Carbon fiber energy-saving heat generation line and fabrication method thereof

A technology of carbon fiber heating and production methods, which is applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of increasing heating power, increasing current, and reducing resistance, so as to reduce heating power, increase resistance, The effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

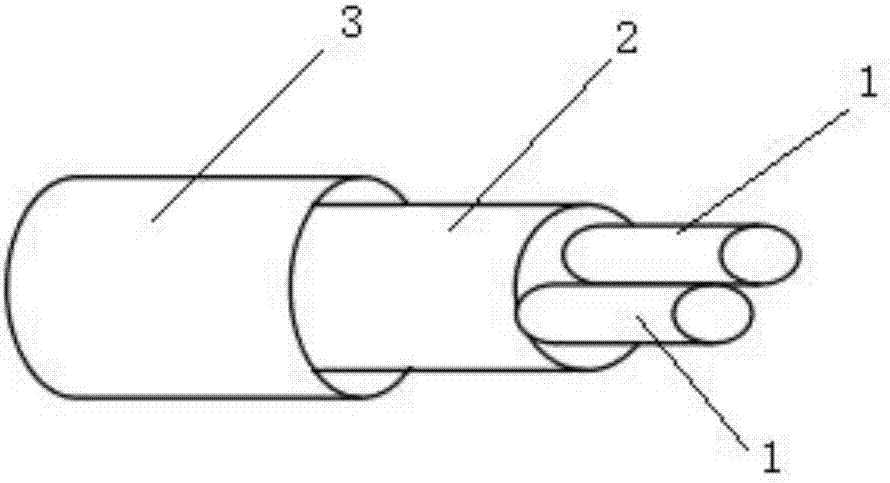

[0033] In one embodiment of the present invention, a carbon fiber energy-saving heating wire is provided, see figure 2 , the carbon fiber energy-saving heating wire includes at least two carbon fiber heating unit wires 1 arranged in a bundle, each carbon fiber heating unit wire 1 includes a plurality of carbon fiber filaments and an insulating layer 2 arranged in a bundle, and the plurality of carbon fiber filaments Arranged in the insulating layer 2, the number of carbon fiber filaments of different carbon fiber heating unit wires 1 is the same or different.

[0034] In this embodiment, each carbon fiber heating unit wire 1 is formed by twisting 6000 carbon fiber heating wires, and the outer layer of the twisted 6000 carbon fiber heating wires is covered with an insulating layer 2, and the insulating layer 2 is high temperature resistant The high temperature resistance range here is about 260°C, preferably Teflon material, the scientific name of Teflon is Polytetrafluoroethy...

Embodiment 2

[0039] Different from Embodiment 1, there are three carbon fiber heating unit wires 1 in this embodiment, and each carbon fiber heating unit wire 1 includes 4000 carbon fiber filaments. Compared with the single 12K carbon fiber heating wire (12000 carbon fiber heating wires) in the prior art, it can also reduce the power consumption.

[0040] Correspondingly, the carbon fiber heating wires of the three carbon fiber heating unit wires 1 are all wrapped by the insulating layer 2, and the thermally conductive protective layer 3 is wrapped around the three carbon fiber heating unit wires 1, and the carbon fiber energy-saving heating wires made of other numbers of carbon fiber heating unit wires 1 are This is not listed one by one.

Embodiment 3

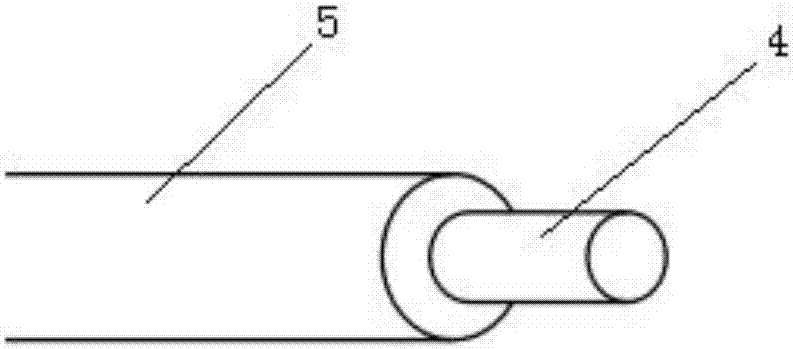

[0042] In one embodiment of the present invention, a method for manufacturing a carbon fiber energy-saving heating wire is provided, see Figure 4 , the method includes the following steps:

[0043] S1. Wrap the insulation layer on the outside of multiple carbon fiber filaments to make a single carbon fiber heating unit wire;

[0044] S2. Wrap the heat conduction protective layer on the outside of multiple carbon fiber heating unit wires;

[0045] S3, cutting to obtain a carbon fiber energy-saving heating wire.

[0046] Wherein, in S1, the single carbon fiber heating unit line includes 6000 carbon fiber filaments, and the insulating layer is made of high temperature resistant insulating material; in S2, the heat conducting protection layer is made of high temperature resistant PVC flame retardant material or high temperature resistant CPVC Made of flame retardant material, the specific description is as above, and will not be repeated here.

[0047] Further, after S3, it also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com