Patents

Literature

80results about How to "Excellent light diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

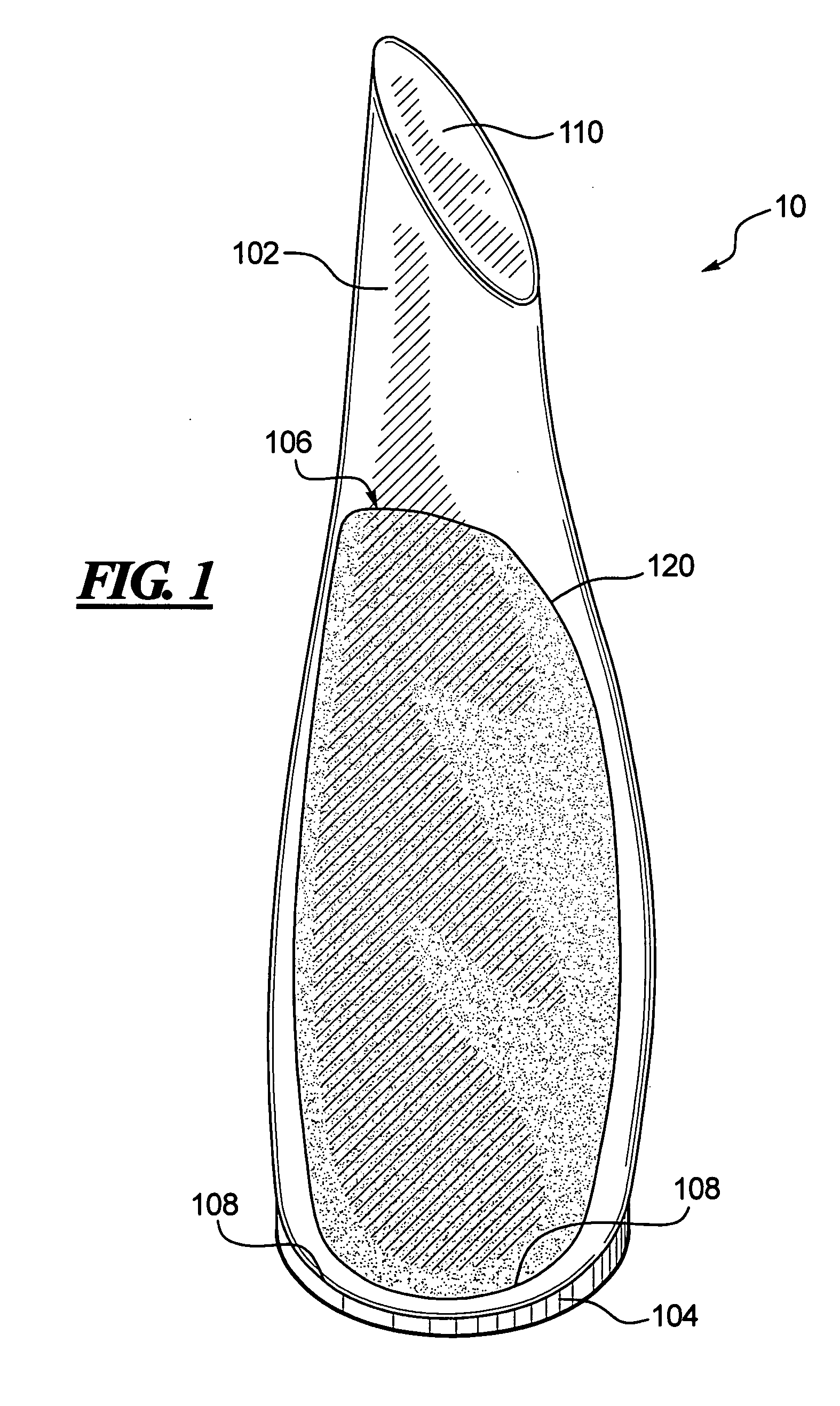

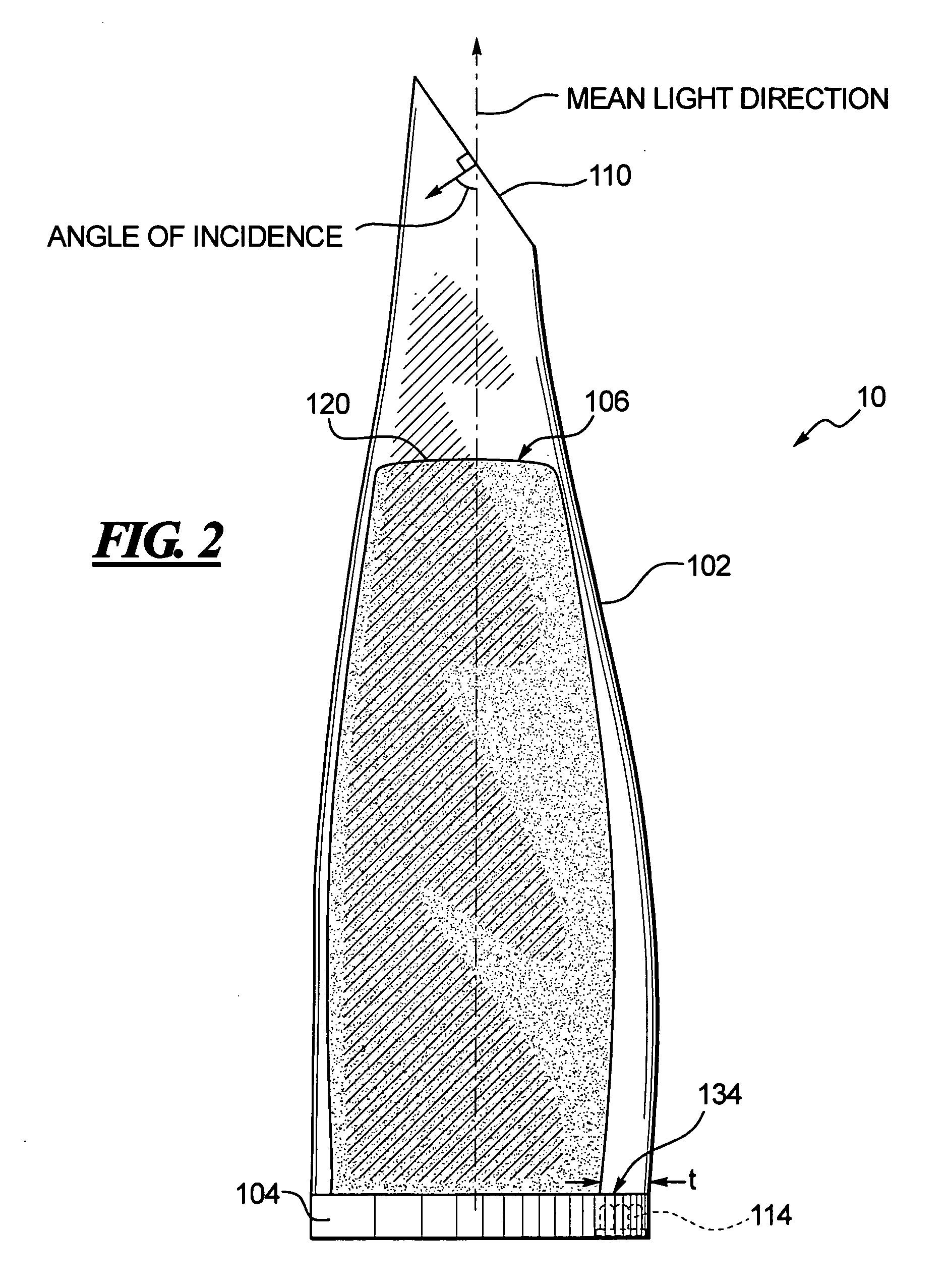

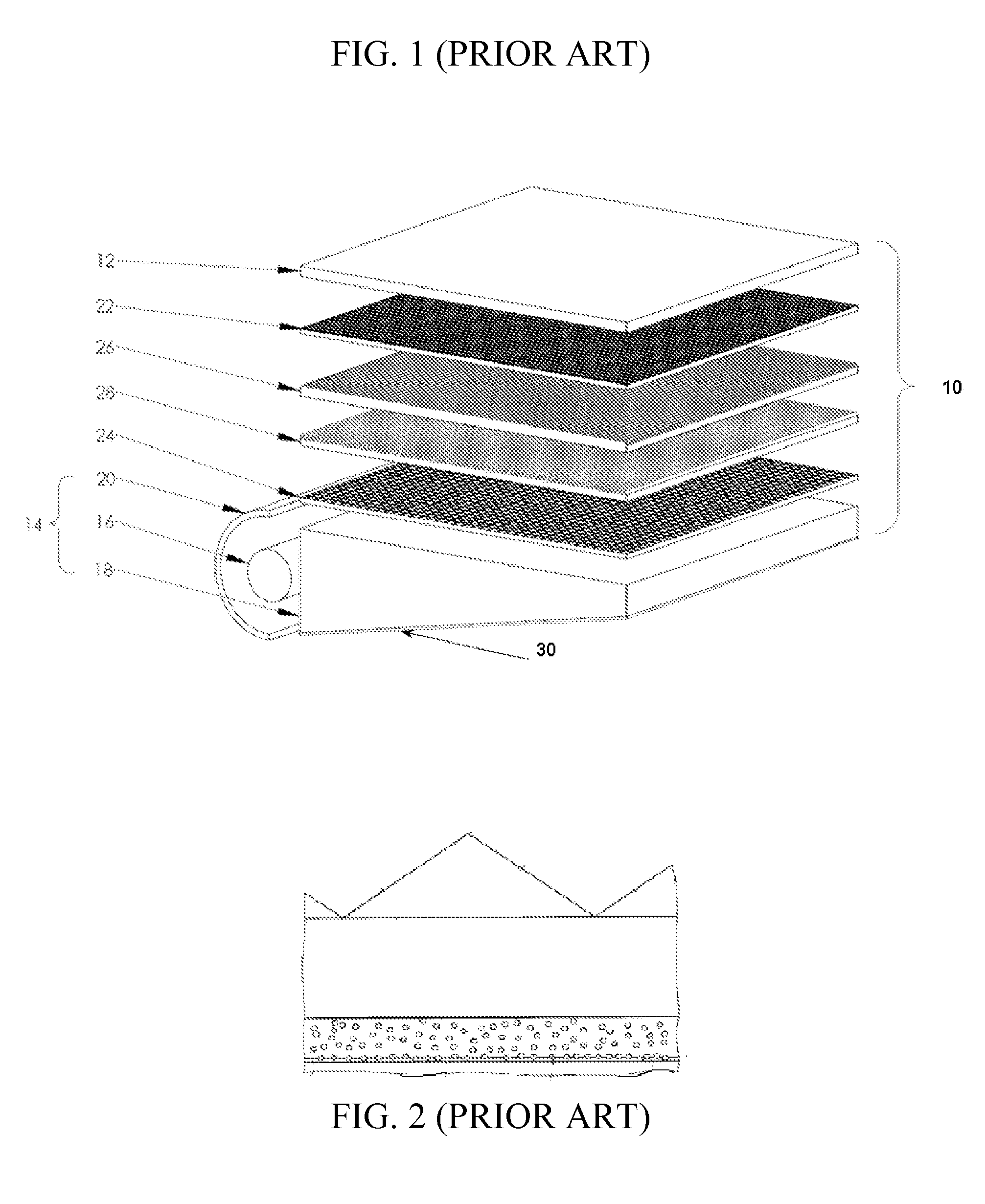

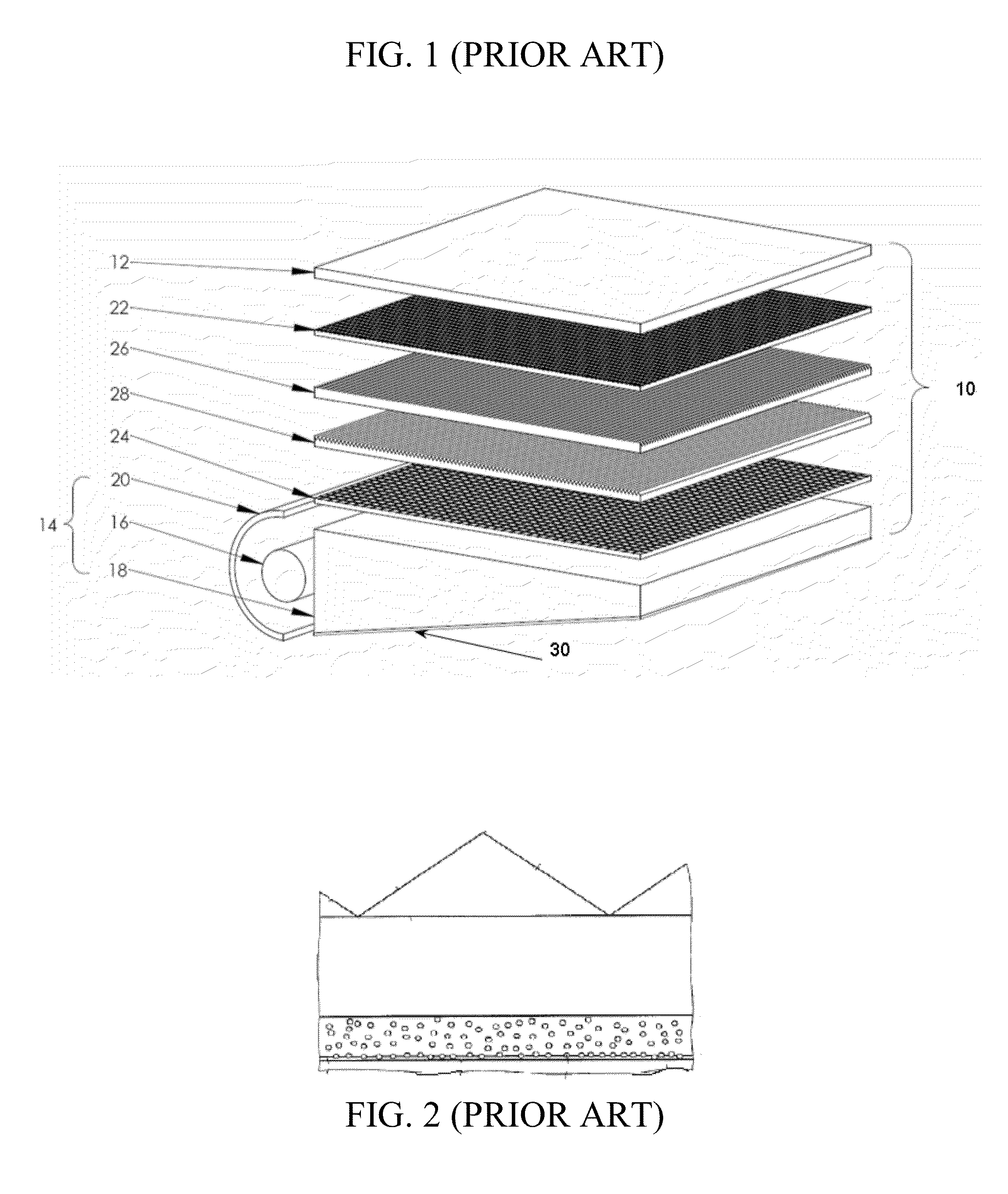

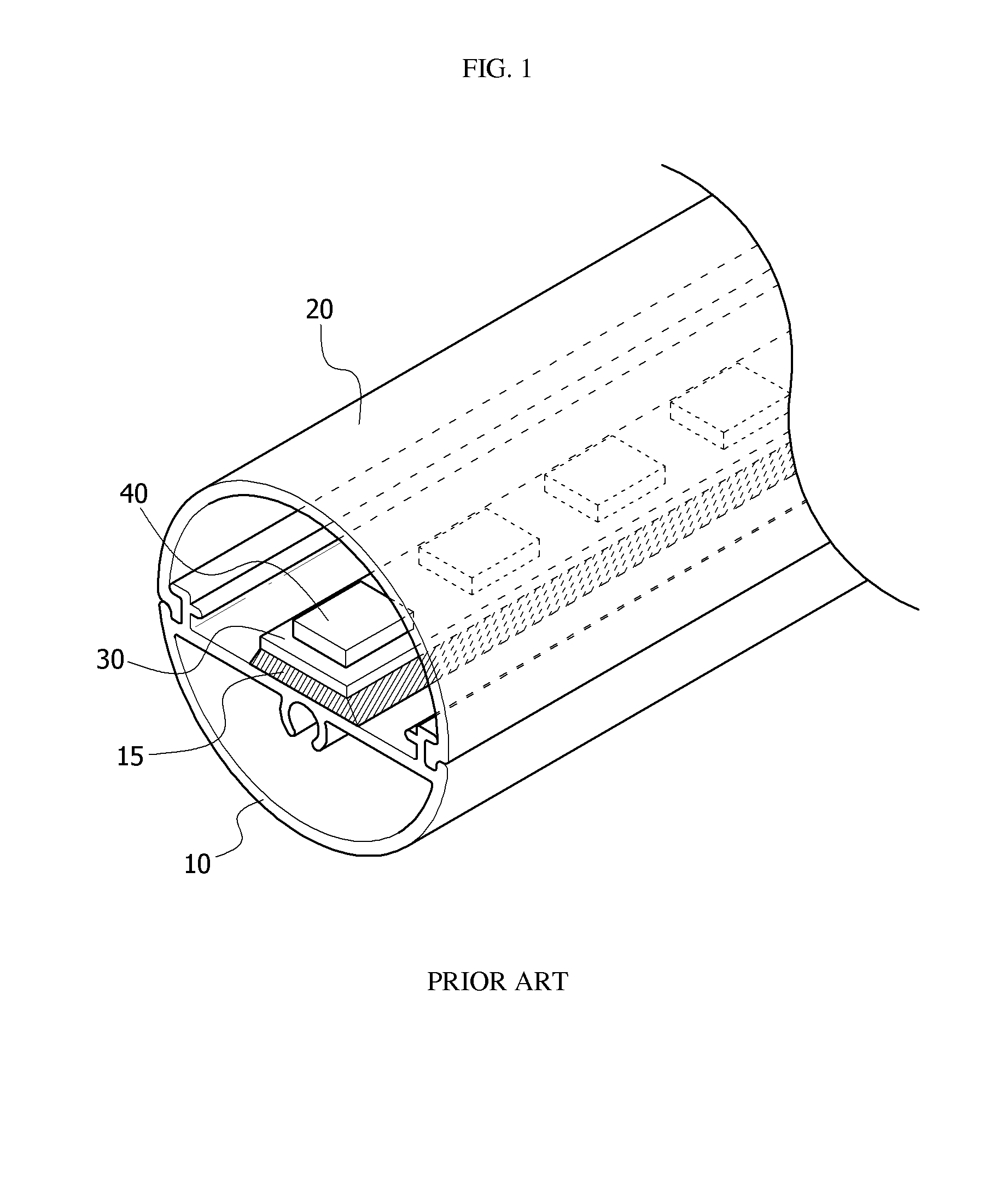

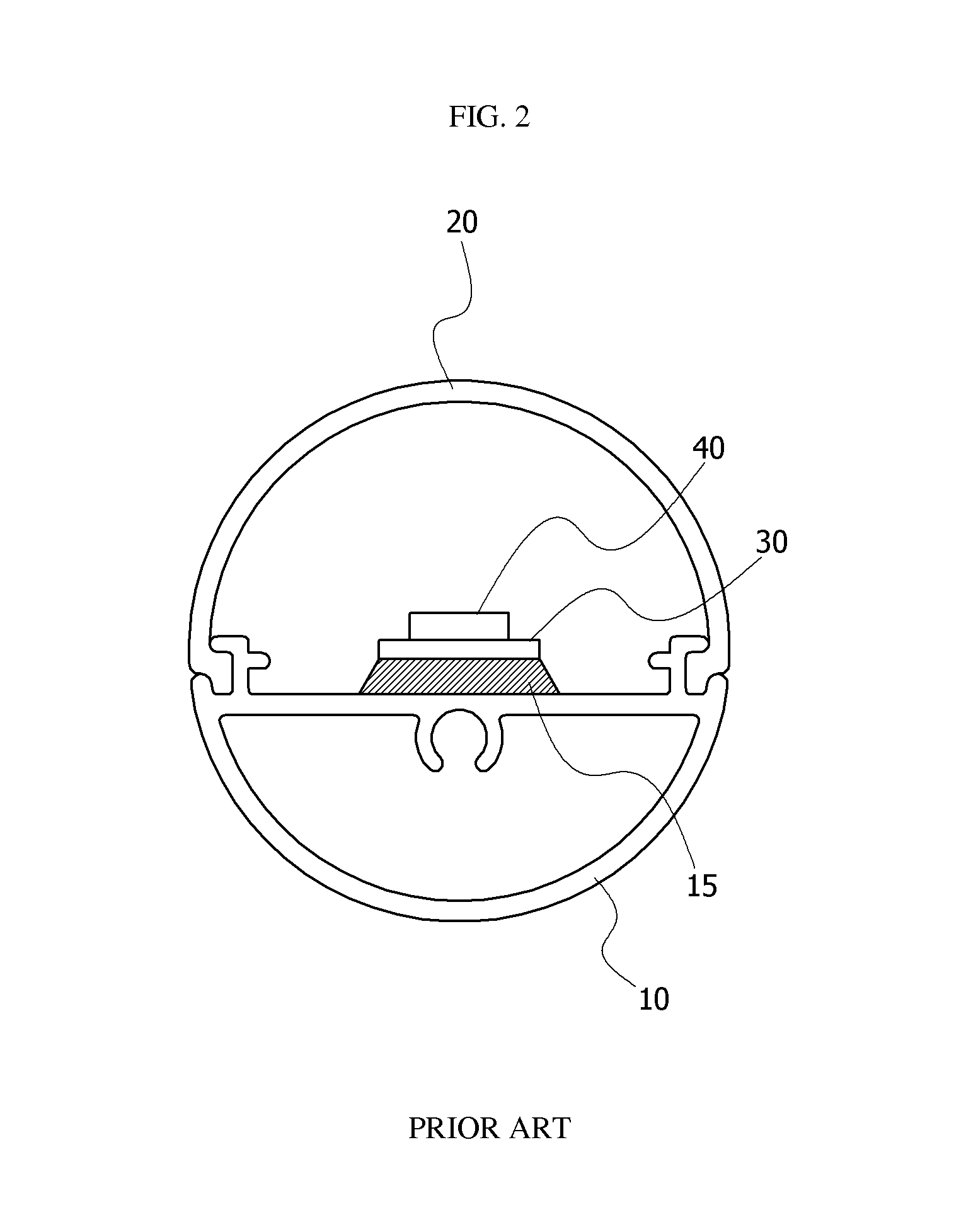

Color changing light object and user interface for same

InactiveUS20060158138A1Excellent light diffusionEliminate needPoint-like light sourceElectrical apparatusEffect lightColor changes

Illuminated, decorative light objects are disclosed that provide at least one aesthetic lighting display or light show, and to a user interface for the same. A disclosed decorative light object includes a translucent housing. The housing has a bottom opening leading into a cavity. The object also includes a base assembly that covers the bottom opening of the housing. The base assembly includes a user interface. The user interface includes light show circuitry, memory for storing a plurality of light shows, switches or buttons for recalling the light shows from the memory and at least one light group comprising red, green and blue lights. The switches of the user interface are supported in the bottom opening. The light show circuitry, memory and lights are supported within the cavity. Preferably, a translucent light pipe with a roughened lambertian outer surface covers and hides the circuitry and the lights. As the light shines through the light pipe it is diffused thereby creating a warm glowing appearance.

