Patents

Literature

47results about How to "Emission smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

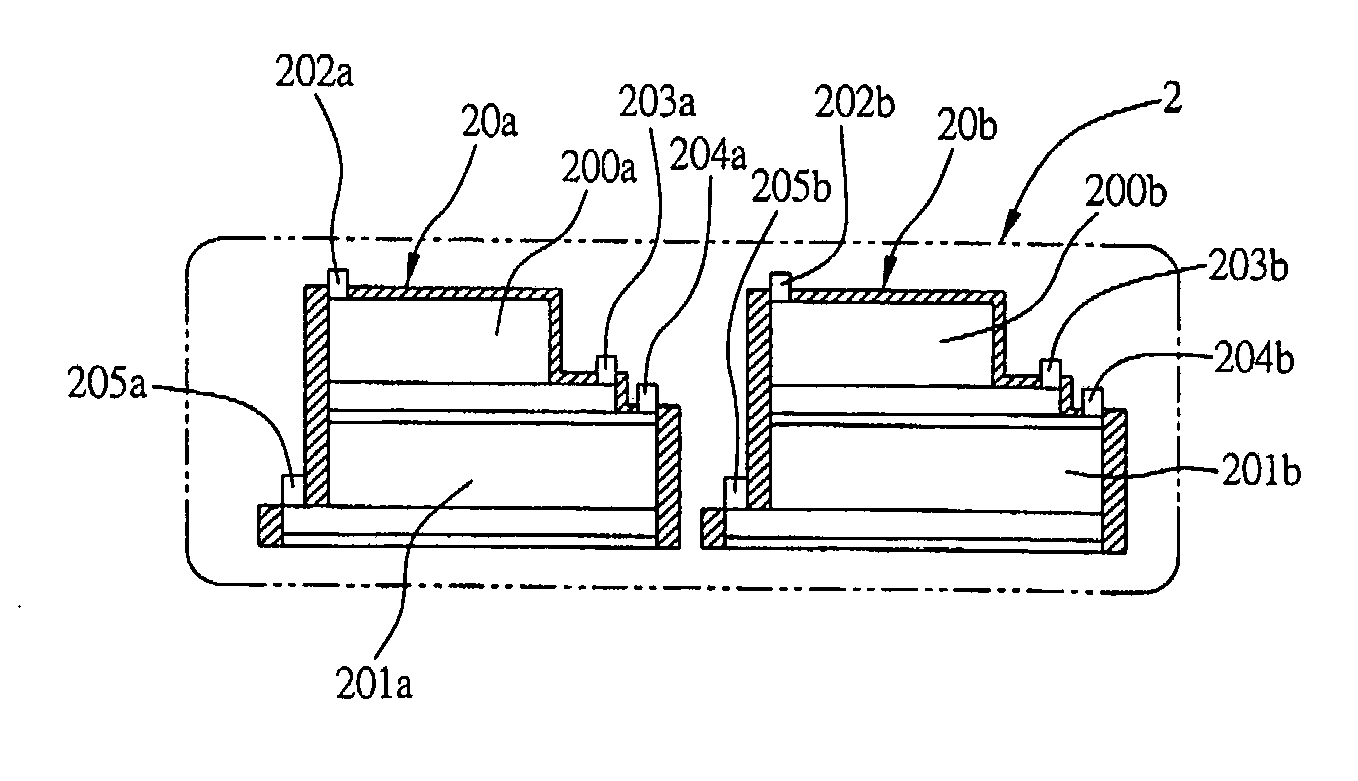

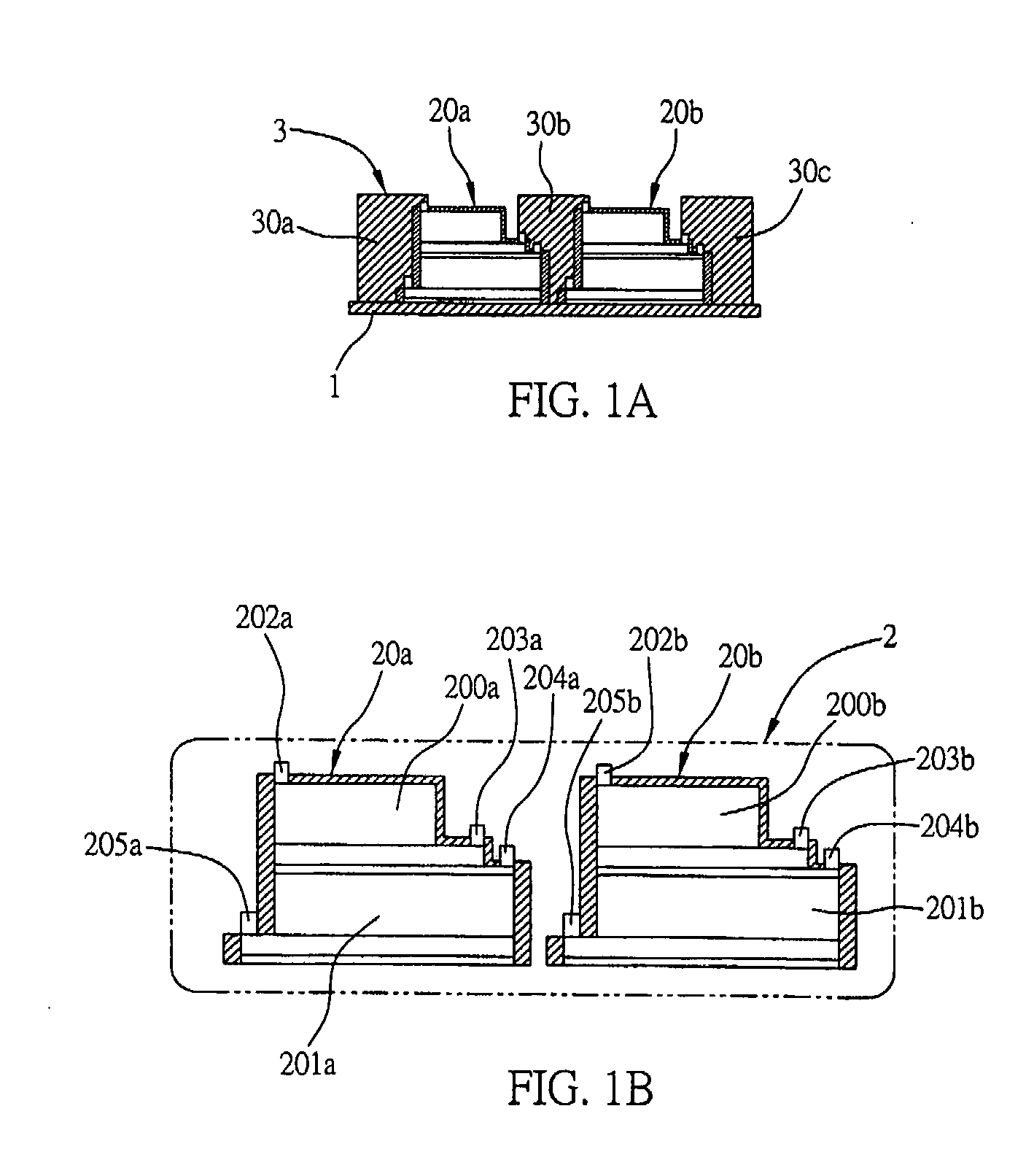

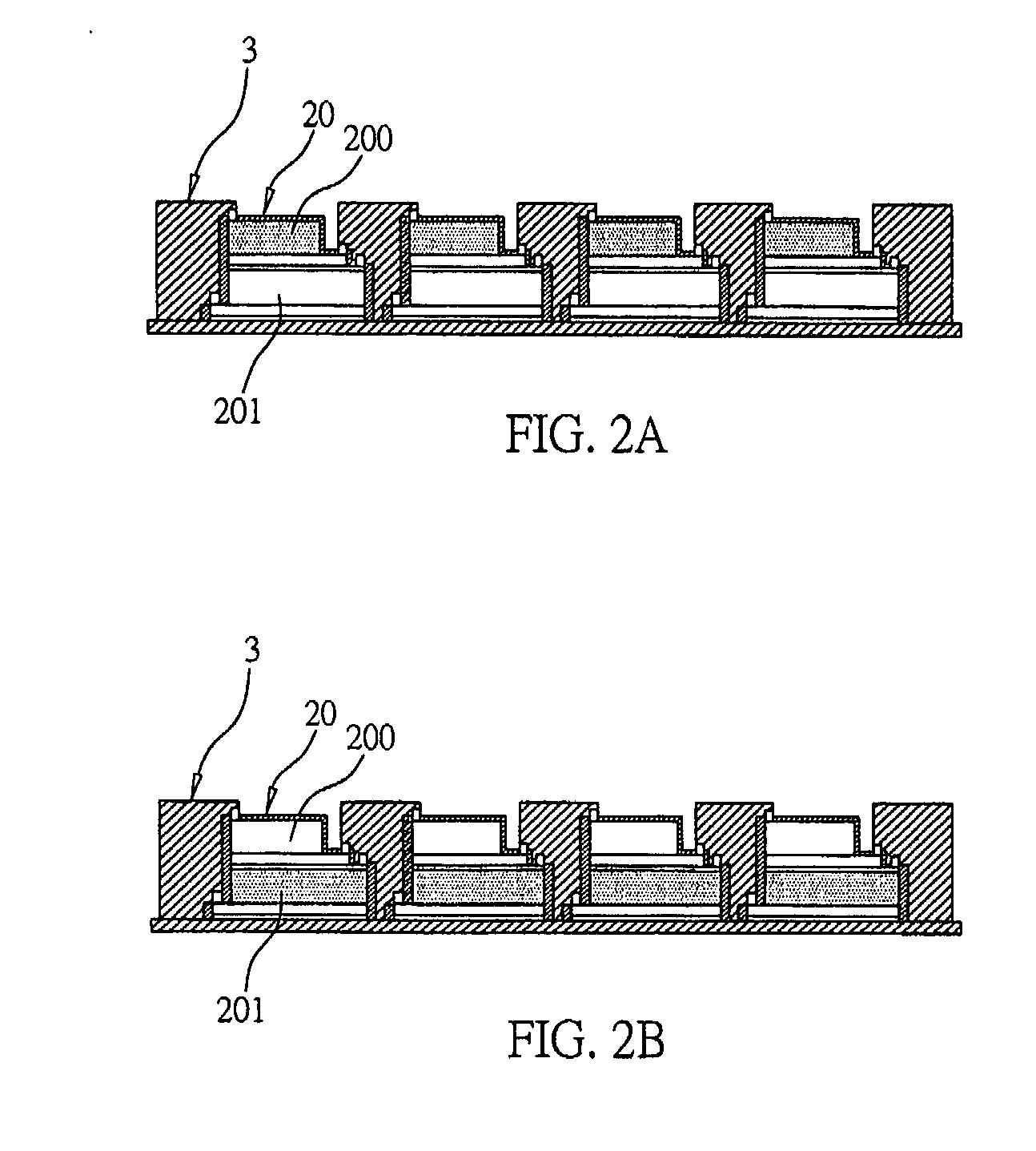

Alternating current light-emitting device

ActiveUS7474681B2Small sizeUniform lightSolid-state devicesMaterial analysis by optical meansAlternating currentFull scale

