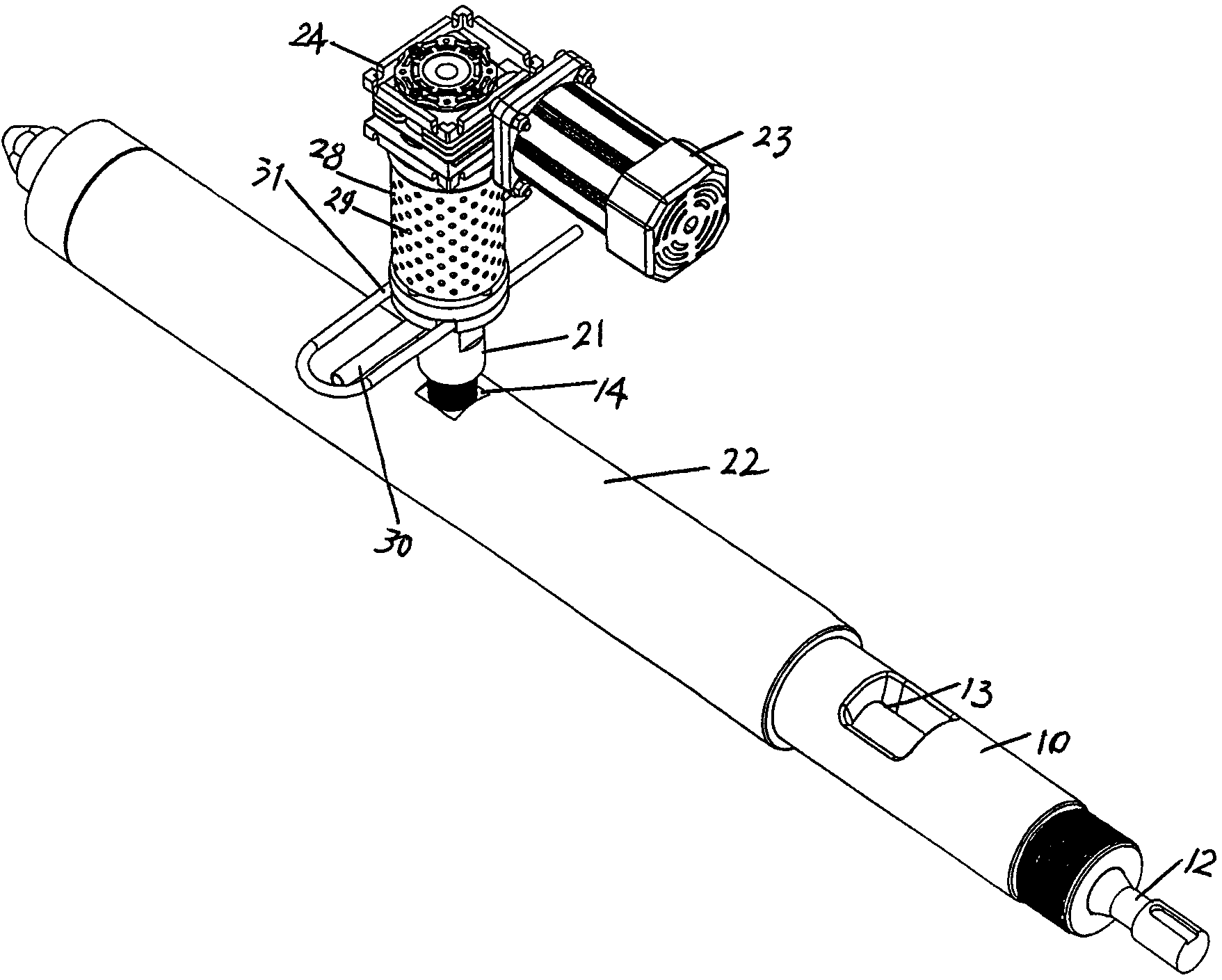

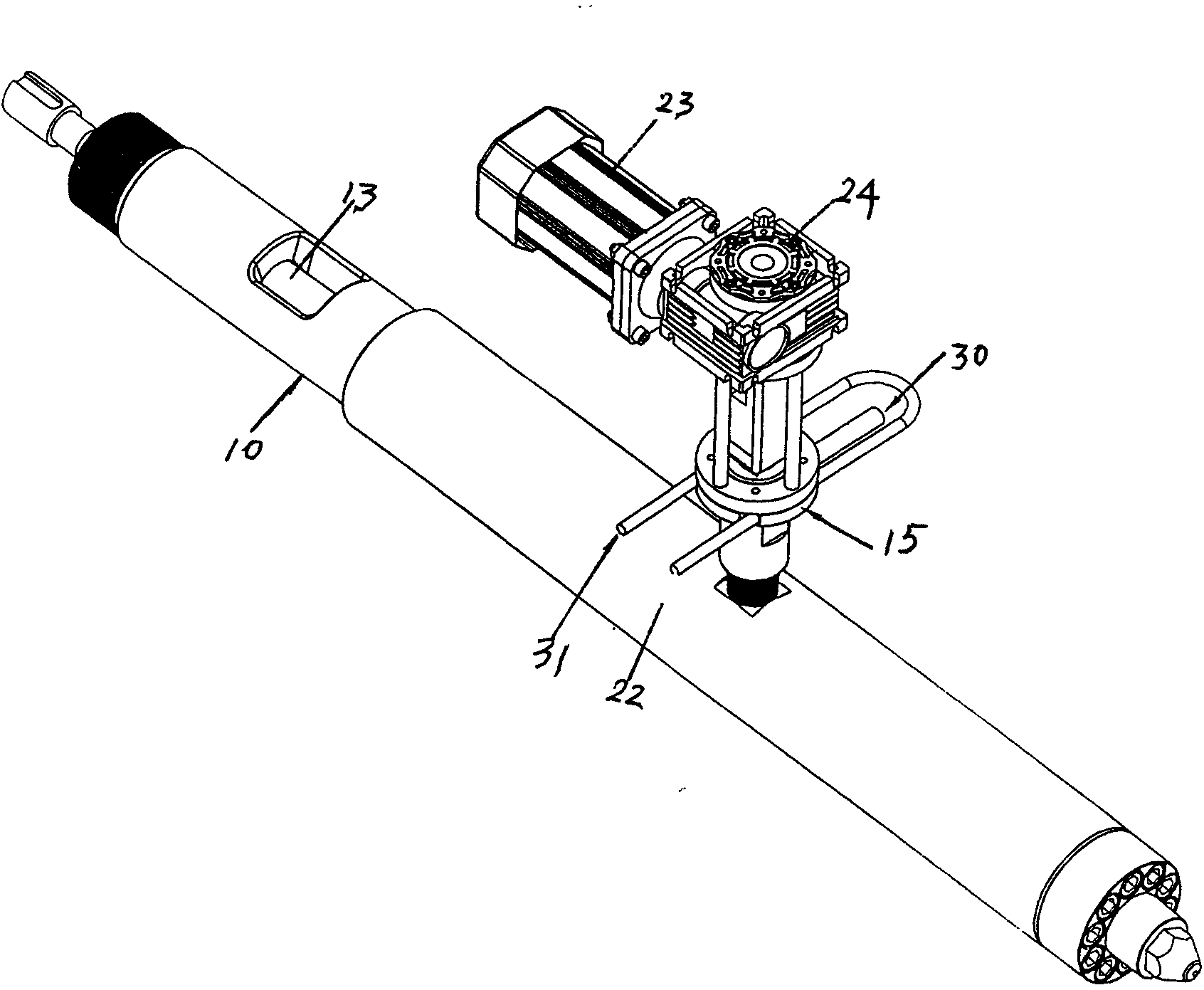

Rotor shaft sealing structure for oil-free rotary compressor

InactiveUS20080240963A1Maintaining atmospheric pressureRisk of intrusionRotary/oscillating piston combinations for elastic fluidsEngine sealsOil freeEngineering

A rotor shaft sealing structure of an oil-free rotary compressor is provided, with which is reduced a risk of occurrence of lubrication oil intrusion into the compression chamber (9) of the compressor which is liable to occur when negative pressure is produced in the compression chamber (9). The rotor shaft sealing structure is composed such that two shaft seal means (20, 30) are provided in the rotor casing (1) between the oil lubricated bearing (10, 10′) and the compression chamber (9) such that an annular airspace (24) is formed between the two shaft seal means (20,31), at least one communicating hole (34,34′) is provided to communicate the annular airspace (24) to the outside of the rotor casing (1), and the annular airspace (24) of the male rotor shaft (6) sealing part and the annular airspace (24) of the female rotor shaft (7) sealing part are connected by a between-rotor shaft communication passage (35).