Owner:SC JOHNSON & SON INC

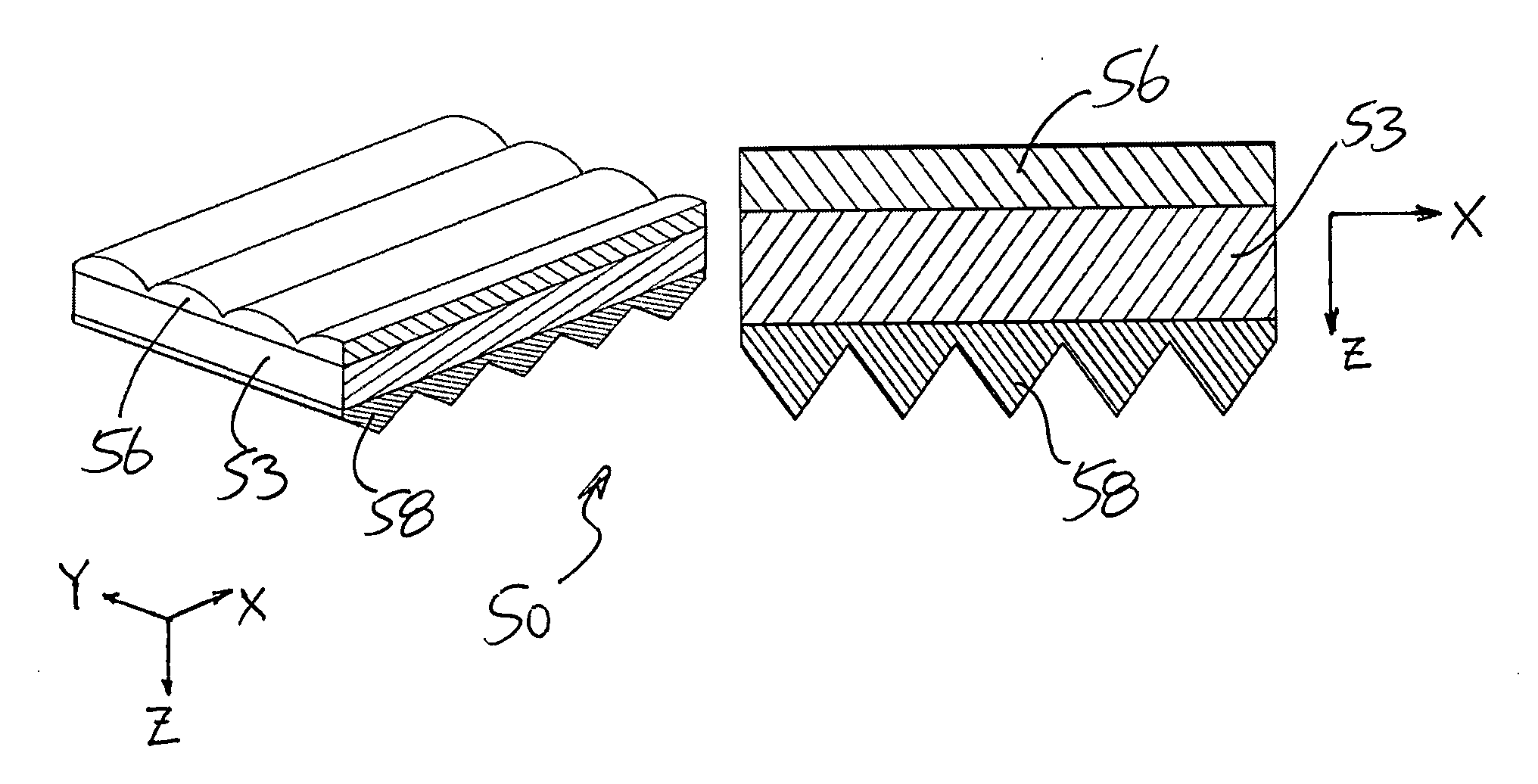

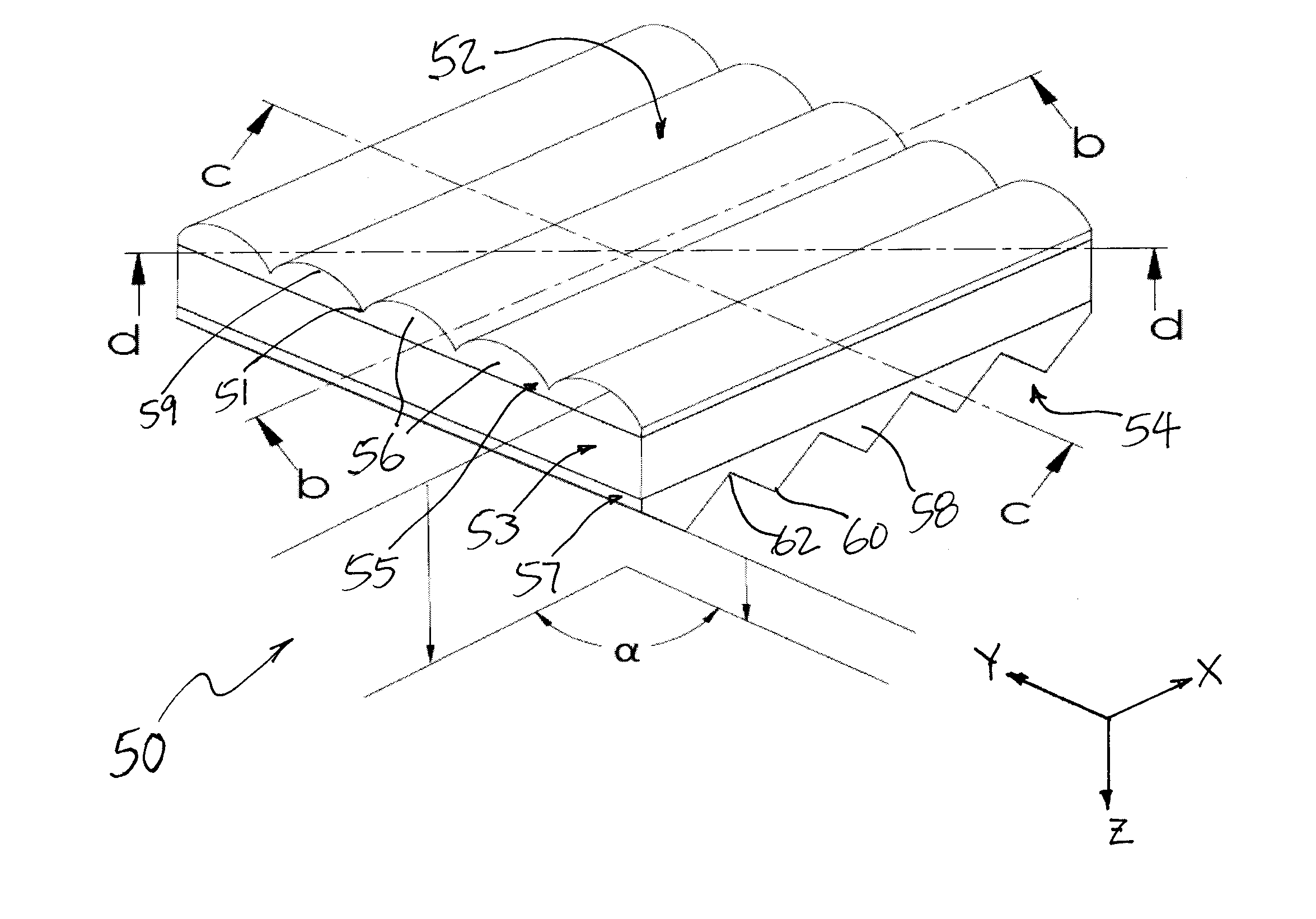

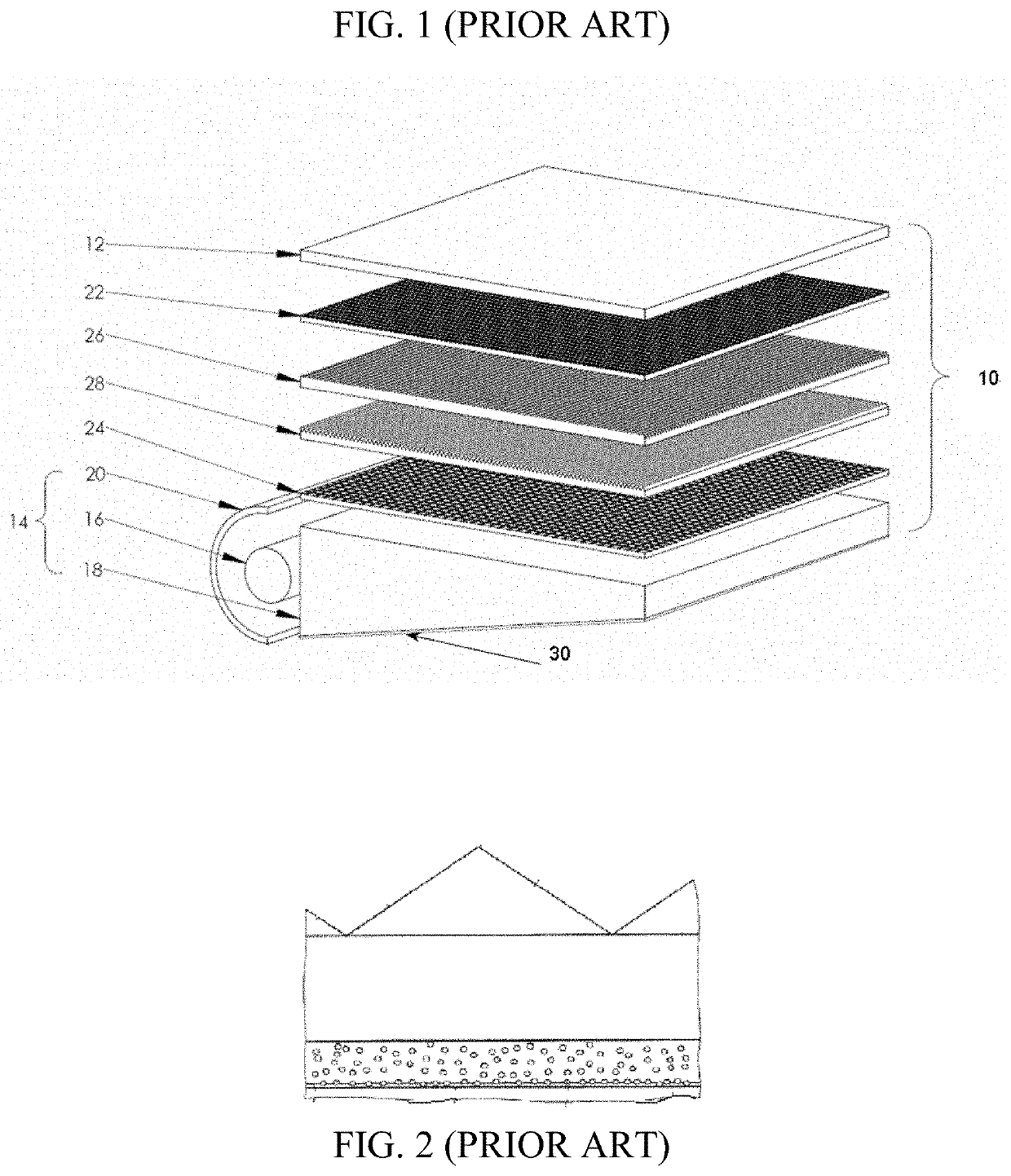

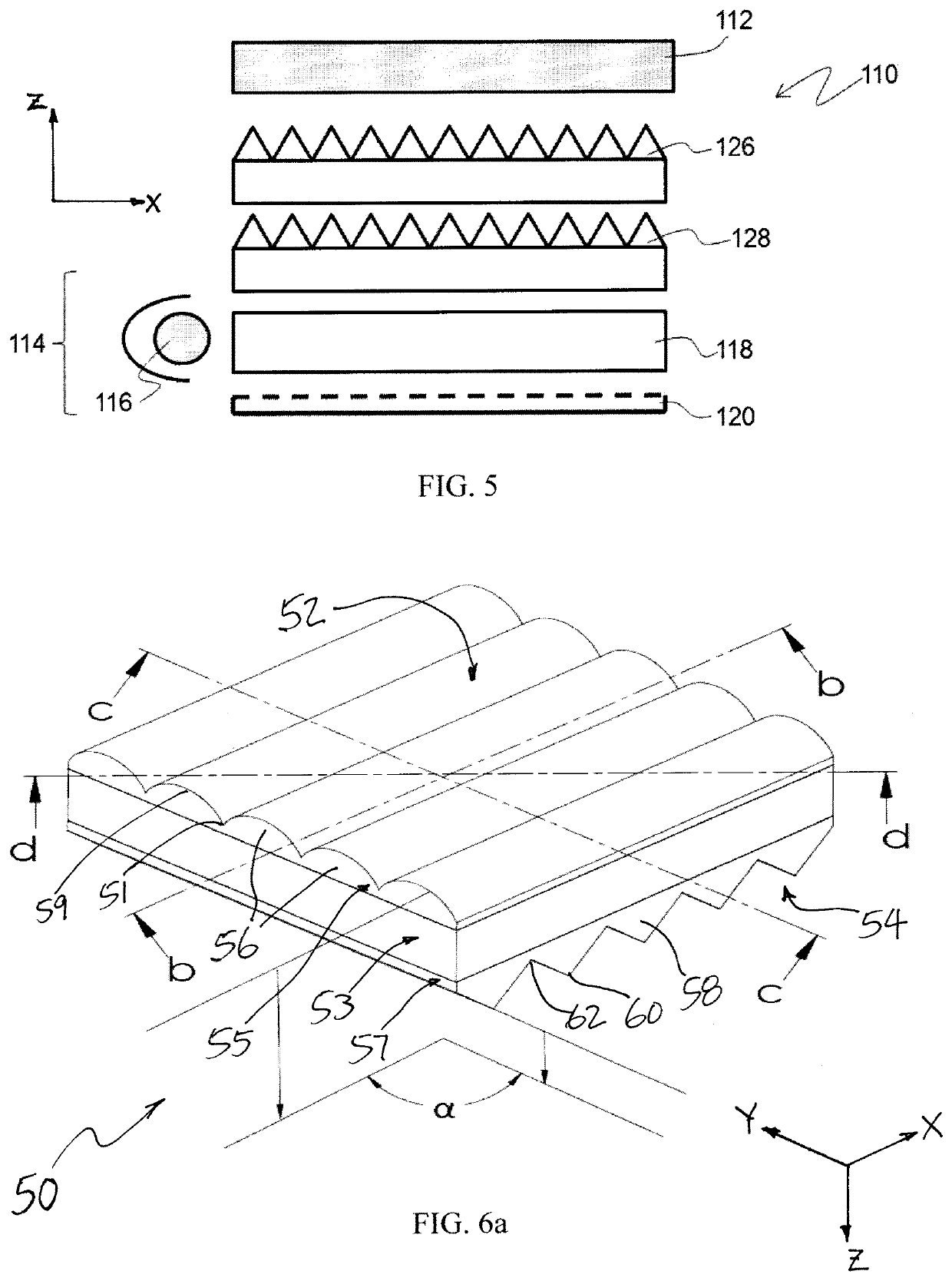

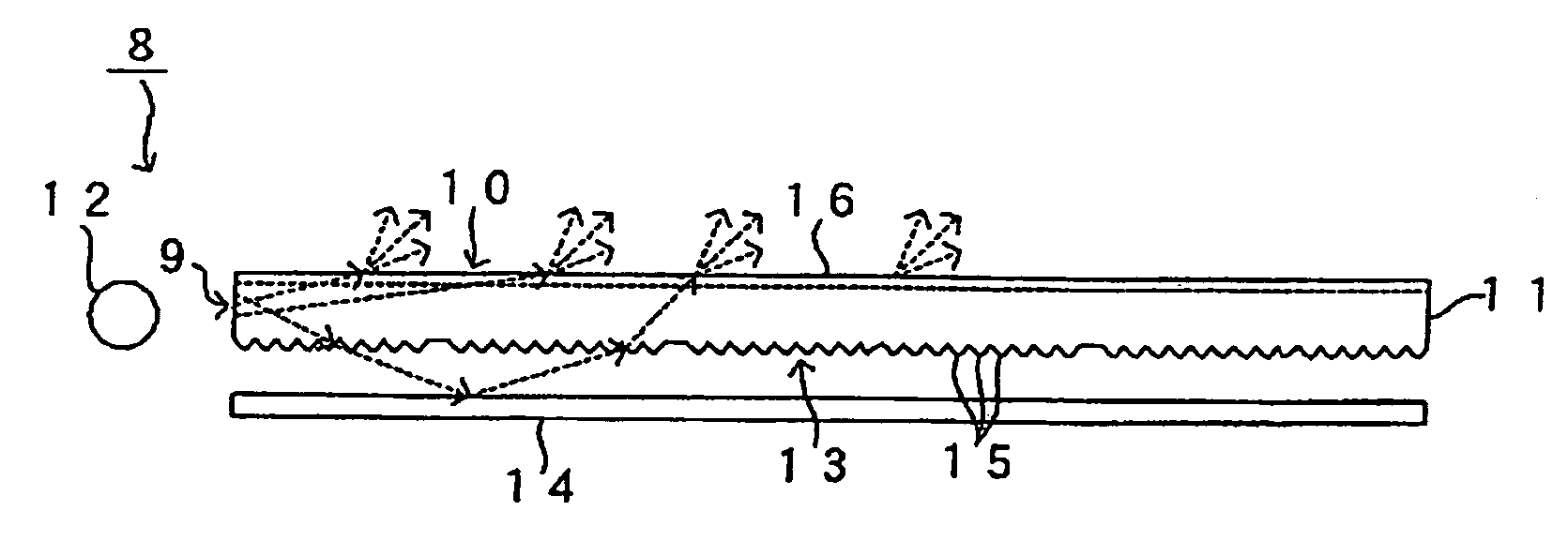

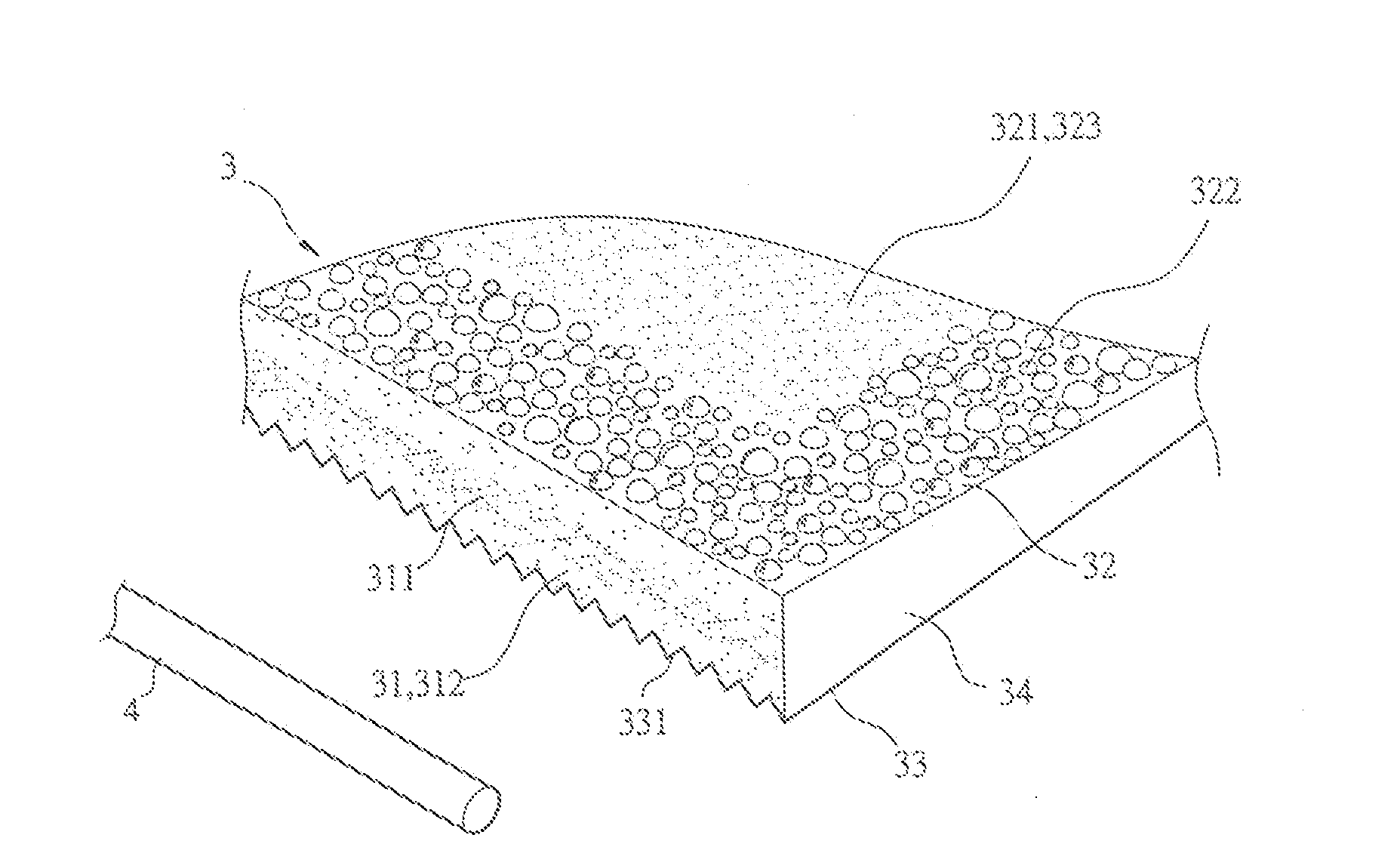

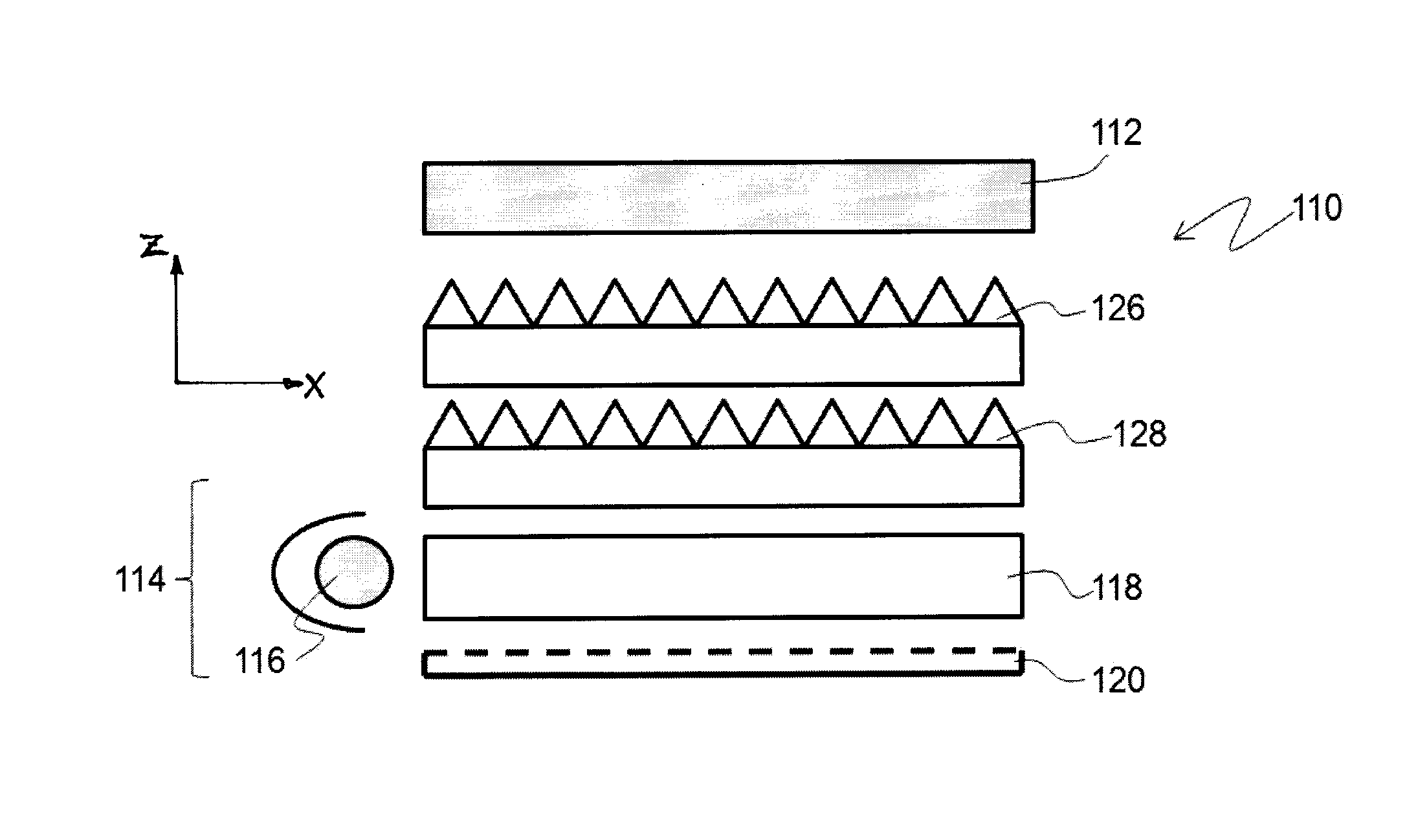

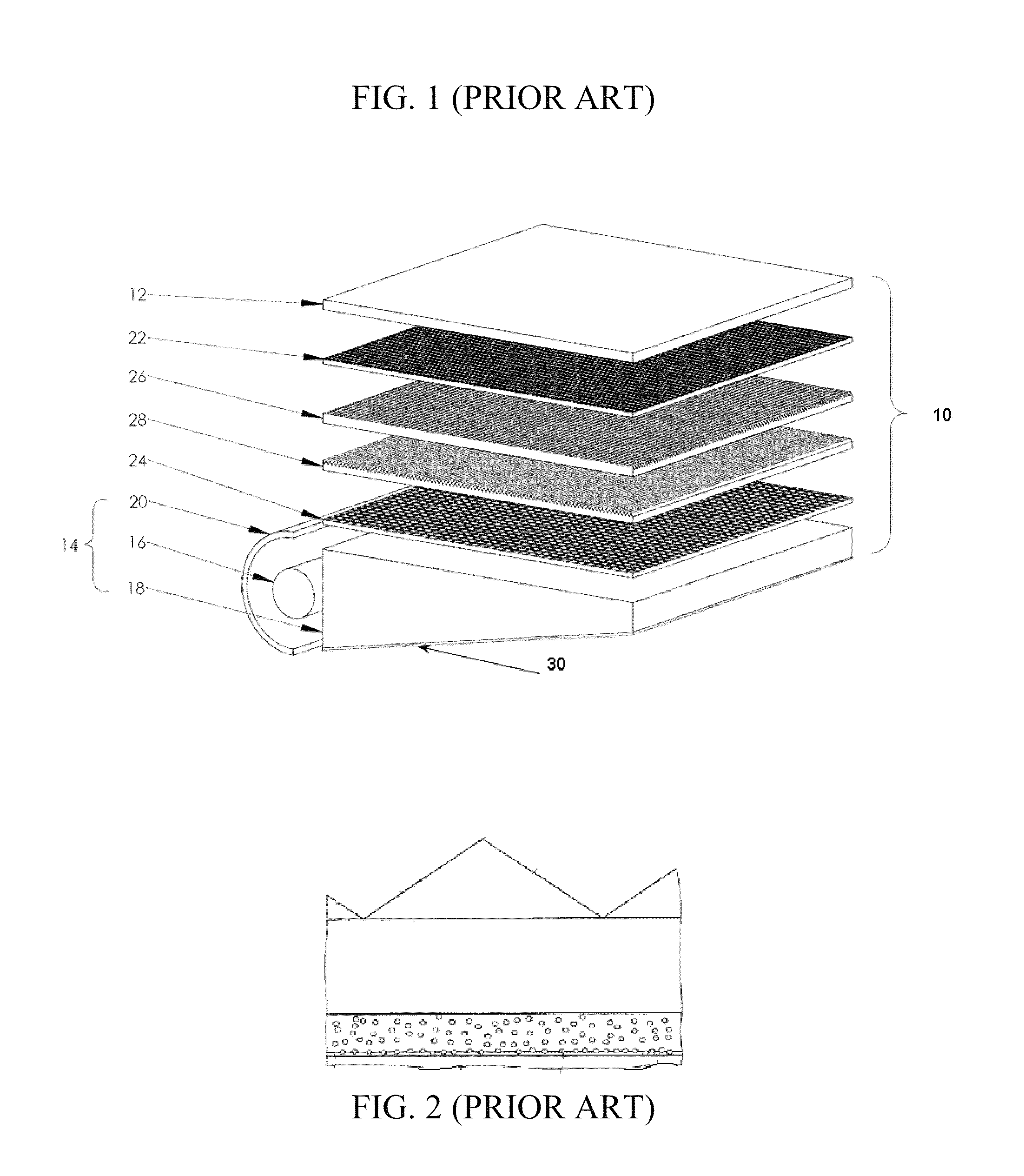

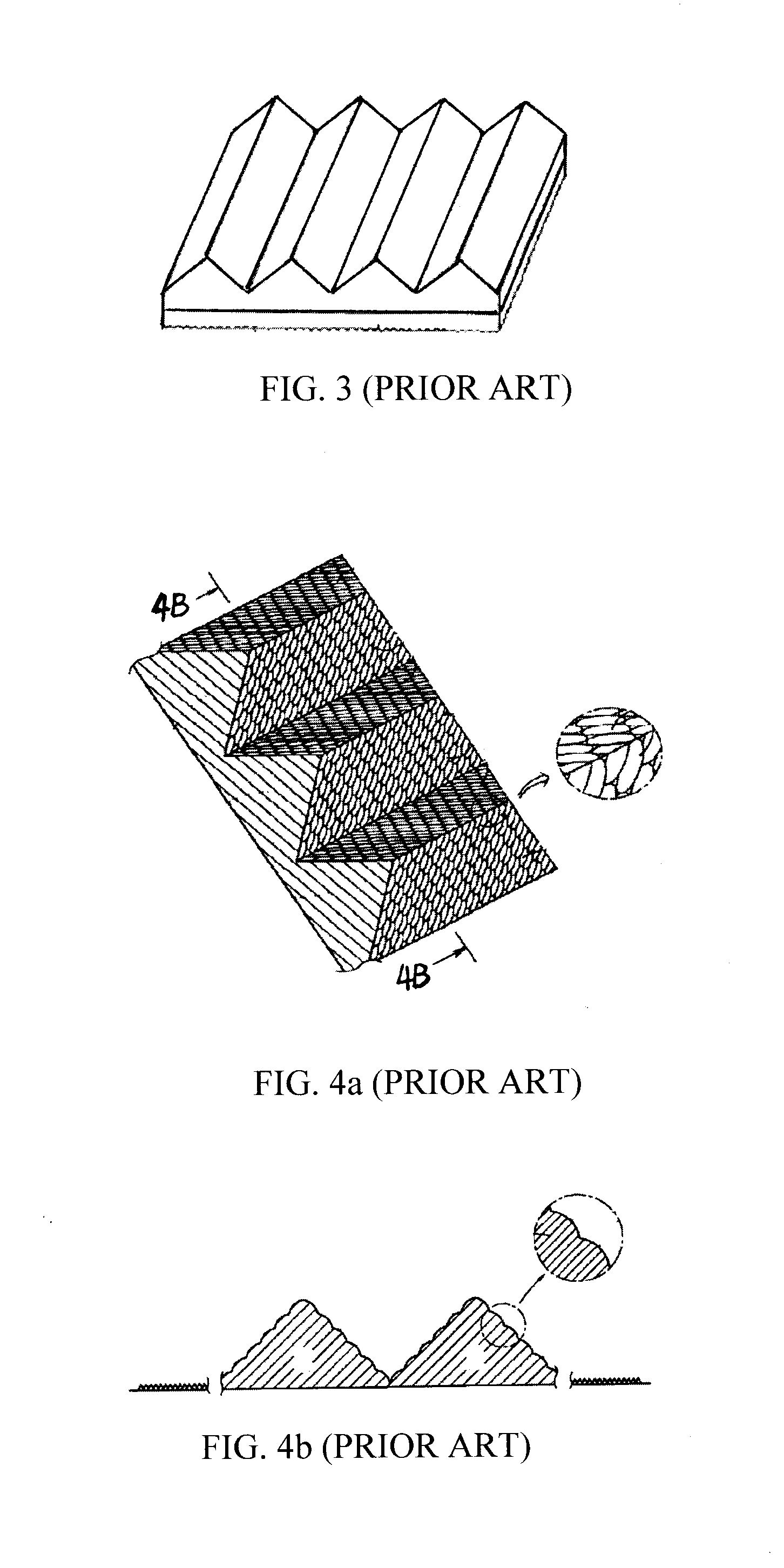

Optical substrates having light collimating and diffusion structures

ActiveUS20140240839A1Increase brightnessReduce distortion and warpageDiffusing elementsOptical light guidesPhysicsPrism

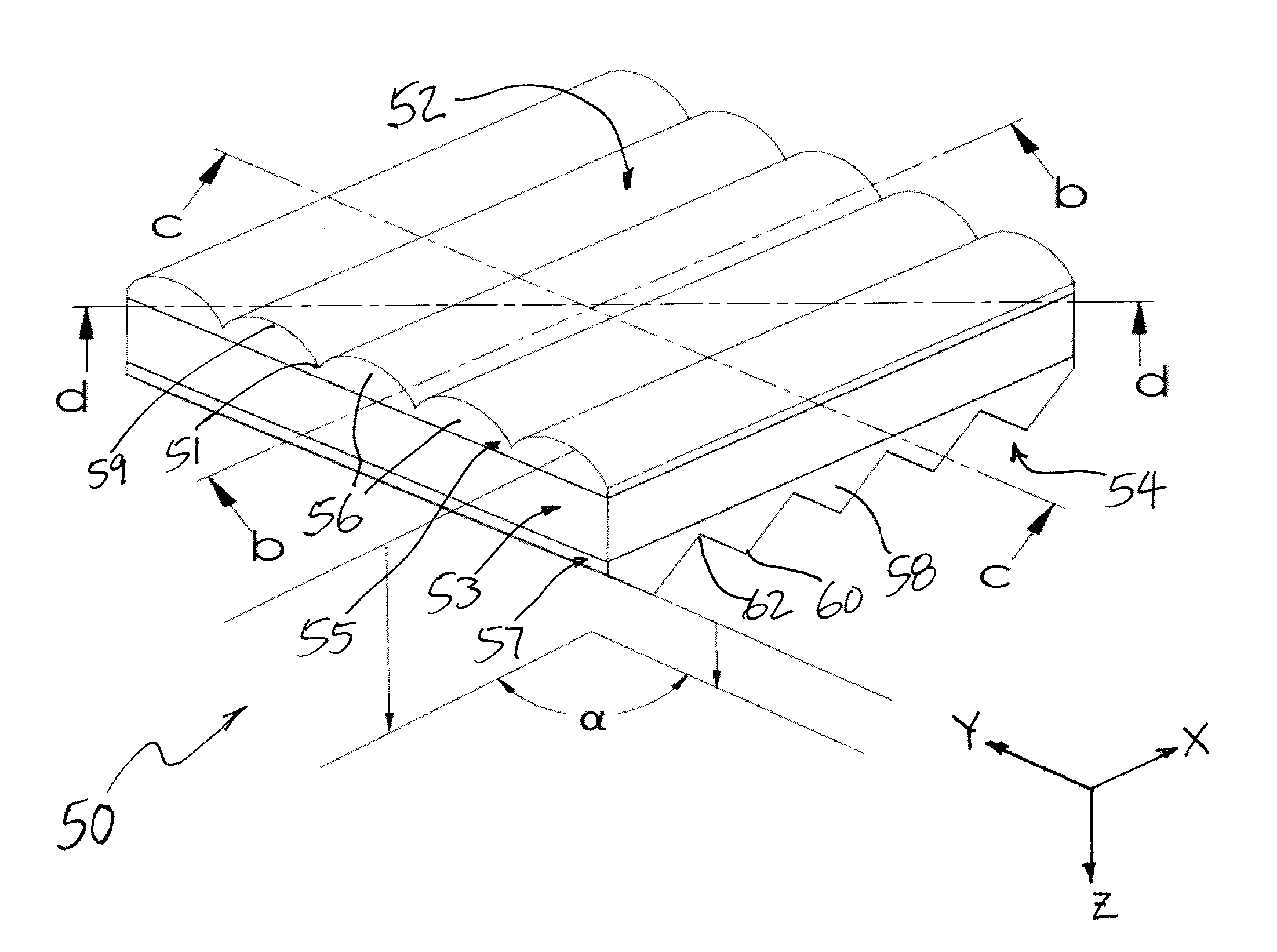

An optical substrate having a structured prismatic surface and an opposing structured lenticular surface. The structured lenticular surface includes shallow-curved lens structures. Adjacent shallow-curved lens structure may be continuous or contiguous, or separated by a constant or variable spacing. The lens structure may have a longitudinal structure with a uniform or varying cross section. The lenticular lenses may have a laterally meandering structure. Sections of adjacent straight or meandering lenticular lenses may intersect or partially or completely overlap each other. The lenticular lenses may be in the form of discontinuous lenticular segments. The lenticular segments may have regular, symmetrical shapes, or irregular, asymmetrical shapes, which may be intersecting or overlapping, and may be textured. The lens structure may be provided with isolated ripples, in the form of a single knot, or a series of knots.

