Patents

Literature

35results about How to "Enough temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for overlaying welding of duplex stainless steel

ActiveCN102941394AEnough temperaturePrevent hot and cold cracksArc welding apparatusFurnace typesThermal insulationRoom temperature

A method for the overlaying welding of a duplex stainless steel comprises the following steps: A, integral preheating: the preheating temperature is 250-300 DEG C, and thermal insulation is carried out for 0.8-1.2 hours; B, overlaying welding implementation: the welding current is 180-220A, the welding voltage is 25-29V, the welding velocity is 350-450mm / min, and the interlayer temperature is 250-300 DEG C; C, annealing heat treatment: the initial temperature is 200-300 DEG C and is gradually increased to 700-750 DEG C, and thermal insulation is carried out for 1.8-2.5 hours; and D, a workpiece is cooled in a furnace to below 150 DEG C and then is discharged to be naturally cooled to the room temperature in the air. According to the method for the overlaying welding of the duplex stainless steel, the parameters of the welding temperature, heat treatment temperature after the welding and the like are reasonably selected, cracks due to hot and cold are obviously reduced, the toughness and the machinability of the duplex stainless steel are increased, and when the method is used for the overlaying welding of the duplex stainless steel of a ship lift guide wheel, all the performance indexes can satisfy the requirements.

Owner:WUHAN MARINE MACHINERY PLANT

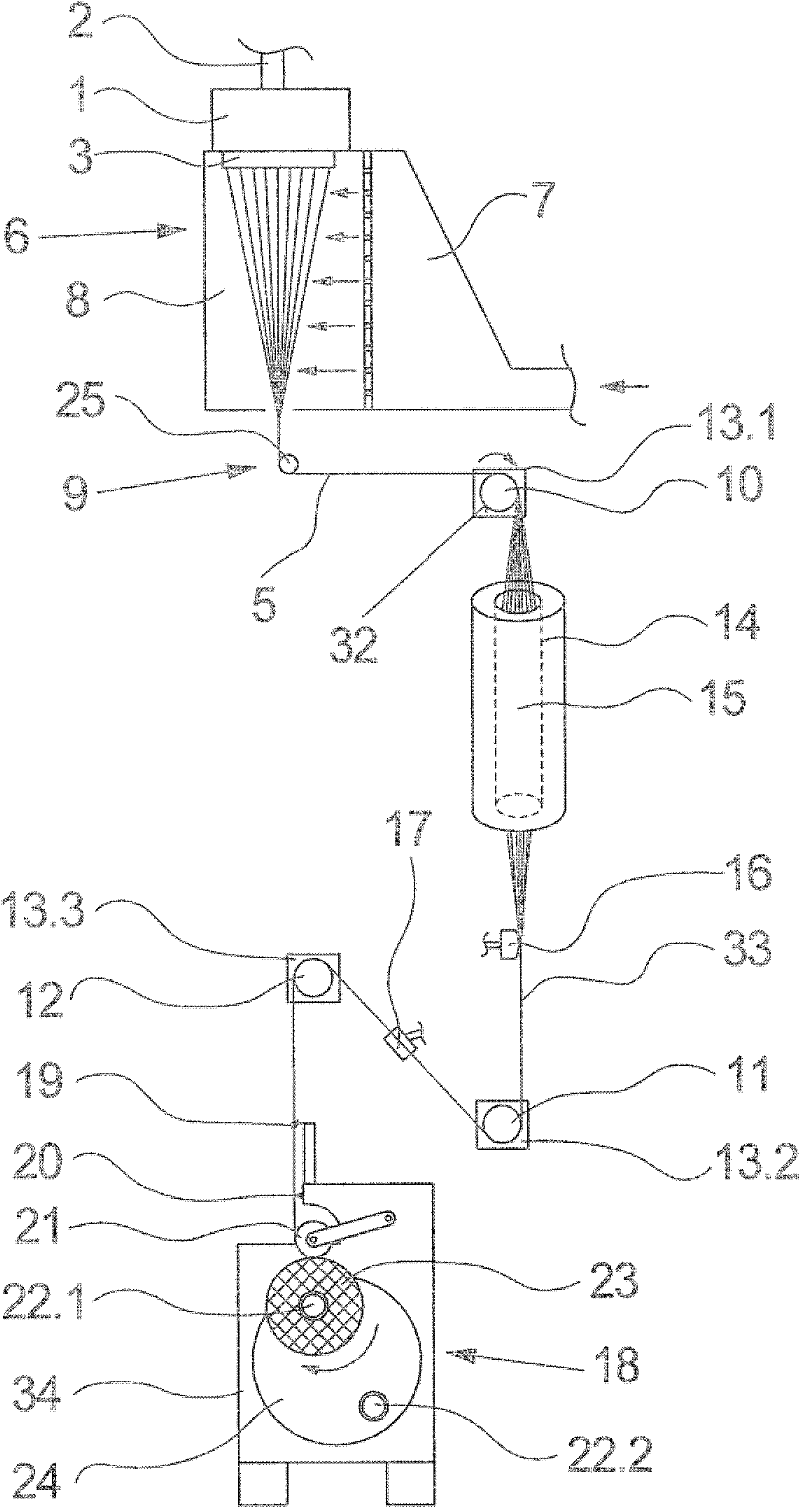

Natural energy storage power generation method and power generation system thereof

InactiveCN102996359AEfficient SupplementEnough temperatureGas turbine plantsEmission reduction for energy storageElectricityPower grid

Owner:周登荣 +1

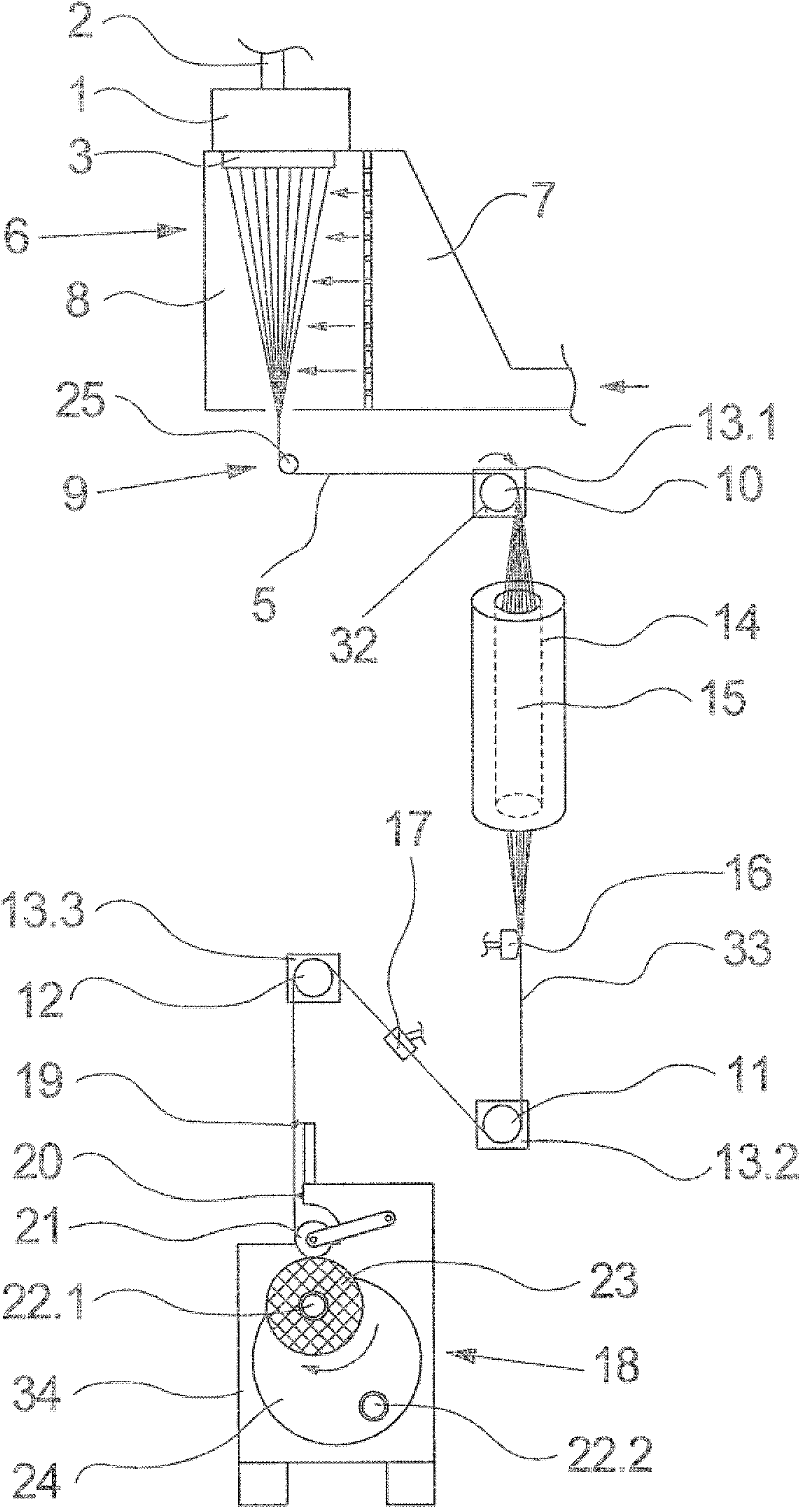

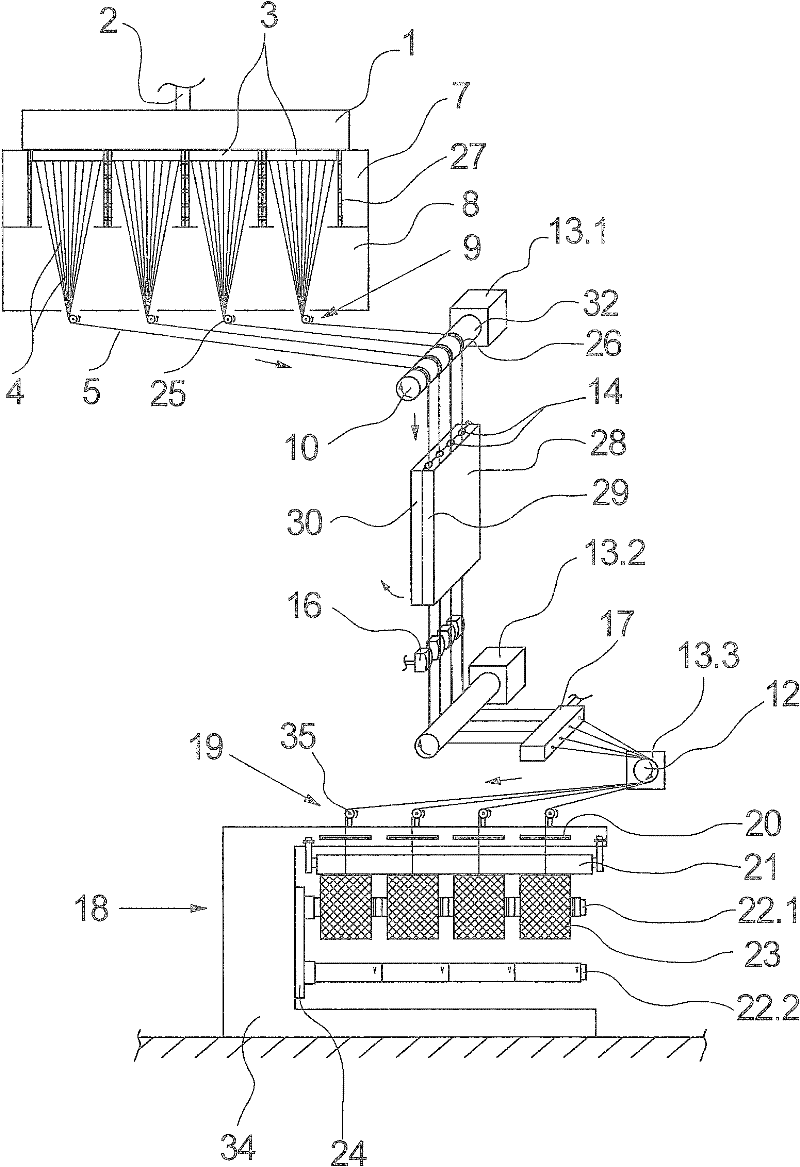

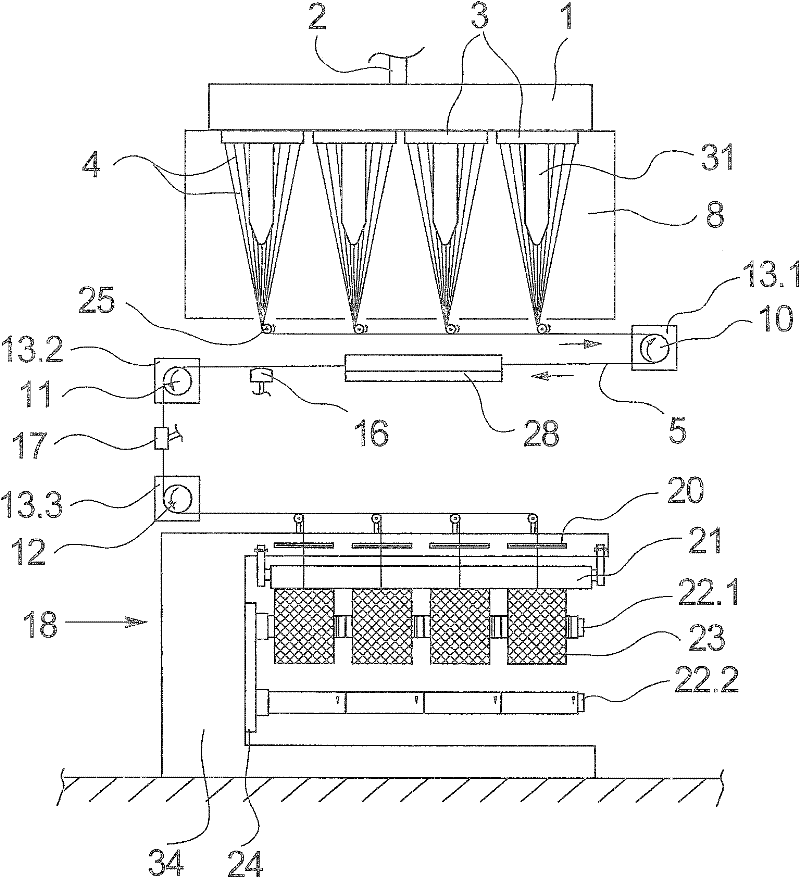

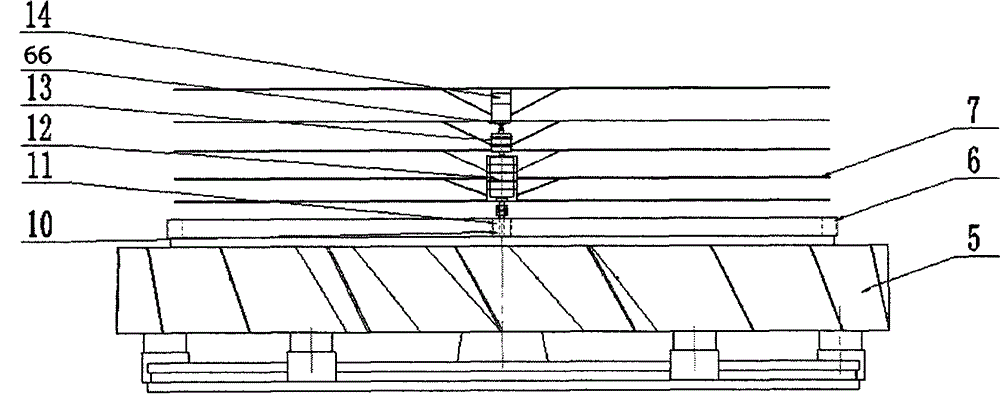

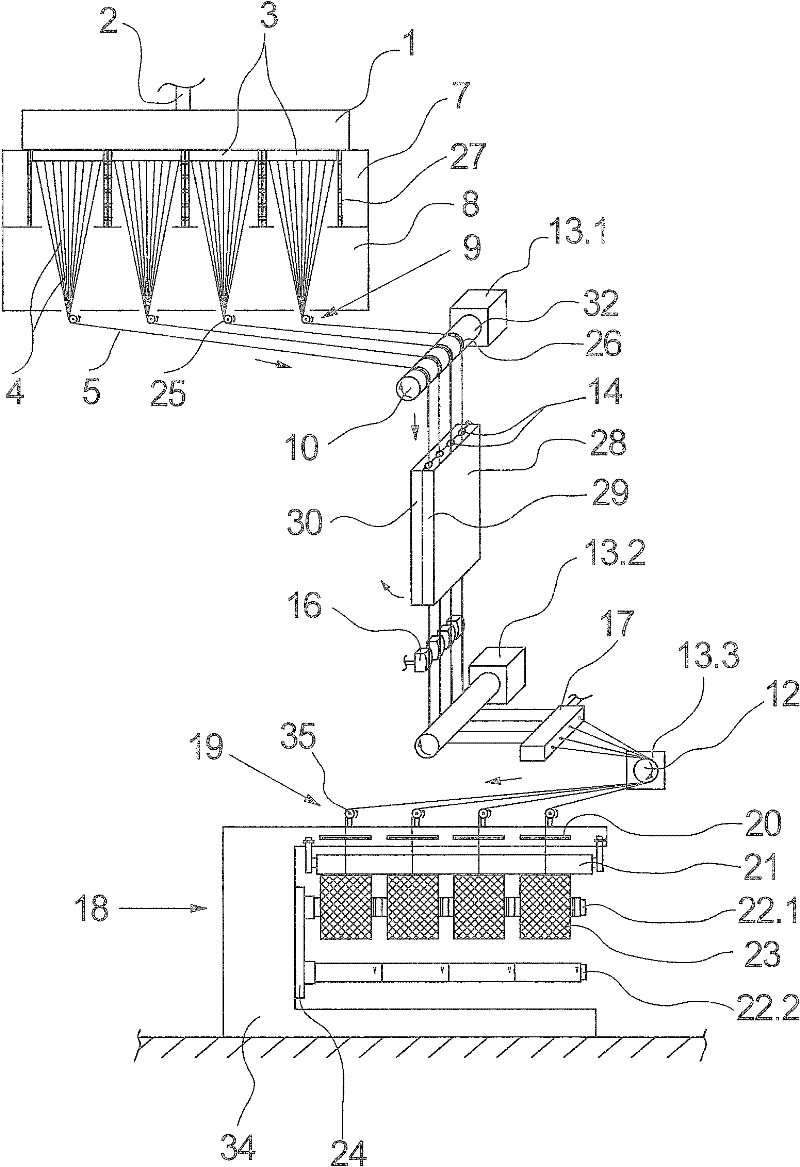

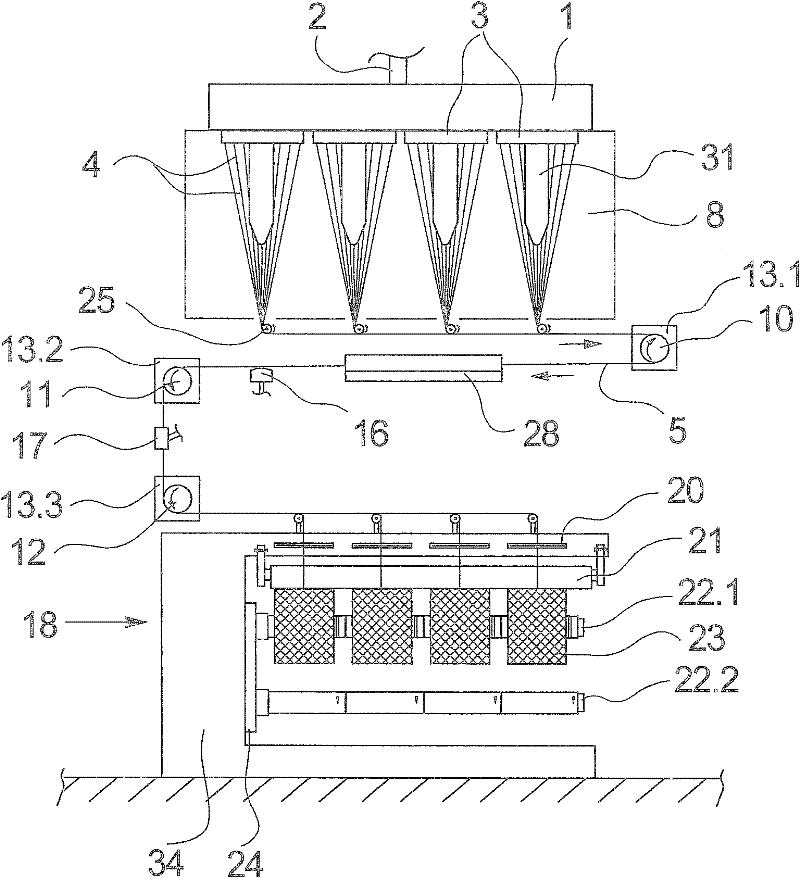

Method for melt spinning, stretching and winding multifilament thread and device for carrying out same

InactiveCN102131965AReached temperatureDesired temperatureArtificial thread manufacturing machinesArtificial filament heat treatmentPolymer sciencePlastic materials

The invention relates to a method for melt spinning, stretching and winding a multifilament thread to form an FDY yarn, and a device for carrying out the method. First, a plurality of filaments made from a thermoplastic melt are extruded, cooled to a temperature below the glass transition temperature of the plastic material, and combined to form a filament bundle with no addition of a preparation fluid. Then, the filament bundle is drawn off at a speed of greater than 1500 m / min, heated to a temperature above the glass transition temperature of the thermoplastic material and stretched at a stretching speed of greater than 4000 m / min. The filament bundle is led through a hot air atmosphere of a heating tube for providing non-contact heating. Then, the filament bundle is prepared with a preparation fluid and the thread is wound into a coil. In the device according to the invention, the preparation device is disposed downstream of the heating means in the thread direction, wherein the heating means, which is a heating tube with a hot air atmosphere for non-contact heating of the filament bundle, is disposed between the drawing-off galette and the stretching galette.