Owner:ANEST IWATA CORP

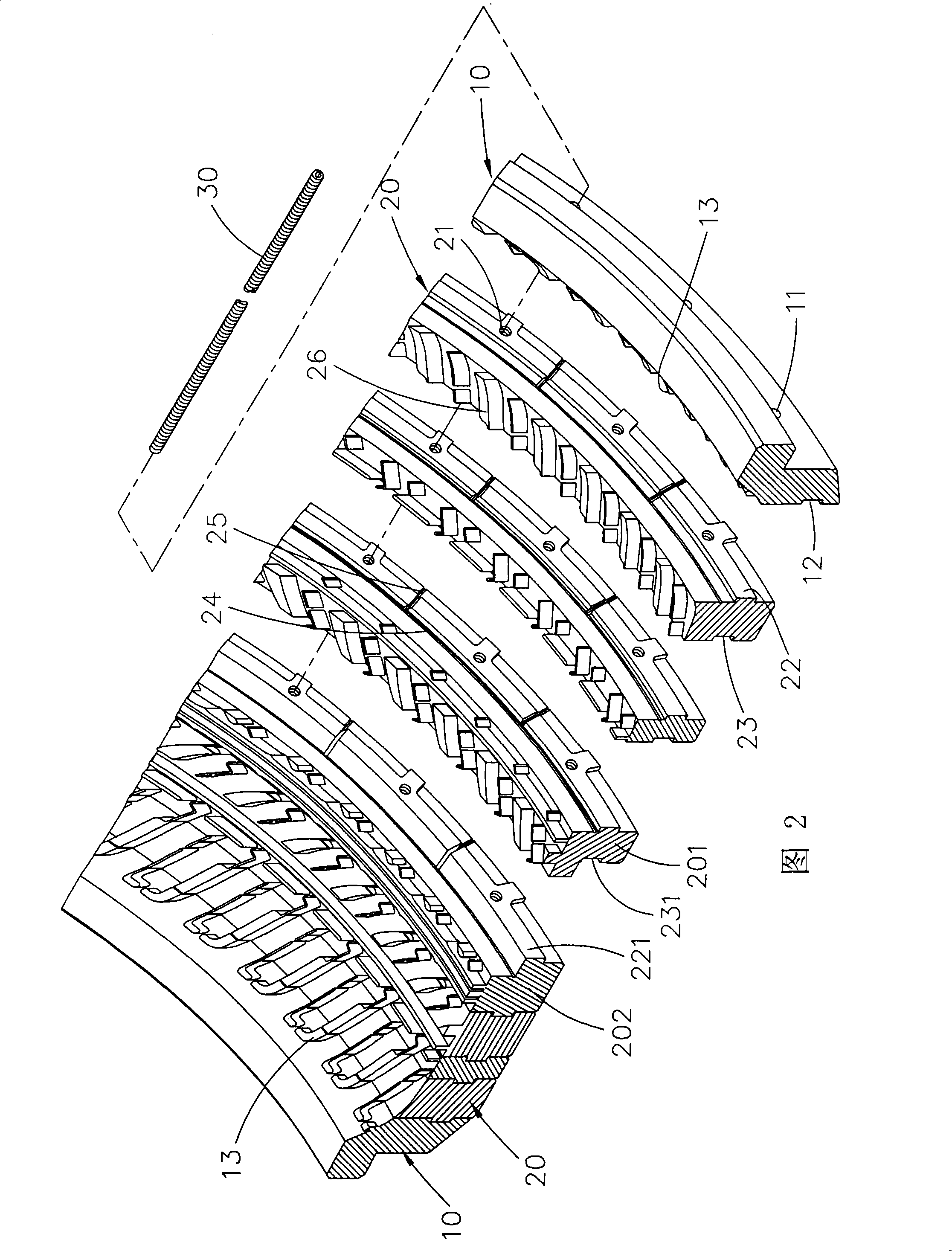

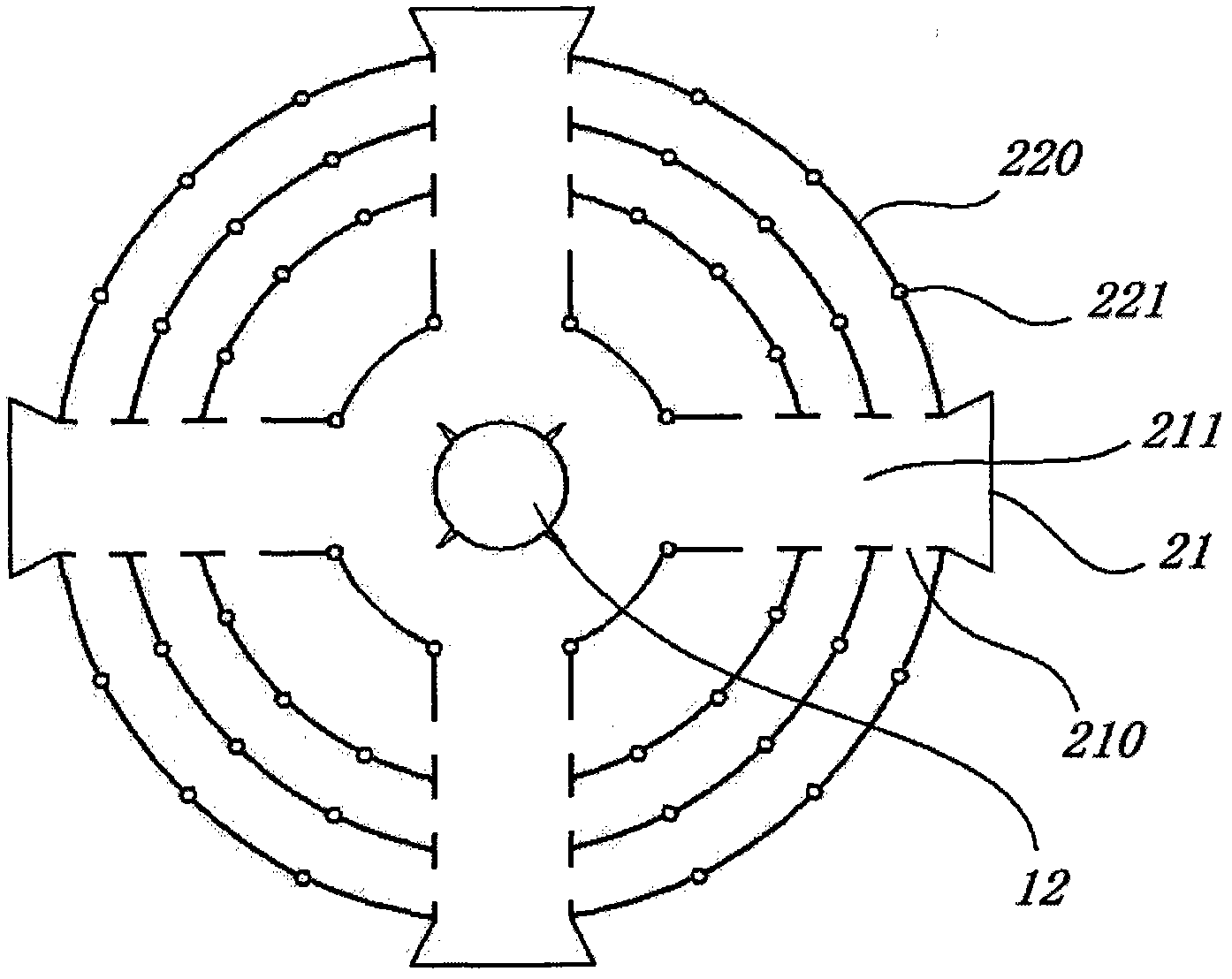

Templet assembly device for mould

The invention relates to a template assembly device for tyre mould consisting of a plurality of ring-shaped external templates 10 and internal templates 20, and a connecting piece 30. The tire mould is formed by connecting a plurality of internal templates 20 between two external templates 10 in parallel and group-puncturing the internal templates and external templates through the connecting piece 30, so as to ensure that the assembly of various templates of the tyre presents a segmentation model relatively along the radial ring surface of the tire and the templates of the tyre mould are different from the previous templates of the mould presenting segmentation model relatively along the cross section of the tire, thus achieving the goal of a simple structure and being easy to clean the tyre mould.

