Electronic control steam electric iron and temperature control method thereof

An electronic control and electronic controller technology, applied in hand irons, washing devices, textiles and papermaking, etc., can solve the problems of poor ironing effect, the soleplate can not play the best steam effect, etc., to save the response time and achieve the best ironing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings of the description.

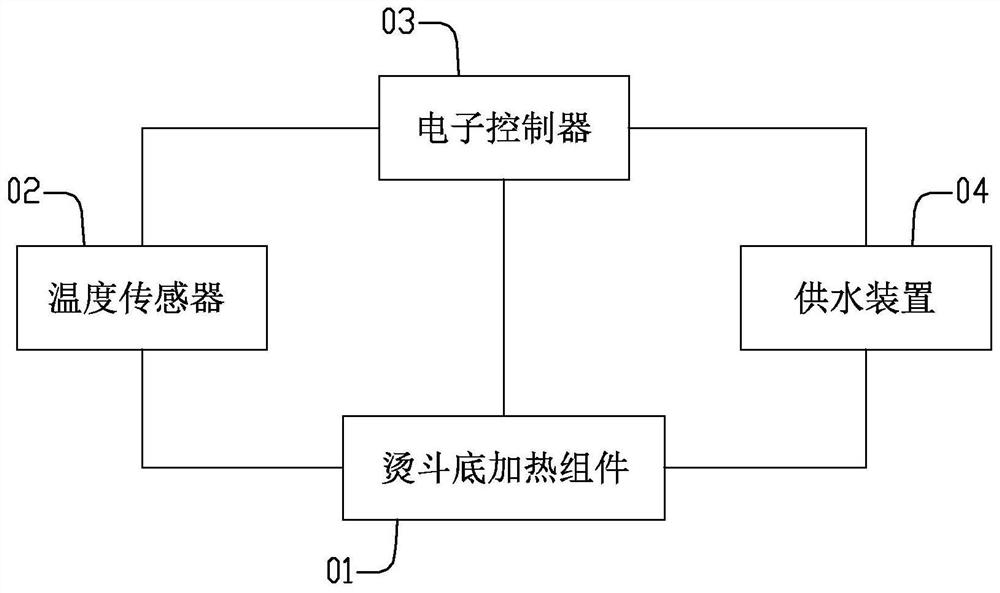

[0028] Such as figure 1 As shown, the electronically controlled steam electric iron includes a bottom heating assembly 01 for generating steam, an electronic controller 03, and a water supply device 04 for controlling water supply by the electronic controller. The heating assembly at the bottom of the iron is provided with a water inlet hole and a steam outlet hole, heating element, the temperature sensor 02 used to measure the actual temperature of the heating element at the bottom of the iron is installed on the heating element at the bottom of the iron, the electronic controller is connected with the temperature sensor, and under the control of the electronic controller, the water supply device can flow to the The heating assembly at the bottom of the iron supplies water, and the heating assembly at the bottom of the iron is heated by the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com