Owner:OERLIKON TEXTILE GMBH & CO KG

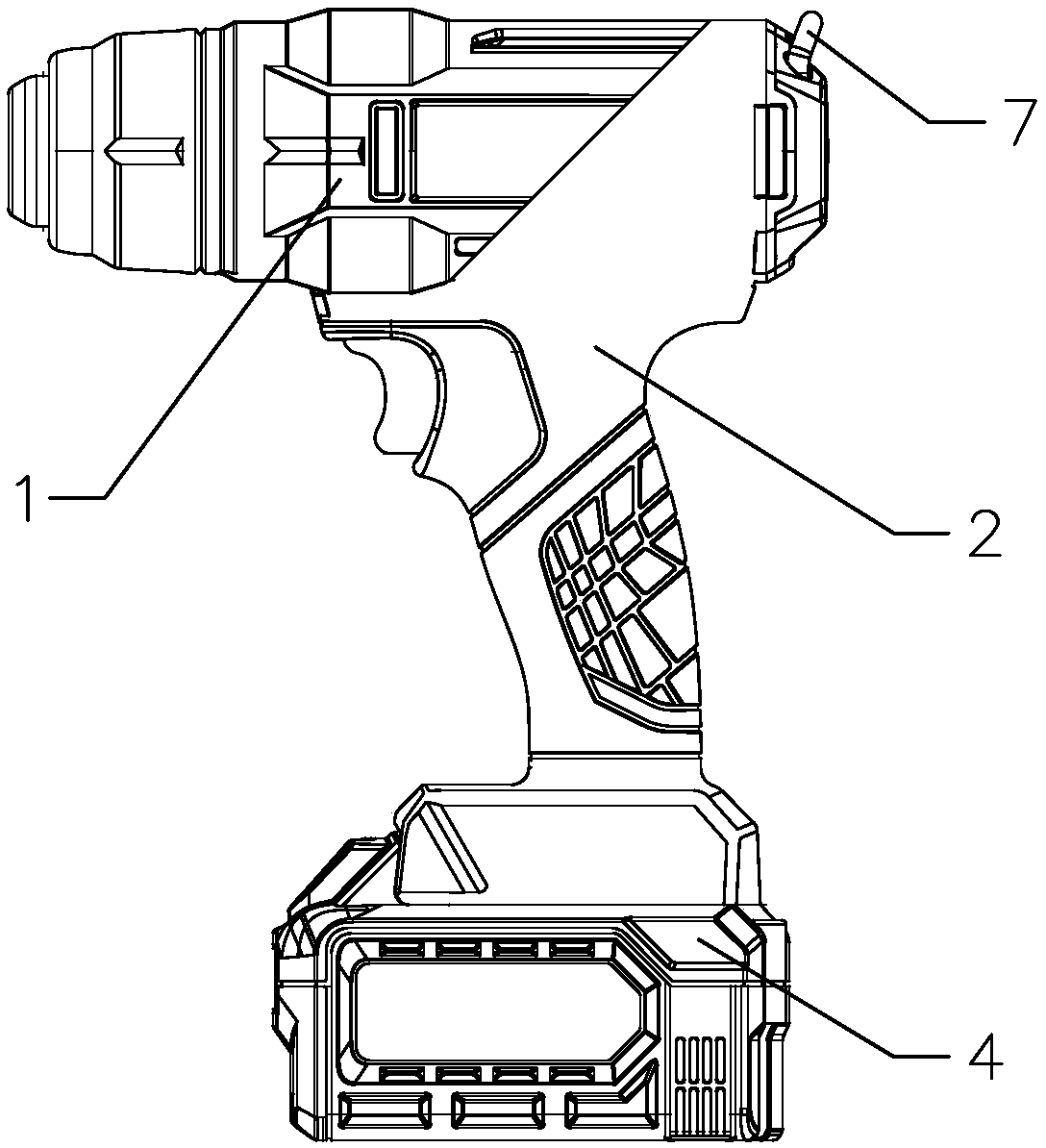

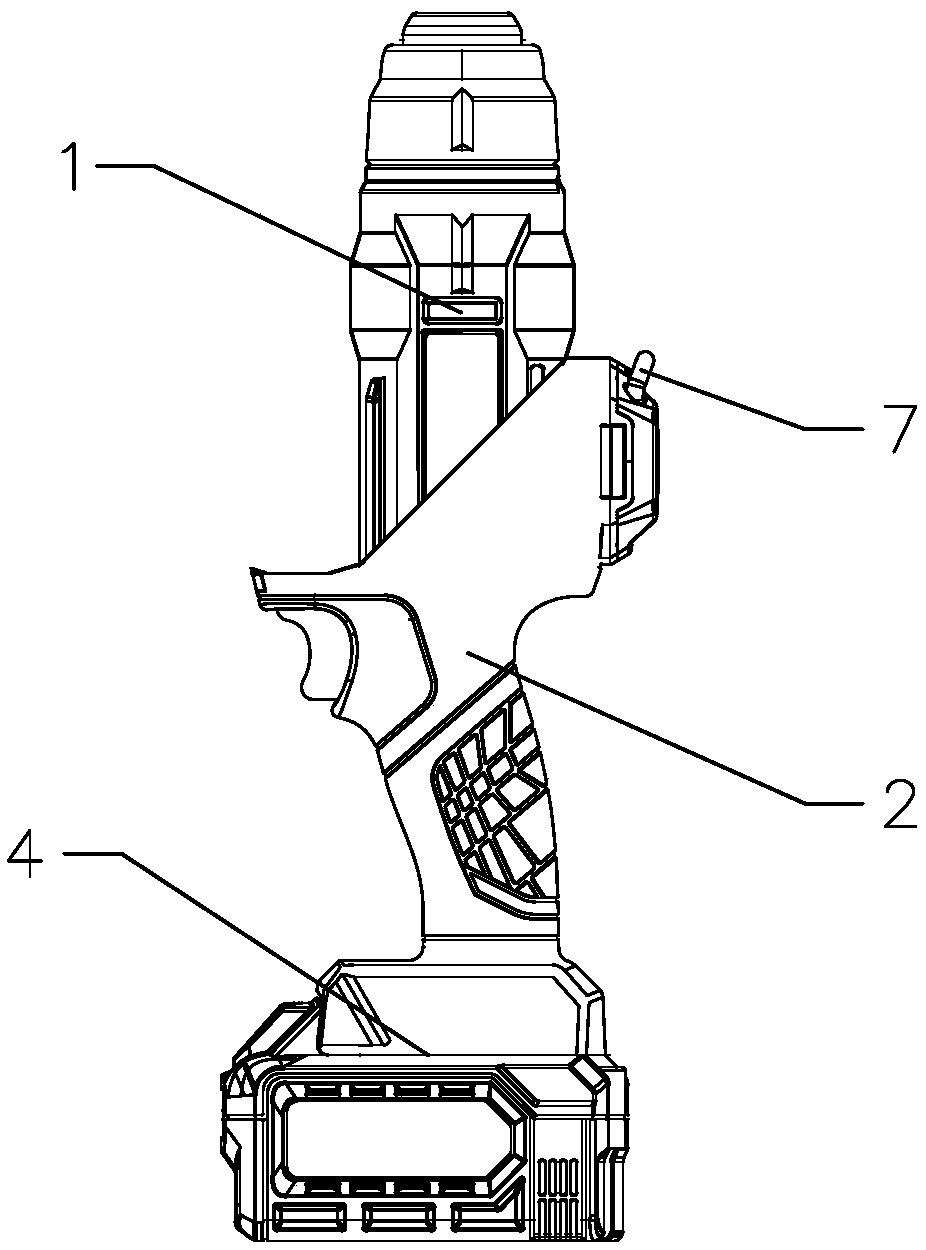

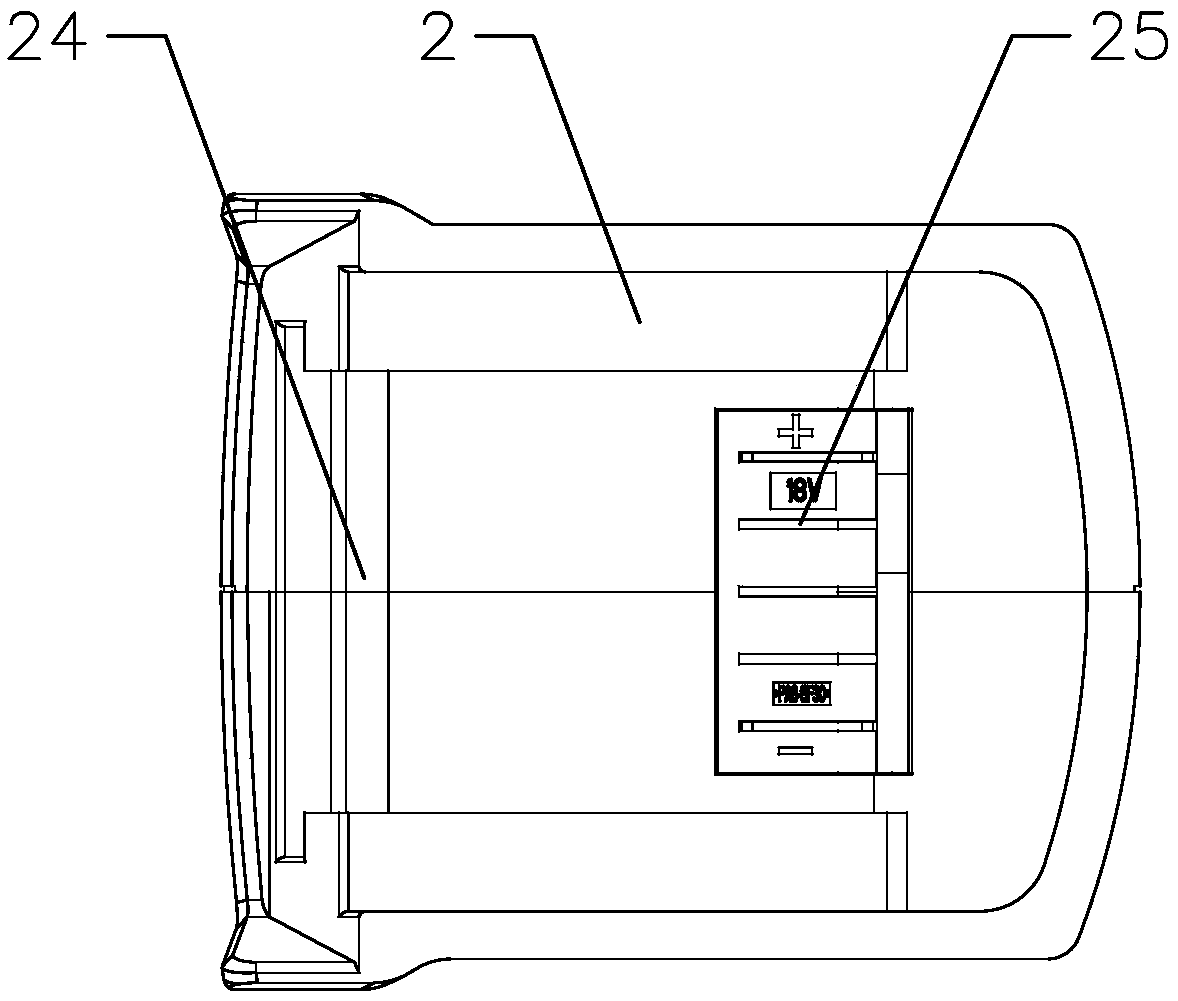

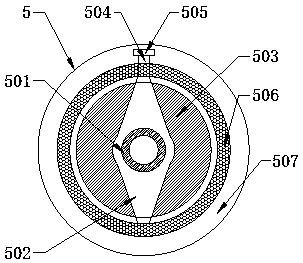

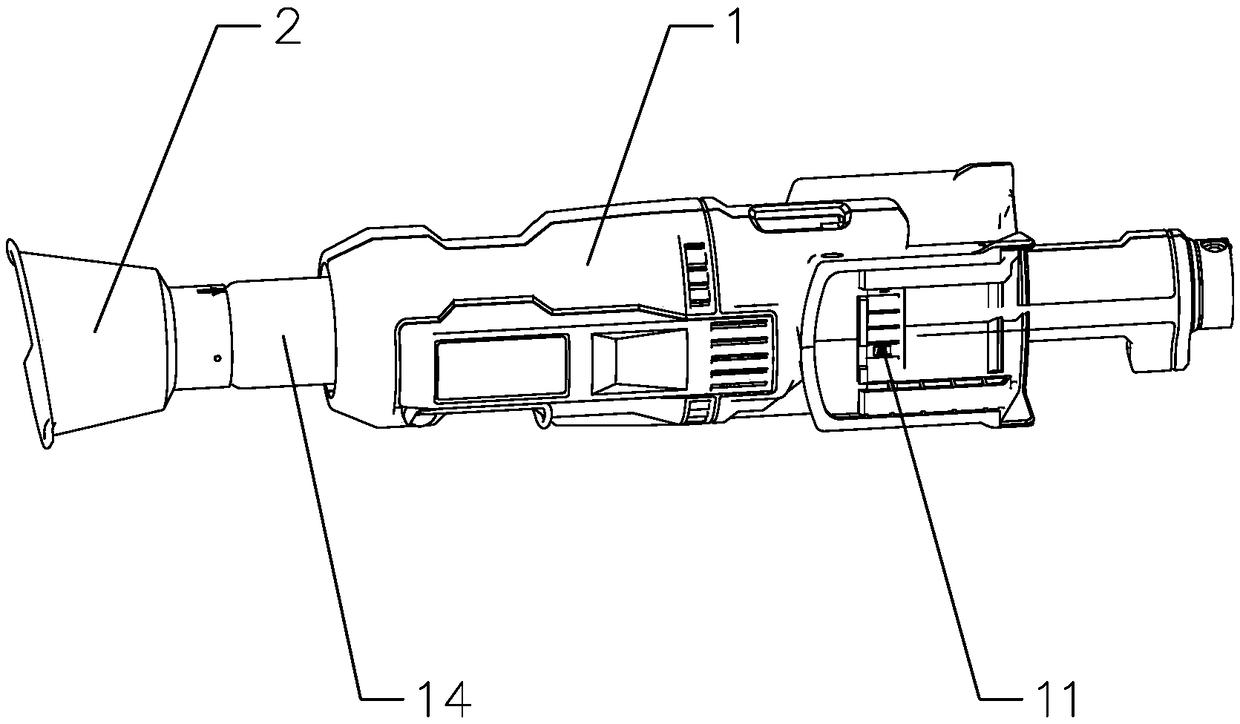

Multi-functional hot air gun

The invention provides a multi-functional hot air gun. The multi-functional hot air gun includes a machine head and a handle assembly; a hot air device for generating the hot air is arranged in the machine head, the handle assembly comprises a handle and an extension rod detachably connected to the handle, the handle is connected to the machine head and can be rotated relatively, and the hot air gun further includes a detachable battery pack; and the battery pack is electrically connected with the hot air device and supplies the power to the hot air device so as to enable the hot air device towork, and the handle is connected with the machine head and can be rotated relatively, in this way, a user can operate conveniently in different use environments; when the direction of the hot air blowing out of the machine had is coincide or parallel or approaching parallel to the axis of the handle, the hot air gun can be used as a carbon igniting machine and can be used as a lawn mower with the extension rod; and when the direction of the hot air blowing out of the machine head intersects with the axis of the handle or is located on one side of the handle, the hot air gun can be used for the conventional hot air operation such as plastic product melting for melting connecting.