Owner:UBRIGHT OPTRONICS CORP

Optical substrates having light collimating and diffusion structures

ActiveUS20110234580A1Reduce certain undesired optical effectReduce brightnessOptical articlesPlanar/plate-like light guidesDiffusionPrism

An optical substrate having a structured prismatic surface and an opposing structured lenticular surface. The structured lenticular surface includes shallow-curved lens structures. Adjacent shallow-curved lens structure may be continuous or contiguous, or separated by a constant or variable spacing. The lens structure may have a longitudinal structure with a uniform or varying cross section. The lenticular lenses may have a laterally meandering structure. Sections of adjacent straight or meandering lenticular lenses may intersect or partially or completely overlap each other. The lenticular lenses may be in the form of discontinuous lenticular segments. The lenticular segments may have regular, symmetrical shapes, or irregular, asymmetrical shapes, which may be intersecting or overlapping, and may be textured. The lens structure may be provided with isolated ripples, in the form of a single knot, or a series of knots.

Owner:UBRIGHT OPTRONICS CORP

Optical substrates having light collimating and diffusion structures

ActiveUS20140367873A1Increase brightnessReduce distortionOptical articlesOptical light guidesControl systemEngineering

This invention discloses a method of forming an uneven structure on a substrate. Cut a plurality of trenches in an order on a surface of a mold through a control system, wherein the plurality of trenches comprise at least one first trench, wherein for any second trench of the at least one first trench, the second trench overlaps with at least one third trench different from the second trench such that the second trench is cut off by the at least one third trench. Use the surface of the mold to emboss a thin film on the substrate to form the uneven structure.

Owner:UBRIGHT OPTRONICS CORP

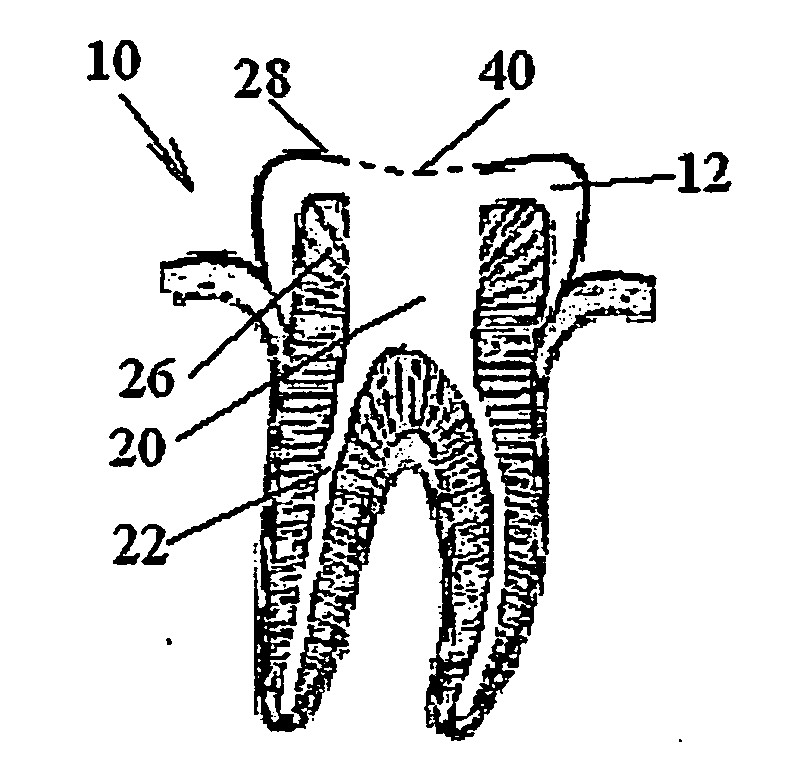

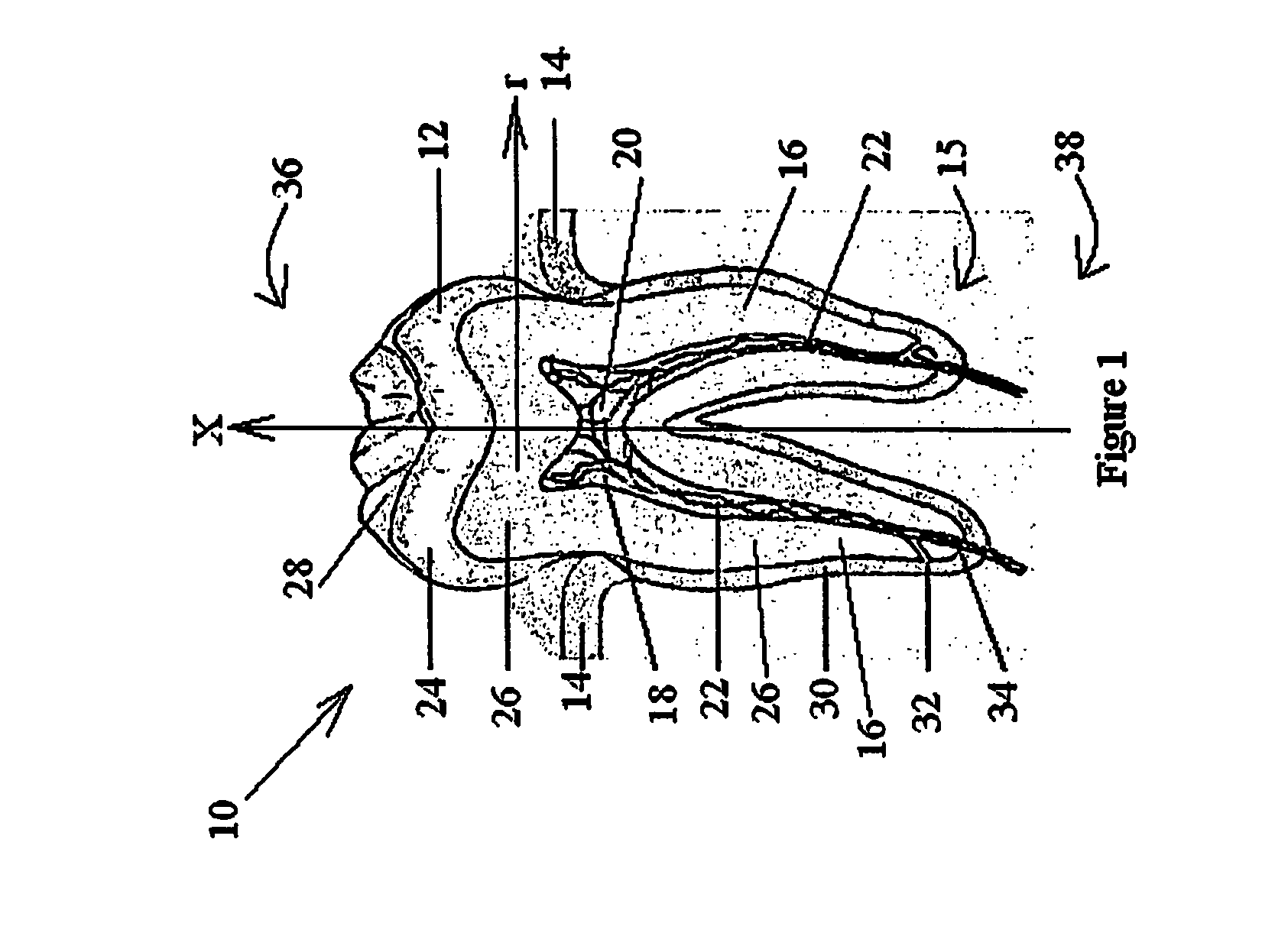

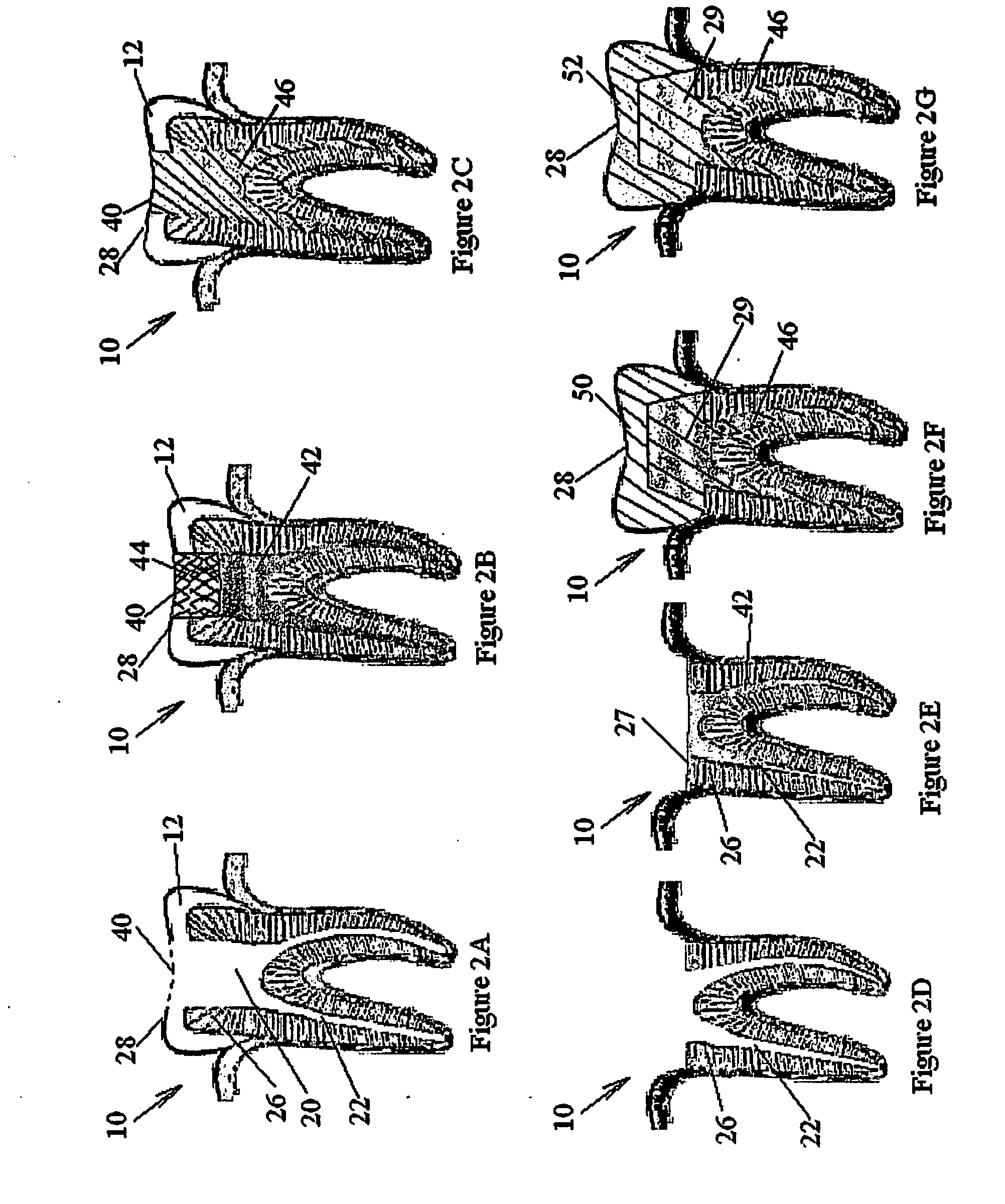

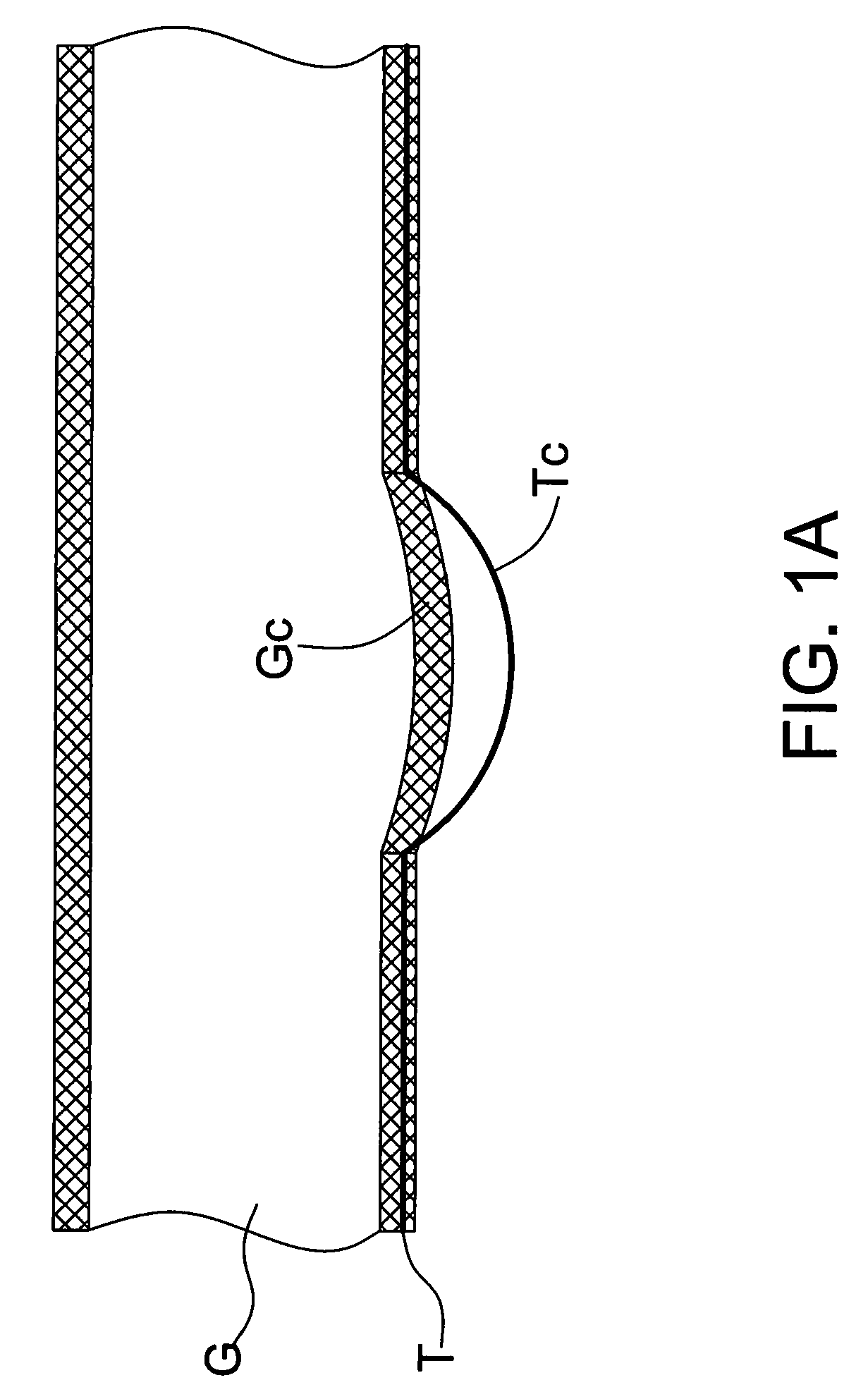

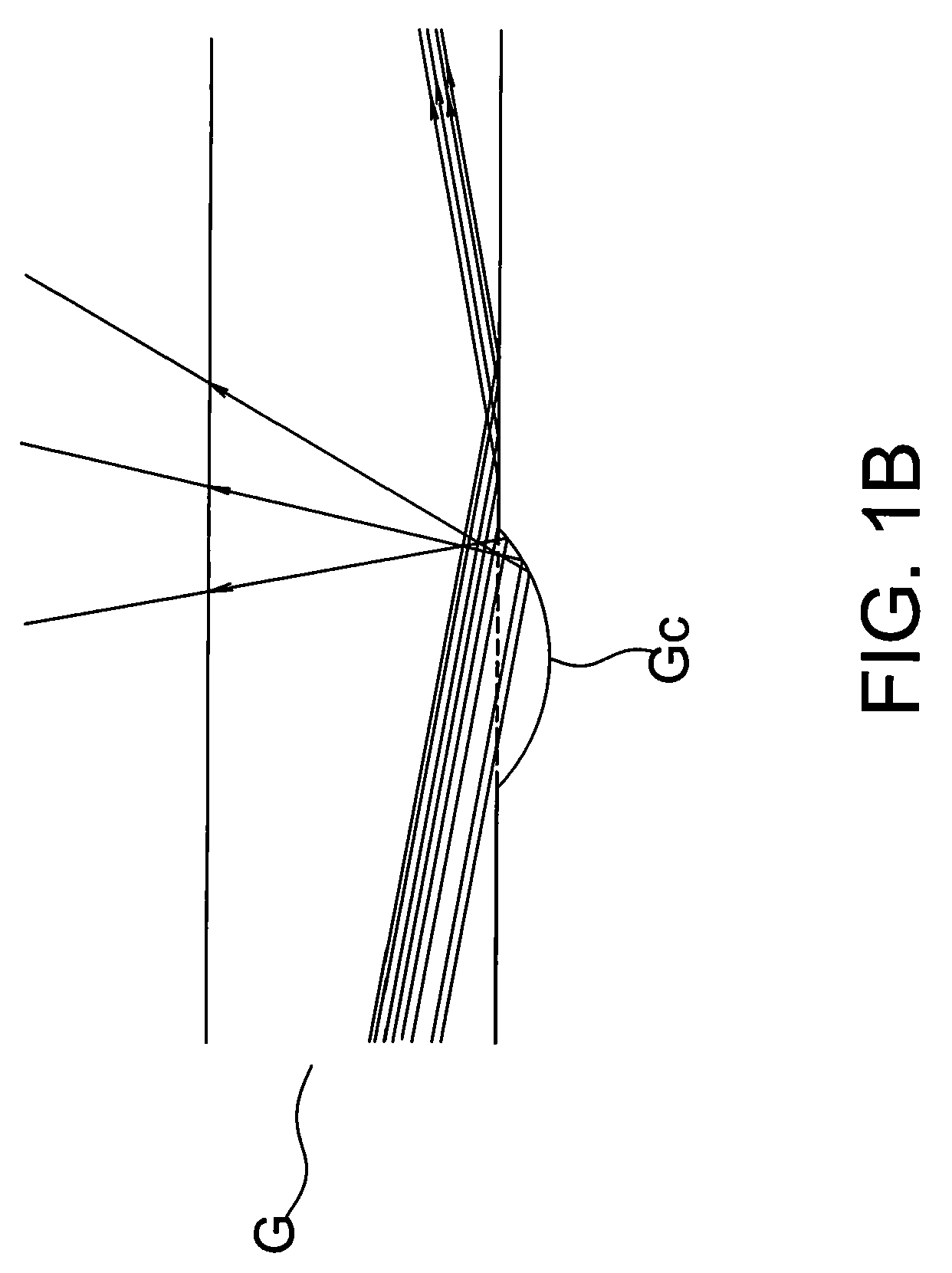

Photo-sterilization

InactiveUS20070072153A1Excellent light diffusionHigh light transmittanceDisinfectionLight therapyEndodontic therapyMedicine

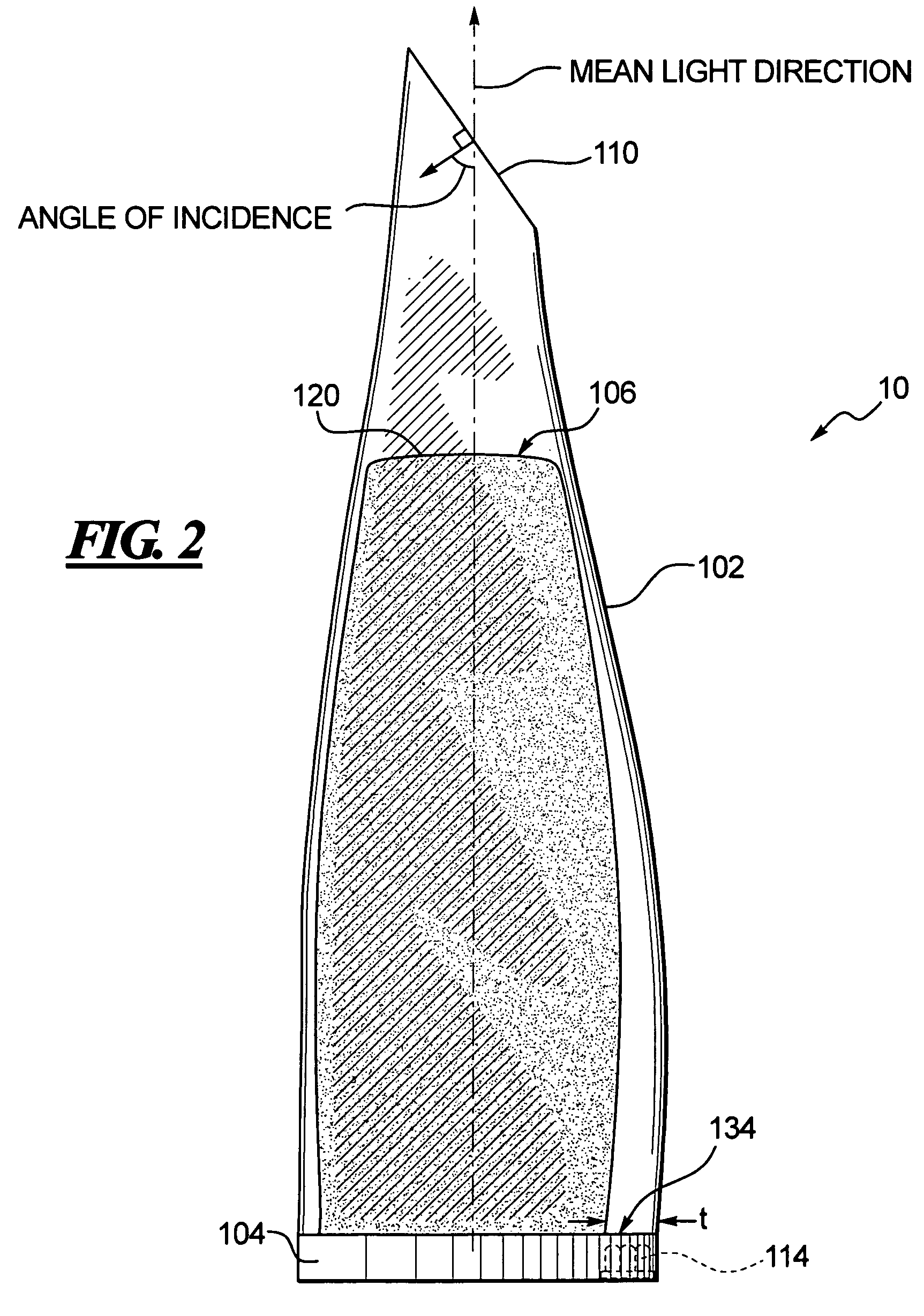

The present invention provides substances, devices, methods, and kits for photo-sterilization of a root canal, prior to and when performing endodontics, as well as periodically as post-endodontic prophylactic measures. The root-canal filling includes a light-transmitting element, operative as a diffuser, and methods are provided for communicating light to the diffuser, for disinfecting the walls of the root canals, by photo sterilization. The diffuser may be formed of silicone polymers, synthetic fused silica, quartz or the like, and may be surrounded by a light-transmitting sealer. The diffuser may be incorporated with an endodontic post, or a specially designed post, which may be transparent and (or) hollow. In a preferred embodiment, the diffuser is formed of a light transmitting conical shell of Cyclic Olefin Copolymers (COC), filled with a fluid such as air, distilled water, or silicone oil.