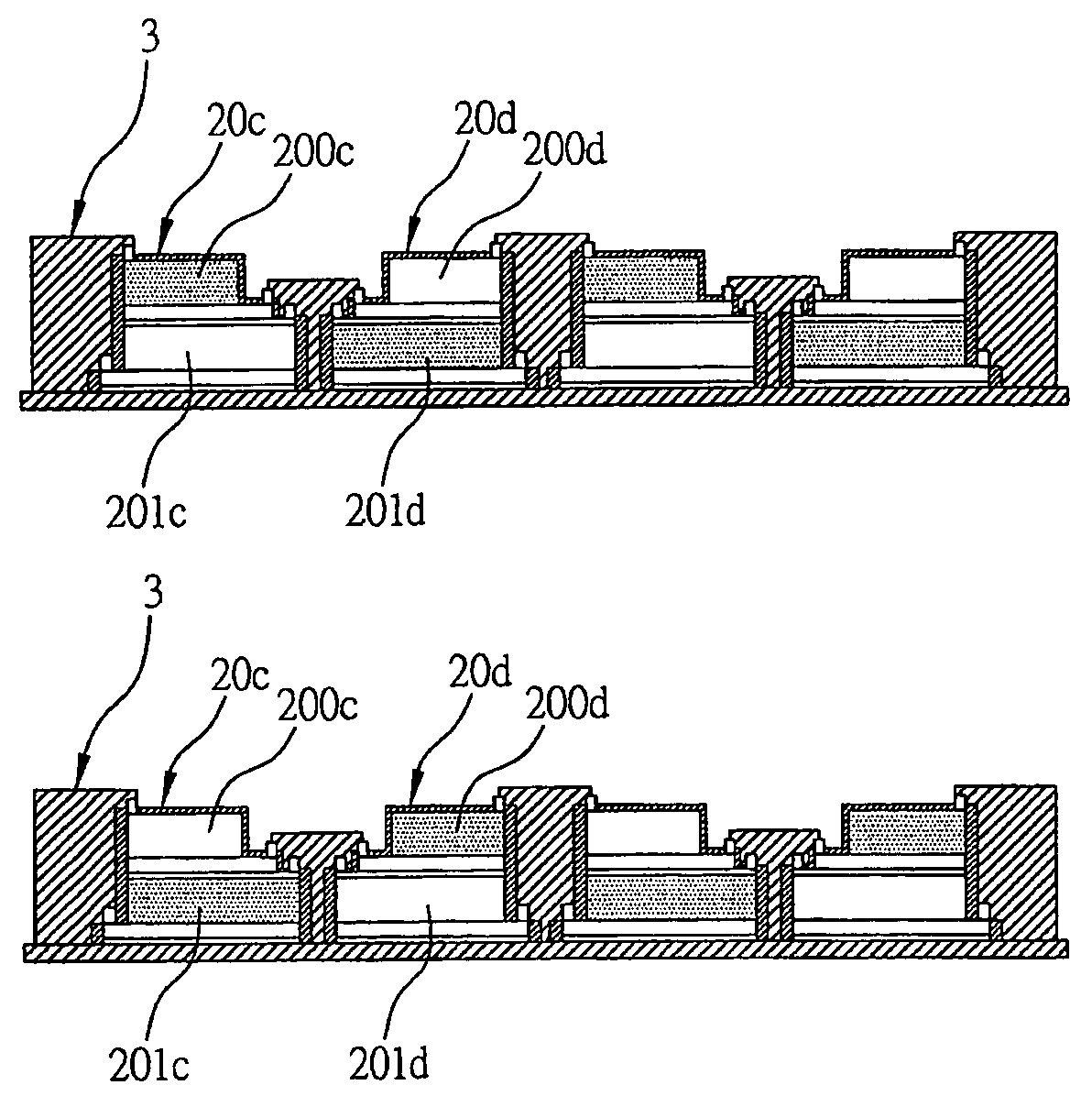

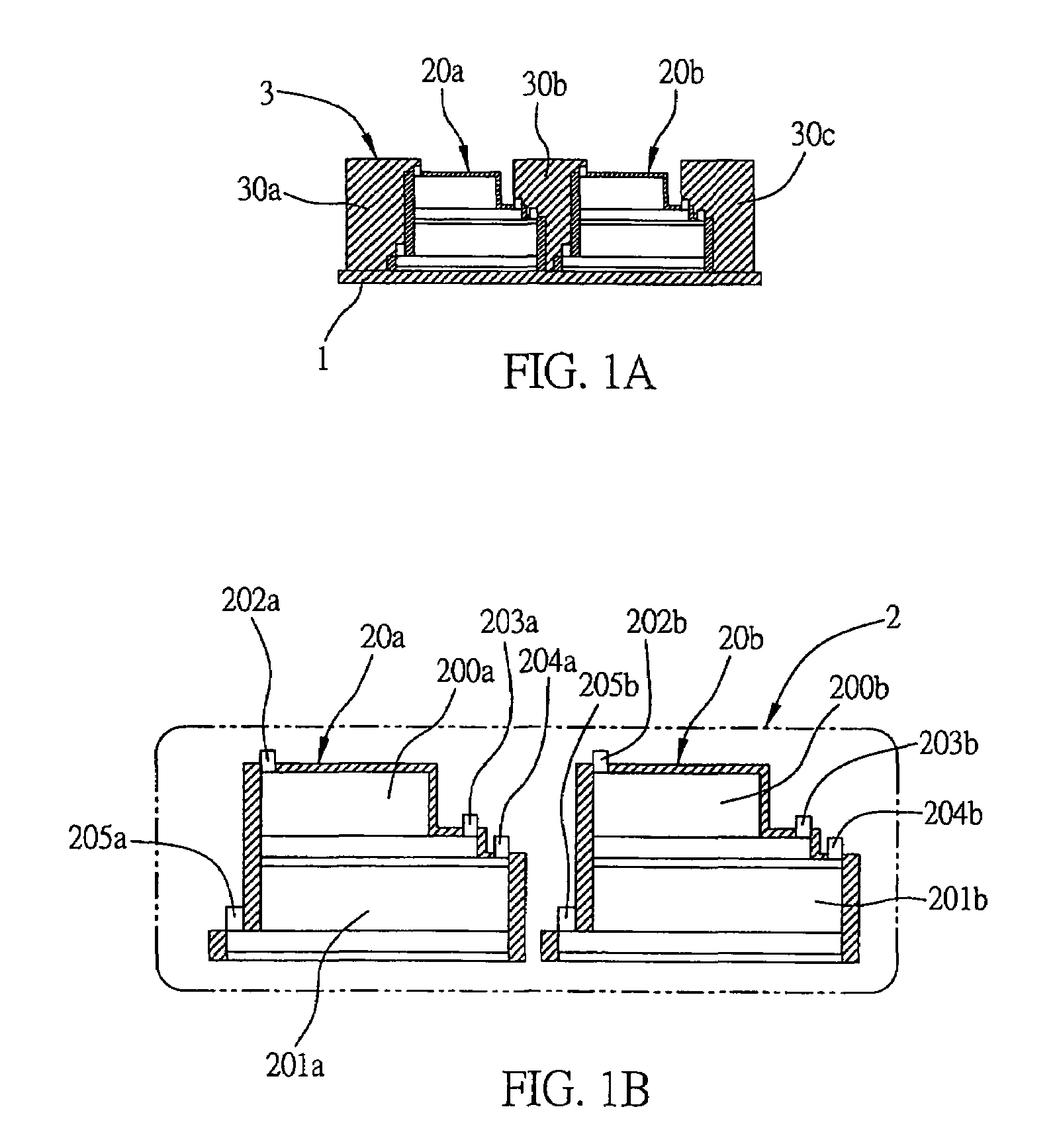

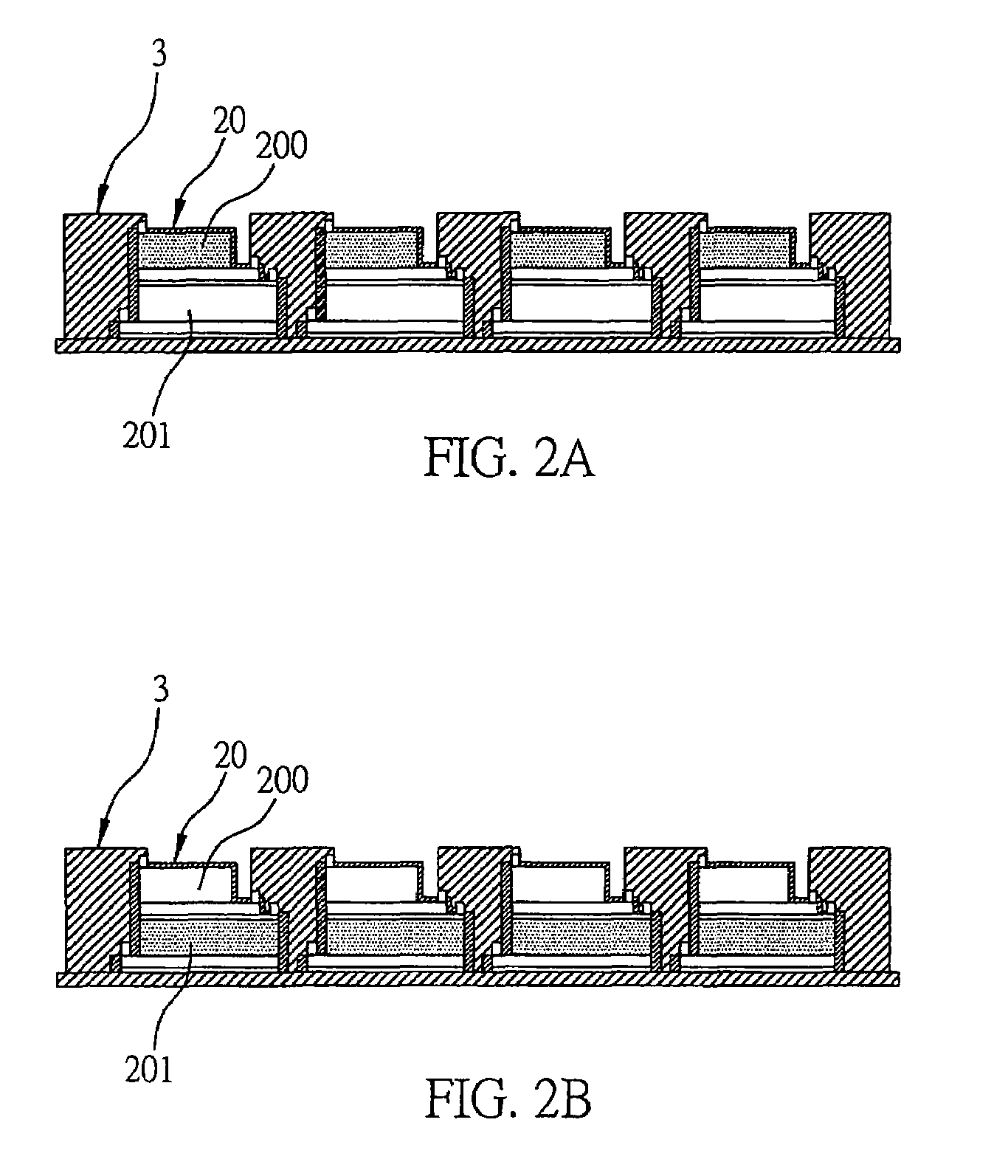

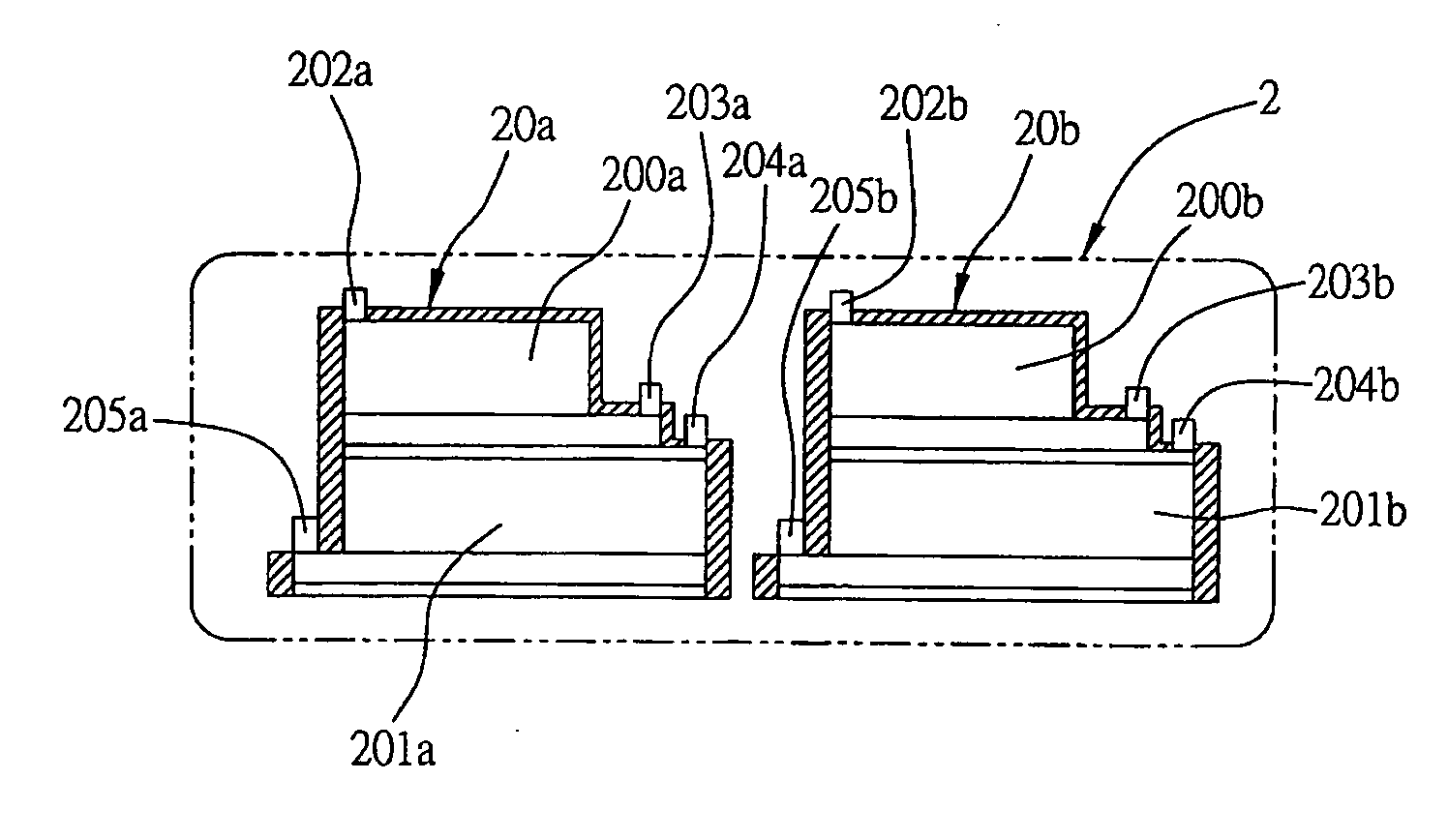

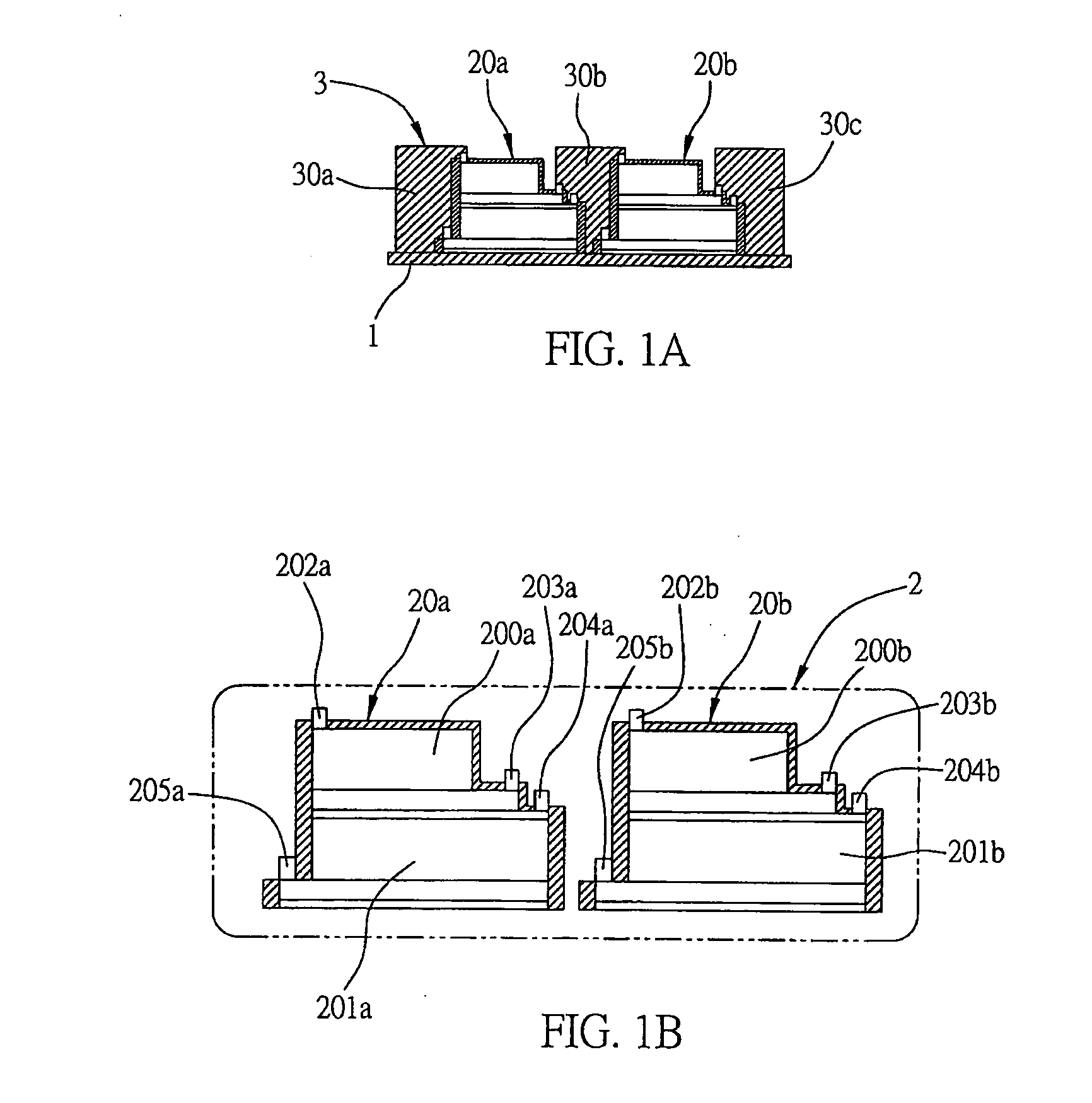

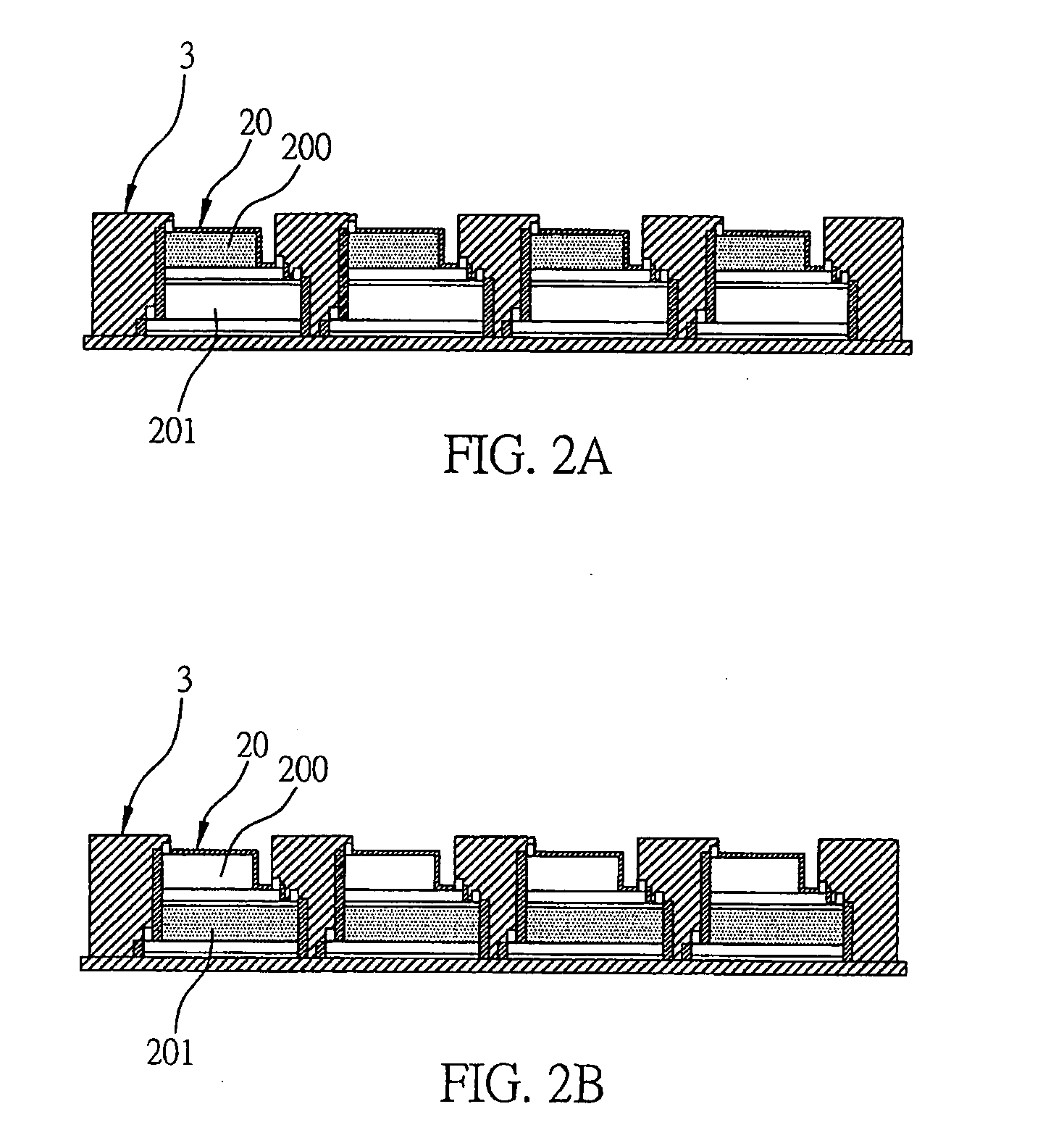

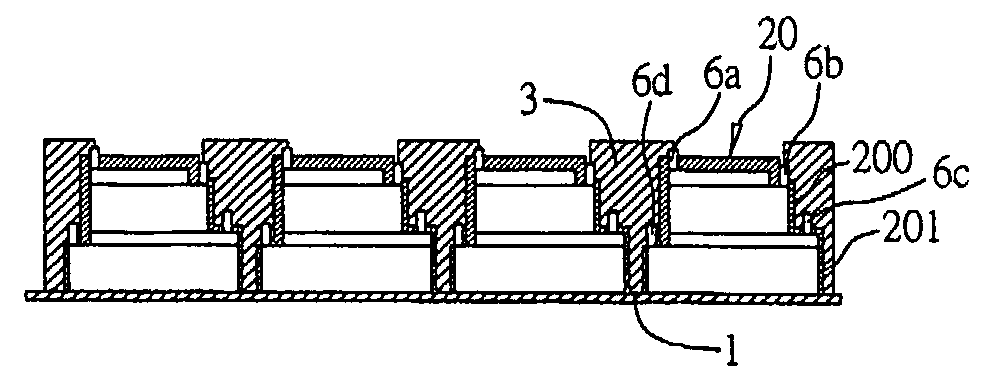

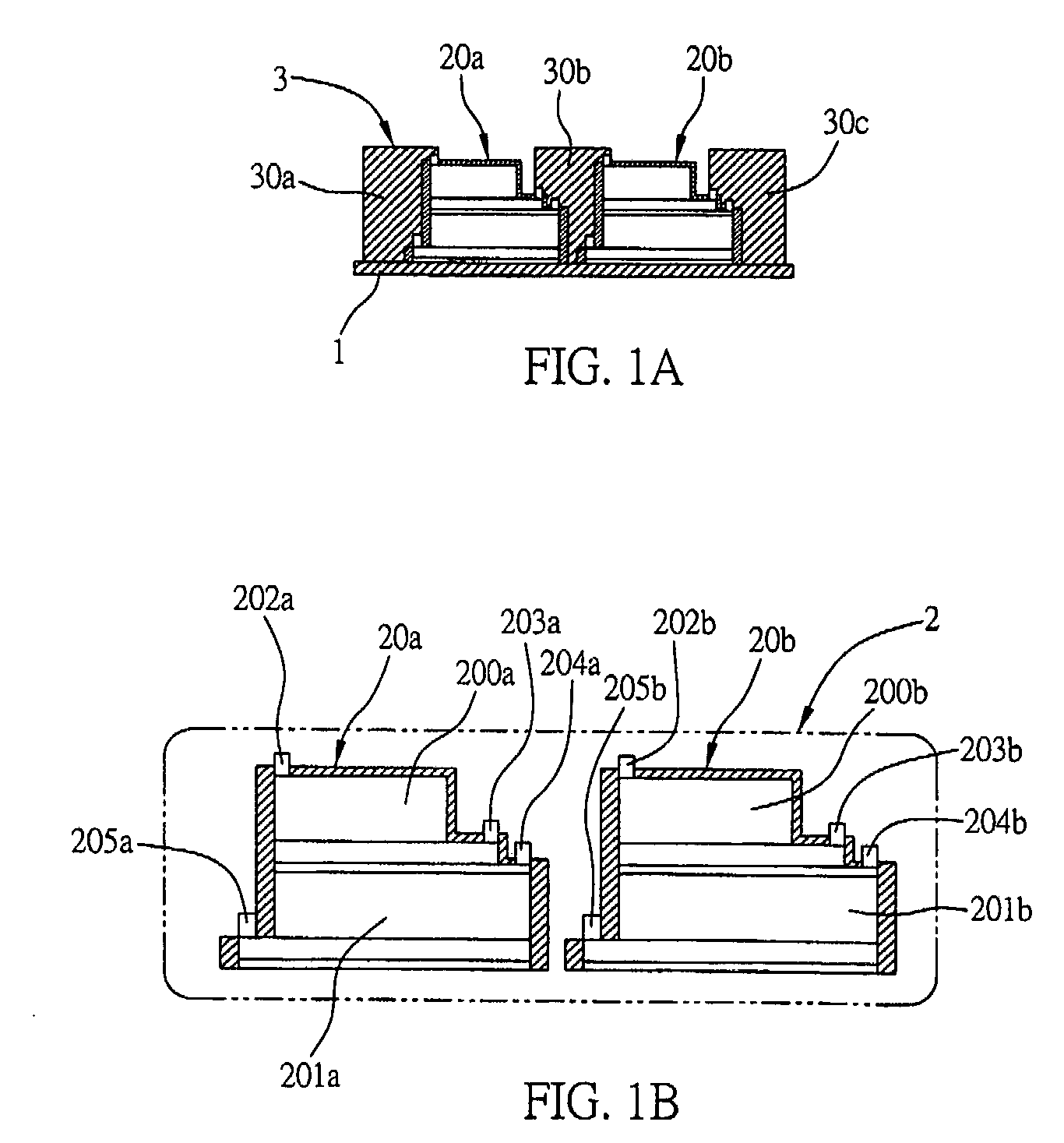

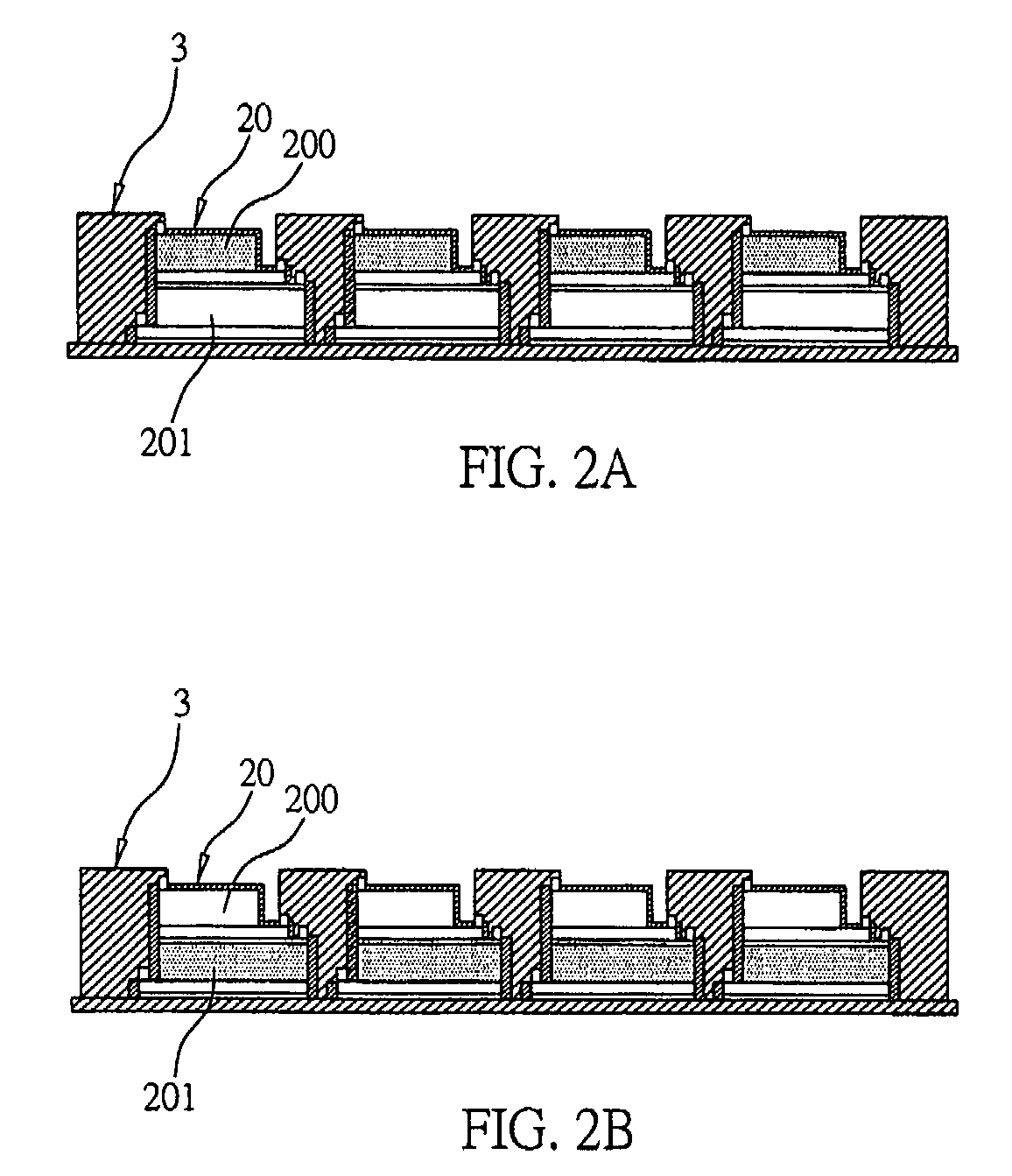

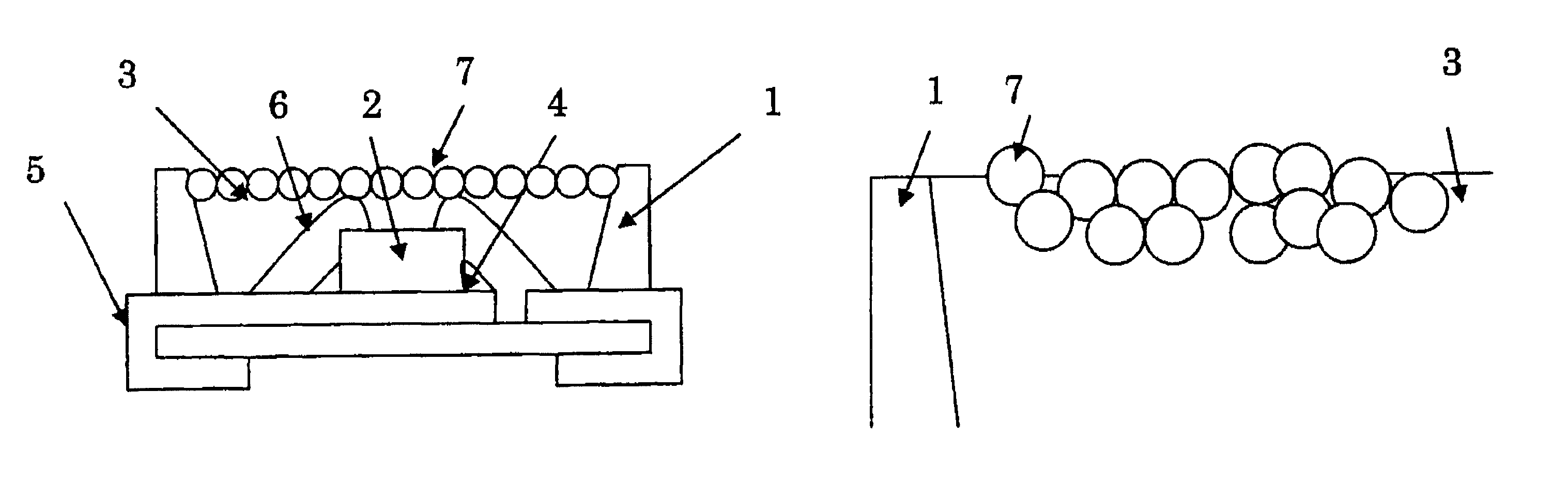

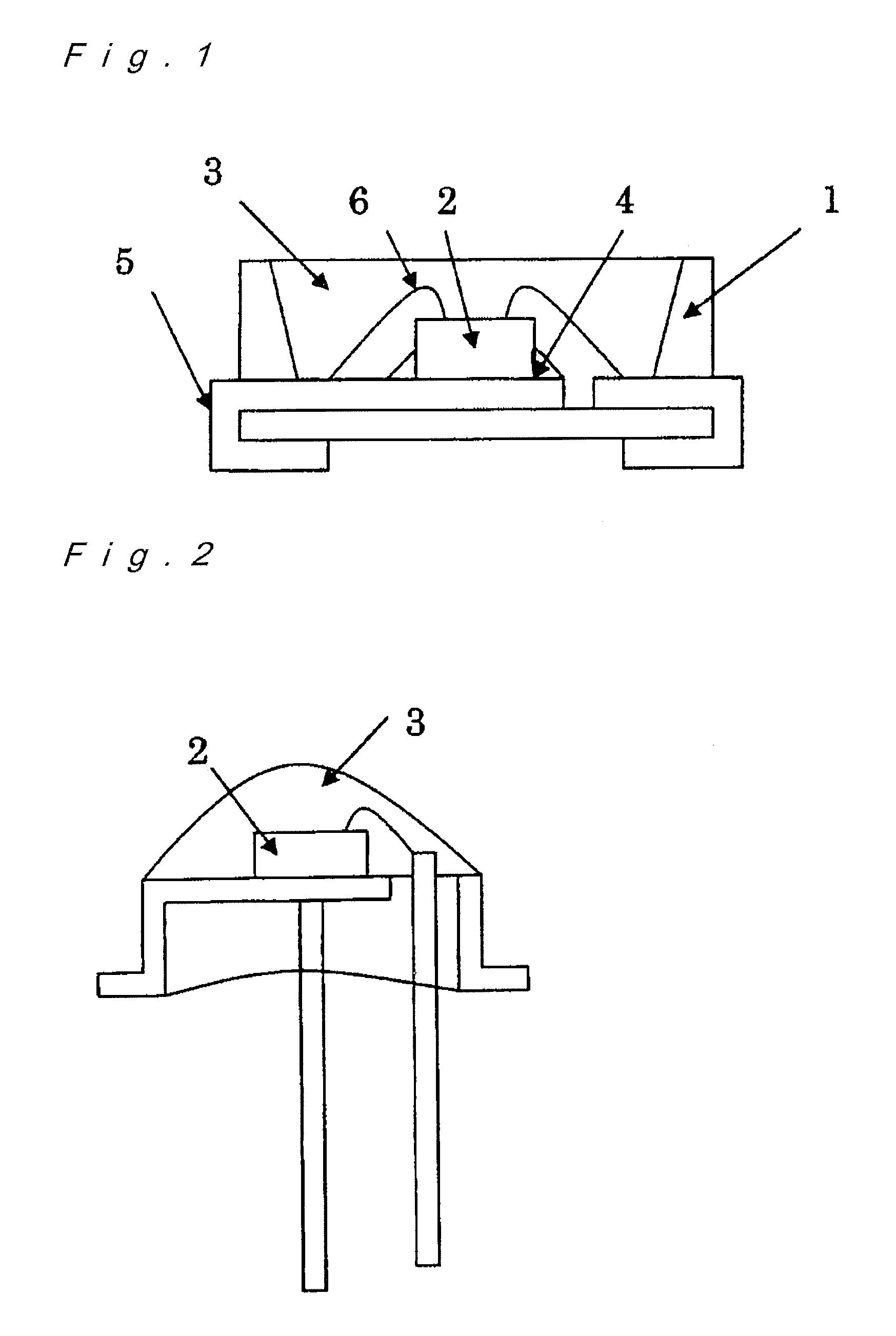

An alternating current light emitting device and the fabrication method includes forming one or more alternating current micro diode light emitting modules on a substrate, wherein the alternating current micro diode light emitting module has two micro diodes connected to one another, and each micro diode has at least two active layers and is electrically connected by a conductive structure, such that the active layers of each micro diode can take turns emitting light during the positive / negative half cycles of alternating current. A continuous and full-scale light emitting effect is thereby achieved.

Owner:EPISTAR CORP

Alternating current light-emitting device

ActiveUS20060256826A1Small sizeUniform lightSolid-state devicesMaterial analysis by optical meansAlternating currentFull scale

An alternating current light emitting device and the fabrication method includes forming one or more alternating current micro diode light emitting modules on a substrate, wherein the alternating current micro diode light emitting module has two micro diodes connected to one another, and each micro diode has at least two active layers and is electrically connected by a conductive structure, such that the active layers of each micro diode can take turns emitting light during the positive / negative half cycles of alternating current. A continuous and full-scale light emitting effect is thereby achieved.

Owner:EPISTAR CORP

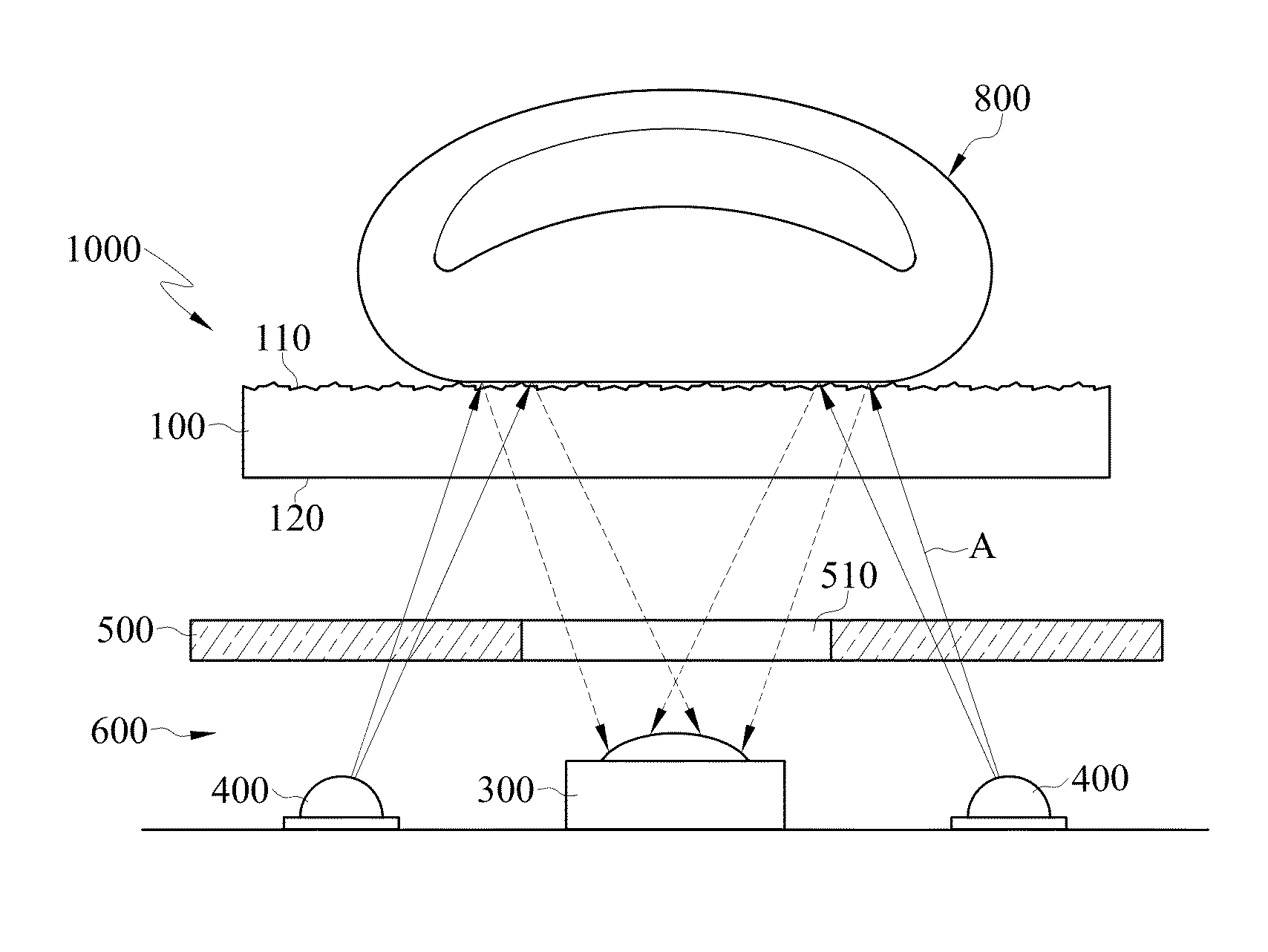

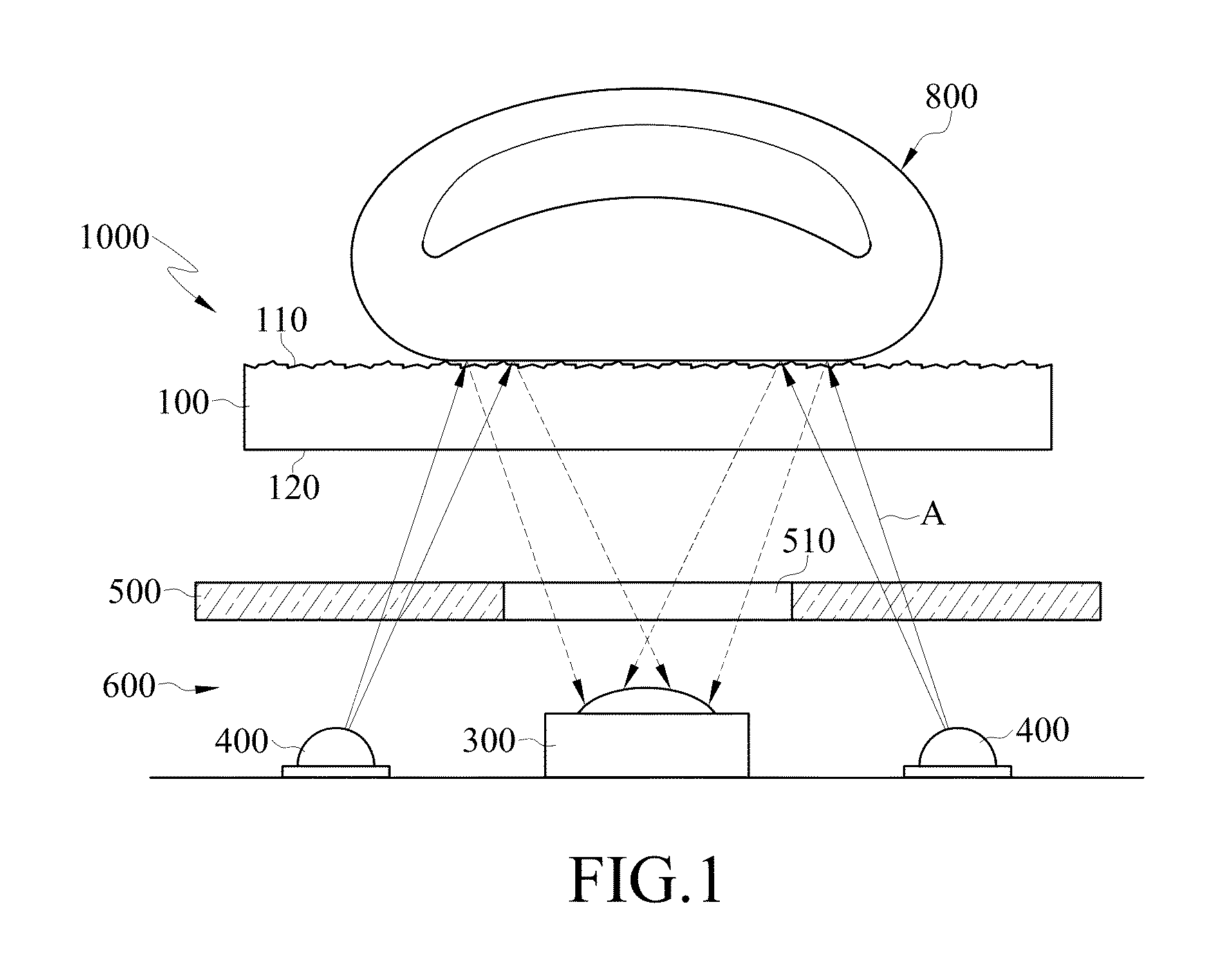

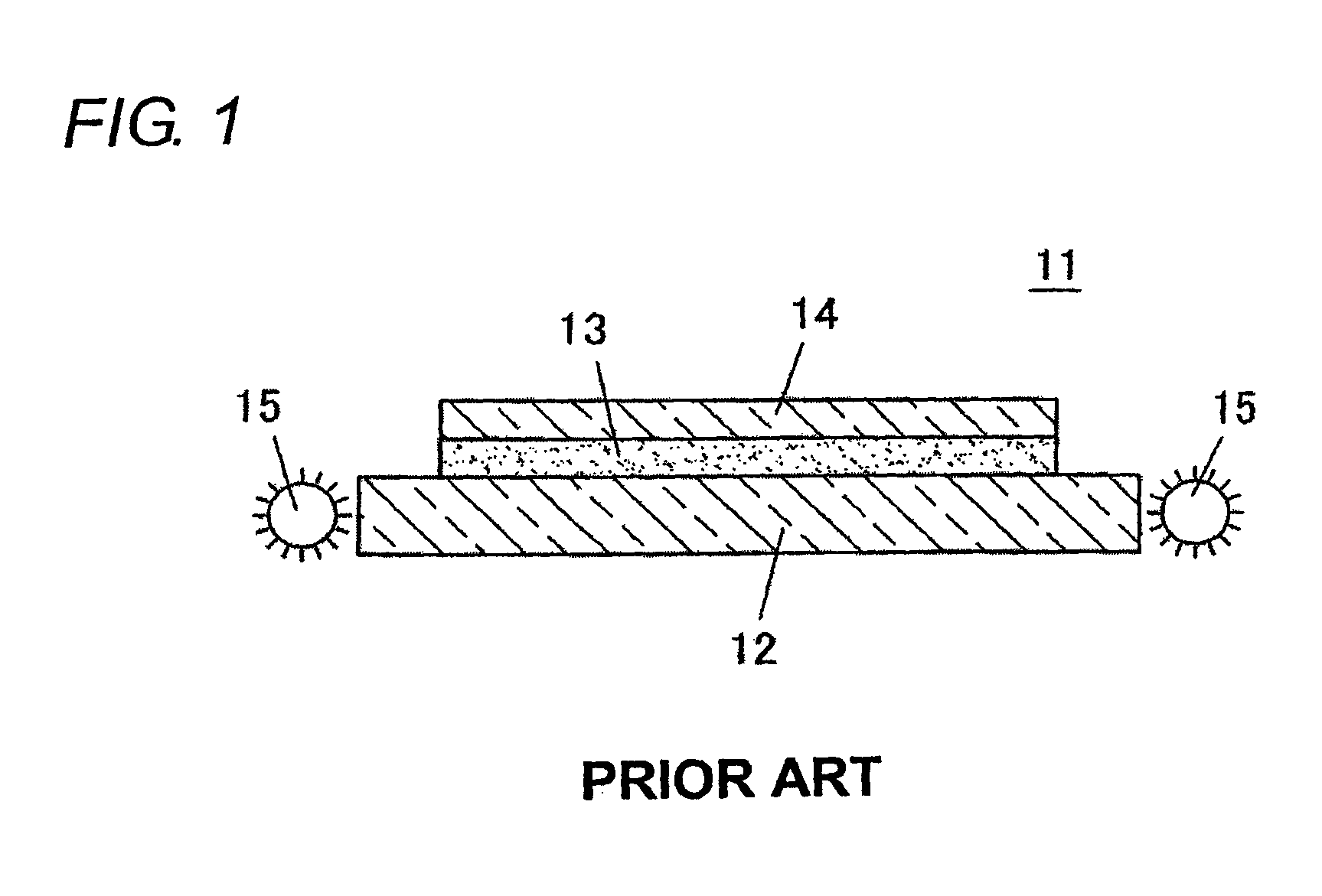

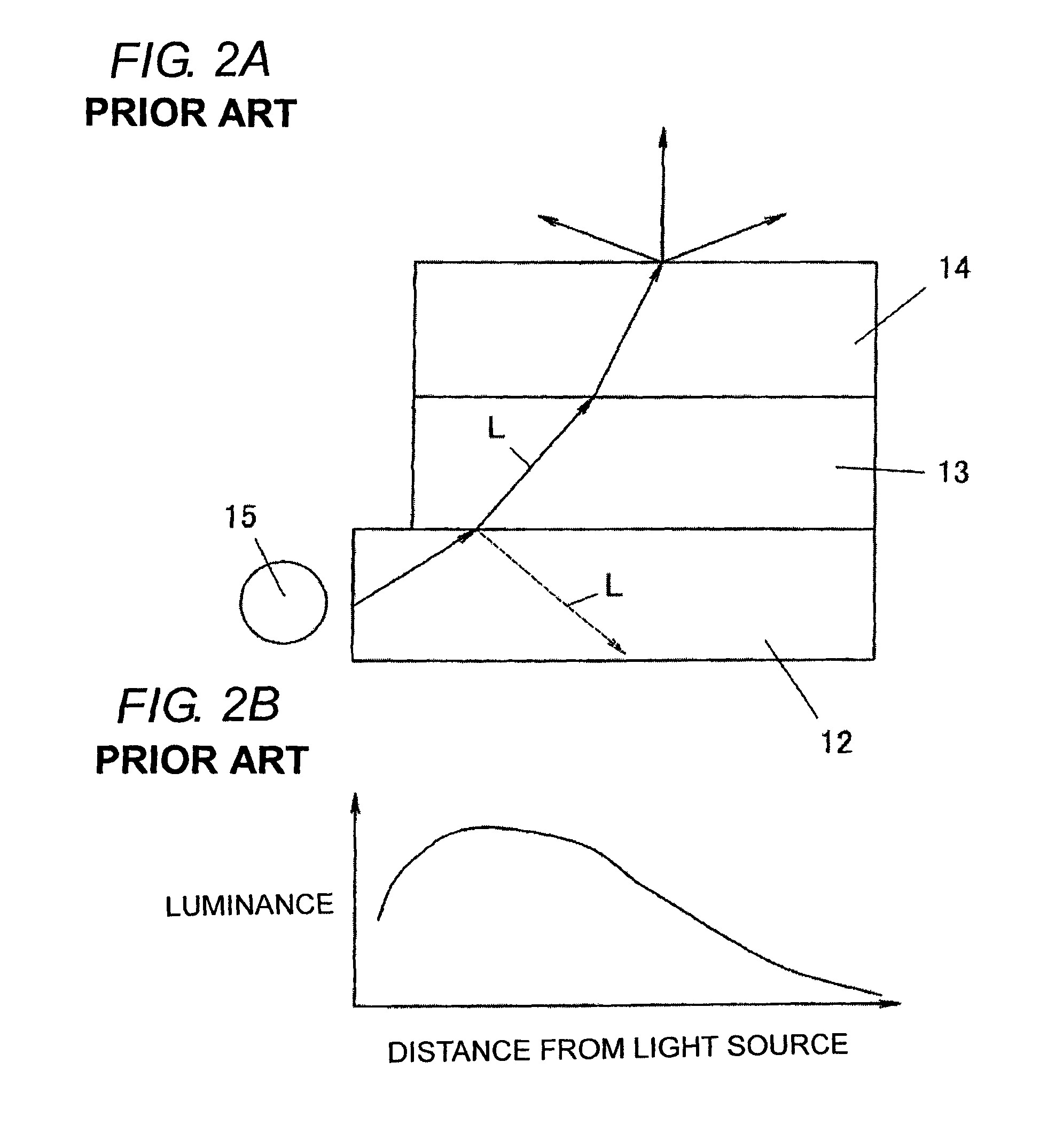

Substrate for fingerprint contact

ActiveUS20130051635A1Increase lighting brightnessWeakening unnecessary scattered lightAcquiring/reconising fingerprints/palmprintsFingerprintScattered light

A substrate for fingerprint contact includes a plate, and the plate includes a first surface and a second surface. The first surface is an optical diffusing surface. The optical diffusing surface is used for being contacted by a finger, and features hazed particles. The second surface faces an optical imaging system. The optical diffusing surface of the plate helps to enhance light to be evenly emitted to the finger and weakens the unnecessary scattered light to the optical imaging system, so as to enhance the recognition rate of a fingerprint when the optical imaging system is used for intercept the light applied on a finger.

Owner:GINGY TECH

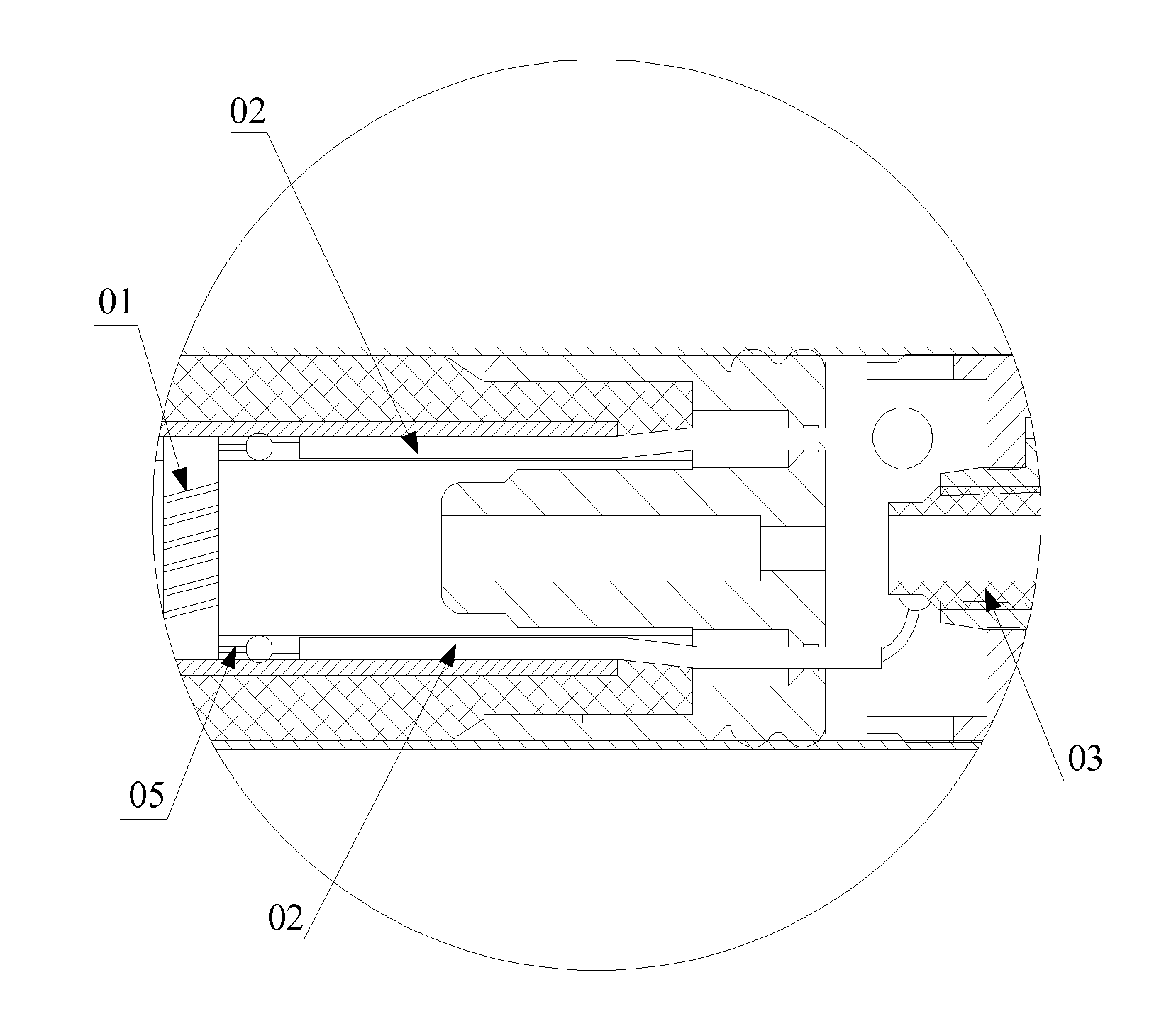

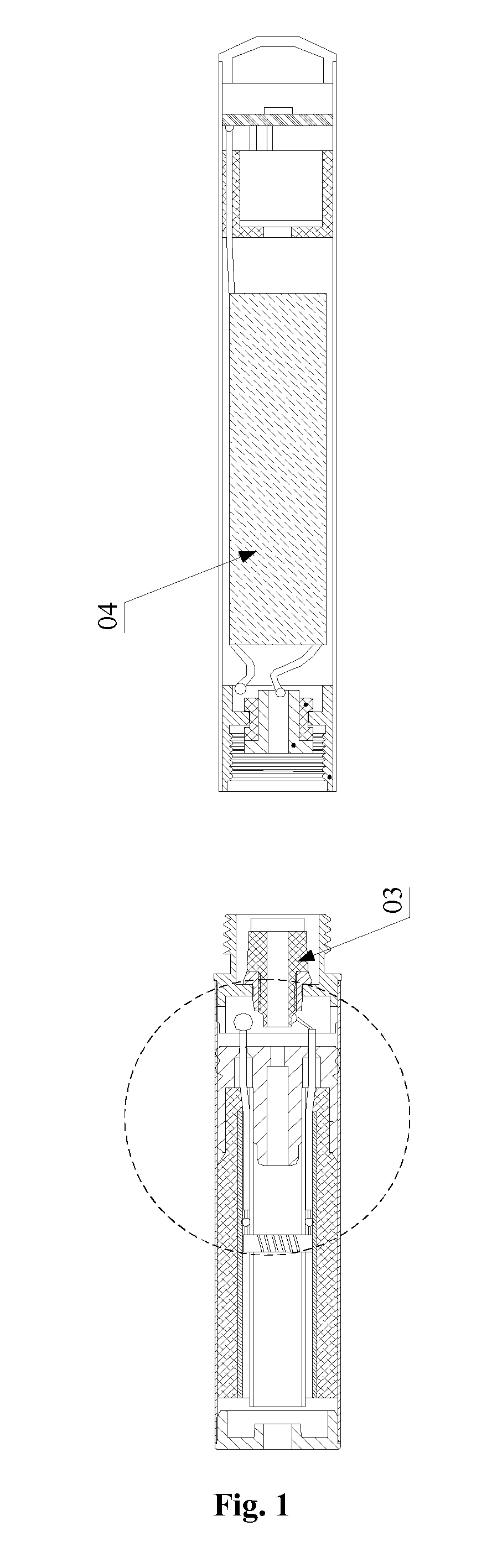

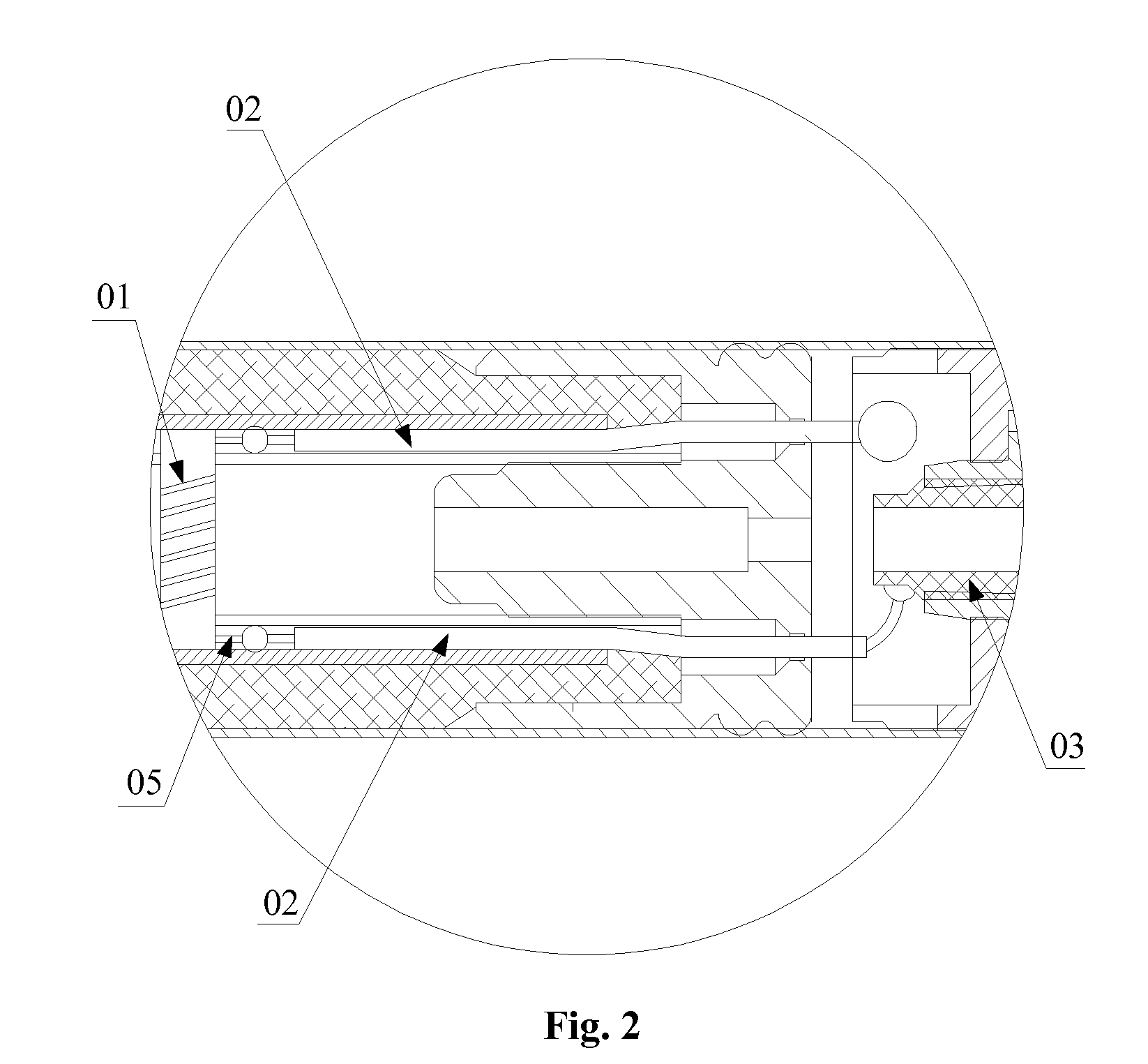

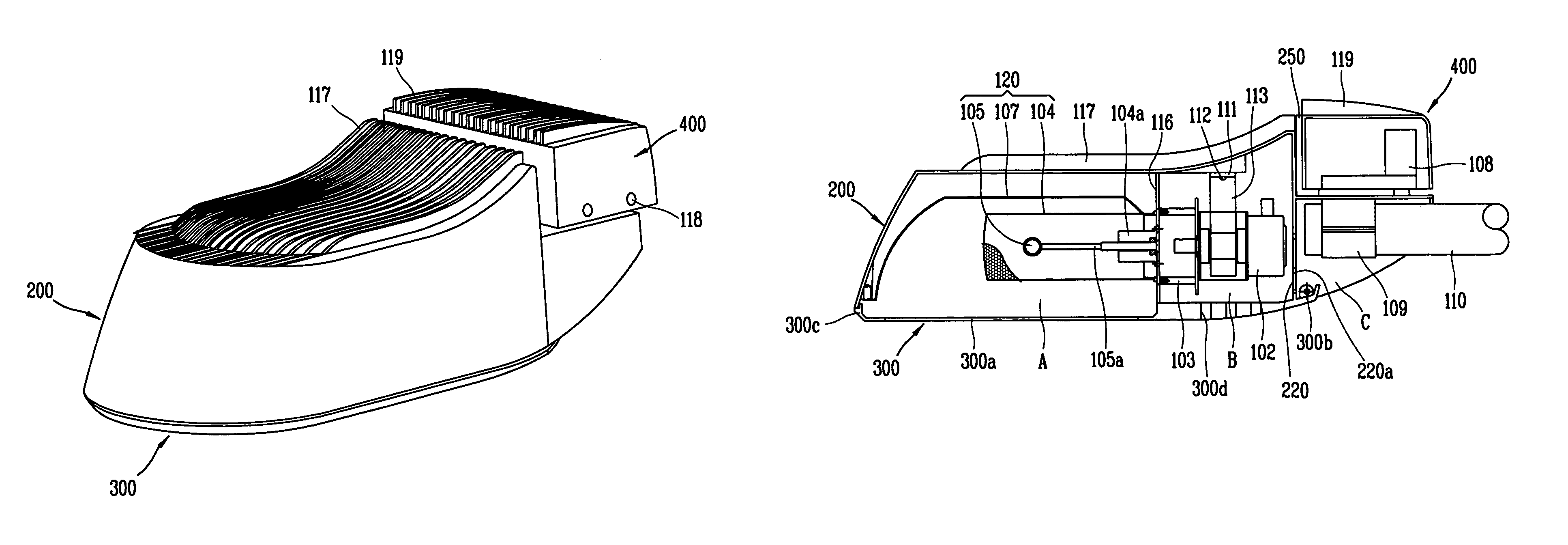

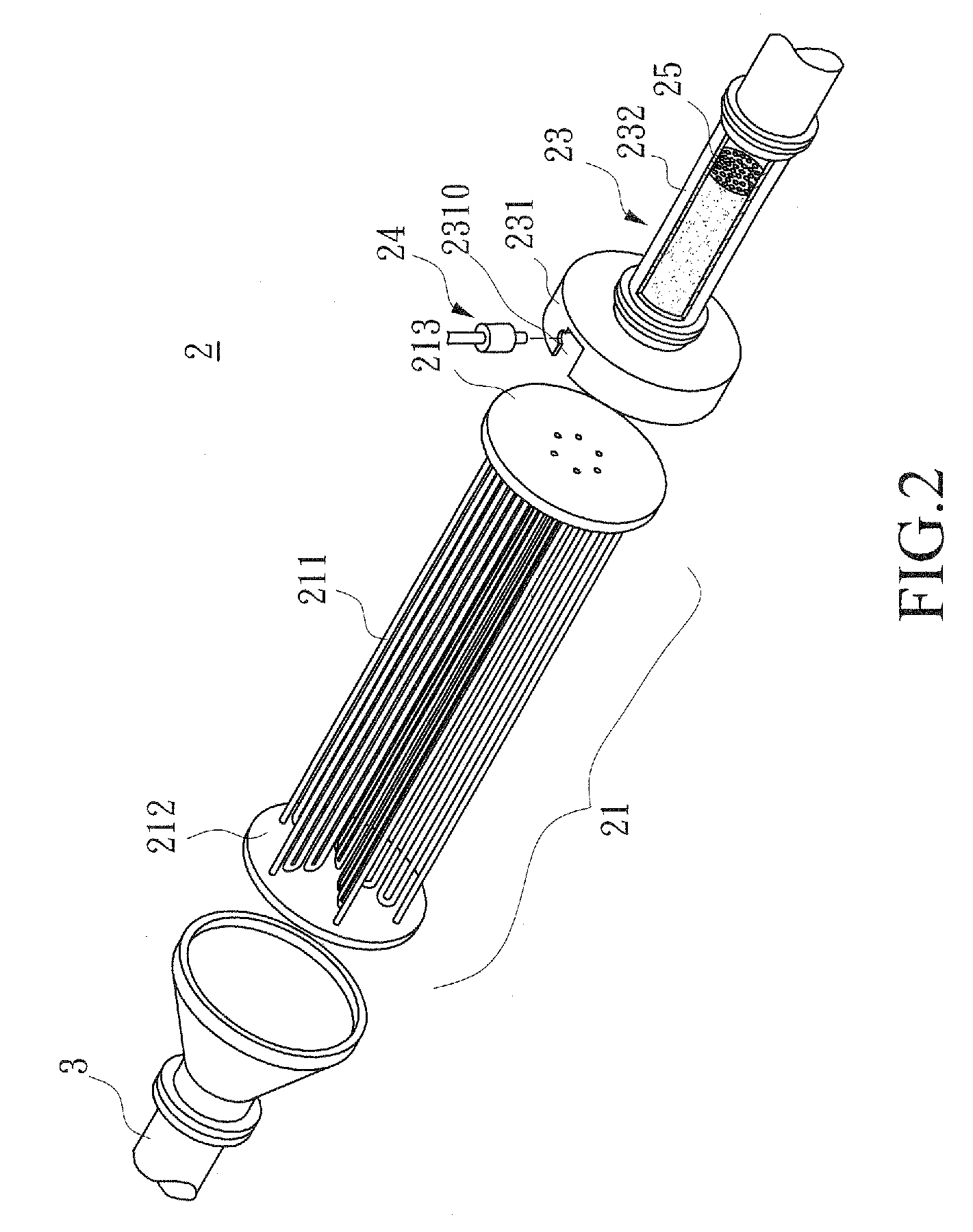

Electronic cigarette

InactiveUS20160374391A1Improve uniformityEmission smoothTobacco devicesMachines/enginesElectric heatingElectrical conductor

There is provided in the present application an electronic cigarette, including an electric heating wire and an electrode. The electric heating wire is electrically conducted to the electrode via a conductor. In the electronic cigarette according to the present application, the electric heating wire is electrically conducted to the electrode via the conductor, instead of a copper sheet and a lead with smaller volumes. In this way, the problem of poor contact which is likely to occur in connection of various conductors could be avoided, so that a phenomenon of an unstable value of resistance in the circuit may be avoided, and emission of smoke becomes more even.

Owner:KIMREE HI TECH

Alternating current light-emitting device

ActiveUS7544524B2Emission smoothElectroluminescent light sourcesSolid-state devicesEngineeringFull scale

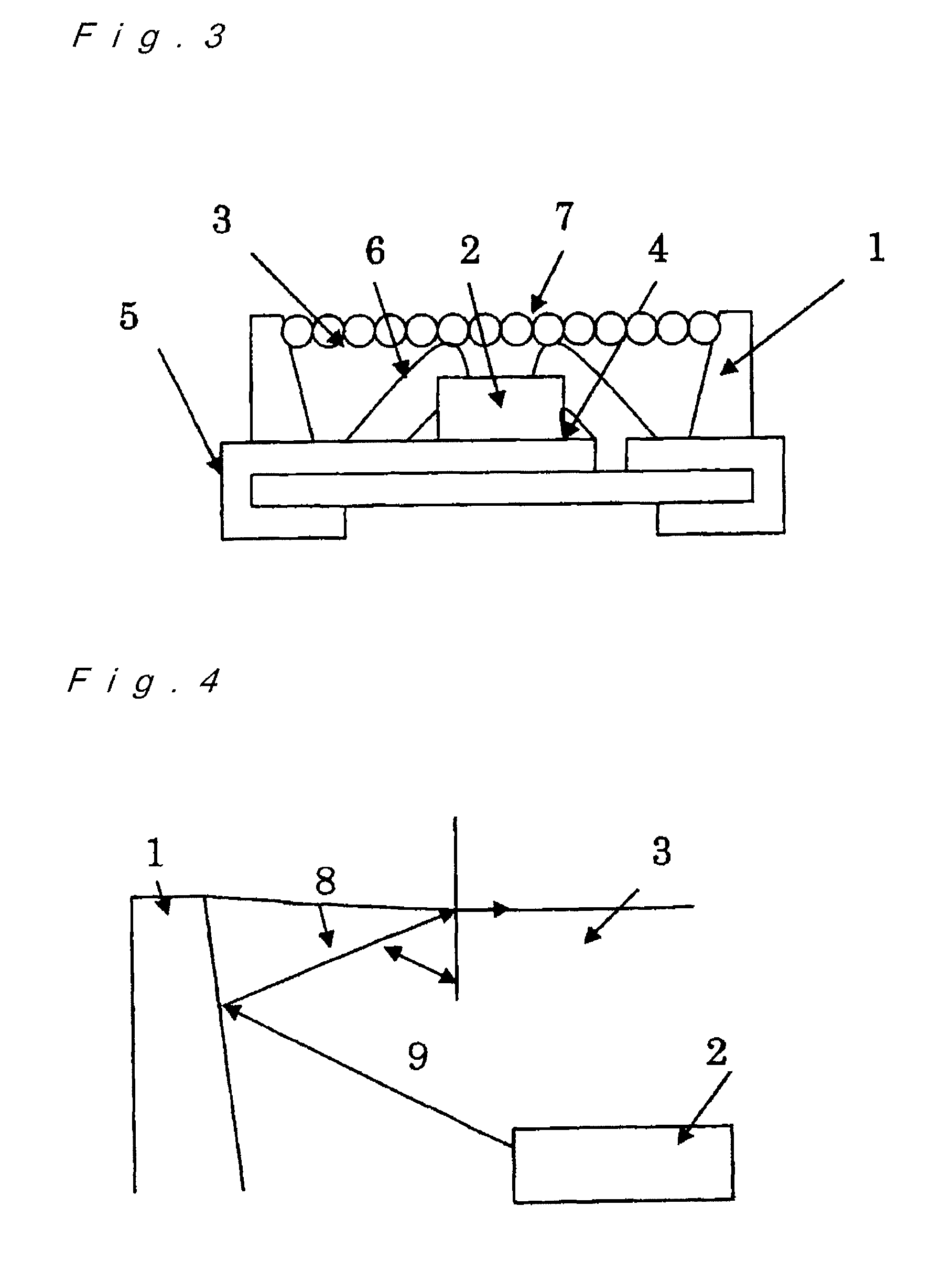

An alternating current light-emitting device and the fabrication method thereof is disclosed. The alternating current light-emitting device includes at least one alternating current micro-die light-emitting module formed on a substrate and composed of at least two micro-dies connected to one another. The micro-dies, each includes at least two active layers, are electrically connected by a conductive structure, such that the active layers of the micro-dies take turns emitting light during positive and negative half cycles of alternating current, thereby providing a full-scale light-emitting area for all-time light emission.