Owner:ZHEJIANG PRULDE ELECTRIC APPLIANCE CO LTD

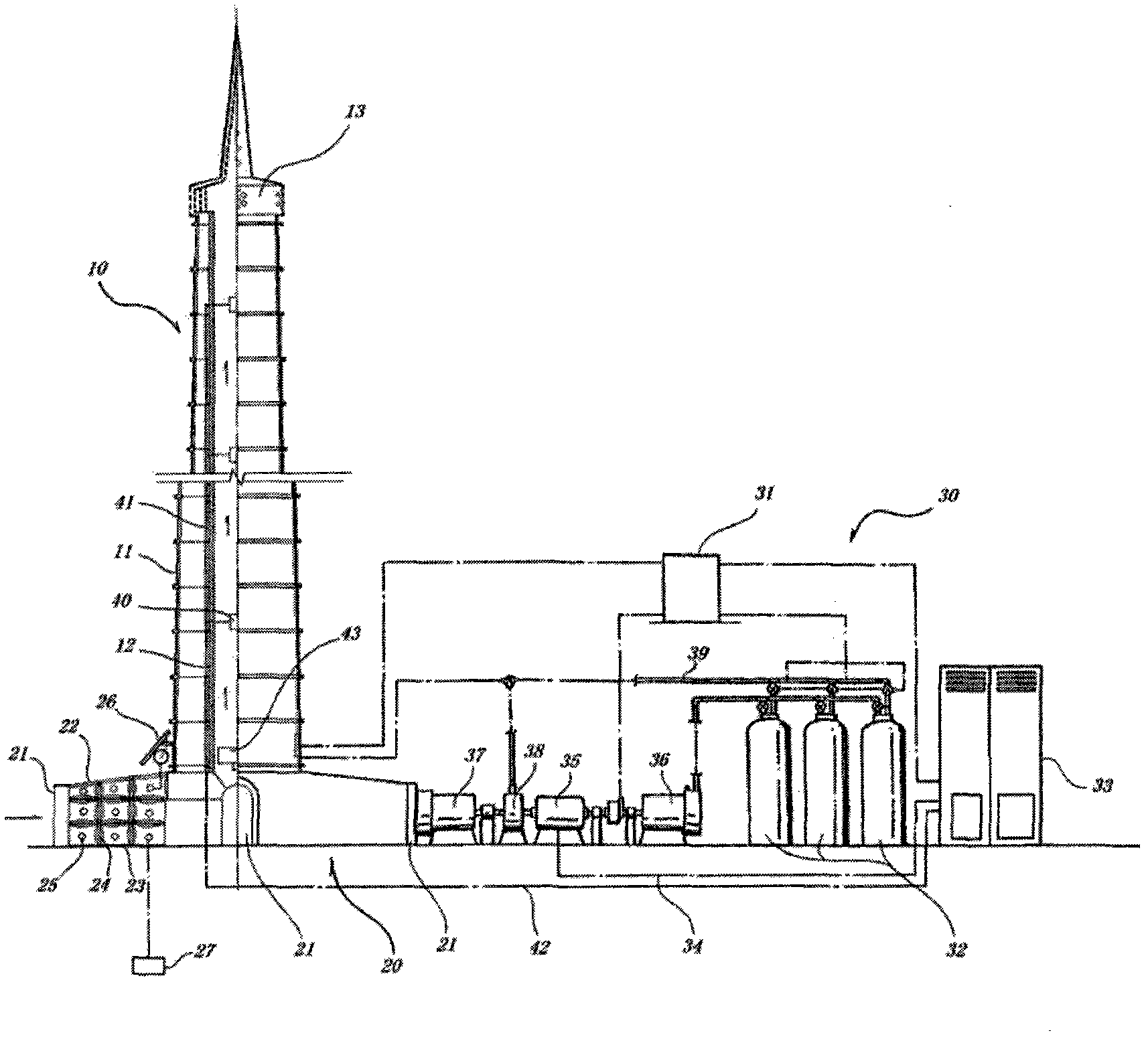

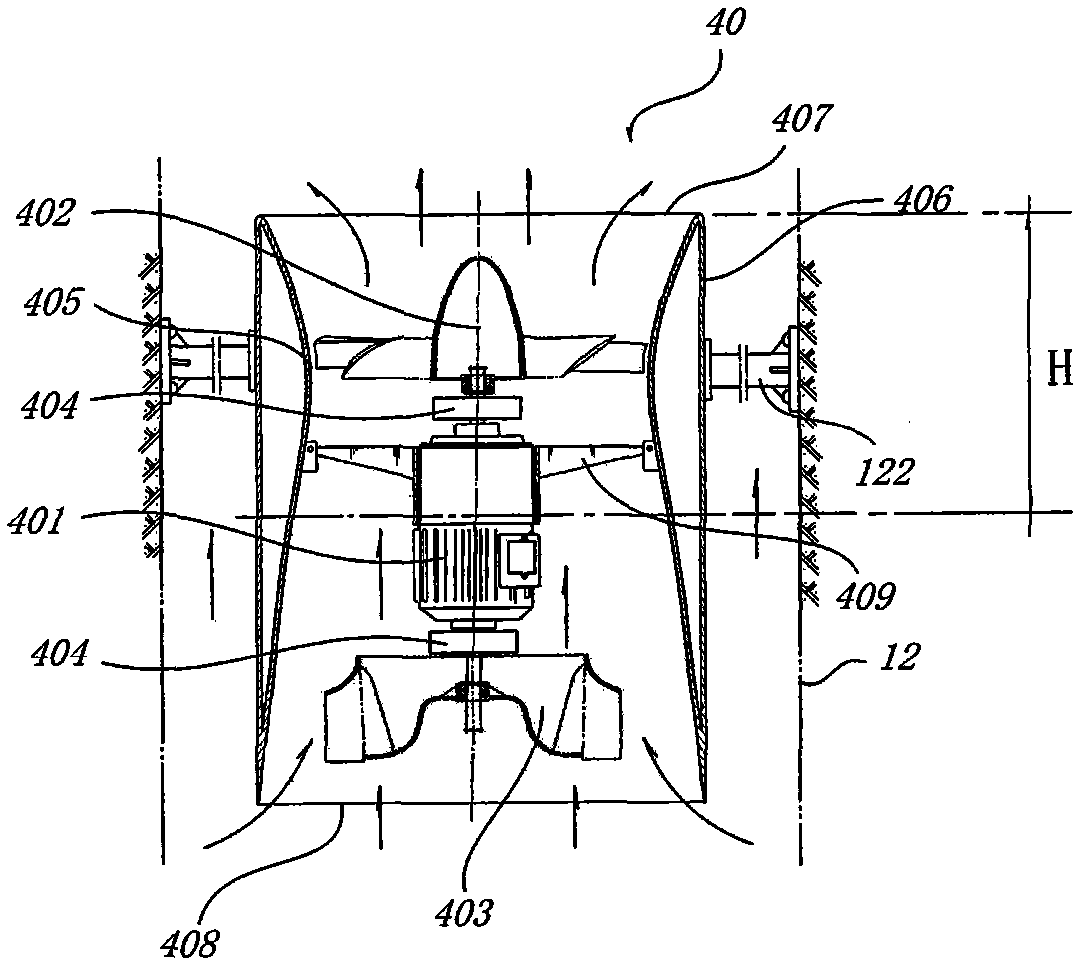

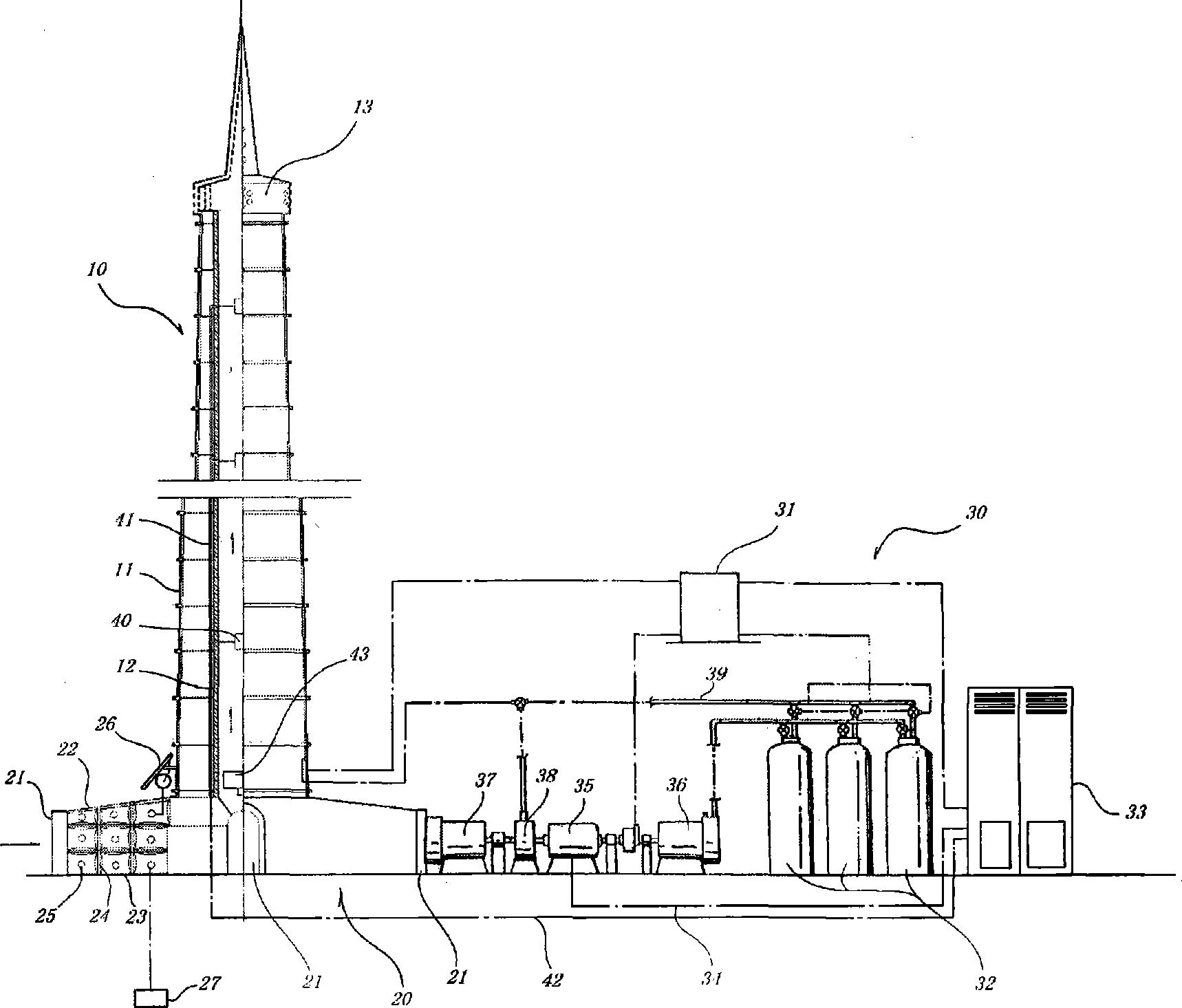

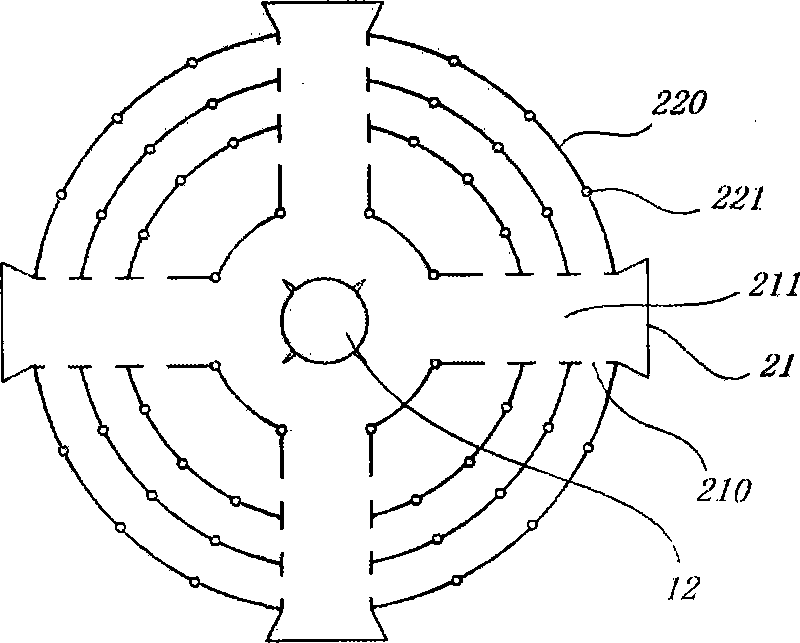

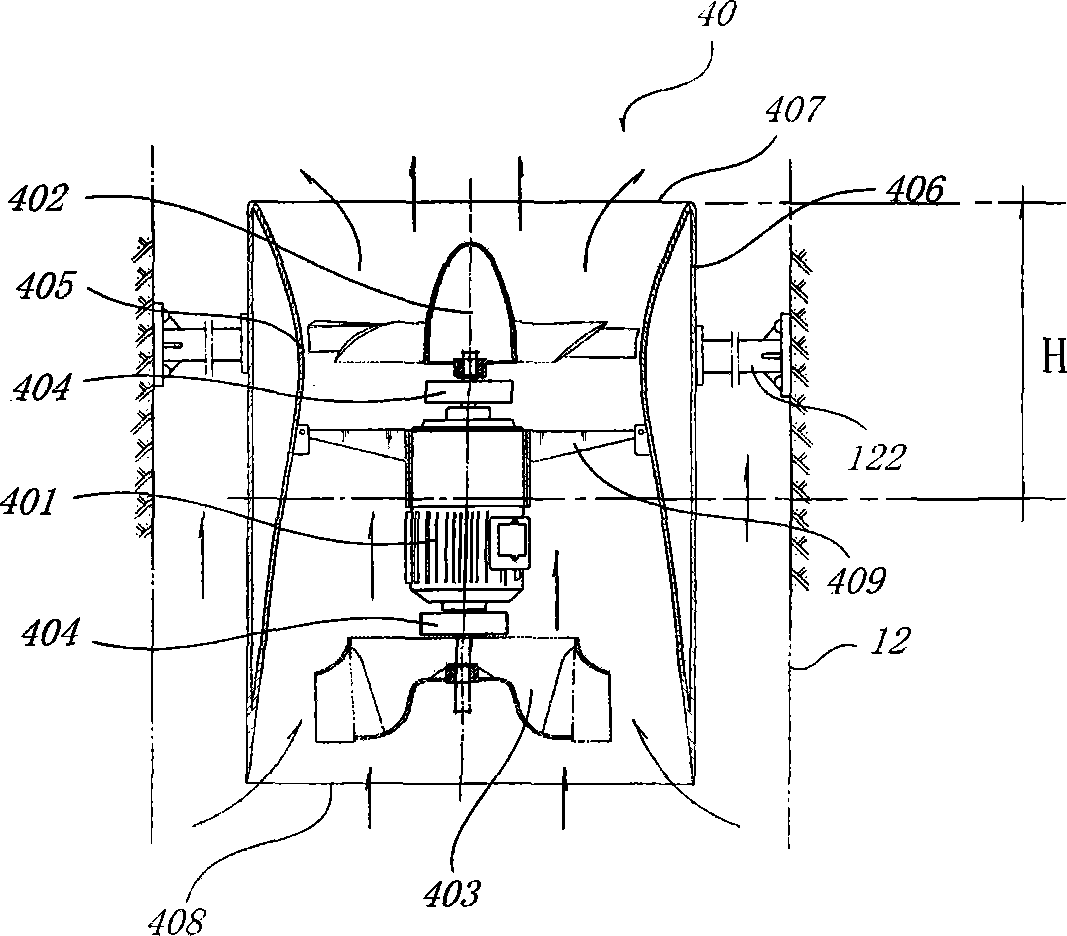

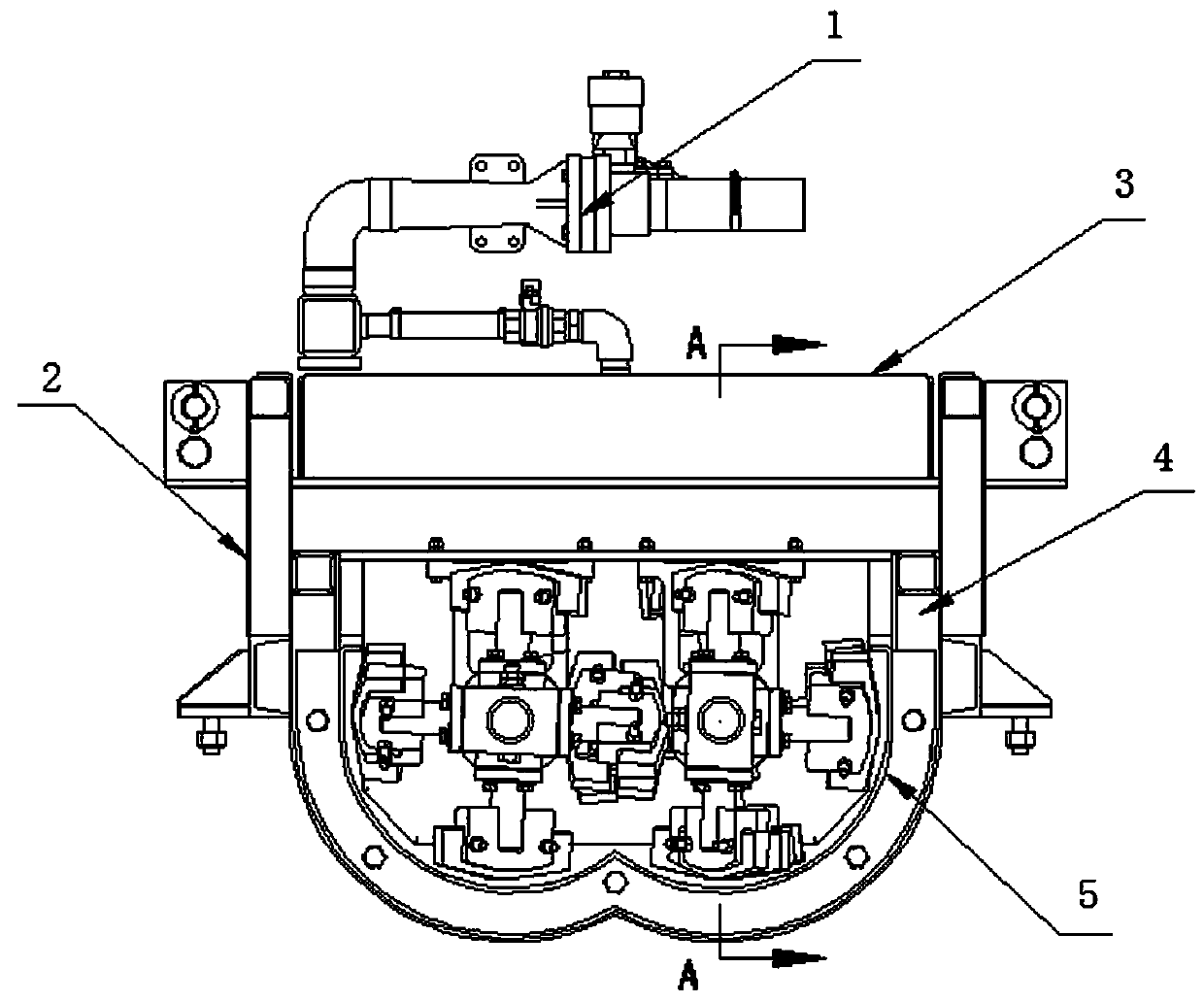

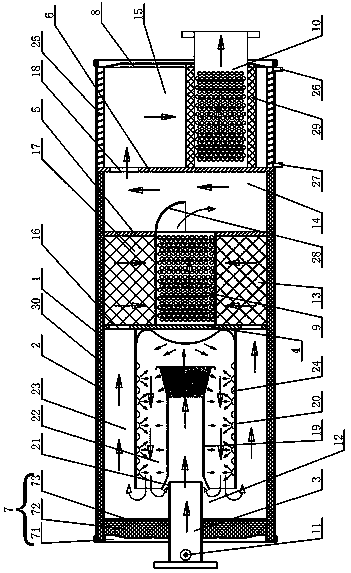

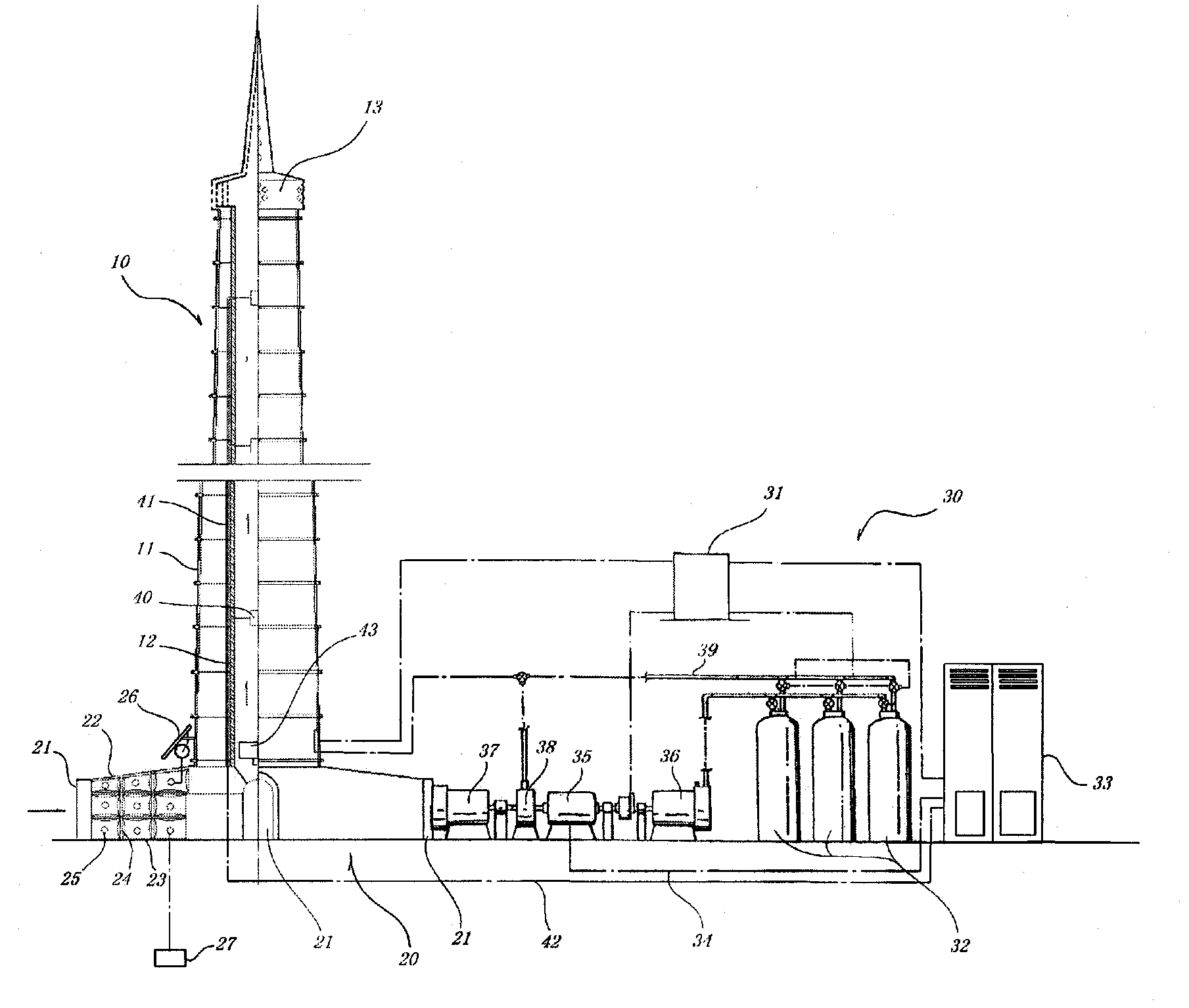

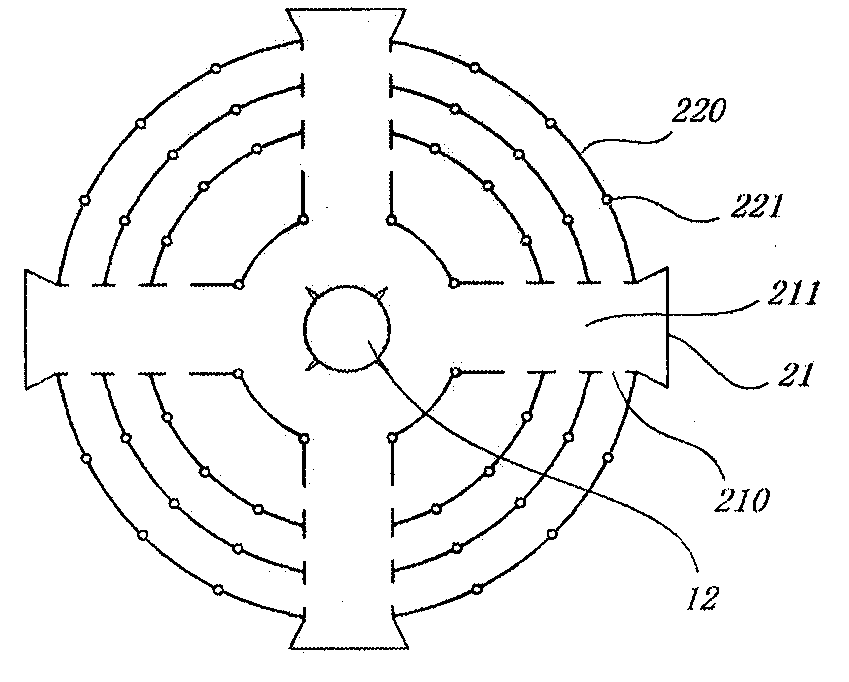

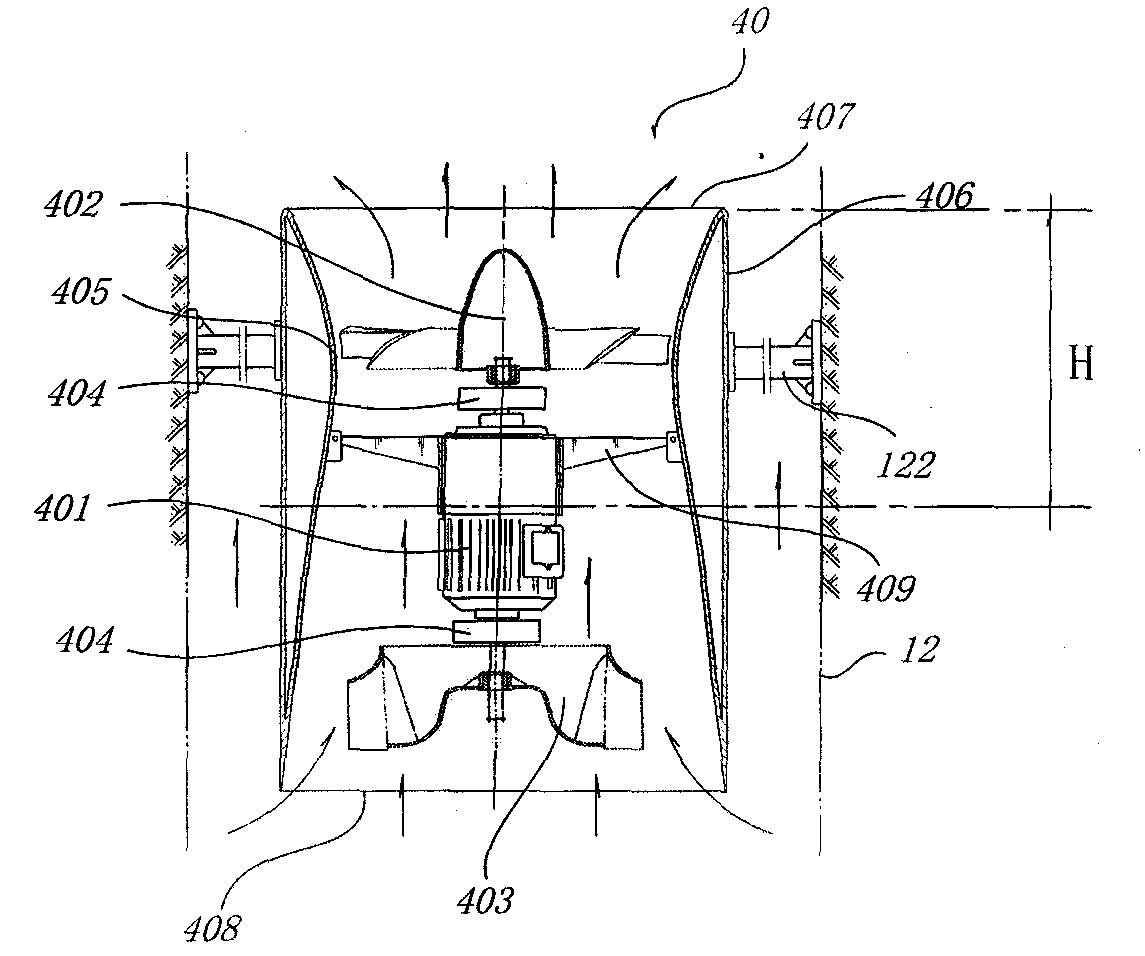

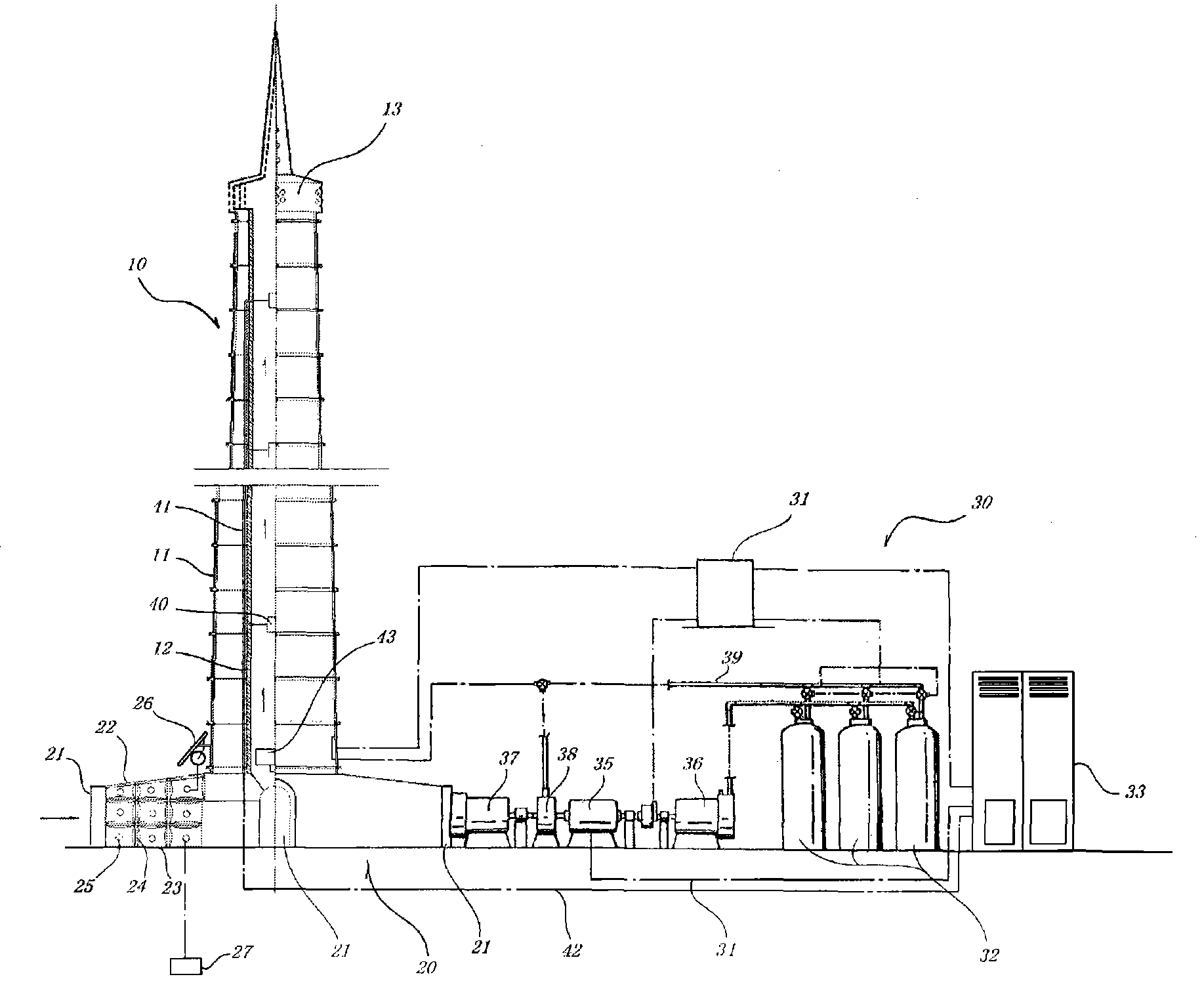

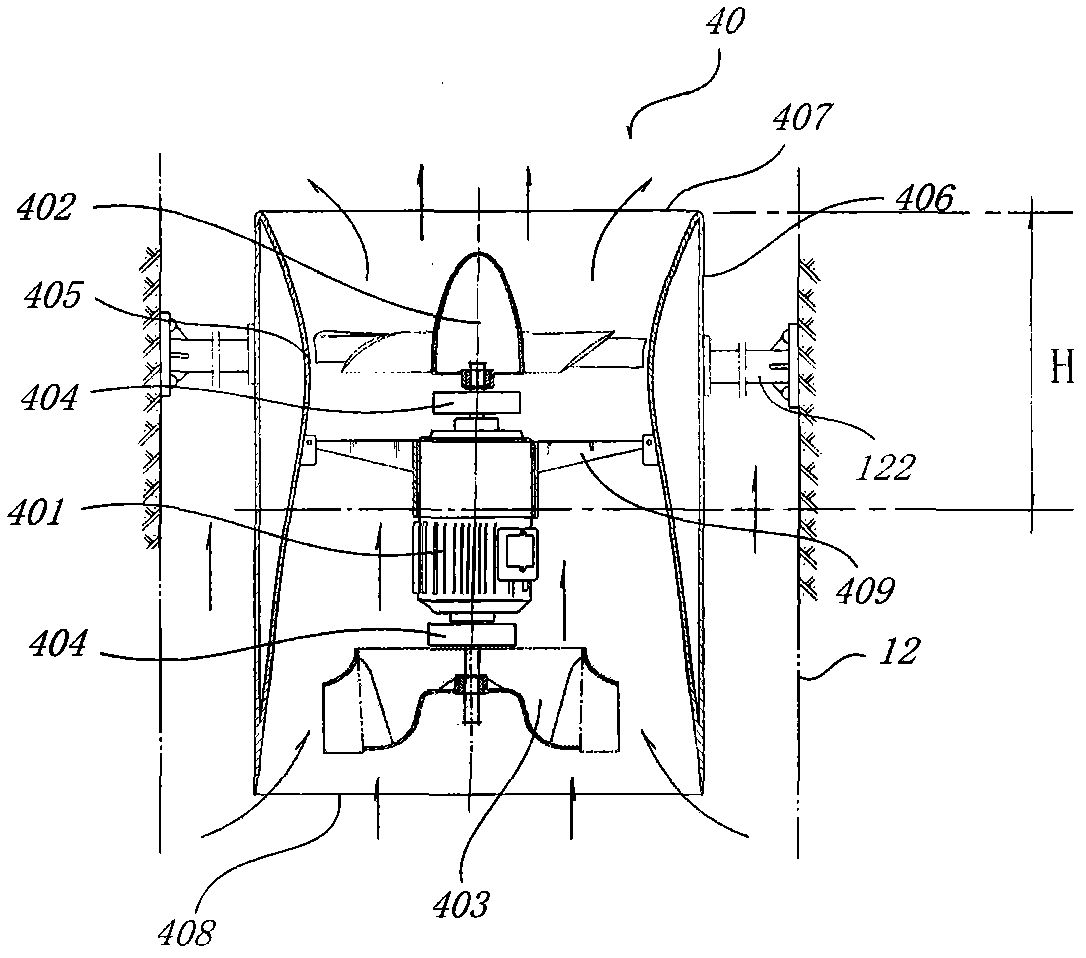

Wind driven generation device of comprehensive energy air channel well power generation station

ActiveCN102996358BEnough temperatureIncrease pressureFrom solar energyMachines/enginesImpellerWind driven

A wind driven generation device of a comprehensive energy air channel well power generation station comprises an air channel well, a power generator and an impeller. The air channel well is perpendicular to the ground and with a plurality of air feeding channels arranged on the base portion. A solar preheating chamber surrounds the periphery of the base portion, and more than one wind driven generator is arranged in the air channel well and comprises a reducing duct device with a diameter shrinkage portion. The power generator is arranged in the duct device. The impeller used for driving the generator to rotate is arranged at the position of the smallest diameter of the diameter shrinkage portion in the duct device and is connected onto a rotor shaft of the power generator. The rotor shaft penetrates through the power generator, and the penetrating end is connected with an air injection turbine which is located in the air feeding direction of the duct device relative to the impeller. Therefore, the wind driven generation device effectively improves air flow acting efficiency.

Owner:周登荣 +1

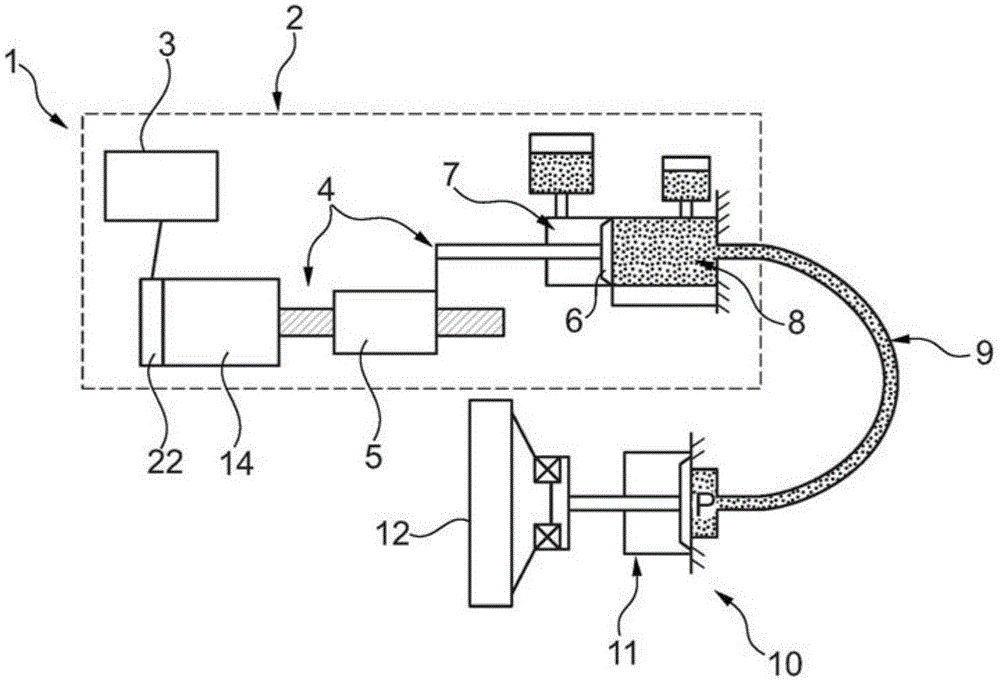

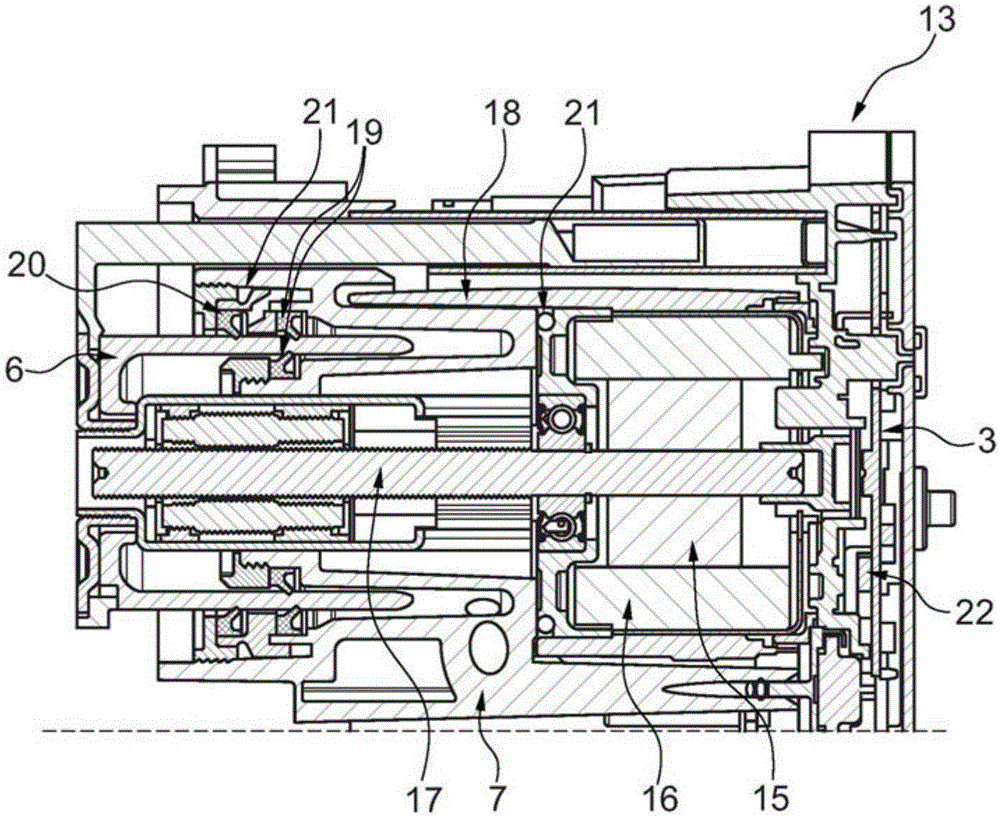

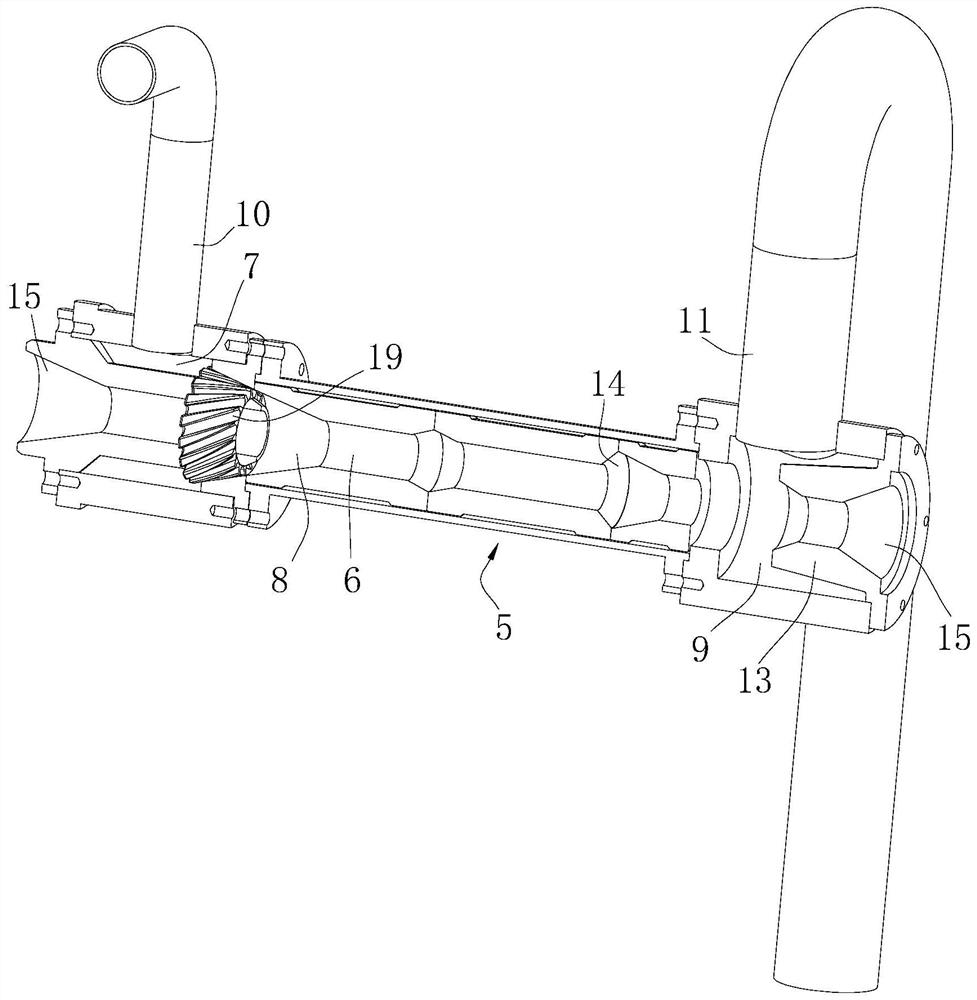

A method for local heating of a viscous elastic component of a hydrostatic actuator of a vehicle and a hydrostatic clutch actuator

ActiveCN105370750AIncrease temperatureEnough temperatureFluid actuated clutchesCouplingsElastic componentHydraulic fluid

