A pumpless injection refrigeration system and refrigeration method

A refrigeration system and jet technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problem of high cost of circulating pumps and achieve the effect of improving refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

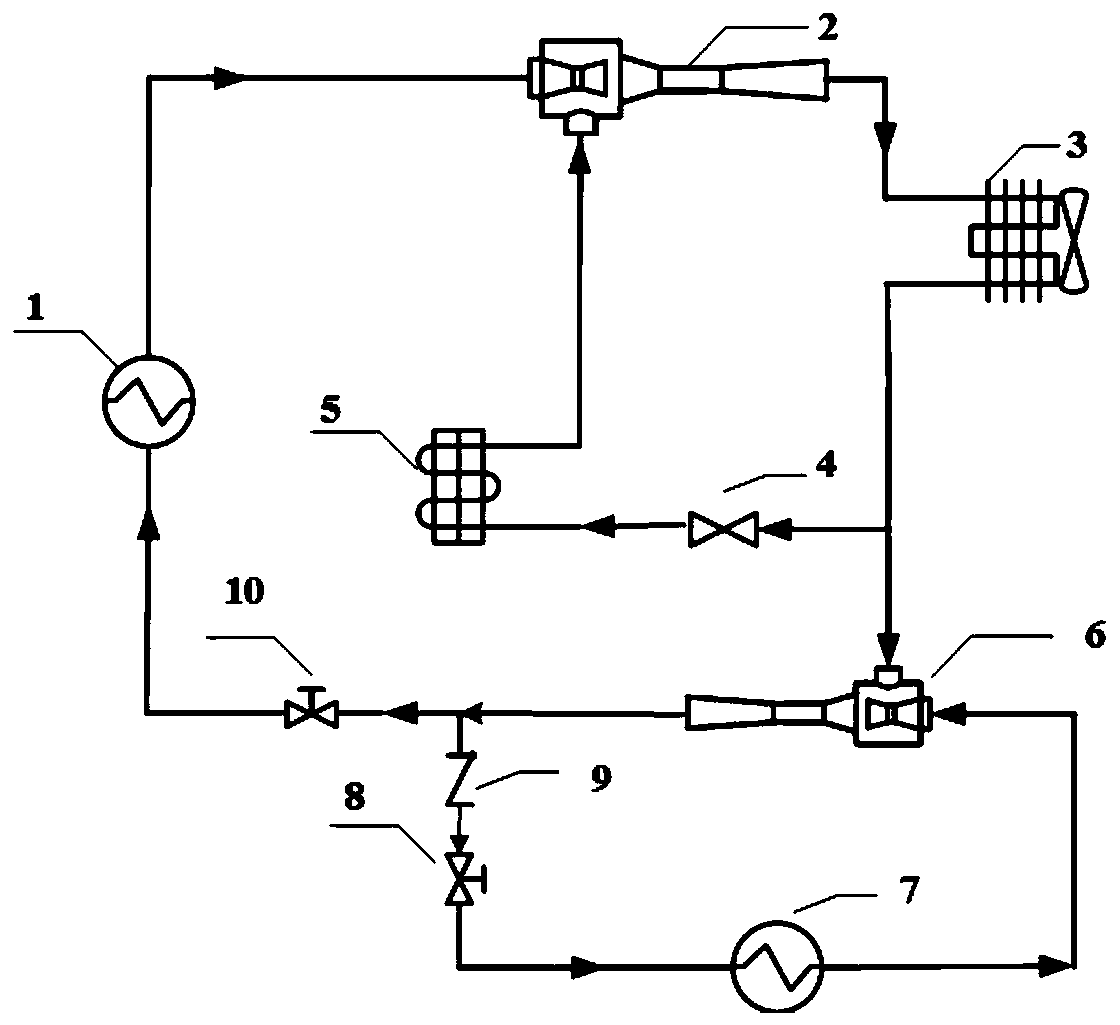

Embodiment 1

[0027] If R134a is used as the refrigerant, the refrigerant is heated by industrial waste heat (temperature: 120°C) in the first generator 1 to become superheated steam, the temperature of the superheated steam is 90°C, and the pressure is 2.8MPa. The gas injector 2 sucks the refrigerant vapor from the evaporator 5, pressurizes it and enters the condenser 3 together, where it is condensed into a liquid, and the temperature of the liquid is 45°C. Part of the liquid flowing out of the condenser 3 enters the evaporator 5 after being throttled and cooled by the throttle valve 4, and the other part of the liquid is injected and pressurized in the gas-liquid ejector 6 by the steam from the generator 7. The volume ratio of the liquid is 1:2.5. Part of the liquid flowing out of the condenser 3 has a pressure of 2.85 MPa after being pressurized by the gas-liquid ejector 6 . After pressurization, it becomes liquid; it is divided into two paths, one path enters the first generator 1 thr...

Embodiment 2

[0029]If HFO-1234ze(E) is used as the refrigerant, the refrigerant is heated by industrial waste heat (temperature: 80°C) in the first generator 1 to become superheated steam, the temperature of the superheated steam is 55.7°C, and the pressure is 1.15MPa. The gas injector 2 sucks the refrigerant vapor from the evaporator 5, pressurizes it and enters the condenser 3 together, where it is condensed into a liquid, and the temperature of the liquid is 24°C. Part of the liquid flowing out of the condenser 3 enters the evaporator 5 after being throttled and cooled by the throttle valve 4, and the other part of the liquid is injected and pressurized in the gas-liquid ejector 6 by the steam from the generator 7. The volume ratio of the liquid is 1:2.5. Part of the liquid flowing out of the condenser 3 has a pressure of 1.15 MPa after being pressurized by the gas-liquid ejector 6 . After pressurization, it becomes liquid; it is divided into two paths, one path enters the first genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com