Owner:INTERLIGHT

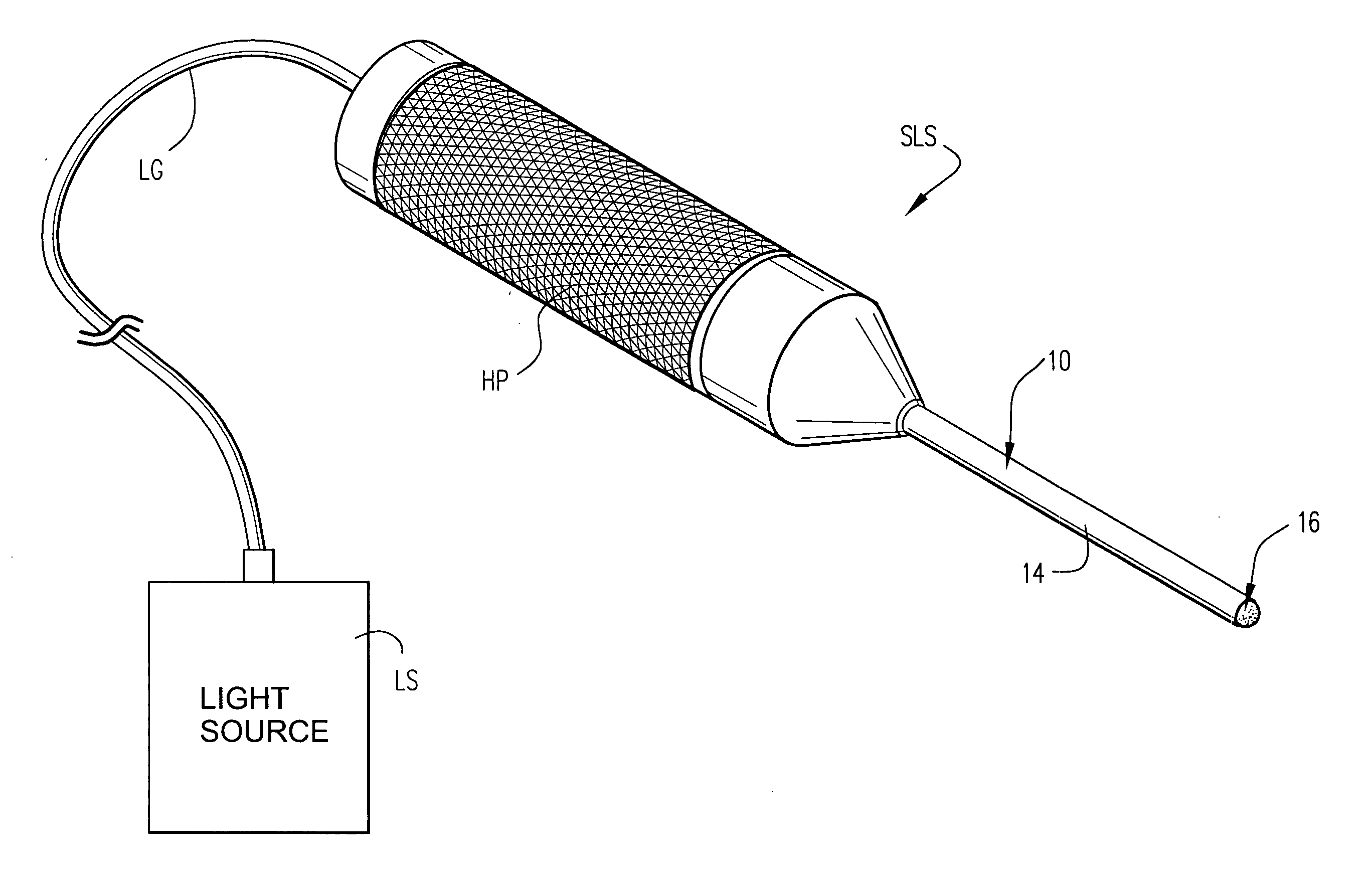

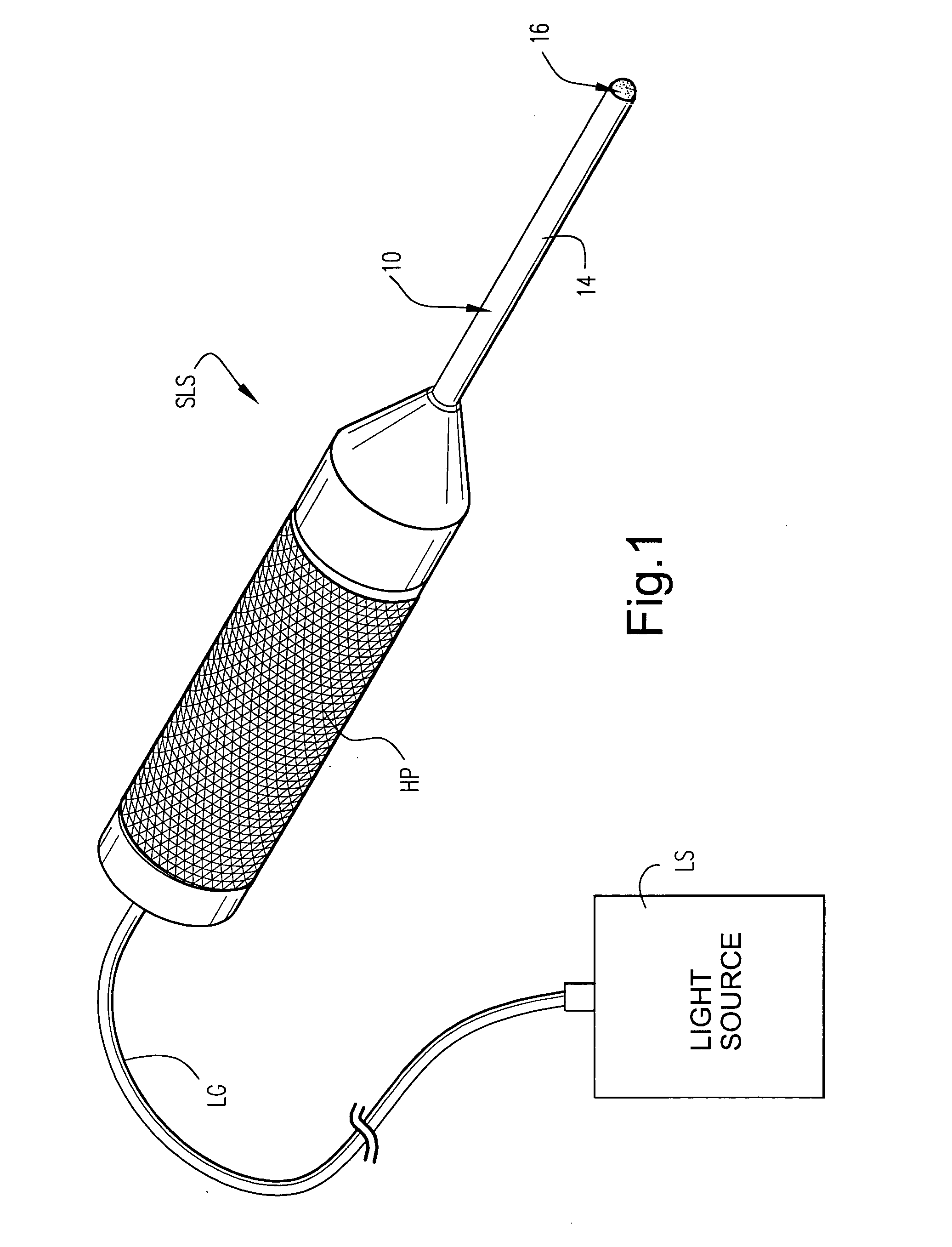

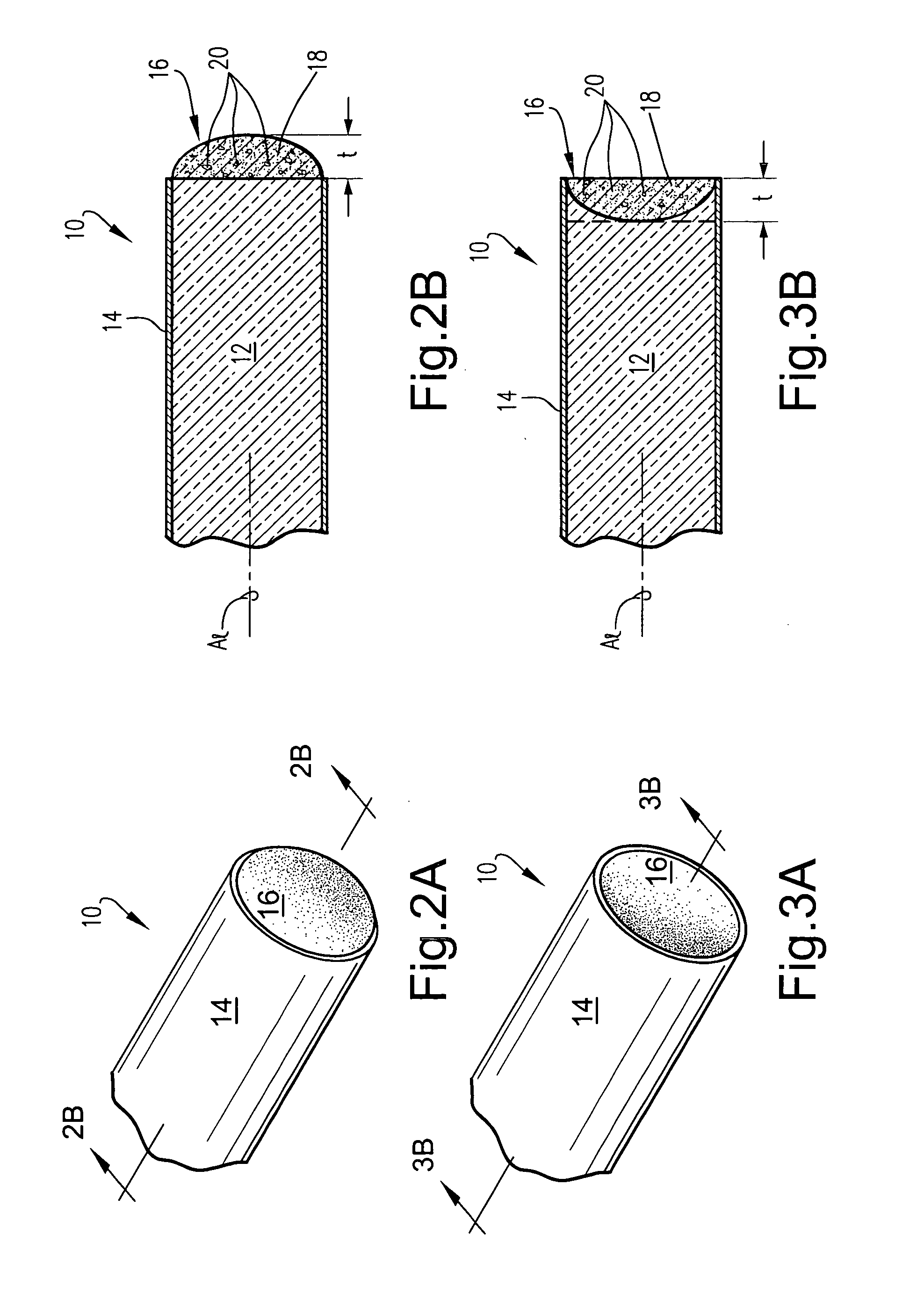

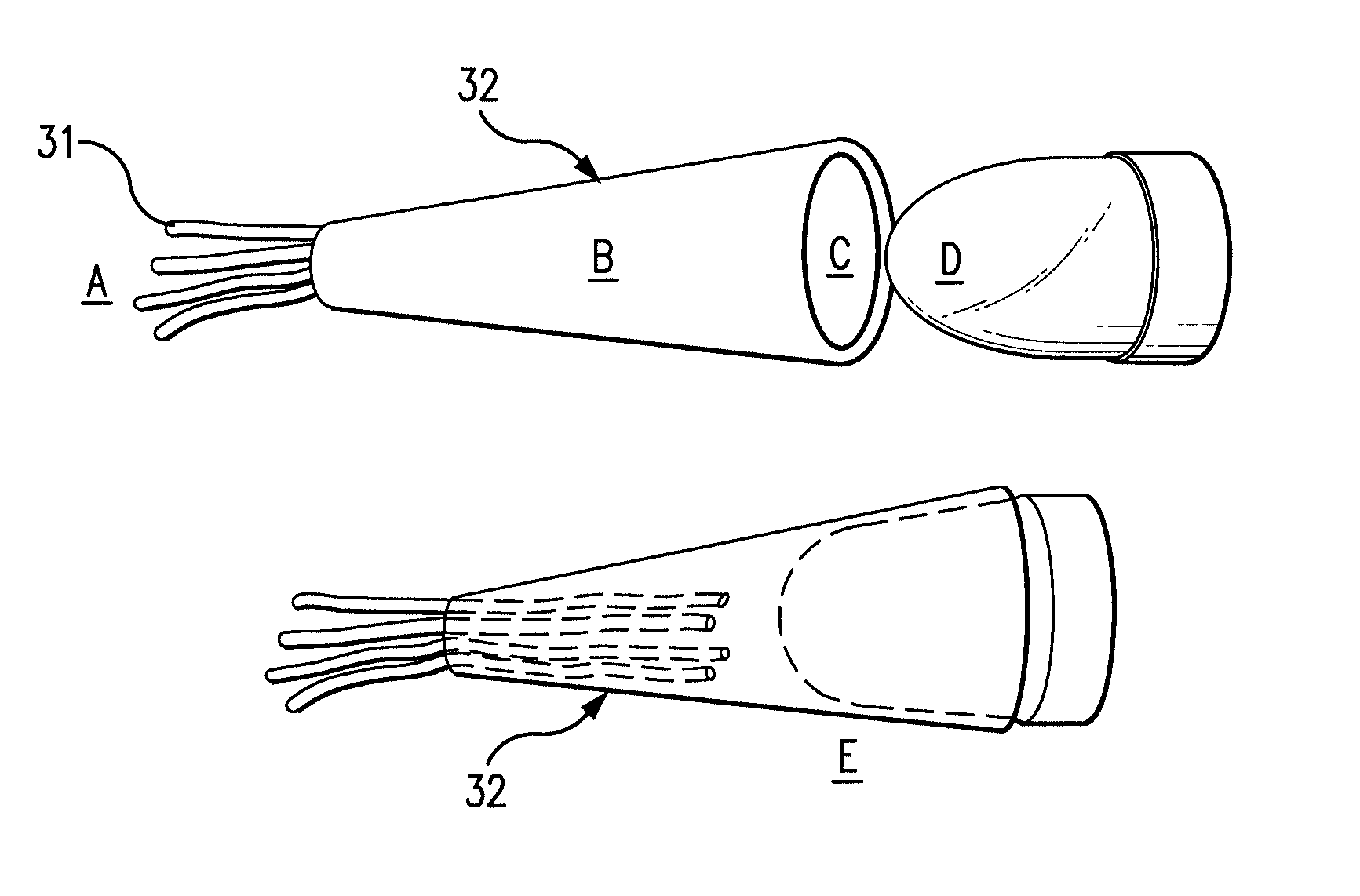

Optical fiber illuminators having integral distal light diffusers especially useful for ophthalmic surgical procedures, and methods of making the same

Optical fiber illuminators are embodied in light-diffusing particles affixed to an optical fiber's terminal end. Most preferably, the light-diffusing particles are optically transparent solid particles dispersed symmetrically or asymmetrically in an optically transparent bonding material to thereby form a light diffusion medium (LDM). The solid particles may thus be dispersed in the bonding material while the bonding material is in a liquid state to form the LDM. A mass of the LDM may thus be applied onto the terminal optical fiber end while the bonding material is in such a liquid state. Allowing the bonding material to solidify will therefore affix the light-diffusing particles to the terminal end of the optical fiber. In such a manner, optical fiber illuminators having high light throughput and diffusion may be made.

Owner:DUKE UNIV

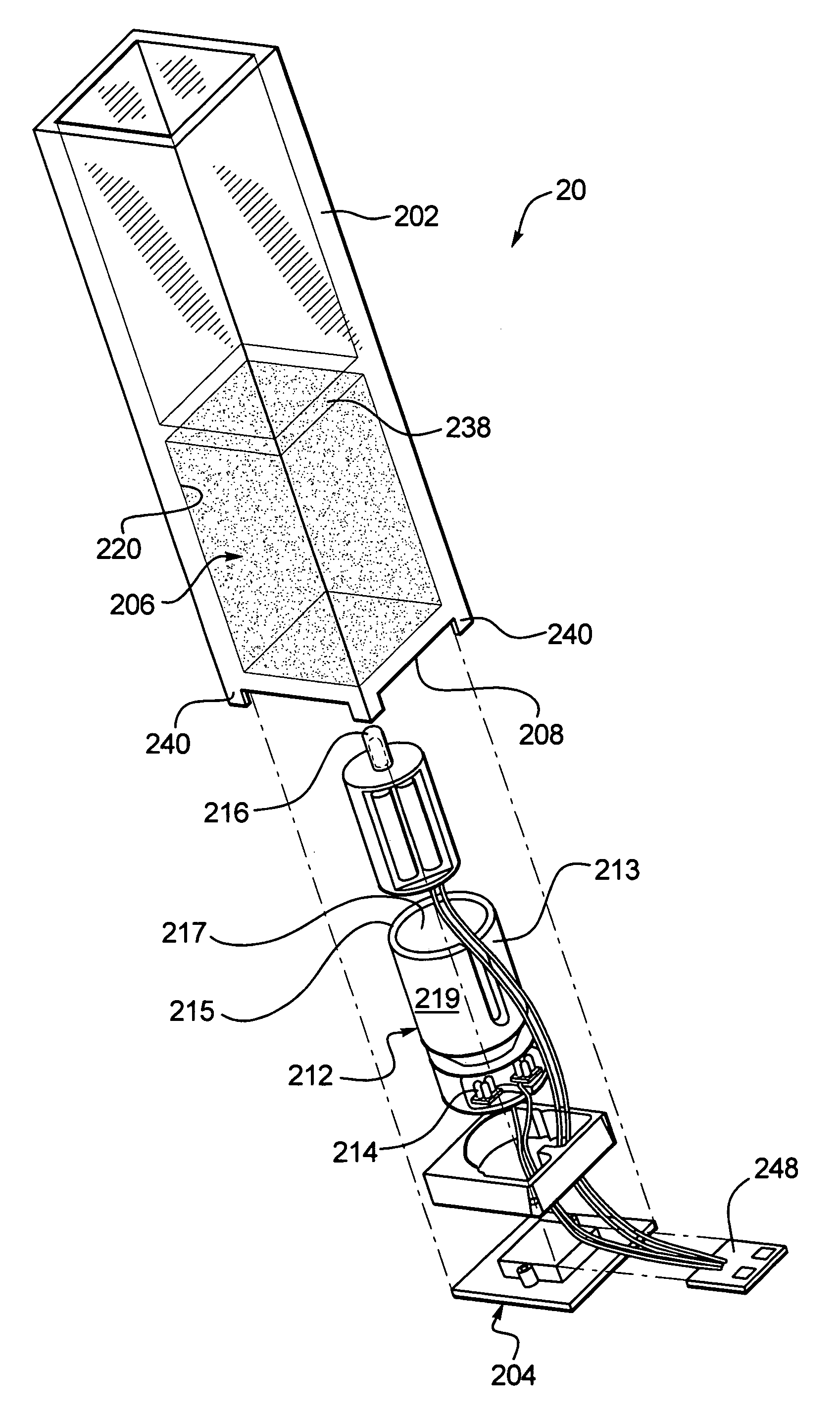

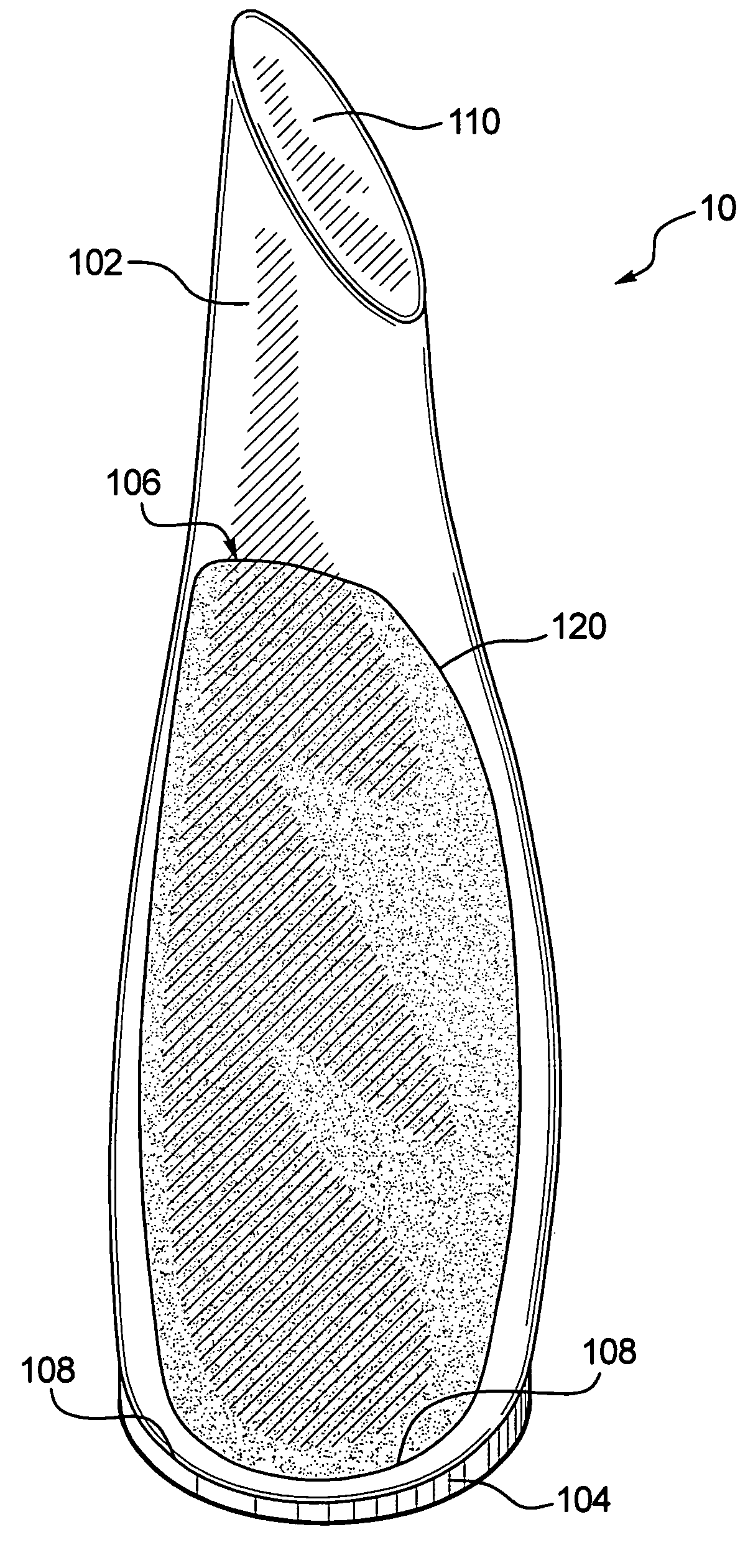

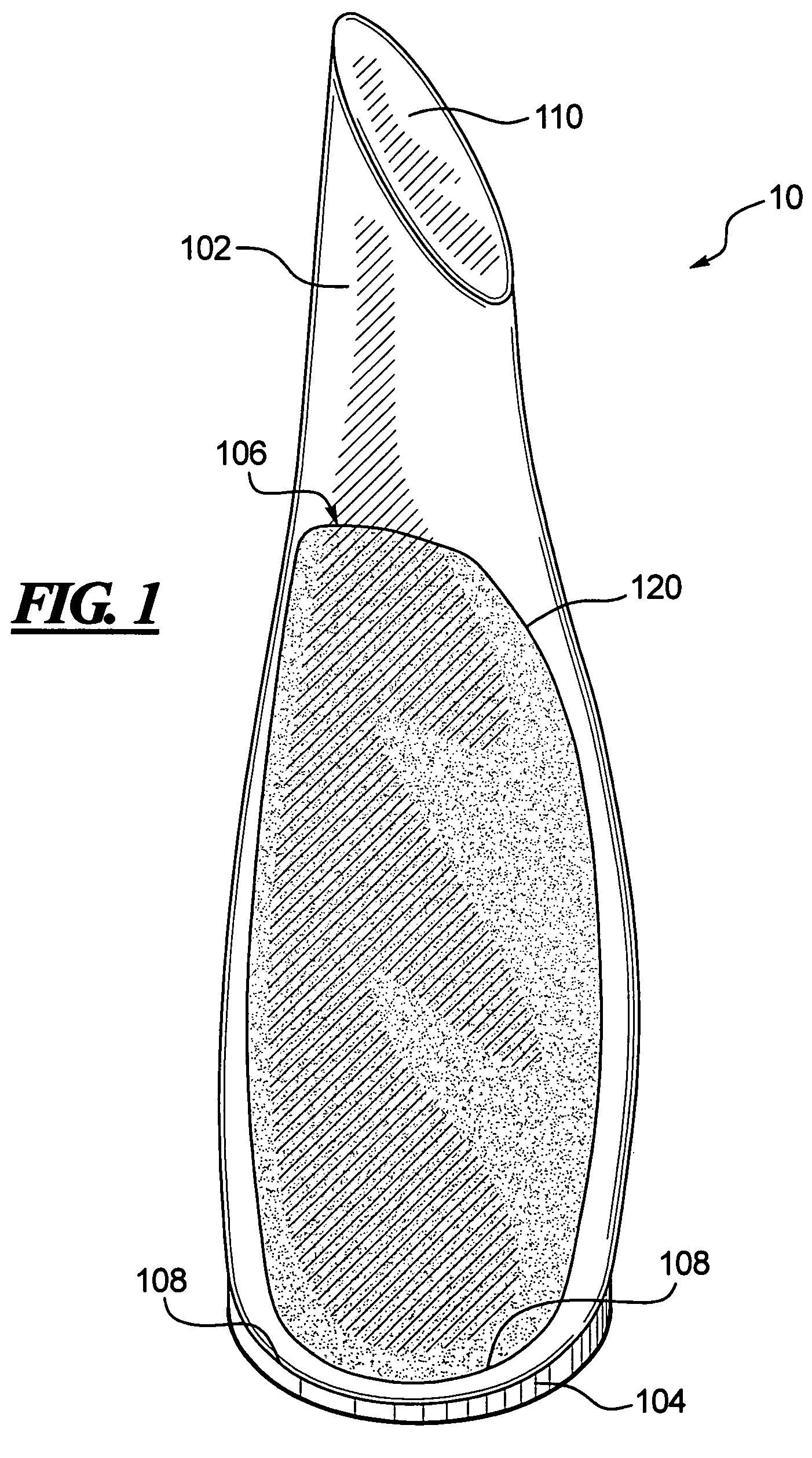

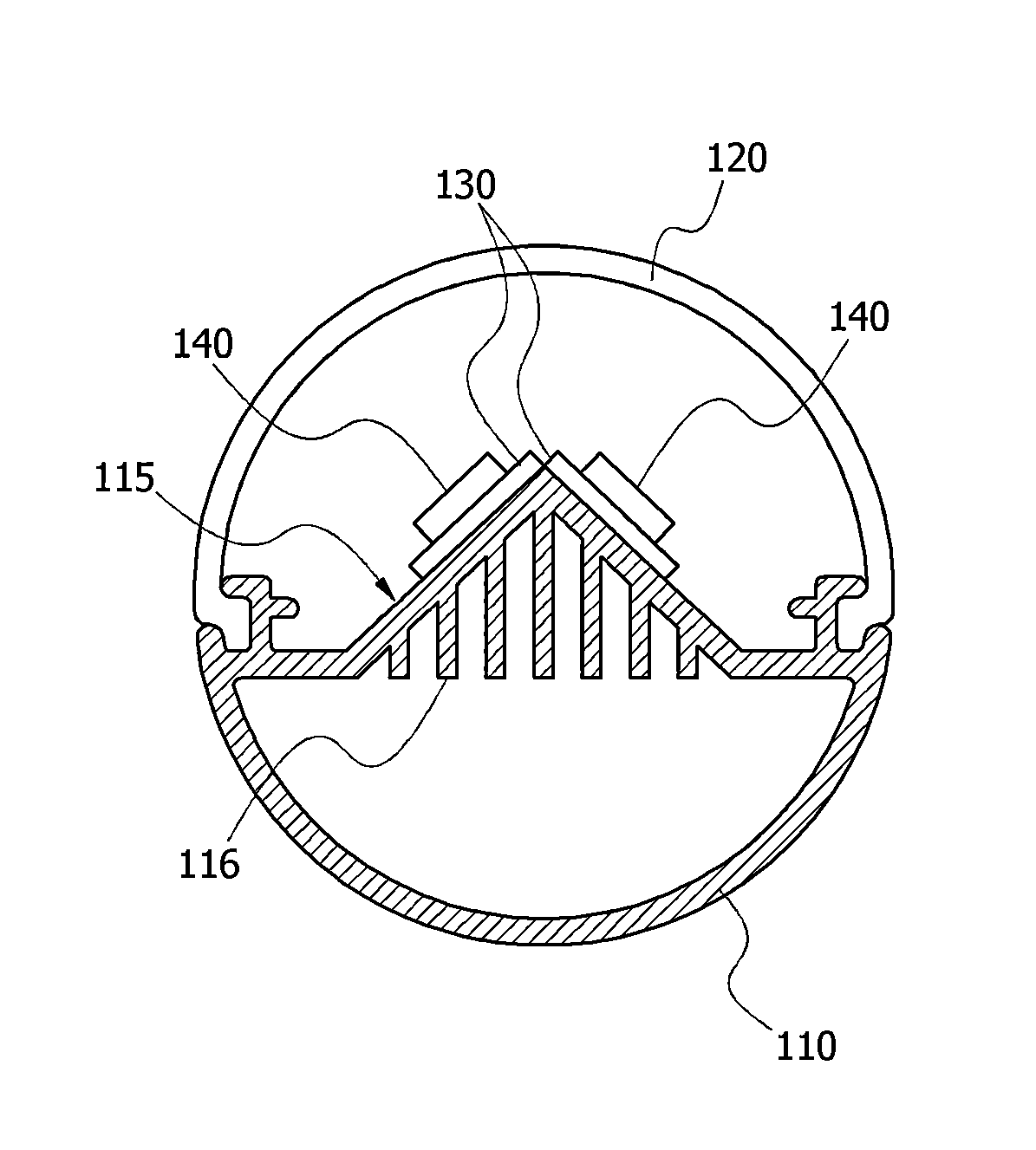

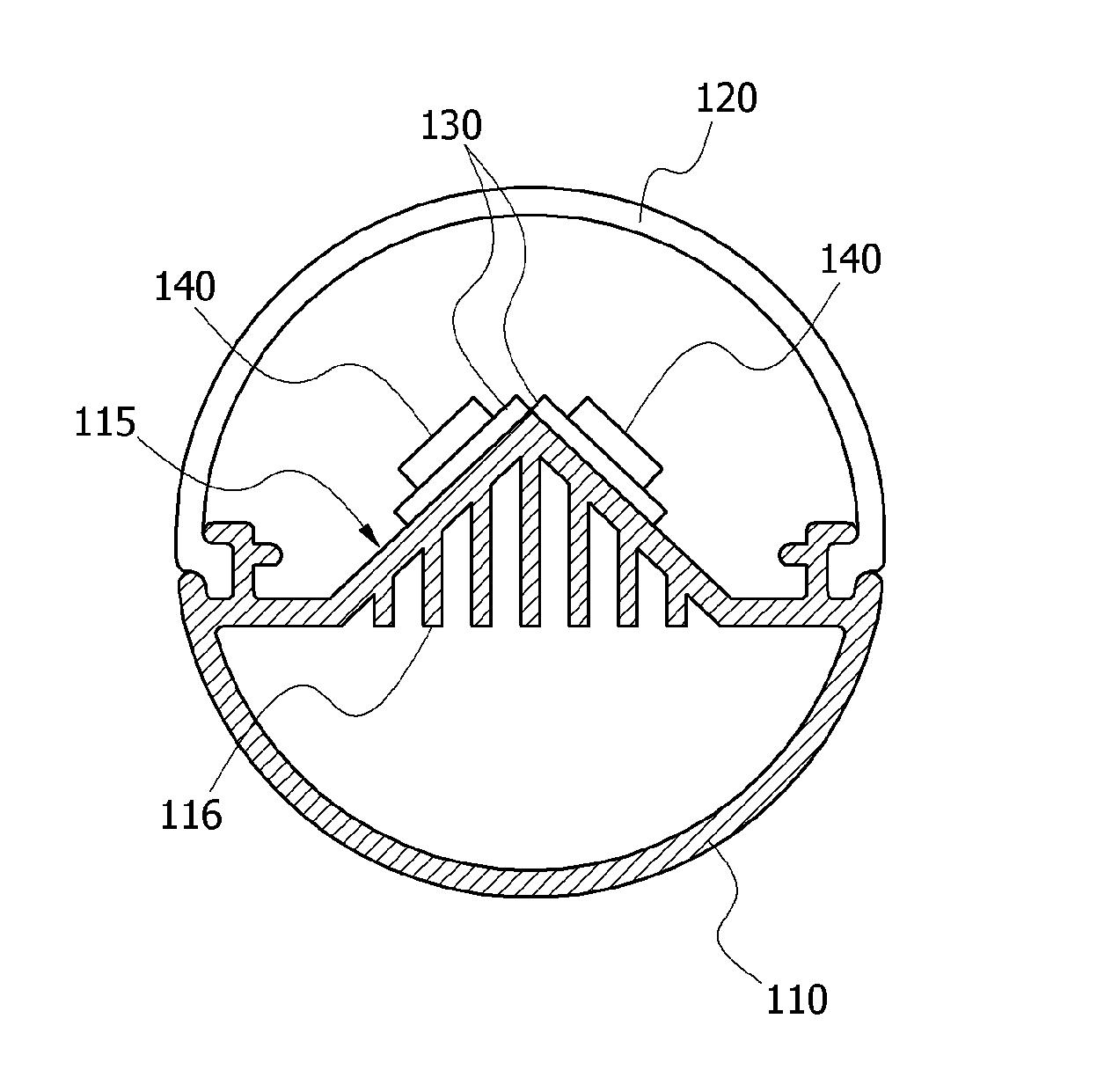

Color changing light object and user interface for same

InactiveUS7824051B2Excellent light diffusionEliminate needElectrical apparatusPoint-like light sourceLight pipeDisplay device

Illuminated, decorative light objects are disclosed that provide at least one aesthetic lighting display or light show, and to a user interface for the same. A disclosed decorative light object includes a translucent housing. The housing has a bottom opening leading into a cavity. The object also includes a base assembly that covers the bottom opening of the housing. The base assembly includes a user interface. The user interface includes light show circuitry, memory for storing a plurality of light shows, switches or buttons for recalling the light shows from the memory and at least one light group comprising red, green and blue lights. The switches of the user interface are supported in the bottom opening. The light show circuitry, memory and lights are supported within the cavity. Preferably, a translucent light pipe with a roughened lambertian outer surface covers and hides the circuitry and the lights. As the light shines through the light pipe it is diffused thereby creating a warm glowing appearance.

