Piezoresistor and manufacturing process thereof

A piezoresistor and electrode technology, which is applied in the manufacture of resistors, piezoresistors, resistors, etc., can solve the problems of piezoresistor flow capacity drop, electrode offset, side flashing, etc., to reduce typesetting The effect of inspection, edge density improvement, and long dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

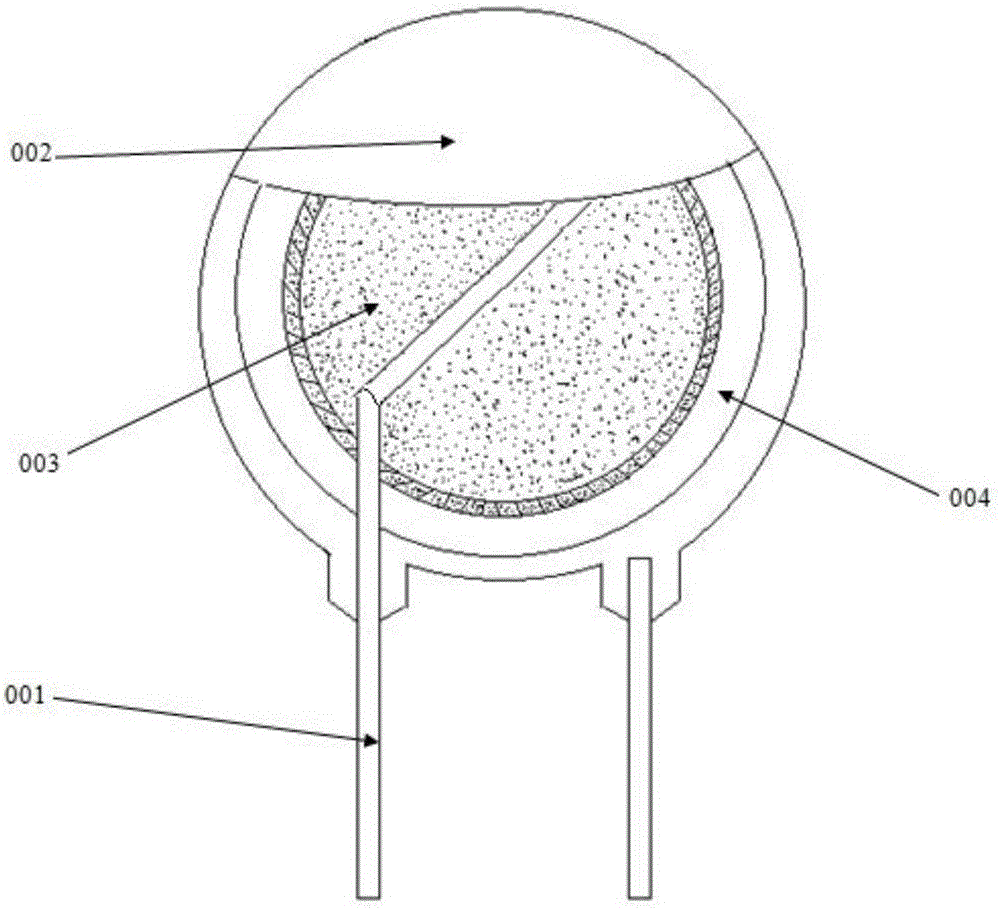

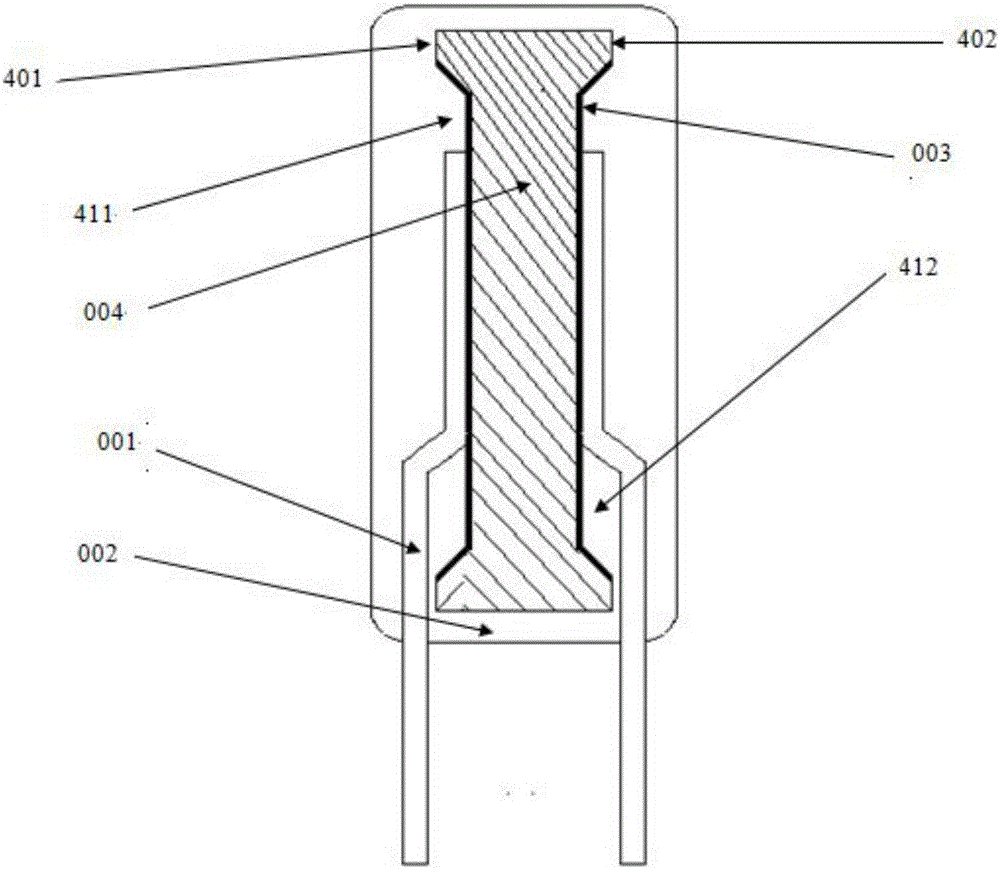

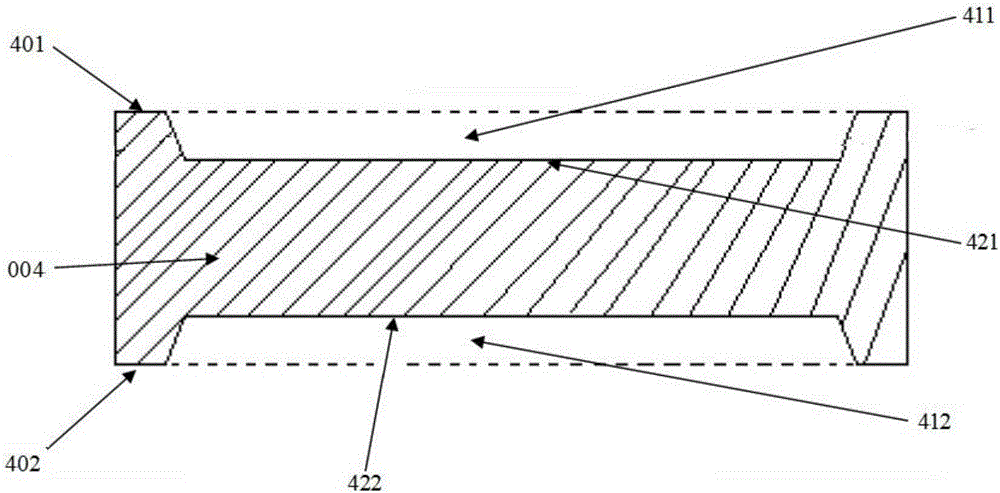

[0029] Embodiment 1, see attached figure 1 , 2 , 3, the present invention relates to a varistor, which includes a lead end 001, an insulating layer 002, an electrode layer 003 and a ceramic substrate 004, the ceramic dielectric substrate 004 is circular, and the ceramic substrate 004 The upper and lower bottom surfaces 401, 402 each have a prefabricated concave electrode area 411, 412, the bottom surface 421 of the prefabricated concave electrode area 411 is parallel to the bottom surface 401 of the ceramic substrate 004 where it is located, and the bottom surface 422 of the prefabricated concave electrode area 412 is parallel to the ceramic substrate 412 where it is located. The bottom surface 402 of the substrate 004, the bottom surface 421 of the prefabricated concave electrode region 411, and the bottom surface 422 of the prefabricated concave electrode region 412 are all circular, and the depths of the prefabricated concave electrode region 411 and the prefabricated conca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com