Owner:EPISTAR CORP

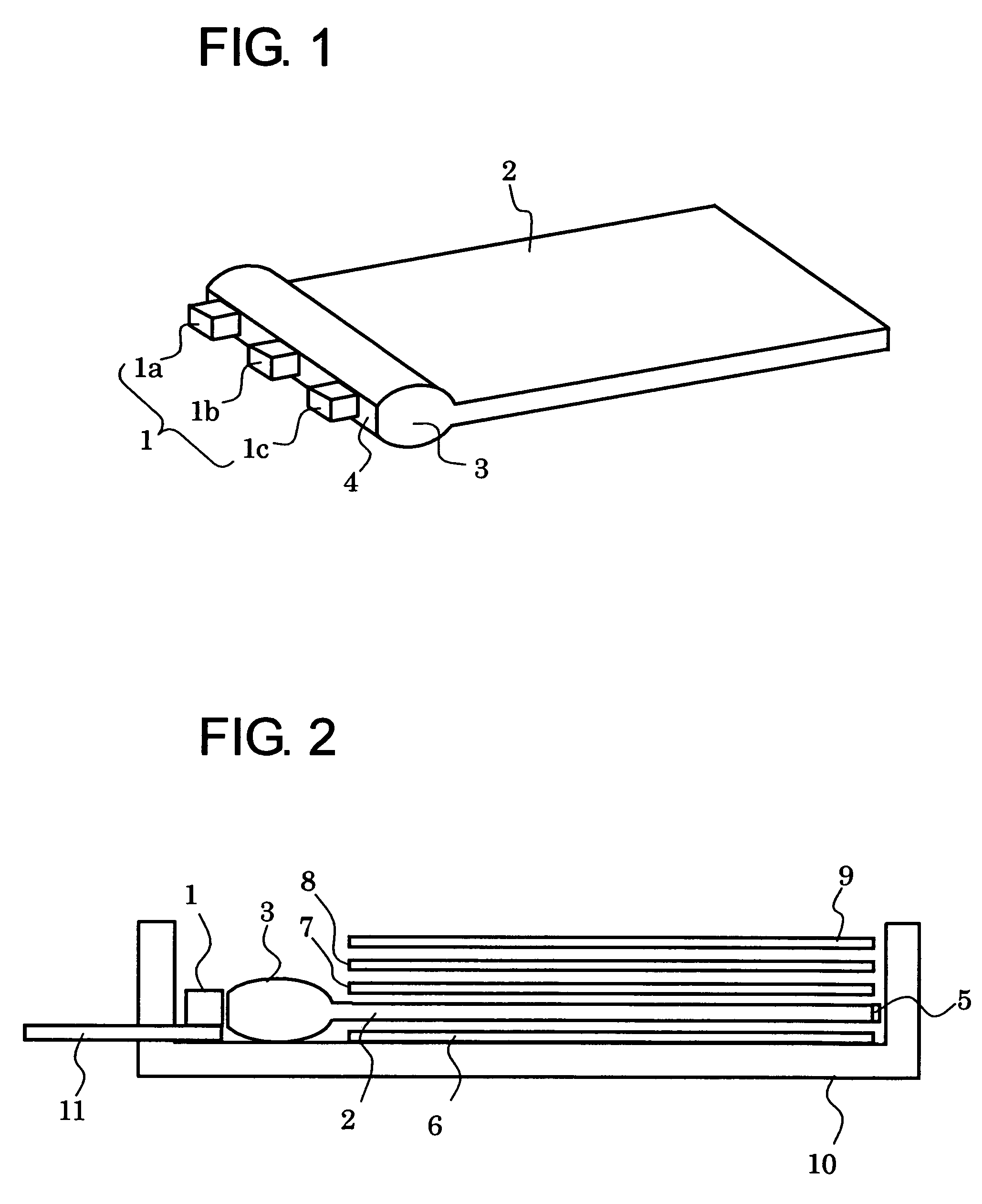

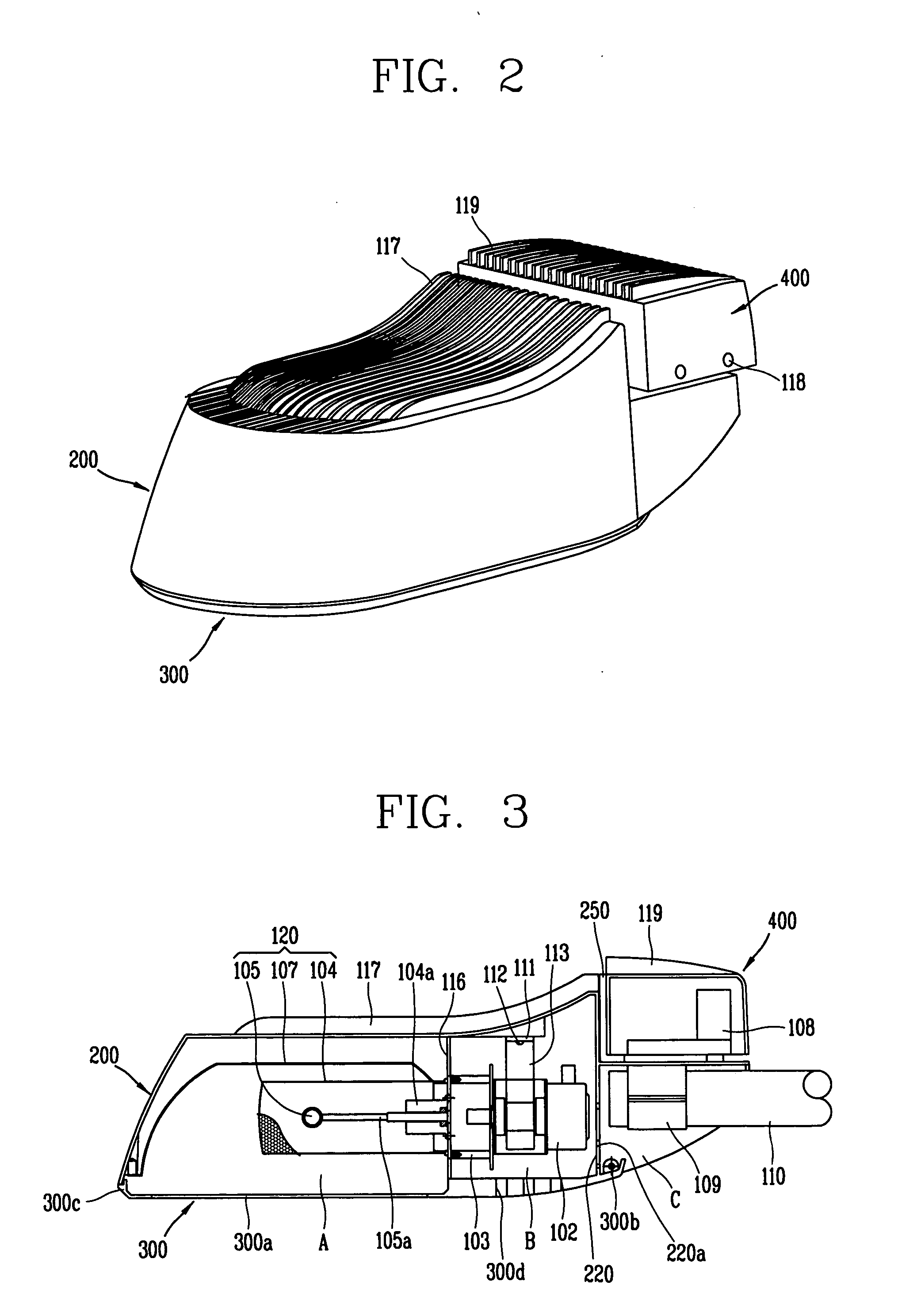

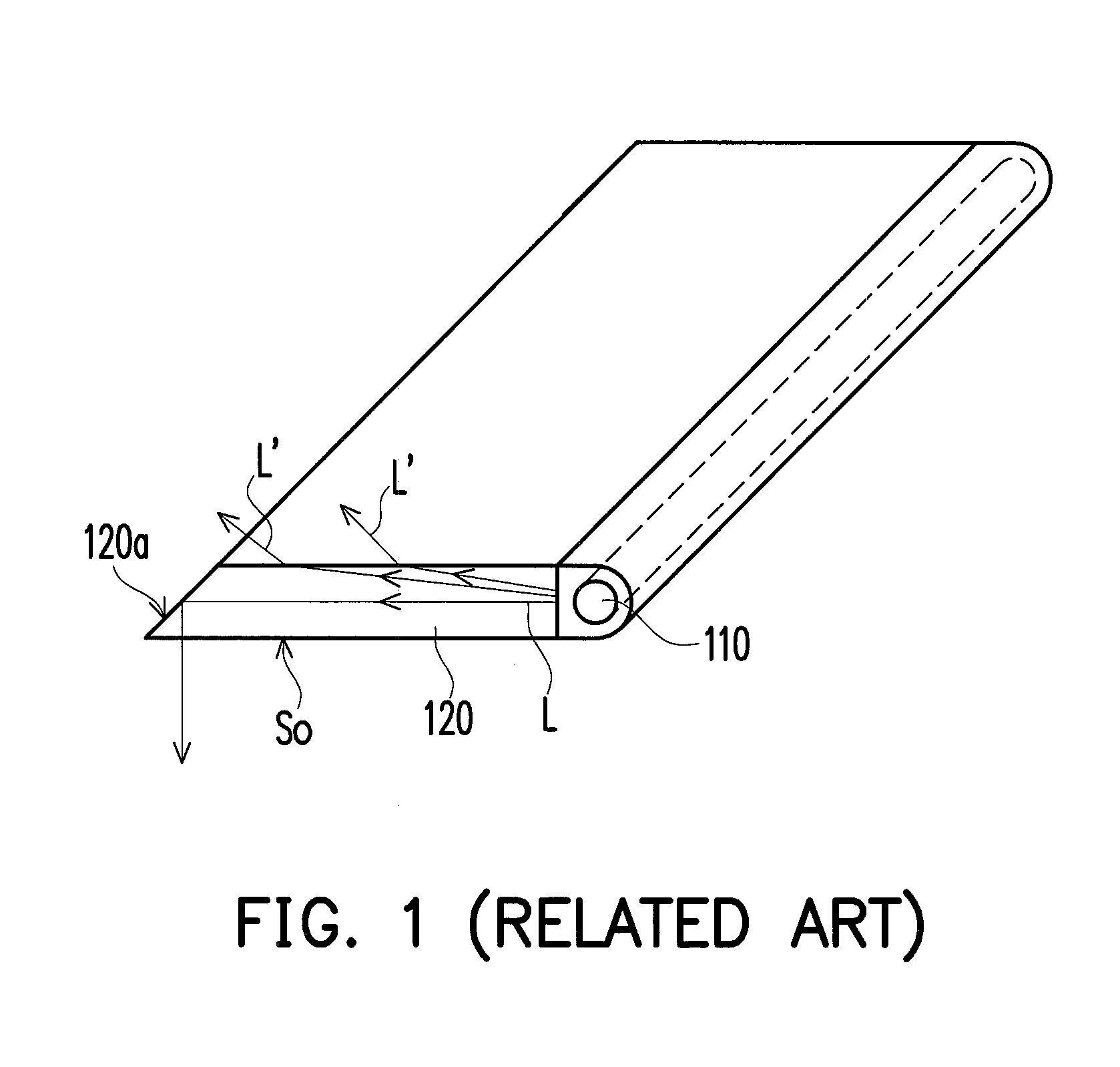

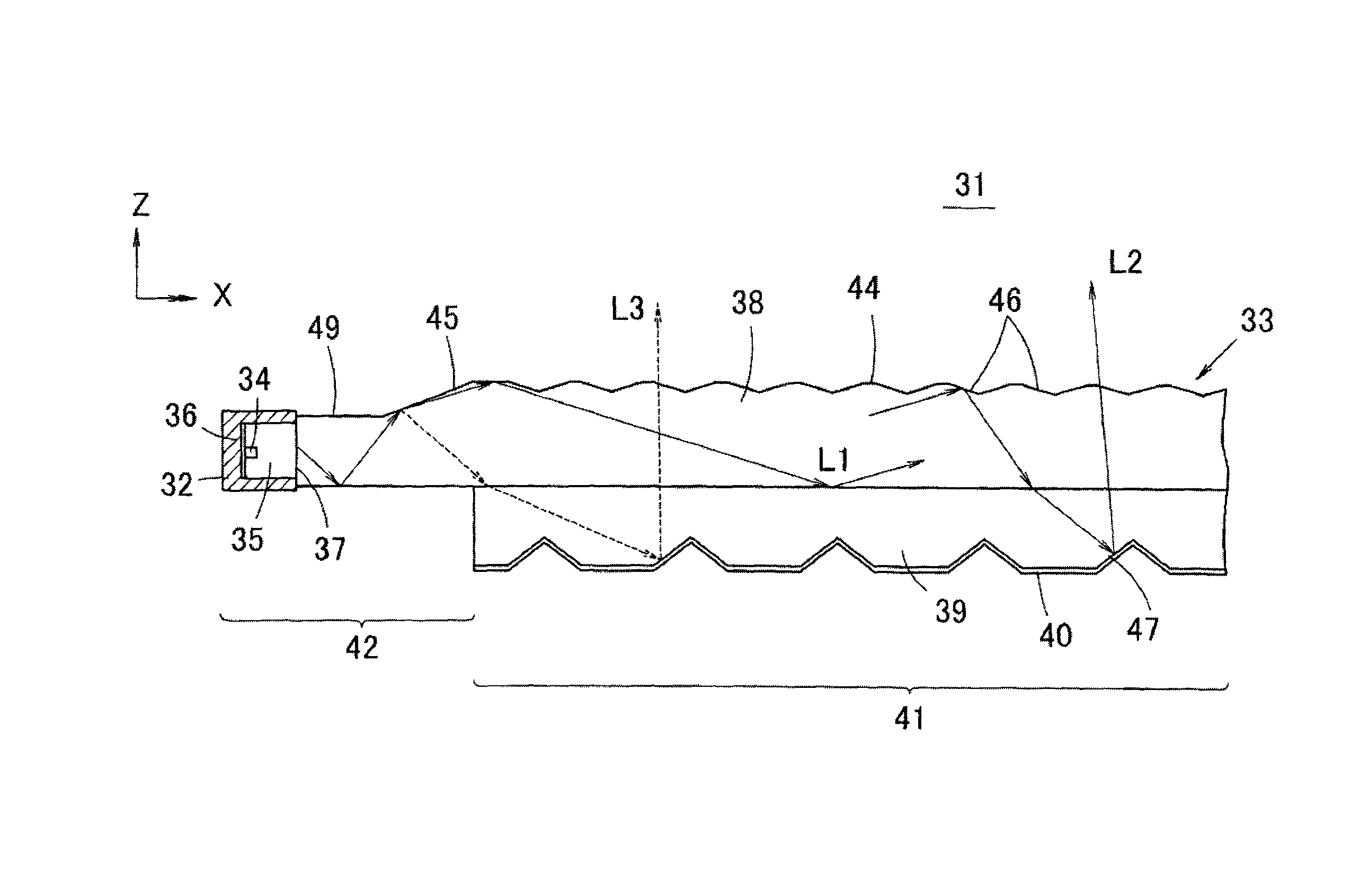

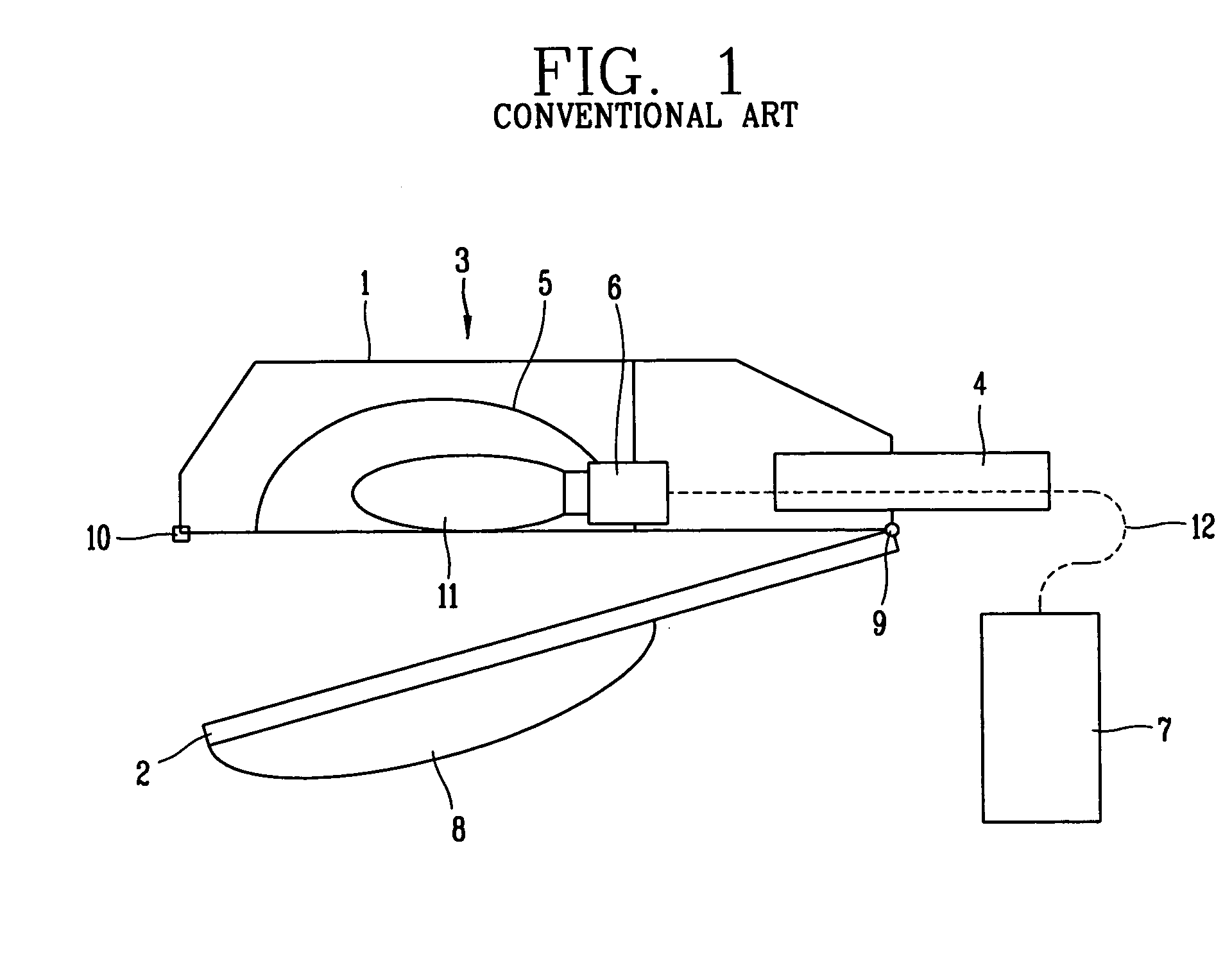

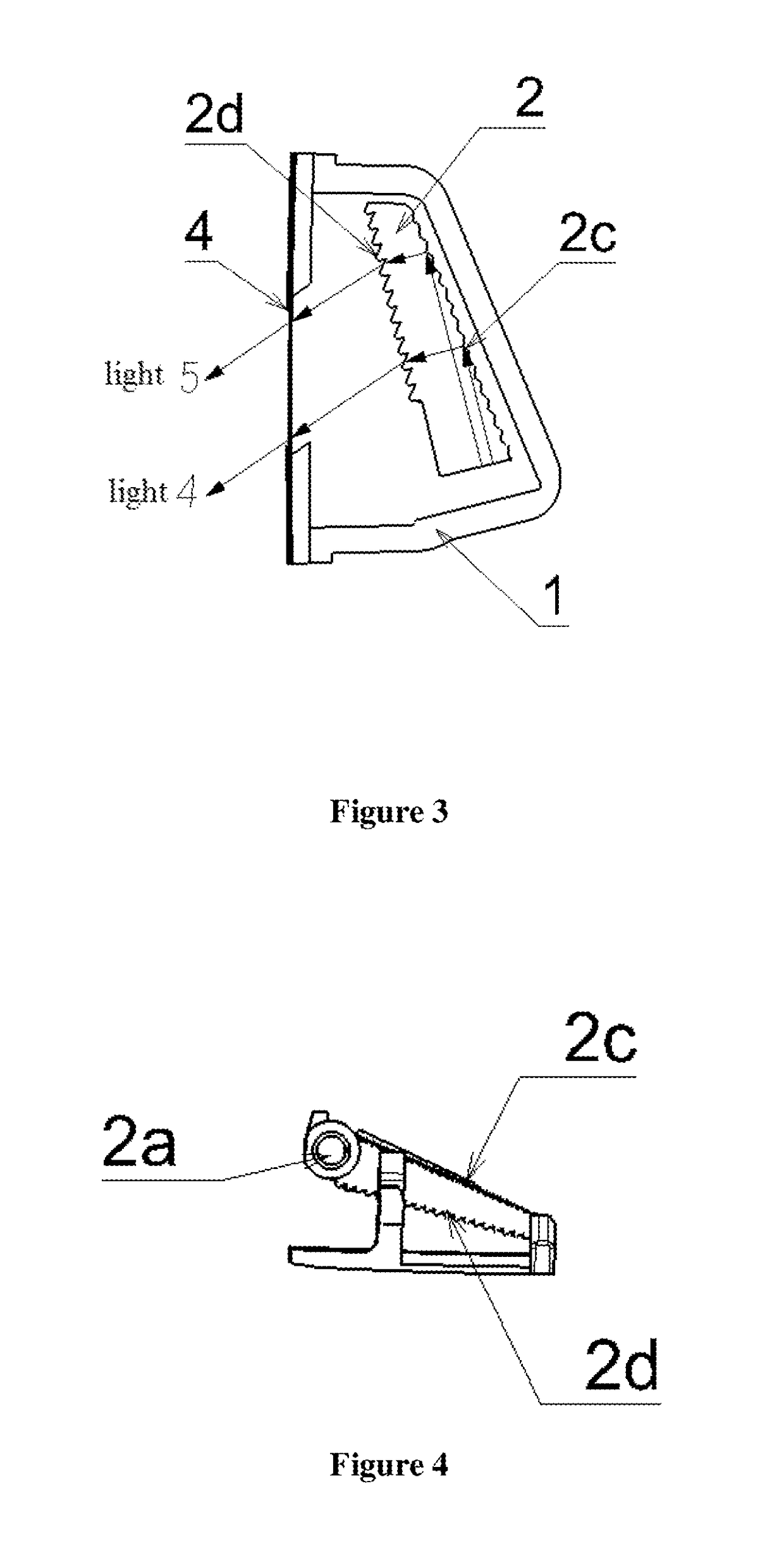

Illumination device having elliptical body and display device using the same

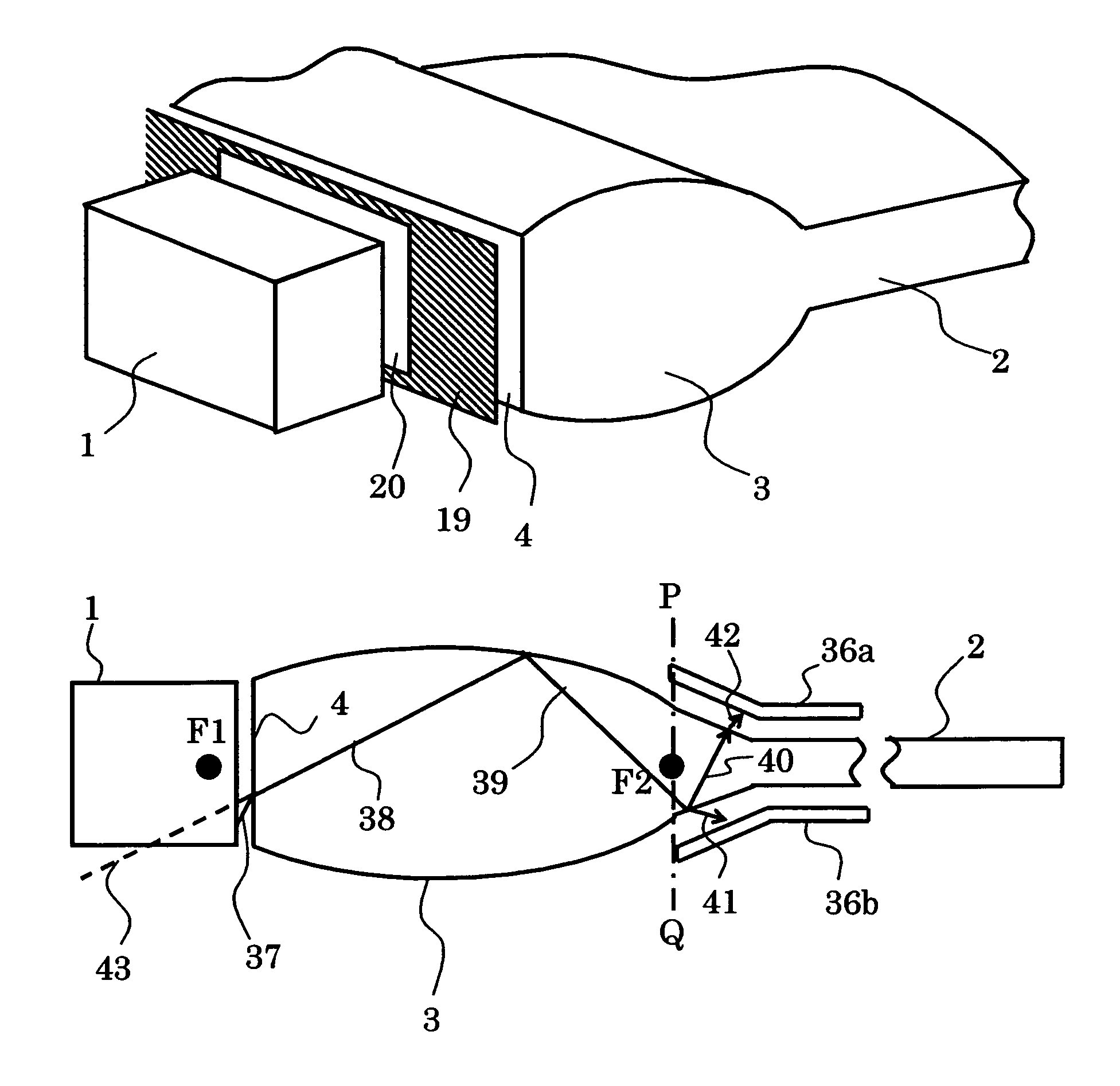

ActiveUS7484873B2Efficient disseminationEmission smoothPlanar/plate-like light guidesTelephone set constructionsLight guideDisplay device

An illumination device for emitting light includes a light incident body having a first end portion that has a light incident surface on which light from a light source is incident, a second end portion, and an outer oval-shaped surface portion interconnection the first and second end portions. A light guide plate is optically coupled to the second end portion of the light incident body and has a light emitting surface through which light that propagates through the light incident body is emitted. The light guide plate and the light incident body are integrally formed and may comprise a one-piece body. A display device utilizes the illumination device for illuminating a display element of the non-self light emitting type.

Owner:DAWNCREST IP LLC

Alternating current light-emitting device

ActiveUS20070080355A1Emission smoothElectroluminescent light sourcesSolid-state devicesFull scaleAlternating current

An alternating current light-emitting device and the fabrication method thereof is disclosed. The alternating current light-emitting device includes at least one alternating current micro-die light-emitting module formed on a substrate and composed of at least two micro-dies connected to one another. The micro-dies, each includes at least two active layers, are electrically connected by a conductive structure, such that the active layers of the micro-dies take turns emitting light during positive and negative half cycles of alternating current, thereby providing a full-scale light-emitting area for all-time light emission.

Owner:EPISTAR CORP

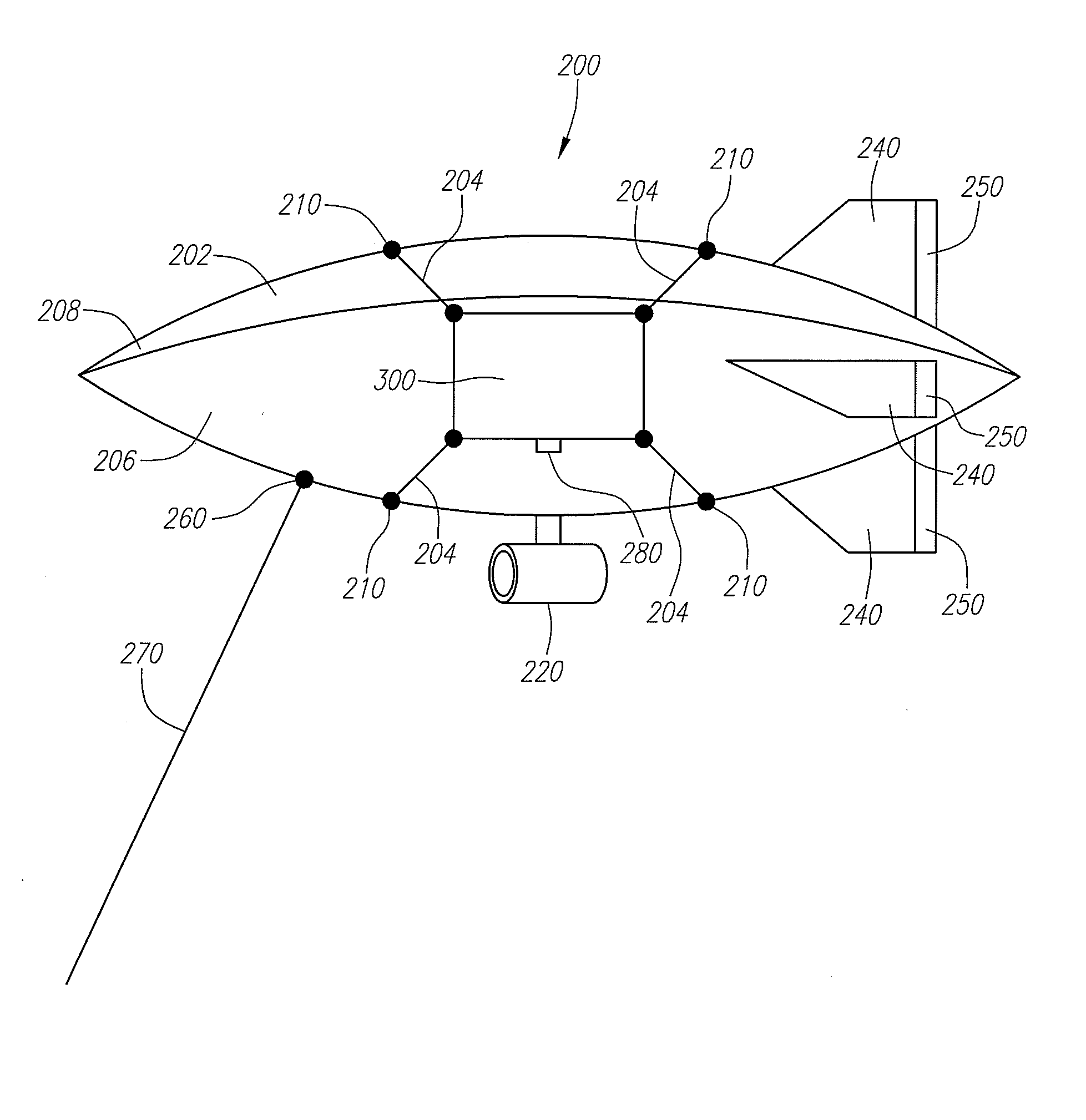

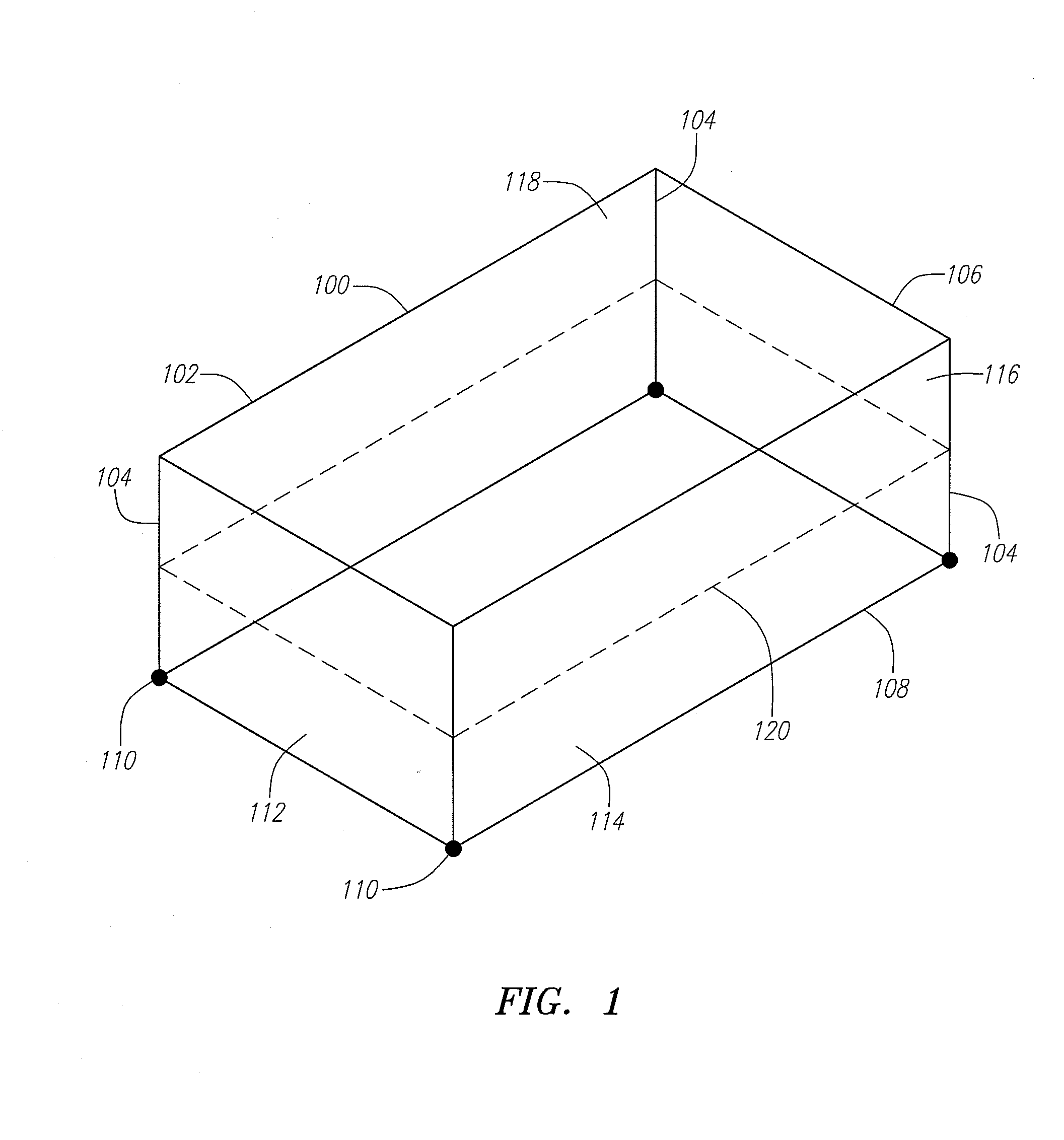

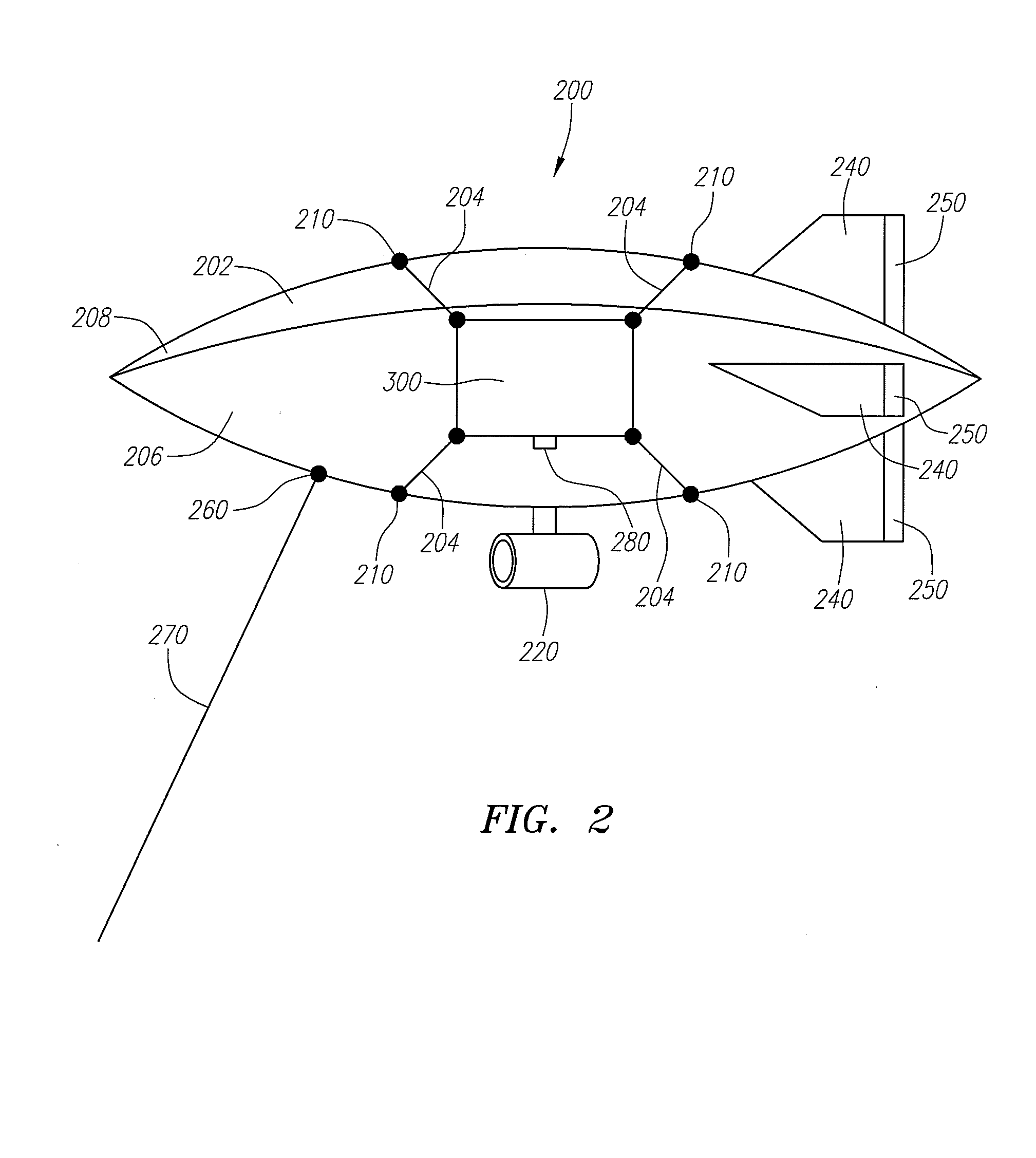

Helium-cooled leds in a floating illumination system

InactiveUS20100123040A1Operational securityMinimizing heatsink 's sizePlanar light sourcesLighting support devicesLed arrayFlexible circuits

A balloon-mounted light source includes an array of LEDs mounted on, and cooled by, a balloon structure filled with a lightweight gas such as helium. The LEDs are preferably mounted in long series arrangements with small gauge wire to minimize weight. They may be mounted on heatsinks that are dispersed in a mesh-like structure over the balloon. The LED circuitry may also be mounted on flexible circuit boards, which may be porous to reduce weight. The balloon may include an envelope compartment with a leak-resistant seal or zipper to allow the interior of the envelope to be accessed, and a pressure relief valve. The envelope of the balloon may be clear in the front in order to maximize the projection of light but reflective along the back and sides as to minimize spill. The balloon may take the form of a controllable dirigible.