Owner:MING KING IND

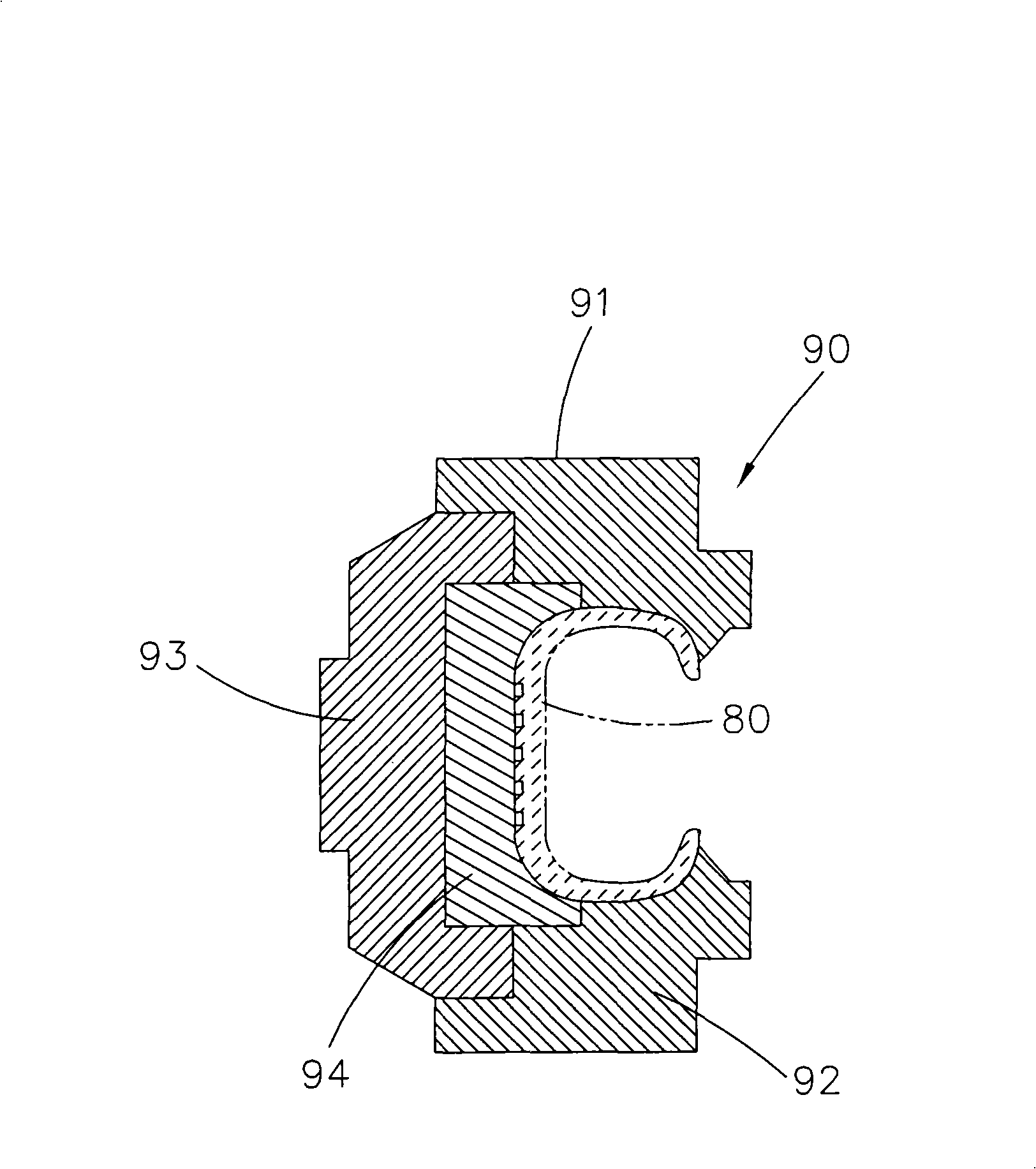

Gas discharge valve and compressor with same

ActiveCN106609758ASmooth exhaustAvoid fatigue failureRotary/oscillating piston pump componentsLiquid fuel engine componentsProduct gasEngineering

The invention discloses a gas discharge valve. The gas discharge valve comprises a valve seat, a valve body and a valve deck. A containing cavity is formed in the valve deck. A gas channel communicating with the containing cavity is formed in the circumferential wall of the containing cavity. A gas outlet hole communicating with the containing cavity is formed in the top wall of the containing cavity. A blind hole is formed in the valve body. The valve body is contained in the containing cavity of the valve deck. When compressed gas having a preset pressure is discharged out from a gas discharging hole, the valve body contained in the containing cavity of the valve deck is ejected by the discharged gas and is sucked to the inner side of the top wall of the containing cavity, and the compressed gas discharged from the gas discharging hole flows out from the gas channel of the valve deck. According to the gas discharge valve, when the gas is discharged, the valve body can be reliably sucked to the inner side of the top wall of the containing cavity of the valve deck; and in this way, the gas discharge valve can be reliably kept at the opened state when the gas is discharged, gas discharging is guaranteed to be smooth, and the situation that the gas discharge valve is frequently switched and fatigued and is ineffective because of gas pressure fluctuation can be avoided.