Owner:SC JOHNSON & SON INC

Optical substrates having light collimating and diffusion structures

ActiveUS10527775B2Increase brightnessImprove luminanceMechanical apparatusDiffusing elementsThin membraneEngineering

This invention discloses a method of forming an uneven structure on a substrate. Use a hard tool to penetrate into a mold to cut a first trench and a second trench in an order on a surface of a mold, wherein the hard tool has a smoothly-curved shape such that the transverse width of each of the first trench and the second trench increases as the penetrating depth of the hard tool increases, wherein when each of the first trench and the second trench marches along a first direction, the penetrating depth of the hard tool is controlled by repeating moving the hard tool up and down to cut the mold such that the transverse width of each of the first trench and the second trench varies according to the controlled penetrating depth of the hard tool, wherein the first trench and the second trench completely overlap with each other with no space therebetween. Then, use the surface of the mold to emboss a thin film on a substrate.

Owner:UBRIGHT OPTRONICS CORP

Tube-type LED illumination lamp

InactiveUS8919991B2Quality improvementExcellent light diffusionElongate light sourcesLighting heating/cooling arrangementsIlluminanceEngineering

Owner:KUMHO ELECTRIC INC

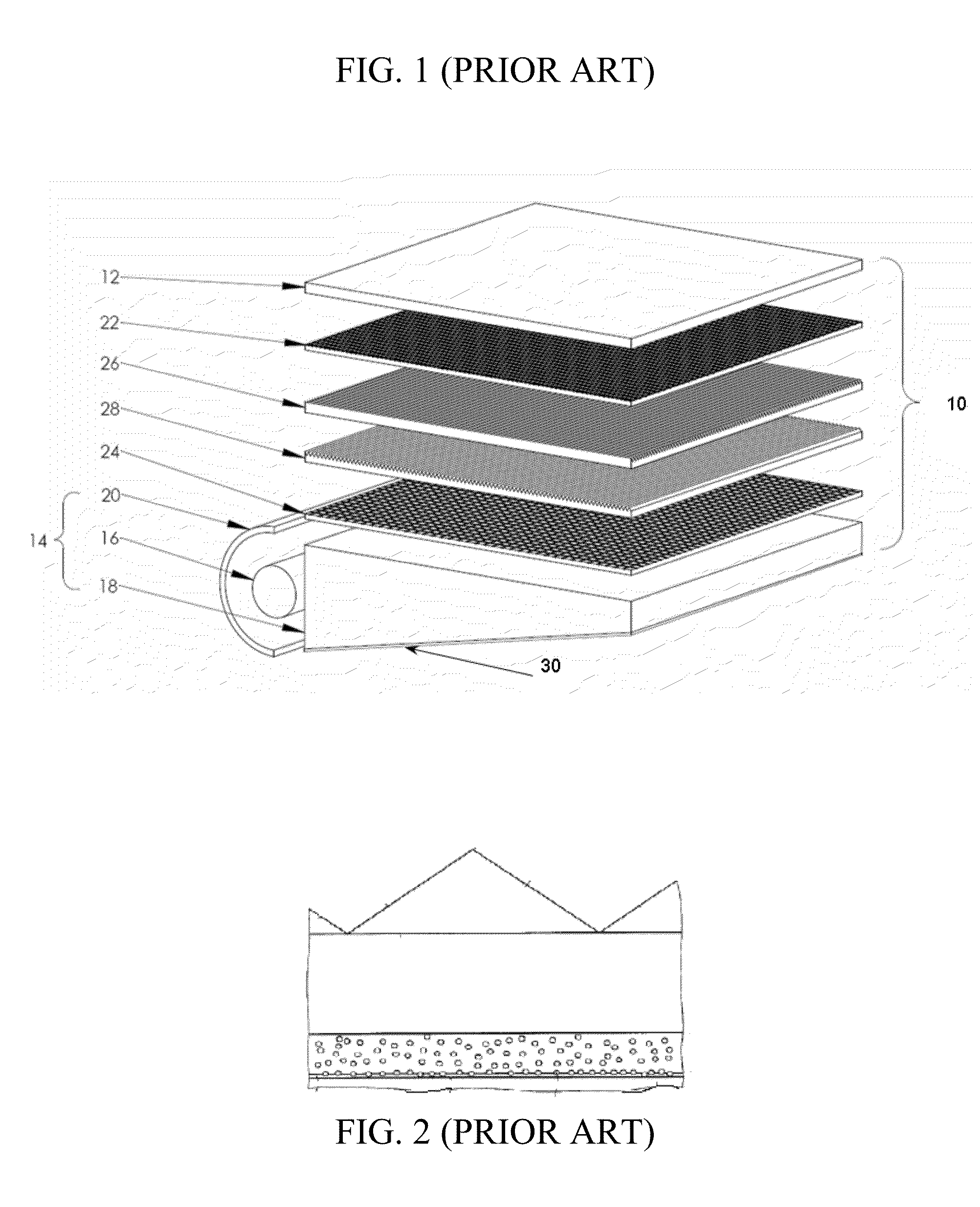

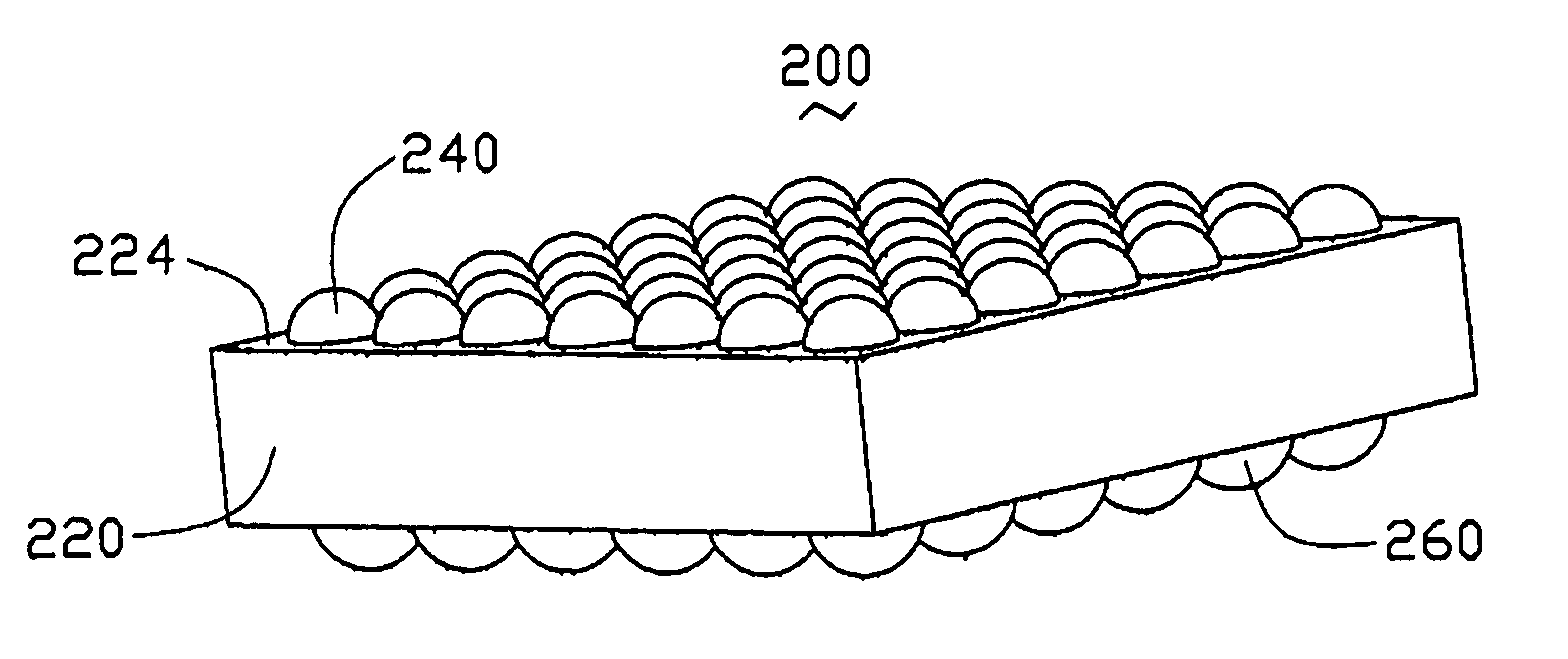

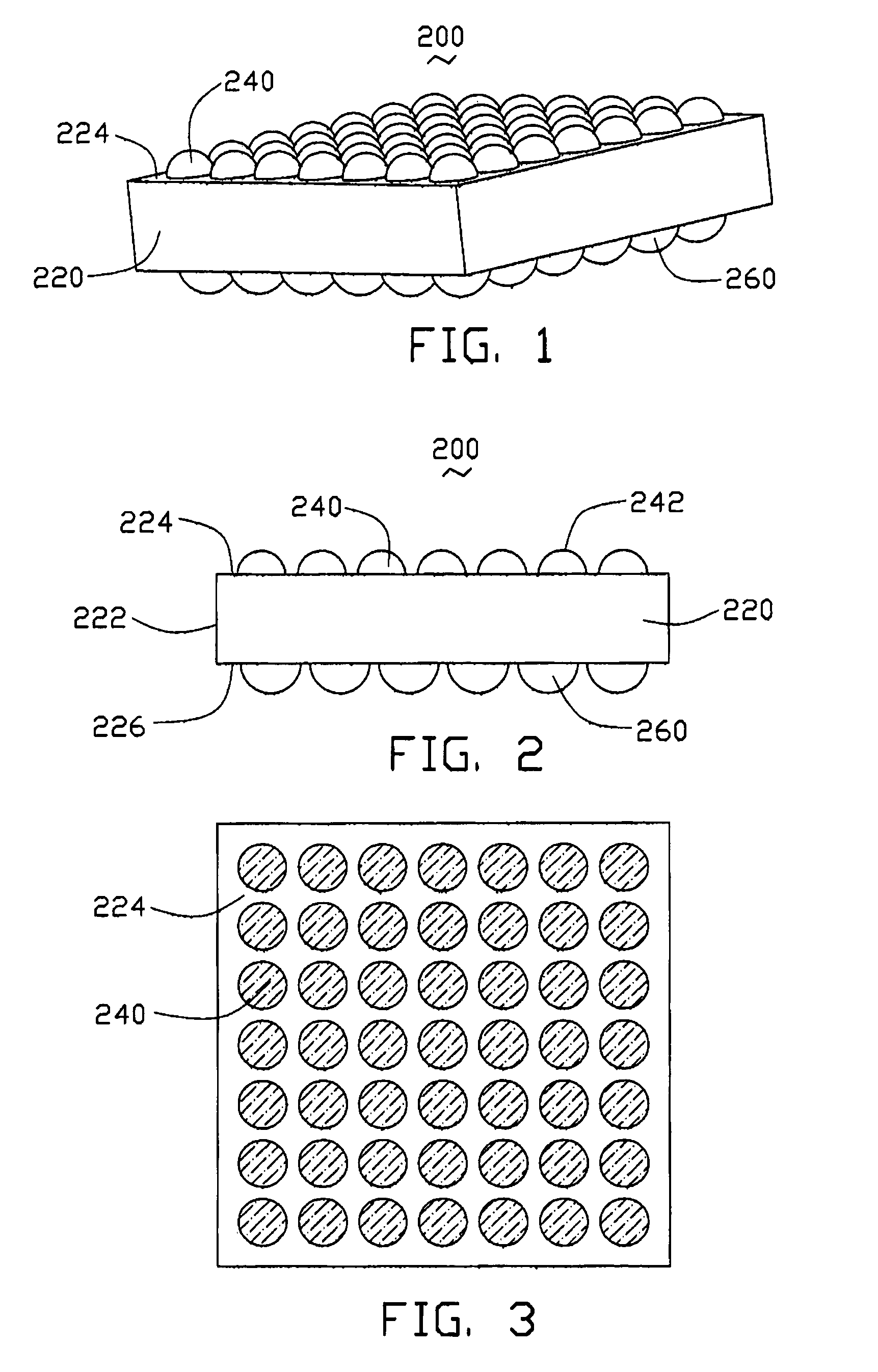

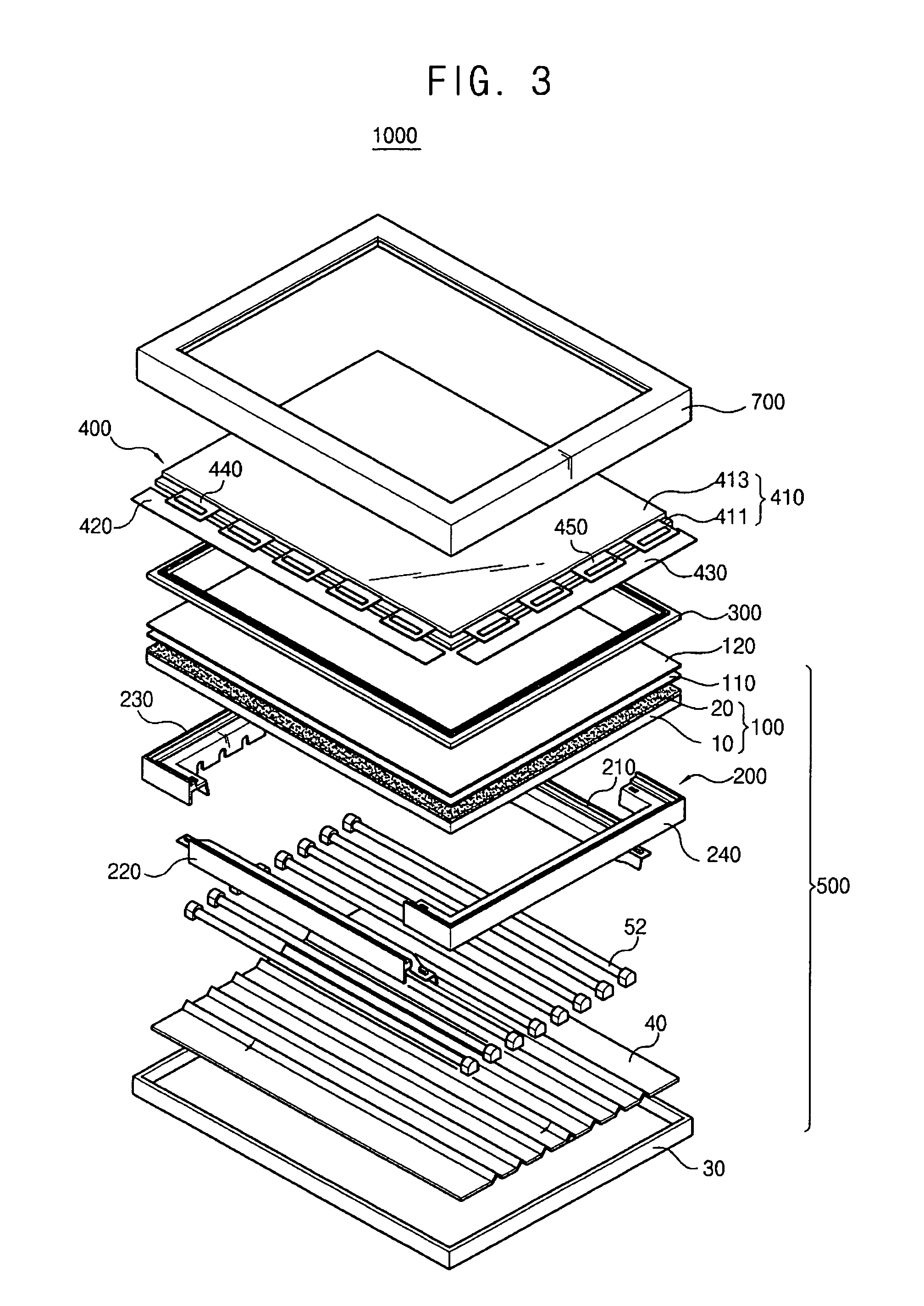

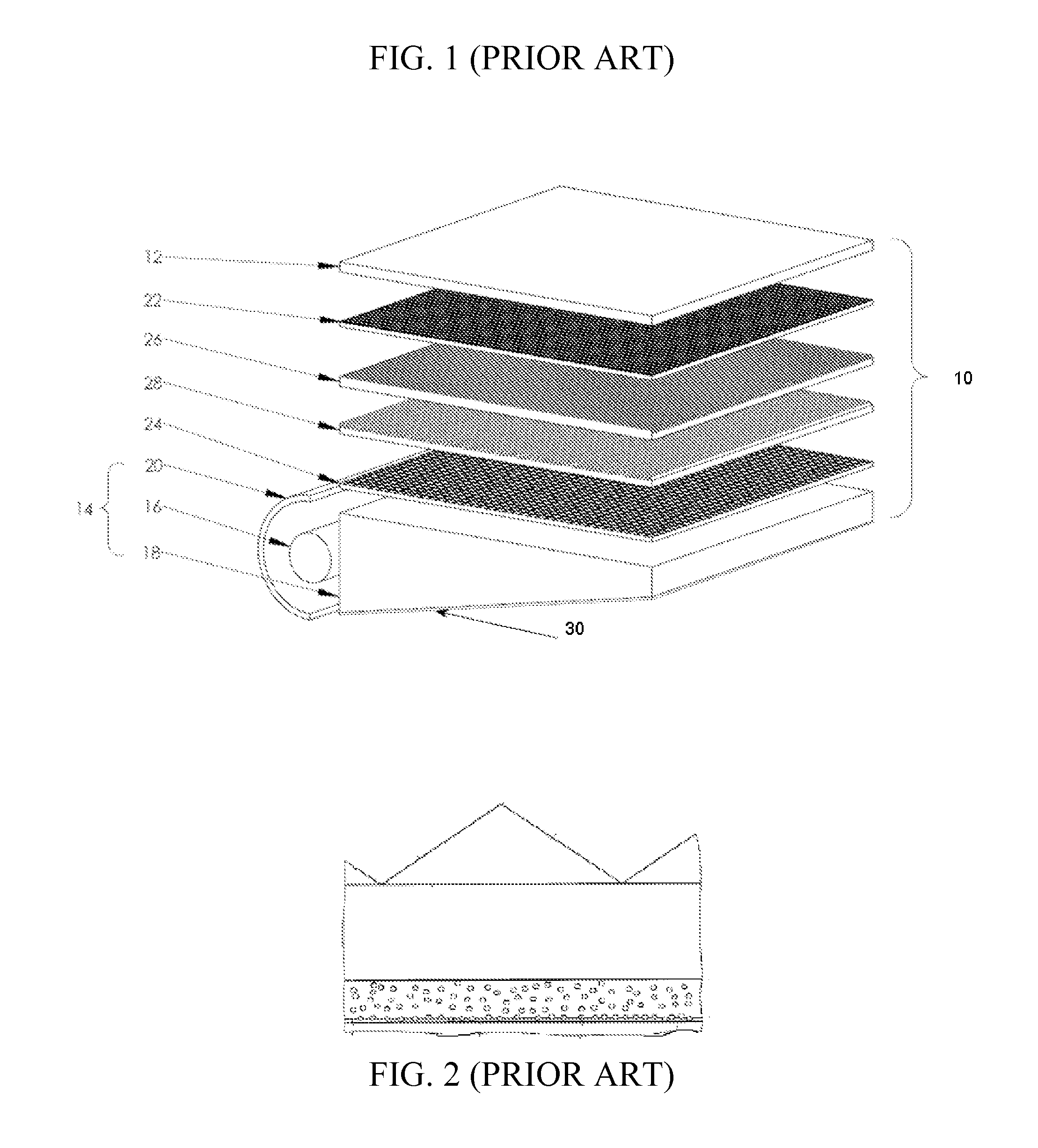

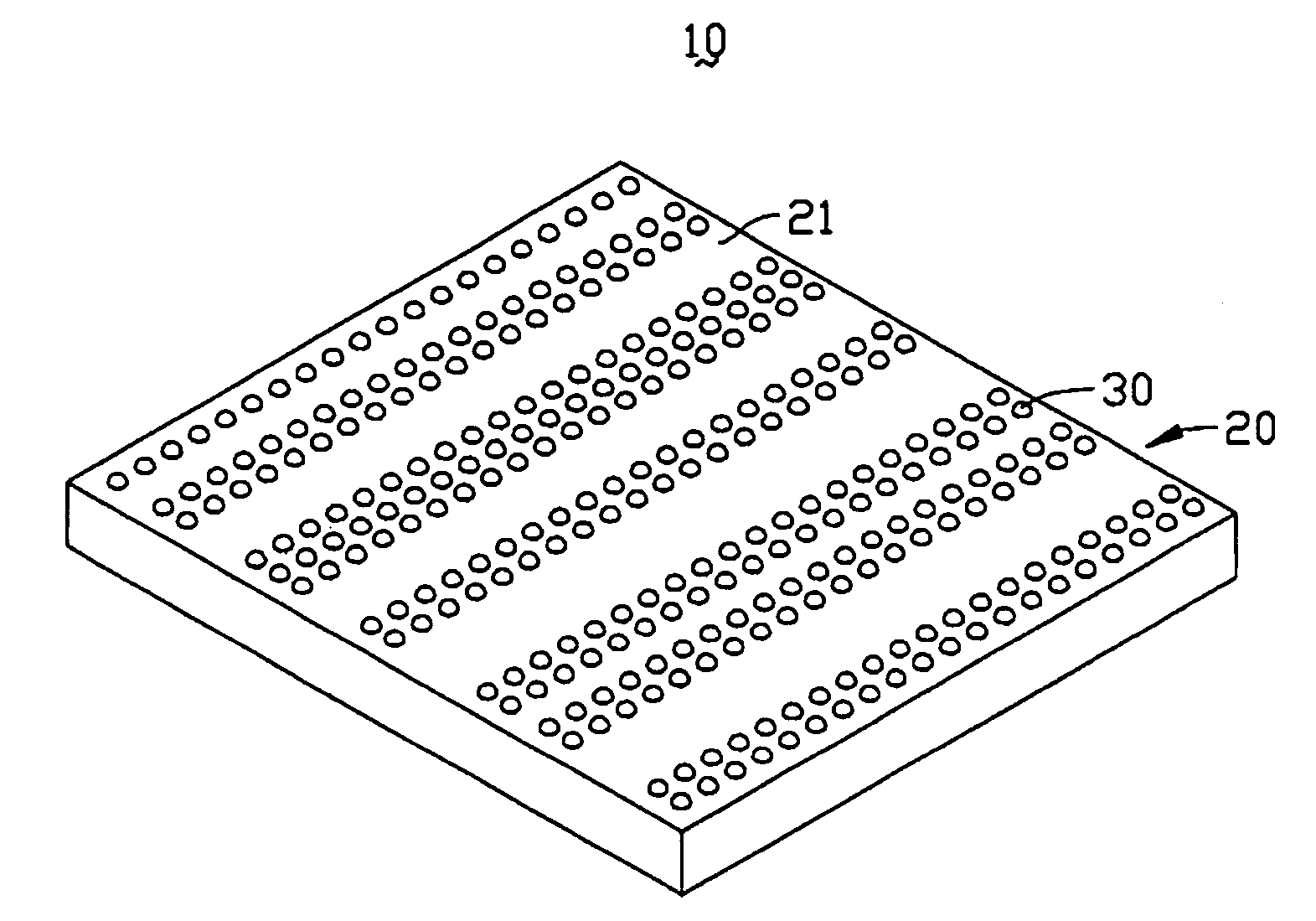

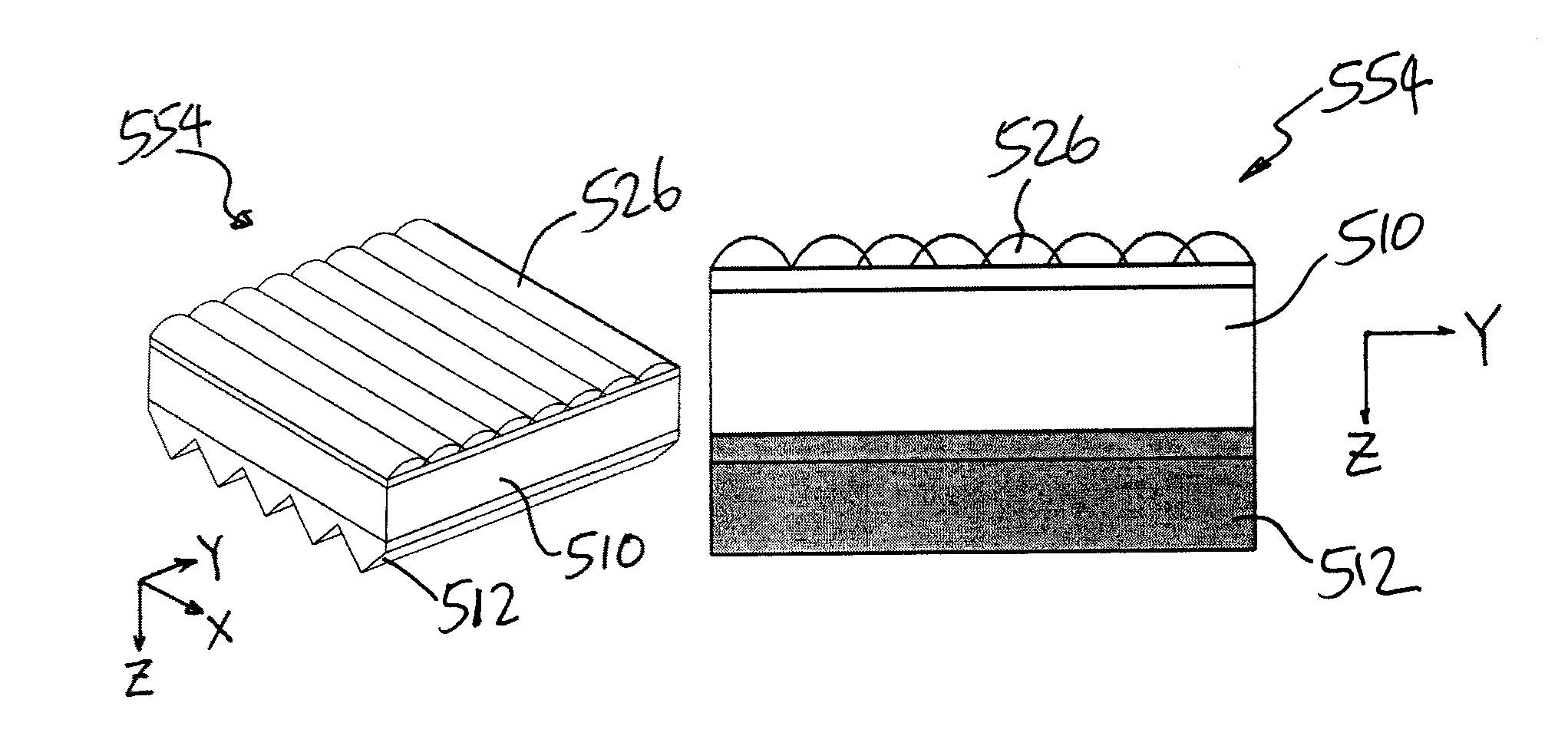

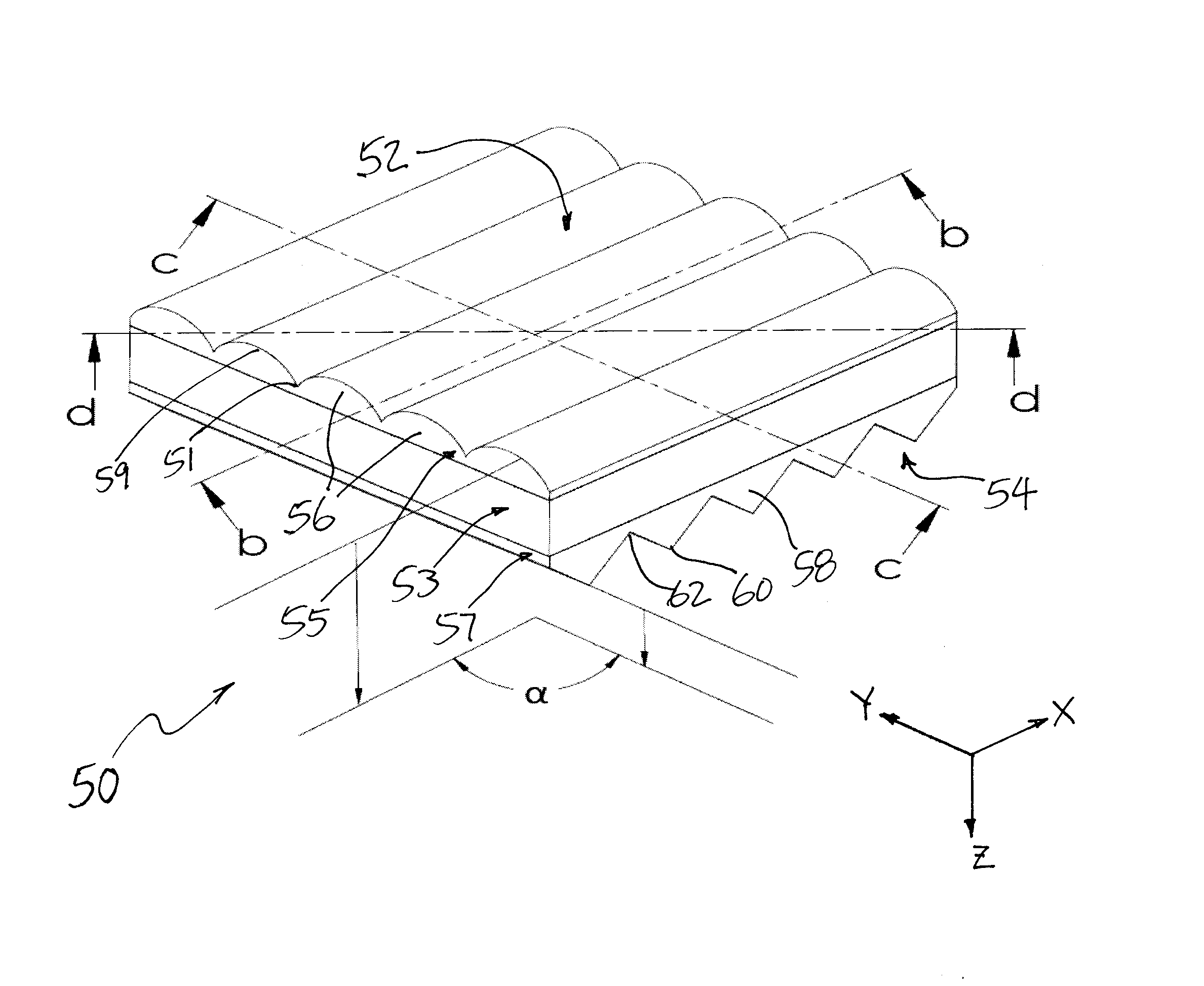

Light guide plate with embossments and backlight system using the same

InactiveUS7081933B2Reduce manufacturing costReduce light lossMechanical apparatusLight guides for lighting systemsLight guideEngineering

The present invention provides a light guide plate (500) including a transparent plate (220) having an emitting surface (524) with a plurality of hemispherical embossments (540) formed thereon continuously side-by-side in rows and columns. The transparent plate also has a bottom surface (226) opposite to the emitting surface, with a plurality of hemispherical embossments (260) formed on the bottom surface. The embossments of the emitting and bottom surfaces all face in a direction away from the transparent plate. Other embodiments are also provided.