Owner:BAXTER KEVIN C +2

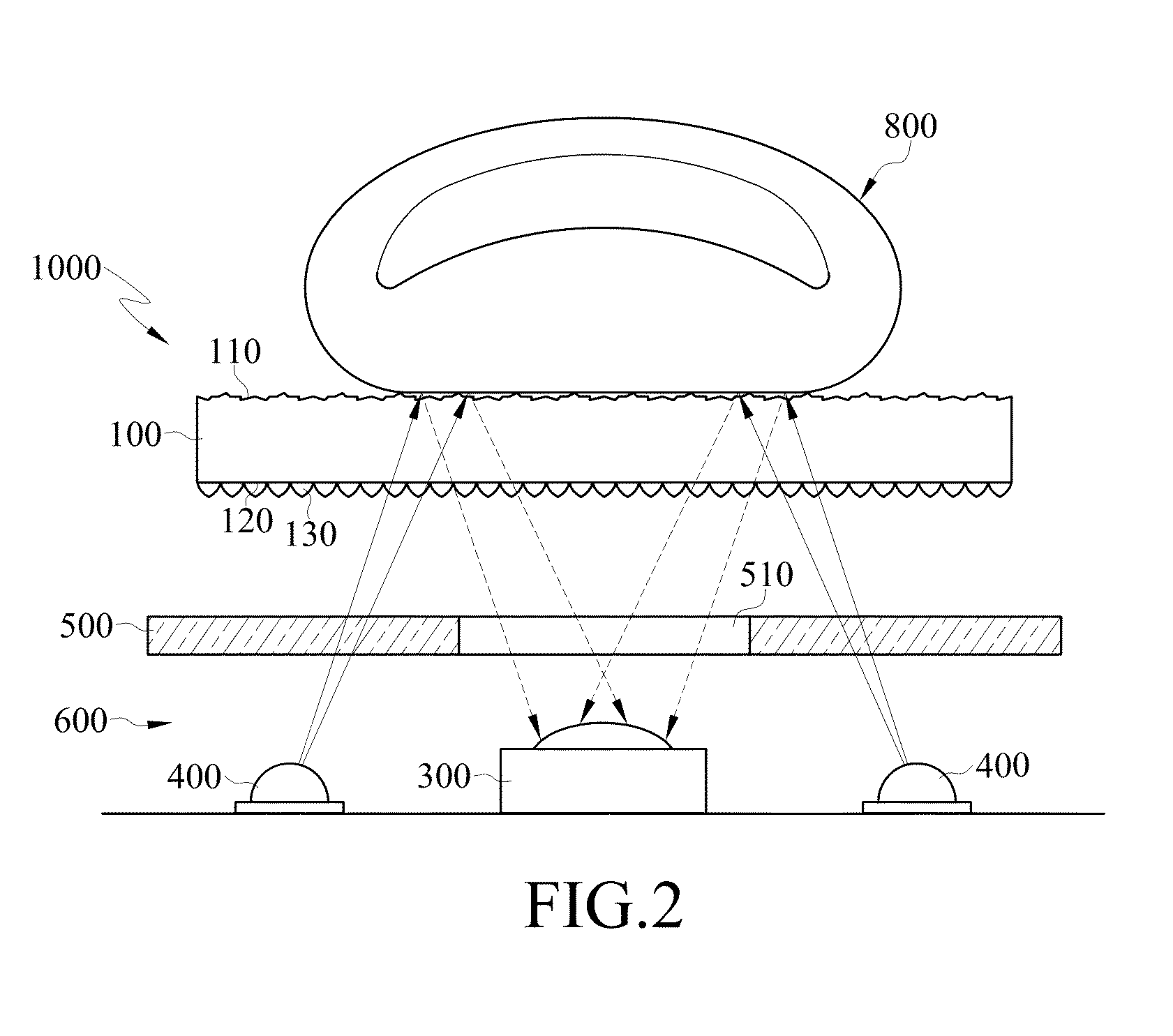

Substrate for fingerprint contact

ActiveUS8649001B2Difficult to recognizeEnhanced light scatteringAcquiring/reconising fingerprints/palmprintsFingerprintScattered light

Owner:GINGY TECH

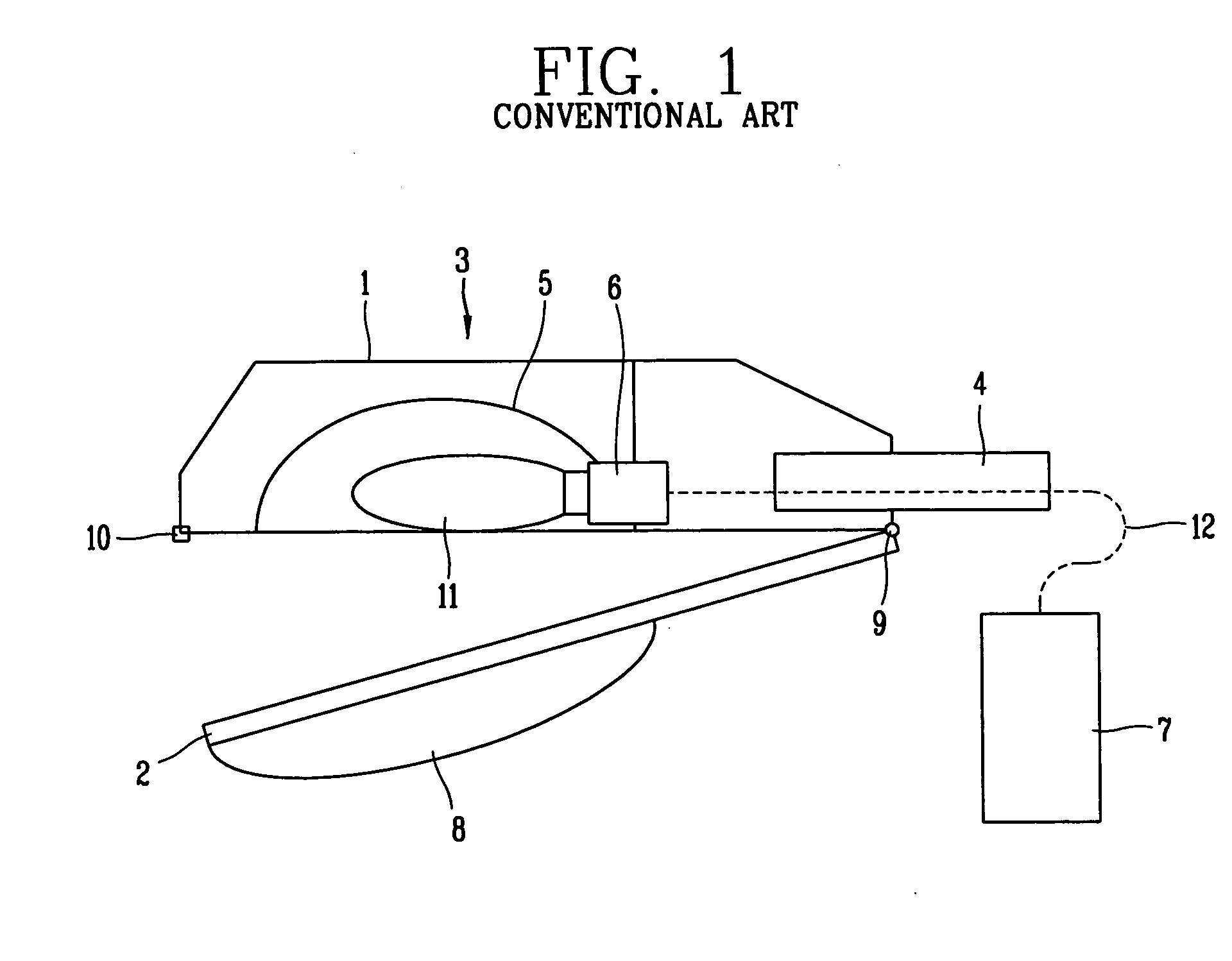

Electrodeless lighting system

InactiveUS20060087257A1Emission smoothNon-electric lightingMechanical apparatusMicrowaveEffect light

An electrodeless lighting system comprises: a first case in which a microwave generator, a waveguide for guiding microwave energy and a luminous part communicating with the waveguide, for emitting light by the microwave energy are installed, wherein one side of the first case is opened so that light from the luminous part is emitted to the outside; a second case coupled to the first case to open or close the opened one side of the first case and configured to pass the light from the luminous part; and a third case positioned at one outer side of the first case, in which a high voltage generator for supplying a high voltage to the microwave generator is installed. Accordingly, in the electrodeless lighting system, lateral lighting can be made like a streetlight, heat generating components and lighting components can be installed at separated spaces, respectively, and the generated heat can be smoothly emitted to the outside.

Owner:LG ELECTRONICS INC

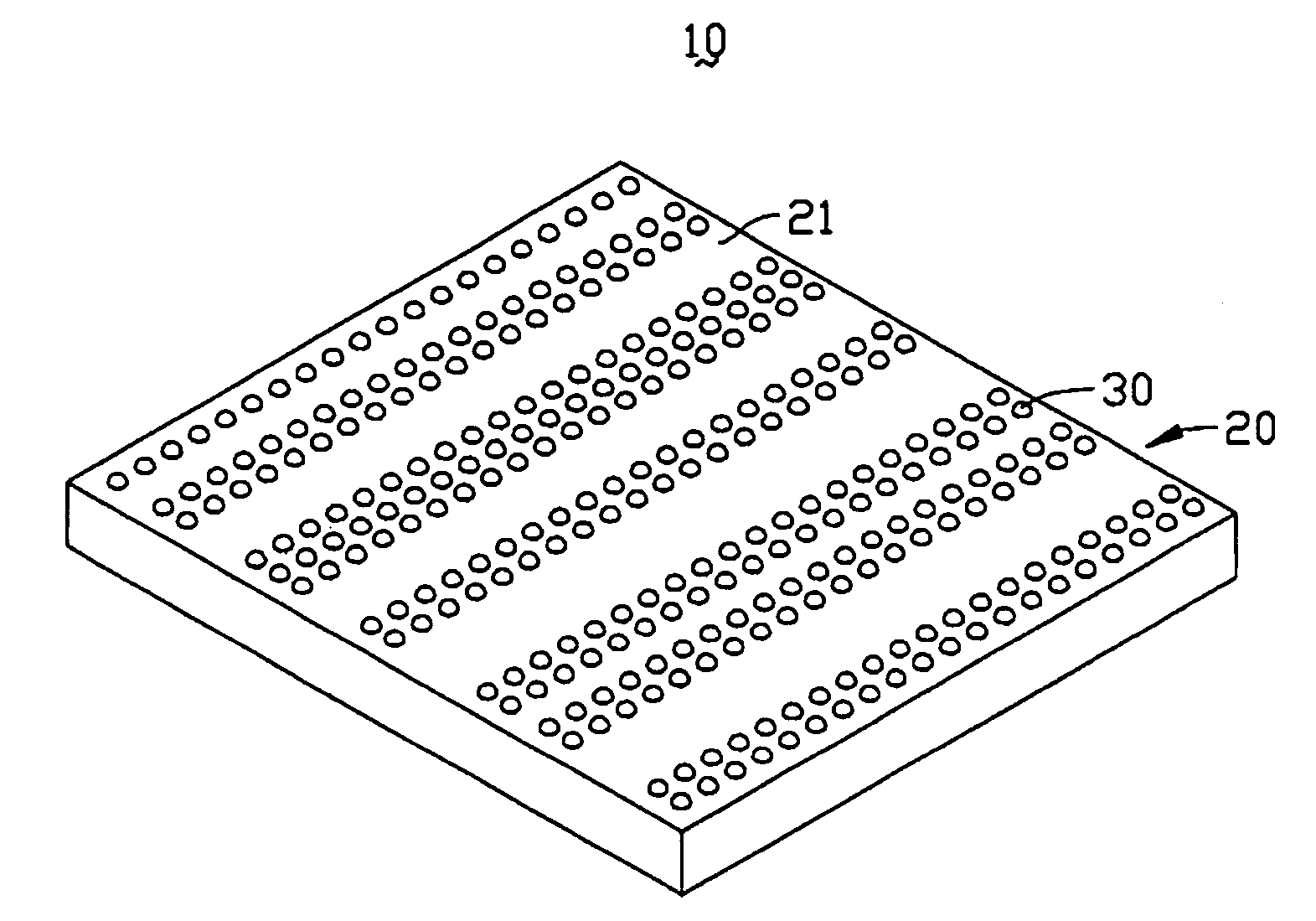

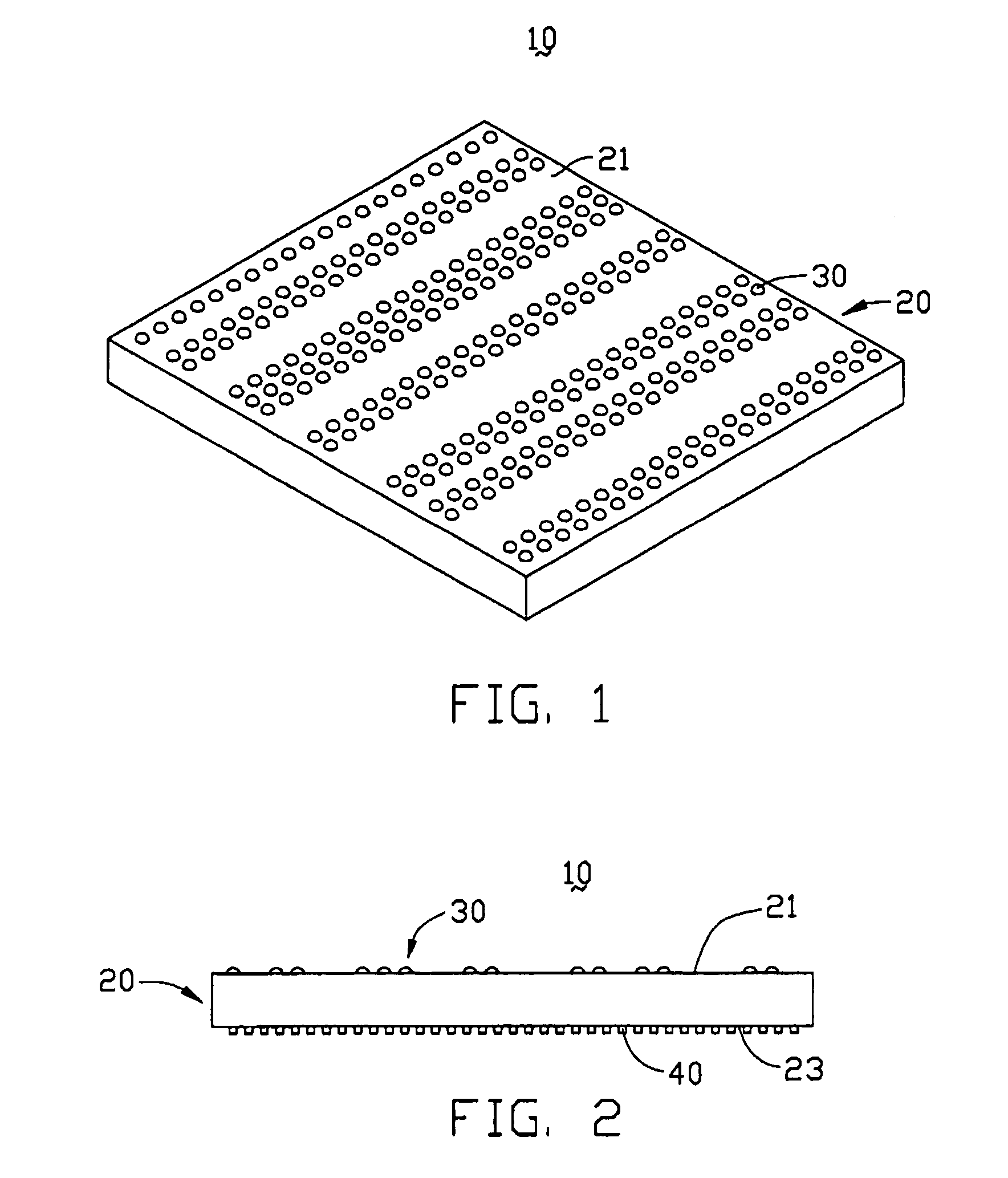

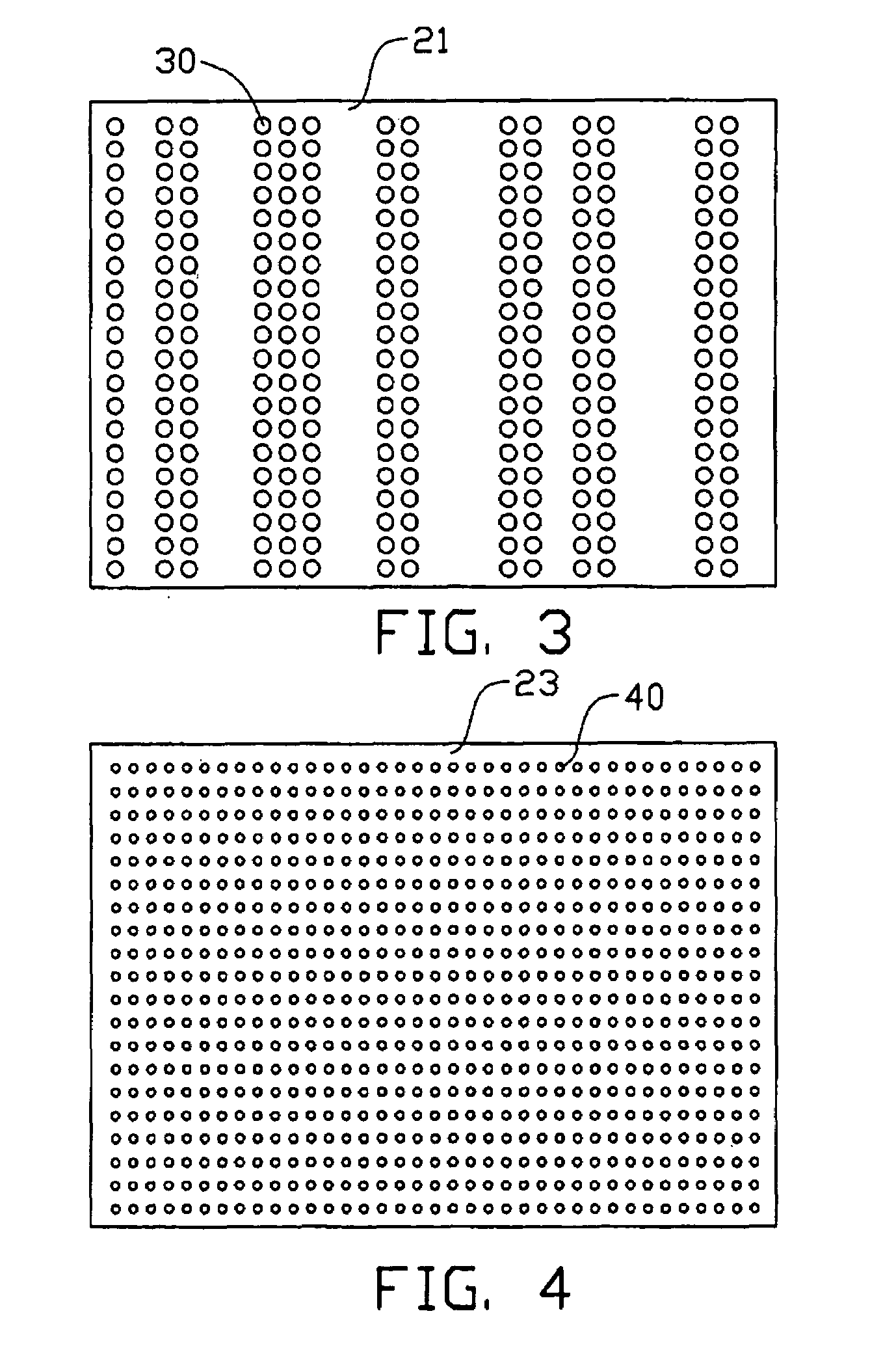

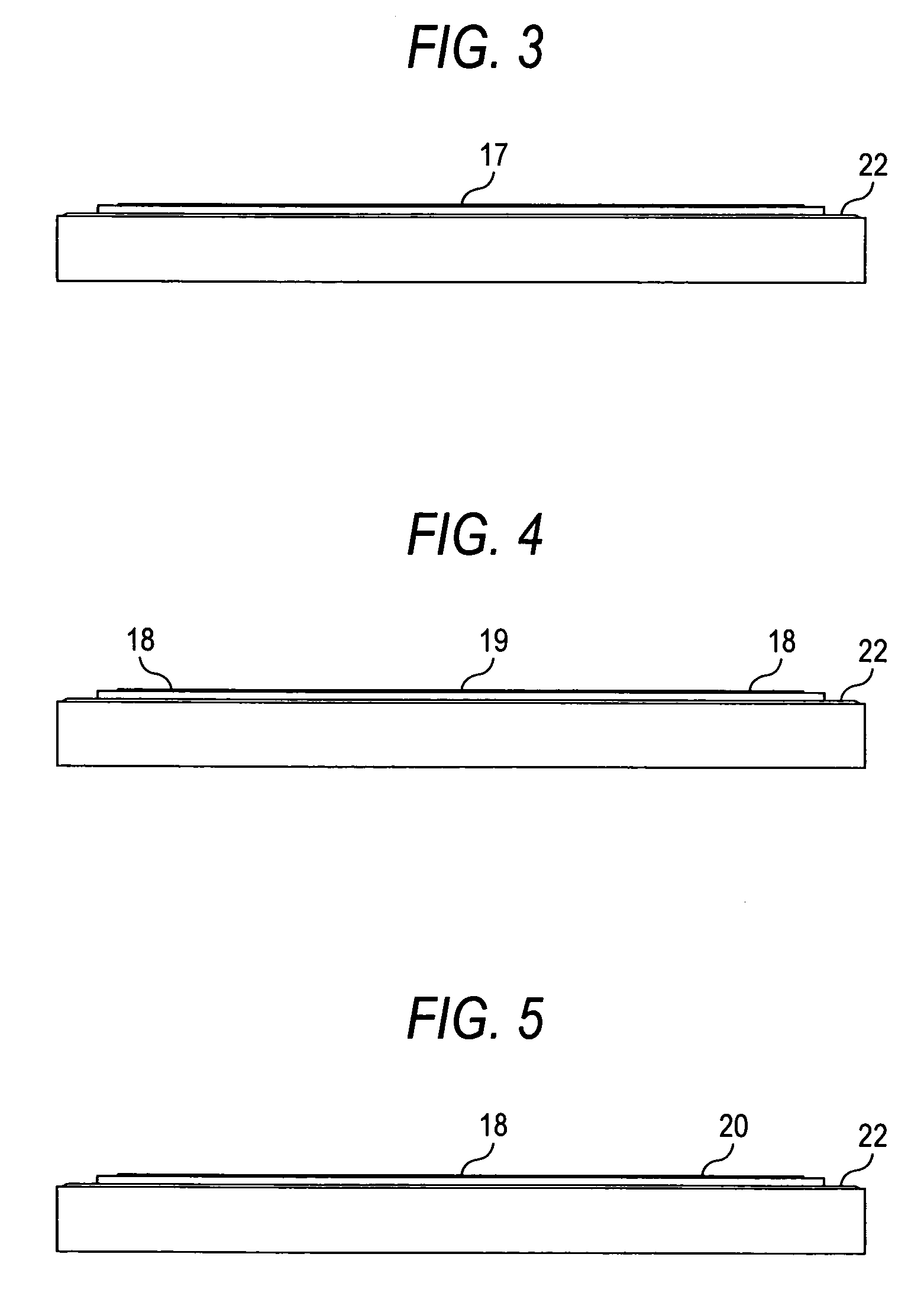

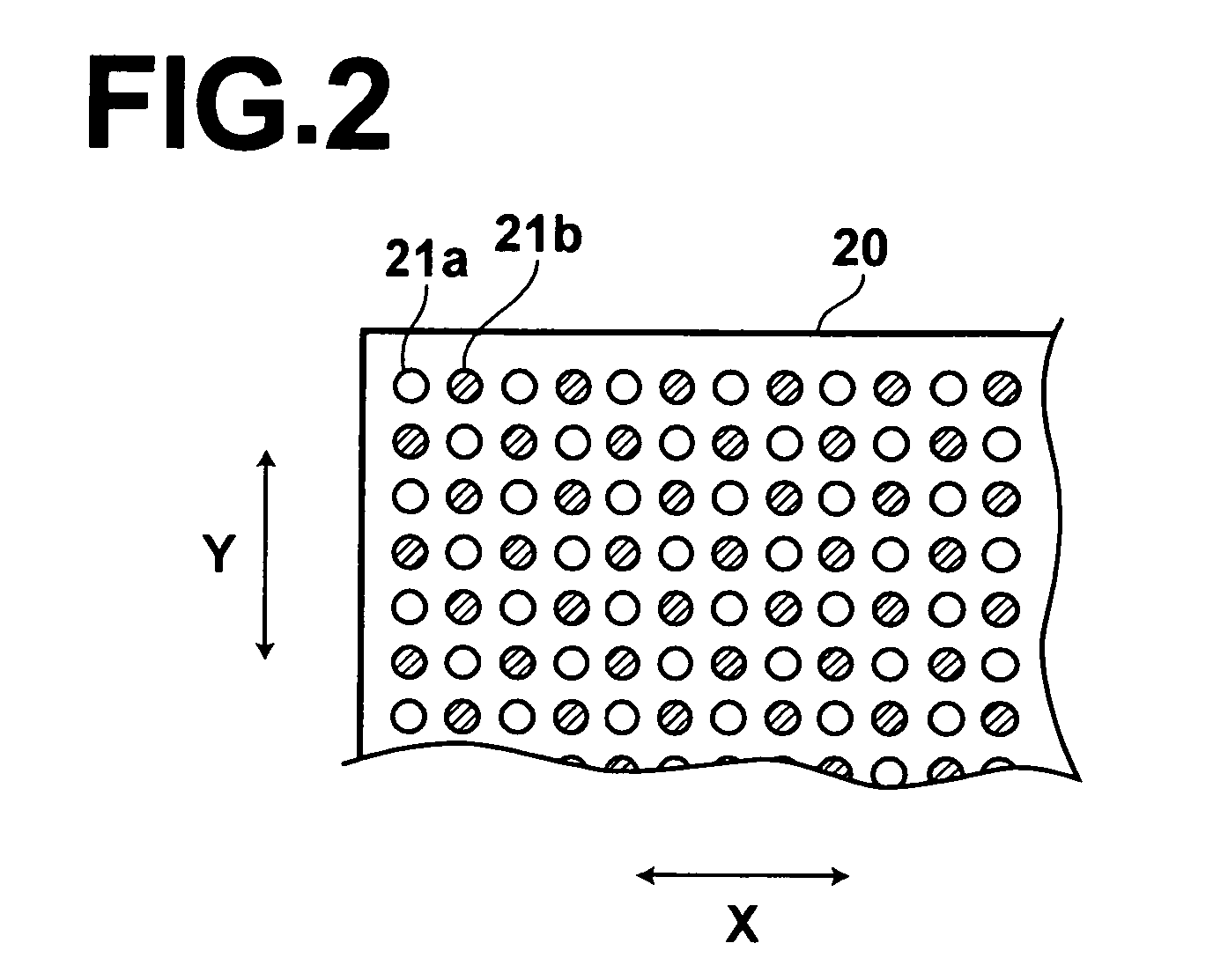

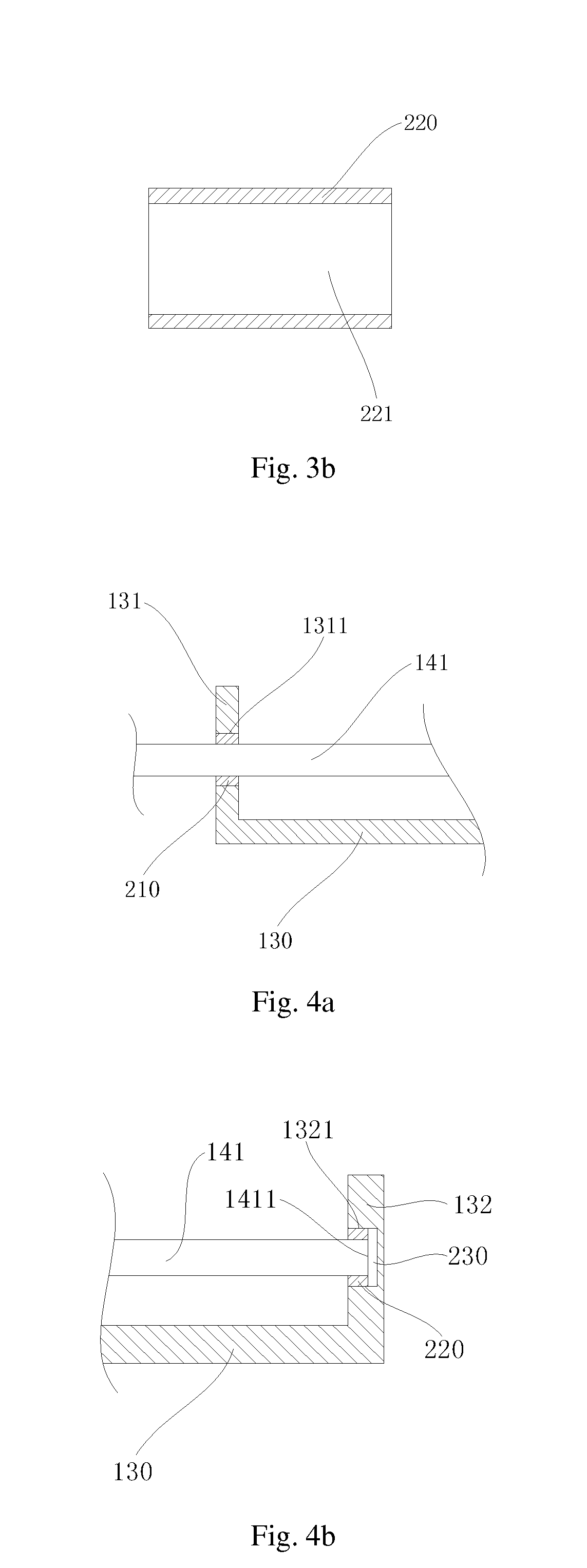

Light guide plate with diffusing protrusions

InactiveUS7014343B2Excellent light diffusionReduce brightness unevennessMechanical apparatusLight guides for lighting systemsLight guideLight beam

A light guide plate (10) includes a transparent plate (20), and a plurality of diffusing protrusions (30). The transparent plate includes an emitting surface (21), and a bottom surface (23) opposite to the emitting surface. The diffusing protrusions are distributed evenly on the emitting surface of the transparent plate, and are integrated with the transparent plate. The diffusing protrusions are hemispherical or sub-hemispherical, and a diameter of each diffusing protrusion is in the range from 10 μm˜50 μm. The light guide plate provides high emitting brightness and uniformity. The diffusing protrusions can diffuse light beams emitting from the emitting surface of the transparent plate, in order to achieve a plane light source having even brightness. The present Invention also discloses a method for fabricating the light guide plate.

Owner:HON HAI PRECISION IND CO LTD

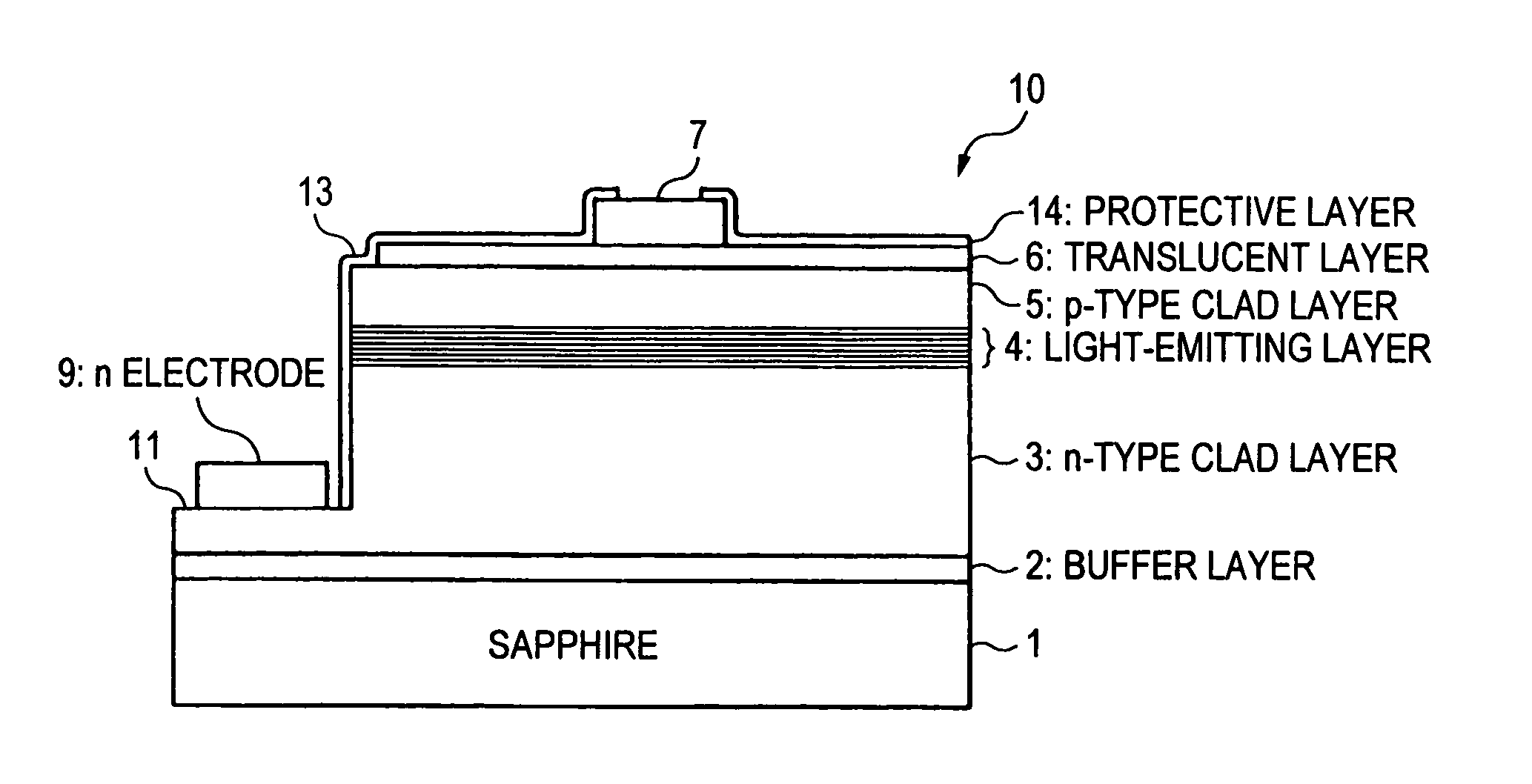

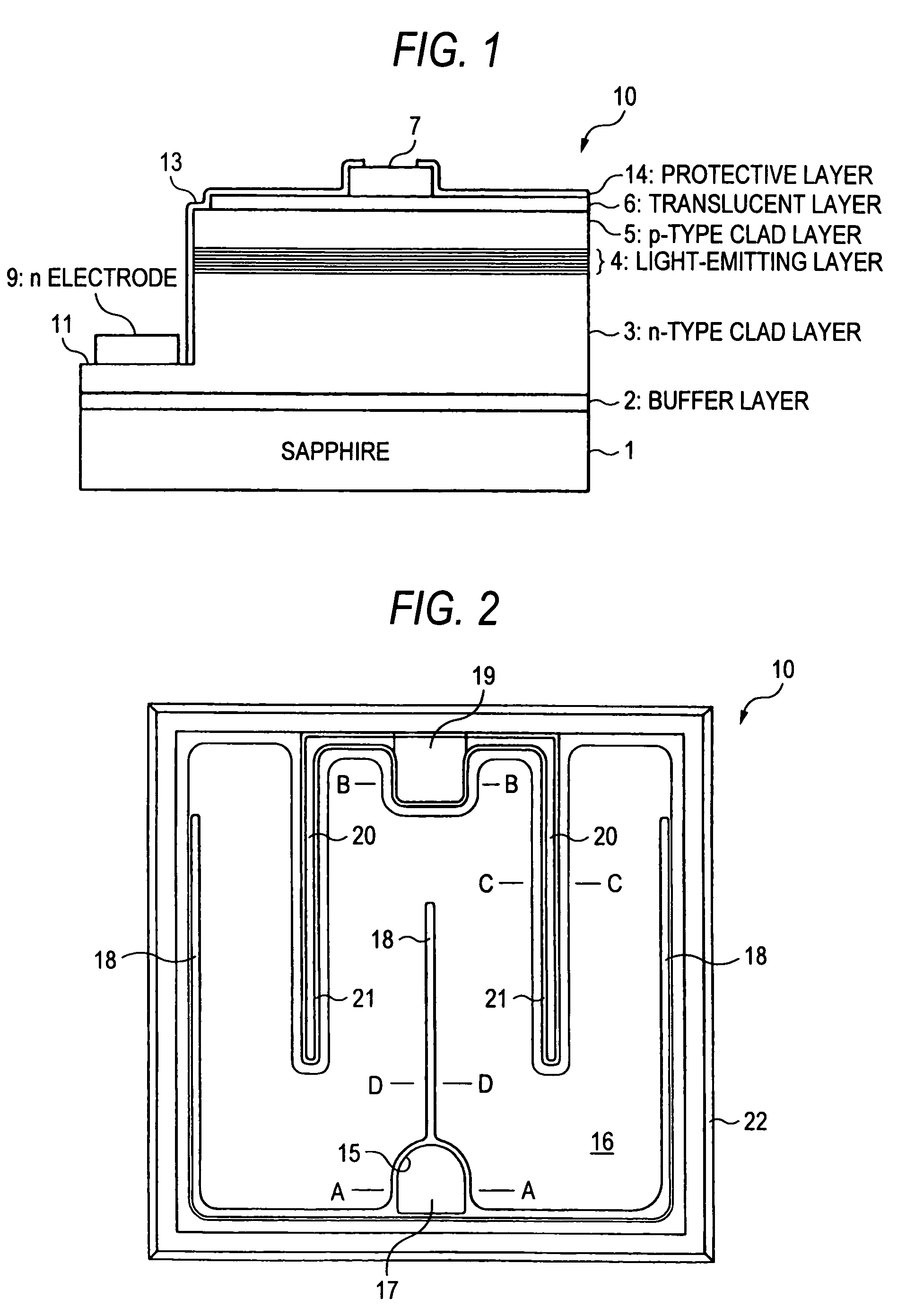

Group III nitride compound semiconductor device

InactiveUS7042089B2Prevent occurrenceSufficient currentSemiconductor/solid-state device detailsSolid-state devicesLight emissionCompound semiconductor

An object of the present invention is to provide a large-size light-emitting device from which uniform light emission can be obtained.That is, in the present invention, in a device having an outermost diameter of not smaller than 700 μm, a distance from an n electrode to a farthest point of a p electrode is selected to be not larger than 500 μm.

Owner:TOYODA GOSEI CO LTD

Light emitter

InactiveUS7897989B2Improve light output efficiencyIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingEffect lightEngineering

The invention relates to a light emitter, such as an LED sealed with a resin, in particular, an LED wherein irregularities in a surface of a sealing resin can be formed through a simpler process in order to improve the light output efficiency of the LED. The LED is an LED wherein a liquid sealing resin is mixed with a solid transparent resin different from the sealing resin in specific gravity and subsequently the mixture is injected into a package into which an LED chip is integrated and then cured, thereby sealing the chip, characterized in that the solid transparent resin is fixed to the sealing resin to be partially naked to the sealing-resin-side surface of the LED through which light from the LED chip is emitted to the outside, and be partially embedded in the sealing resin, thereby being projected into the form of convexes. This LED is used for an LED displayer, an LCD backlight source, a lighting device or the like.