Owner:DANFOSS (TIANJIN) CO LTD

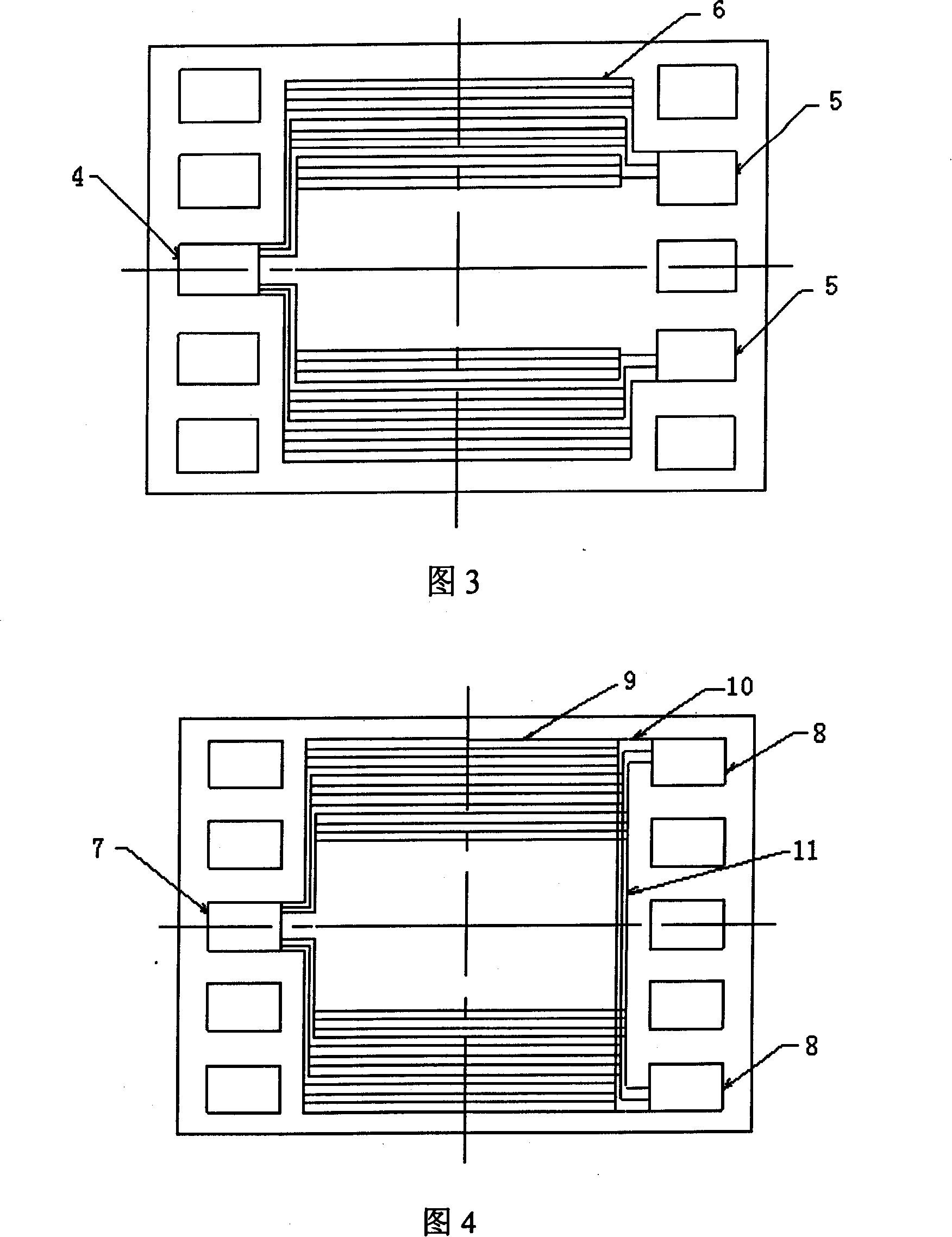

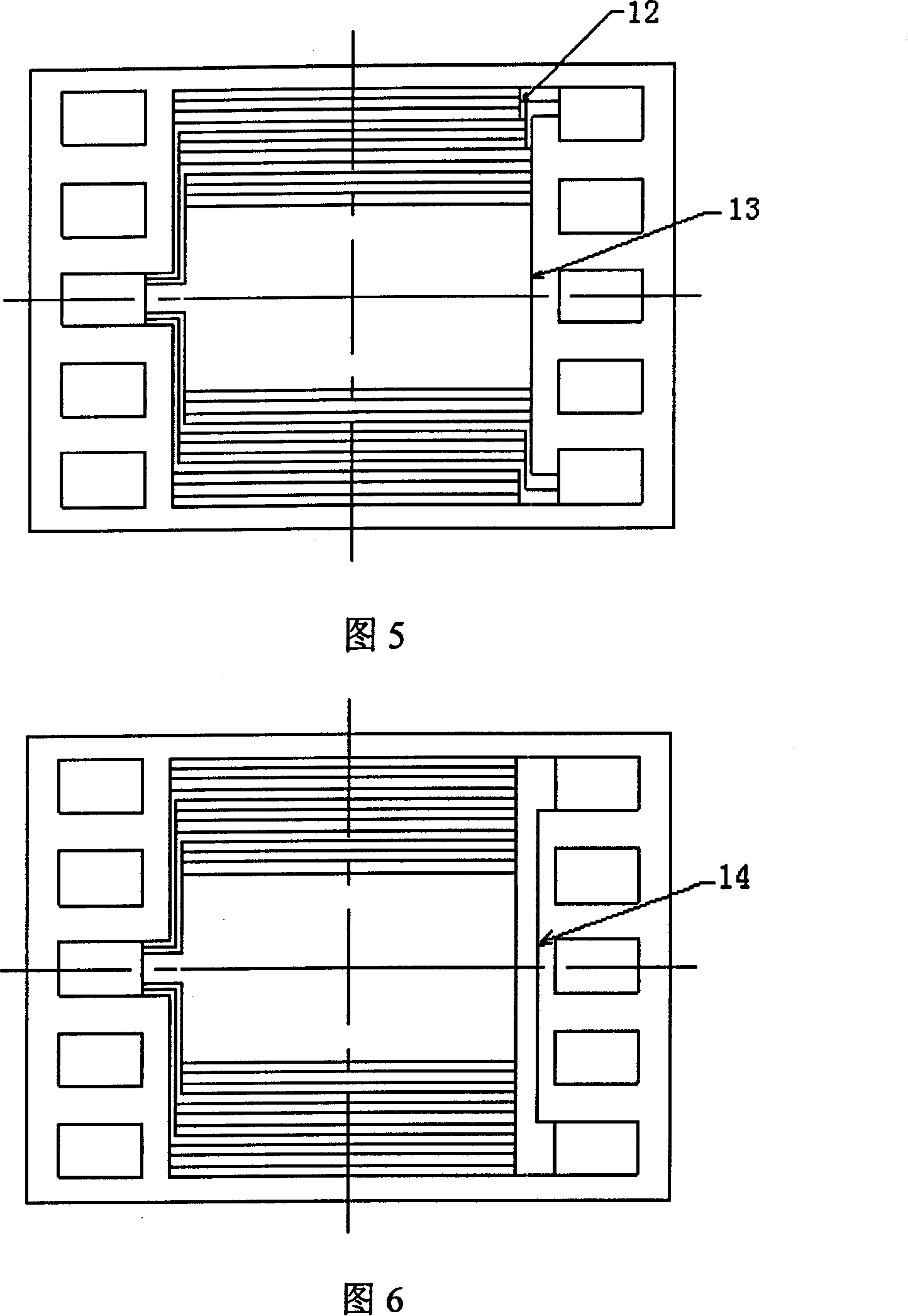

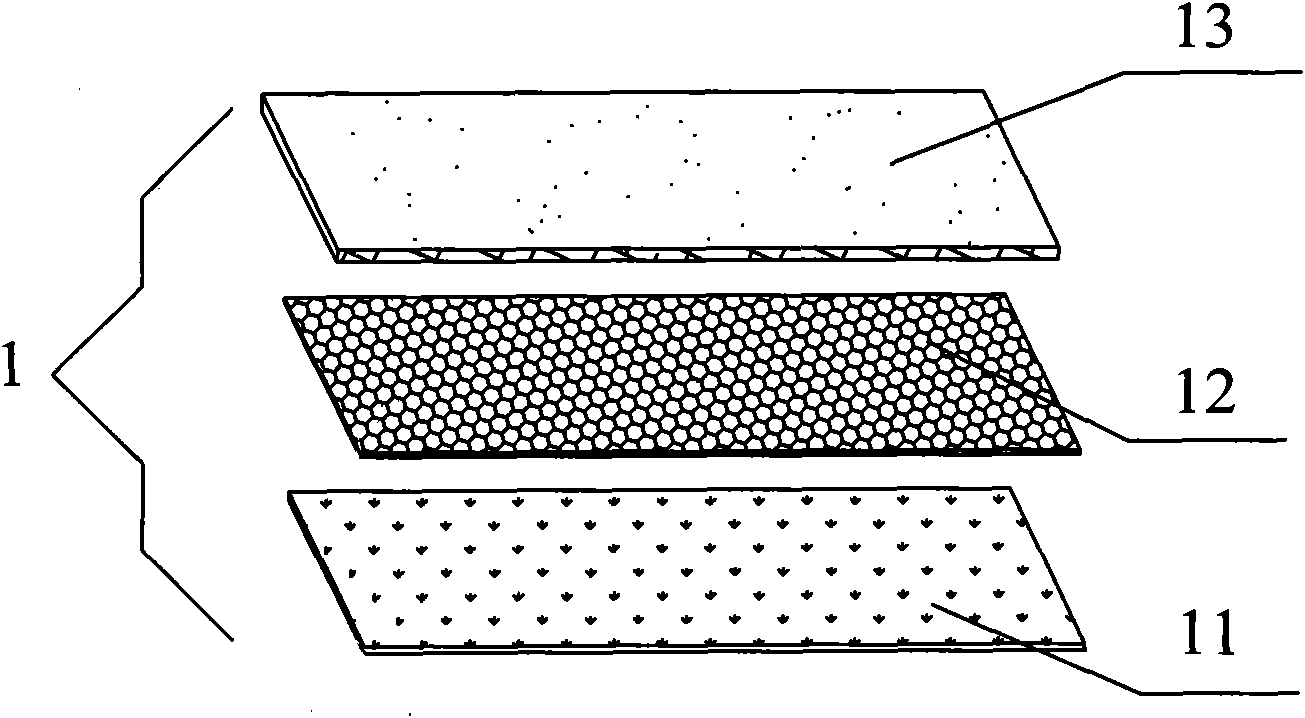

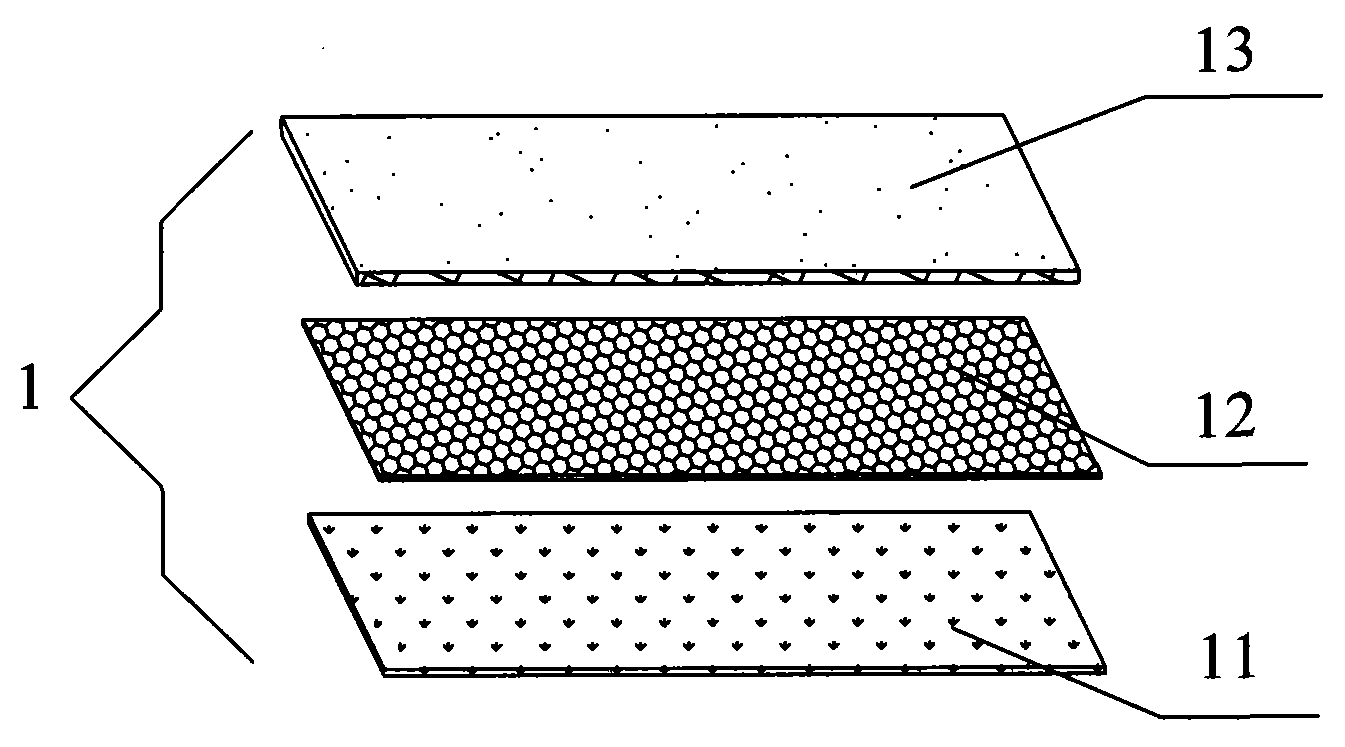

Chip type oxygen sensor and preparation method thereof

ActiveCN102109486AHigh sensitivityExtended service lifeMaterial analysis by electric/magnetic meansProtection layerYttrium

The invention provides a chip type oxygen sensor and a preparation method thereof. A porous protection layer of the chip type oxygen sensor comprises a transition layer, a porous layer and an absorption layer; holes are formed on all the layers, so that the bottom of the porous protection layer is communicated with the top of the porous protection layer; the holes on the transition layer with thediameters ranging from 0.1mu.m to 1.5 mu.m account for above 80 percent of the total holes on the transition layer; the holes on the porous layer with the diameters ranging from 0.3 mu.m to 8 mu.m account for above 80 percent of the total holes on the porous layer; the holes on the absorption layer with the diameters ranging from 0.1 mu.m to 2 mu.m account for above 80 percent of the total holes on the absorption layer; the transition layer contains zirconium oxide with stable yttrium oxide and magnesia-alumina spinels; the porous layer contains zirconium oxide, magnesia-alumina spinels and noble metal; and the absorption layer contains magnesium oxide, calcium oxide, aluminum oxide, magnesium sulfate and barium oxide. Compared with the prior art, the chip type oxygen sensor has the advantages of high sensitivity and thermal shock resistance and long service life.

