Method for melt spinning, stretching and winding multifilament thread and device for carrying out same

A technology of drawing yarn and melt spinning, applied in the field of devices implementing the method, can solve problems such as high equipment costs, and achieve the effect of efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

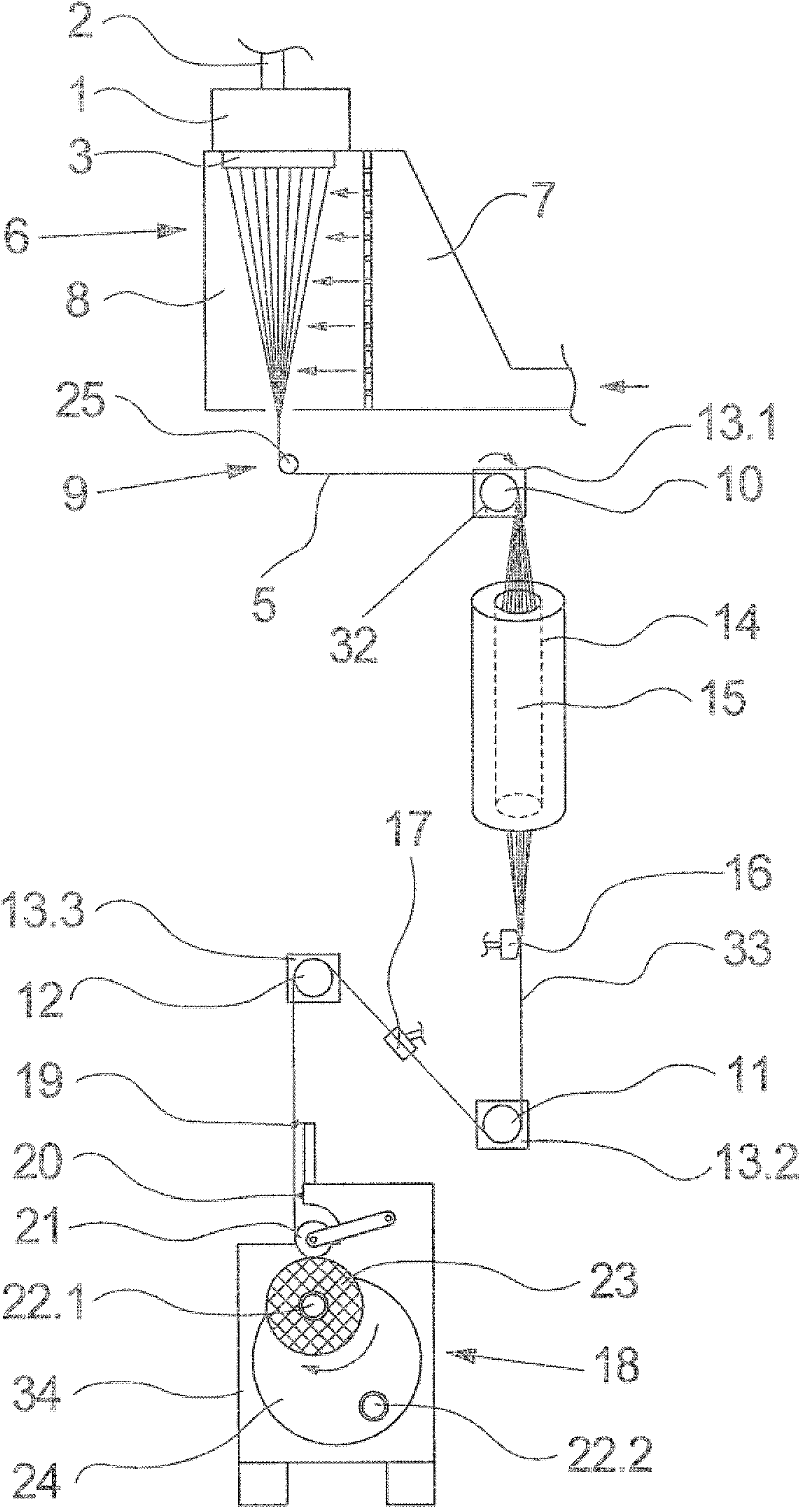

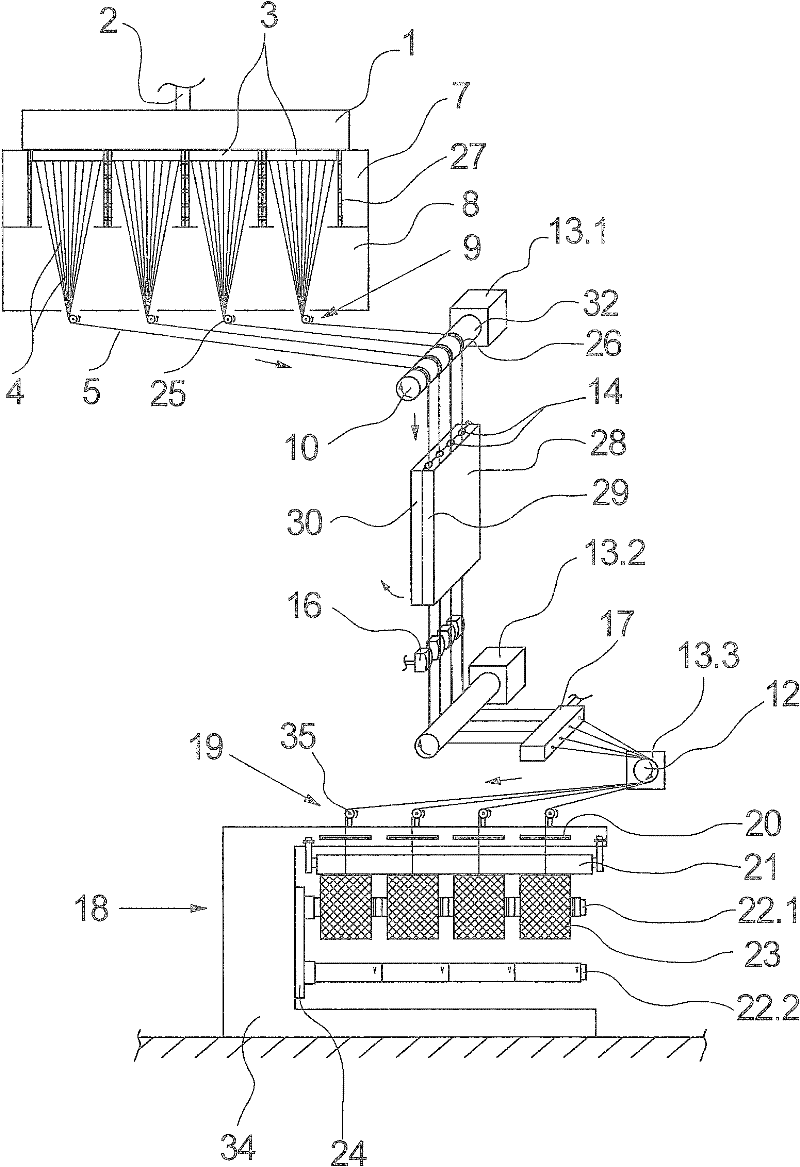

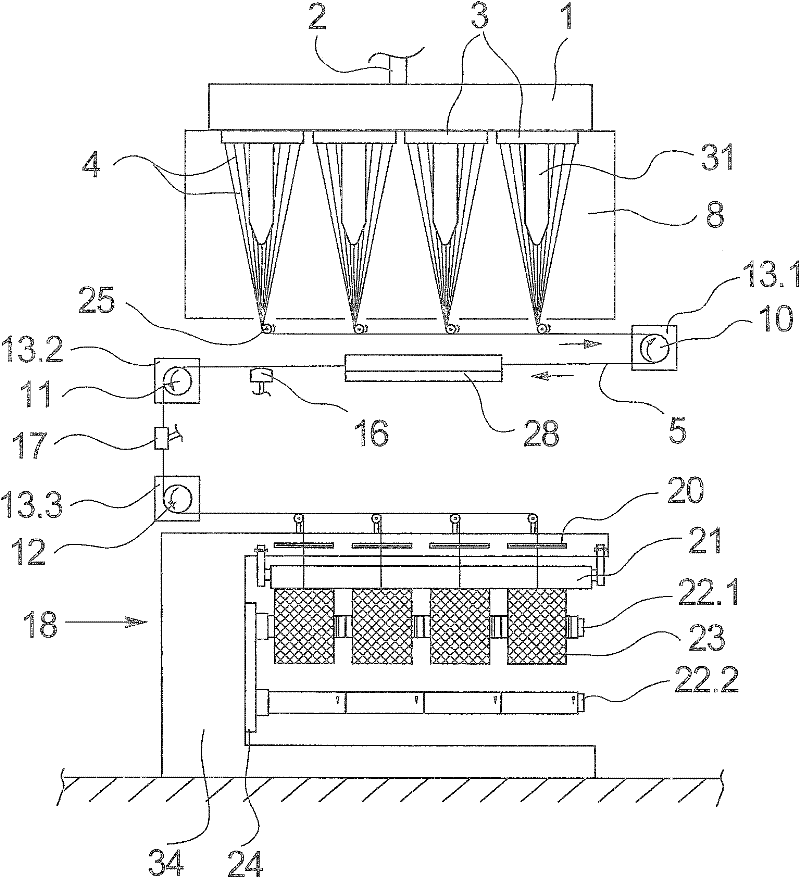

[0036] figure 1 A first exemplary embodiment of a device according to the invention for carrying out the method according to the invention for producing FDY yarns is shown. For the melt-spinning of multifilaments, a heatable spinning head 1 is provided, which has spinning nozzles 3 with a plurality of nozzle openings on its lower side and a melt feed pipe 2 on its upper side. The melt supply line 2 is connected to a melt source not shown here, for example an extruder. Further melt-guiding and melt-transporting components can be arranged in the spinneret, which will not be discussed in detail here.

[0037] In this exemplary embodiment, the spinneret 1 has only one spinneret 3 on its underside. In practice, however, spinnerets of this type are equipped with a plurality of spinning nozzles arranged in a row in order to simultaneously produce a plurality of parallel yarns side by side. However, since the number of threads has no influence on the method according to the inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com