Liquid storage container and liquid filling method and liquid refilling method using the same

A liquid container and filling method technology, applied in printing and other directions, can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0058] (General structure of a liquid ejecting device)

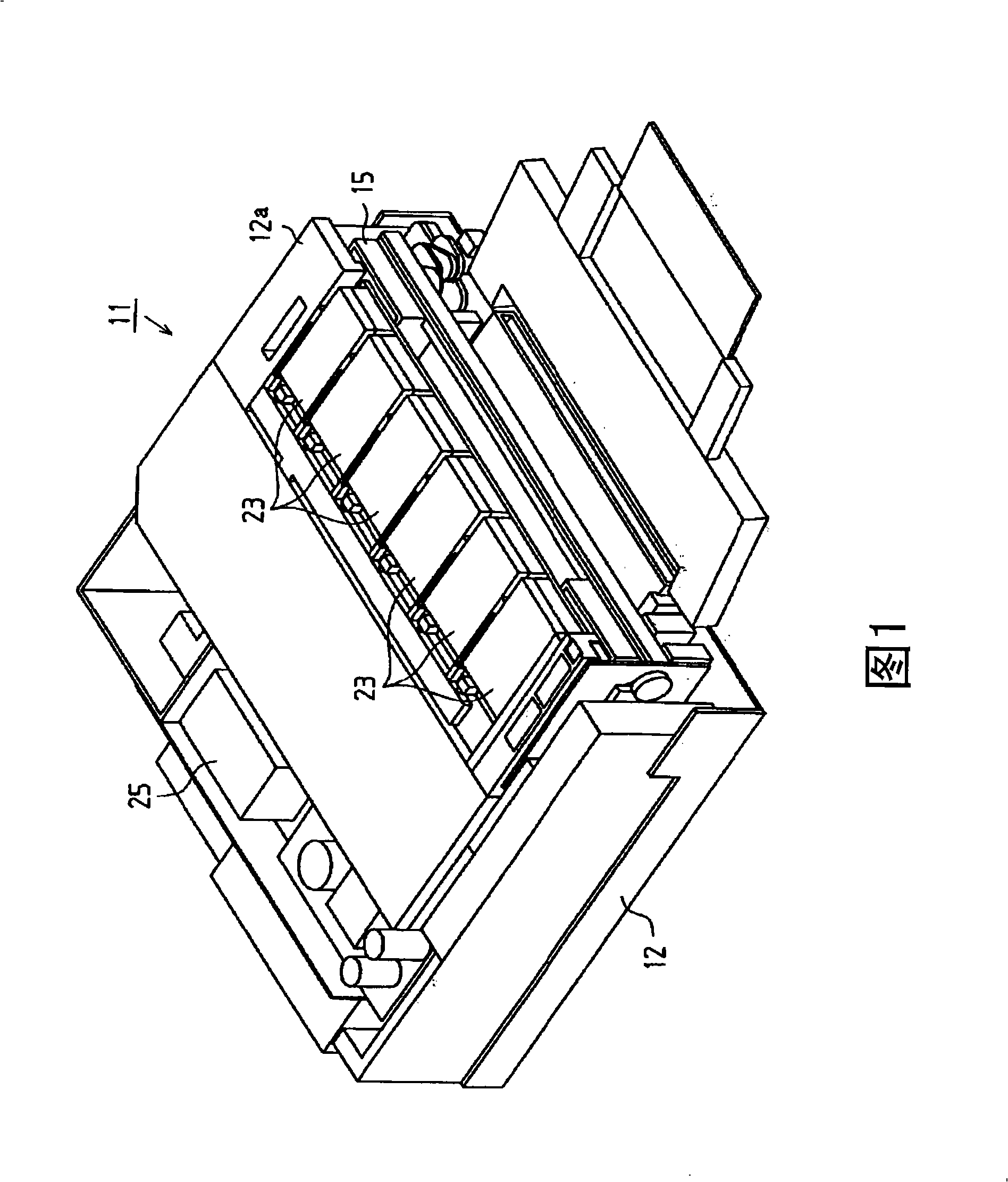

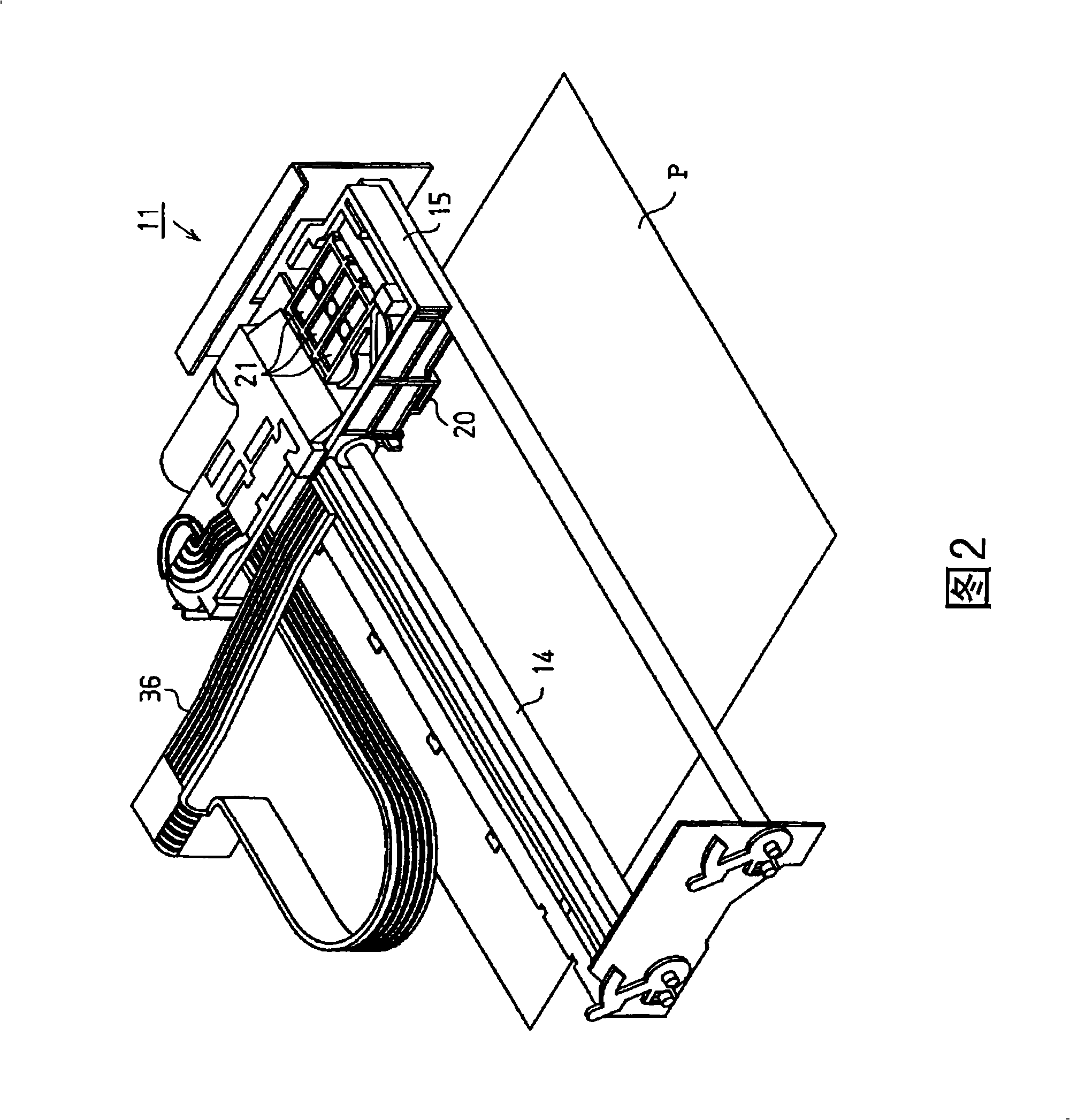

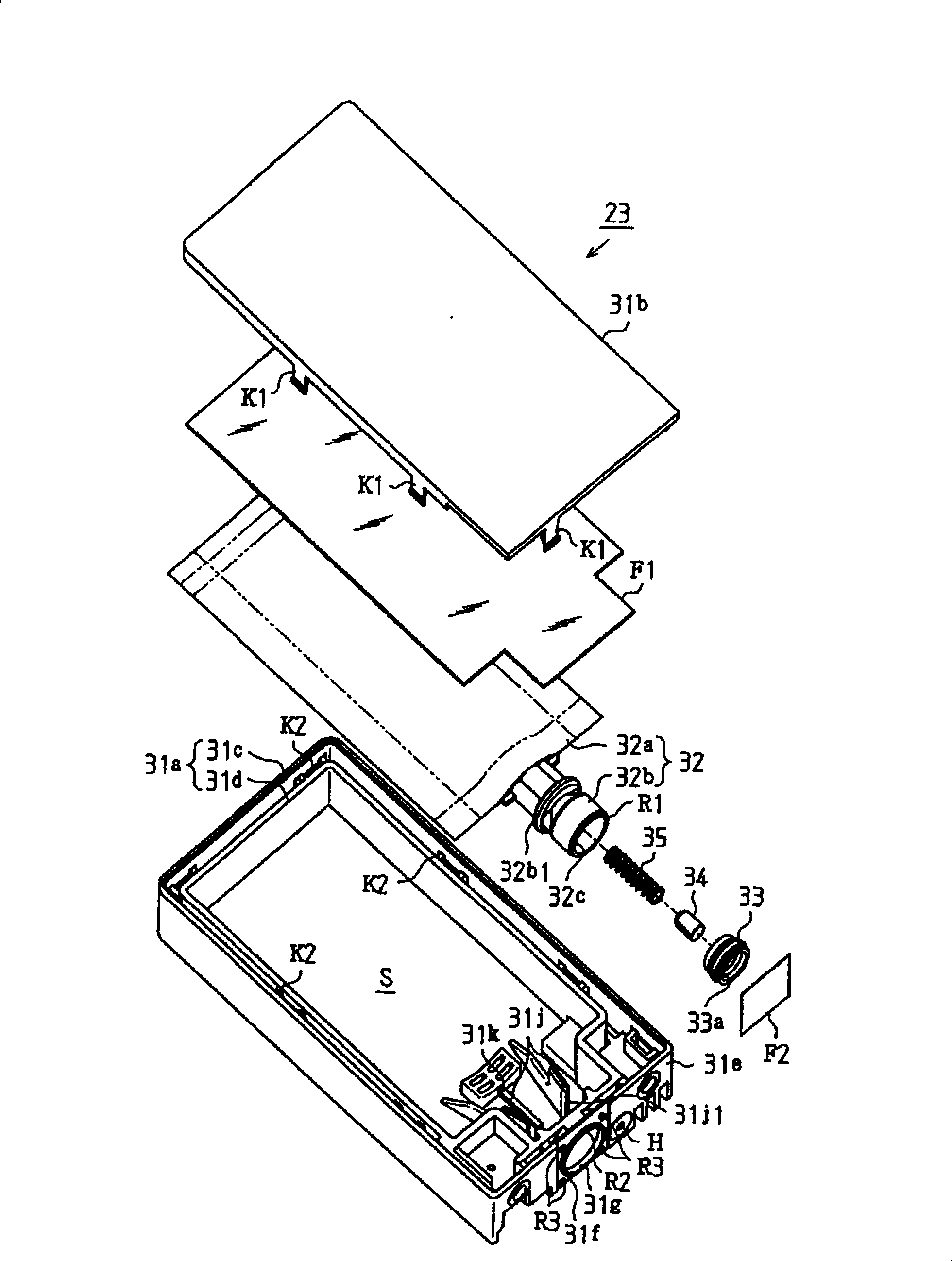

[0059] As shown in FIG. 1 , a printer 11 serving as a liquid ejecting device according to this embodiment is covered by a frame 12 . And as shown in FIG. 2, inside the frame 12 includes: a guide shaft 14, a bracket 15, a recording head 20 as a liquid ejection head, a valve unit 21, an ink cartridge 23 (refer to FIG. 1 ) as a liquid container, and a booster pump 25. (Refer to Figure 1).

[0060] As shown in FIG. 1 , the frame 12 is a box of approximately rectangular parallelepiped shape, and a box seat 12 a is formed on the front thereof.