The invention relates to a method for local heating of a viscous elastic component of a hydrostatic actuator of a vehicle, in particular a hydrostatic clutch actuator, in which the hydrostatic actuator (13) comprises a cylinder (7), in which a piston (6) is mounted axially movable , by an electric motor (14) is moved via a transmission (5), whereby a hydraulic fluid (8) in a hydraulic path of the hydrostatic actuator (13) is moved opposite to the area with viscous elastic components (19, 20, 21) is sealed. is the case of a method in which the operation of the hydrostatic actuator over a wide temperature range, at least one viscous elastic component (19, 20, 21) at low outdoor temperatures, and when the ignition of the vehicle is controlled by a current supply of an electrical circuit (22).

Owner:SCHAEFFLER TECH AG & CO KG

Method for overlaying welding of duplex stainless steel

ActiveCN102941394BEnough temperaturePrevent hot and cold cracksArc welding apparatusFurnace typesThermal insulationRoom temperature

Owner:WUHAN MARINE MACHINERY PLANT

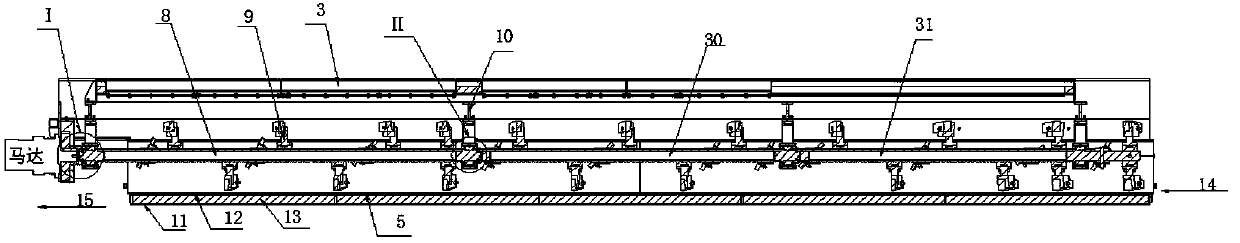

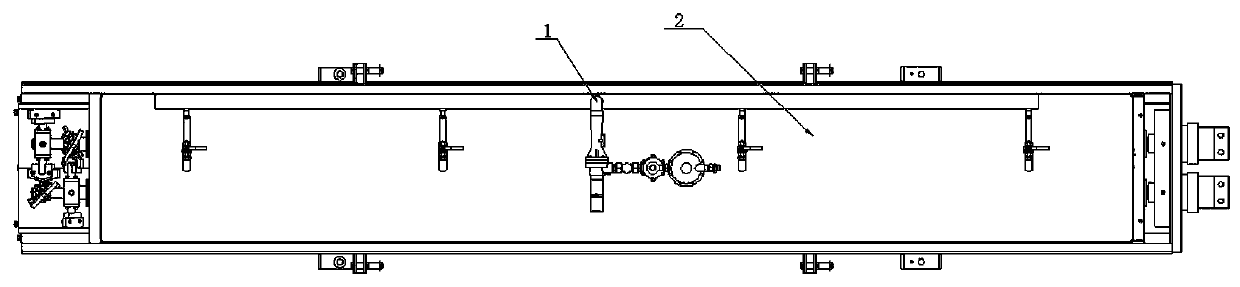

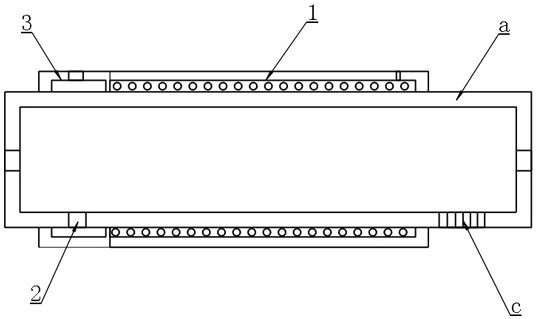

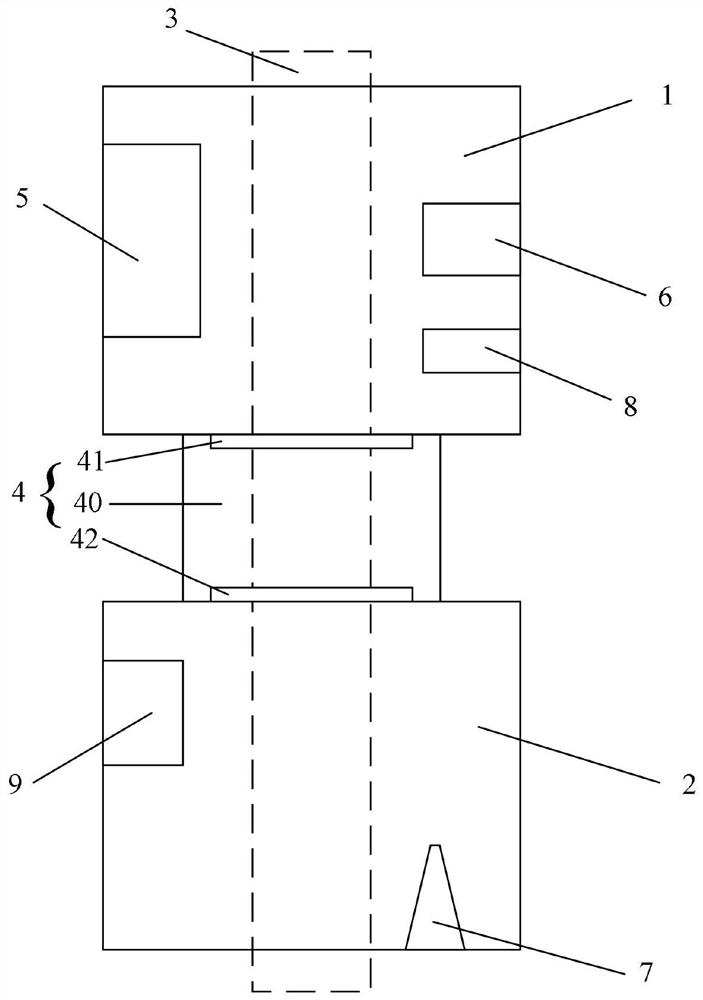

Slender type double-shaft mixer with heating heat-preservation function

PendingCN107829349AEnough temperatureEasy thermal bondingRoads maintainenceRoad surfacePulp and paper industry

The invention discloses a slender type double-shaft mixer with a heating heat-preservation function and belongs to the technical field of hot in-place recycling of asphalt pavements. The slender typedouble-shaft mixer comprises a mixing cylinder and two stirring shafts. The mixing cylinder is constituted by an outer cylinder body and an inner cylinder body, and the part between the outer cylinderbody and the inner cylinder body is filled with a heat-preservation material; an abrasion-resistant lining plate is mounted in the mixing cylinder in a sleeved mode, and the top of the mixing cylinder is covered with a heating plate; each stirring shaft is in a sectional type, and the sections of each stirring shaft are connected through connecting short shafts; mounting frames are arranged in the positions, on the upper portions of the connecting short shafts, of the mixing cylinder and provided with bearing seats in a hoisting mode; and the connecting short shafts are mounted in the bearingseats. The adopted structure is convenient to maintain, errors are small, and a new asphalt and used asphalt mixture is heated and mixed, so that a constructed asphalt pavement is higher in quality and better in effect.

