Condensing heat exchanger with inverted-V-shaped structure for gas water heater

A gas-fired water heater and condensing heat exchanger technology, which is applied in the directions of water heaters, air heaters, heat exchanger shells, etc., can solve the problems of easy generation of main heat exchangers, large overall structure and volume, complicated manufacturing processes, etc. It is beneficial to the design of the whole machine, the overall structure is compact, and the volume is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

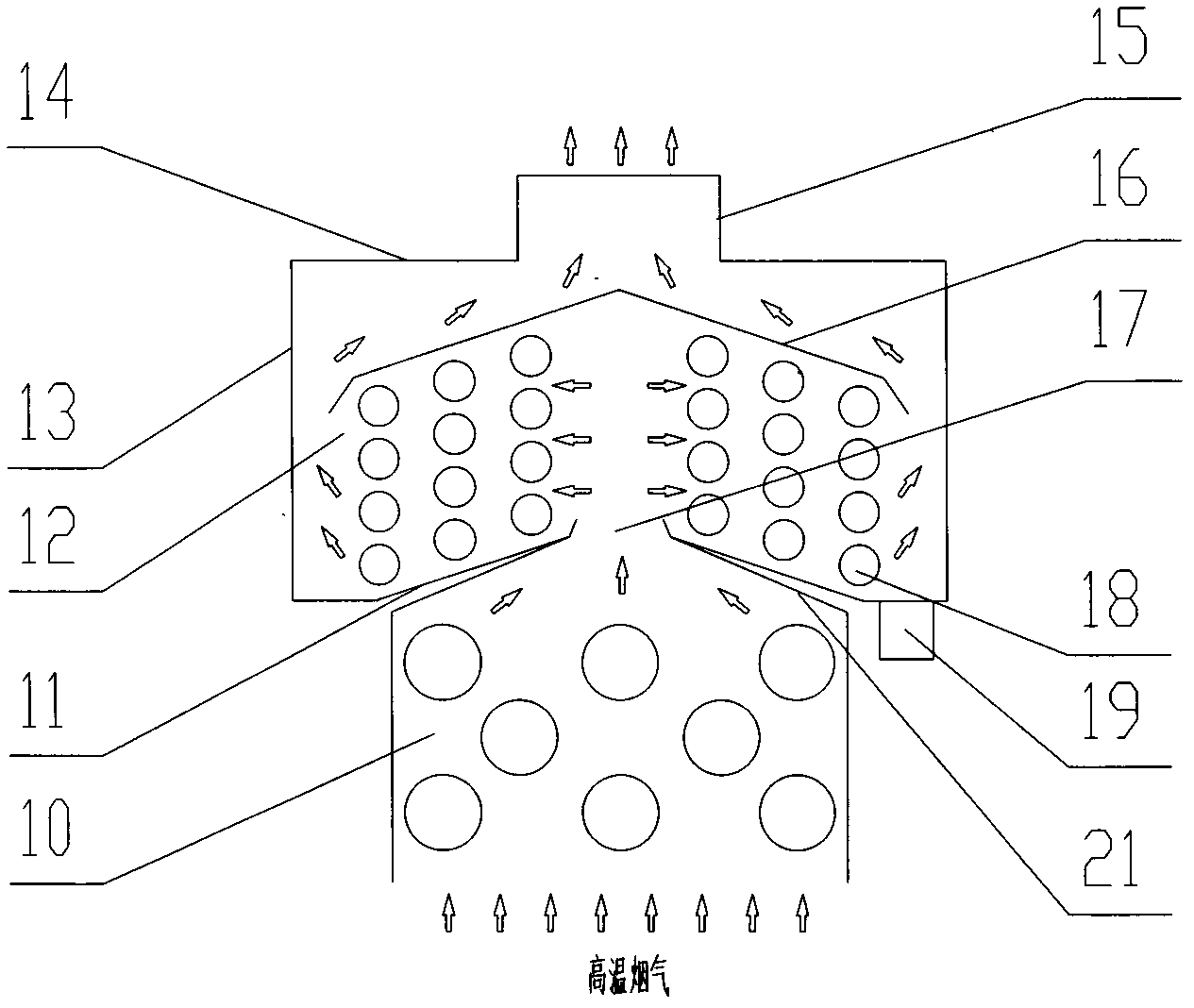