Owner:HON HAI PRECISION IND CO LTD

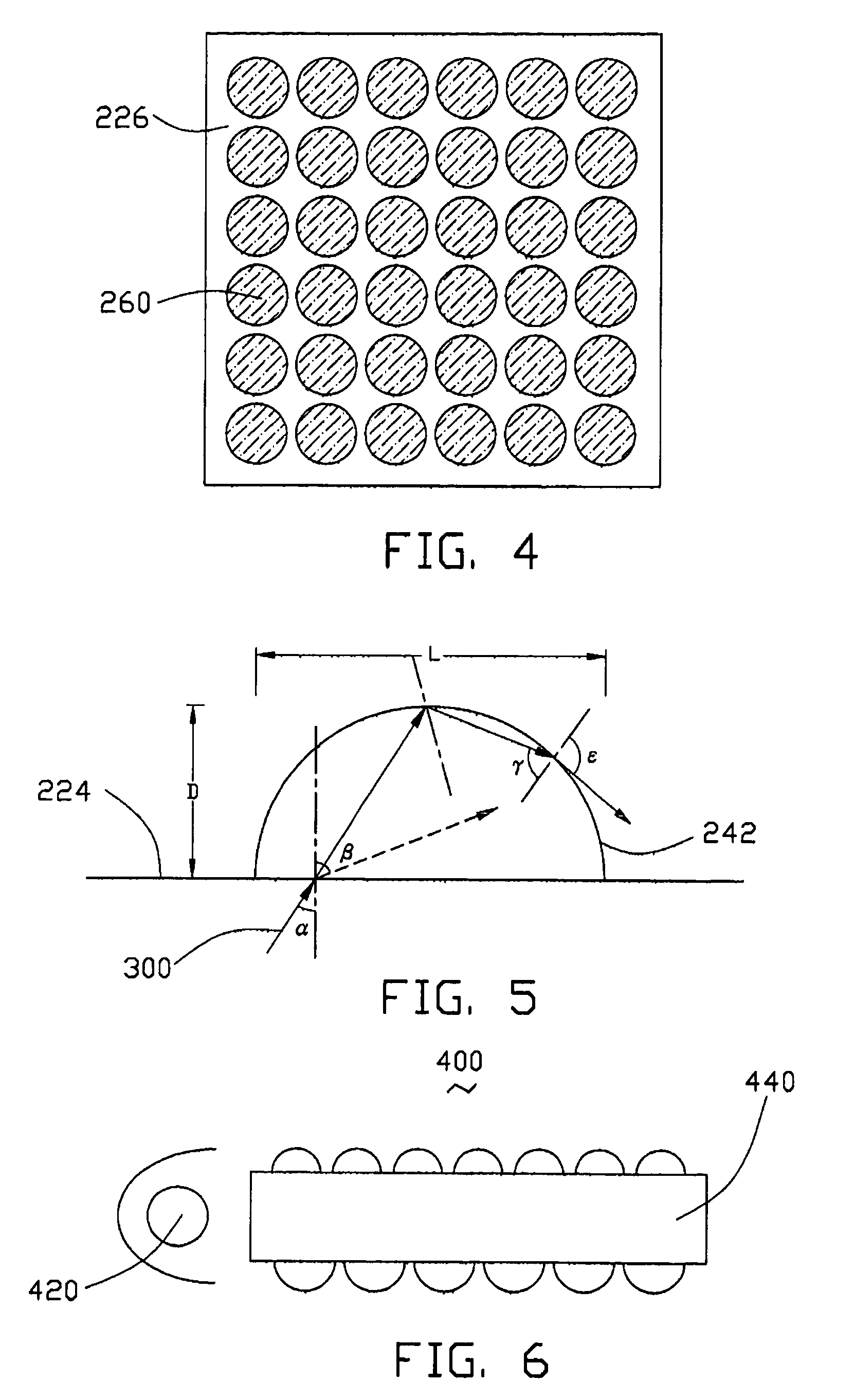

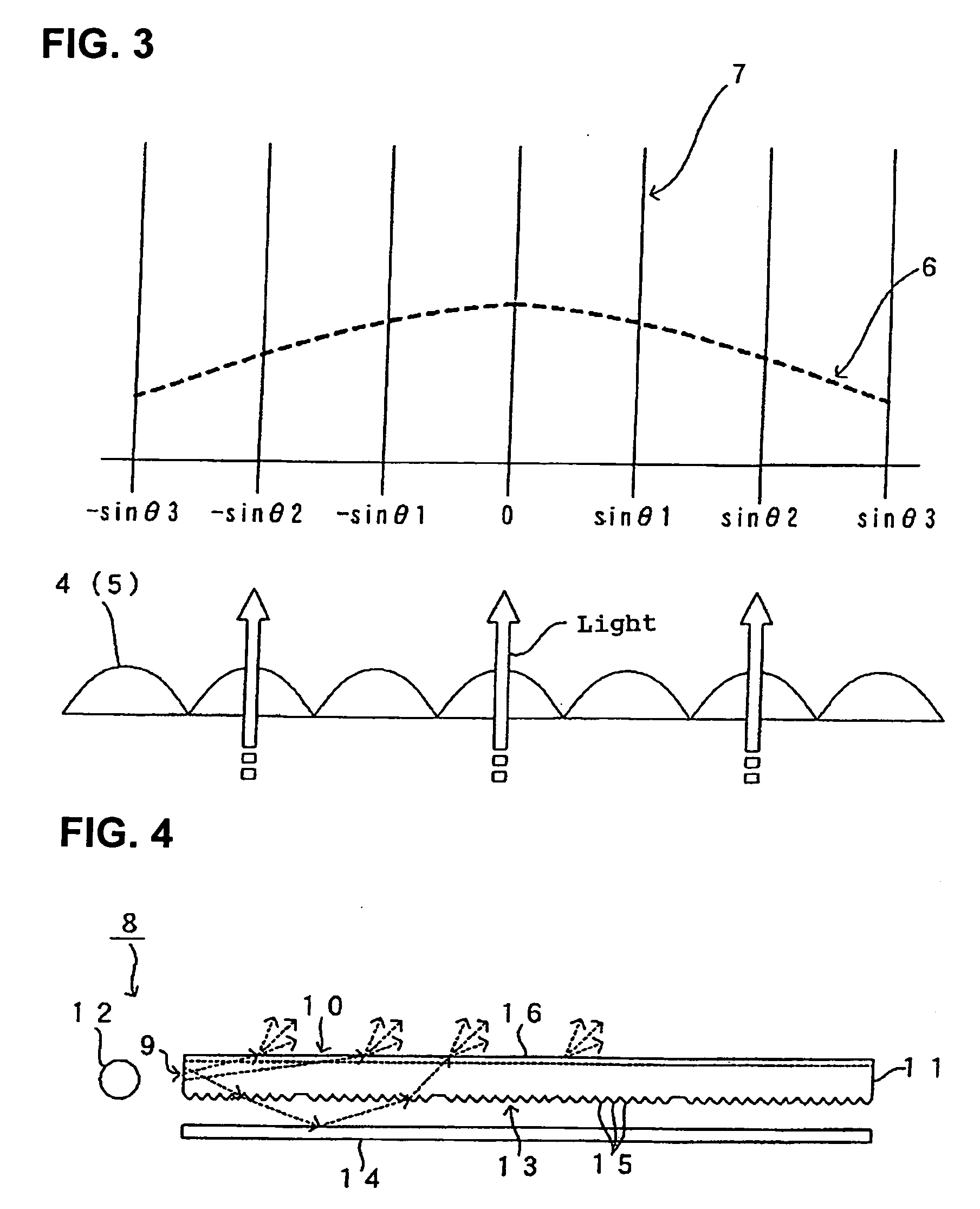

Optical Component and Backlight Unit Using the Optical Component

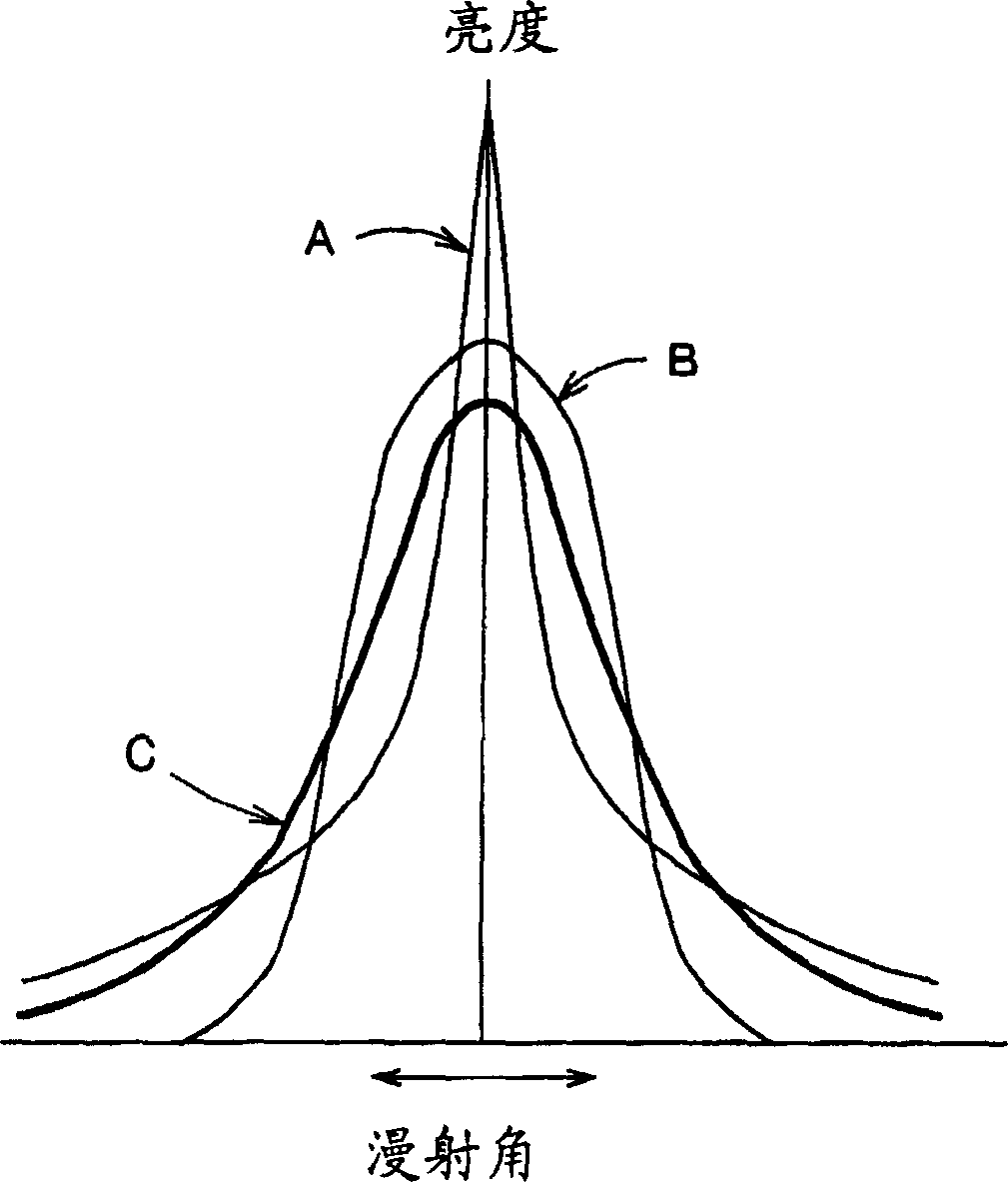

InactiveUS20070285941A1Wide viewing angleExcellent light diffusionPrismsMechanical apparatusHigh intensityPlane of incidence

[PROBLEMS] An optical component in which the viewing angle can be widened while sustaining a high luminance and the defect of a display can be made inconspicuous, and a backlight employing the optical component. [MEANS FOR SOLVING PROBLEMS] When a substantially collimated light impinges on the plane of incidence (9), an outgoing light from the outgoing plane (10) exhibits anisotropy in its intensity along an azimuth of 30° to normal to the outgoing plane (10), the anisotropy being such that the ratio between a highest intensity and a lowest intensity in the intensity distribution of outgoing light intensity along the azimuth of 30° is set to not smaller than 1.2.

Owner:SAKARI +1

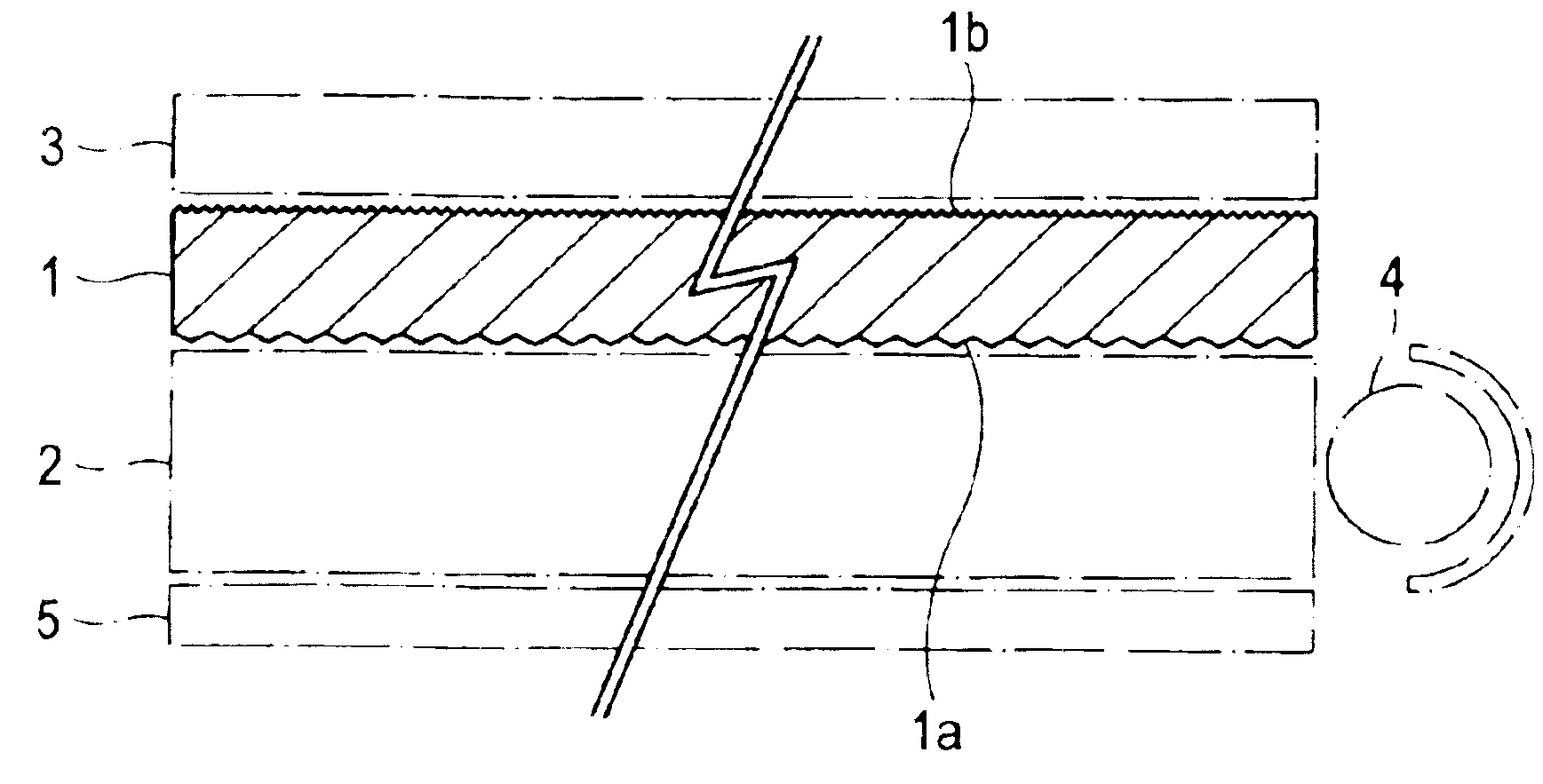

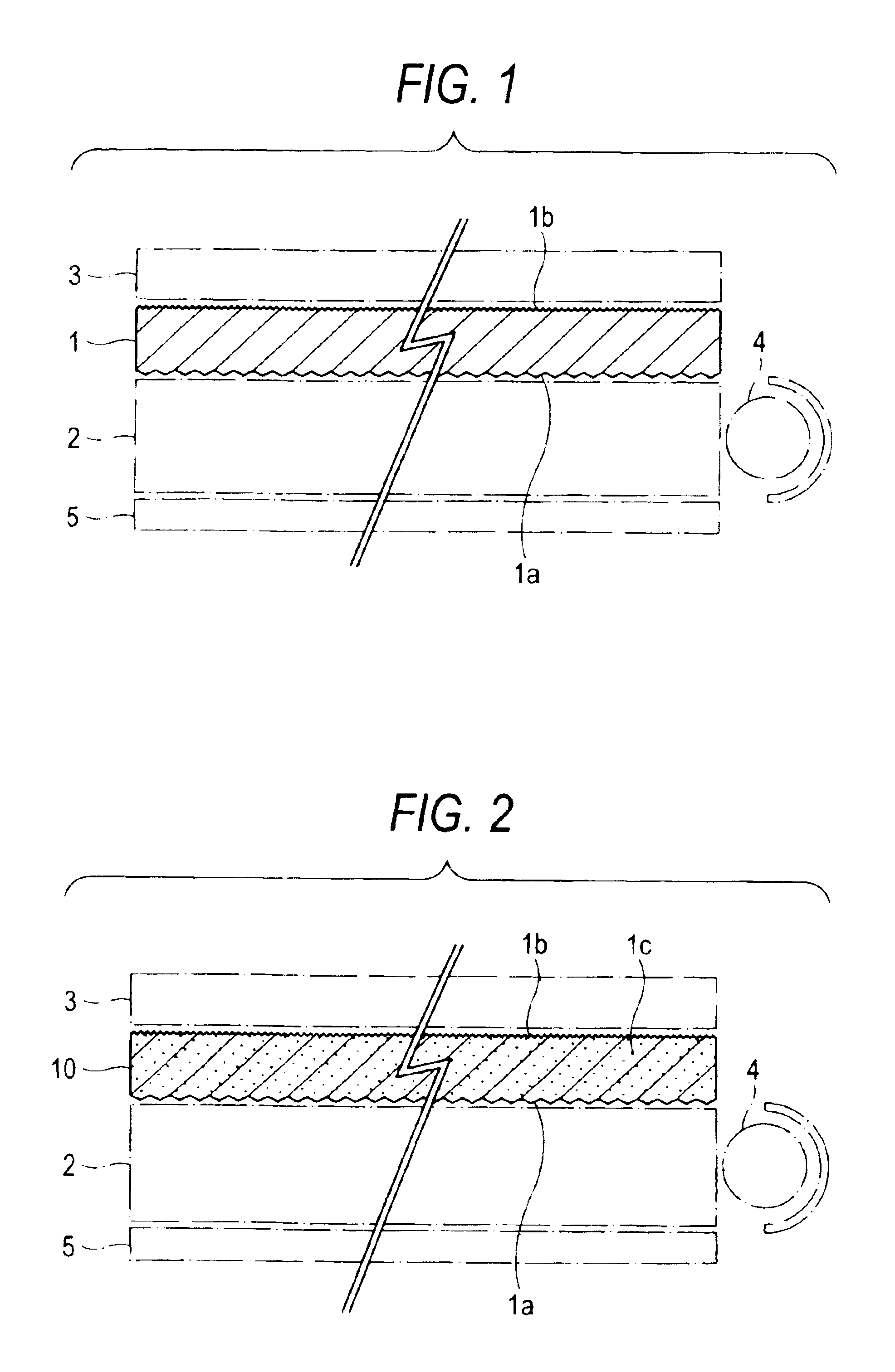

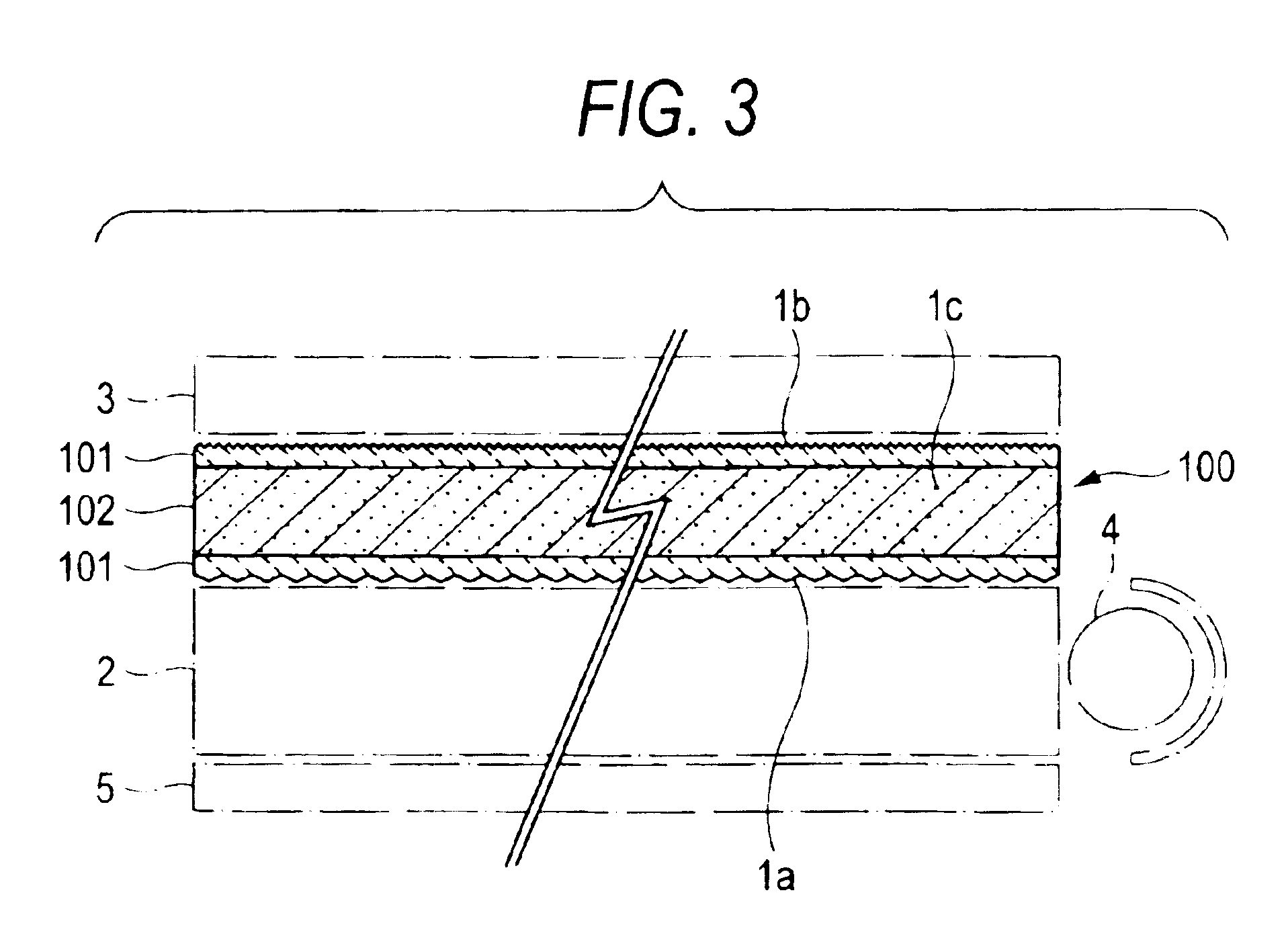

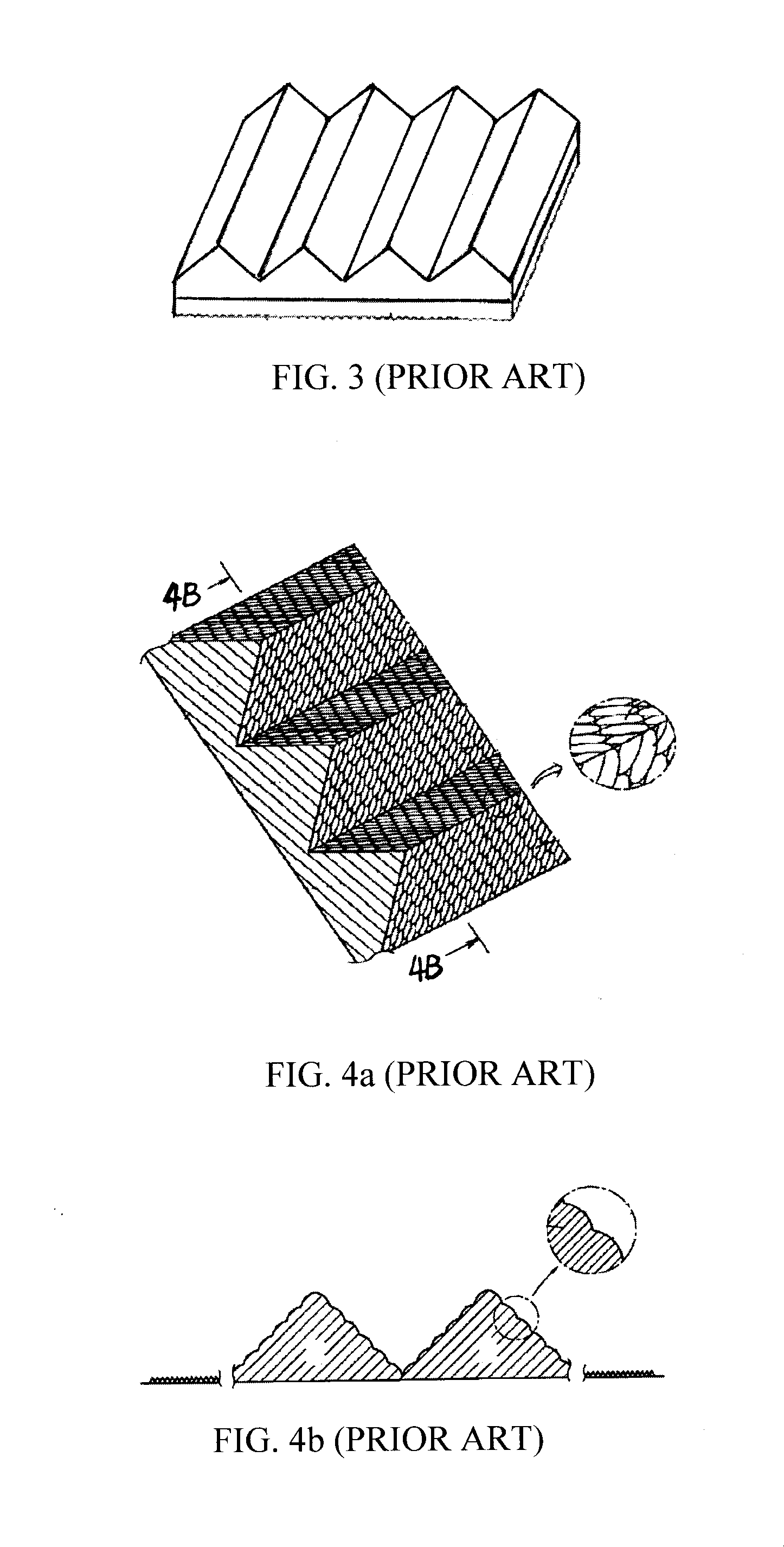

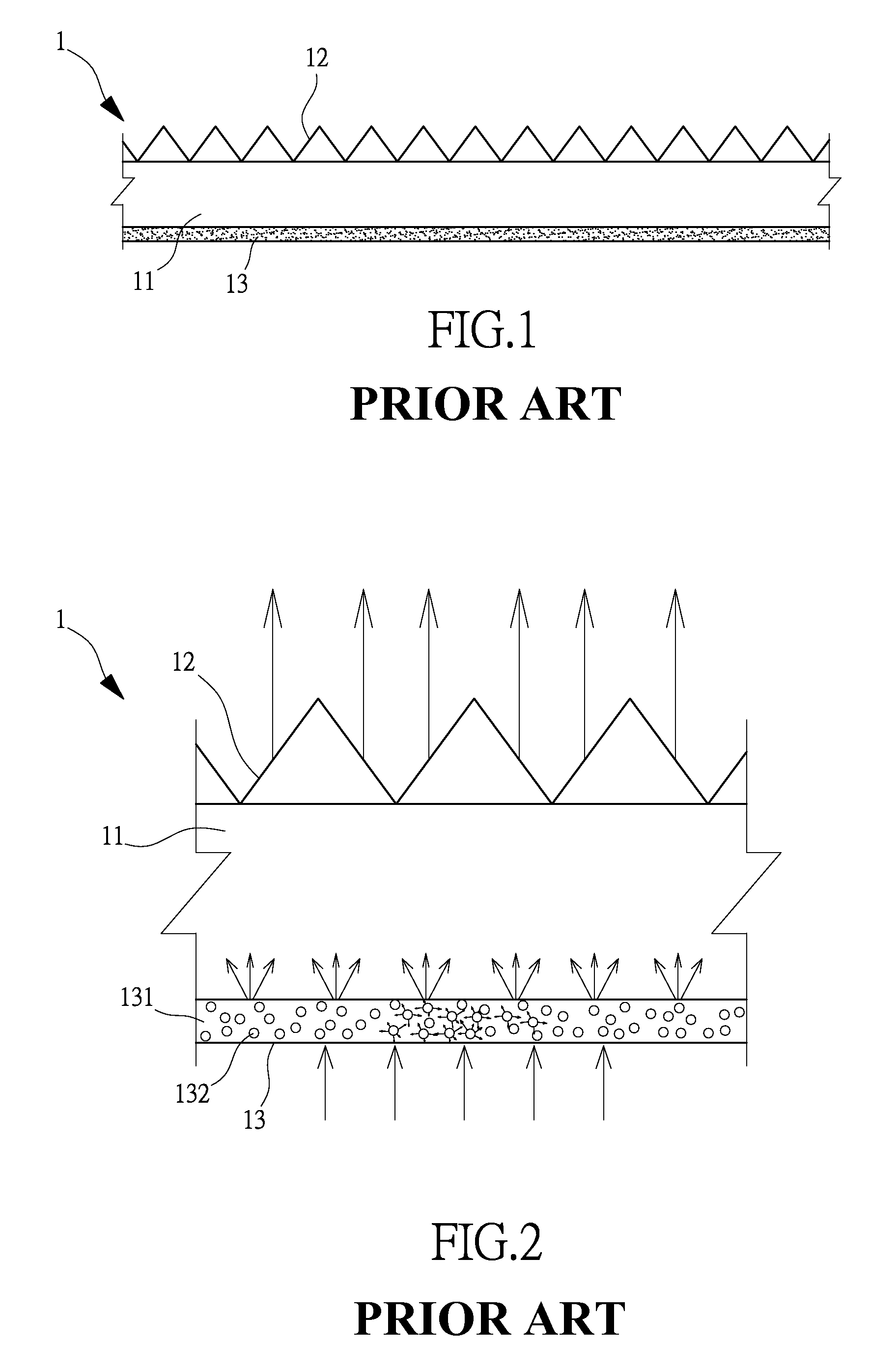

Light diffusive sheet

InactiveUS6963451B2Excellent in light diffusion actionExcellent light diffusionPrismsDiffusing elementsSurface roughnessMaterials science

The invention provides a sheet (1) comprising a light-transmittable resin, in which irregularities are formed on both sides (1a) and (1b) of the sheet, the average surface roughness of one side (1a) which becomes the light-entering side is from 0.2 to 5.0 μm and larger than the average surface roughness of the opposite side (1b) that becomes the light-departing side, wherein the average surface roughness of the opposite side (1b) is from 0.2 to 2.0 μm, and the surface area ratio of the one side (1a) is smaller than the surface area ratio of the opposite side (1b).