Owner:E E JAPAN

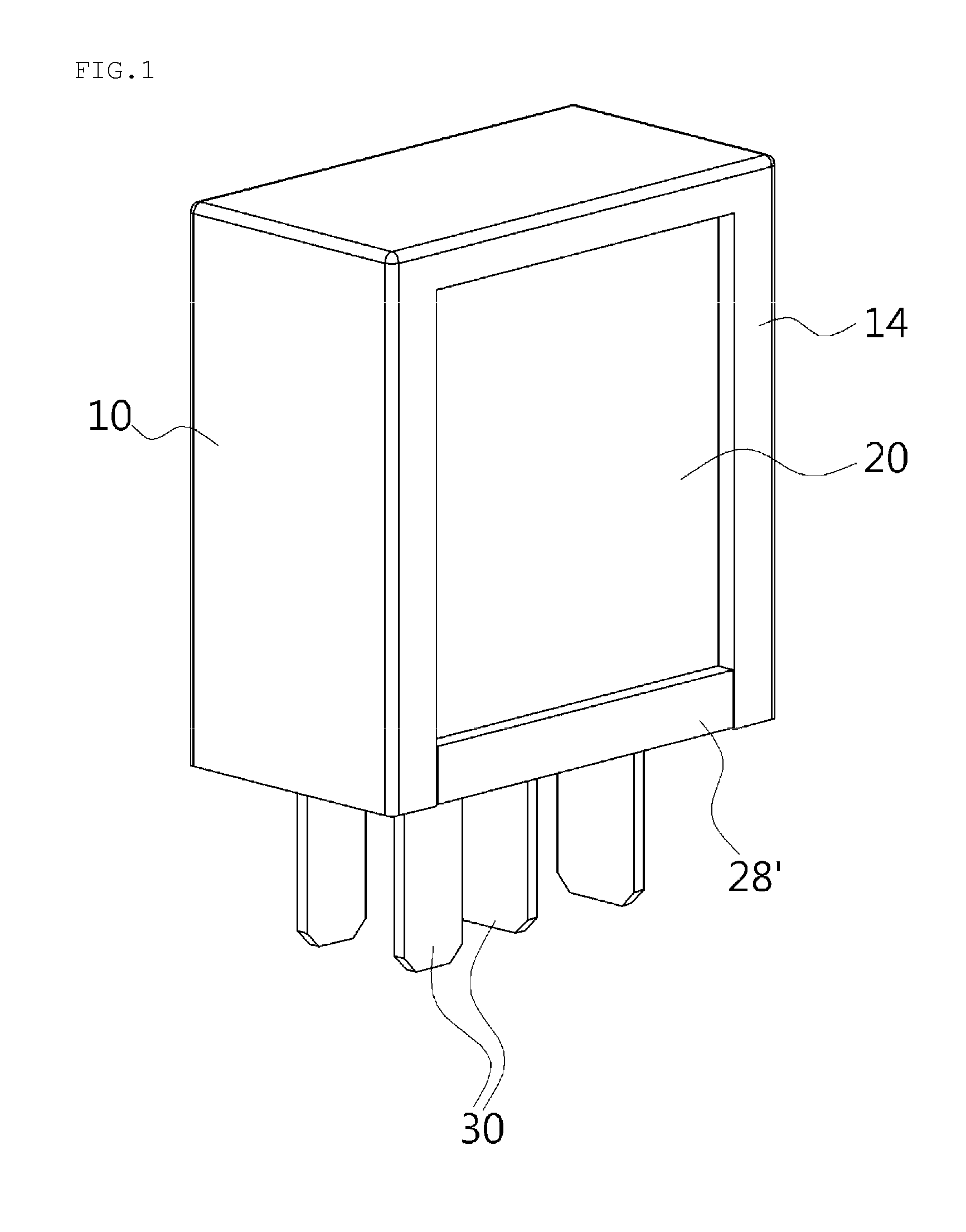

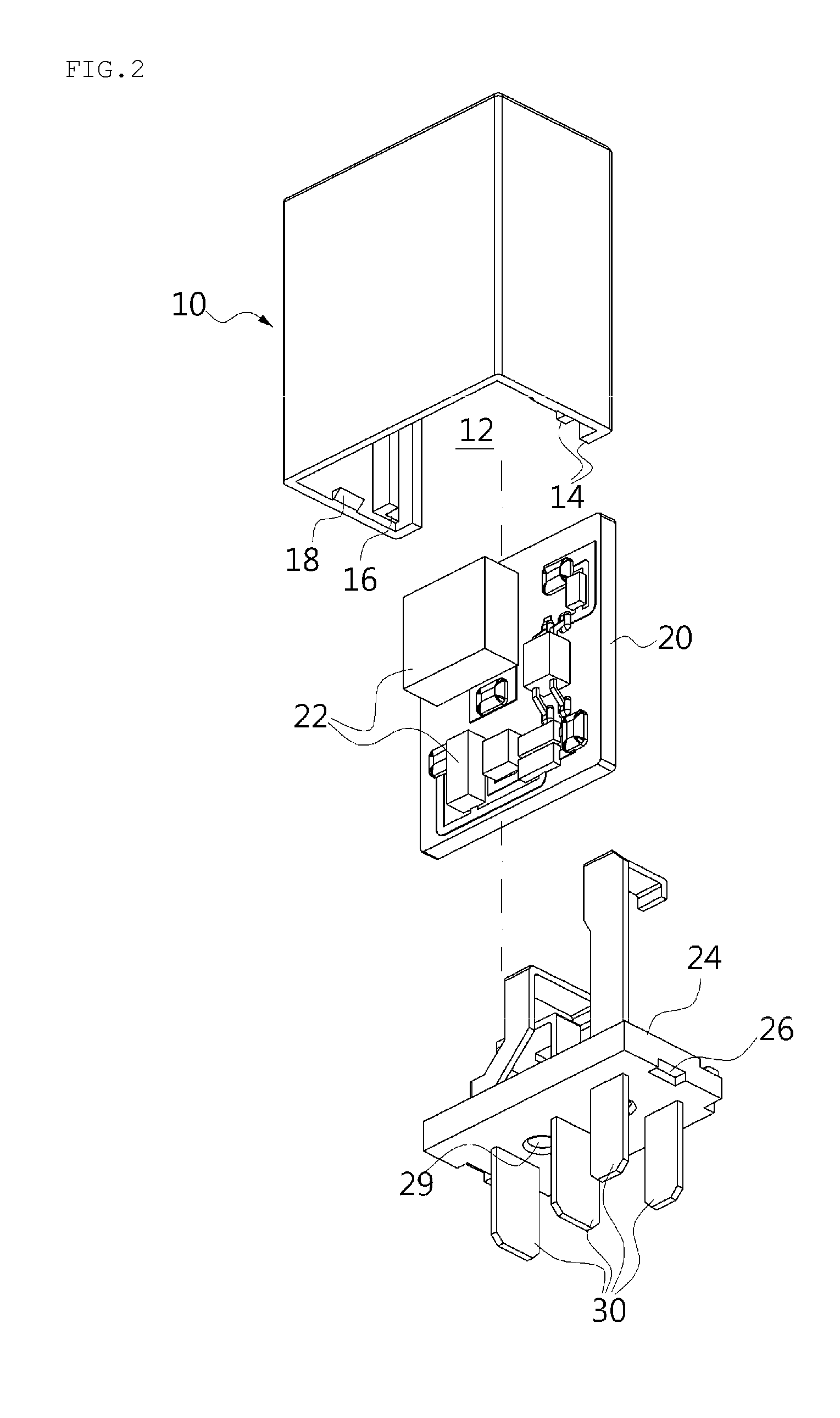

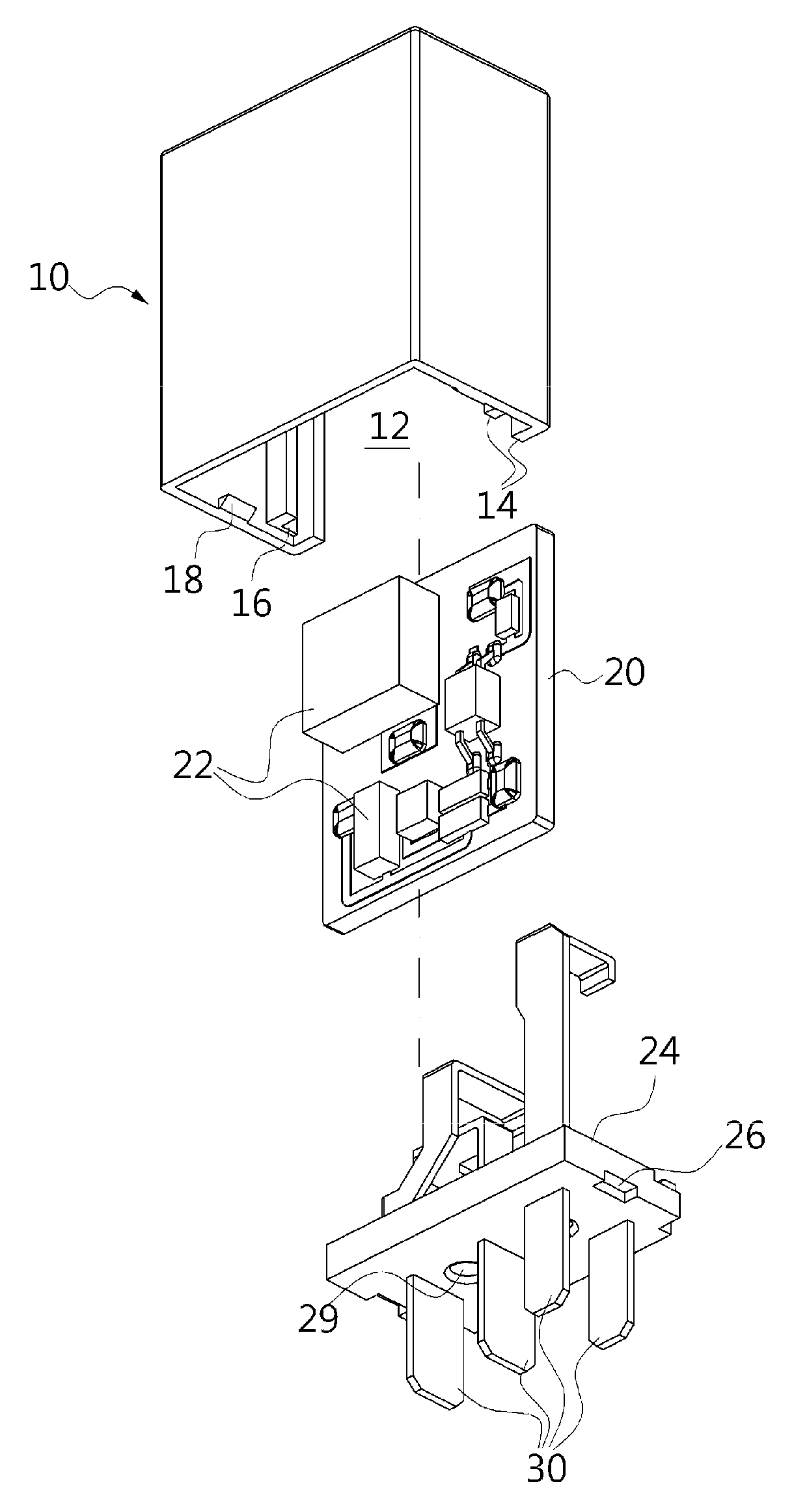

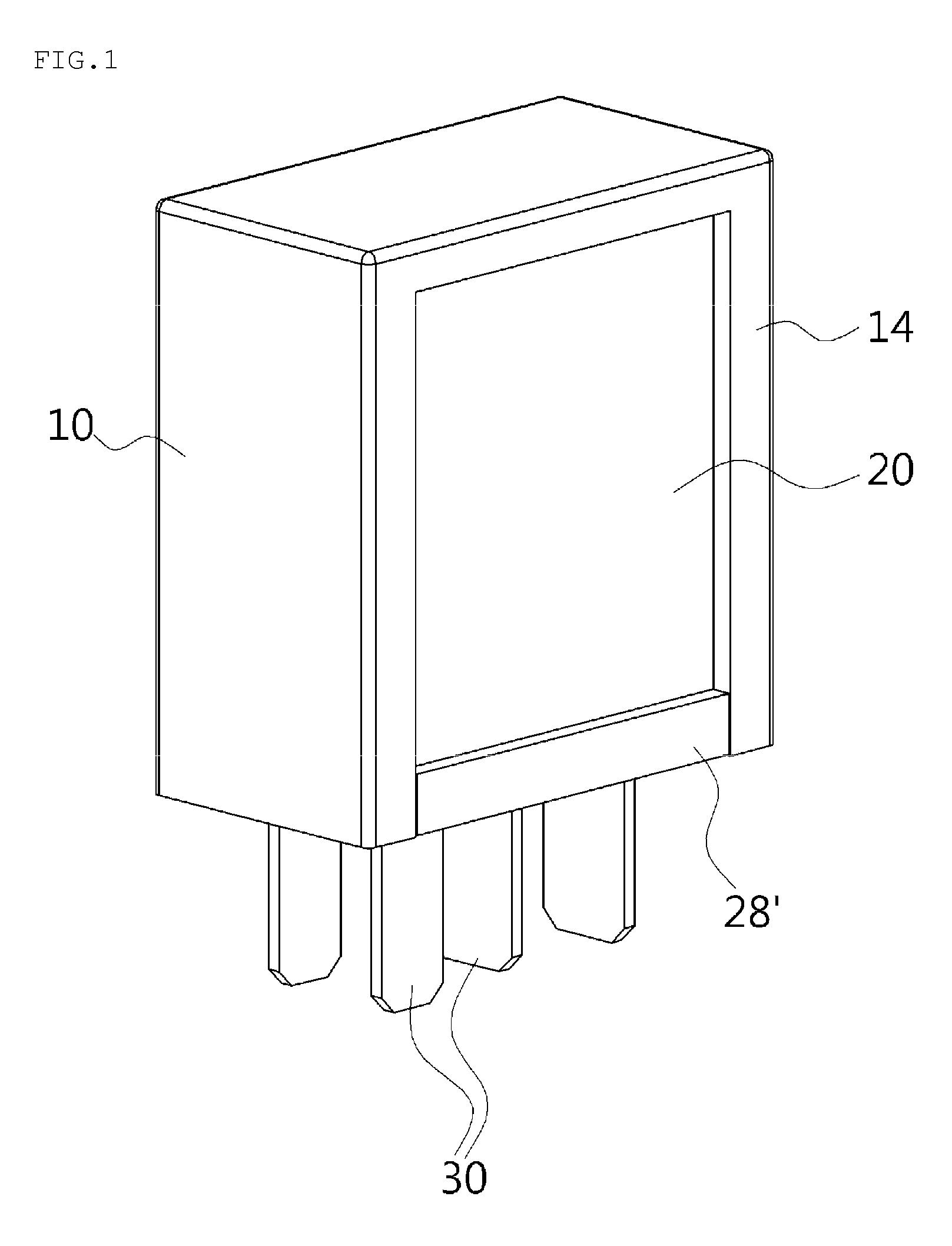

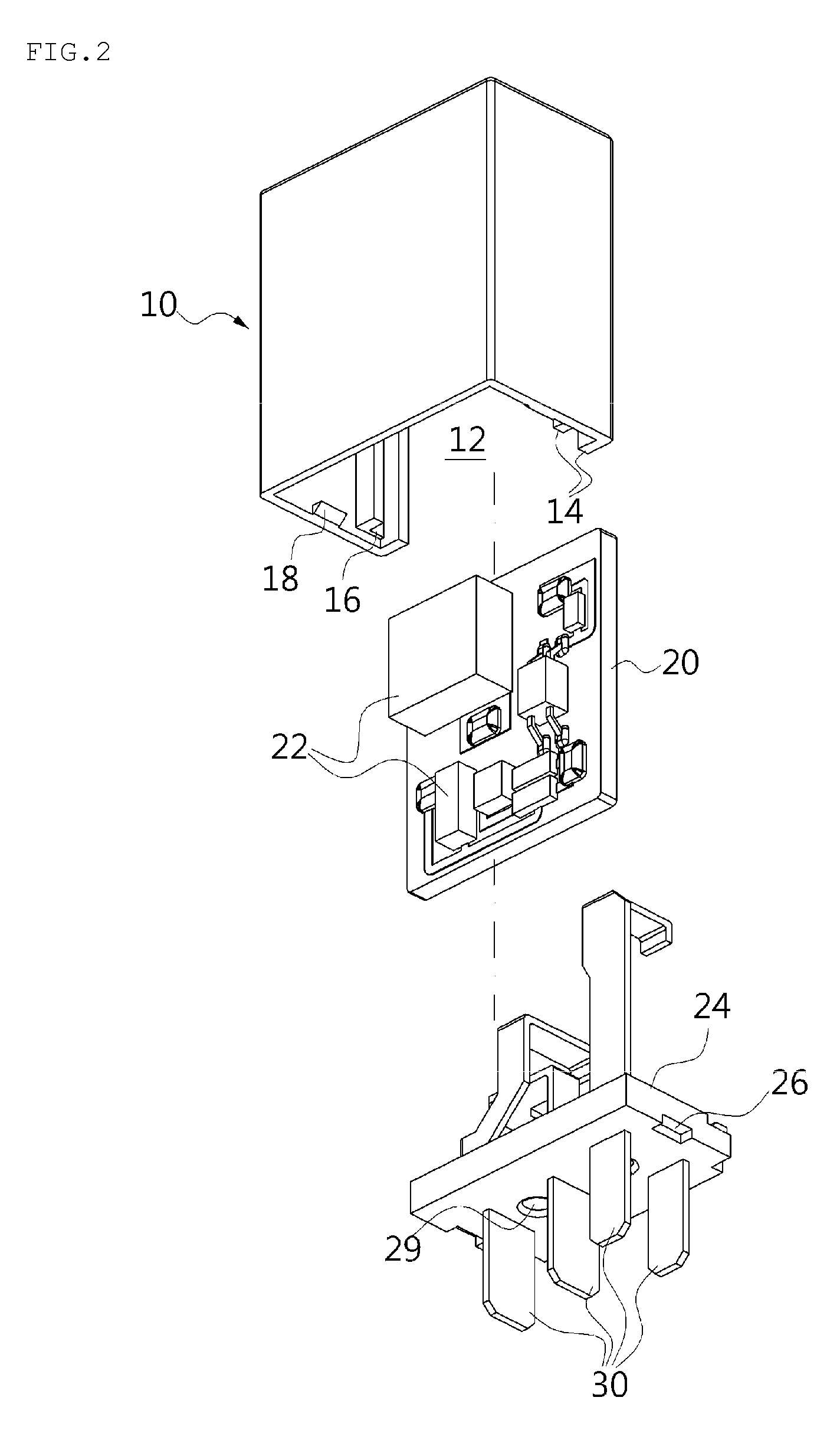

Electronic relay

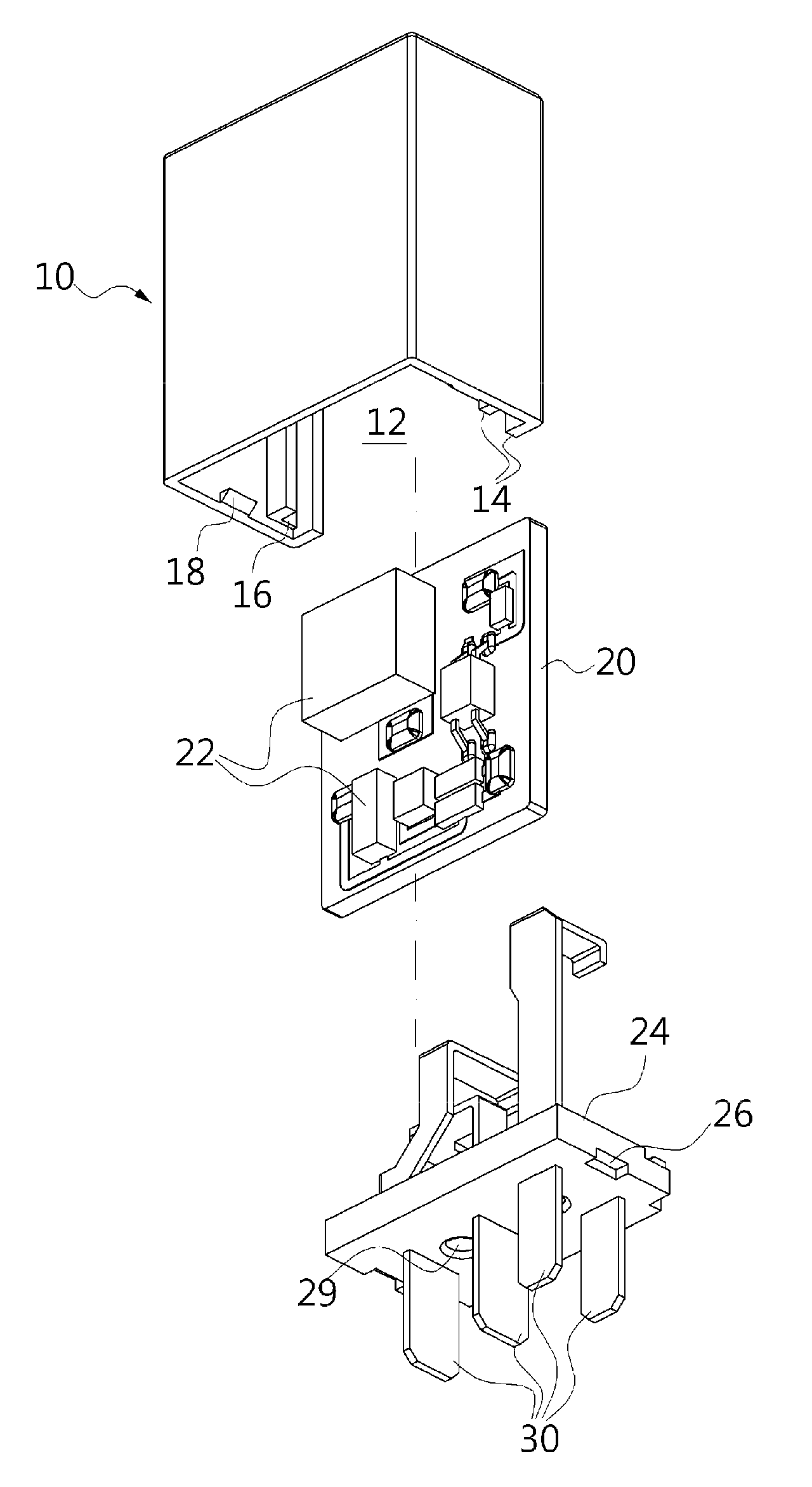

ActiveUS20130141831A1Improve Noise PerformanceEmitted heatElectric switchesElectromagnetic relay detailsInterior spaceElectricity

An electronic relay includes: a housing having an interior space therein and a lateral side and a lower side of which are opened, a board installation part being formed along a periphery of the opened side of the housing; a printed circuit board a periphery of which is inserted into and installed in the board installation part of the housing, for shielding the opened side of the housing and performing a switching function; a lower cover for shielding a lower side of the housing, one side edge of the printed circuit board being fixed to the lower cover; and terminals ends of which are electrically connected to the printed circuit board and opposite ends of which pass through the lower cover to protrude to the outside.

Owner:KOREA ELECTRIC TERMINAL

Radiation image detection method and system

InactiveUS7420197B2Improve image qualityLow costX-ray/infra-red processesRadiation/particle handlingLatent imagePhosphor

A radiation image detector includes an up-conversion phosphor layer for emitting fluorescence by irradiation with infrared light, a first electrode layer for transmitting the infrared light, the fluorescence and radiation carrying a radiation image, a photoconductive layer for recording, a charge storage portion, a photoconductive layer for readout, and a second electrode layer for transmitting the infrared light and the readout light. Radiation is recorded as latent image charge in the charge storage portion. The electric charge is read out from the charge storage portion by irradiating the photoconductive layer for readout with the readout light from the second electrode layer side. The up-conversion phosphor layer is irradiated with the infrared light from the second electrode layer side and remaining charge in the vicinity of the first electrode layer is erased by fluorescence emitted from the up-conversion phosphor layer by irradiation with the infrared light.

Owner:FUJIFILM CORP +1

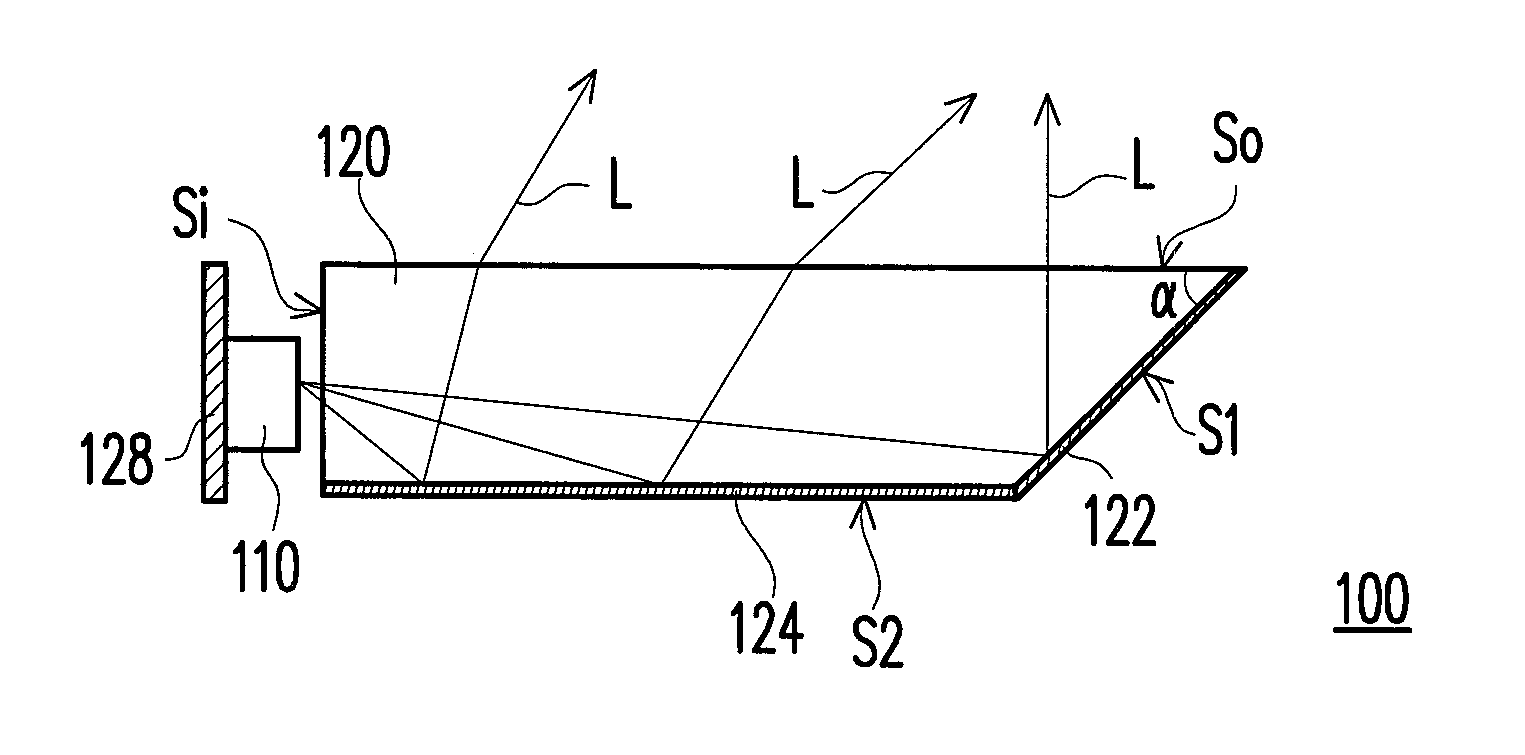

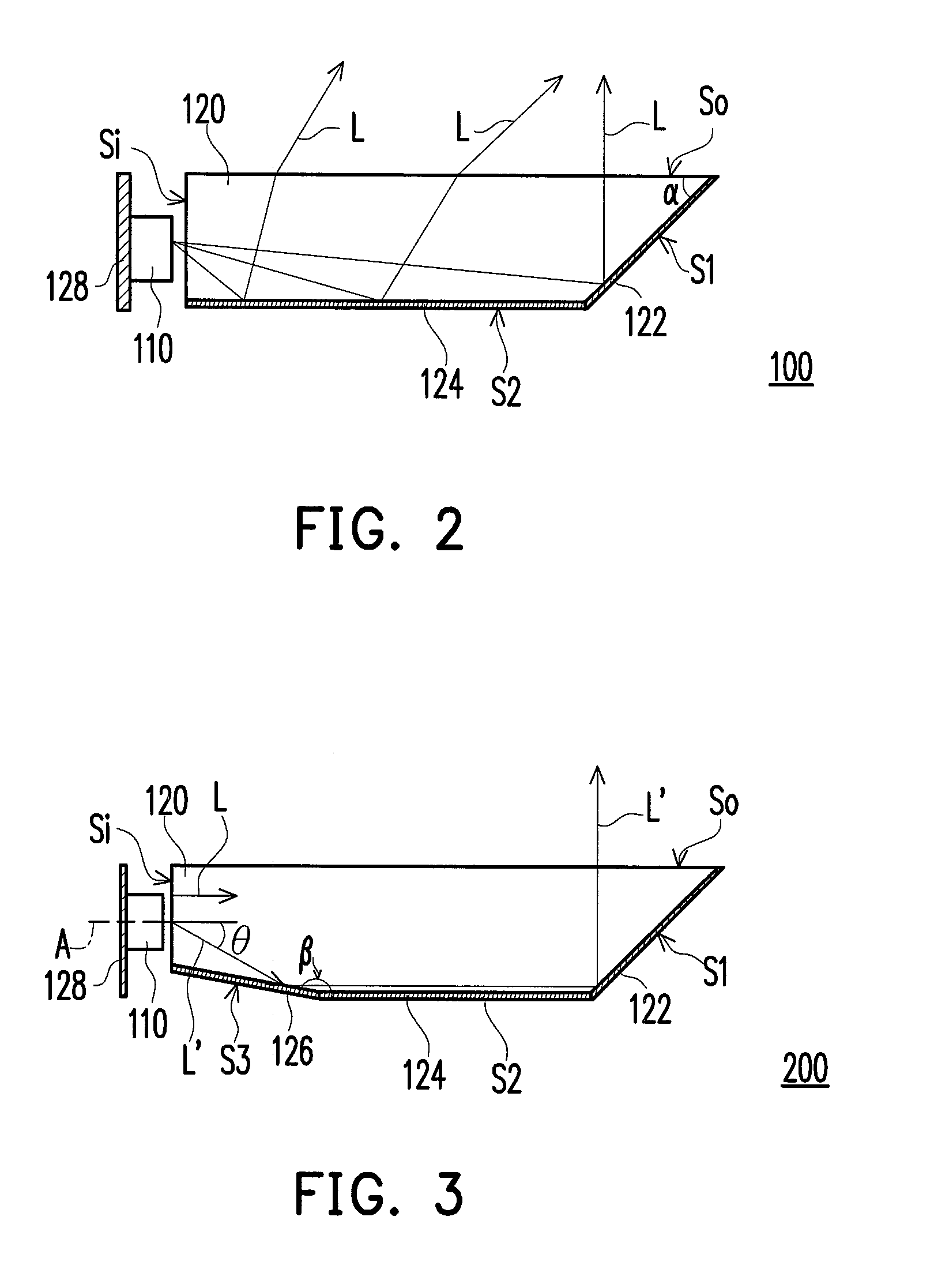

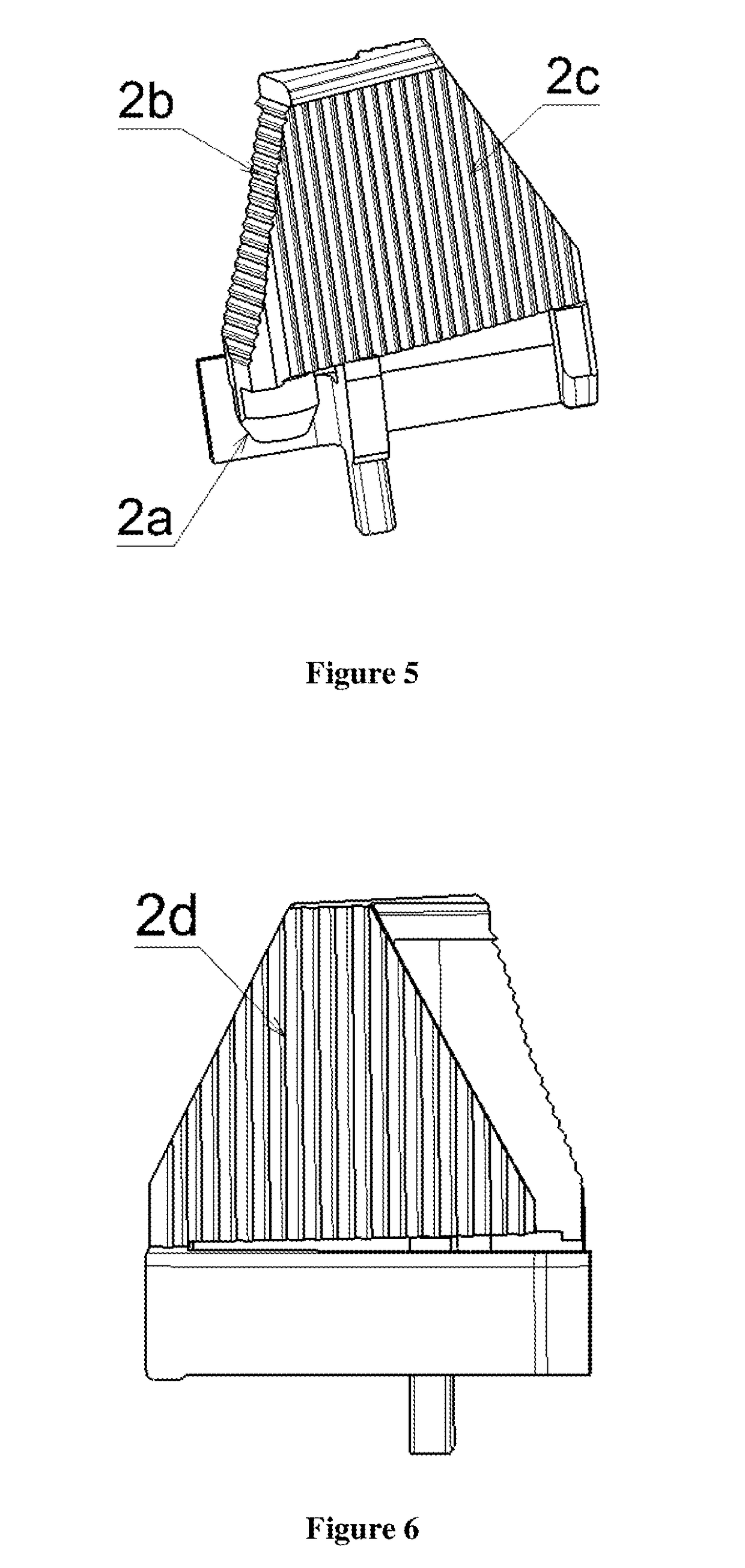

Light source module

InactiveUS20140029305A1Light utilization efficiency can be improvedImprove uniformity of light emissionMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

A light source module including a light emitting element and a light guiding element is provided. The light guiding element has a light incident surface, a light emitting surface, a first surface, a second surface, a first reflective layer, and a second reflective layer. The light emitting element faces to the light incident surface. The light incident surface is connected to the light emitting surface. The first surface is connected to the light emitting surface and opposite to the light incident surface. The first surface is non-parallel to the light incident surface. The second surface is connected to the first surface and opposite to the light emitting surface. The first reflective layer is disposed on the first surface. The second reflective layer is disposed on the second surface.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