[0061] As shown in FIG. 2 , the guide shaft 14 is formed in a rod shape, and is mounted on the frame 12 . In the present embodiment, the direction in which the guide shaft 14 extends is referred to as the main scanning direction. The bracket 15 is penetrated by the guide shaft 14 so as to be relatively movable relative to the guide shaft 14 , and can reciprocate in the main scanning...

no. 2 approach

[0138] (Structure of isolation parts)

[0139] This embodiment is based on the above-mentioned first embodiment, and the Figure 10 and Figure 11 (A), (B) shown in the isolation member 200 is replaced by Figure 14 and Figure 15 The form of the isolation member 300 shown in (A) and (B). exist Figure 14 and Figure 15 In (A) and (B), the spacer member 300 is formed of a bonding restricting member in which a plurality of holes 310 are penetratingly formed on the peripheral surface of the cylinder. In addition, if Figure 14 As shown, the insulating member 300 is also arranged below the direction of gravity in the flexible bag 107b due to its own weight.

[0140] (The role of the isolation part)

[0141] In this embodiment, if Figure 15 As shown in (A), the ink remaining in the ink pack 107 until the end is accommodated in the ink remaining space 140 formed by the spacer 300 between the two opposing flexible films 107b1, 107b2. In addition to the ink remaining space...

no. 3 approach

[0147] In this embodiment, the spacer member 200 as the sticking regulation member arranged below the gravity direction in the flexible bag 107b in the above-mentioned first embodiment is replaced with a spacer member extending on a straight line of the flow path of the ink delivery member 107a. 400 way. Therefore, except for the structure and operation of the spacer, it is the same as the first embodiment, and the description thereof will be omitted. In addition, the components having the same functions as those in the first embodiment are denoted by the same reference numerals, and descriptions thereof are omitted or simplified.

[0148] (Structure of isolation parts)

[0149] Figure 16 shows the Figure 9The shown ink lead-out member 107a is connected and arranged in the spacer member 400 of the third embodiment in the ink pack 107. FIG. Exploded stereogram. (A) to (D) of FIG. 18 show the spacer member 400 in the third embodiment. In FIG. 16, the following state is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com