Owner:TAKIRON CO LTD

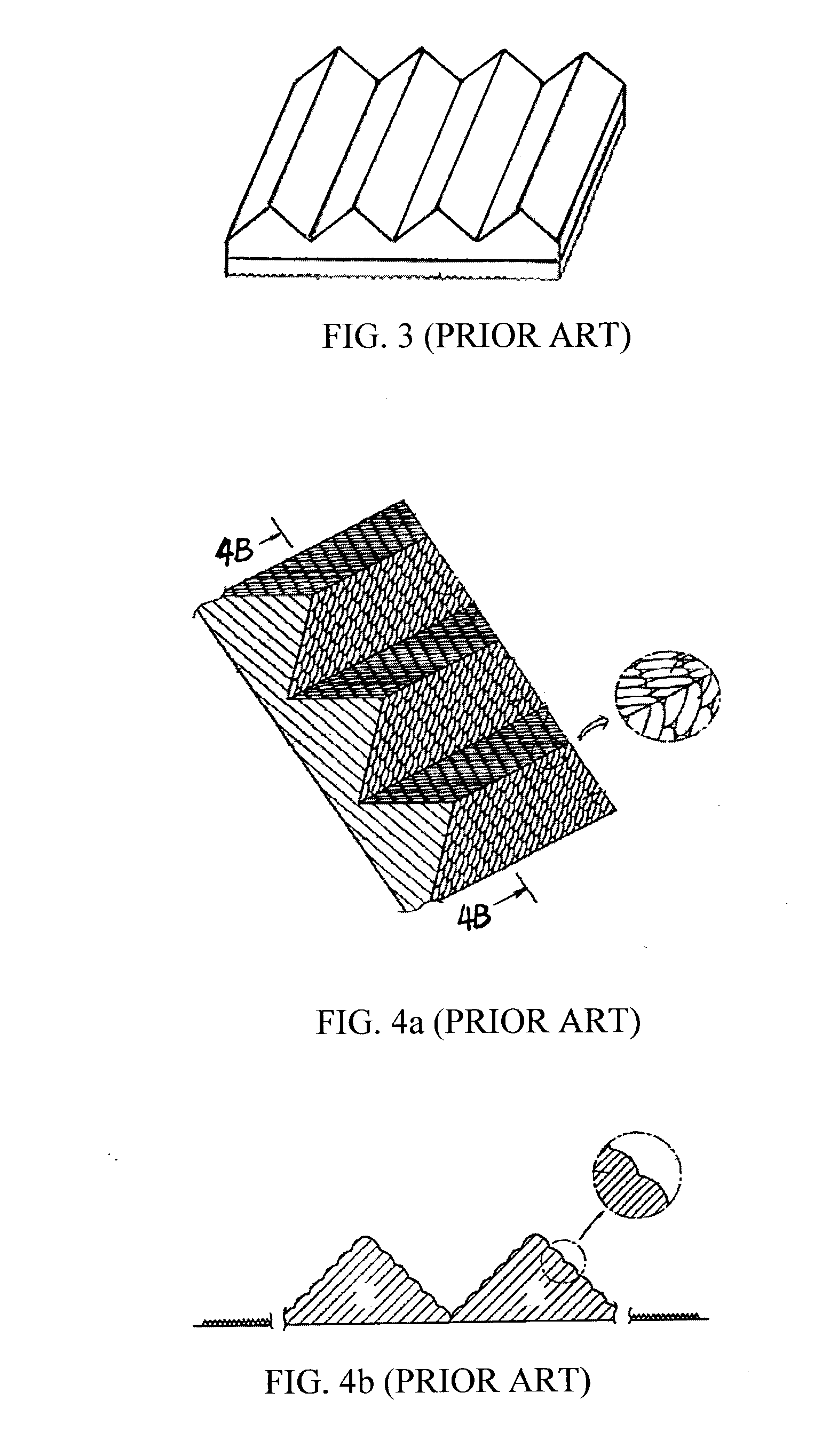

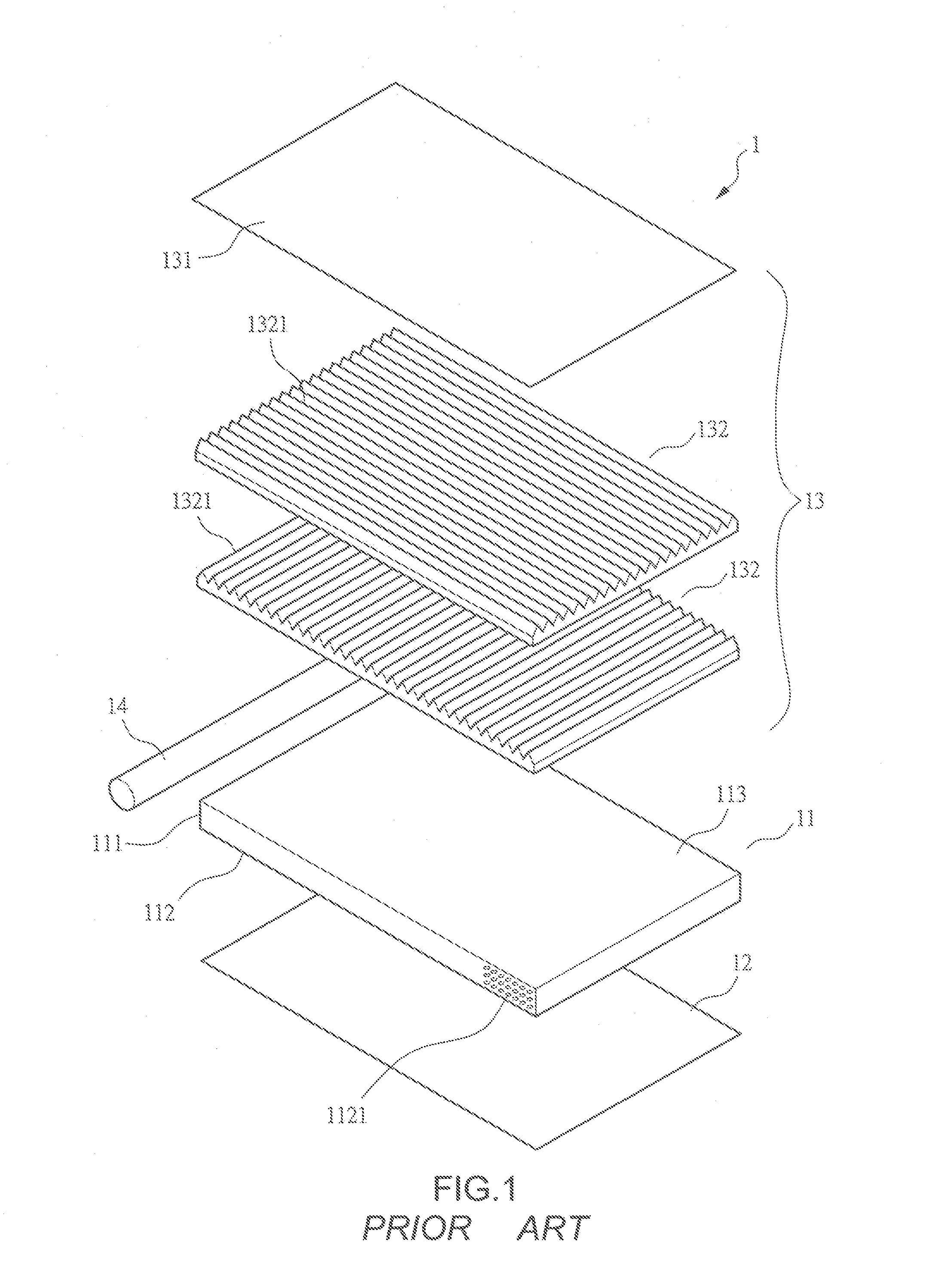

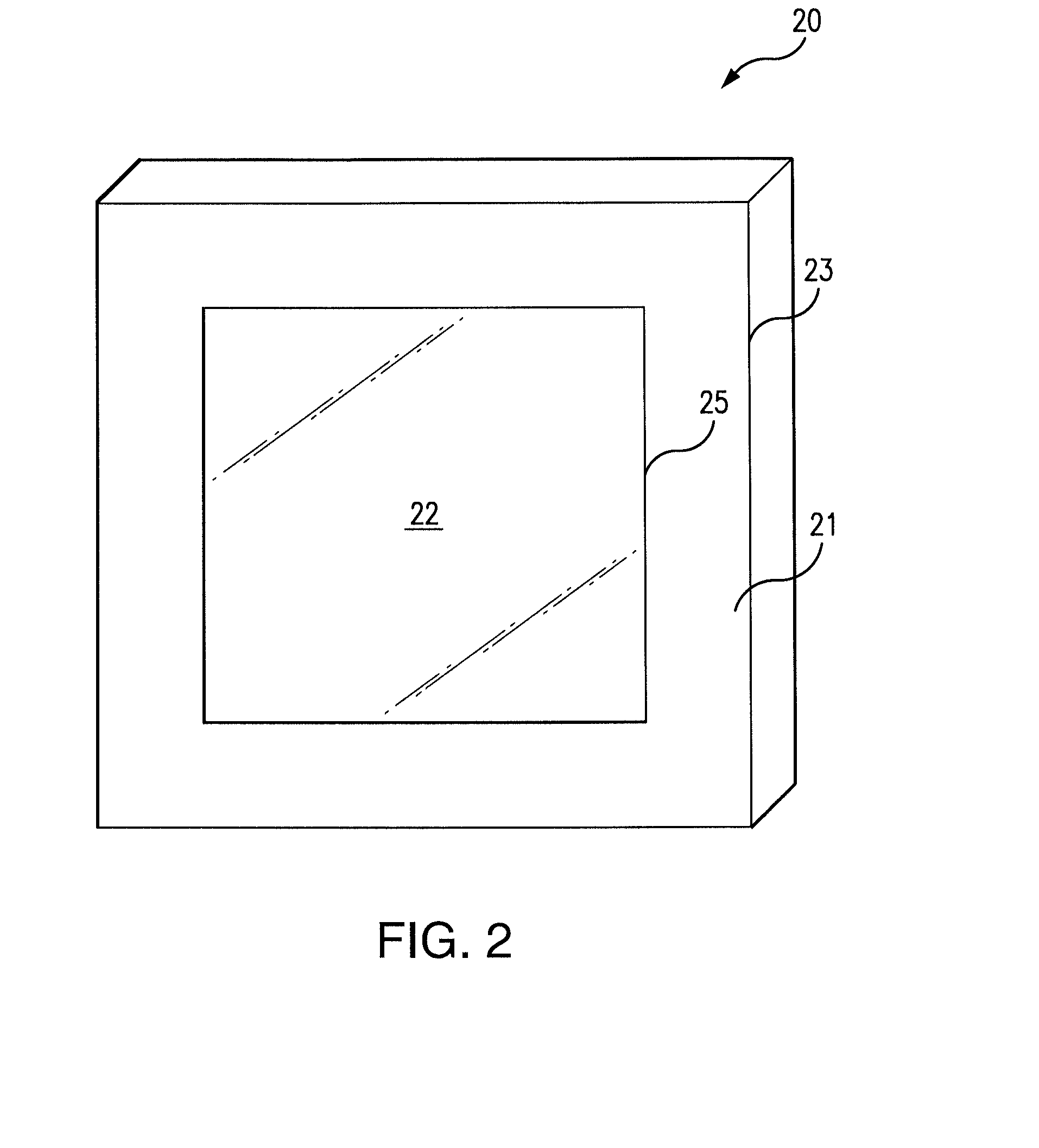

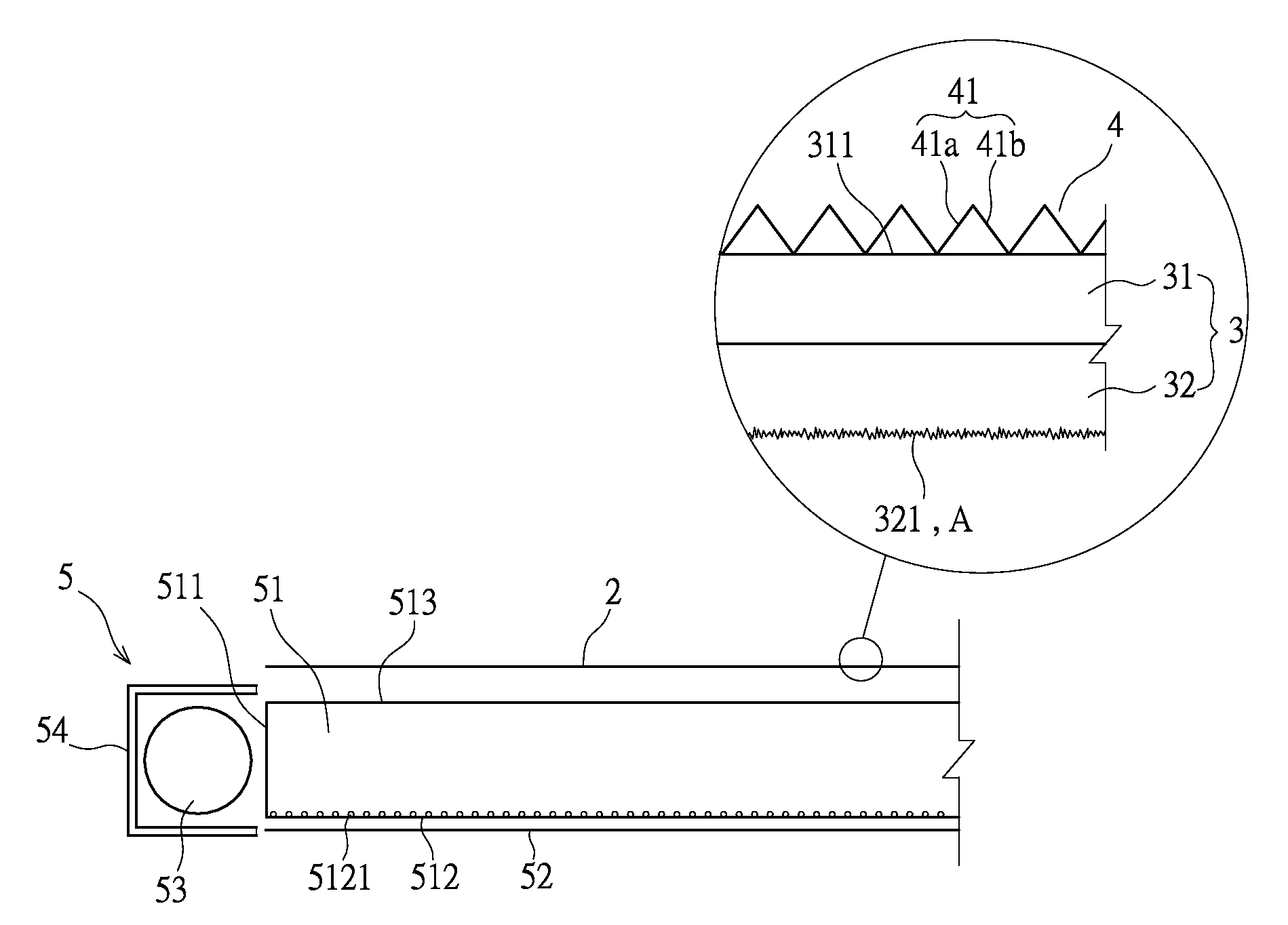

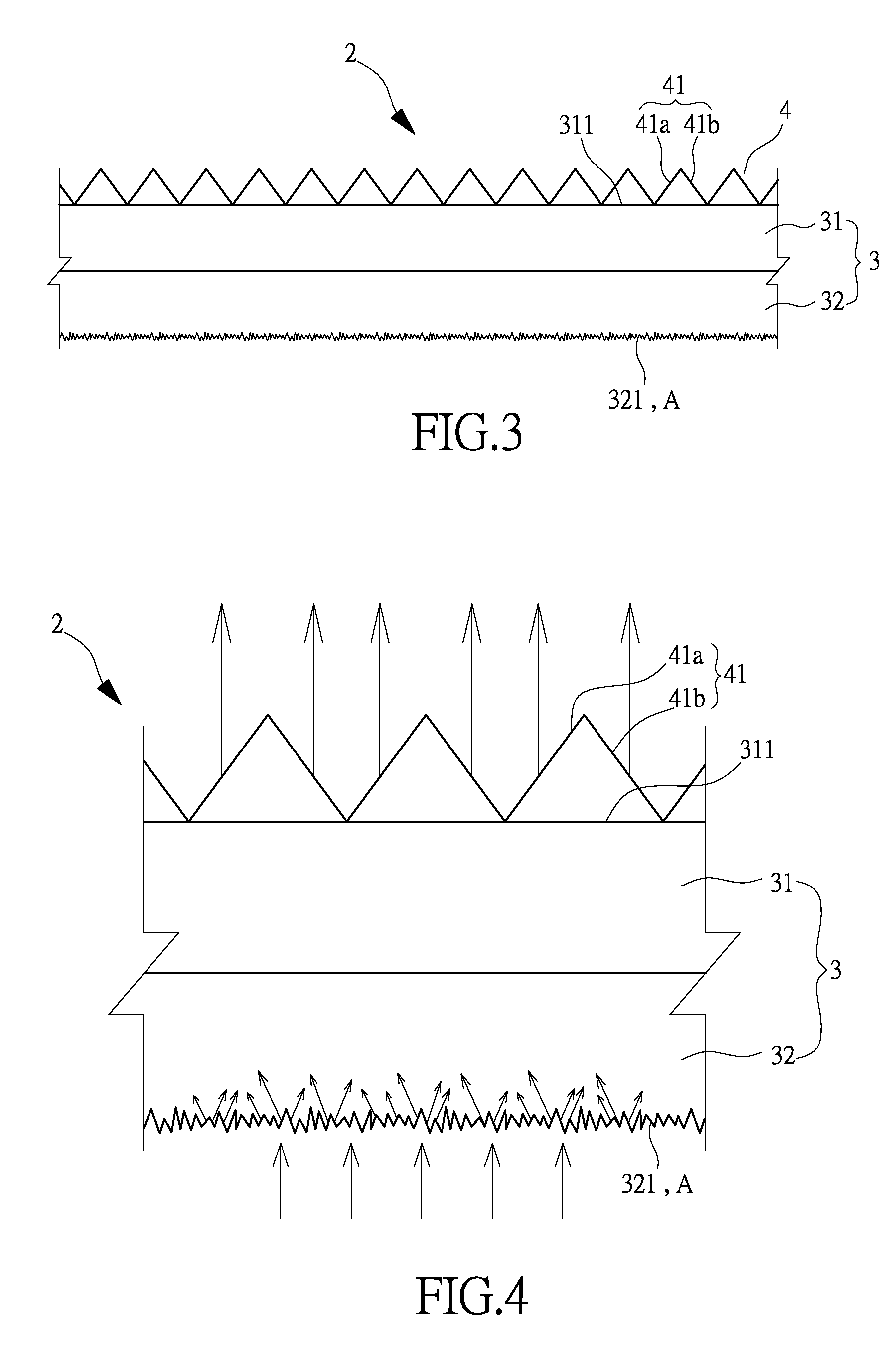

Light guide plate structure

InactiveUS20090279324A1Improve surface roughnessIncreasing light diffusing efficiencyOptical light guidesReflectorsComposite structureOptoelectronics

The invention discloses a light guide plate structure. The light guide plate structure includes a light-receiving surface, a light-emitting surface and a light-reflecting surface. The light-receiving surface receives emitting light from at least a light source, and the light propagating in the light guide plate exits through the light-emitting surface. The light-reflecting surface is opposite to the light-emitting surface for guiding the light that passes through the light-receiving surface to the light-emitting surface. The light-emitting surface and / or the light-reflecting surface include at least a composite structure. The composite structure includes a primary structure and a secondary structure where the secondary structure is disposed to a side of the primary structure.

Owner:WINTEK CORP

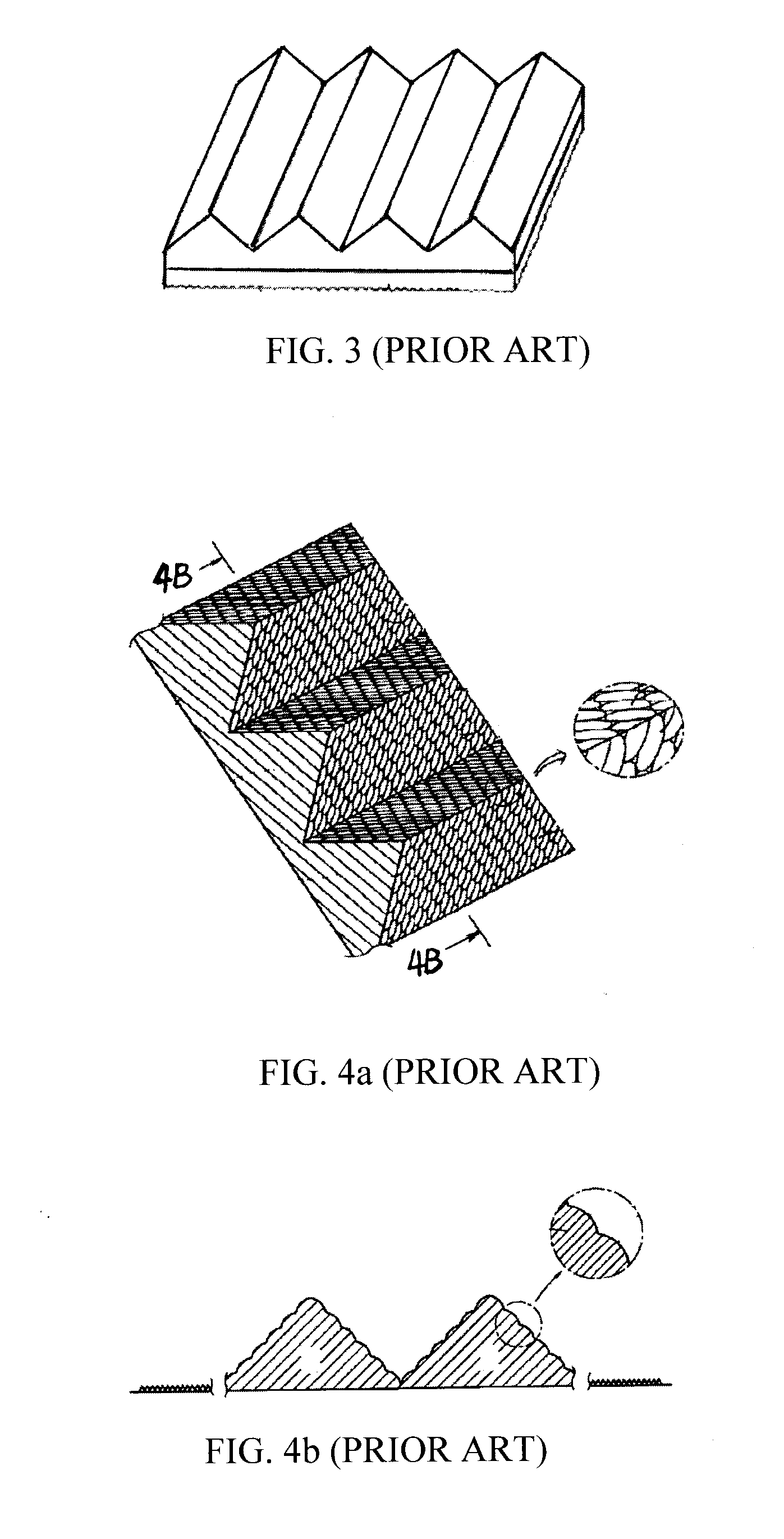

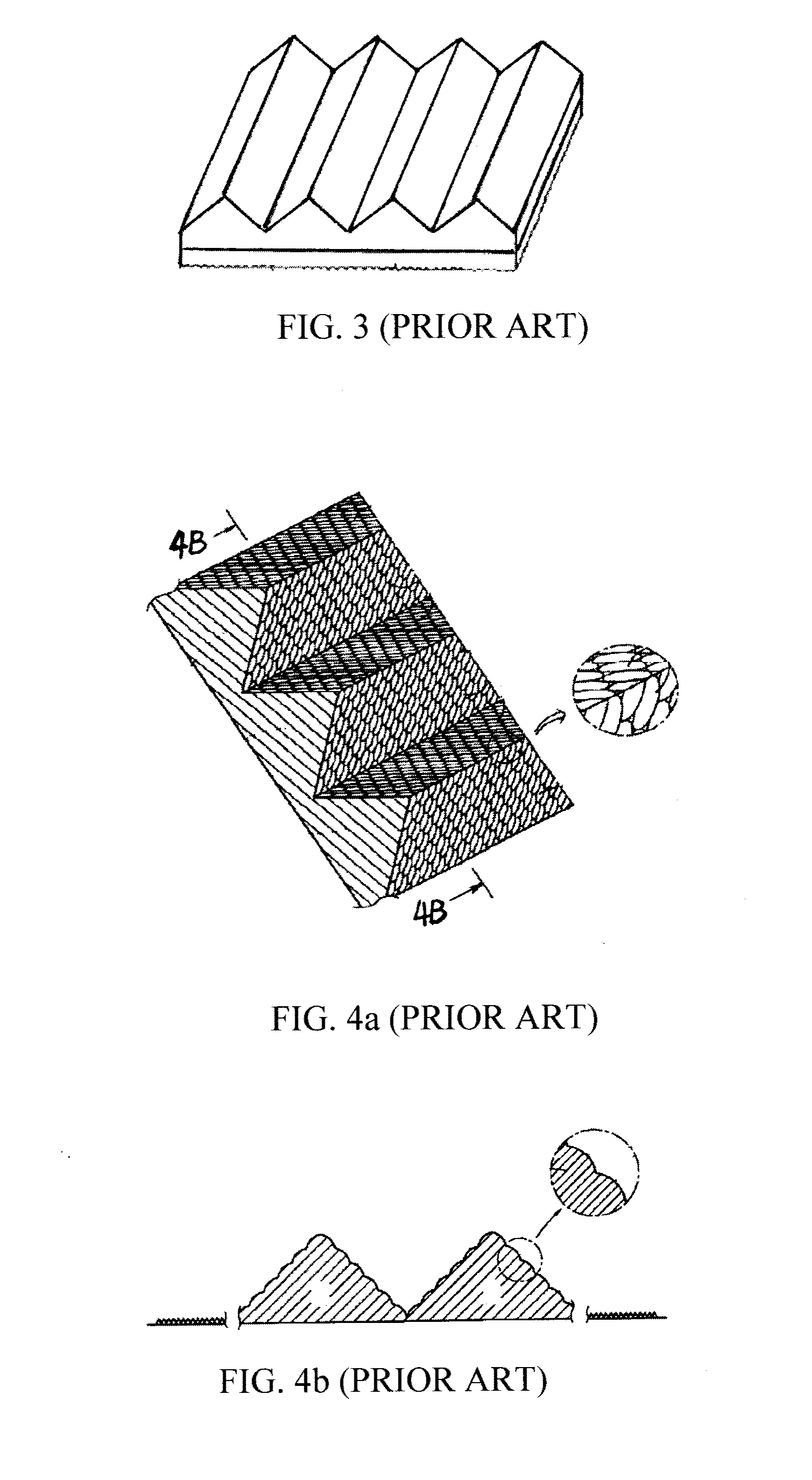

Structure of light guide board

InactiveUS20080123364A1Improve surface roughnessFacilitated DiffusionMechanical apparatusPlanar/plate-like light guidesMicro structureDiffusion

A light guide board includes an incidence surface, an emitting surface, and a reflection surface. The incidence surface is frosted and has a roughness-enhanced zone corresponding in location to a light source. The emitting surface forms micro-structures on portions adjacent to the incidence surface and two opposite end surfaces. The portions of the emitting surface forming the micro-structures have magnitude increased roughness as compared to portions that are not provided with micro-structures so that light transmitting through the micro-structures is subject to further diffusion. The reflection surface forms a plurality of prisms extending from the incidence surface with a small (shallow) depth to an opposite surface with a large (deep) depth, with the height of the prisms increasing with the length thereof so that the prism surface of the prisms changes from minimum to maximum, which ensures uniformity of the light emitted from the light guide board.