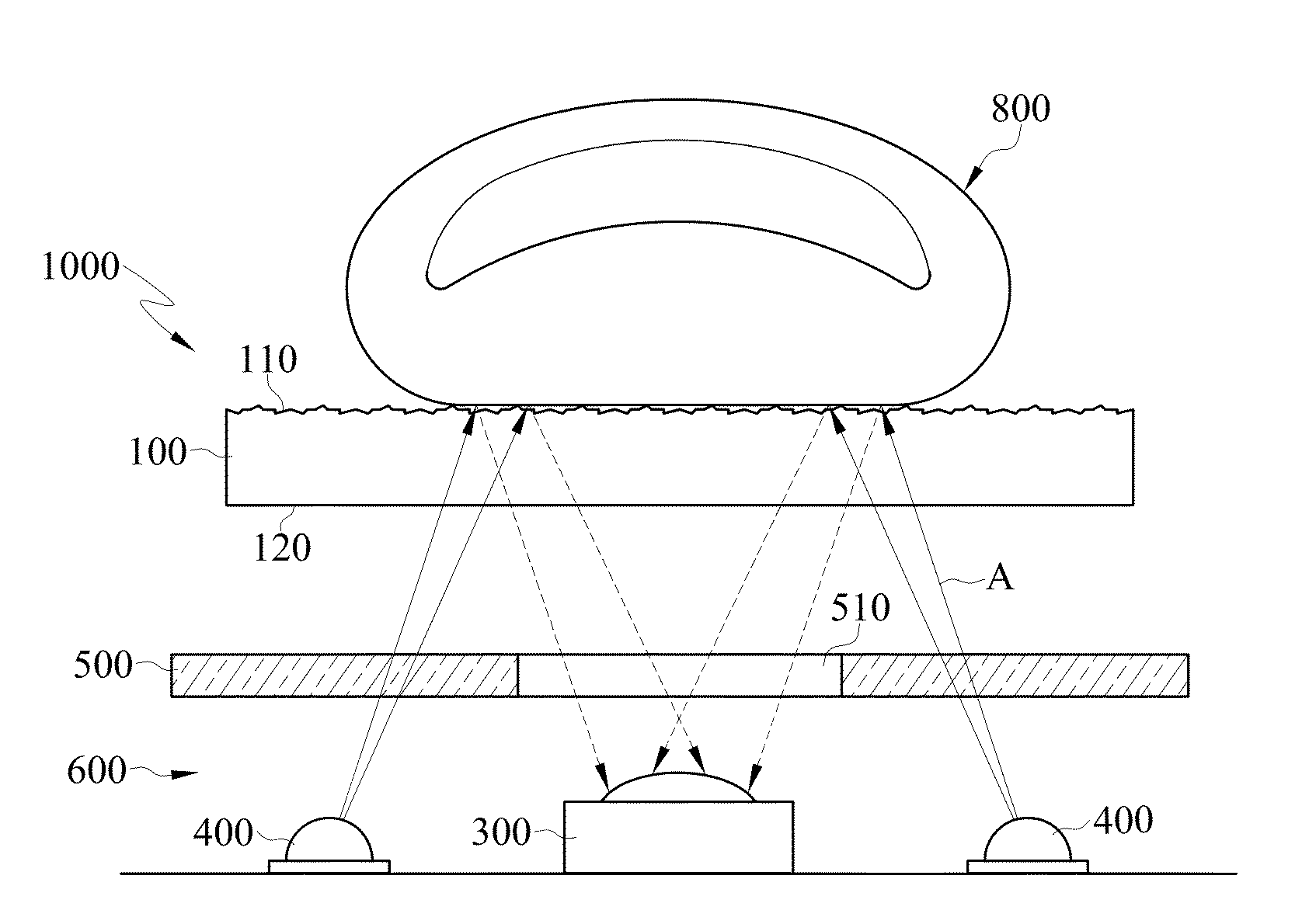

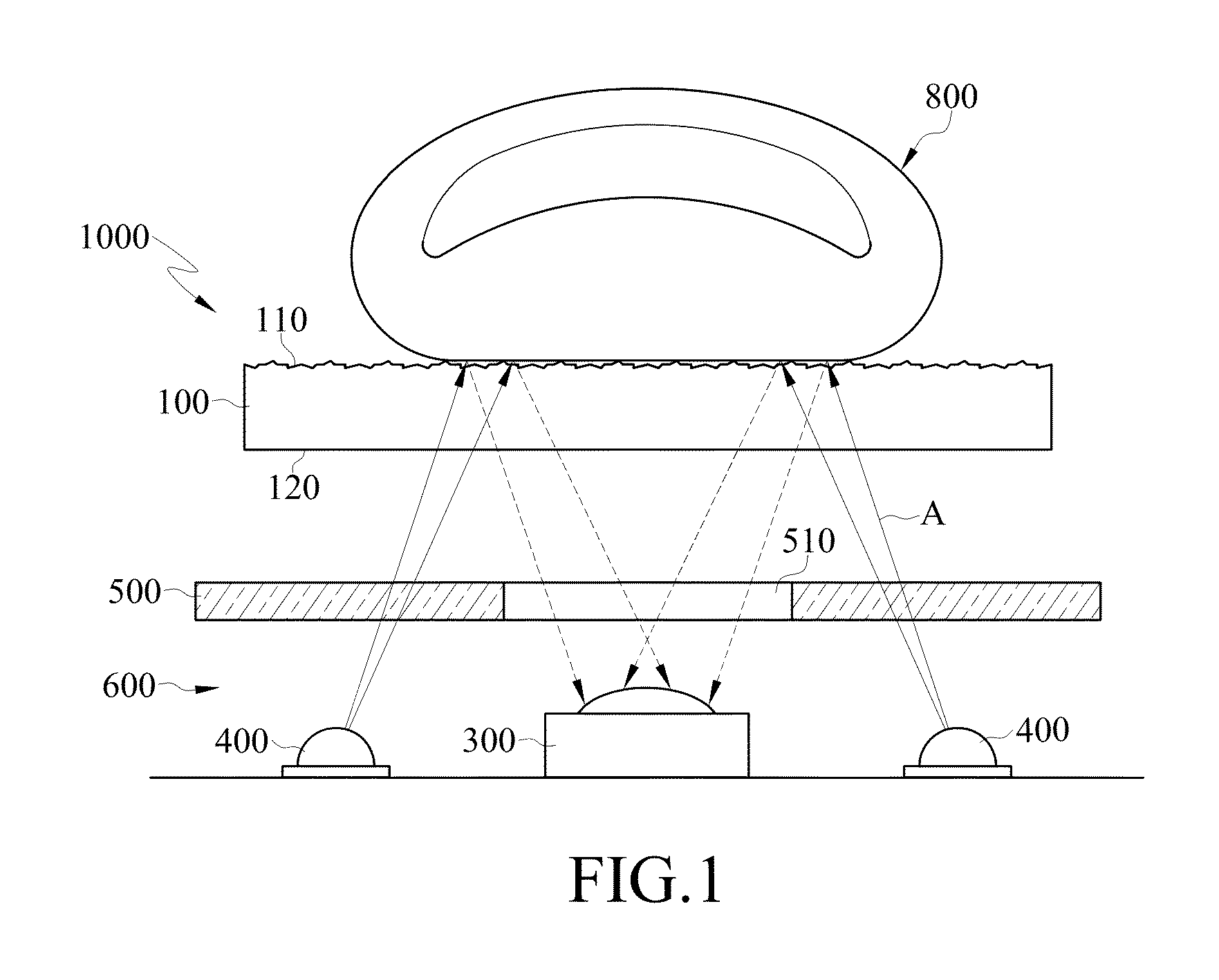

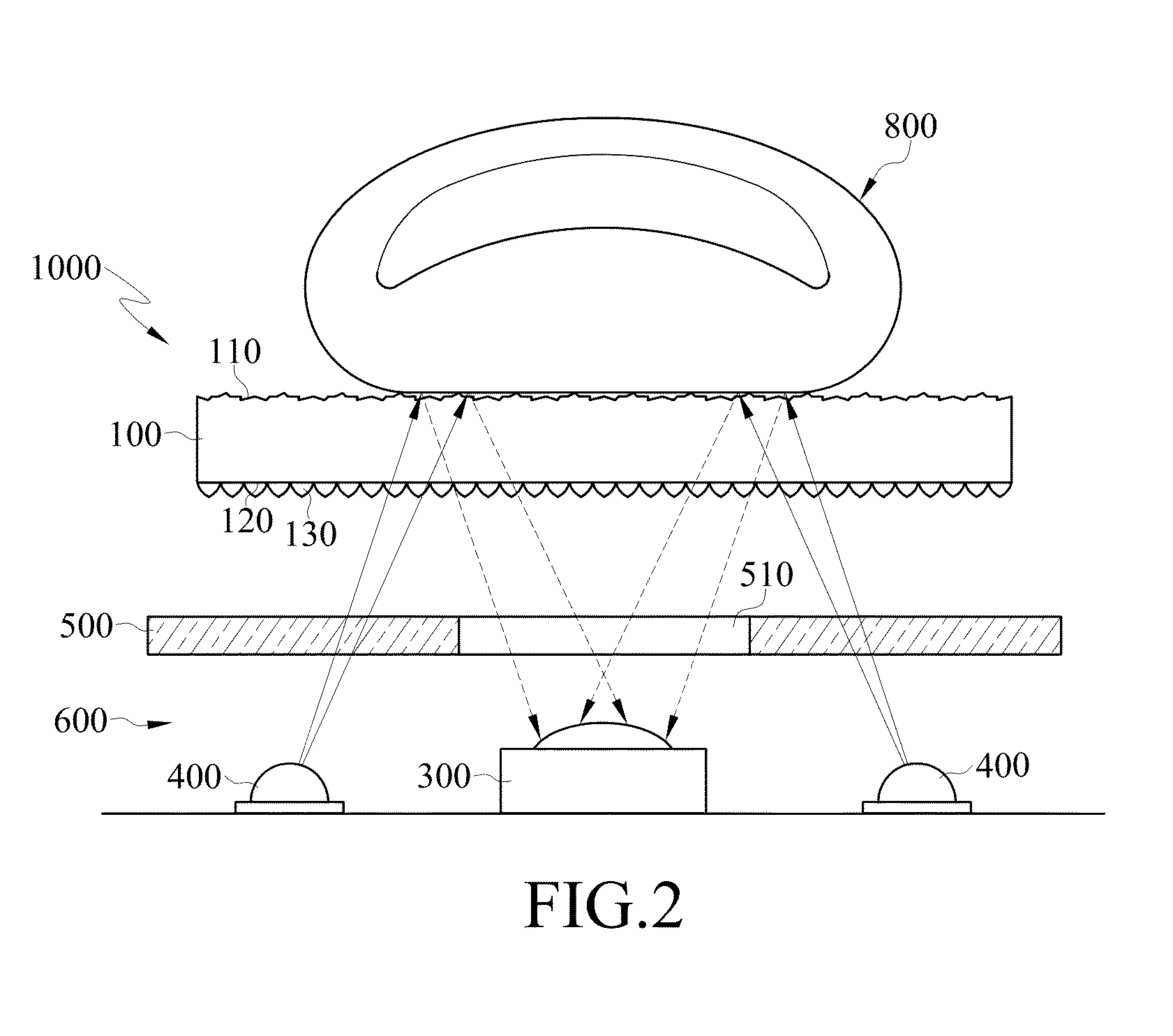

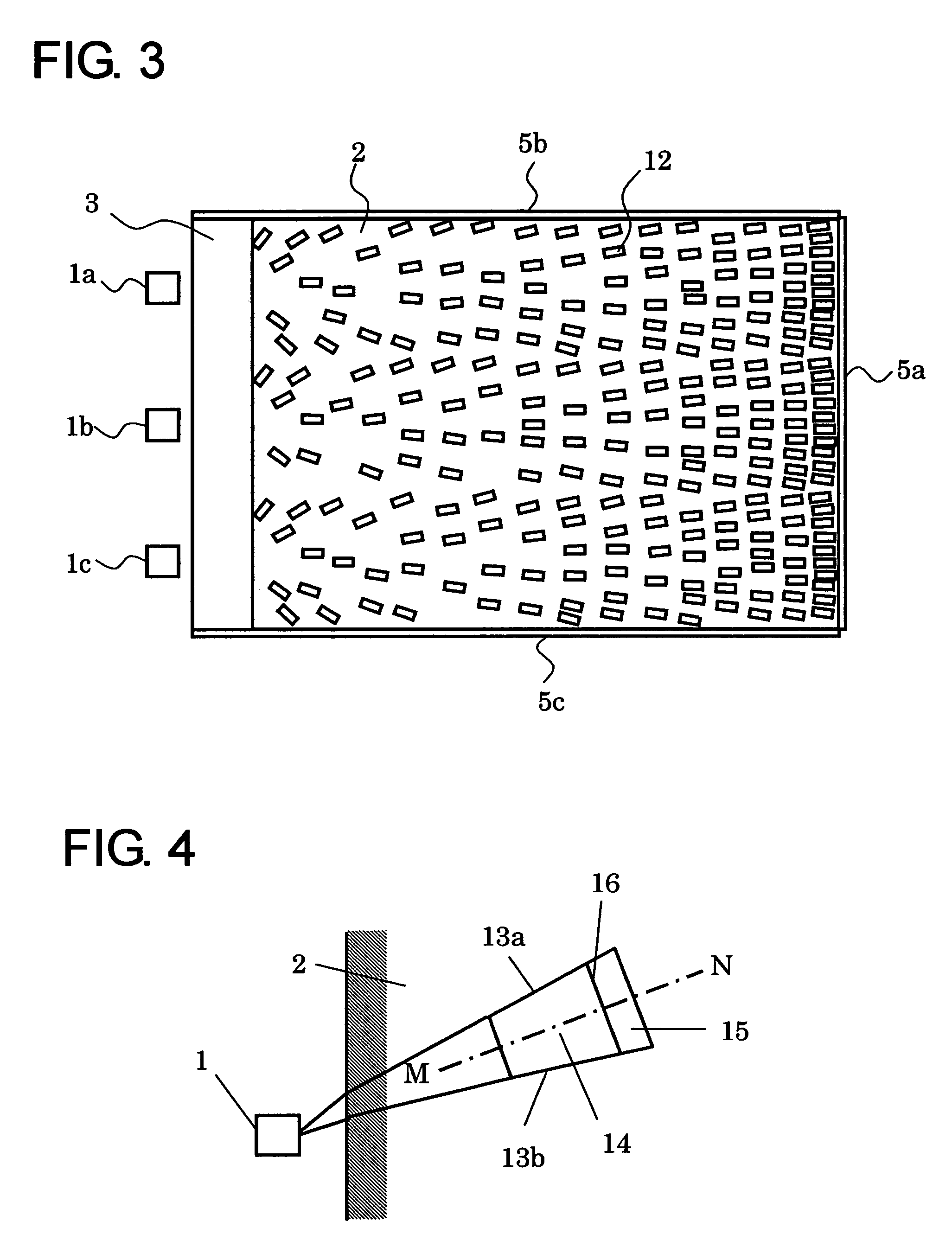

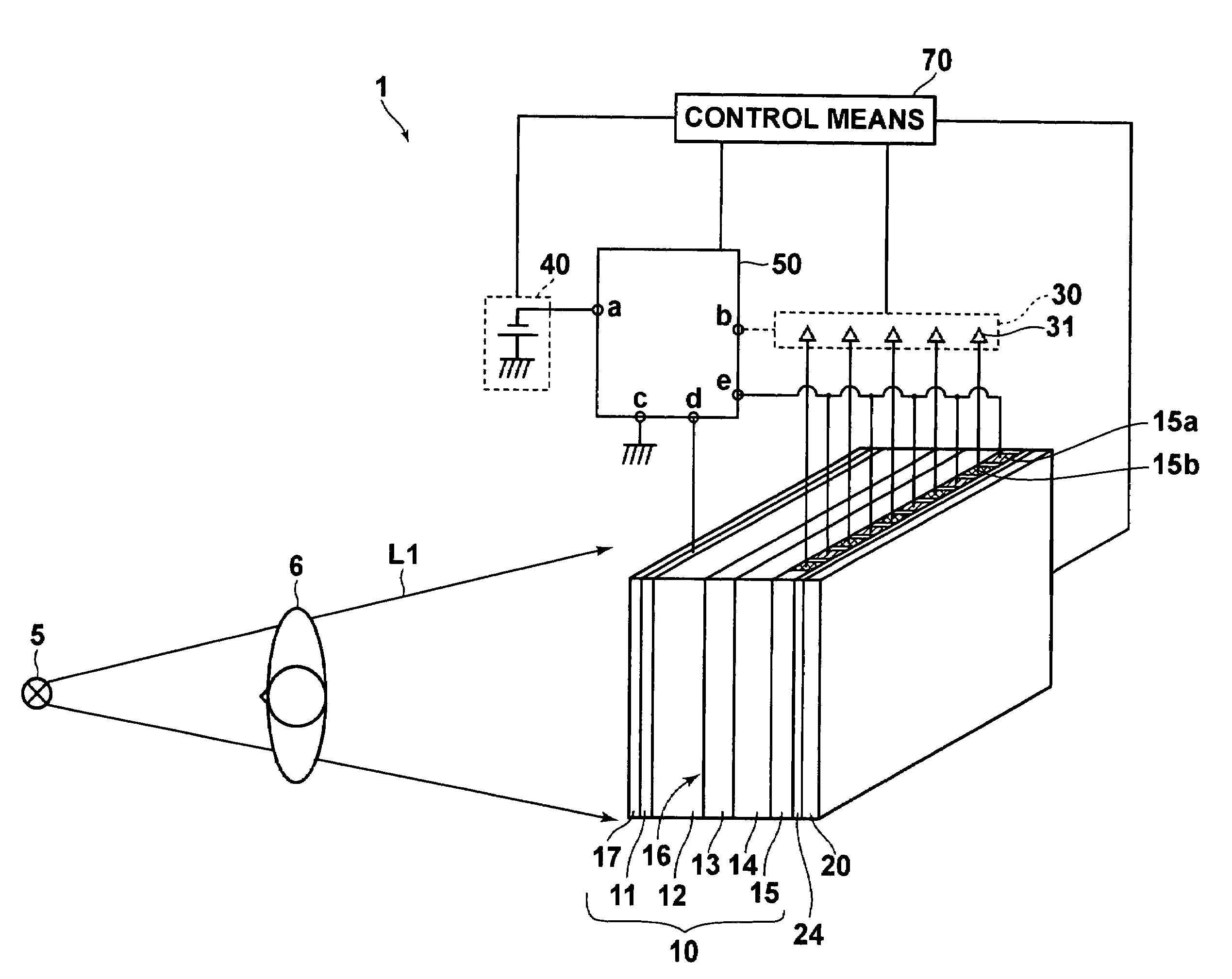

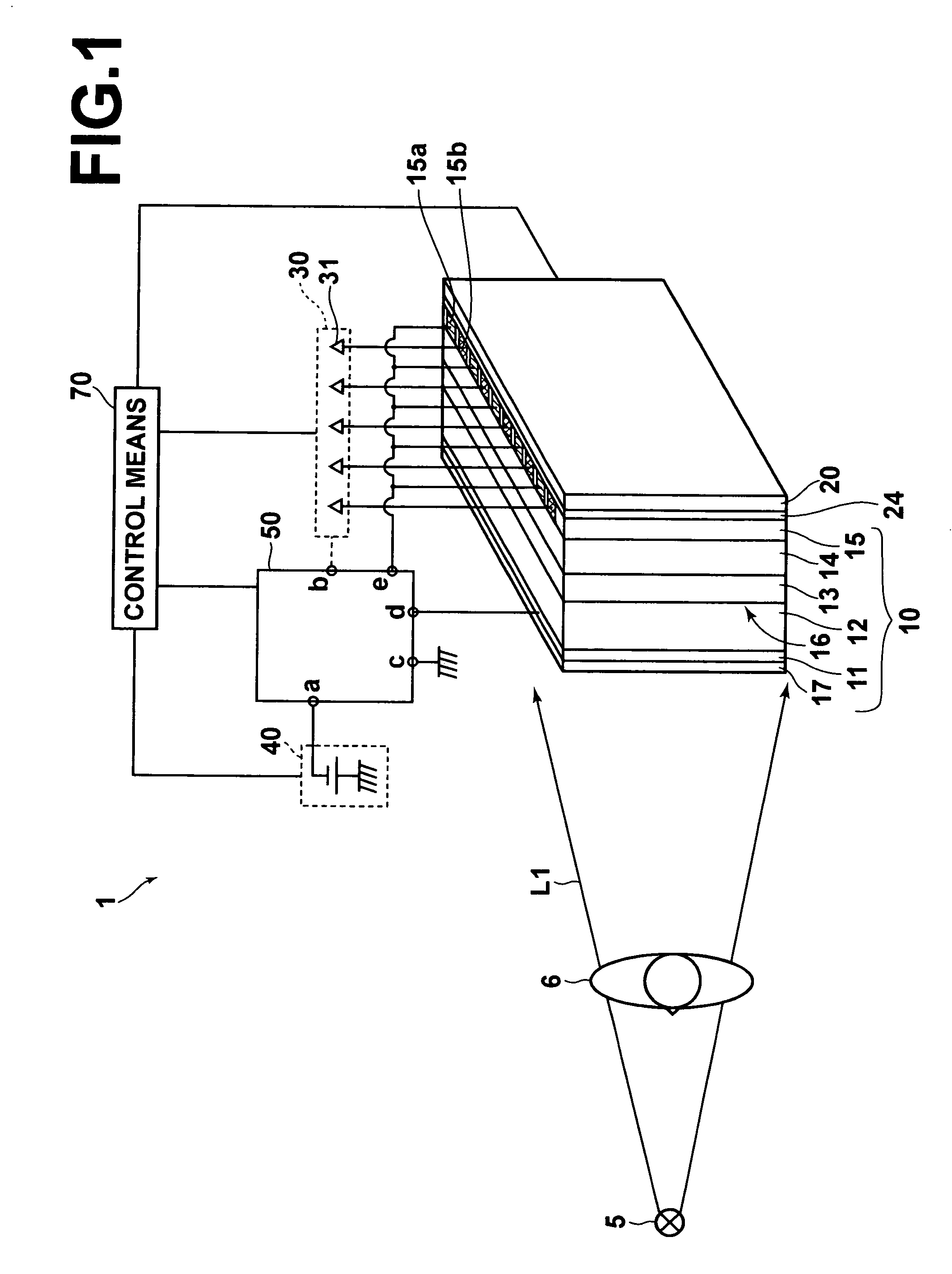

Area light source device and liquid crystal display device

ActiveUS8368844B2Emission smoothReduce light leakagePlanar/plate-like light guidesNon-linear opticsDiffusionLiquid-crystal display

An area light source device that is capable of more evenly emitting light and capable of enhancing the light emission luminance by exiting light of narrower directional characteristics. A light guide substrate includes a light introducing section and a light guide plate main body for exiting the light from a light exit surface. A number of diffusion patterns are formed at the light exit surface. A low refraction index layer is formed at the lower surface of the light guide plate main body, and a reflection layer is formed at the lower surface of the low refraction index layer. The point light source is arranged at a position facing the end face of the light introducing section. A tapered portion inclined to gradually increase the thickness of the light introducing section the farther away from the light source is arranged on the upper surface of the light introducing section.

Owner:ORMON CORP

Electrodeless lighting system

Owner:LG ELECTRONICS INC

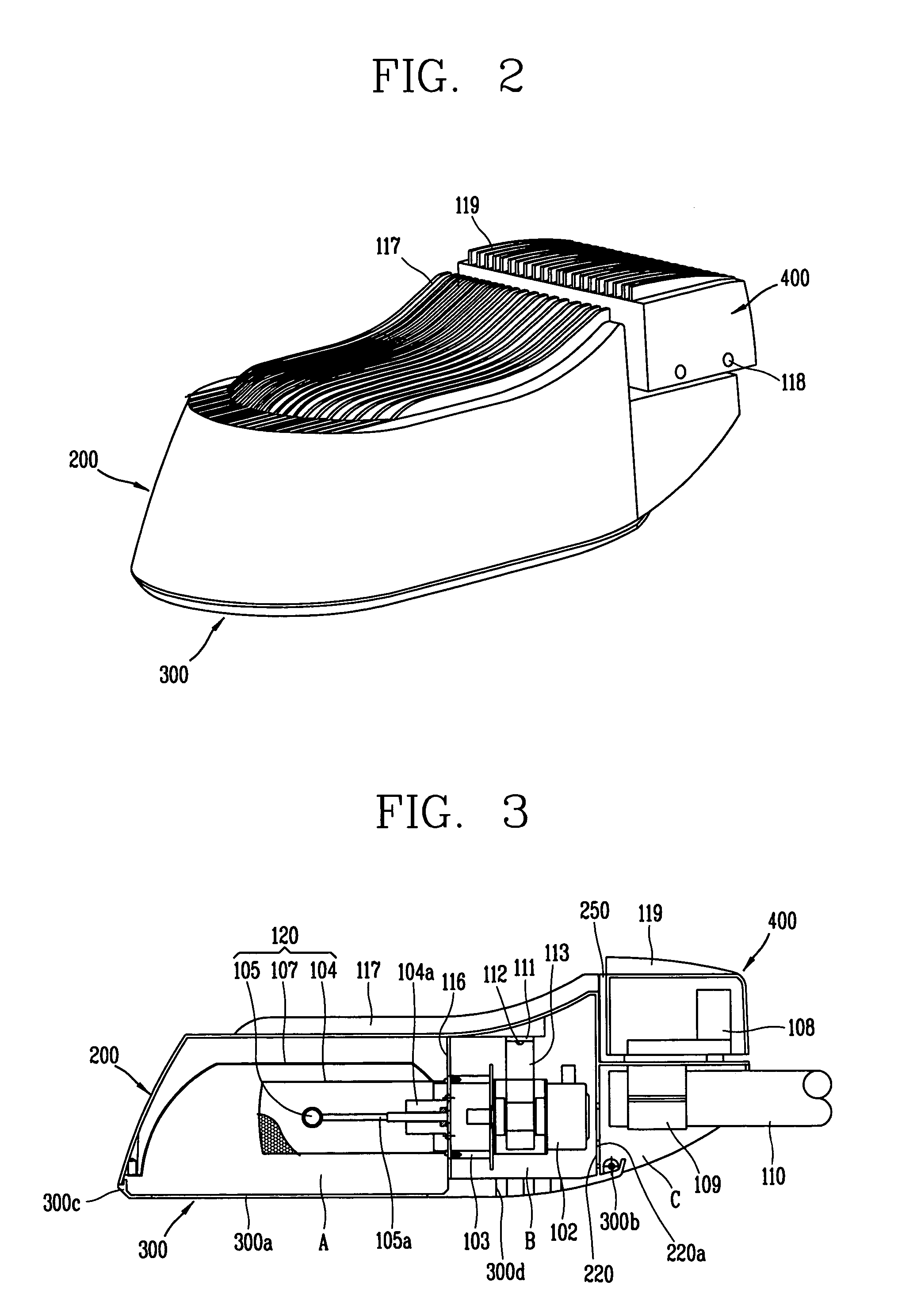

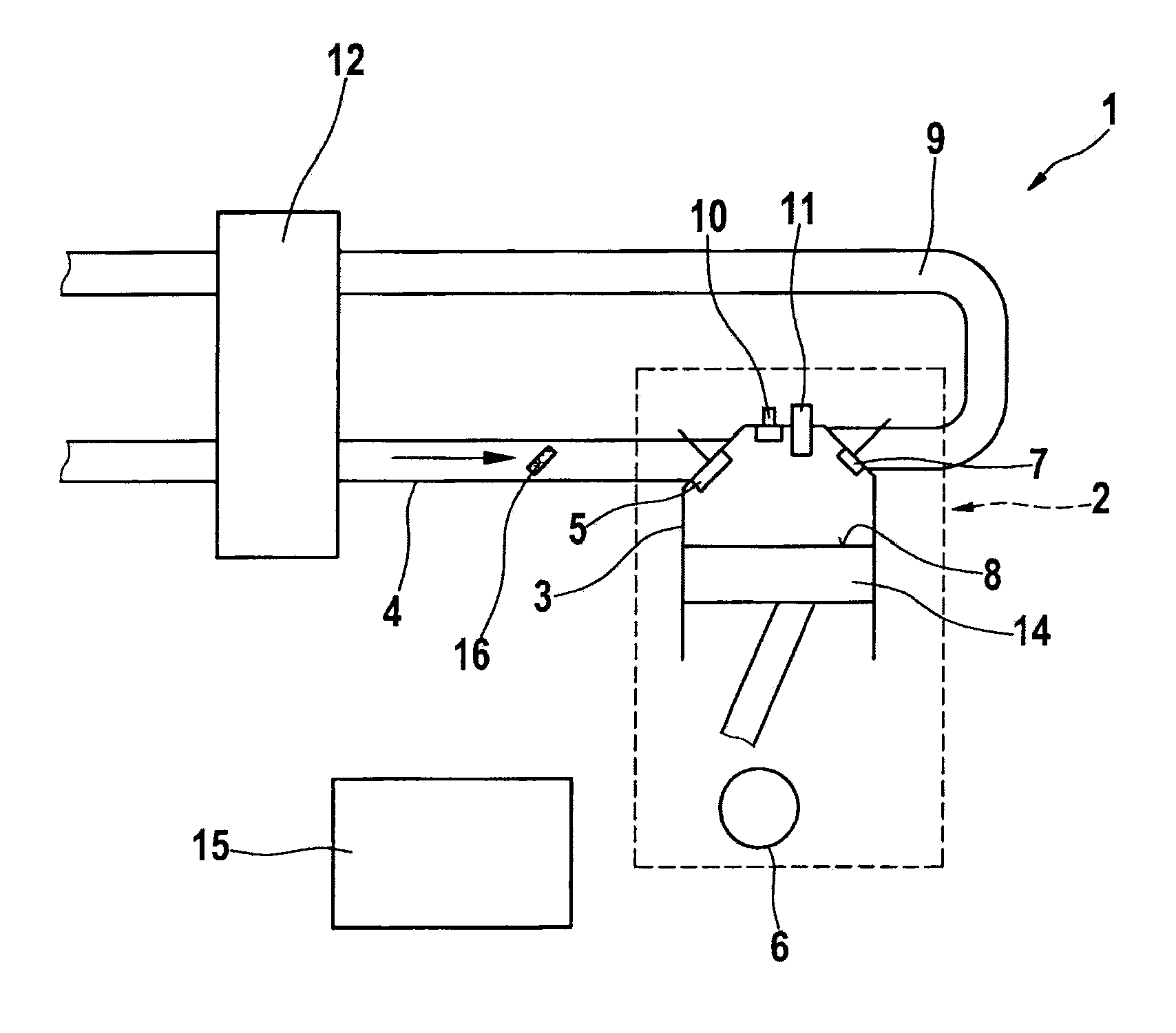

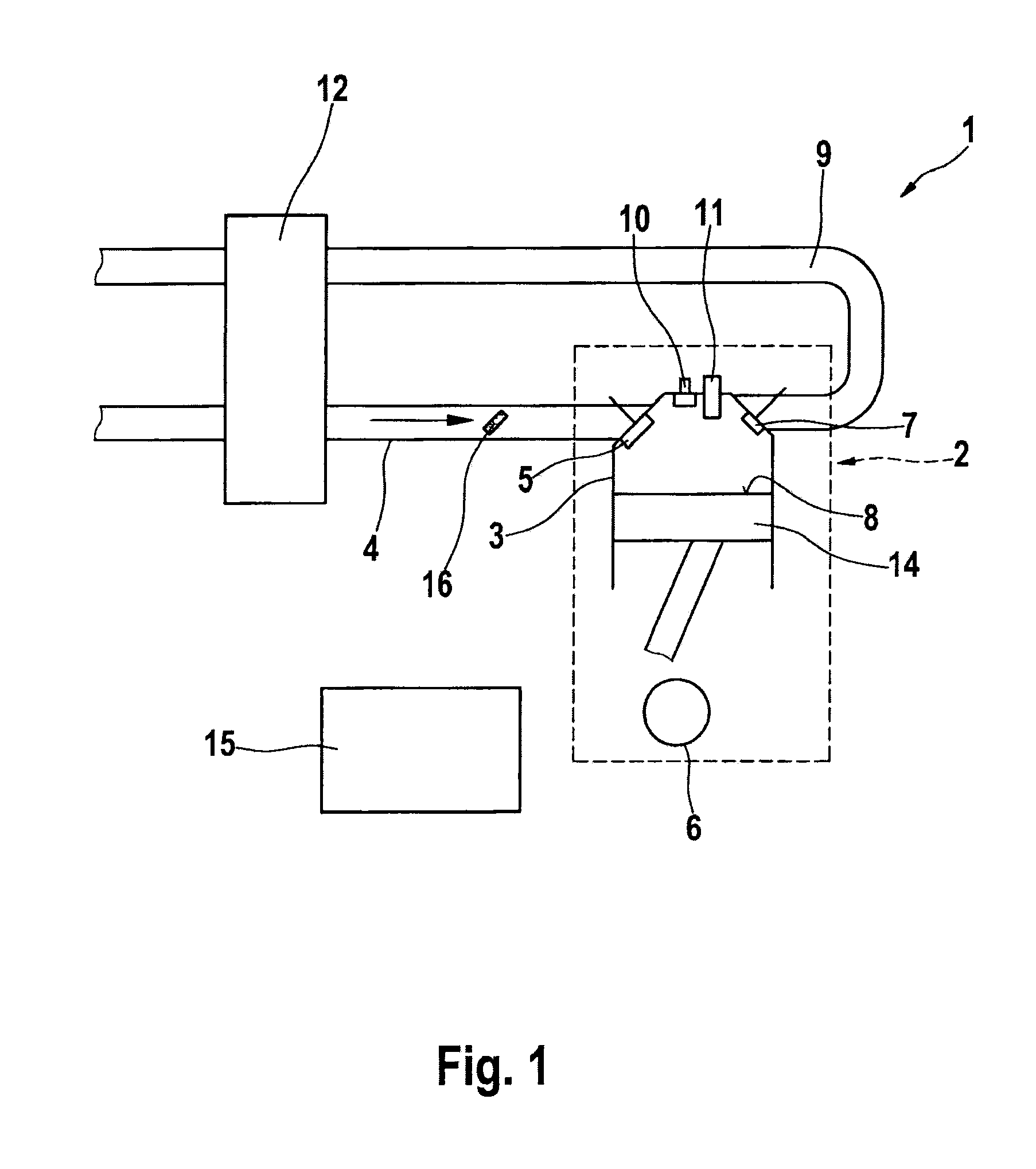

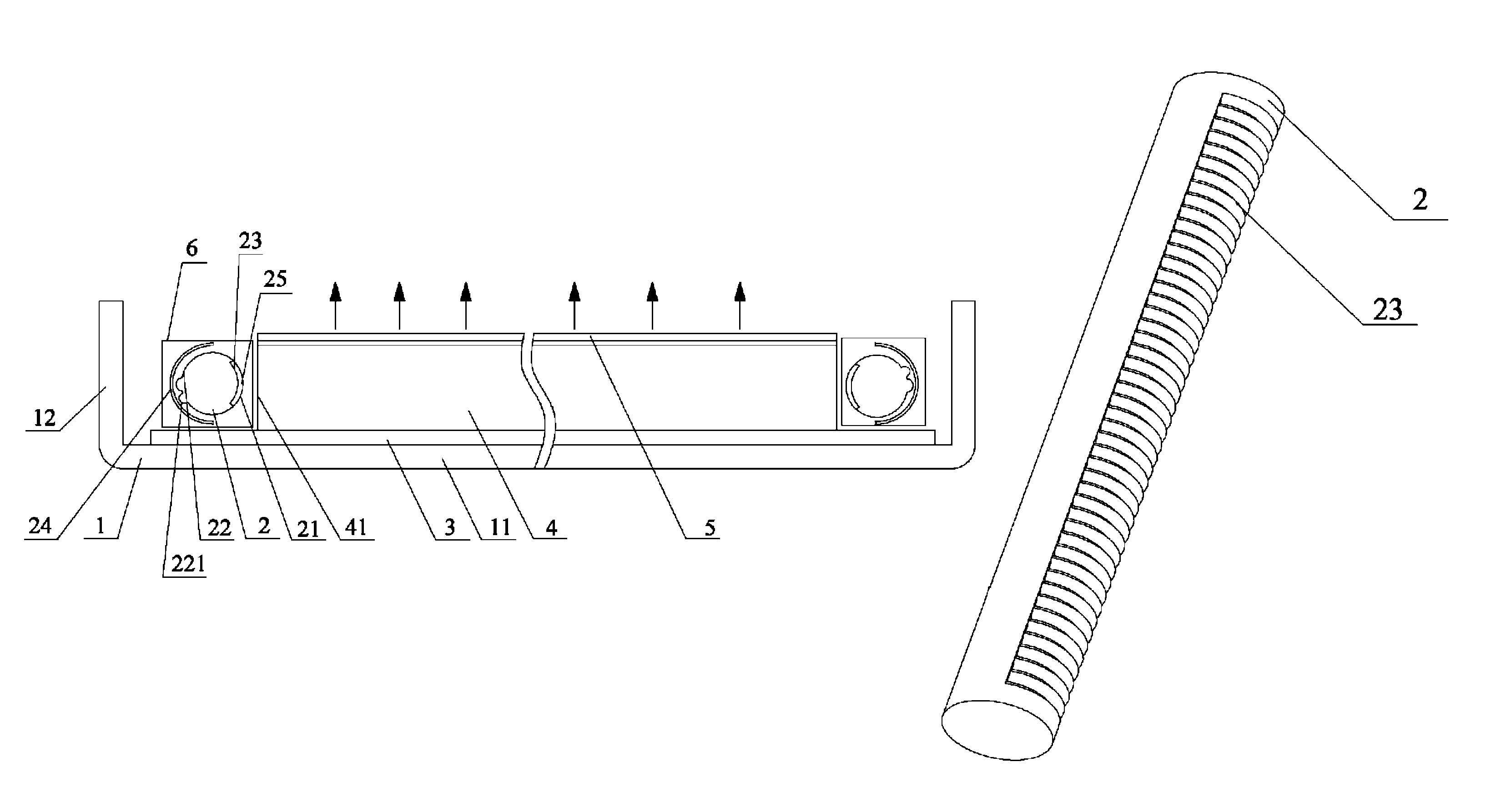

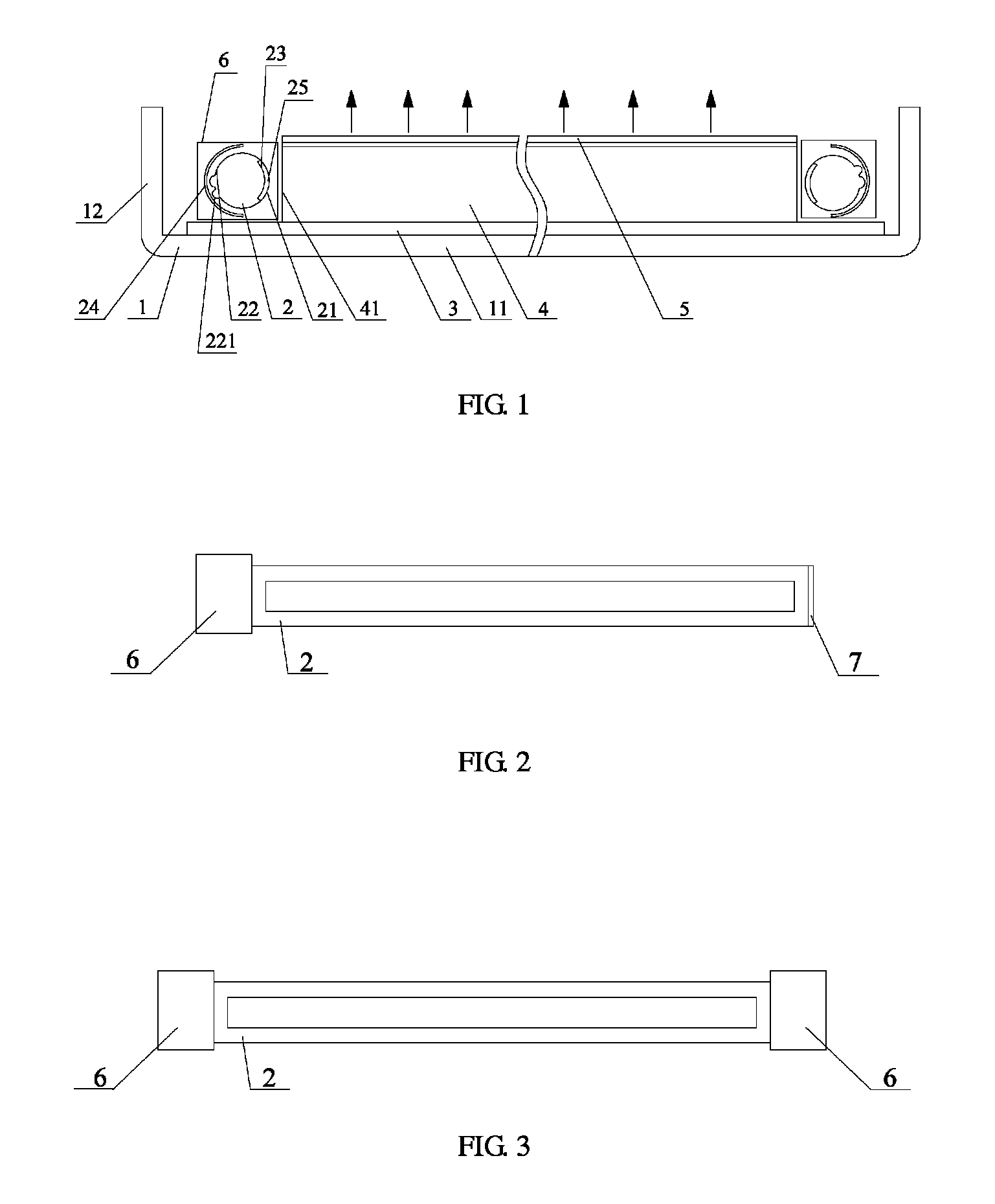

Exhaust Purification Device Capable of Performing Regeneration by Using Quick Combustion

InactiveUS20140294677A1Temperature of engine increaseSolution has disadvantageExhaust apparatusTemperatue controlElectricityFiltration

An exhaust purification device for vehicles comprises a connection unit, a combustion unit, a buffer unit, a filtration unit, an emission unit, and a control unit. The connection unit is adapted to be connected to an exhaust pipe of a vehicle's engine. The combustion unit includes a main housing, a fuel-atomization nozzle, and an igniter. The nozzle and the igniter are arranged in an open-end container. The nozzle is connected to a fuel tank. An air pump is connected to the open-end container. The buffer unit is provided with a temperature sensor, an exhaust-buffering mask, and a fan. The filtration unit can remove the soot contained in the exhaust gas. The emission unit includes an L-shaped porous tail pipe being sealed with a porous cover. The control unit is electrically connected with the igniter, the fuel pump, the air pump, and the temperature sensor for controlling their operations.

Owner:CHEN WEN LO

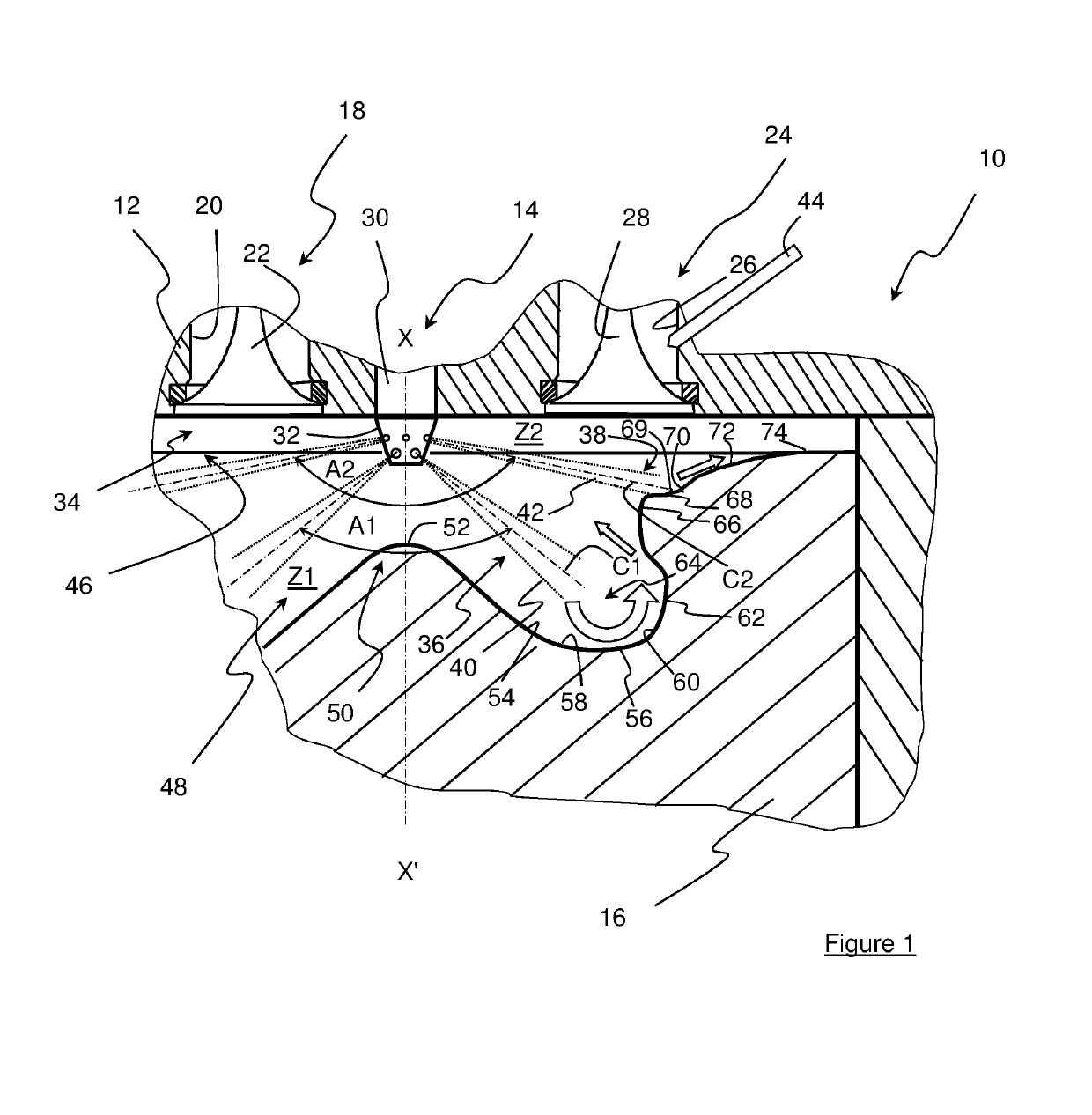

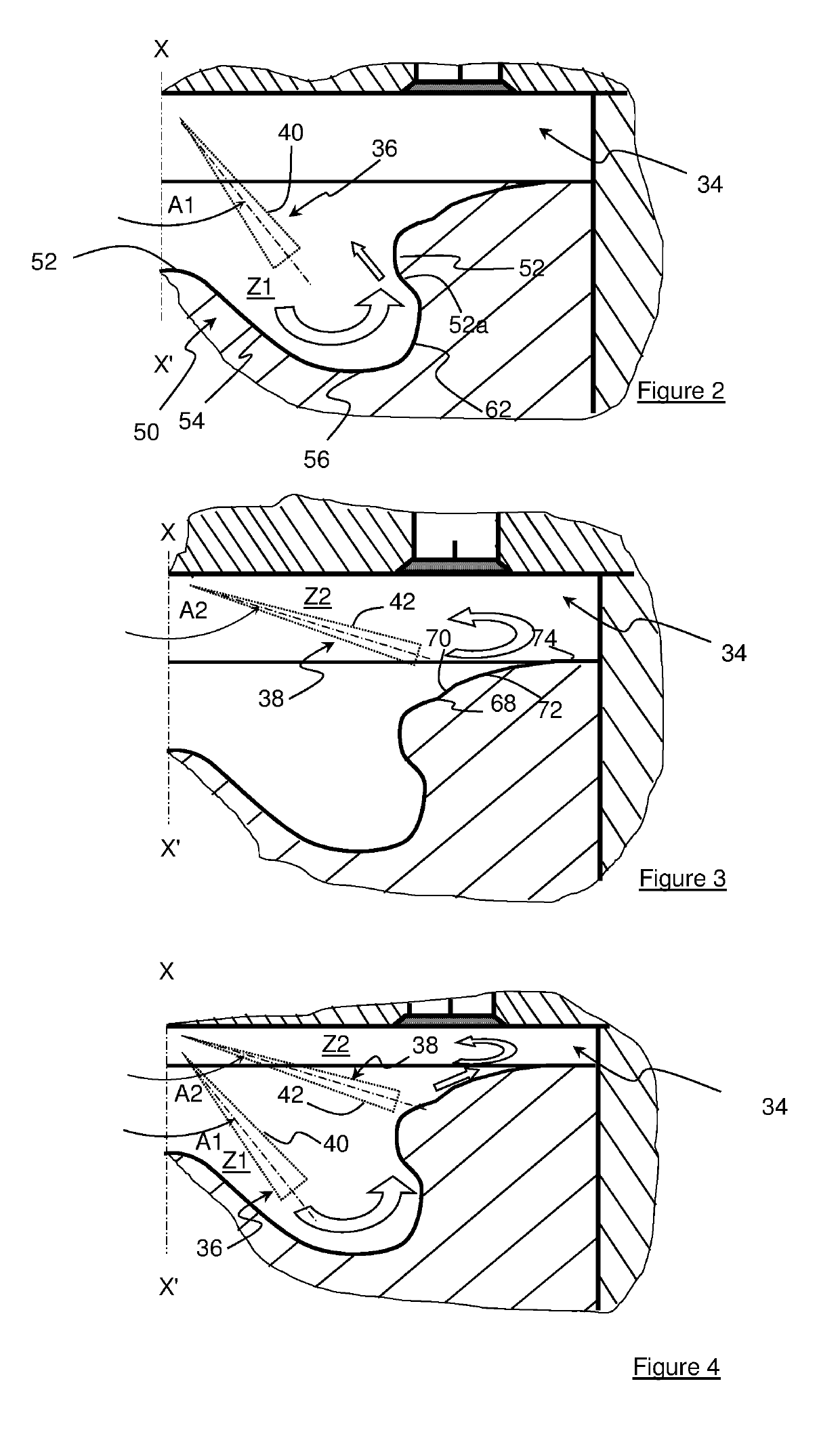

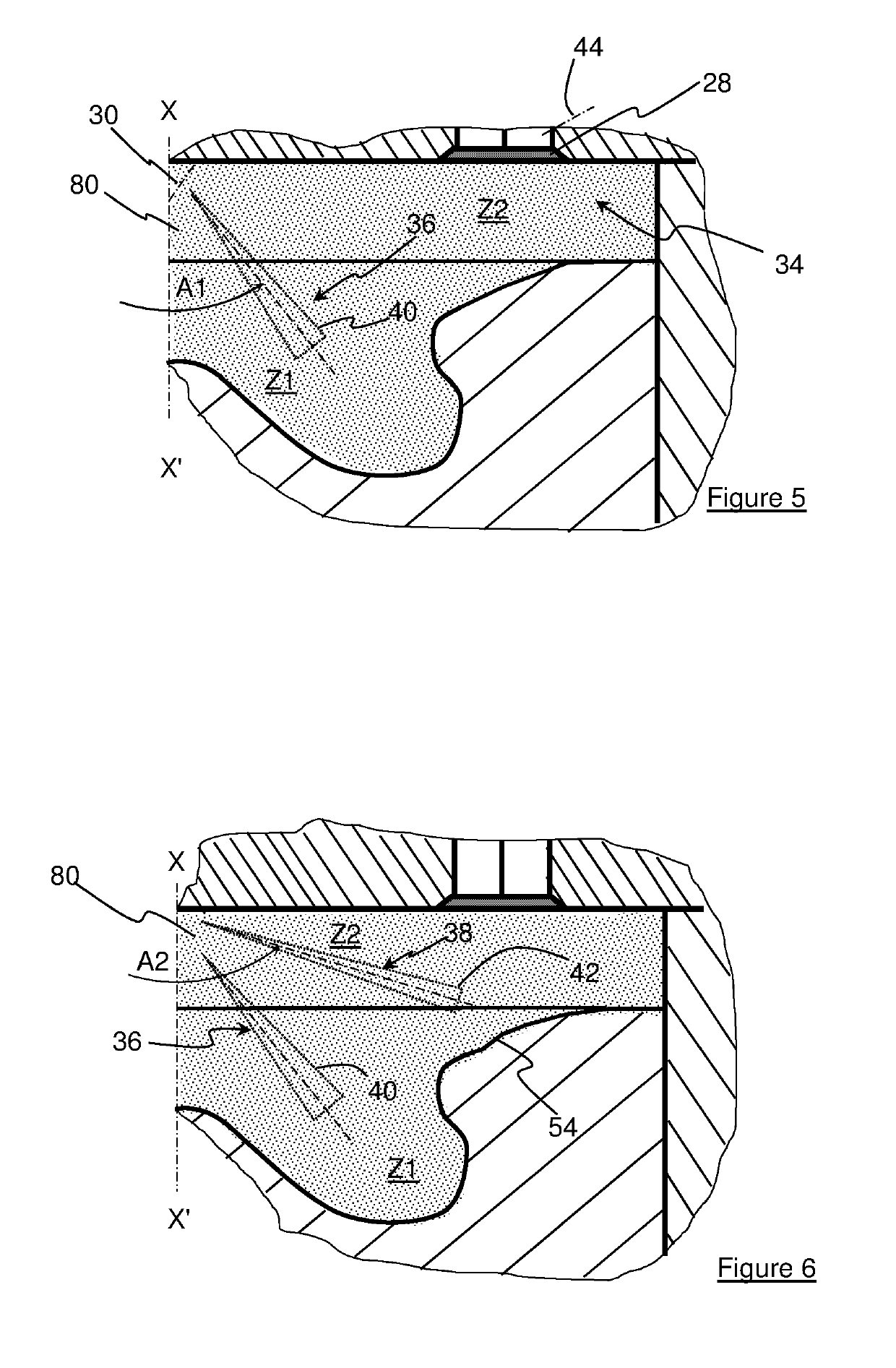

Injection method and device for controlling an injection process in an internal combustion engine

InactiveUS20110079198A1Reduced static flowReduce trafficElectrical controlInternal combustion piston enginesCombustionExternal combustion engine

A method for controlling an injection of fuel in an internal combustion engine, in particular in a gasoline engine having direct injection, a drive fuel quantity, which indicates the fuel quantity required by the internal combustion engine to provide a torque, being injected in a working cycle before a combustion stroke of the working cycle into a cylinder of the internal combustion engine, a cooling fuel quantity, which indicates the fuel quantity which is used to cool the combustion exhaust gases, being injected in the working cycle in addition to the drive fuel quantity, at least part of the cooling fuel quantity being injected after completion of the combustion in the combustion stroke and / or the immediately following exhaust stroke of the working cycle.