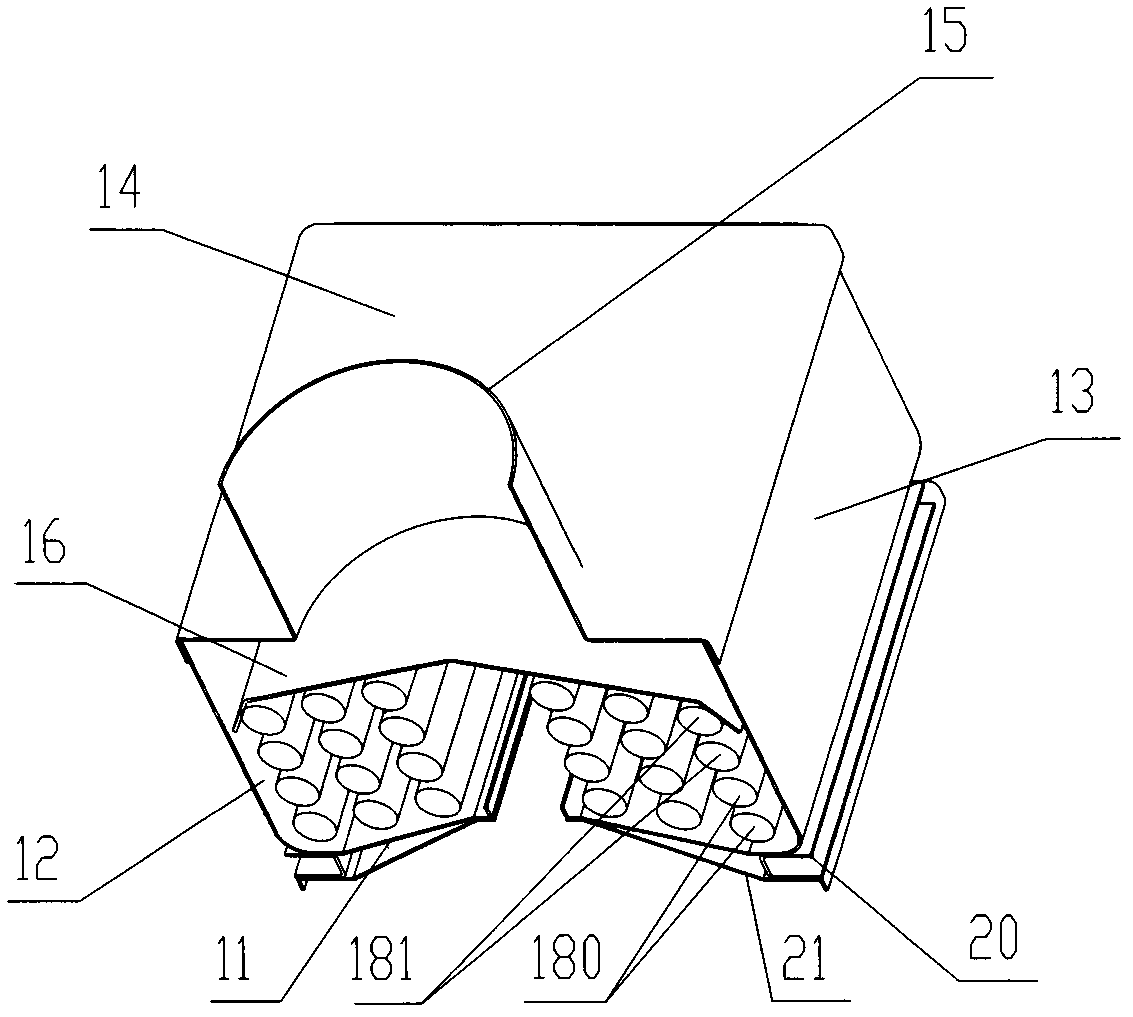

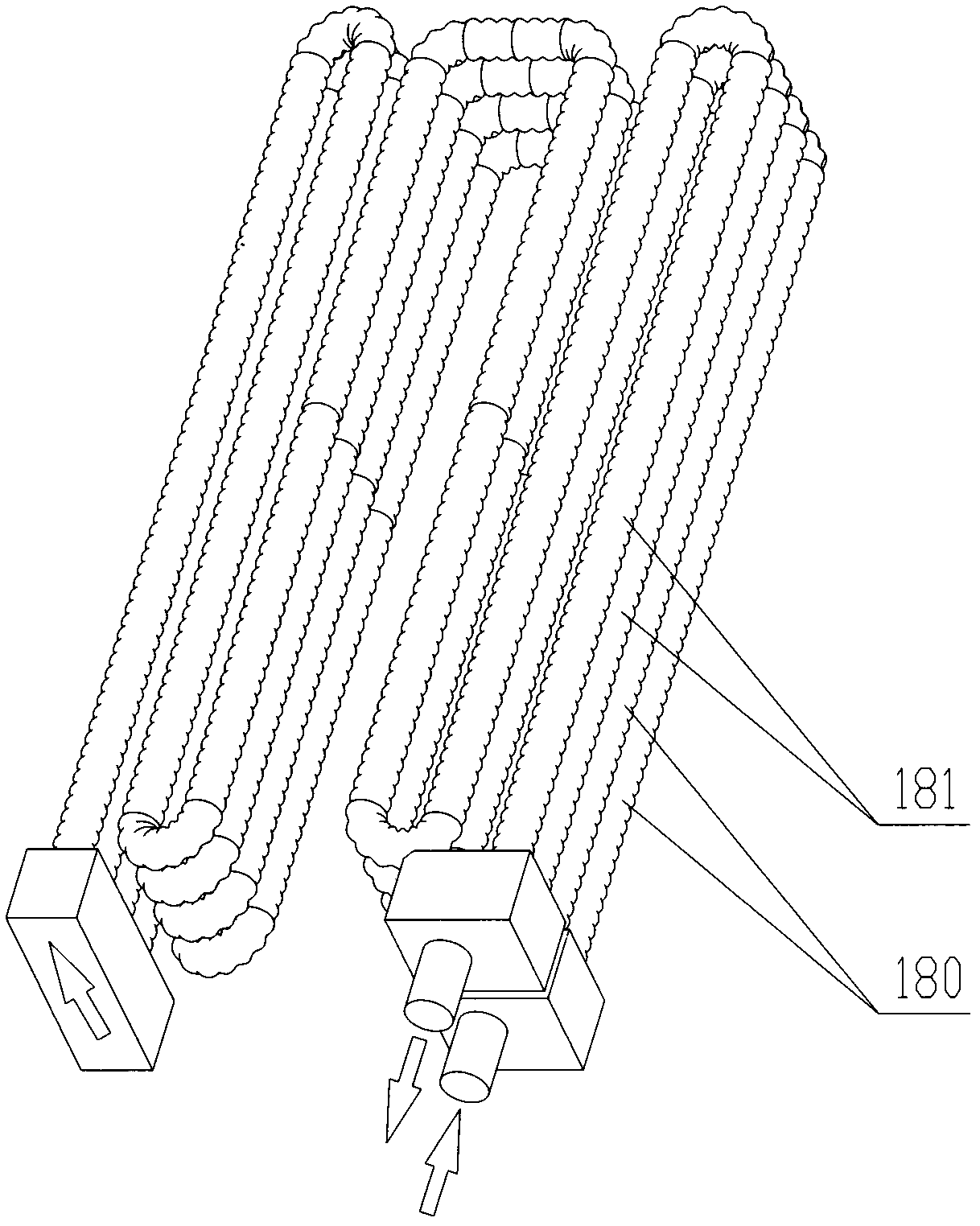

[0030] see Figure 1 ~ Figure 2 , the condensing heat exchanger 12 is arranged above the main heat exchanger 10, and is characterized in that it includes a fume collecting hood 21, the condenser box 13 is arranged above the fume collecting hood 21 through the condenser bracket 20, and the bottom of the condenser box 13 condenses There is no direct contact between the bottom 11 of the condenser box and the smoke collection hood 21; the smoke inlet 17 is set at the middle position of the bottom of the condenser box 11, and is matched with the opening at the top of the smoke collection hood 21; the bellows array composed of bellows 18 is set on Above the bottom 11 of the condenser box, an inverted V-shaped baffle 16 is arranged above the bellows array, and a condenser cover 14 is arranged on the top of the condenser box 13, and the bellows array and the inverted V-shaped baffle 16 are covered on the condenser box 13, the smoke outlet 15 is set on the condenser cover 14; the conde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com