Owner:NANJING FREETECH ROAD MAINTENANCE VEHICLE MFG CORP

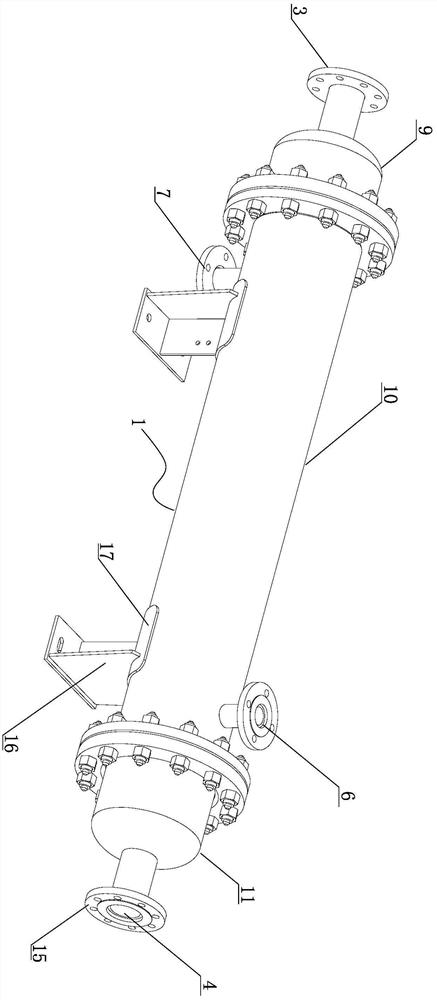

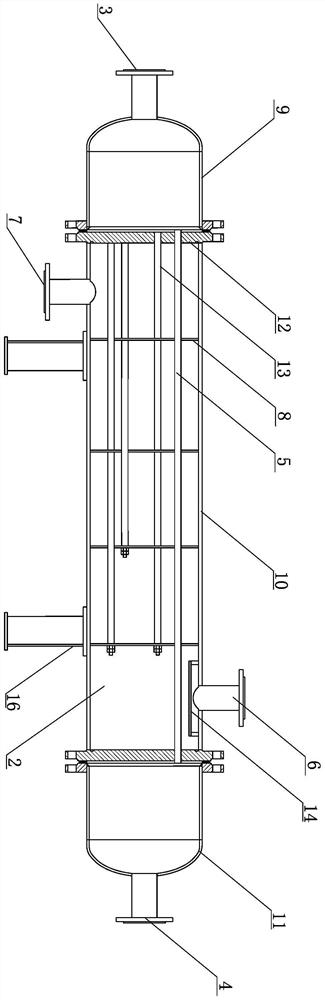

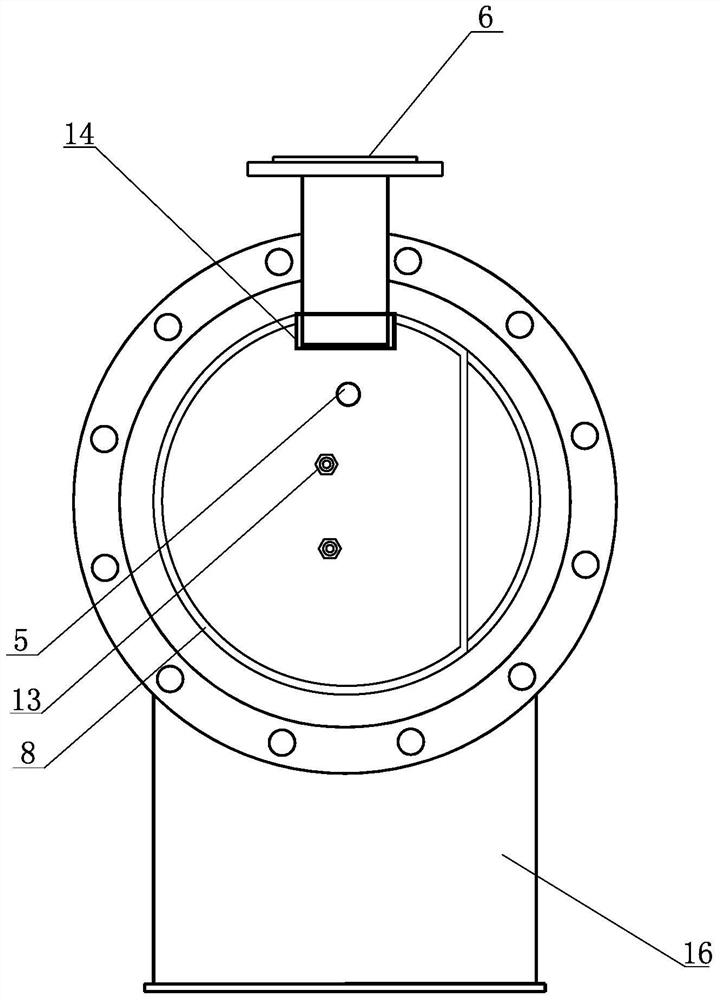

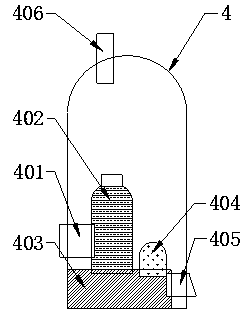

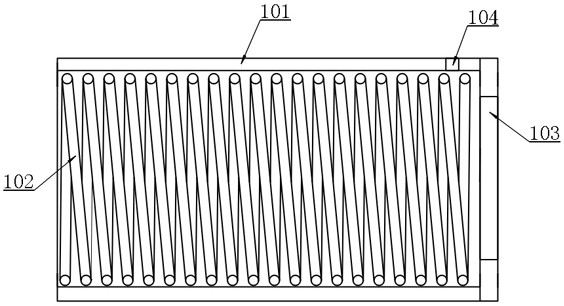

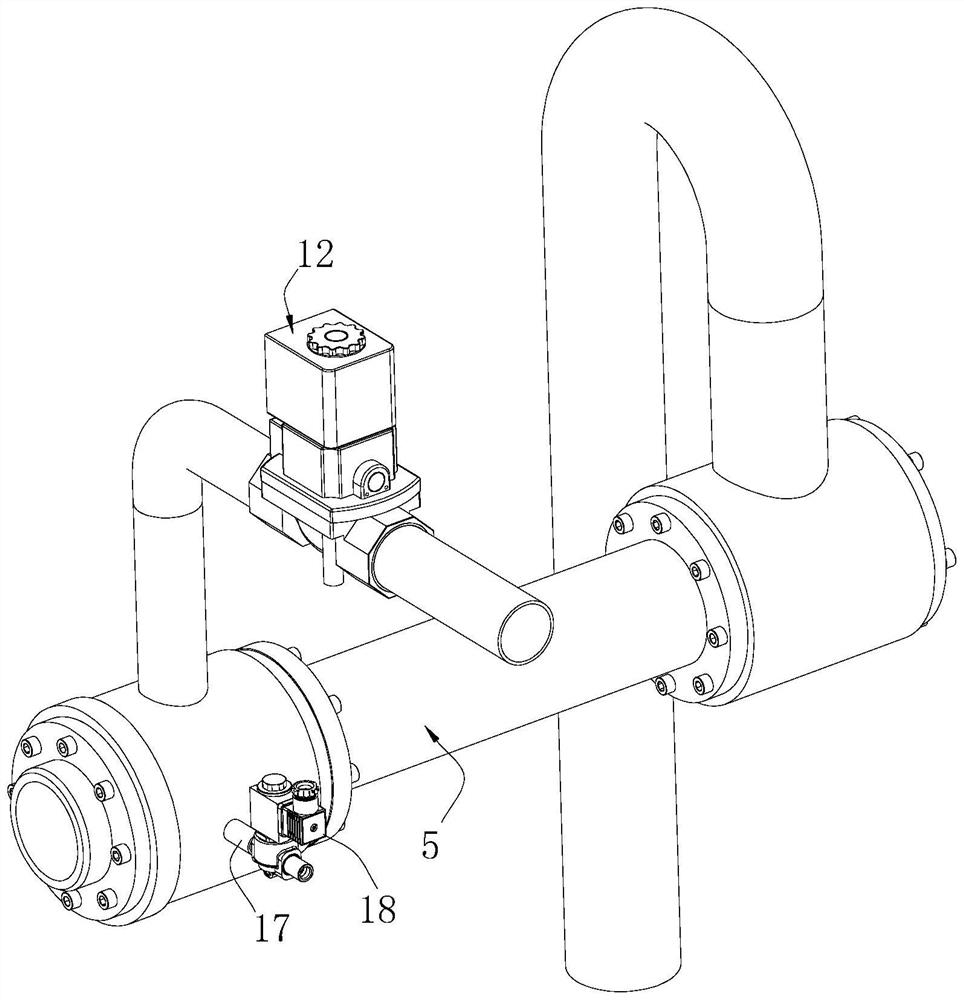

Nitrogen heater

PendingCN112524978AImprove heating efficiencyAvoid damageHeat exchanger casingsStationary tubular conduit assembliesThermodynamicsEngineering

The invention provides a nitrogen heater. The nitrogen heater comprises a cylinder with a gas storage space inside, a nitrogen inlet and a nitrogen outlet, wherein the nitrogen inlet and the nitrogenoutlet are arranged at two ends of the cylinder; at least one heat exchange tube is arranged in the cylinder; one end of the at least one heat exchange tube is connected with the nitrogen inlet, and the other end of the at least one heat exchange tube is connected with the nitrogen outlet; the cylinder is further provided with a steam inlet and a steam outlet which communicate with the gas storagespace; a plurality of baffle plates arranged in parallel are arranged between the steam inlet and the steam outlet in the cylinder; and every two adjacent baffle plates are arranged in a staggered manner. Heating is performed through heat exchange between steam and nitrogen; while it is guaranteed that the nitrogen can be heated to the enough temperature, the temperature of the nitrogen is not too high, so that damage to a precision device to be cleaned or dried is avoided, and meanwhile, the situation that the volume of the nitrogen is excessively expanded due to the fact that the nitrogen is excessively heated, thus avoiding the explosion of the cylinder.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

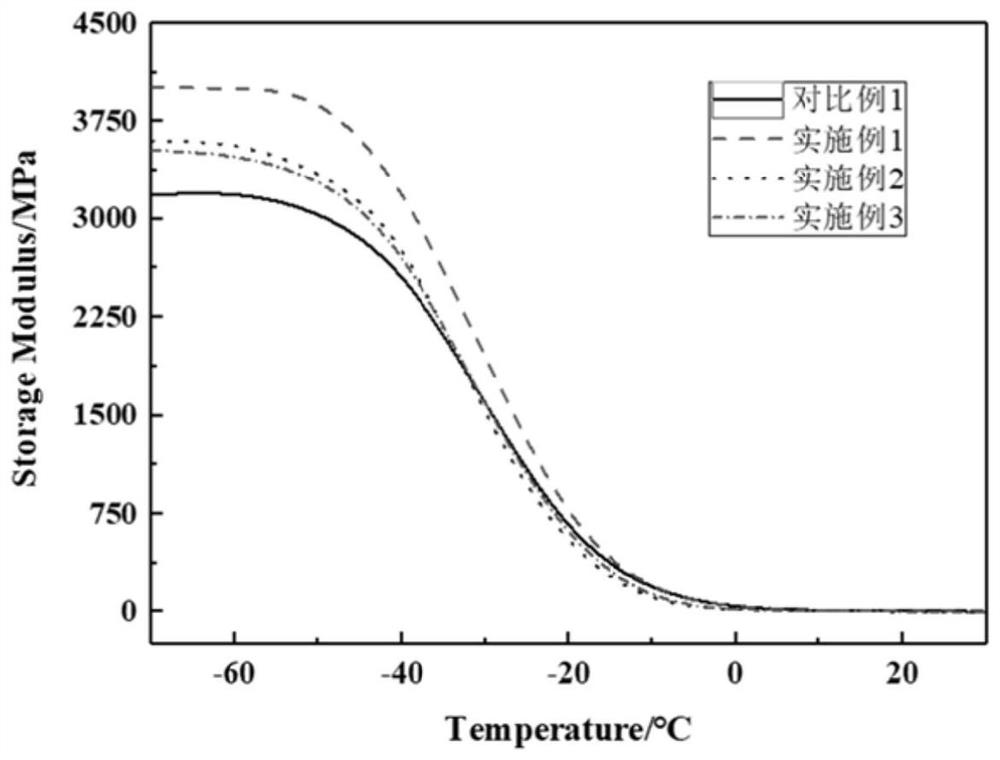

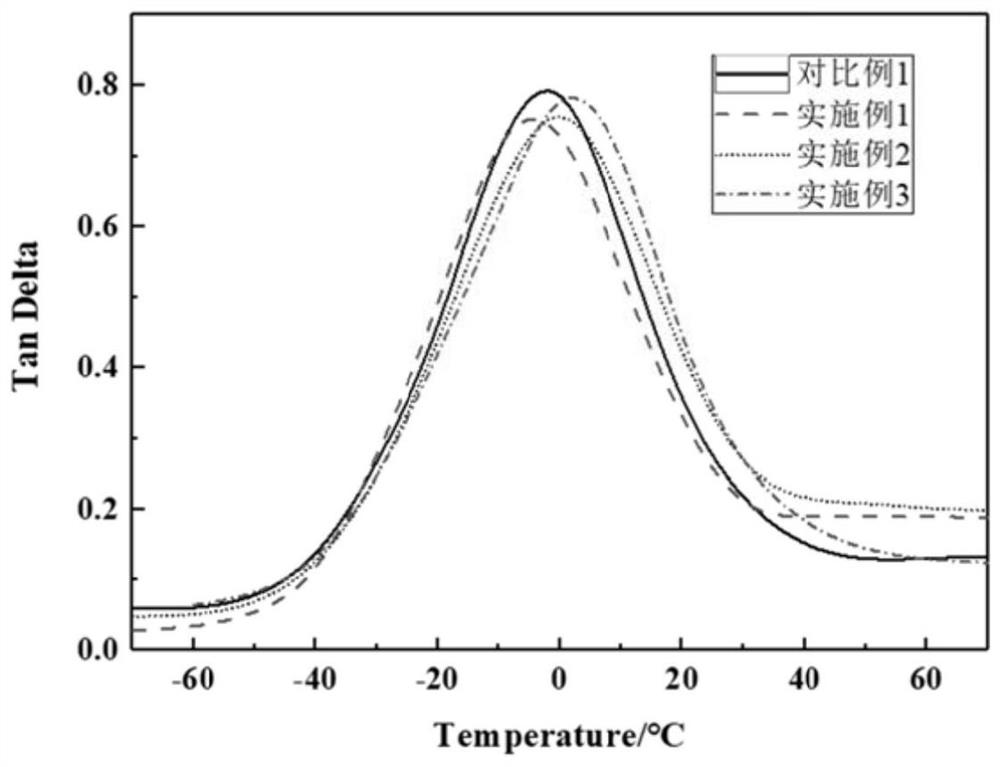

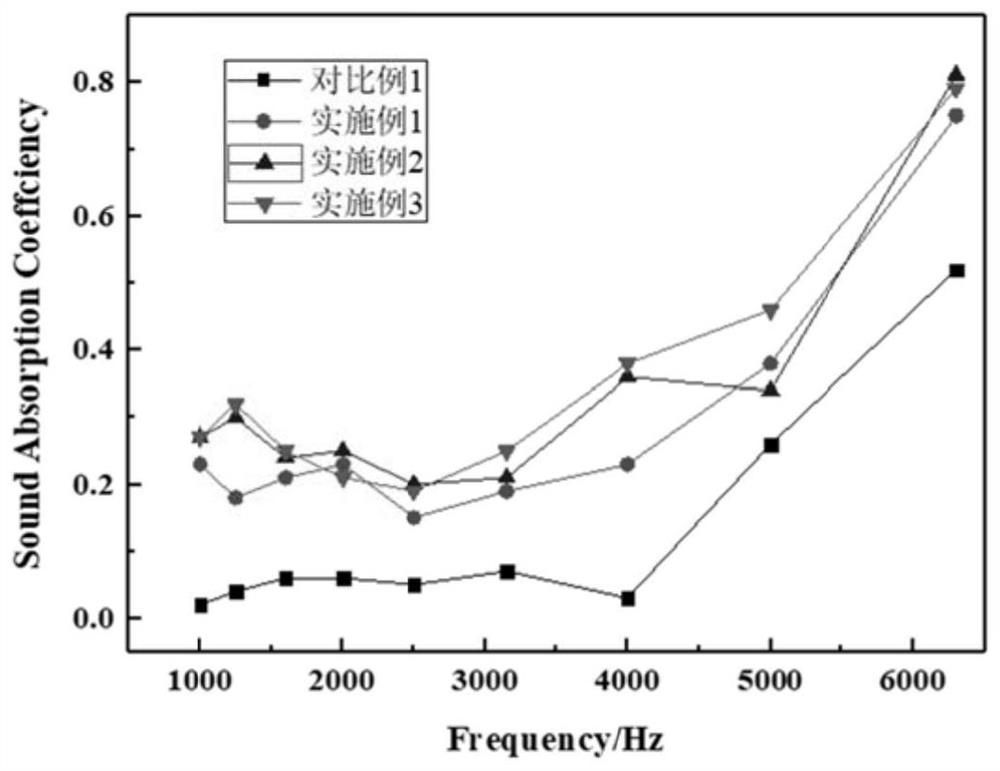

Polyvinyl chloride-based composite material suitable for medium-high frequency sound absorption and preparation method thereof

PendingCN112694691AAvoid premature decompositionEnsure successful sample preparationButadiene DioxideFoaming agent

The invention provides a polyvinyl chloride-based composite material suitable for medium-high frequency sound absorption and a preparation method thereof. The polyvinyl chloride-based composite material comprises the following raw material components by mass: 100 parts of polyvinyl chloride, 3-5 parts of an organic tin stabilizer, 100-130 parts of a plasticizer, 25-30 parts of an acrylonitrile-butadiene-styrene terpolymer, 0-50 parts of diatomite and 0-4 parts of an AC foaming agent. The polyvinyl chloride-based composite material provided by the invention has excellent sound absorption performance, the average sound absorption coefficient within 1000-6300Hz is 0.2-0.35, and the polyvinyl chloride-based composite material is suitable for medium-high frequency sound absorption materials.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

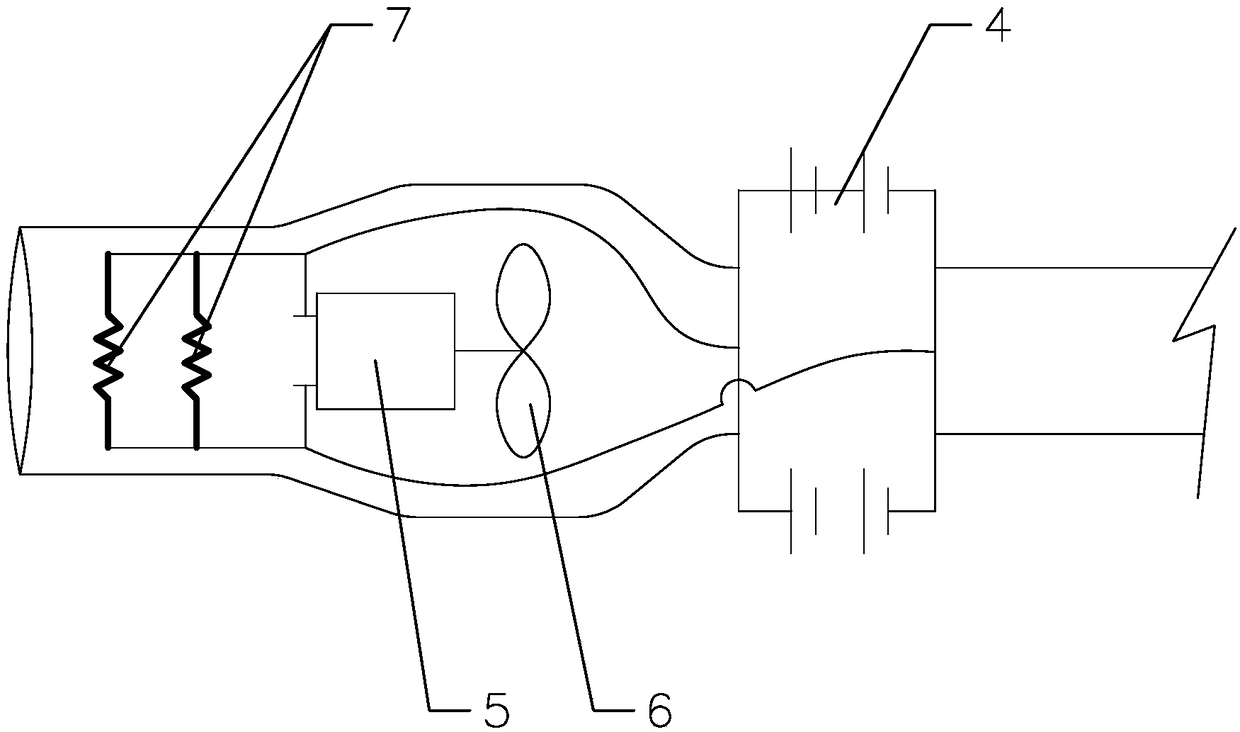

Nozzle type catalytic muffler for automobile diesel engine

ActiveCN111550301AShorten the lengthSave spaceAir-treating devicesInternal combustion piston enginesHeating systemHeat conservation

The invention relates to a nozzle type catalytic muffler for an automobile diesel engine. The nozzle type catalytic muffler is characterized in that an adblue nozzle is arranged on an air inlet pipe outside the SCR catalytic muffler, and meanwhile, a flow guide device for changing the air flow direction is arranged in the muffler; by changing the air flow direction, tail gas and a high-purity ureasolution for a vehicle are fully mixed and then subjected to catalytic reduction treatment, so that the length of an exhaust pipeline of the engine is shortened, space is saved, and cost is reduced;in addition, heat preservation layers are arranged outside an air inlet cavity and a catalytic cavity of the catalytic muffler, the heat preservation effect on the tail gas is achieved, and a catalytic reduction reaction is facilitated; and a cooling flow channel for cooling water to flow is arranged outside an exhaust cavity of the catalytic muffler, cooling water in the cooling flow channel andan automobile heating system are arranged in the cooling flow channel, waste heat in the tail gas is used for providing a heat source for the automobile heating system, and therefore the purposes of saving energy and reducing emission are achieved.