Owner:BYD CO LTD

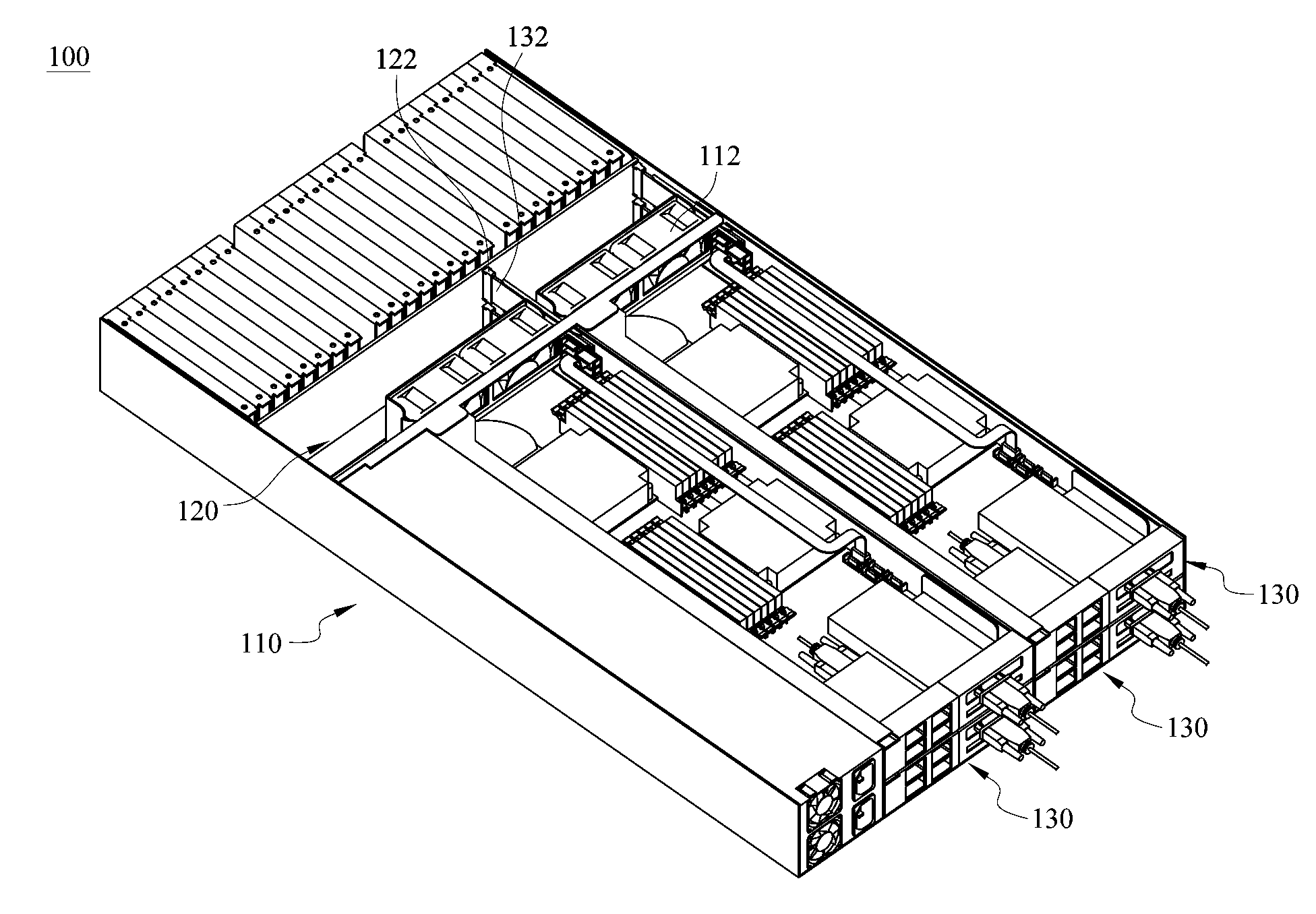

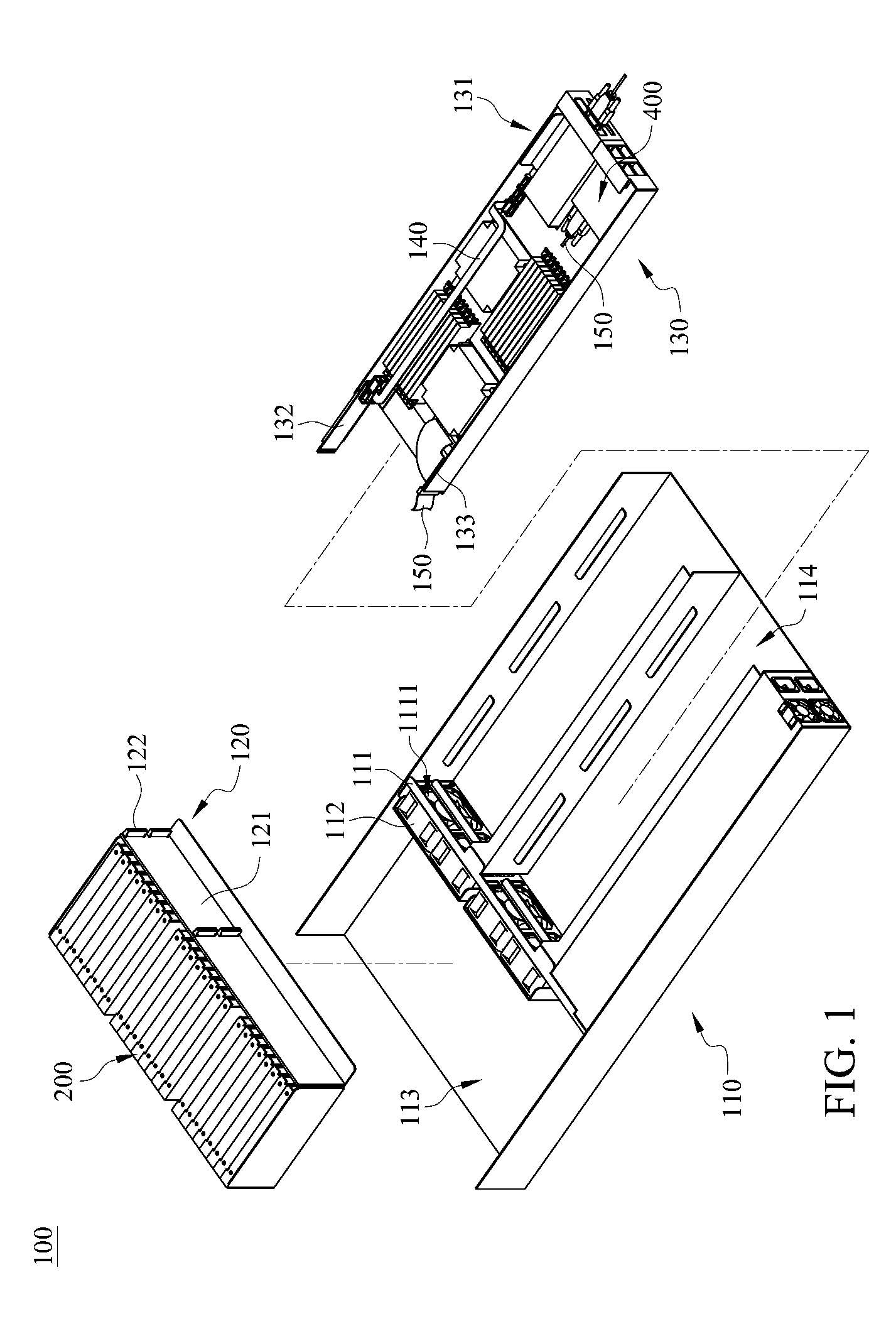

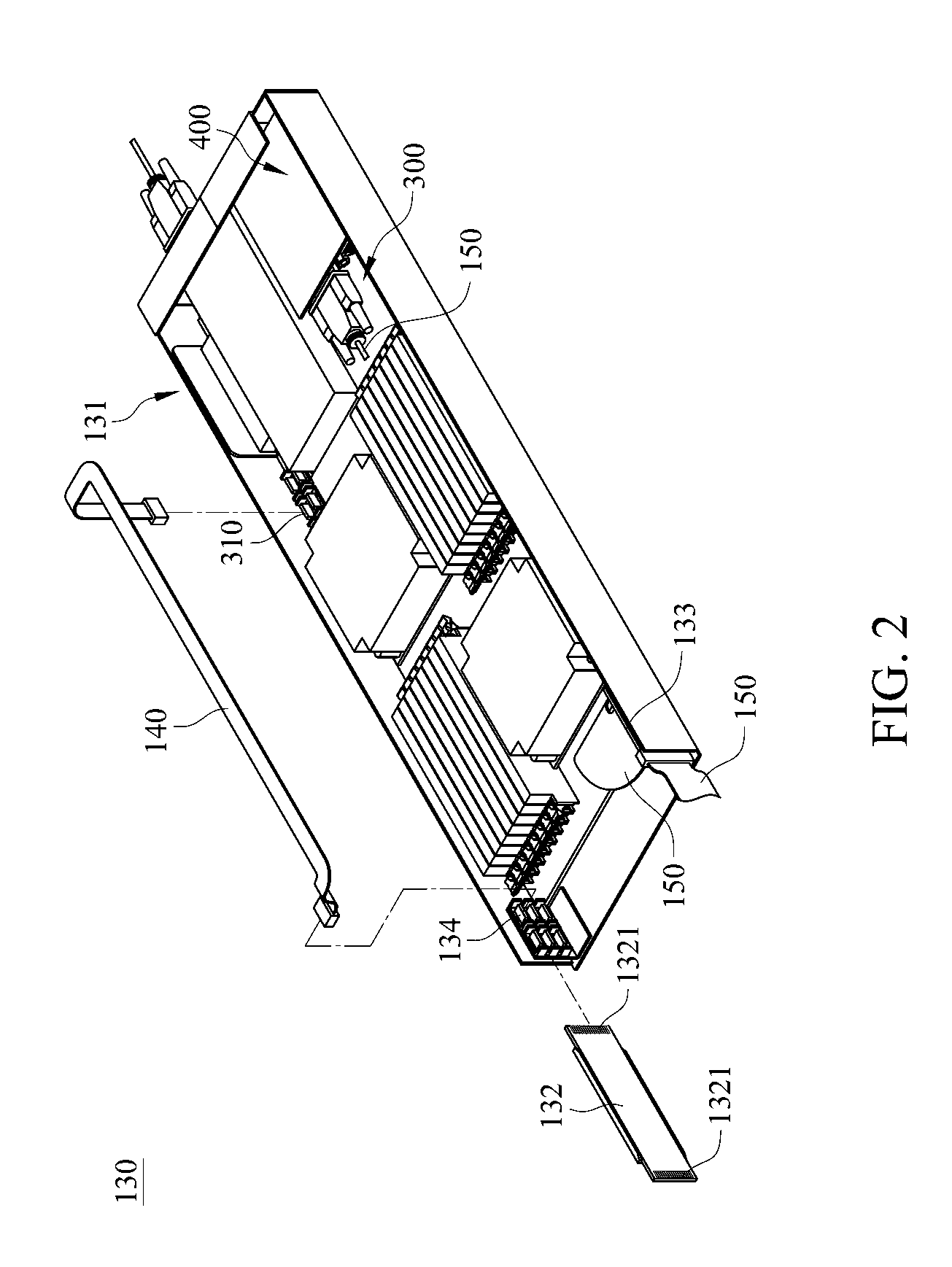

Server chassis

InactiveUS8711569B2Shorten assembly timeLow costServersDigital data processing detailsElectricityEngineering

A server chassis includes a frame for accommodating a plurality of data storage devices and at least one tray for disposing a circuit board. The frame is provided with a connector and the tray is provided with a signal bridge board electrically connecting the circuit board with the connector. The circuit board could be coupled with the data storage devices through the signal bridge board without any use of cables.

