Exhaust Purification Device Capable of Performing Regeneration by Using Quick Combustion

a technology of exhaust purification and quick combustion, which is applied in the direction of machines/engines, process and machine control, instruments, etc., can solve the problems of increasing the pressure in the exhaust pipe that mounts the filter, the working temperature of the engine cannot be increased to a level at which a regeneration process can be properly performed, and the uneconomical and troublesome problems, so as to achieve the effect of increasing the working temperature of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]To allow those skilled in the art to implement the present invention easily, one embodiment is illustrated in detail in the following paragraphs with reference to the accompanying drawings.

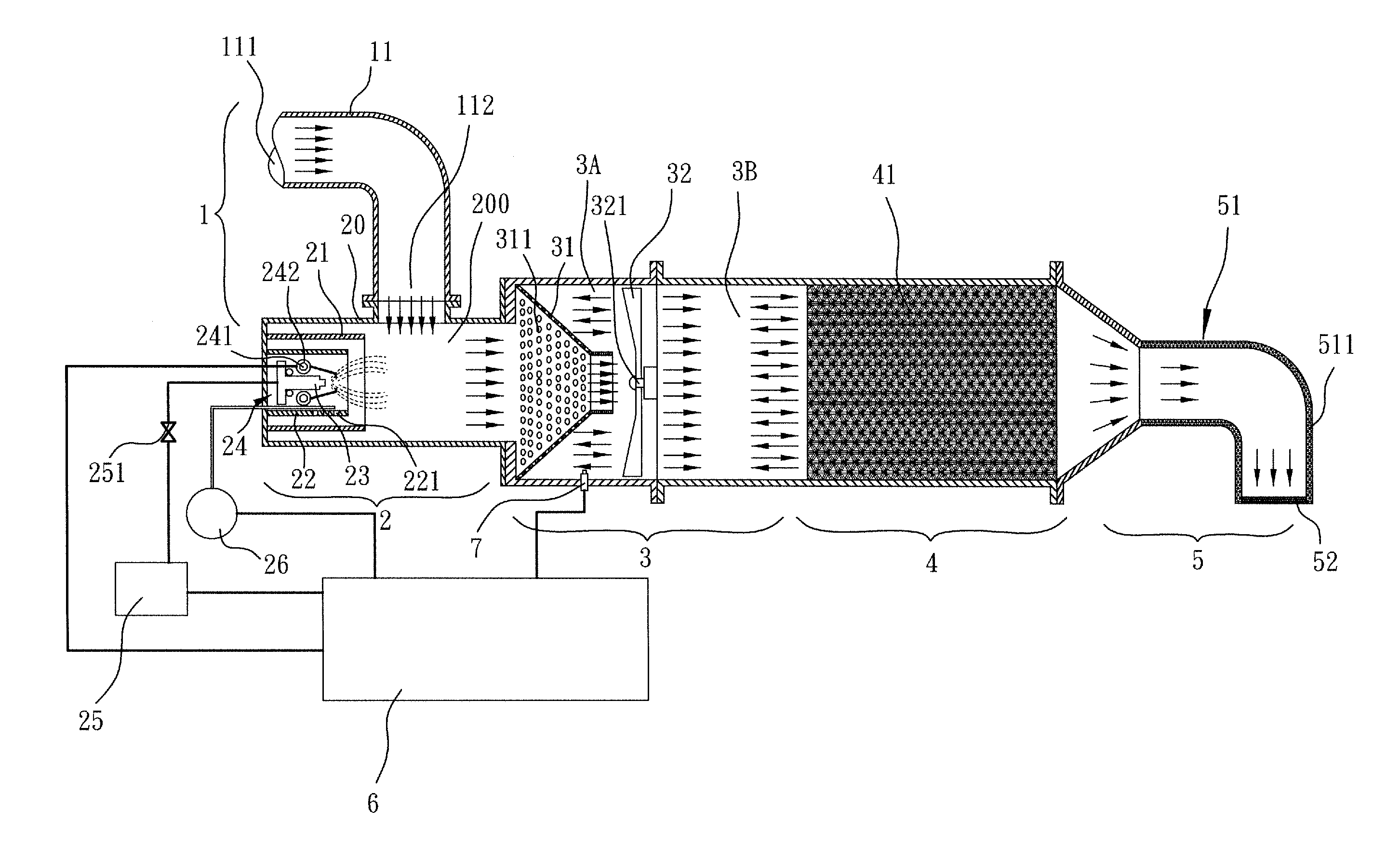