Owner:安阳职业技术学院

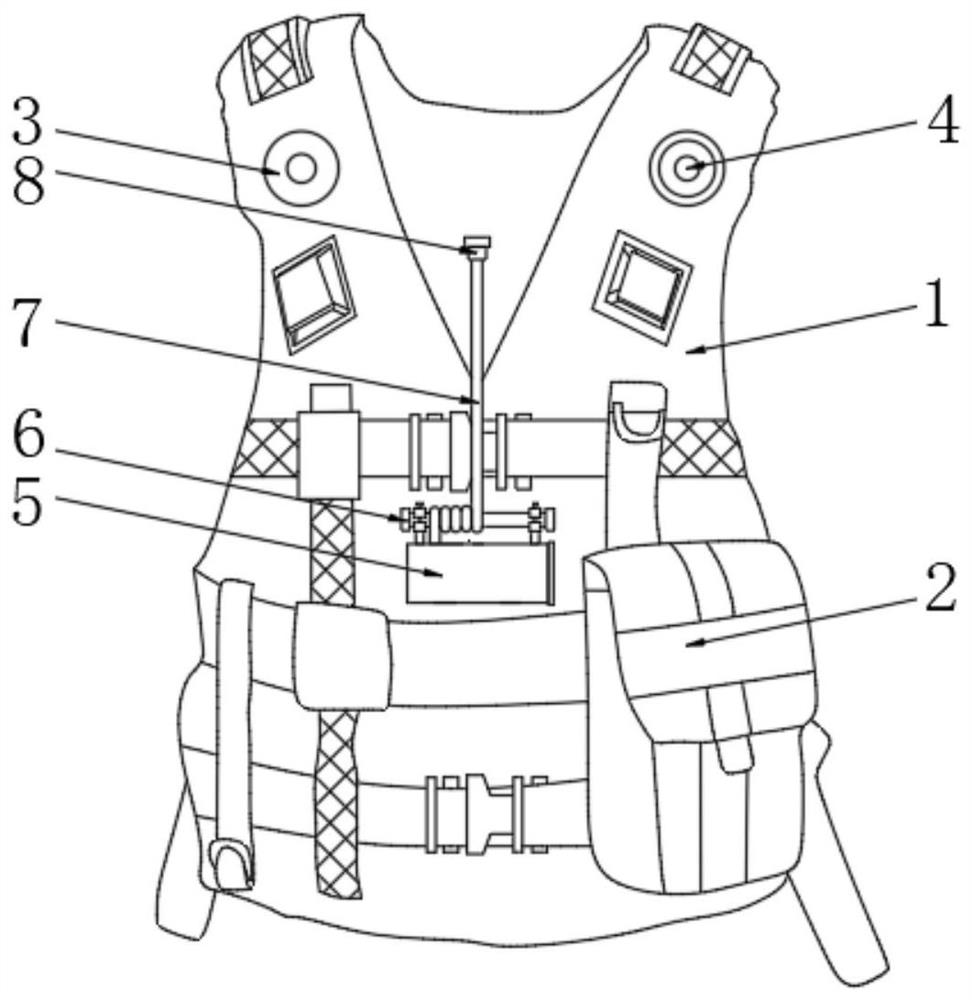

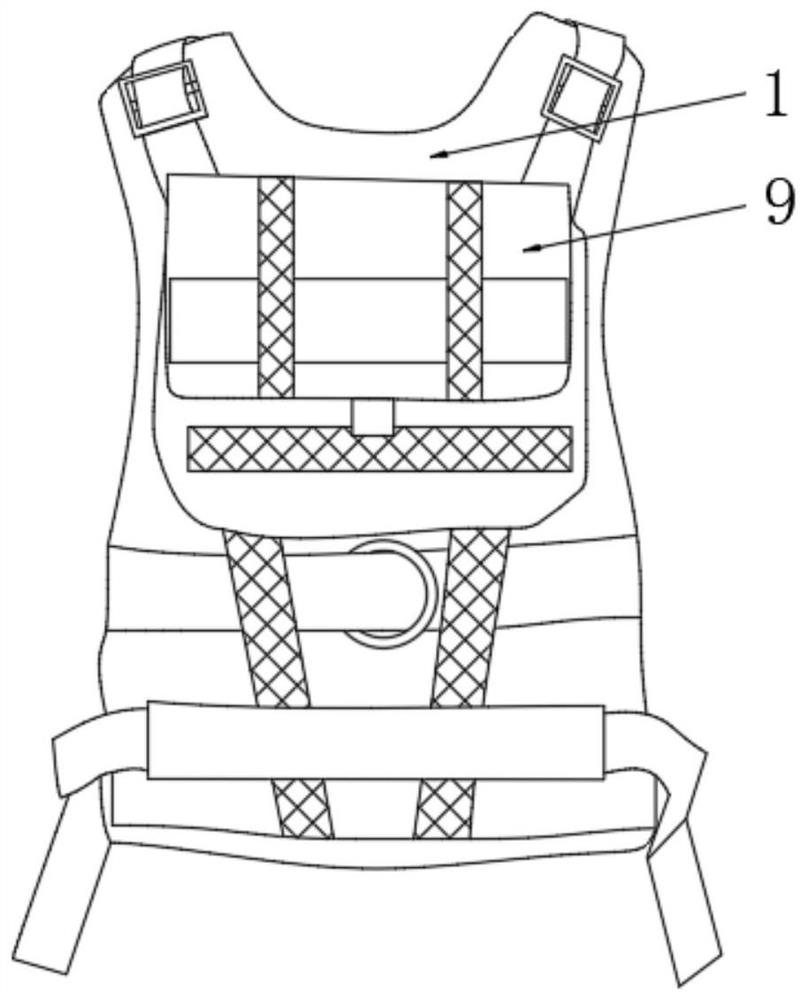

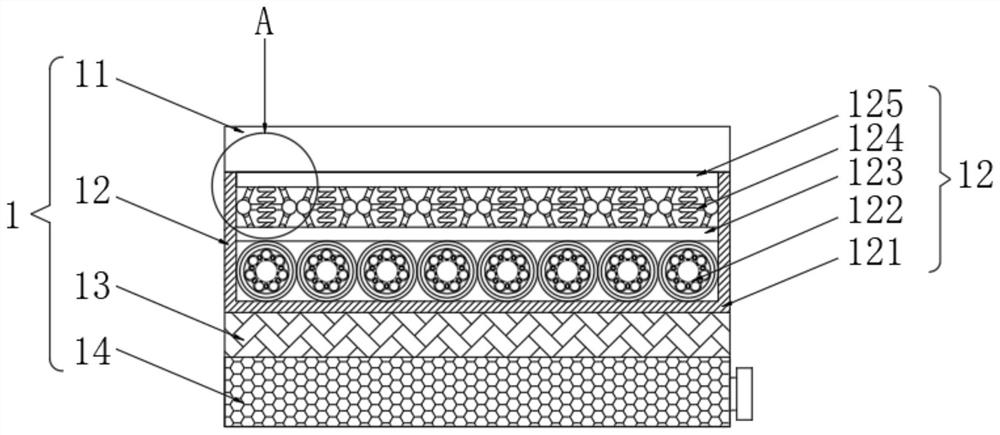

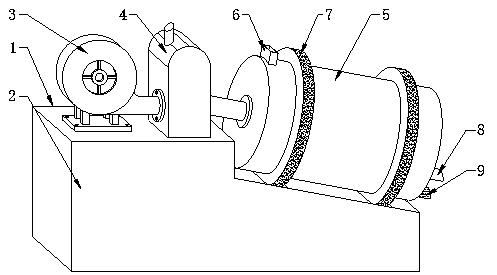

Multifunctional torrent rescue life jacket with high safety and using method

ActiveCN111746761AMeet the needs of useEnough temperatureSynthetic resin layered productsBody suitsMarine engineeringStructural engineering

The invention discloses a multifunctional torrent rescue life jacket with high safety and a using method, and belongs to the technical field of life jackets. The rescue life jacket comprises a rescuelife jacket body, wherein a pocket is arranged at the waist part of the front side of the rescue life jacket body; a waterproof illuminating lamp is arranged at the position, which is close to the shoulder on the right side, of the front side of the rescue life jacket body; a flashing lamp is arranged at the position, which is close to the left shoulder, of the front side of the rescue life jacketbody; a water storage assembly is arranged at the chest of the rescue life jacket body; a storage assembly is fixedly arranged at the top of the water storage assembly; and an elastic scaling hose iswound on the storage assembly. By arranging the waterproof illuminating lamp and the flashing lamp, the rescue life jacket body has the functions of illuminating and prompting the position of a lifeguard, the rescue is facilitated, the lifeguard can be easily found by a drowning person, and the use requirements of the lifeguard during night rescue can be met.

Owner:万舟救生装备(东台)有限公司

Rapeseed drying device

InactiveCN109210888AImprove drying efficiencyWith drying effectSievingScreeningPulp and paper industryRapeseed

The invention discloses a rapeseed drying device. The rapeseed drying device comprises a drying device body, a supporting seat and a fan; the bottom end of the drying device body is fixedly connectedwith the supporting seat, the fan is fixedly connected to one side of the top end of the supporting seat, and a hot blast furnace is fixedly connected to one side of the fan; an air inlet pipe is connected to the bottom of one side in the hot blast furnace in an embedded mode; a heat exchanger is connected to one side of the air inlet pipe in a nested mode; a hot air pipe is connected to the bottom end of the heat exchanger in a nested mode; and a roller is movably connected to one end of the hot blast furnace. Through the roller, rapeseed can be dried and output, the creativity of the dryingdevice body is effectively improved through the roller, air output by the hot blast furnace has the better drying effect through a heater, and the drying efficiency of the drying device body is effectively improved through the heater; the roller has the better sealing effect during drying of the rapeseed through a disc plate, and the sealing property of the drying device body is effectively improved through the disc plate; and the rapeseed drying device is suitable for being used and has the wide development prospects in the future.

Owner:ANHUI HUAYIN CAMELLIA OIL

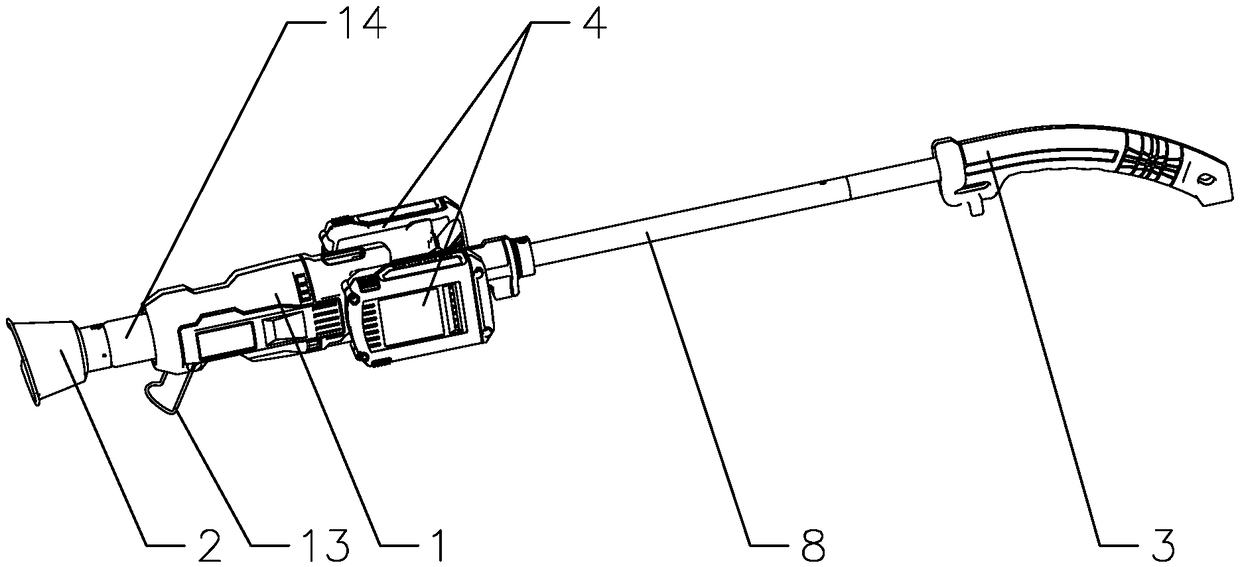

Hand-held high-temperature weeding machine convenient to operate

InactiveCN108925542AImprove operational convenienceIncrease flexibilityWeed killersElectricityWorking environment

The invention provides a hand-held high-temperature weeding machine convenient to operate. The weeding machine comprises a machine head, a weeding attachment and a handle; a high-temperature generating device is arranged in the machine head, and the weeding attachment communicates with the high-temperature generating device; and the weeding machine further comprises a battery pack, and the batterypack is electrically connected with the high-temperature generating device and supplies power to the high-temperature generating device to make the high-temperature generating device operate. According to the weeding machine provided by the invention, the power is supplied to the high-temperature generating device through the battery pack, so that the weeding machine works; and compared with a current power supply mode through a power line, the power supply mode disclosed by the invention makes the weeding machine more convenient to operate, the weeding machine is not pulled by the power linewhen working, the weeding machine can be operated in any directions, the weeding machine is not affected by a length of the power line to affect operation distance, and the weeding machine can be conveniently held to each working environment; and the problem that operation cannot be performed because a socket cannot be found when working is performed outdoors is well avoided, the weeding machinecan be very suitable for outdoor work, an application range of the weeding machine is improved, and operational convenience of the weeding machine is improved.

Owner:ZHEJIANG PRULDE ELECTRIC APPLIANCE CO LTD

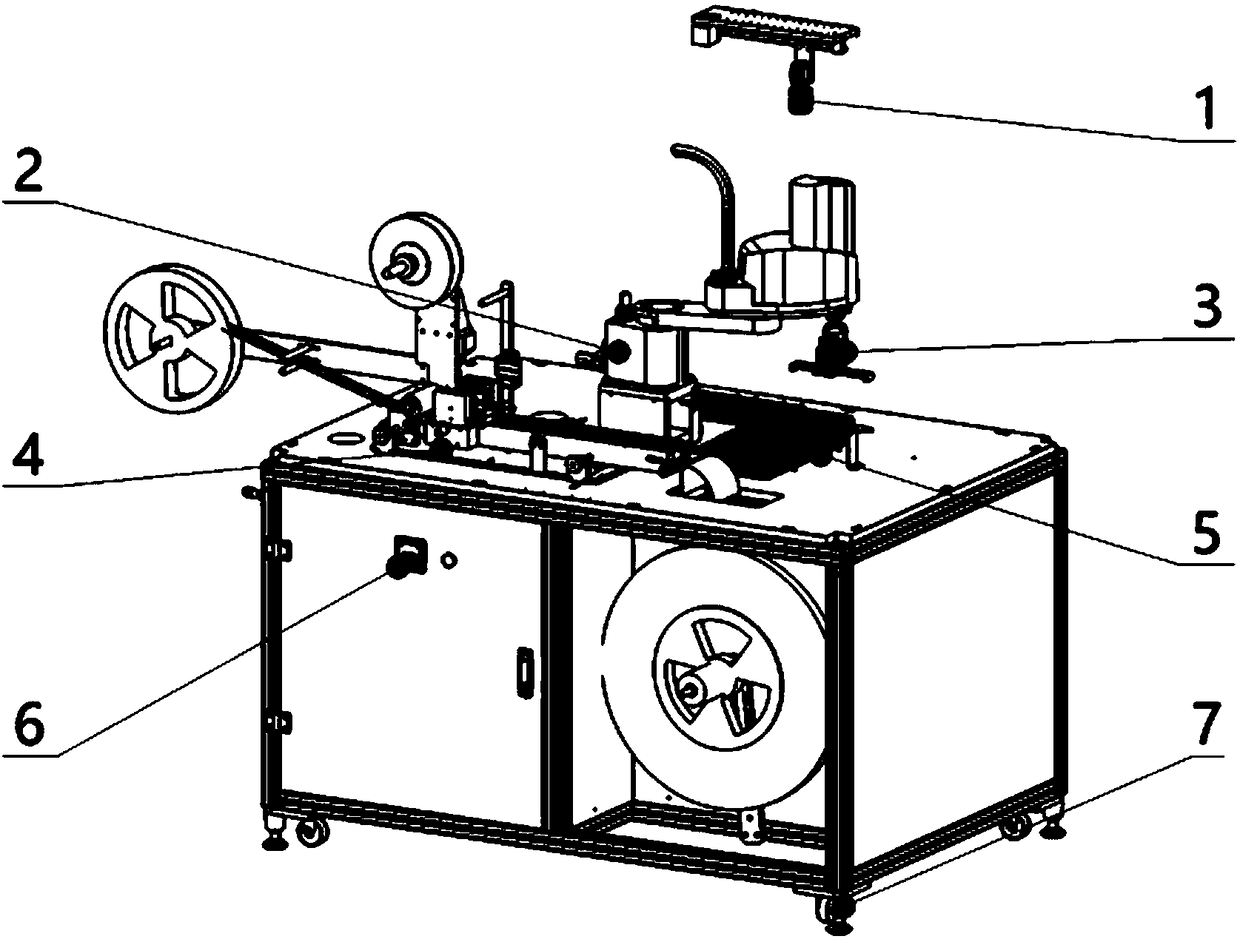

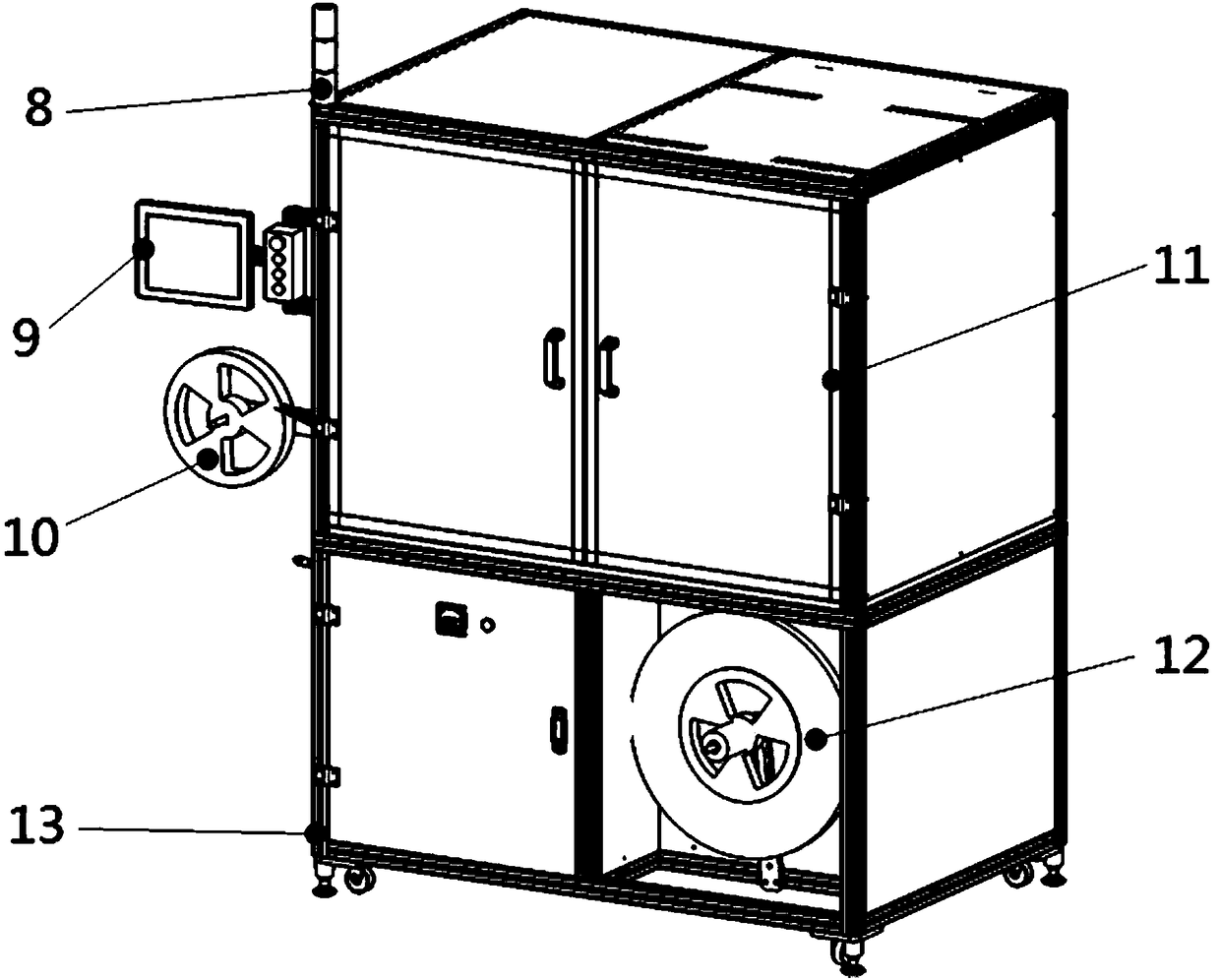

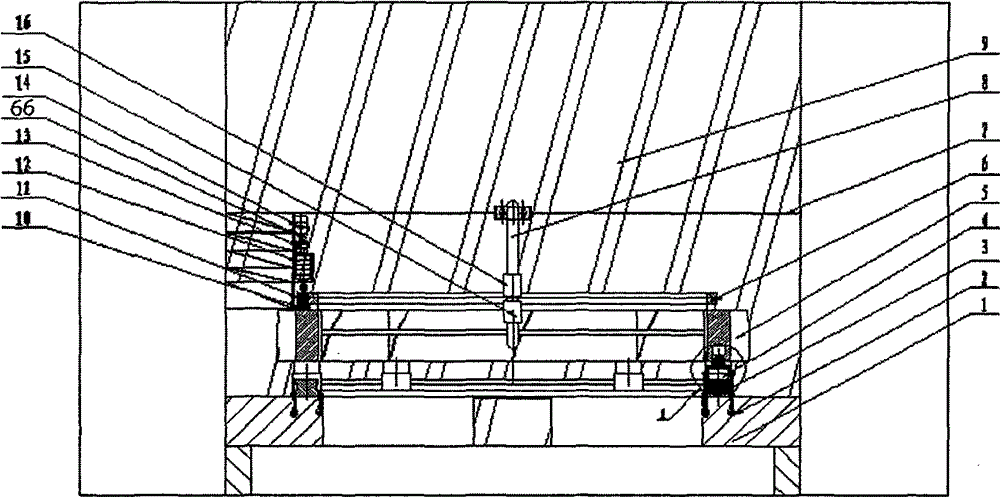

Automatic packaging equipment based on machine vision

PendingCN108657534ARandomly placedIncrease freedomPackaging automatic controlMachine visionComputer module

The invention relates to automatic packaging equipment based on machine vision. The automatic packaging equipment comprises a multi-axis robot and a winding band packaging machine used for packaging grabbed modules. The multi-axis robot is provided with a mechanical gripper used for grabbing the modules to be packaged. The mechanical gripper is in screwing connection with the multi-axis robot. Thepackaging equipment further comprises a camera used for collecting module images. After the camera collects the module images, the multi-axis robot rotates the mechanical gripper to the designated angle according to the placing angle of the modules in the module images, and the mechanical gripper grabs the modules and conveys the modules to the winding band packaging machine to be packaged. Compared with the prior art, based on the machine vision, the placing direction of the modules can be recognized, then the modules can be located at any position and placed at will, the freedom degree is high, and thus the working efficiency is improved.