Owner:GIGA BYTE TECH CO LTD

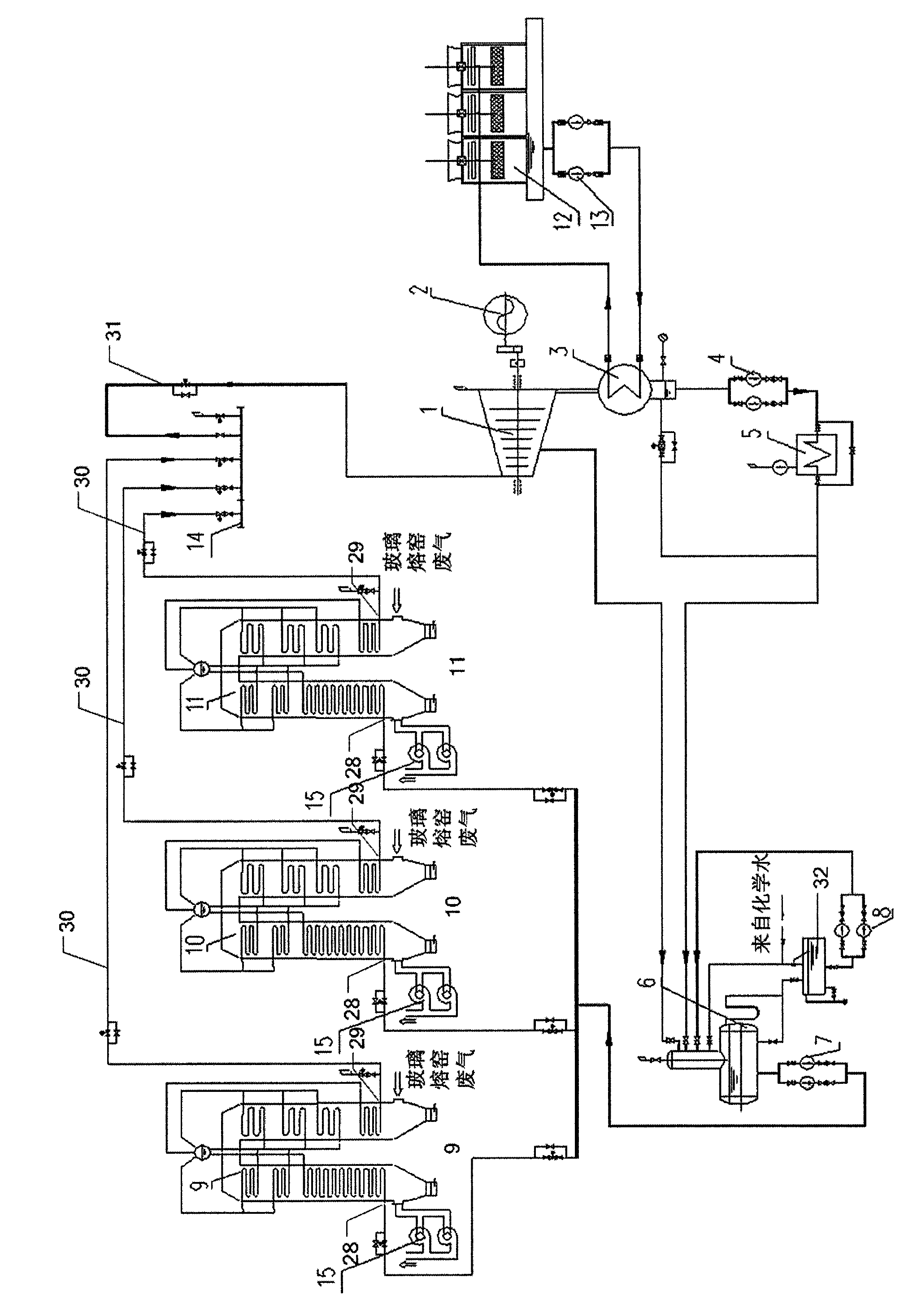

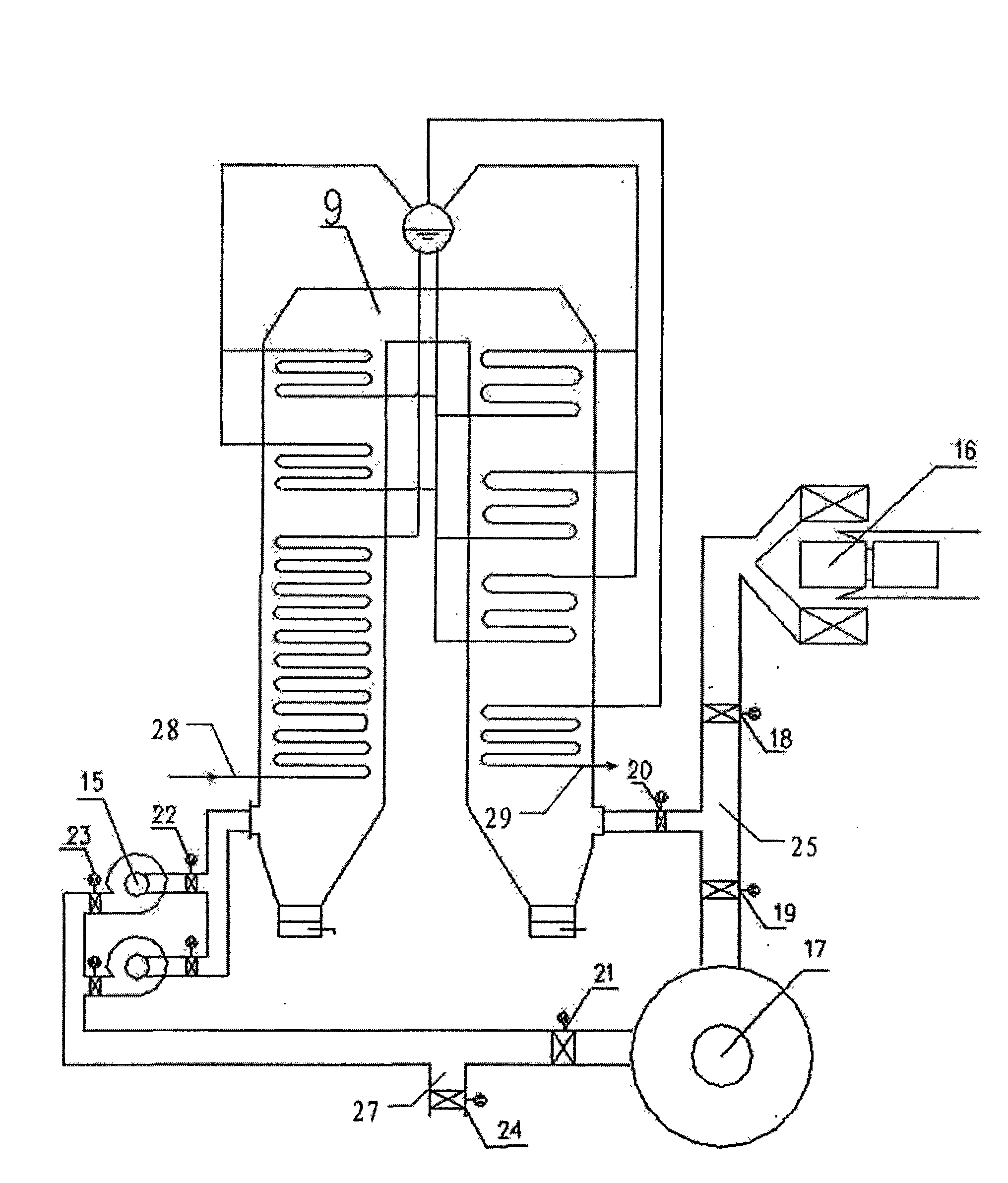

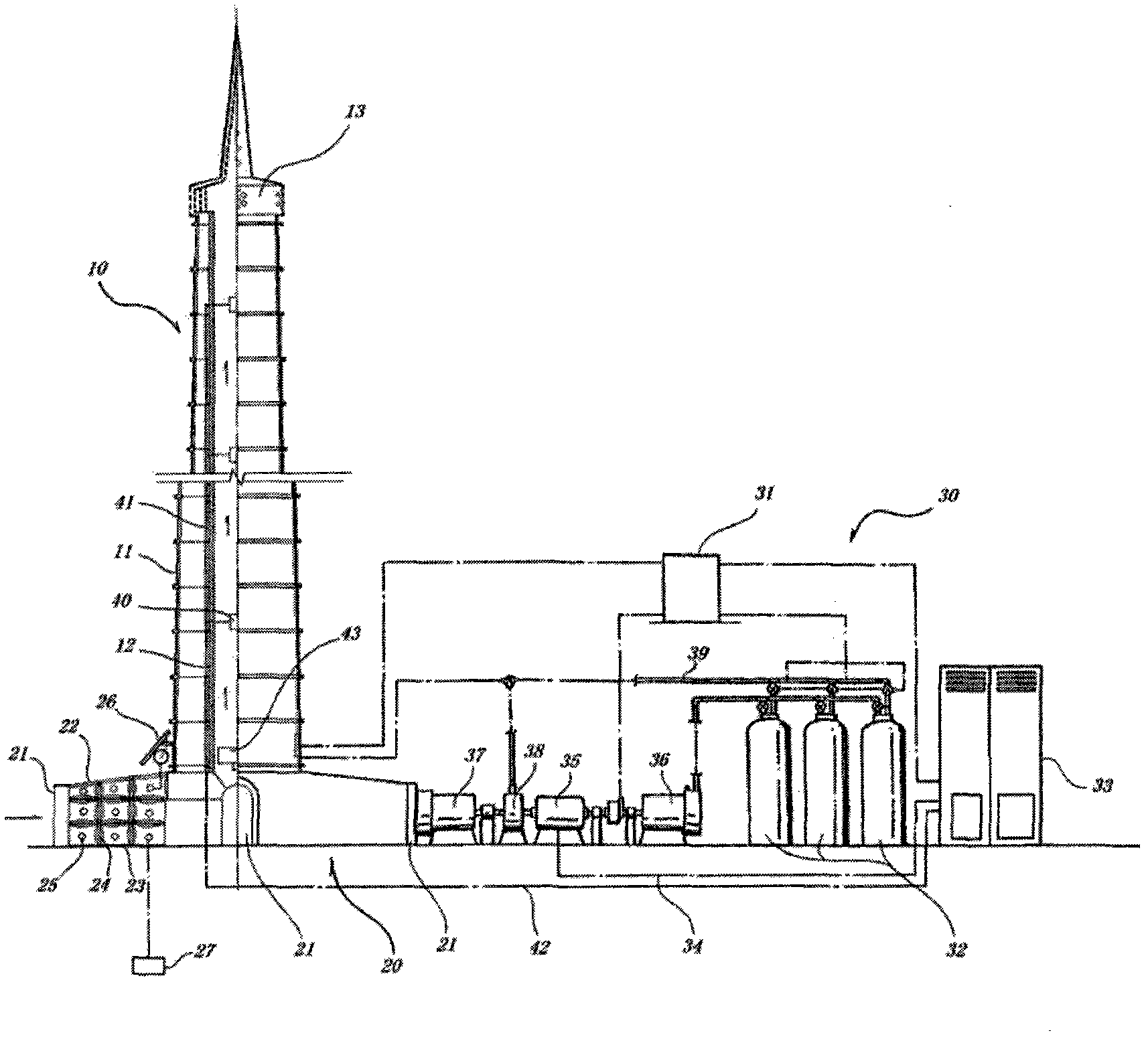

Float glass melting furnace parallel connection waste heat power generation system

InactiveCN101639211AImprove power generation qualityImprove adjustabilityGlass furnace apparatusFeed water supplyElectric generatorSystem stability

The invention relates to the technical field of power generation by using float glass melting furnace waste heat, aiming to solve the technical problems of low waste heat utility efficiency, low powergeneration efficiency, poor system stability, large heat recovery cost, large fluctuation range of waste gas and waste heat parameter, serious environment pollution, high cost of once investment andthe like when using waste heat in the traditional float glass melting furnace. The gas outlets of a plurality of float glass melting furnaces of the invention are communicated with the gas inlets of aplurality of parallel connection waste heat boilers, and the gas outlets of the waste heat boilers are communicated with a chimney; the water outlet of a boiler water feed pump is respectively communicated with the circulation water inlets of a plurality of parallel connection waste heat boilers, the vapor outlets of a plurality of parallel connection waste heat boilers are communicated with a gas collection cylinder, the outlet of the gas collection cylinder is communicated with the vapor inlet of a steam turbine, and the steam turbine is connected with a generator; and the steam discharge pipe of the steam turbine is connected with a condensate water system which is communicated with the water inlet end of the boiler water feed pump via a deaerating device. The invention is suitable fortwo or more than two float glass melting furnaces to perform waste heat power generation.