Owner:ROBERT BOSCH GMBH

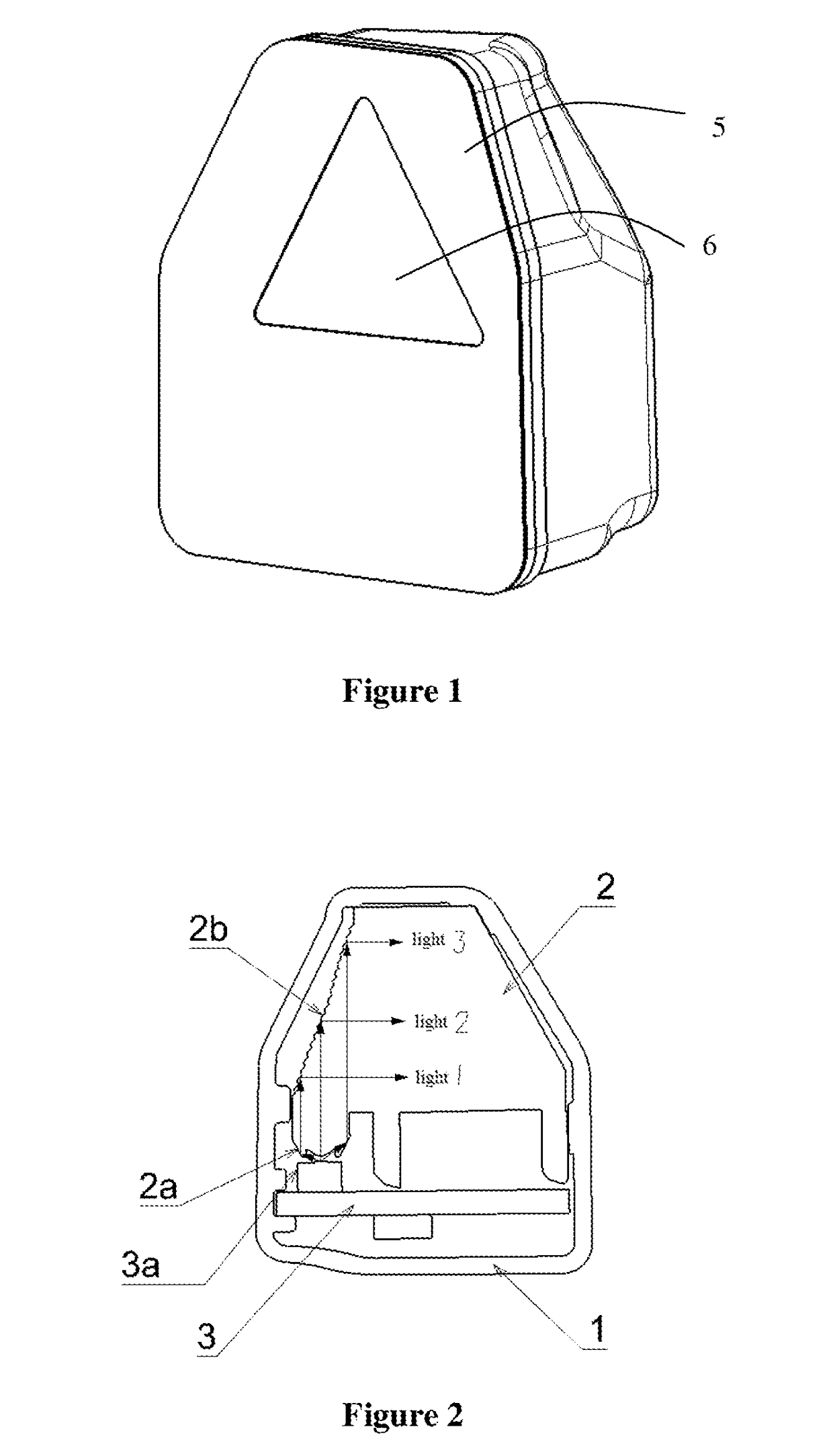

Light-guided warning lamp used in lane change at blind zone of a vehicle

ActiveUS20190039508A1Uniform lightConvenient lightingLighting and heating apparatusOptical signallingBlind zoneOptoelectronics

A warning lamp used in lane change at blind zone of a vehicle includes a light source and a light guide including a light entrance surface, a first reflective surface, a second reflective surface, and a light exit surface, the light entrance surface is located above the light source so that the light emitted from the light source is converted to parallel light through the light entrance surface, said first reflective surface is arranged aslope above the light entrance surface, sides of s the first reflective surface are provided with the second reflective surface and the light exit surface, respectively, the first and second reflective surface are provided with total reflection stripes configured so that said parallel light is totally reflected to the second reflective surface through the first reflective surface and then totally reflected by the second reflective surface to said light exit surface to form uniform warning light.

Owner:MAGNA MIRRORS (TAICANG) AUTOMOTIVE TECHNOLOGY CO LTD

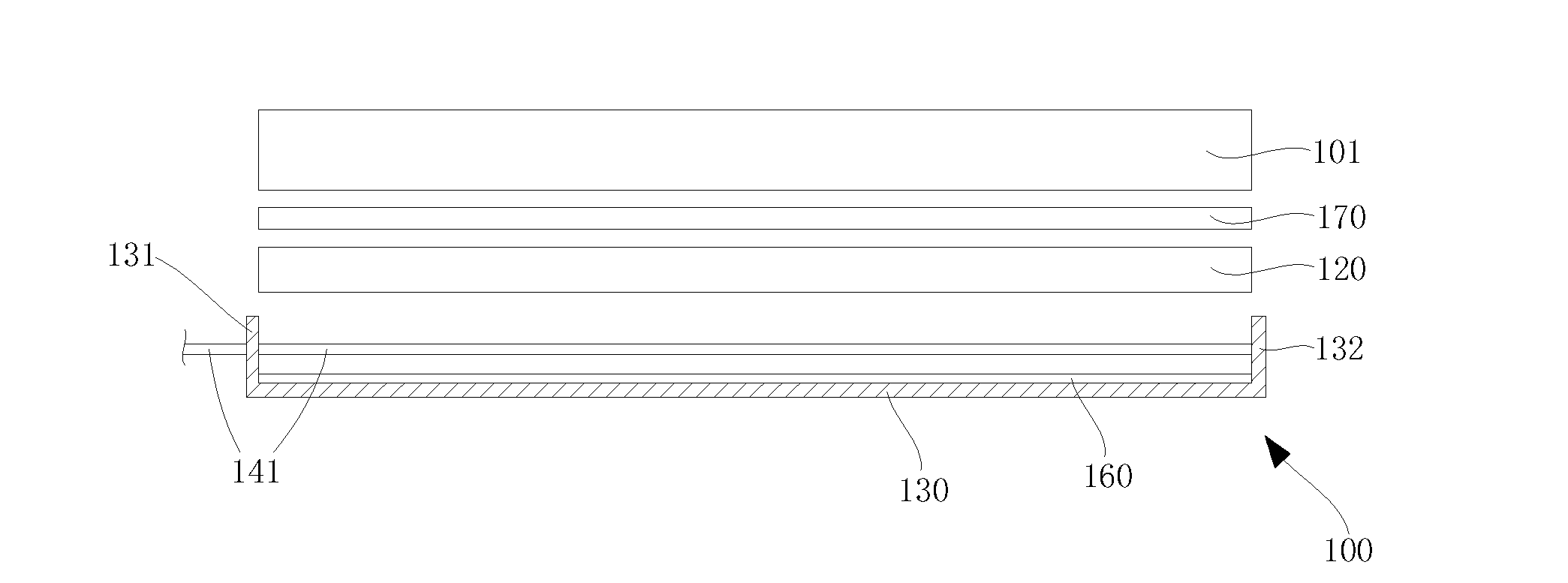

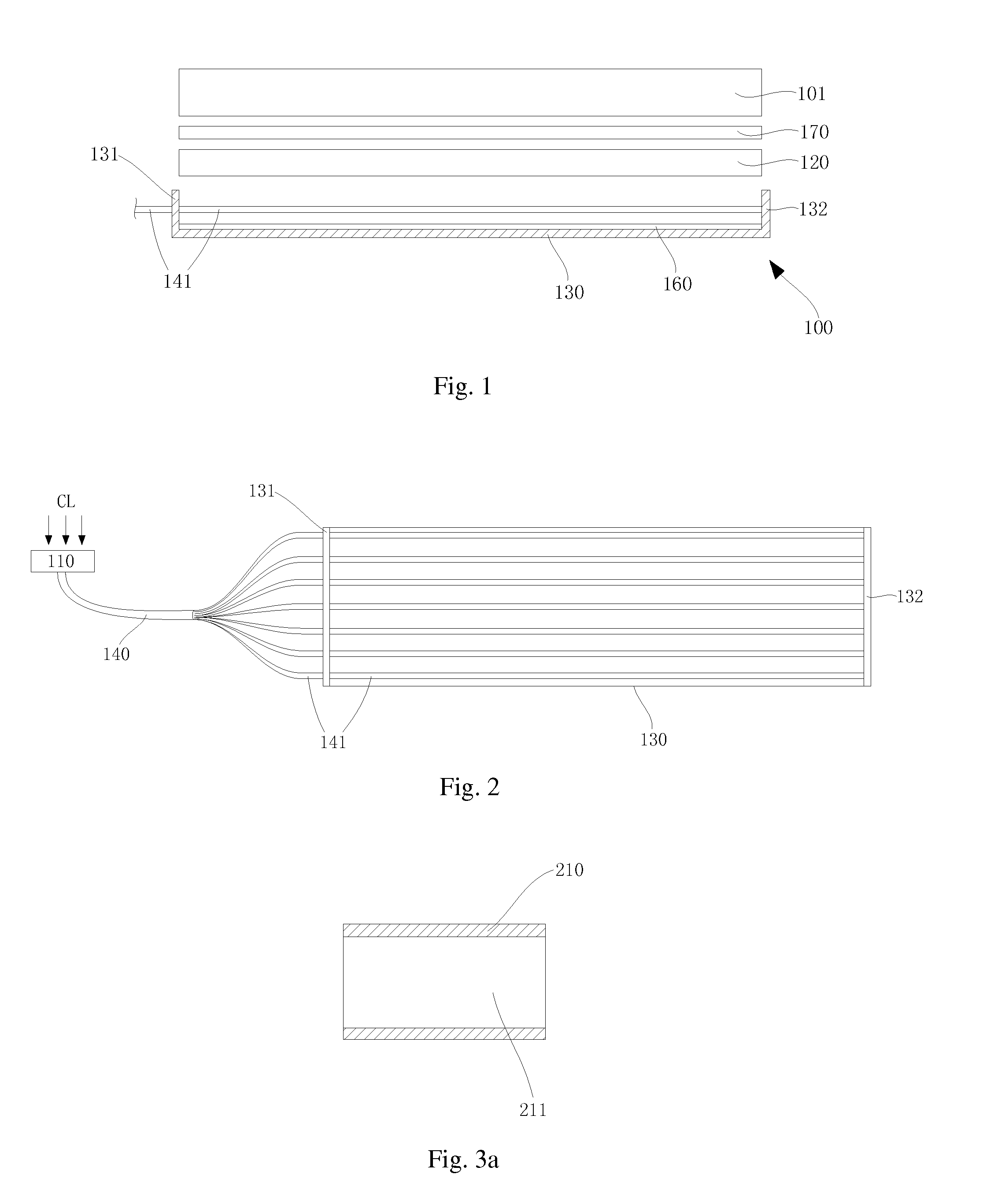

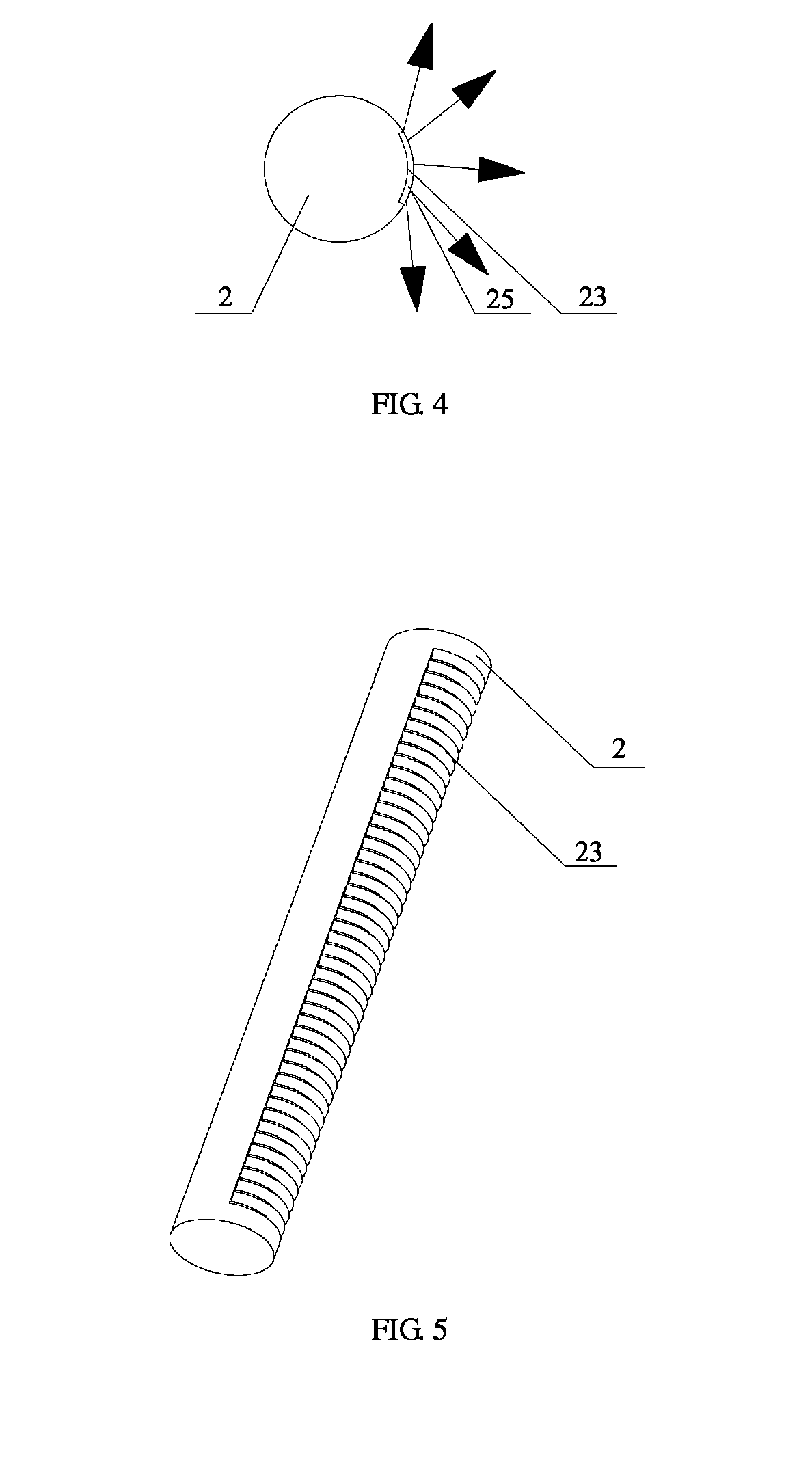

LCD and Backlight Module Thereof

ActiveUS20150015827A1Equally distributedEffective guidanceMechanical apparatusElectric discharge tubesLiquid-crystal displayEngineering

An LCD having a backlight module is proposed. The backlight module includes an ambient light collector for collecting ambient light; a back plate; a diffuser plate on the back plate; a plurality of optical fibers straightly fixed between the diffuser plate and the back plate and coupled to the ambient light collector. Microstructure is formed on the surface of the optical fibers straightly fixed between the diffuser plate and the back plate, and the microstructure makes light from the optical fibers evenly being emitted. The backlight module utilizes microstructure formed on a surface of optical fibers for evenly distributing light from the surface of the optical fibers. In hence, it effectively guides ambient light into the backlight module via the optical fibers and ensures at the same time that the light is evenly distributed to the backlight module.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

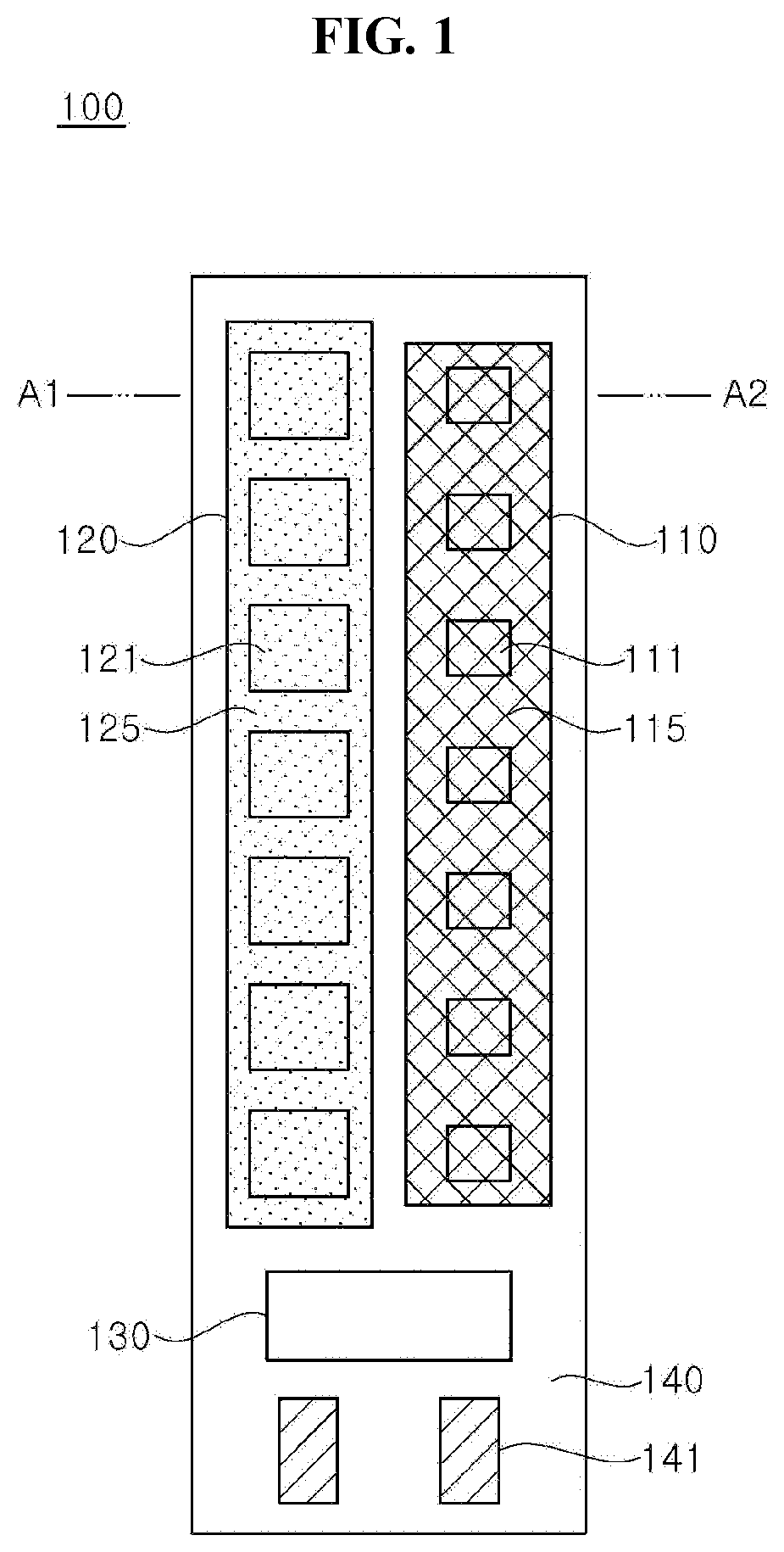

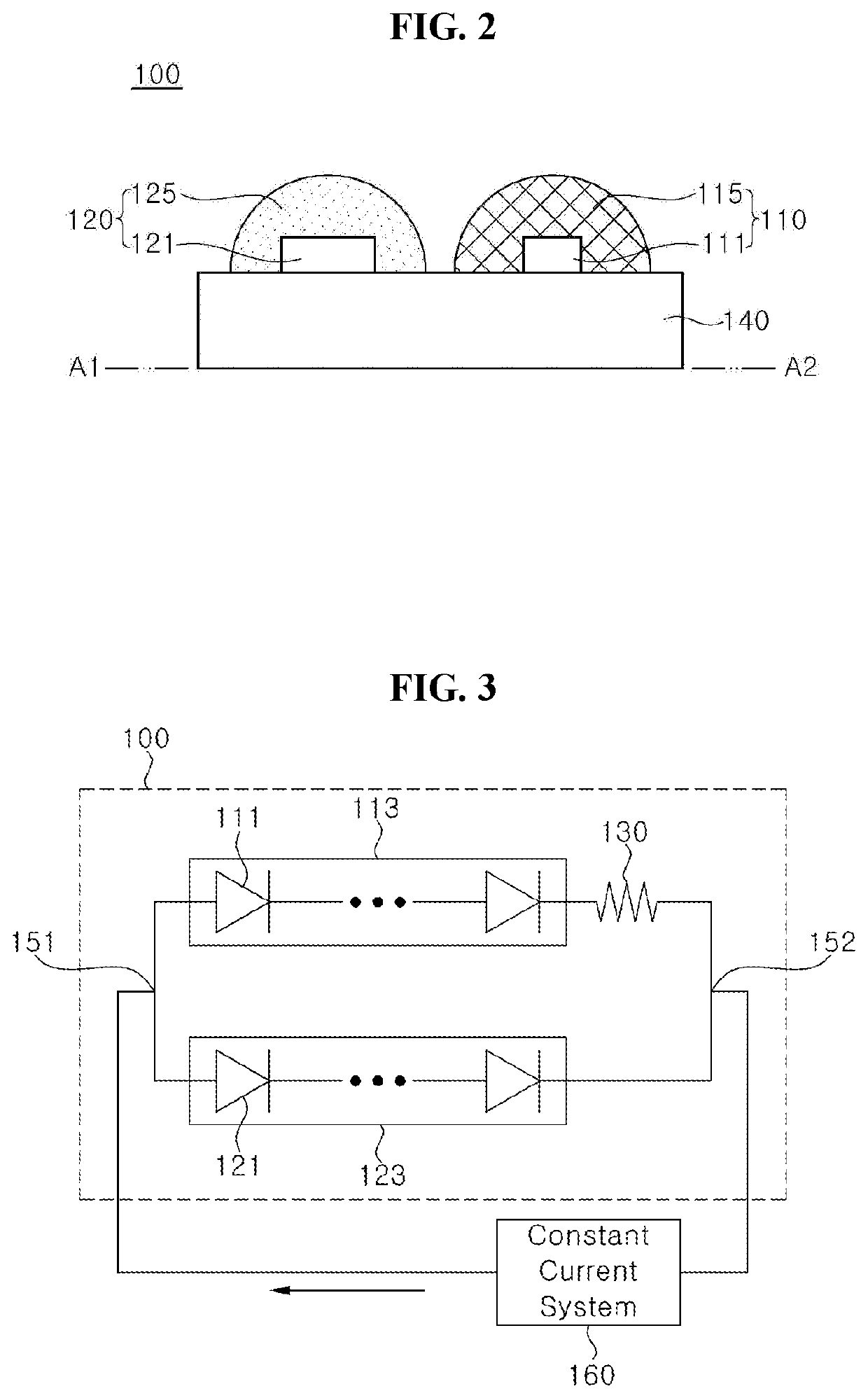

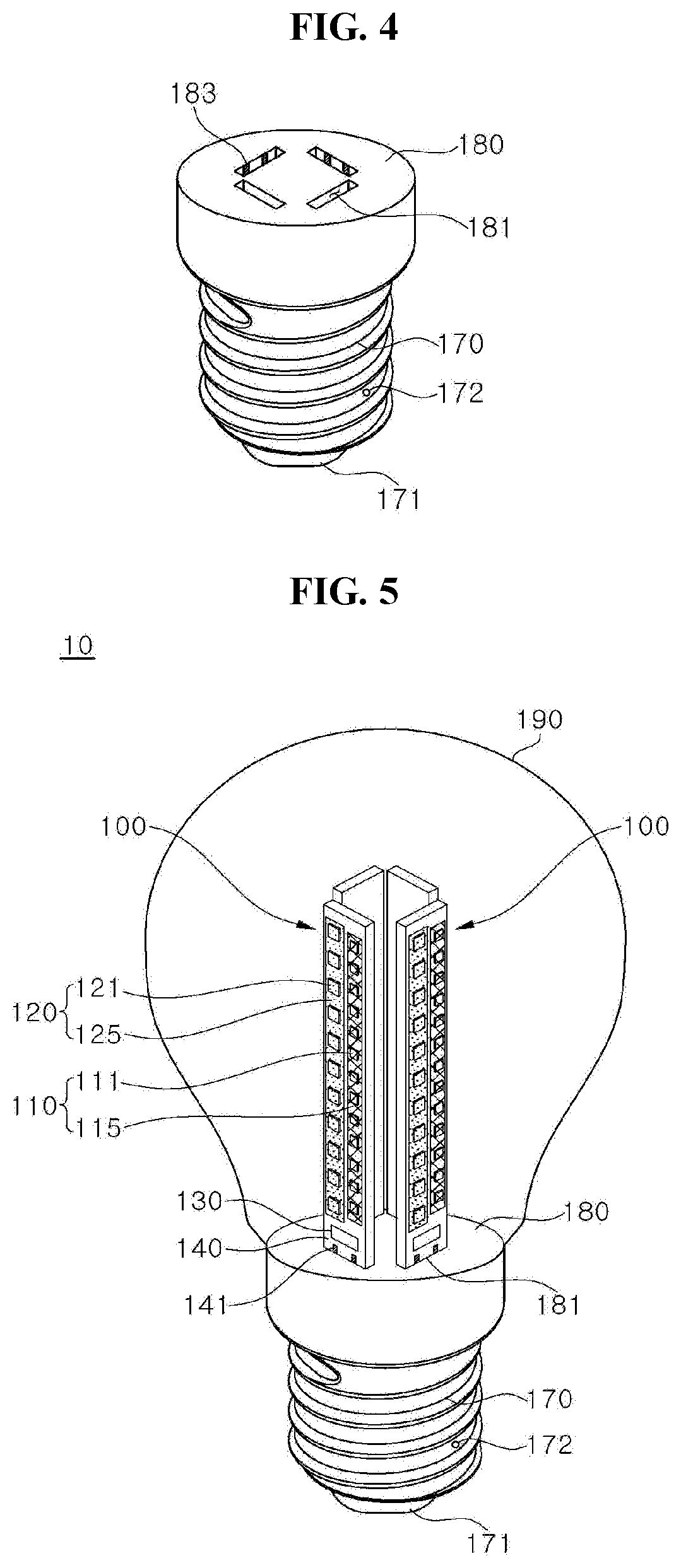

LED package set and LED bulb including same

ActiveUS20200168660A1Highly economicalExtend your lifeLight source combinationsElectroluminescent light sourcesEngineeringMaterials science

An LED package set including a substrate, a first LED package disposed on the substrate and including at least one first LED chip, a second LED package disposed on the substrate and including at least one second LED chip, and a resistor disposed on the substrate, connected to the first LED package in series, and connected to the second LED package in parallel, in which the second LED package is connected in parallel to the first LED package and the resistor, and the first LED package and the second LED package are configured to emit light having different color temperatures.

Owner:SEOUL SEMICONDUCTOR

Method of injecting fuel into the combustion chamber of an internal-combustion engine running in single-fuel or multi-fuel mode

InactiveUS10294876B2Burn evenlyEmission smoothElectrical controlInternal combustion piston enginesCombustion chamberLiquid fuel

Owner:INST FR DU PETROLE

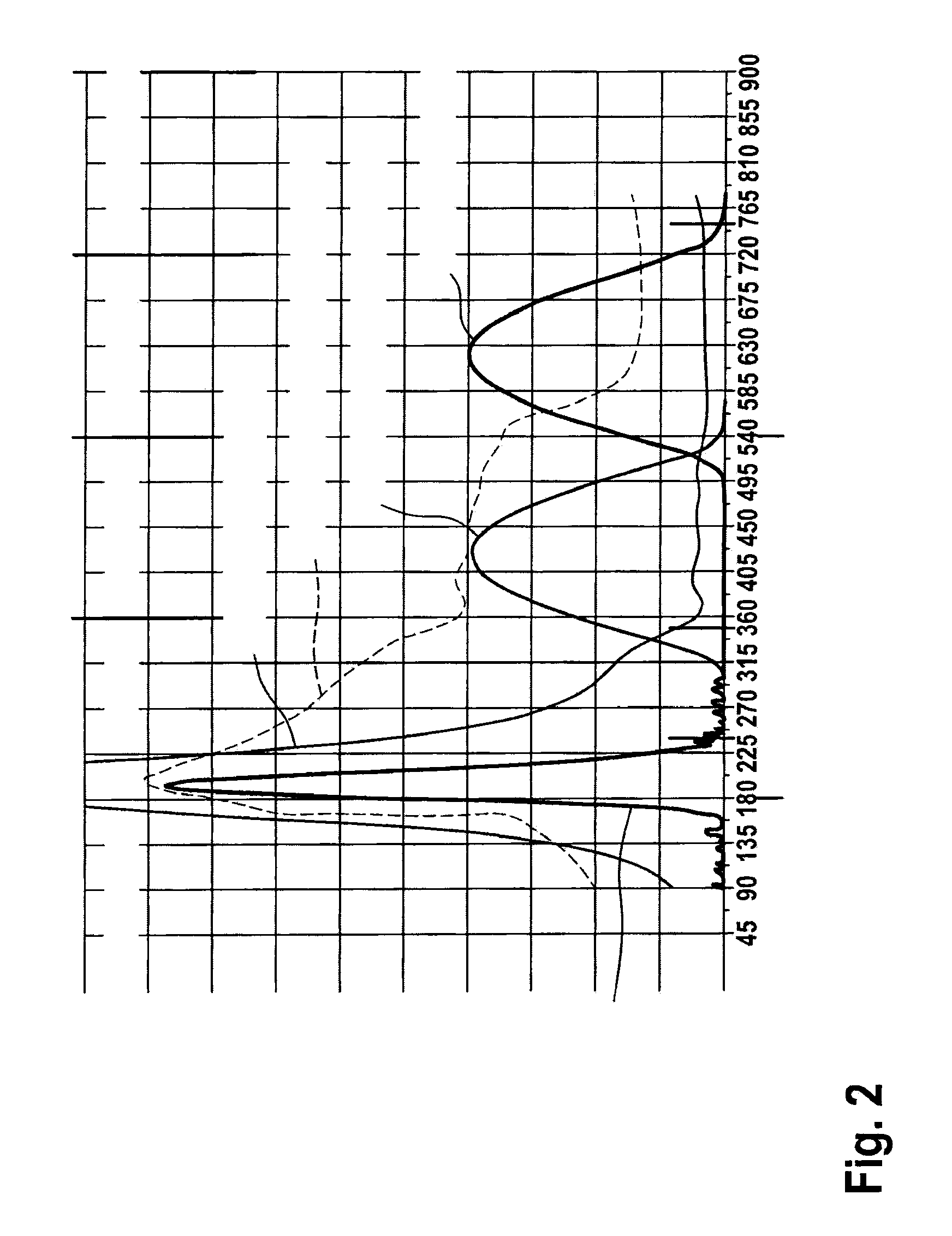

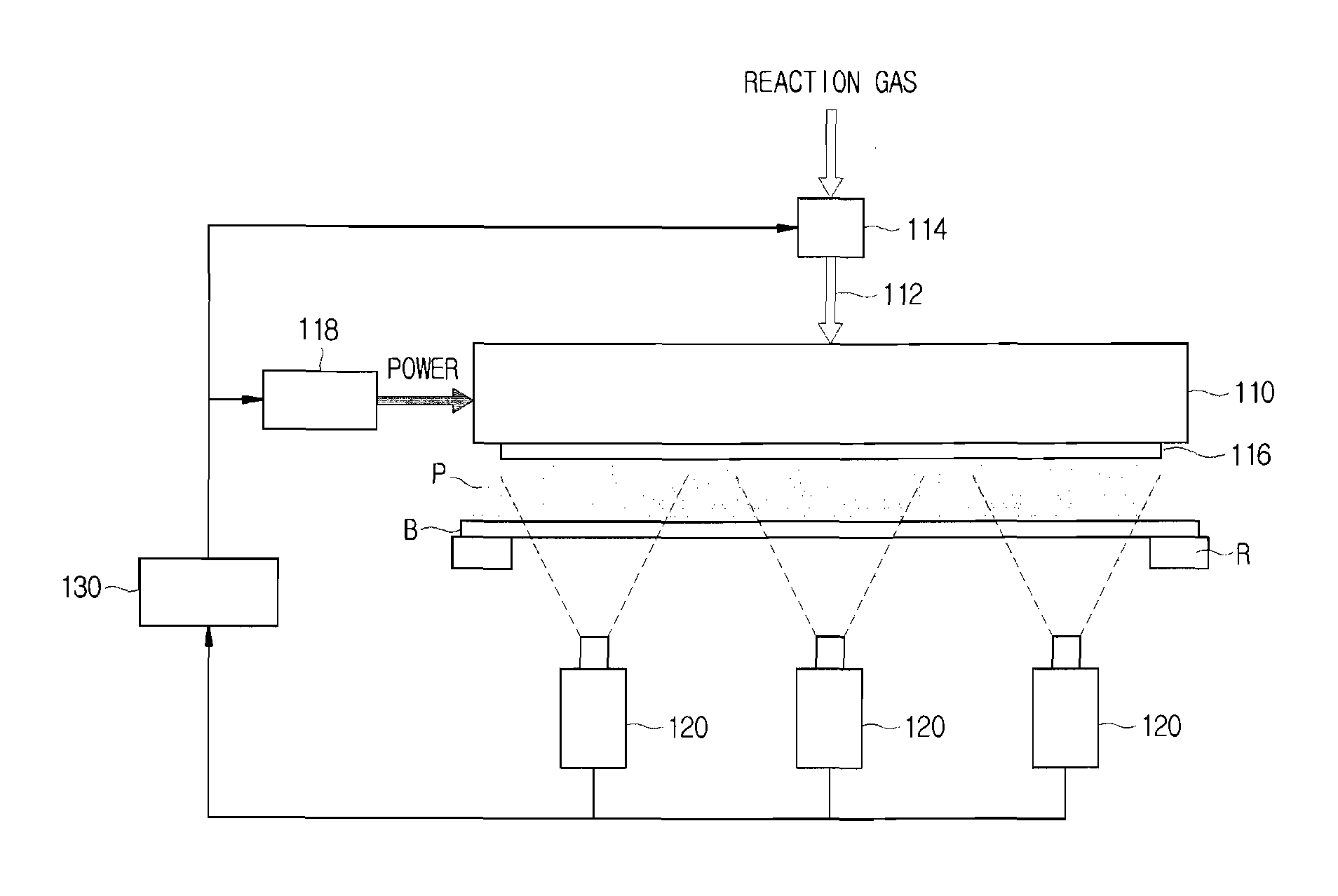

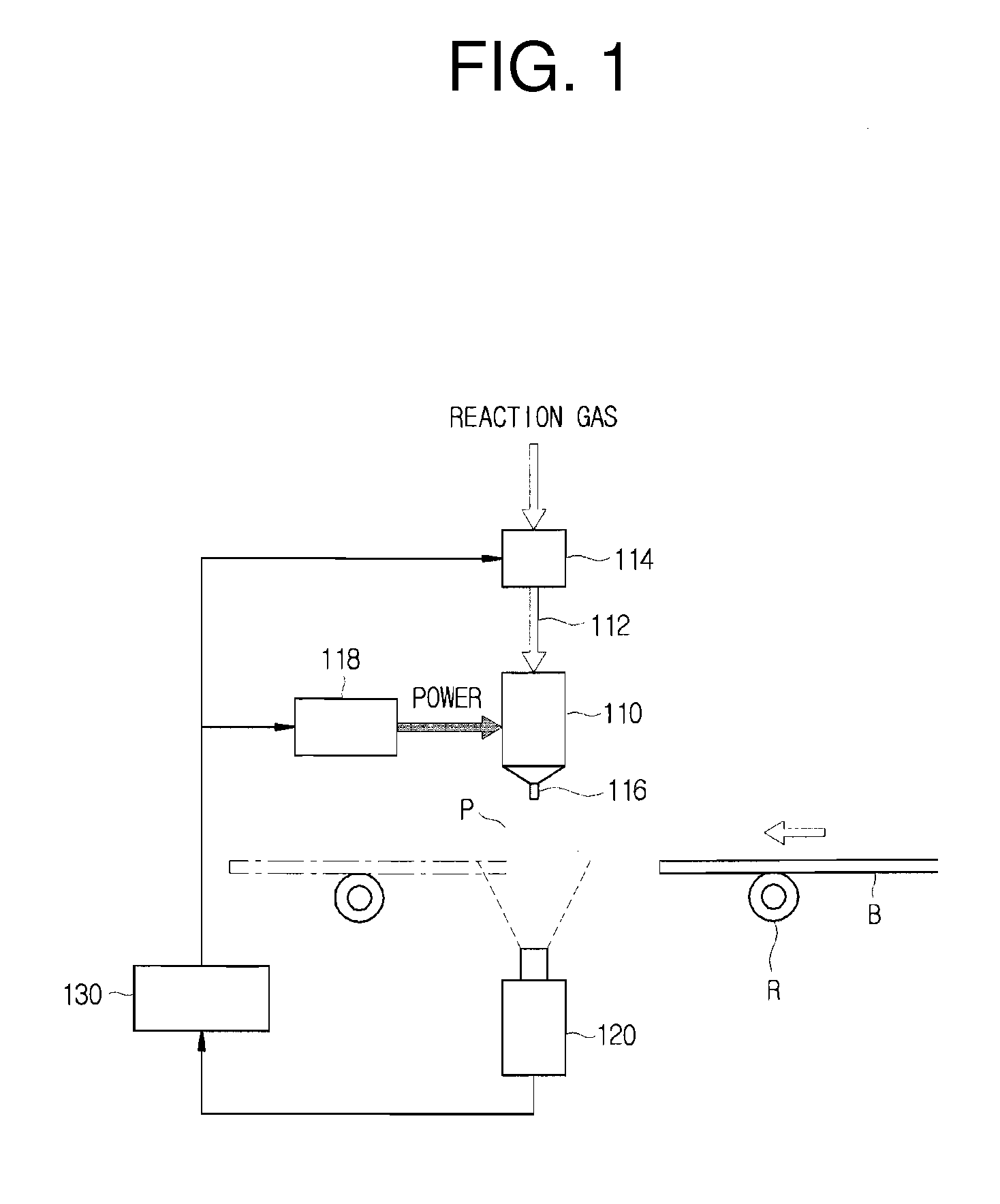

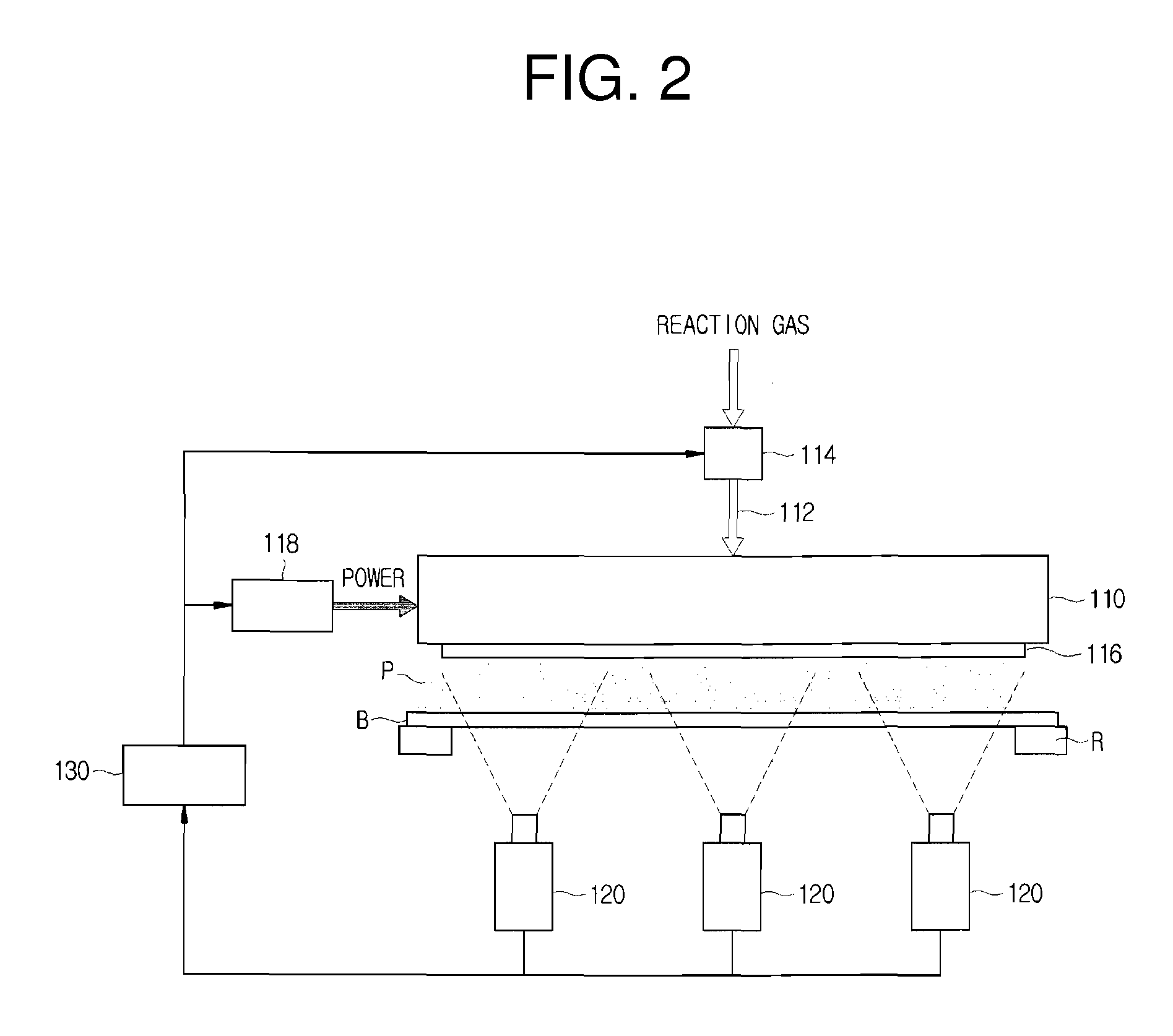

Plasma monitoring device and method

InactiveUS20100149326A1Emission smoothTelevision system detailsElectric discharge tubesGas supplyAtomic physics

A plasma monitoring device includes a plasma supplier including a power supply, a reaction gas supply line, and an emission nozzle for emitting plasma, which is generated therein, toward an object; a camera unit for obtaining an image of the plasma emission state; and a controller for obtaining a measurement value by converting pixel information of the image into a numerical value and comparing it with a reference value, which is a measurement value in a normal emission state, to check the plasma emission state. The camera unit obtains an image of the plasma emission state, and the controller analyzes the image to obtain a measurement value, which is used to monitor the state of plasma in real time and control the amount of reaction gas supplied to the plasma supplier and the plasma discharge condition, so that plasma is evenly emitted from the plasma supplier.