Owner:晓视自动化科技(上海)有限公司

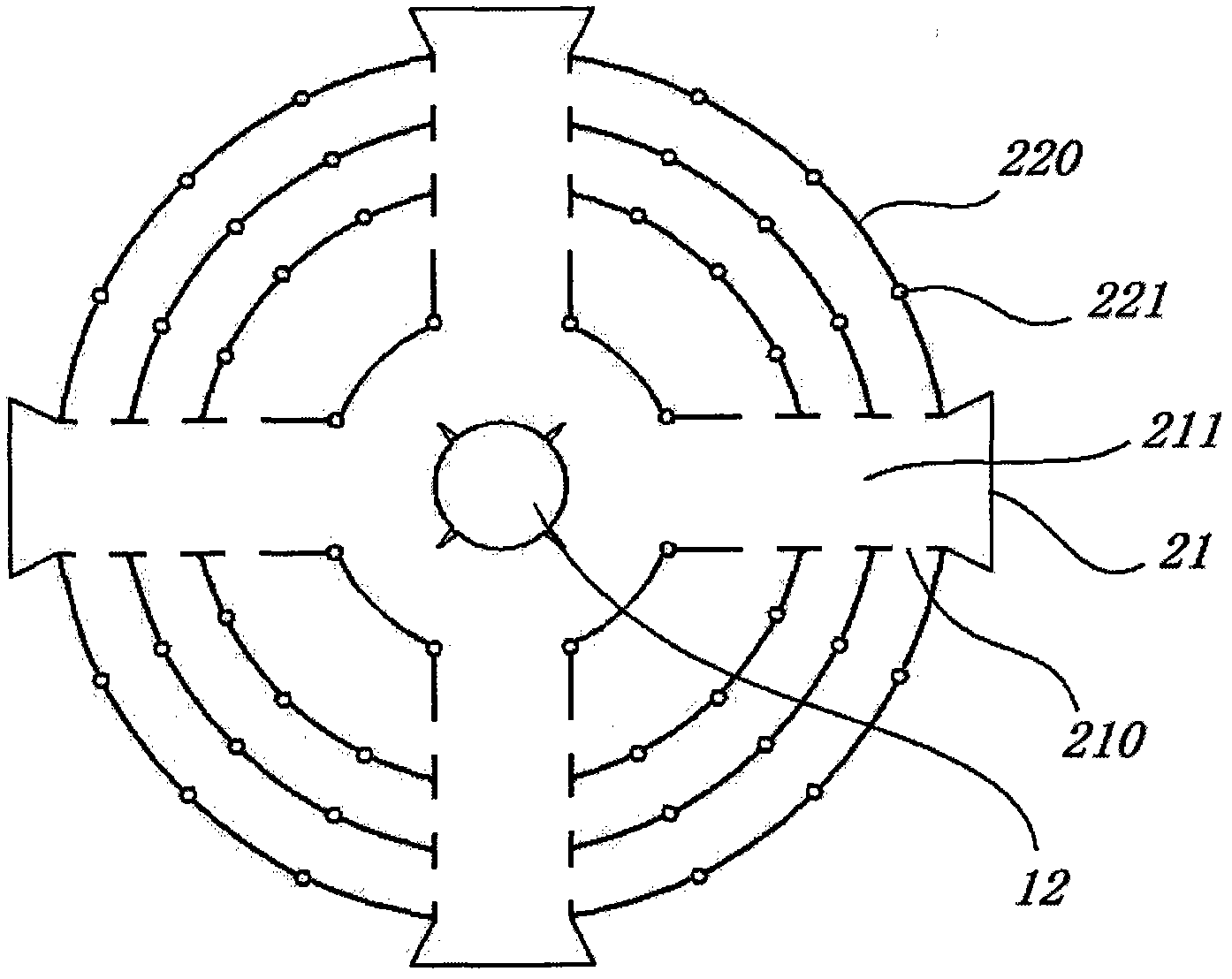

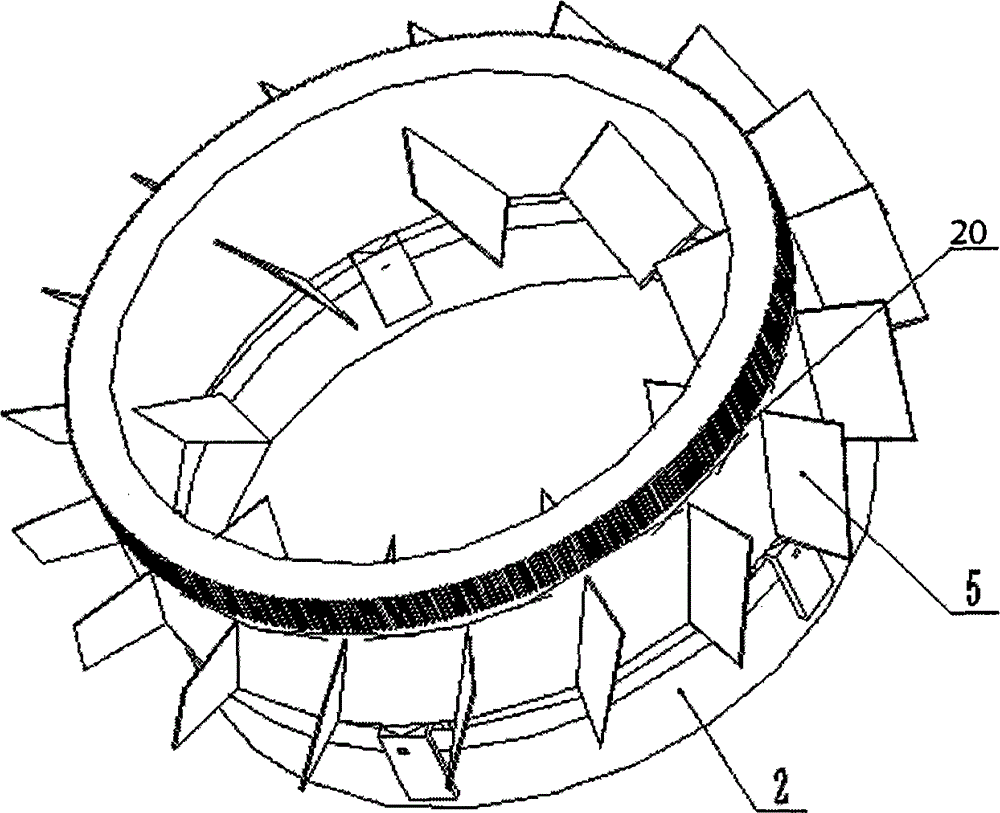

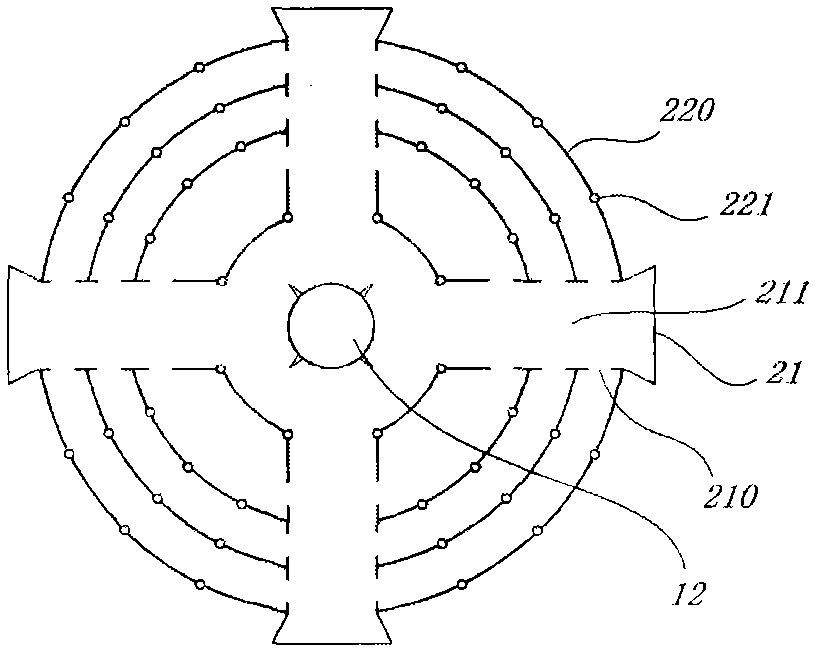

Electricity generating tower turbine turbofan revolving structure

ActiveCN103133244BEnough temperatureUniform power generationMachines/enginesWind motor combinationsImpellerElectricity

The invention relates to an electricity generating tower turbine turbofan revolving structure. The structure comprises a traveling orbit, a turbine turbofan, a revolving gear ring, a shaft component, a fixing support and a motor component. The traveling orbit is placed on a concrete base platform. Bolt sets are evenly distributed at the bottom of the traveling orbit and used for fixing the traveling orbit on the concrete base platform. The turbine turbofan is arranged on the traveling orbit. Five support posts are evenly distributed on the traveling orbit. The revolving gear ring is placed on a top face of the turbine turbofan. The shaft component is connected with the fixing support. A driving component and a braking component are fixed on the fixing support. The whole component is placed in a cylindrical barrel provided with static vanes. The electricity generating tower turbine turbofan revolving structure has the advantages of being simple in turbine turbofan revolving structure, convenient to assemble and disassemble and capable of generating larger electric quantity at the same wind speed compared with existing vanes.

Owner:周登荣 +1

Muffler of comprehensive energy air channel well power generation station

ActiveCN102996204BEnough temperatureIncrease pressureFrom solar energySilencing apparatusInlet channelEngineering

Provided is a muffler of a comprehensive energy air channel well power generation station. The air channel well power generation station comprises an air channel well perpendicular to the ground and with a plurality of air feeding channels arranged on the base portion. A solar preheating chamber surrounds the periphery of the base portion, the air channel well and a bearing frame form an air tower together, and the muffler communicated with the air channel well is arranged at the top end of the air tower. Therefore, the muffler enables air discharge to be smooth without producing air discharge noise and reduces direct impact of the structure at the top end of air tower.

Owner:周登荣 +1

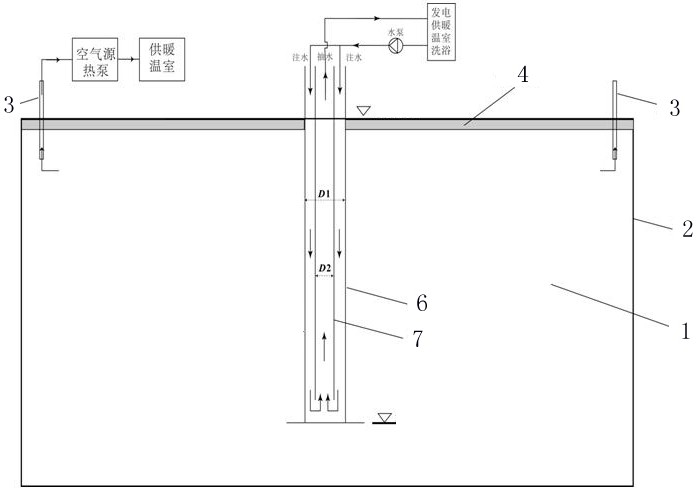

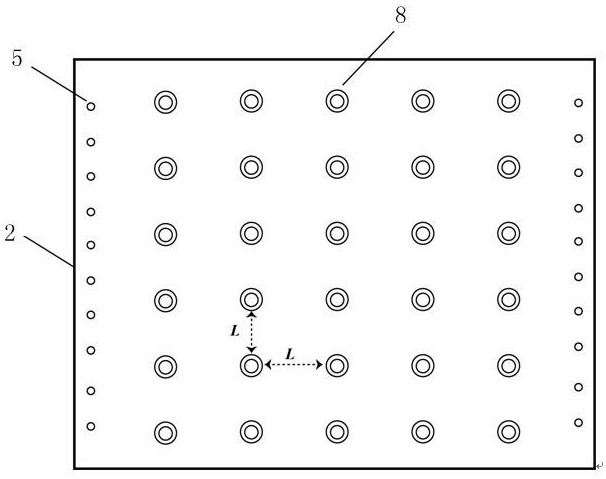

Method for inhibiting spontaneous combustion of coal gangue pile and extracting heat of coal gangue pile for application

InactiveCN113144464ASuppress spontaneous combustionSolve the heating problem in winterLighting and heating apparatusGeothermal energy generationSpontaneous combustionThermodynamics

The invention belongs to the technical field of coal gangue heat utilization, and particularly relates to a method for inhibiting spontaneous combustion of a coal gangue pile and extracting heat of the coal gangue pile for application. The method comprises the following steps: S100, a site without underground water seepage is selected, and a foundation pit is excavated; S200, multiple sets of coaxial sleeves which are arranged in the transverse and longitudinal direction are put into the foundation pit; S300, coal gangue is filled layer by layer, the coaxial sleeves are kept upright and not inclined during backfilling, backfilling is conducted till the position 0.5 m below the ground surface, then a covering layer is laid on the coaxial sleeves for heat preservation, and heat of the coal gangue pile cannot be dissipated into the atmosphere; S400, two rows of exhaust holes are reserved at the two ends of the covering layer, and the exhaust holes are connected with an earth surface air source heat pump for heating; and S500, each of the coaxial sleeves comprises an outer pipe and an inner pipe which are coaxially arranged, water is injected between the outer pipe and the inner pipe through a water pump, water is pumped from the inner pipe, and the pumped hot water is applied.

Owner:TAIYUAN UNIV OF TECH

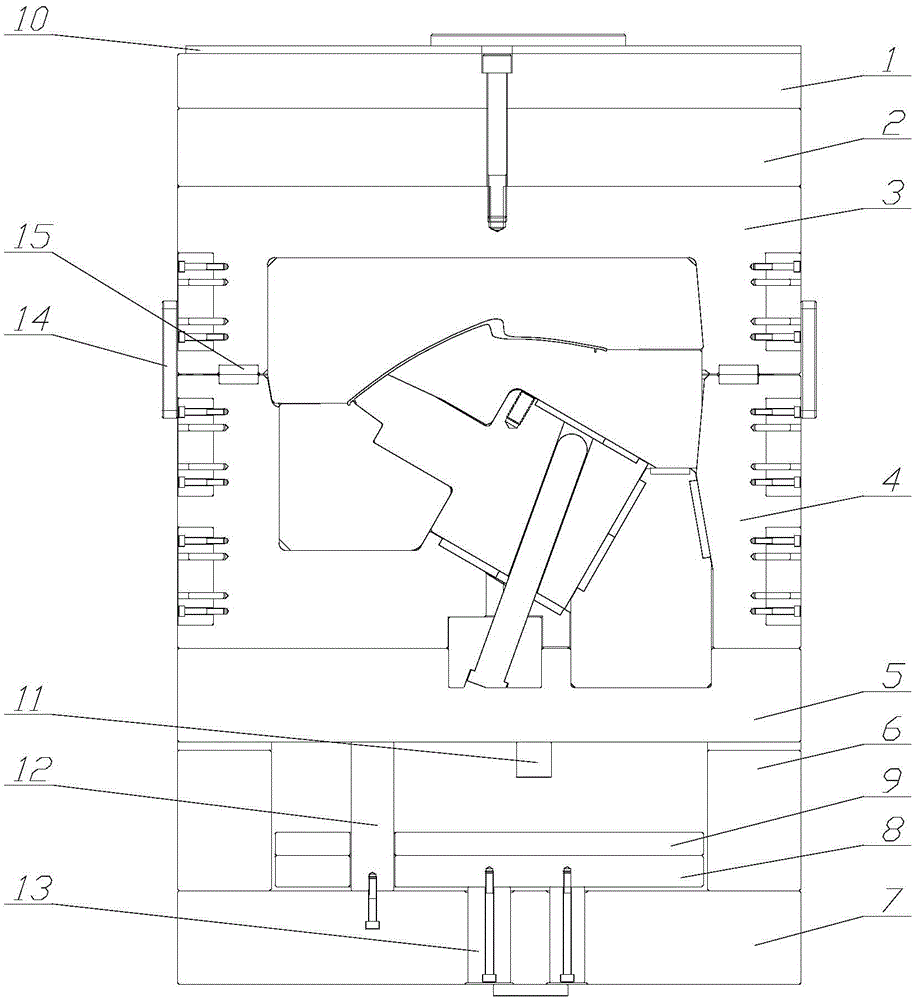

Heat-insulating energy-saving type injection mold

The invention relates to the technical field of injection molds, in particular to a heat-insulating energy-saving type injection mold. The heat-insulating energy-saving type injection mold comprises a face plate, a hot-runner plate, a fixed mold plate, a movable mold plate, a movable mold plate supporting plate, mold feet and a bottom plate which are sequentially arranged from top to bottom. A bottom needle plate located on the upper surface of the bottom plate is arranged between the mold feet. A surface needle plate is arranged on the upper surface of the bottom needle plate. An injection nozzle penetrates through the face plate, the hot-runner plate and the fixed mold plate, and a heat-insulating plate cushion plate is arranged on the upper surface of the face plate. The heat-insulating energy-saving type injection mold is high in use safety, the injection effect of materials which are heated to be molten is good, and the quality reliability of injection products is high.

Owner:贾玉平

Breeding feed for larimichthys crocea fries and preparation method of breeding feed

PendingCN114271409AAdd flavorIncrease attractivenessFeeding-stuffClimate change adaptationBiotechnologyAnimal science

The invention belongs to the technical field of aquatic feed, and particularly relates to breeding feed for larimichthys crocea fries and a preparation method of the breeding feed. According to the invention, the puffed corn flour, the puffed soybean flour, the puffed tapioca flour and the puffed rice flour are added according to a specific proportion, so that the purposes that main nutritional ingredients in the feed are balanced and are easy to digest and absorb are achieved. According to the invention, a preheating type screw bulking machine is also utilized to carry out specific and sufficient bulking operation on the four crushed materials, so that the basic advantages of sterilization, food calling and easy absorption of the bulked powder are realized. The invention has the following advantages: 1, four kinds of puffed powder have basic advantages of high-temperature sterilization, good flavor, high food calling property, easy digestion and easy absorption of nutrient substances; secondly, four kinds of puffed powder are added according to a specific proportion, so that the proportion of main nutrient substances such as starch, grease, vitamins and protein is suitable for breeding the larimichthys crocea fries;

Owner:FUJIAN TIANMA TECH GRP

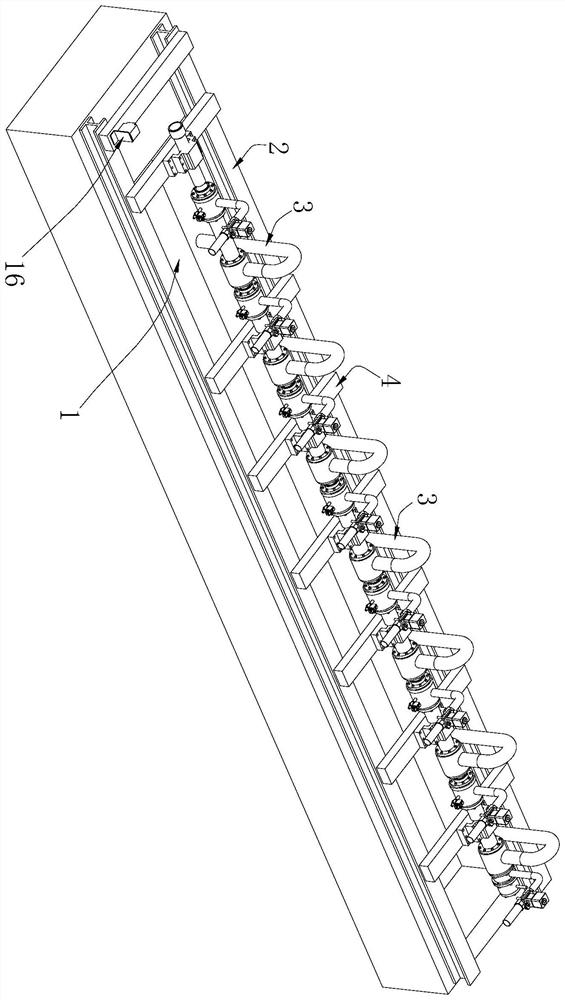

Water penetration device capable of controlling temperature of steel head

PendingCN114643294AEnough temperatureImprove cooling effectWork treatment devicesMetal rolling arrangementsWater blockStructural engineering

The invention discloses a steel head temperature-controllable water penetration device. A steel head penetrating through the water penetration device is not subjected to water treatment or is subjected to less water treatment, so that enough steel head temperature is ensured. Comprising a water tank, a mounting support and a cooler are arranged above the water tank, the cooler is fixed to a supporting beam, the two ends of the supporting beam are fixedly supported on the mounting support, the cooler comprises a water penetrating guide pipe with a through steel running hole, a water filling cavity is formed in the front end of the water penetrating guide pipe, and a first cooling groove is formed in the position, at the rear end of the water filling cavity, in the steel running hole; a second cooling tank provided with a water blocking nozzle is arranged at the rear end of the water penetrating guide pipe, a water inlet guide pipe is arranged at the front end of the water penetrating guide pipe, a first electric control valve is arranged on the water inlet guide pipe, and a water outlet guide pipe is arranged at the rear end of the water penetrating guide pipe; and a hot metal detection device with the detection direction pointing to the axis of the steel running hole is arranged at the front end of the water tank in front of the cooler.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Method for melt spinning, stretching and winding multifilament thread and device for carrying out same

InactiveCN102131965BReached temperatureDesired temperatureArtificial thread manufacturing machinesArtificial filament heat treatmentPolymer sciencePlastic materials

The invention relates to a method for melt spinning, stretching and winding a multifilament thread to form an FDY yarn, and a device for carrying out the method. First, a plurality of filaments made from a thermoplastic melt are extruded, cooled to a temperature below the glass transition temperature of the plastic material, and combined to form a filament bundle with no addition of a preparationfluid. Then, the filament bundle is drawn off at a speed of greater than 1500 m / min, heated to a temperature above the glass transition temperature of the thermoplastic material and stretched at a stretching speed of greater than 4000 m / min. The filament bundle is led through a hot air atmosphere of a heating tube for providing non-contact heating. Then, the filament bundle is prepared with a preparation fluid and the thread is wound into a coil. In the device according to the invention, the preparation device is disposed downstream of the heating means in the thread direction, wherein the heating means, which is a heating tube with a hot air atmosphere for non-contact heating of the filament bundle, is disposed between the drawing-off galette and the stretching galette.