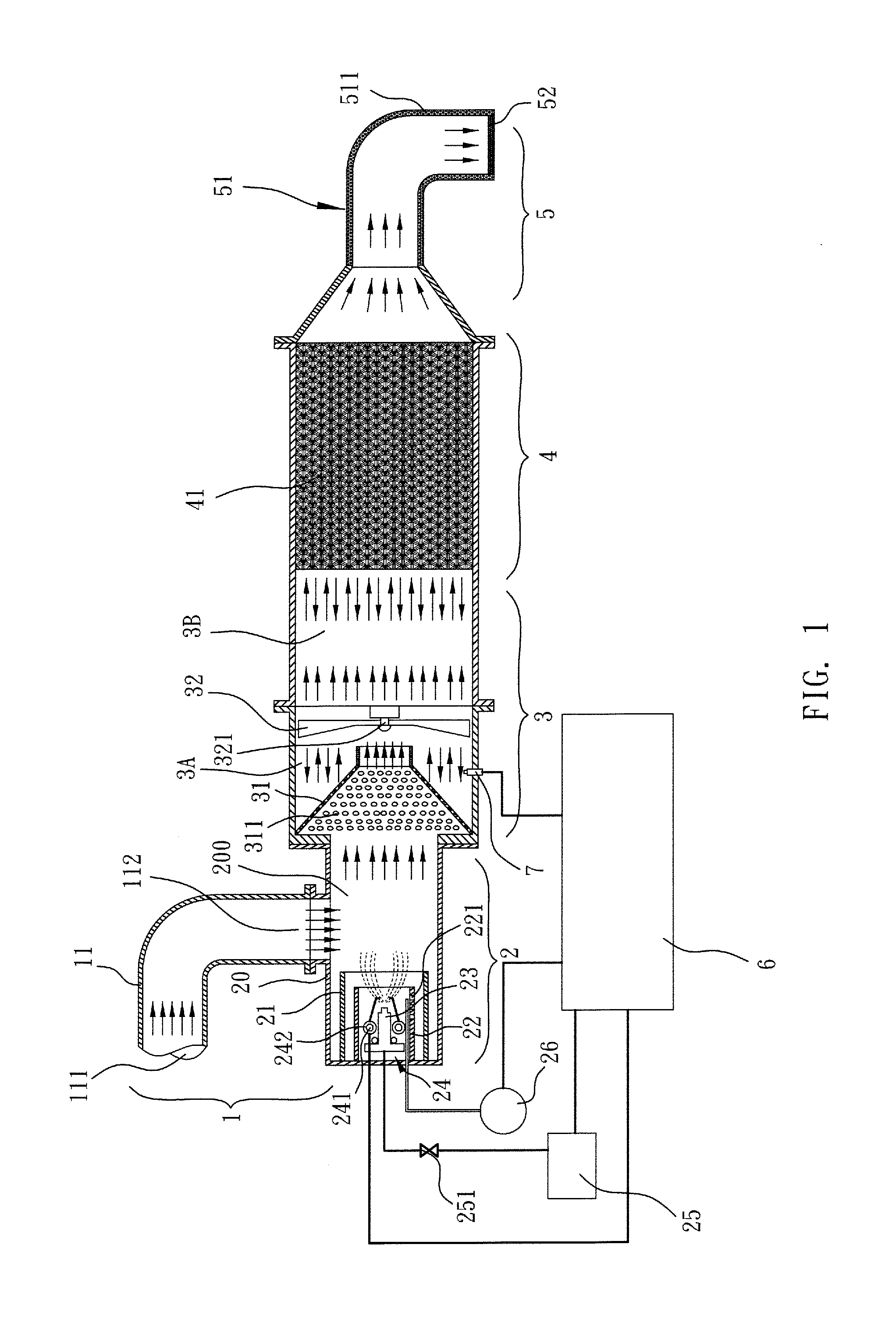

[0015]Referring to FIG. 1, an exhaust purification device for vehicles according to one embodiment of the present invention is shown, which generally comprises a connection unit 1, a combustion unit 2, a buffer unit 3, a filtration unit 4, an emission unit 5, and a control unit 6.

[0016]The connection unit 1 can be formed as a pipe 11, which has an inlet 111 and an outlet 112, wherein the inlet 111 is adapted to be connected to an exhaust pipe of a vehicle's engine (not shown).

[0017]The combustion unit 2 includes a main housing 20, a fuel-atomization nozzle 23, and an igniter 24. The main housing 20 is connected to the outlet 112 of the connection unit 1. The main housing 20 defines a combustion chamber 200 therein and is provided therein with a protective shell 21 and an open-end container 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com