Owner:SNU PRECISION CO LTD

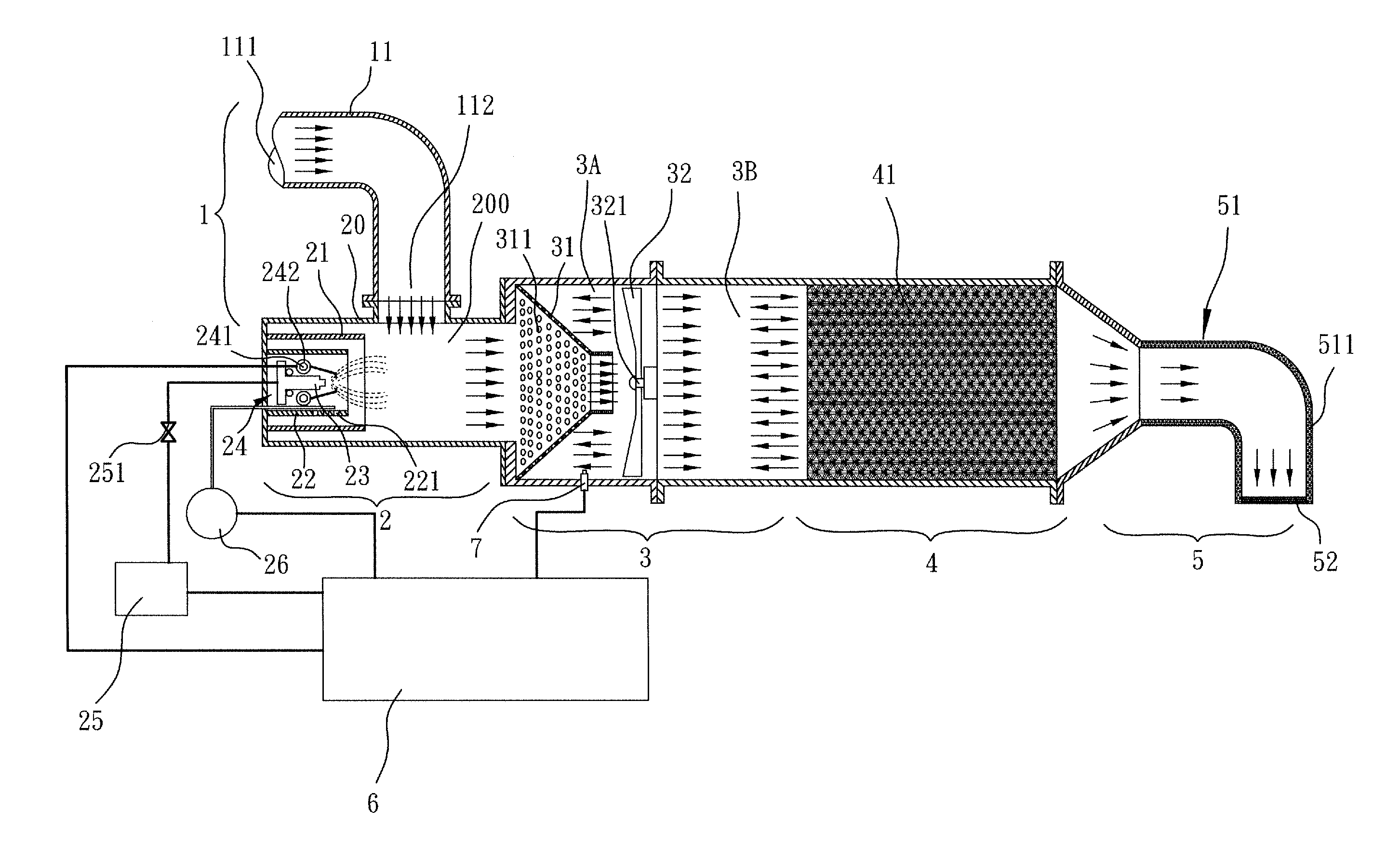

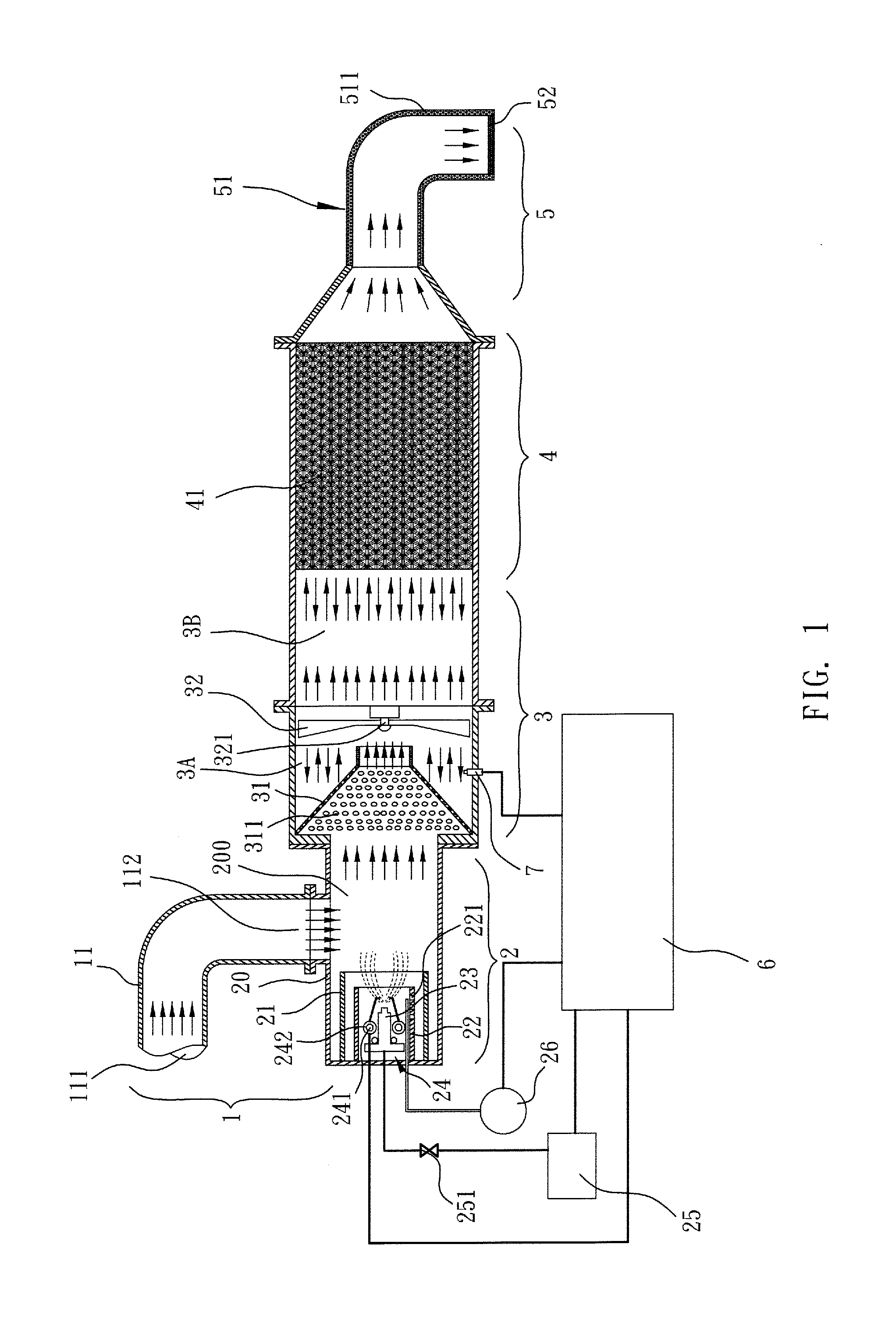

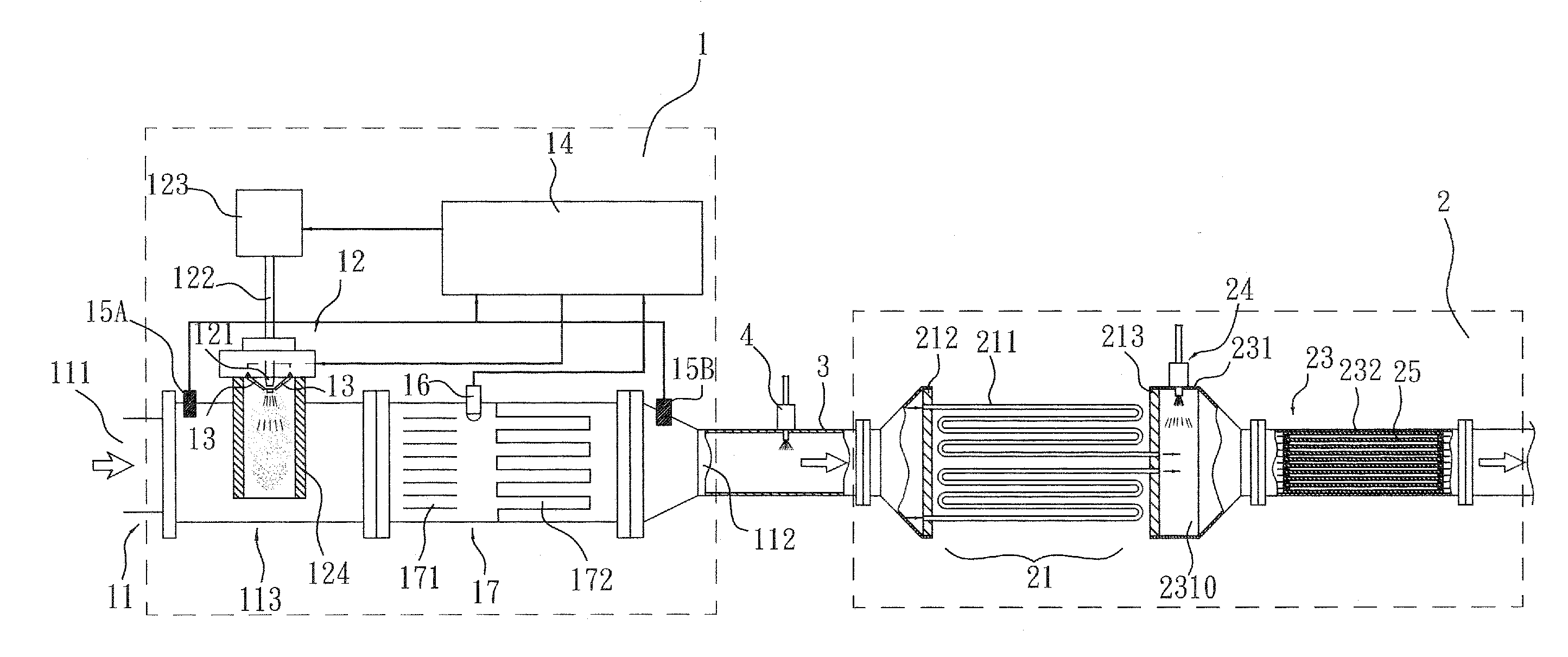

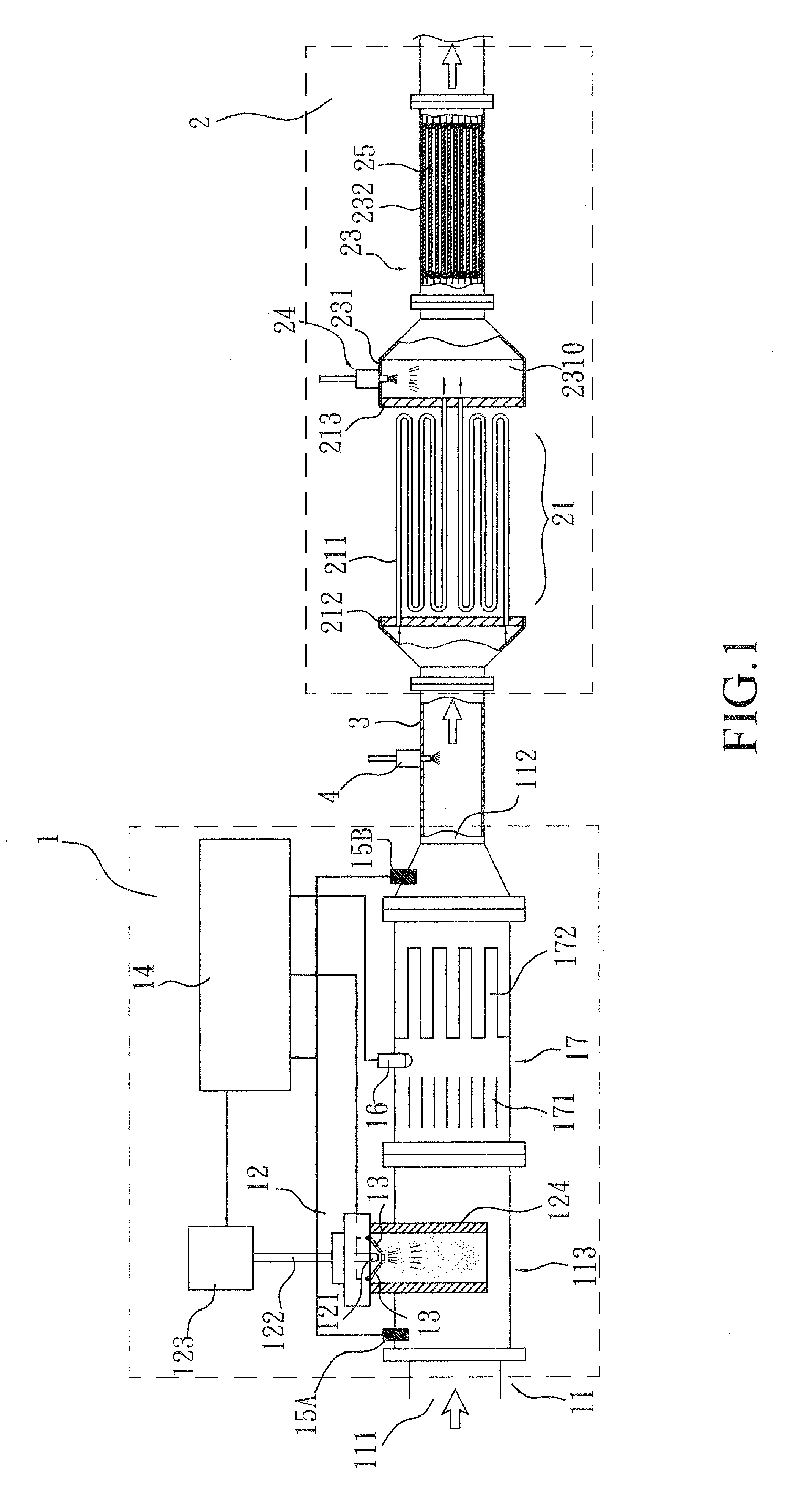

Instantaneous neutralization and purification device for smoke and exhaust gas discharged from automobile

InactiveUS20120216511A1Emission smoothInternal combustion piston enginesExhaust apparatusExhaust gasExhaust fumes

Disclosed is an instantaneous neutralization and purification device for smoke and exhaust gas discharged from an automobile, which includes a first purification treatment device connected to an exhaust pipe, a connection pipe connected to the first purification treatment device, and a second purification treatment device connected to the connection pipe. The first purification treatment device includes a combustion system and a filtration system. A first pressure sensor detects an exhaust gas pressure greater than a threshold and signals a fuel tank to supply fuel to the combustion system for combustion and heating the filtration system to cause combustion of carbon build-up. A second pressure sensor detects the exhaust gas pressure becoming lower than a threshold and signals the fuel tank to stop supply of fuel. The exhaust gas is then conducted through the connection pipe, where an alkaline solution is sprayed to neutralize acids of the exhaust gas.

Owner:CHEN WEN LO

Backlight module and liquid crystal display using the same

ActiveUS8814413B2Improve efficiencyReduce manufacturing costOptical light guidesNon-linear opticsMicro structureLiquid-crystal display

The present disclosure provides a backlight module. The backlight module includes at least one light tube. Each light tube includes a light emitting side for emitting light and a first micro-structure disposed on the light emitting side for breaking total reflections of the light in the light tube. With the first micro-structure disposed on the light emitting side of the light tube, the total reflections of the light in the light tube can be broken to allow the light to be emitted from the light tube evenly. Also, the reflecting structure is disposed on non-light emitting side for improving the using efficiency of the light and reducing the manufacturing cost of the backlight module. Additionally, the fluorescent layer is coated on the light emitting side for improving a color saturation level of a LCD using the backlight module.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

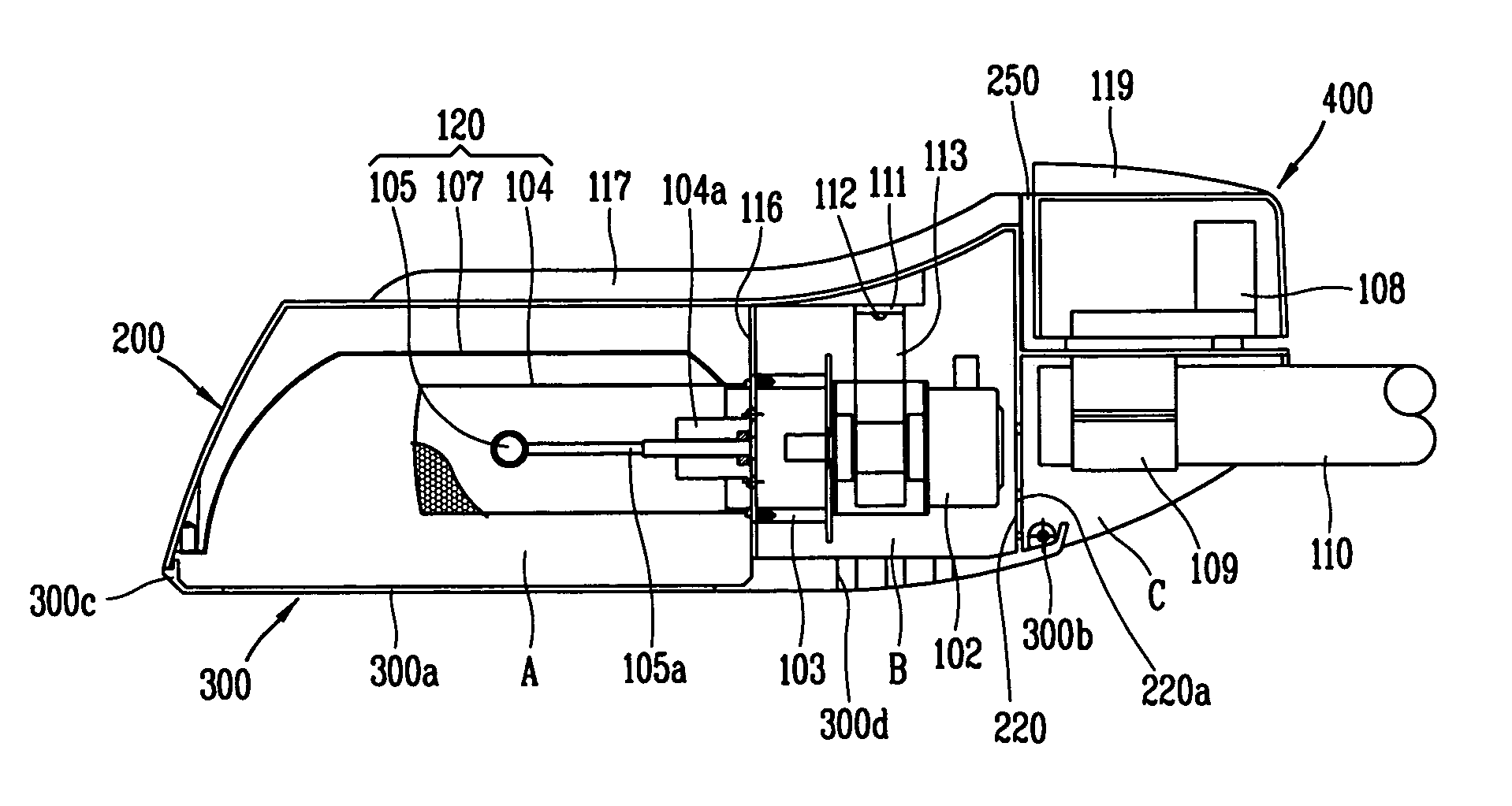

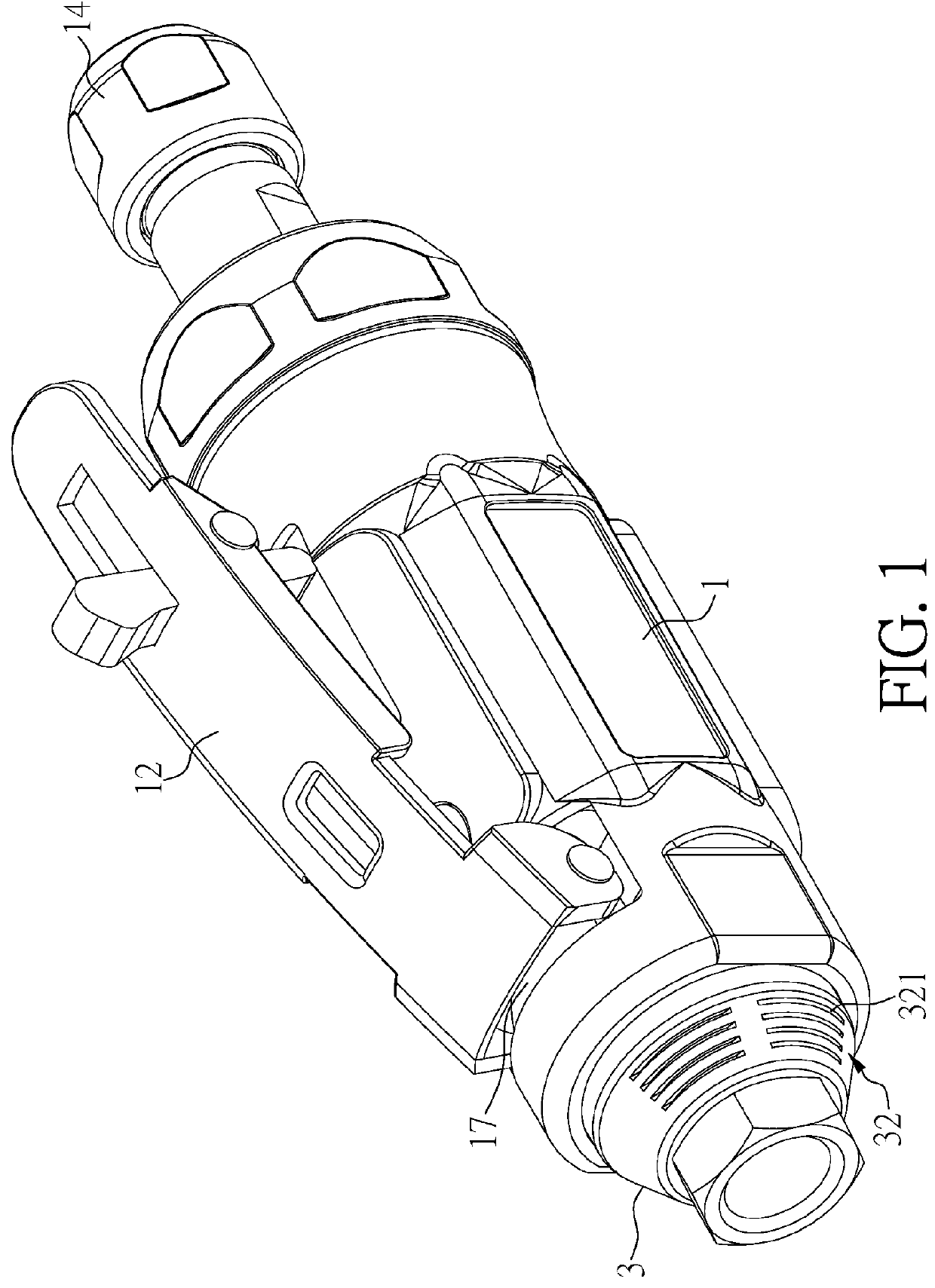

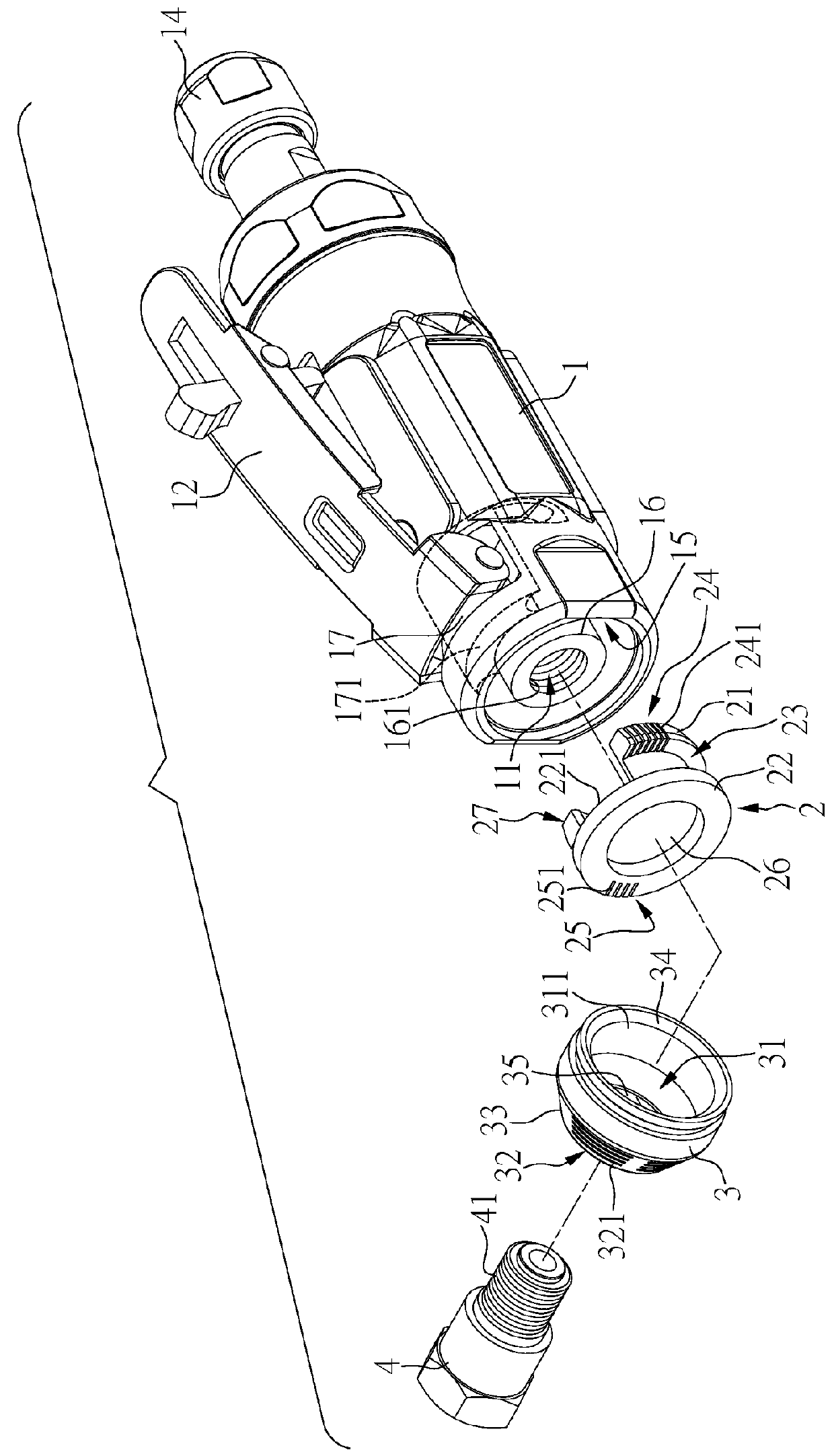

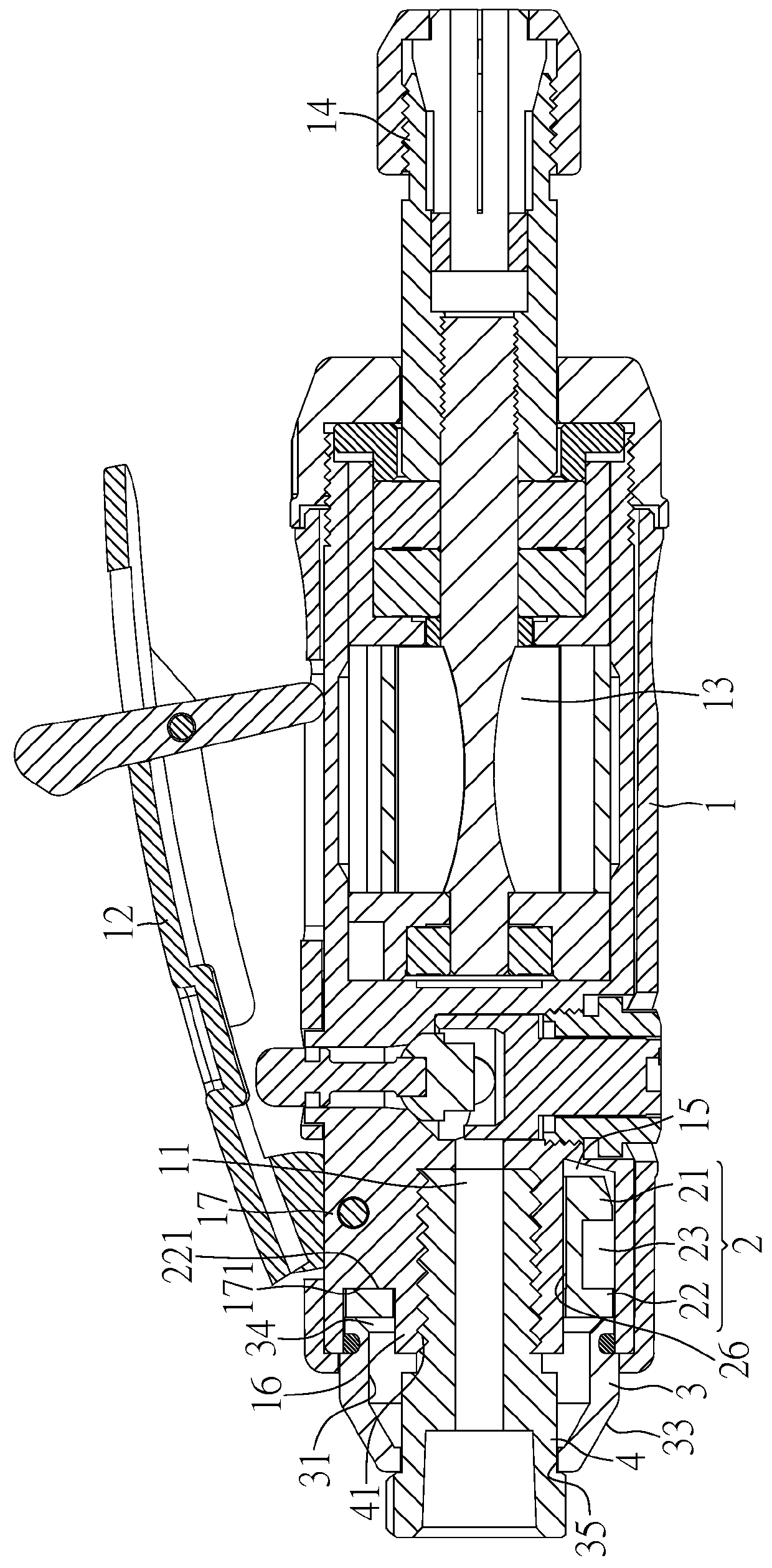

Compressed air tool having silencer structure

ActiveUS9381637B1Being driven inefficiently can be preventedEmission smoothSilencing apparatusPortable percussive toolsMufflerCountersink

The present disclosure illustrates a compressed air tool having a silencer structure. A silencing element and an outer cover are disposed in an air exhaust channel of a main body of the compressed air tool. The silencing element has two walls and a channel. The two walls both have long slits, the long slits of the two walls are misaligned and not directly faced with each other. After the exhaust is inputted via the long slits of one of the two walls, the exhaust is flowed through the channel and emitted to the outside via the long slits of other of the two walls. Therefore, the air flow of the exhaust can be weakened, and the exhaust is then entered the countersink of the outer cover and emitted from the side hole, whereby the effect of silencing and reducing the noise caused by the emitted exhaust can be achieved.

Owner:STORM PNEUMATIC TOOL CO LTD

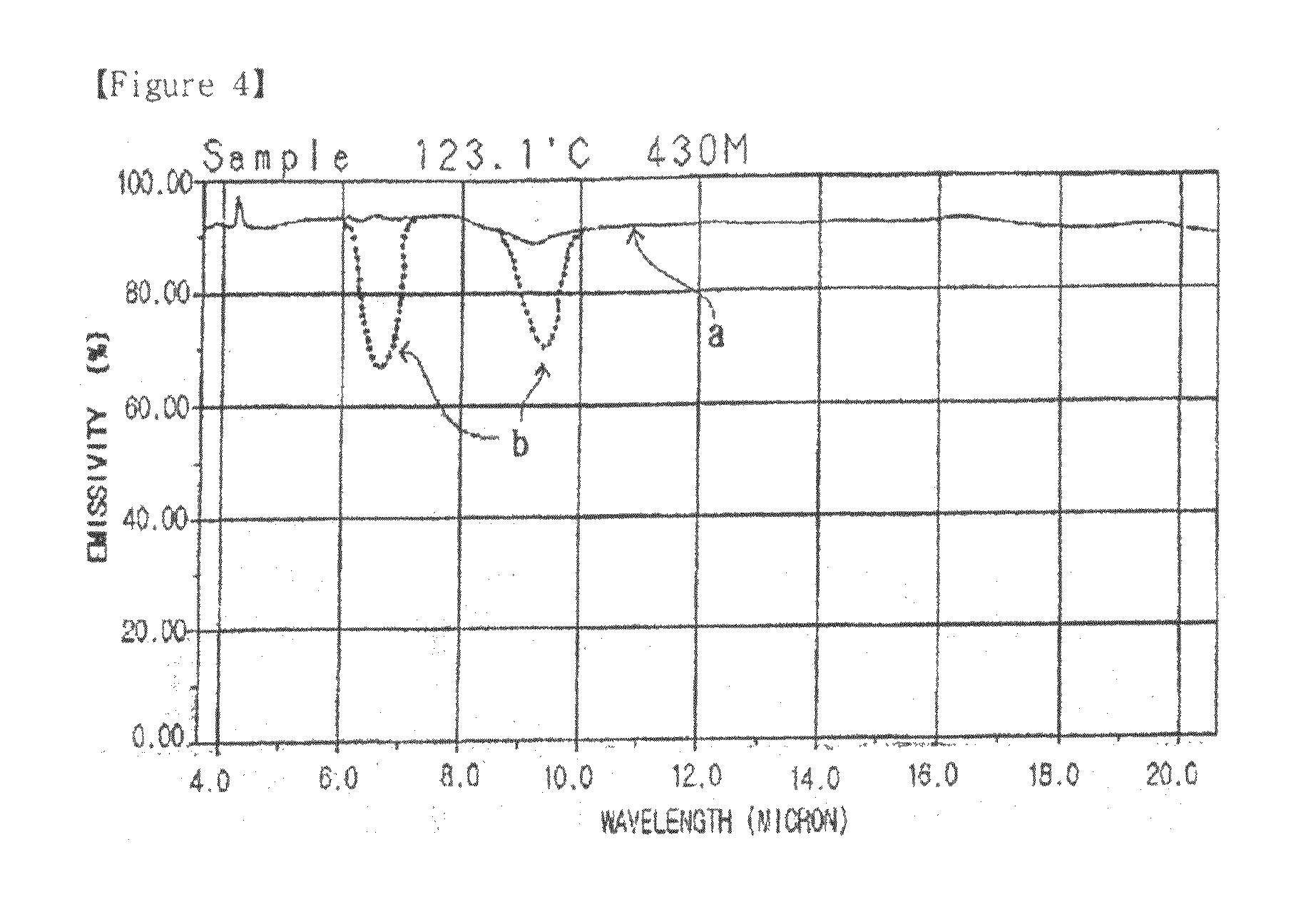

Composition for ceramics with carbon layer and manufactured method of ceramics using this

InactiveUS20100176541A1Superior adiabatic propertyHigh heat resistanceCeramic shaping apparatusClaywaresCeramic glazeCeramic

Disclosed herein is a composition comprising 50 to 73% by weight of loess, 9 to 20% by weight of clay, 3 to 10% by weight of wood flour, 3 to 7% by weight of lignum carbonized carbon body powder, 11 to 15% by weight of water and 1 to 5% by weight of ceramic glaze to manufacture a ceramic moulding including a carbon layer therein. Preferably, the composition according to the present invention further comprises elvan powder and Schmotte. Meanwhile, the present invention also provides a method of manufacturing a ceramic moulding with a carbon layer comprising forming a moulding out of the composition and firing the formed moulding with oxidizing flames.

Owner:KIM KOO HAN

Electronic relay

ActiveUS9025344B2Improve Noise PerformanceEmitted heatFuse disposition/arrangementElectric switchesInterior spaceEngineering

An electronic relay includes: a housing having an interior space therein and a lateral side and a lower side of which are opened, a board installation part being formed along a periphery of the opened side of the housing; a printed circuit board a periphery of which is inserted into and installed in the board installation part of the housing, for shielding the opened side of the housing and performing a switching function; a lower cover for shielding a lower side of the housing, one side edge of the printed circuit board being fixed to the lower cover; and terminals ends of which are electrically connected to the printed circuit board and opposite ends of which pass through the lower cover to protrude to the outside.

Owner:KOREA ELECTRIC TERMINAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com