Owner:OERLIKON TEXTILE GMBH & CO KG

Comprehensive energy air channel well power generation station

ActiveCN102996357BEnough temperatureIncrease pressureFrom solar energyMachines/enginesDistribution controlMotor drive

A comprehensive energy air channel well power generation station comprises an air channel well perpendicular to the ground and with a plurality of air feeding channels arranged on the base portion. A solar preheating chamber surrounds the periphery of the base portion, the base face of the solar preheating chamber is aligned with the base face of the air channel well, and the top face of the solar preheating chamber is higher than the air feeding channel, and more than one wind driven generator with an air flow driving device is arranged in the air channel well. The solar preheating chamber is provided with a heat collection device and a light condensing device. A peak shaving device comprises a motor-driven air compressor connected with the wind driven generator, a charge-discharge device and a power distribution control device. The air compressor is connected with a group of air storage tanks through a pipe. Therefore, the power generation station is capable of comprehensively utilizing various natural energies to generate power and has the functions of shaving peak and compensating.

Owner:周登荣 +1

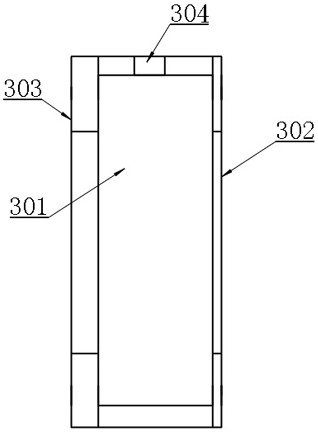

Welding and gas quenching integrated furnace for lengthened cutter

PendingCN113005390AEnough temperatureGuarantee welding qualitySoldering apparatusSolid state diffusion coatingCarbon potentialControl system

The invention provides a welding and gas quenching integrated furnace for a lengthened cutter, and belongs to the technical field of equipment manufacturing. The problem that an existing lengthened cutter is short in service life is solved. The welding and gas quenching integrated furnace for the lengthened cutter comprises a welding bin, a gas quenching bin and a conveying device. The conveying device penetrates through the welding bin and the gas quenching bin, and a vacuum isolation device is arranged between the welding bin and the gas quenching bin. A carburization control system and a temperature sensor are arranged in the welding bin, the carburization control system is used for controlling the carbon potential of the lengthened cutter in the welding process of the lengthened cutter, and the temperature sensor detects the temperature of the lengthened cutter in the welding process of the lengthened cutter. When welding is finished and the temperature of the lengthened cutter is within the preset range, the conveying device is started, and the lengthened cutter is conveyed to the gas quenching bin through the vacuum isolation device. A nitrogen spraying device is arranged in the gas quenching bin and used for spraying nitrogen, and gas quenching is conducted on the lengthened cutter.

Owner:TEDA HUASHI ENG

Manufacturing method for producing tire regenerated rubber by plasticizing through normal-pressure continuous plasticator

PendingCN114102896ASolve the technical problem of different colloidal timeImprove mechanical propertiesPolymer sciencePlasticizer

The invention discloses a manufacturing method for producing tire regenerated rubber by plasticizing with a normal-pressure continuous plasticator, which comprises the following steps: A, extruding and flattening raw materials by using a magnetic suction roller, absorbing metal materials in impurities, shearing the raw materials by using a shearing device, stirring in a stirrer, and selecting rubber powder particles of 5-10 meshes by using a screen; b, adding a mixture of the rubber powder particles without the metal materials, a plasticizer and water into a double-screw plasticator, and heating a front machine barrel of the double-screw plasticator through a heating device outside the double-screw plasticator; the technical problems that the temperature cannot be controlled and the pressure is too high in the current rubber production process can be effectively solved, the situation that carbon-carbon bonds are broken in the vulcanization process is avoided, sufficient temperature can be guaranteed for vulcanization, uniform rubber particles are adopted for vulcanization, the technical problem that the rubber particles are different in time in the vulcanization process is solved, and the production efficiency is improved. The mechanical property of the manufactured rubber is improved.

Owner:仙桃市聚兴橡胶有限公司

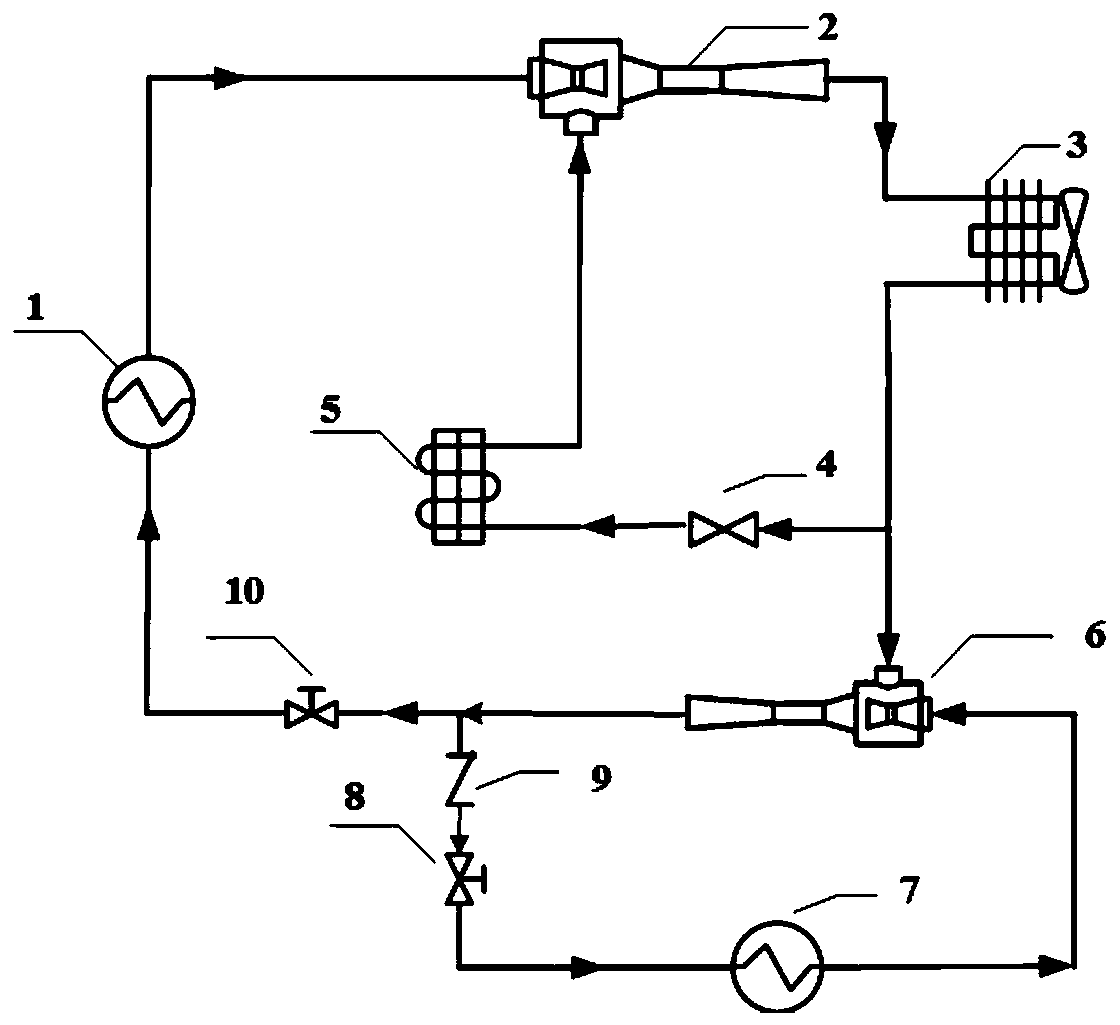

A pumpless injection refrigeration system and refrigeration method

ActiveCN107062684BImprove cooling efficiencyGuaranteed uptimeMechanical apparatusFluid circulation arrangementCirculator pumpEngineering

Owner:SHANDONG UNIV

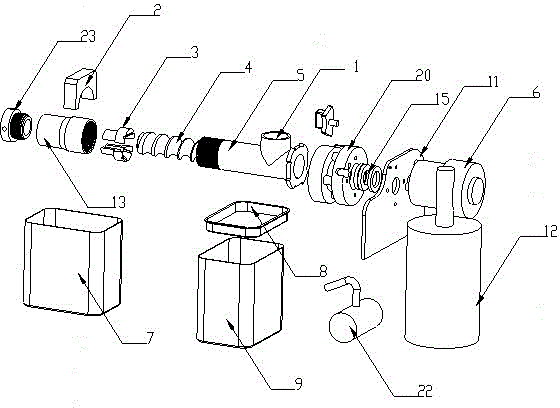

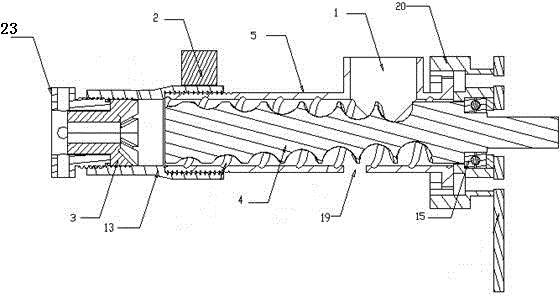

A household two-stage pressing low-temperature oil press machine

InactiveCN102774029BAchieving secondary pressingImprove oil yieldPressesReduction driveElectric machine

The invention relates to a household two-level pressing low temperature oil press. The oil press comprises an oil press base, a pressing mechanism and a driving mechanism, the pressing mechanism is installed on the oil press base, the driving mechanism is used for providing motive power for the pressing mechanism, the pressing mechanism includes a barrel, a pressing head, a pressing shaft and a pressing head casing, the barrel is provided with a feed port and an oil outlet, one end of the barrel is connected with the oil press base, the pressing head casing is connected with the other end of the barrel, one end of the pressing shaft is provided with screw threads and sleeved in a chamber formed by the barrel and the pressing head casing, the other end of the pressing shaft extends out of the barrel to serve as a rotating bar to be connected with the driving mechanism, the pressing head is installed in the pressing head casing, pressing space is formed by one side of the pressing head and one corresponding end of the pressing shaft, one or a plurality of material passing holes is / are arranged on the pressing head, one side surface of the pressing head where the pressing head is in a cut grafting with the pressing shaft is provided with a groove, one or a plurality of oil guide grooves which is / are communicated with the material passing holes is / are mounted on the wall surface of the groove, a heater is arranged on the pressing head casing or the barrel, and the driving mechanism and the heater are connected with a power supply. The driving mechanism includes a motor and a speed reducer which are disposed on the oil press base, and the speed reducer is in a transmission connection with a rotating shaft of the motor and the rotating bar of the pressing shaft. By means of the household two-level pressing low temperature oil press, the low temperature cold pressing can be achieved, the oil yield is high, the produced oil quality is good, and the oil press is easy to clean.

Owner:唐华

A gynecological traditional Chinese medicine physiotherapy device

ActiveCN110292523BAvoid burnsIncrease concentrationDevices for heating/cooling reflex pointsMedical devicesHerb medicineBiology

The invention relates to a gynecological traditional Chinese medicine physiotherapy device. When the temperature is insufficient or the temperature is too high or when the concentration of fumigatingmedicine is insufficient, louver boards are closed, and fumigating is not carried out, so that invalid fumigation or scalding of skin is prevented. An infrared emitter and a receiver are arranged to judge the concentration in the fumigating medicine, it is ensured that the concentration of the fumigating medicine is high enough during fumigating, and the fumigating effect is improved. In actual use, a plurality of use modes are provided; when only an ironing mode is selected, discharged water vapor can play a role in indoor humidification; fumigation and ironing are combined so that fumigatingmedicine steam can be used for steaming moxibustion herbal medicine, and the moxibustion effect of the moxibustion medicine is improved; during ironing, the fumigating medicine steam is used for ironing at the same time, and then the ironing effect can be improved.

Owner:王铭

Nozzle type catalytic muffler for automobile diesel engine

ActiveCN111550301BPlay a role in heat preservationShorten the lengthAir-treating devicesInternal combustion piston enginesExhaust pipeMuffler

The invention relates to a nozzle-type catalytic muffler for an automobile diesel engine. The blue nozzle is arranged on the intake pipe outside the SCR catalytic muffler, and at the same time, a flow guide device for changing the gas flow direction is arranged in the muffler. By changing the gas flow direction, the exhaust gas It is fully mixed with high-purity urea solution for vehicles and then subjected to catalytic reduction treatment, thereby shortening the length of the engine exhaust pipeline, saving space and reducing costs. To keep warm, it is beneficial to the catalytic reduction reaction. A cooling channel for cooling water flow is provided outside the exhaust chamber of the catalytic muffler. The cooling water in the cooling channel is connected with the automobile heating system, and the waste heat in the exhaust gas is used for the automobile heating system. Provide heat source, so as to save energy and reduce emissions.

Owner:安阳职业技术学院

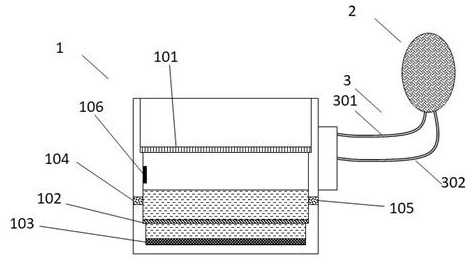

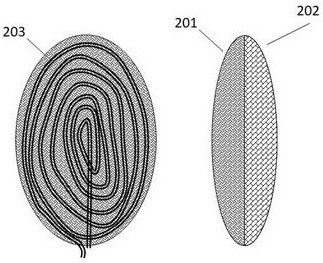

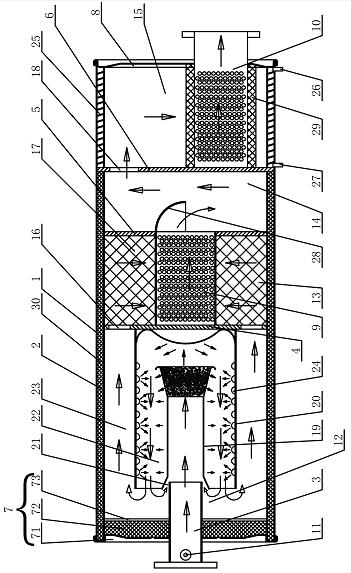

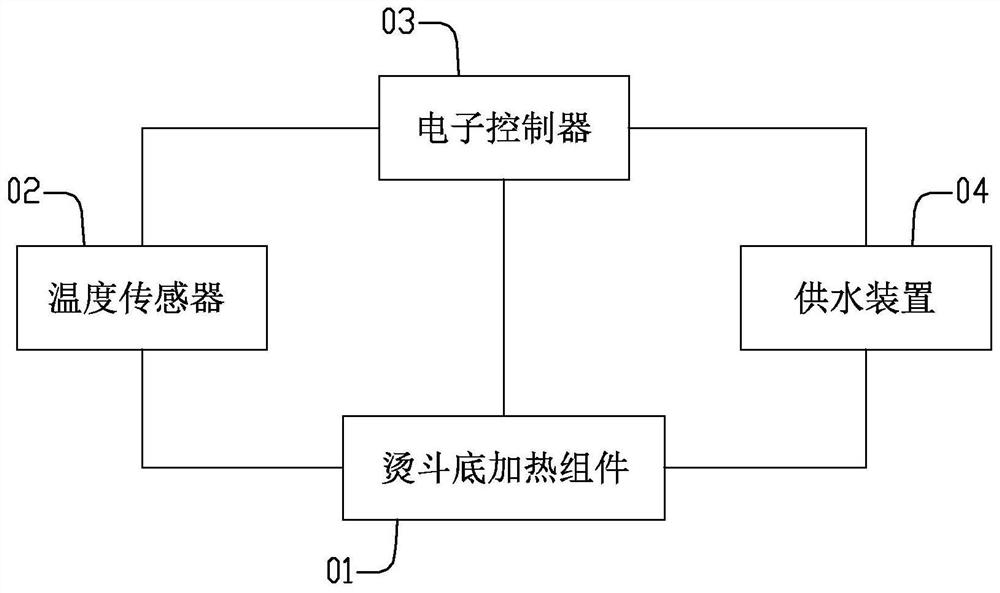

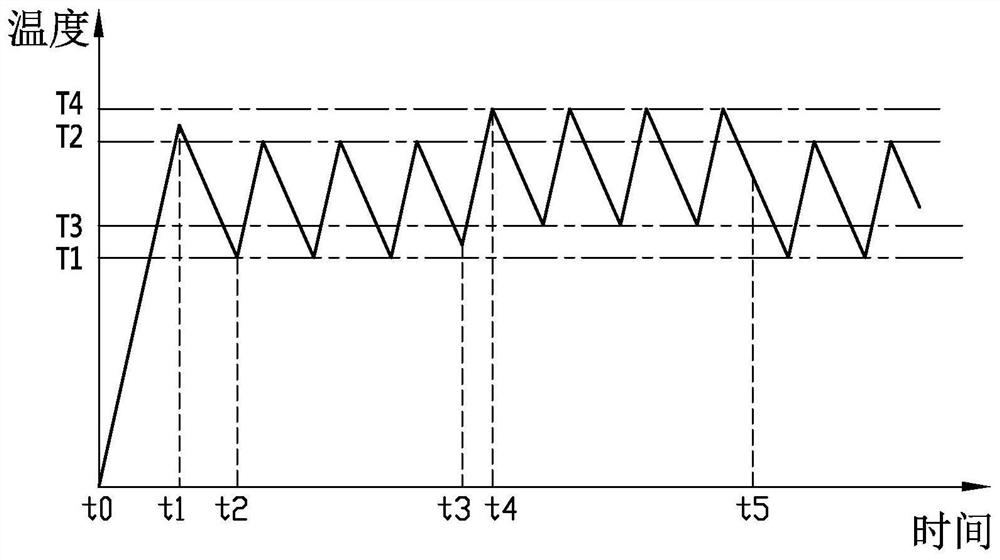

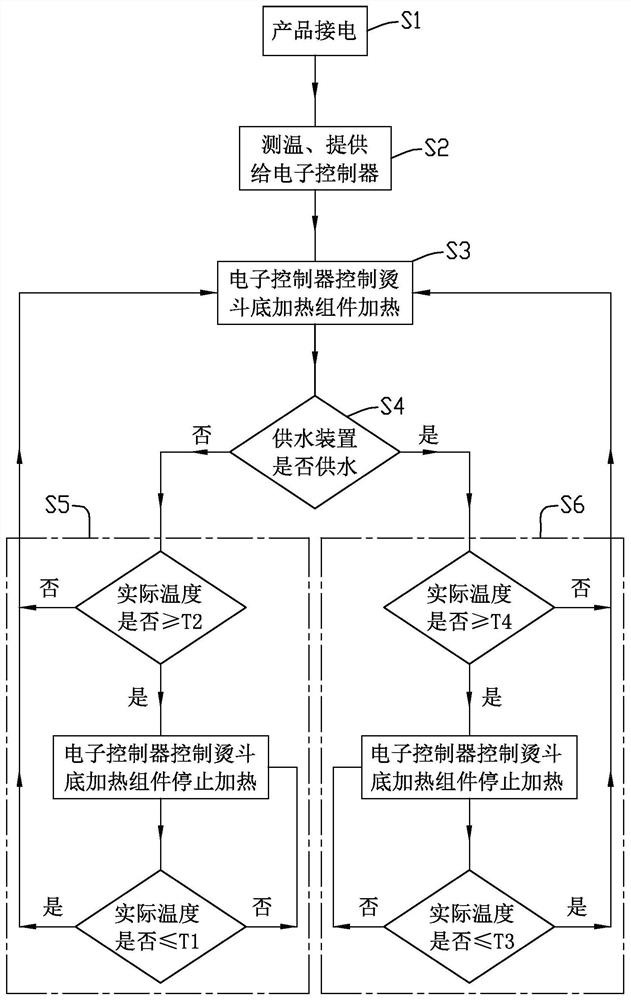

Electronic control steam electric iron and temperature control method thereof

InactiveCN111636180AEnough temperatureShort reaction timeHand ironTextiles and paperTemperature controlElectronic controller

The invention discloses an electronic control steam electric iron and a temperature control method thereof, and belongs to the technology of steam electric irons. According to an existing control method of a steam electric iron, in the steam generation process, after the temperature of an iron bottom heating assembly is reduced, the response to start heating again is slow, the temperature point islow when a bottom plate is started to heat again, the bottom plate cannot achieve the optimal steam effect, and the ironing effect is poor. In the water supply steam generation process, the temperature of the iron bottom heating assembly is controlled within a higher temperature range than that when water is not supplied for generating steam, the starting temperature point for restarting heatingafter the temperature of the iron bottom heating assembly is reduced is increased, the starting time point for restarting heating after the temperature of the iron bottom heating assembly is reduced is advanced, the reaction time of a temperature sensor and an electronic controller is saved, the steam is ensured to have sufficient temperature, the bottom plate can achieve the optimal steam effect,and the better ironing effect is achieved.

Owner:NINGBO KAIBO GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com