Owner:成都南玻玻璃有限公司

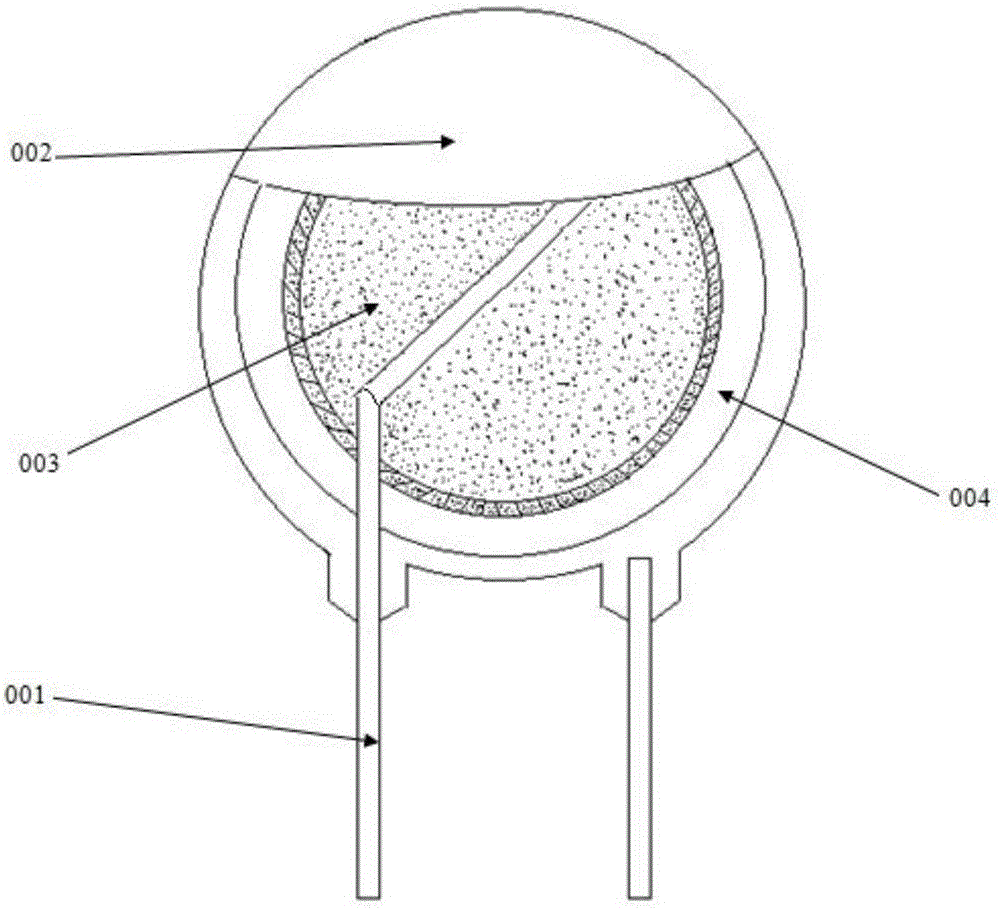

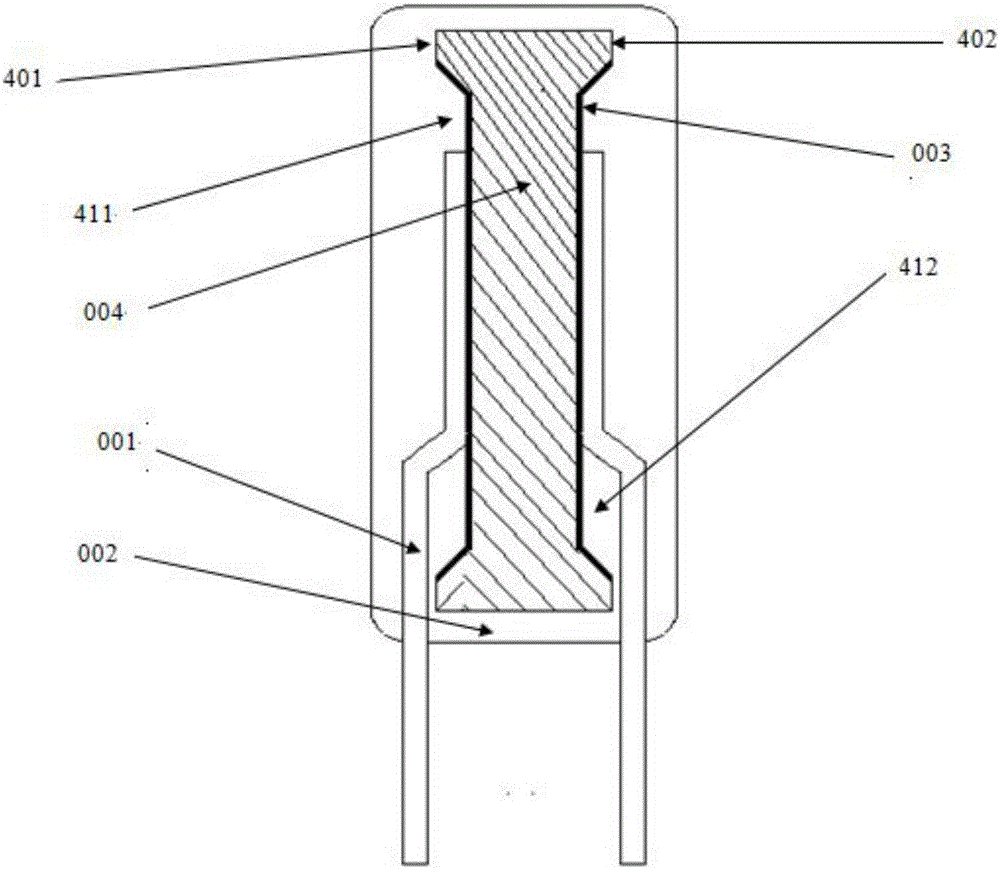

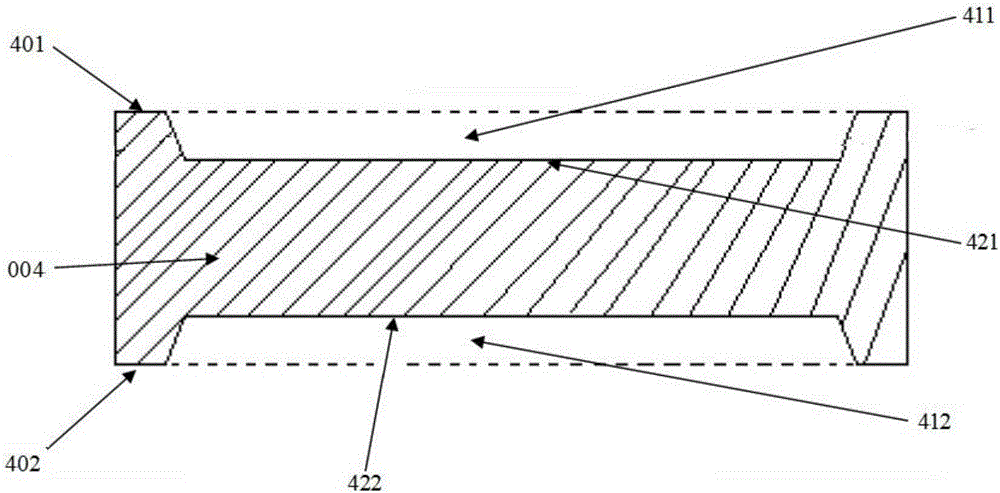

Piezoresistor and manufacturing process thereof

ActiveCN106782953APrecise positioningPrevent overflowResistor manufactureVaristorsCeramic substrateVaristor

The invention relates to a piezoresistor and a manufacturing process thereof. The piezoresistor is composed of a ceramic substrate, a leading-out end, an electrode layer and an insulating layer, wherein a concave area, namely, an electrode positioning area, is prefabricated on the ceramic substrate; the leading-out end is arranged on an electrode; the insulating layer is used for locally or wholly packaging the ceramic substrate, the electrode layer and the leading-out end; in the manner of sputtering or spraying electrode, an electrode hole of a mask plate is positioned and coated on a concave opening; a small electrode hole and a big concave opening form a bottle-shaped structure; the electrode is drifted and deposited into the concave opening so as to form the electrode and realize the concave opening being accurately filled with the electrode; the electrode eccentricity caused by the difference in diameter of the ceramic substrate in a batch sputtering process can be avoided; the thickness of the ceramic substrate at an edge of the concave opening is greater than the thickness of the interior; the reducing of the risk in edge arc crossing is benefited; the edge effect is weakened; the flowing property is greatly promoted; the preparation process of the piezoresistor comprises the following steps: manufacturing the ceramic substrate, performing electric polarization, connecting the leading-out end, coating the insulating layer, printing and testing.

Owner:KUSN WANFENG ELECTRONICS

Condensing heat exchanger with inverted-V-shaped structure for gas water heater

ActiveCN102384588ASmooth exhaustReduce resistanceEnergy efficient heating/coolingAir heatersHeat transfer efficiencyEngineering

The invention relates to a condensing heat exchanger with an inverted-V-shaped structure for a gas water heater. The condensing heat exchanger is characterized in that the condensing heat exchanger comprises a smoke collecting hood, wherein a condenser box is arranged above the smoke collecting hood through a condenser bracket; a smoke inlet is formed in the middle position of the bottom of the condenser box; a symmetrical corrugated pipe array and an inverted-V-shaped baffle plate are sequentially arranged between the bottom of the condenser box and a condenser cover with a smoke exhaust opening; and a condensed water outlet is formed in a low position of the bottom of the condenser box. When the condensing heat exchanger works, due to the blocking function of the inverted-V-shaped baffle plate, flue gas flows backwards in two ways and enters the parallel corrugated array pipe area, and inverted-V-shaped forced convection heat transfer is formed, so that the temperature of the flue gas is reduced and the flue gas is collected on the two sides of the inverted-V-shaped baffle plate and then exhausted via the smoke exhaust opening; and the flue gas flowing path is in a double-inclined-Z-shaped curve, and the heat transfer efficiency is high. The condensing heat exchanger has the advantages of compact structure, simplicity, practicality, energy conservation, material conservation and relative low cost, and condensed water cannot be produced on a main heat exchanger.

Owner:GUANGDONG MACRO GAS APPLIANCE

Vacuum-exhausting-type screw barrel

The invention relates to a vacuum-exhausting-type screw barrel. A heating layer is arranged on the outer wall of the barrel, a feeding screw is arranged in the barrel, a hopper mounting hole and a vent hole are formed in the barrel, the vent hole is connected with a vacuum pump, the feeding screw is divided into a metering feeding plastifying section, a forcedly-pressurizing plastifying section, a feeding pressure-reduction plastifying section and a forcedly-feeding plastifying section, the vent hole is arranged in the feeding pressure-reduction plastifying section, three grooves are formed in the inner wall of the barrel, the lengths of three grooves are consistent to a distance from the hopper mounting hole to the rear end part of the barrel, and an electric heating coil is arranged above the vent hole and at the lower end of the vacuum pump. Compared with the prior art, the vacuum-exhausting-type screw barrel is provided with the three grooves, the lengths of the three grooves are consistent to the distance from the hopper mounting hole to the rear end part of the barrel, and the electric heating coil is arranged above the vent hole and at the lower end of the vacuum pump. The vacuum-exhausting-type screw barrel is used for an exhaust-type injection molding machine.

Owner:乐清市联盛电子科技有限公司

Natural energy storage power generation method and power generation system thereof

InactiveCN102996359AEfficient SupplementEnough temperatureGas turbine plantsEmission reduction for energy storageElectricityPower grid

Owner:周登荣 +1

Heat storage pit warm in winter and cool in summer

InactiveCN103017246AUnobstructed smoke exhaustImprove efficiencyLighting and heating apparatusStove/ranges for heating waterPipingFlue

The invention relates to a heat storage pit warm in winter and cool in summer and belongs to the technical field of indoor worming facilities. The heat storage pit comprises a pit body, ranges and a chimney, wherein the pit body is positioned underground and comprises a pit plate and a grait heat storage bed; a flue is arranged between the pit plate and the grait heat storage bed; the chimney is vertical to the pit plate; the flue is communicated with the chimney; each range comprises a hearth and a dust falling chamber under the hearth, and a grate is arranged between the hearth and the dust falling chamber; the ranges are a winter range and a summer range; a hot water ring is arranged at the upper part in the hearth of the winter range; the two ends of the hot water ring are communicated with one end of a water supply pipe and one end of a water return pipe; the other ends of the water supply pipe and the water return pipe are communicated with a heating radiator; a smoke outlet of the hearth of the winter range is communicated with a smoke outlet cylinder; a smoke outlet of the smoke outlet cylinder is arranged in the chimney; a sleeve is arranged outside the smoke outlet cylinder in a sleeving manner; a hot air chamber is hermetically formed between the smoke outlet cylinder and the sleeve; one end of the hot air chamber is communicated with a blast pipe and a speed-regulating blast blower; and the other end of the hot air chamber is communicated with a hot air outlet pipe.

Owner:LIAONING TECHNICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com