Owner:RADIANT OPTO ELECTRONICS

Light diffusion member, back light assembly including the same and display device including the same

InactiveUS20060133109A1Increase brightnessReduce manufacturing costThin material handlingNon-linear opticsDiffusionLiquid-crystal display

The light diffusion member includes a light diffusing body and a light diffusing layer. The light diffusing body includes a polymer mixture obtained by uniformly blending a first polymer having a first glass transition temperature and a second polymer having a second transition temperature higher than the first transition temperature. Alternatively, the light diffusing body includes a copolymer prepared from the first and the second polymer. The light diffusing body diffuses an incident light through a light exiting surface. The light diffusing layer is formed on the light exiting surface of the light diffusing body and includes a binder resin having beads. A back light assembly including the light diffusion member and a liquid crystal display device including the light diffusion member exhibit an improved luminance and an improved light diffusing efficiency.

Owner:SAMSUNG ELECTRONICS CO LTD

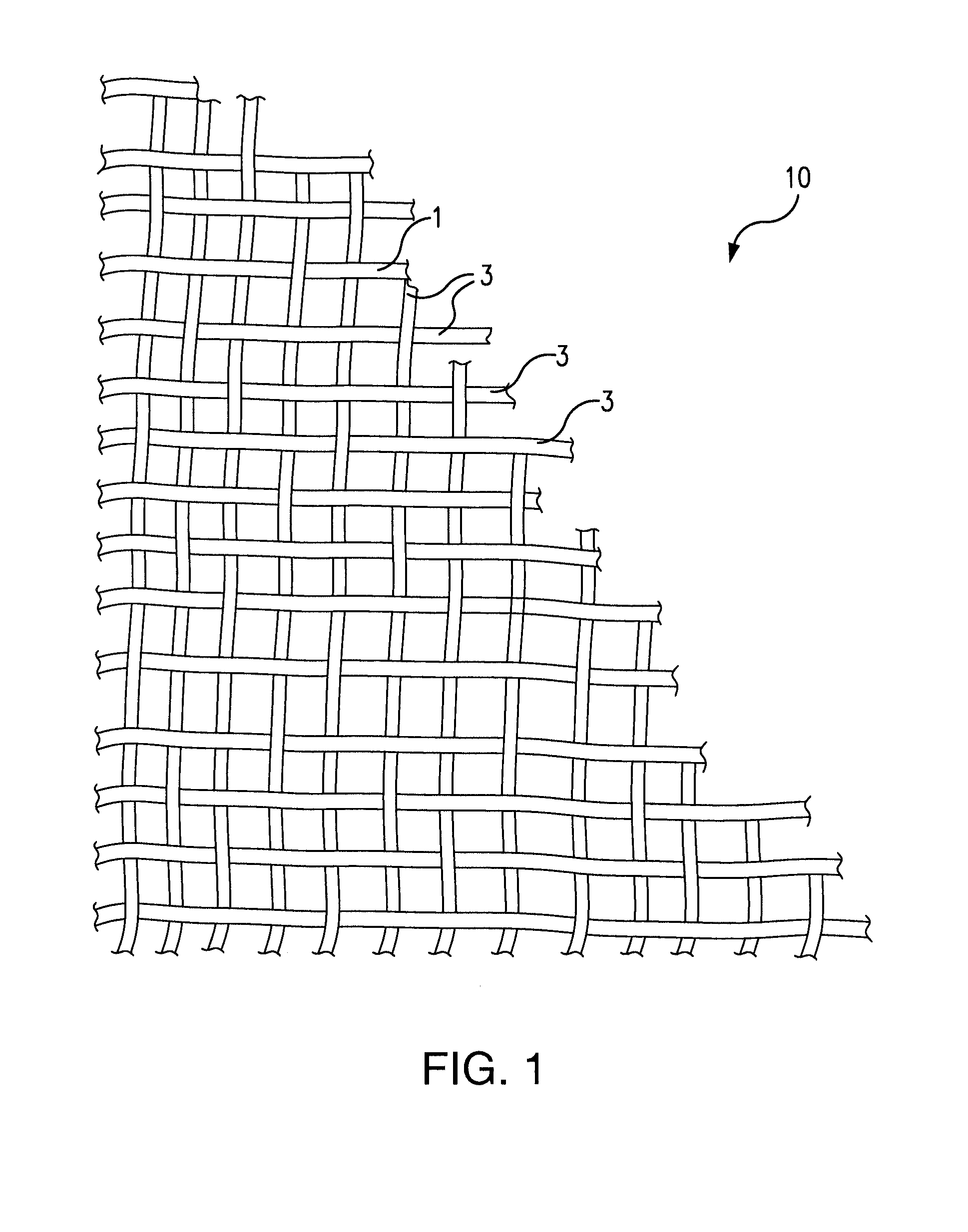

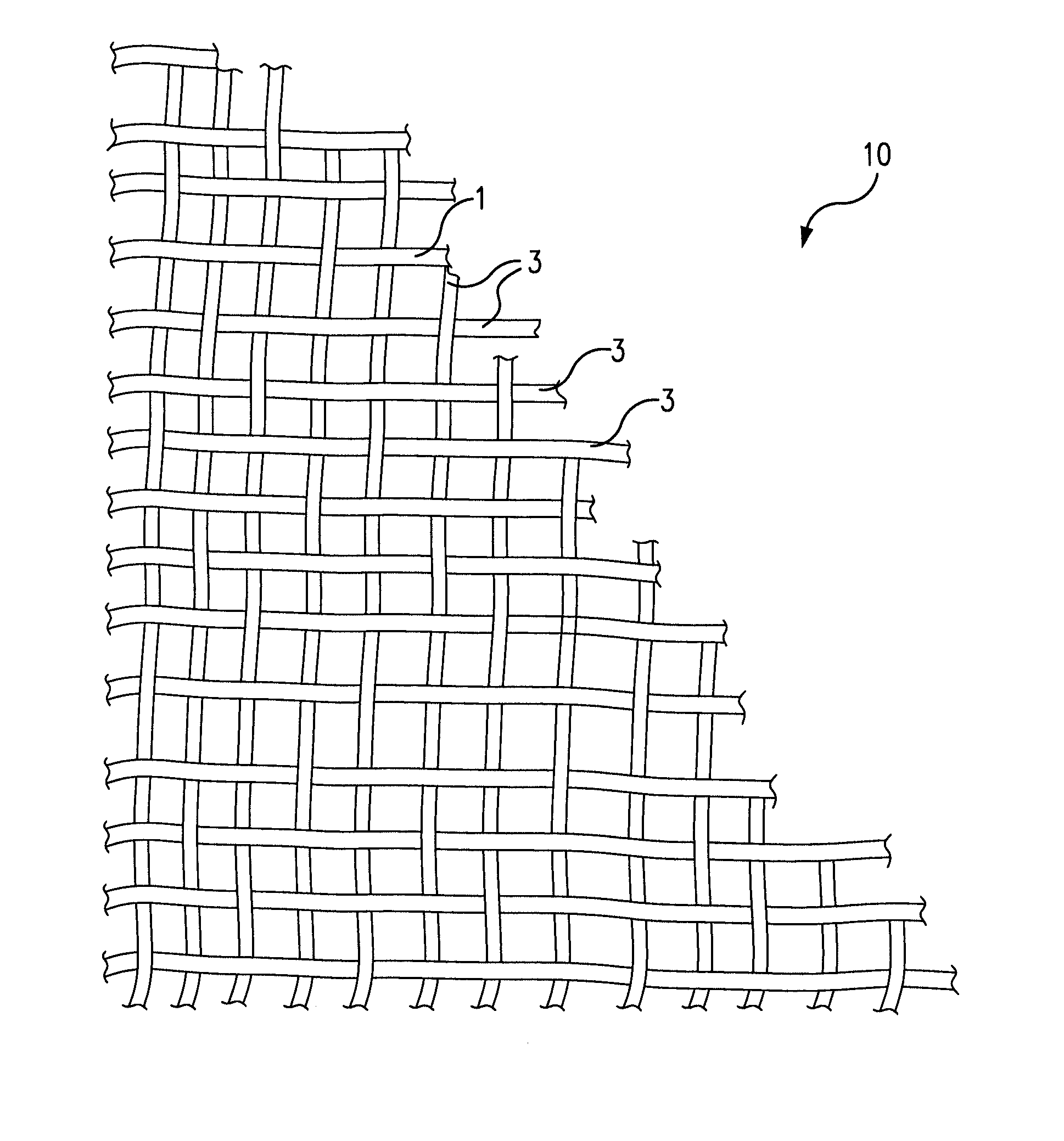

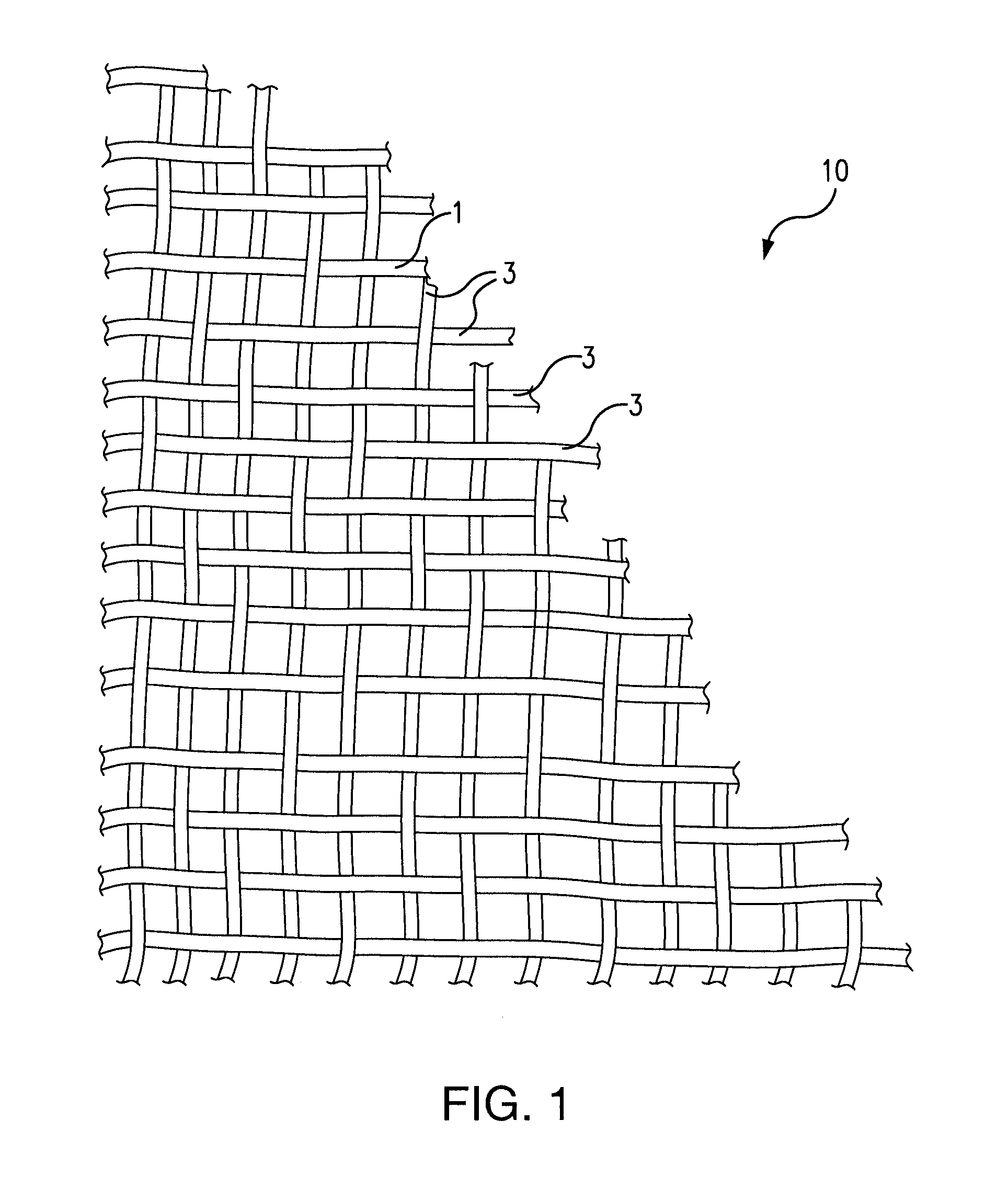

Fiber optic tapestry

InactiveUS20130010004A1Excellent light diffusionFibre light guidesCathode-ray tube indicatorsFiberEngineering

A woven fiber optic tapestry for conveying a specific representation of data on a woven fiber optic threaded surface. The tapestry is provided in a particular system including fiber optic threads threadedly arranged together to form a woven fiber optic panel, in which each of the threads is operatively connected to a light source, and a data interpretation device operatively connected to the light sources so as to provide a transfer of a pre-assigned value of data from the data interpretation device to the light sources and the threads, the transfer of the pre-assigned value causing an illumination of the light sources so as to correlate to a specific representation of the data.

Owner:LIGORANO NORA +1

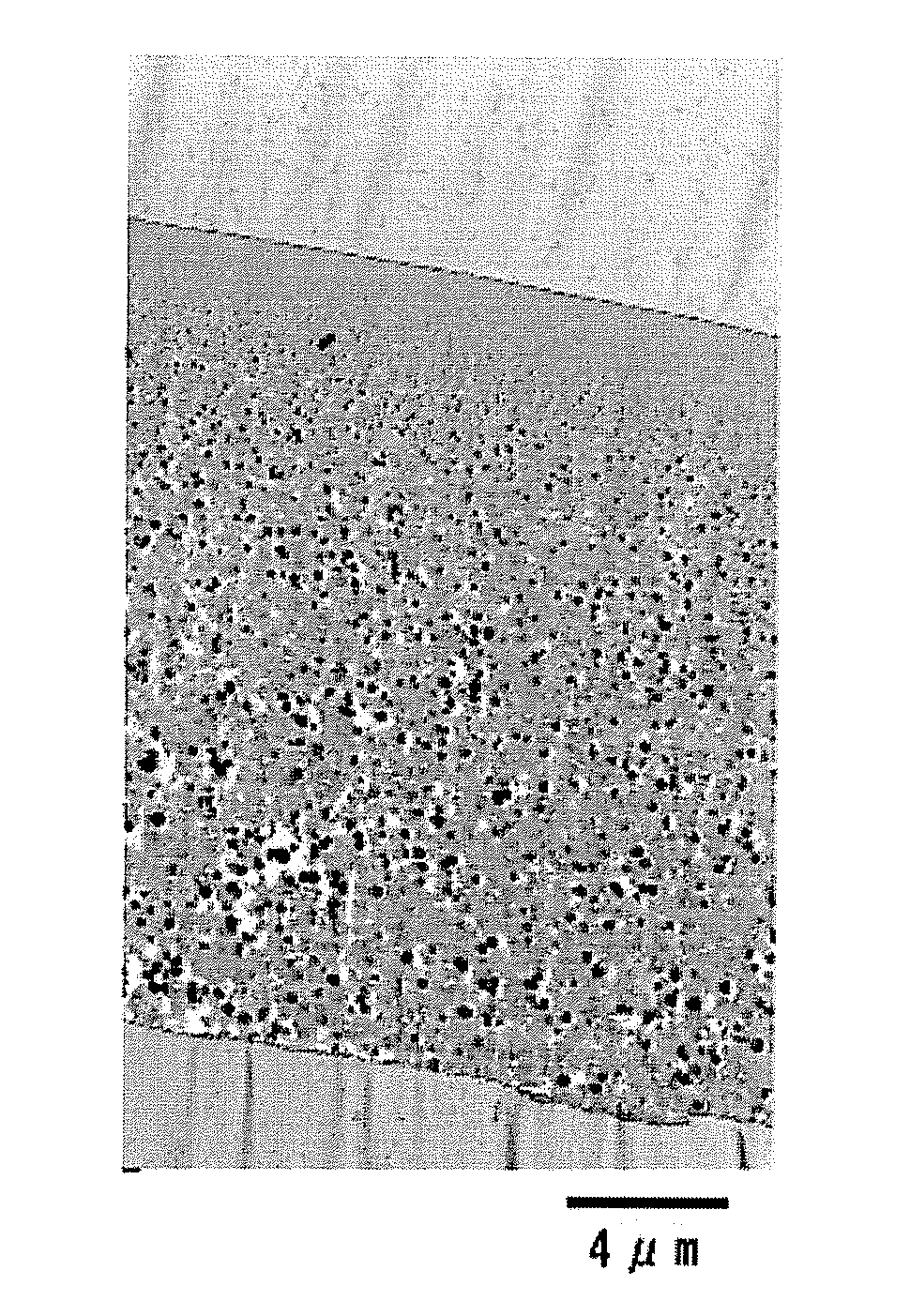

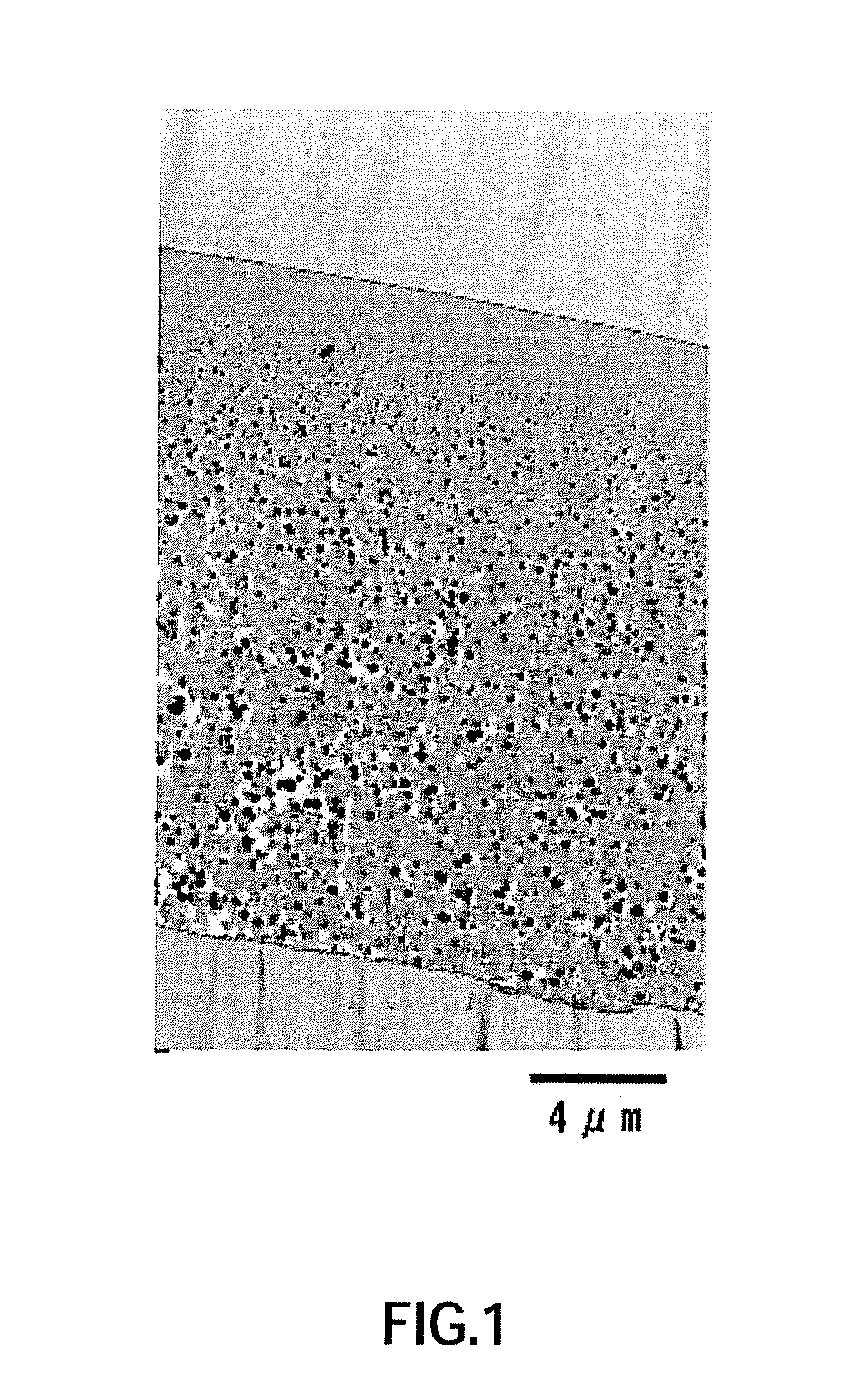

Dental curable composition and composite resin using the same

ActiveUS20110257292A1Excellent light diffusionHigh transparencyImpression capsOther chemical processesInorganic particleRefractive index

The present invention provides a dental curable composition exhibiting both excellent light diffusion and excellent transparency, and having high mechanical strength and surface smoothness and gloss after polishing as a cured product as well as good handling properties as a paste. The present invention is a dental curable composition including: a polymerizable monomer (A) having a refractive index of 1.52 to 1.58 after polymerization; inorganic particles (B) having a refractive index of 1.43 to 1.50; and inorganic particles (C) having a refractive index of 1.52 to 1.58. The inorganic particles (B) are aggregates of inorganic fine particles having an average primary particle size of 2 to 50 nm, and the content of the inorganic particles (B) is 0.1 to 10% by weight.

Owner:KURARAY NORITAKE DENTAL

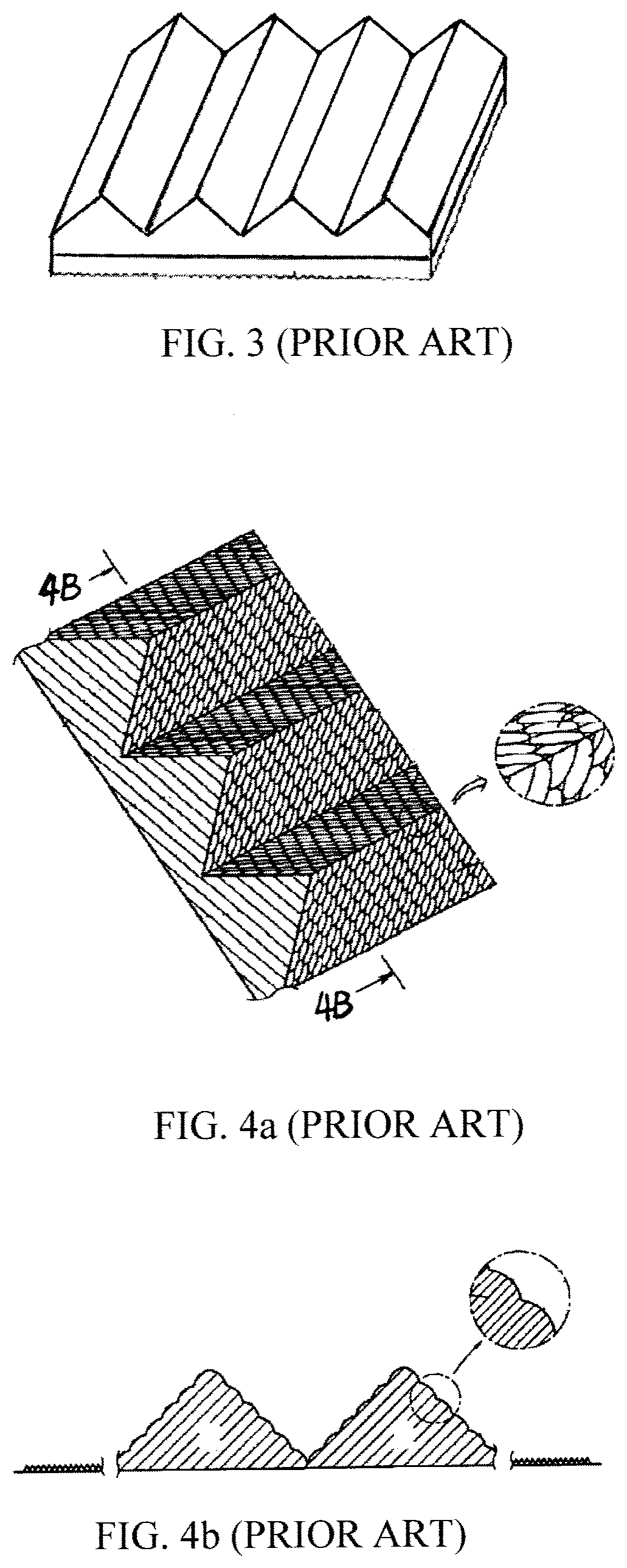

Optical substrates having light collimating and diffusion structures

InactiveUS20160067931A1Increase brightnessReduce distortionLayered productsOptical articlesCurve shapeEngineering

This invention discloses a method of forming an uneven structure on a substrate. Use a hard tool to penetrate into a mold to cut a first trench and a second trench in an order on a surface of a mold, wherein the hard tool has a smoothly-curved shape such that the transverse width of each of the first trench and the second trench increases as the penetrating depth of the hard tool increases, wherein when each of the first trench and the second trench marches along a first direction, the penetrating depth of the hard tool is controlled by repeating moving the hard tool up and down to cut the mold such that the transverse width of each of the first trench and the second trench varies according to the controlled penetrating depth of the hard tool, wherein the first trench and the second trench completely overlap with each other with no space therebetween. Then, use the surface of the mold to emboss a thin film on a substrate.

Owner:UBRIGHT OPTRONICS CORP

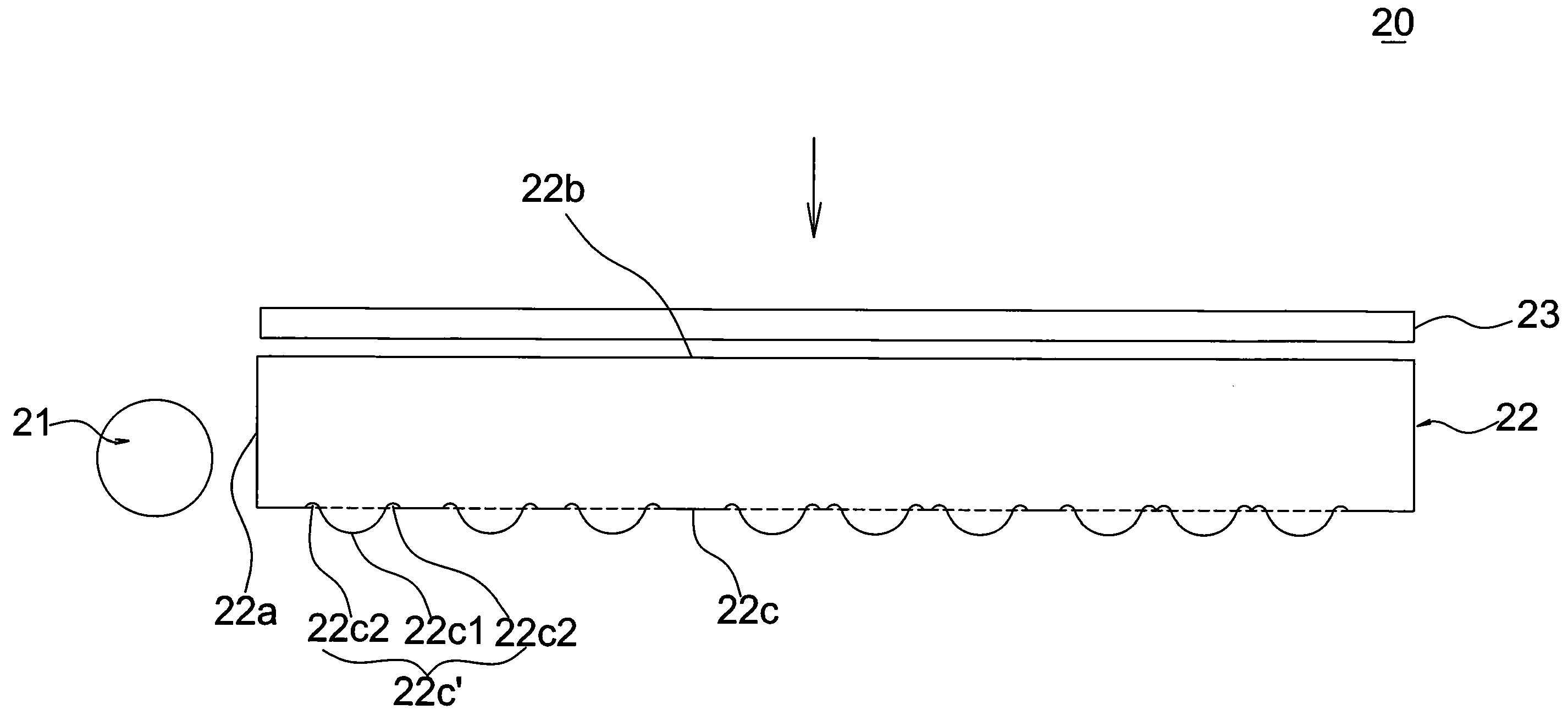

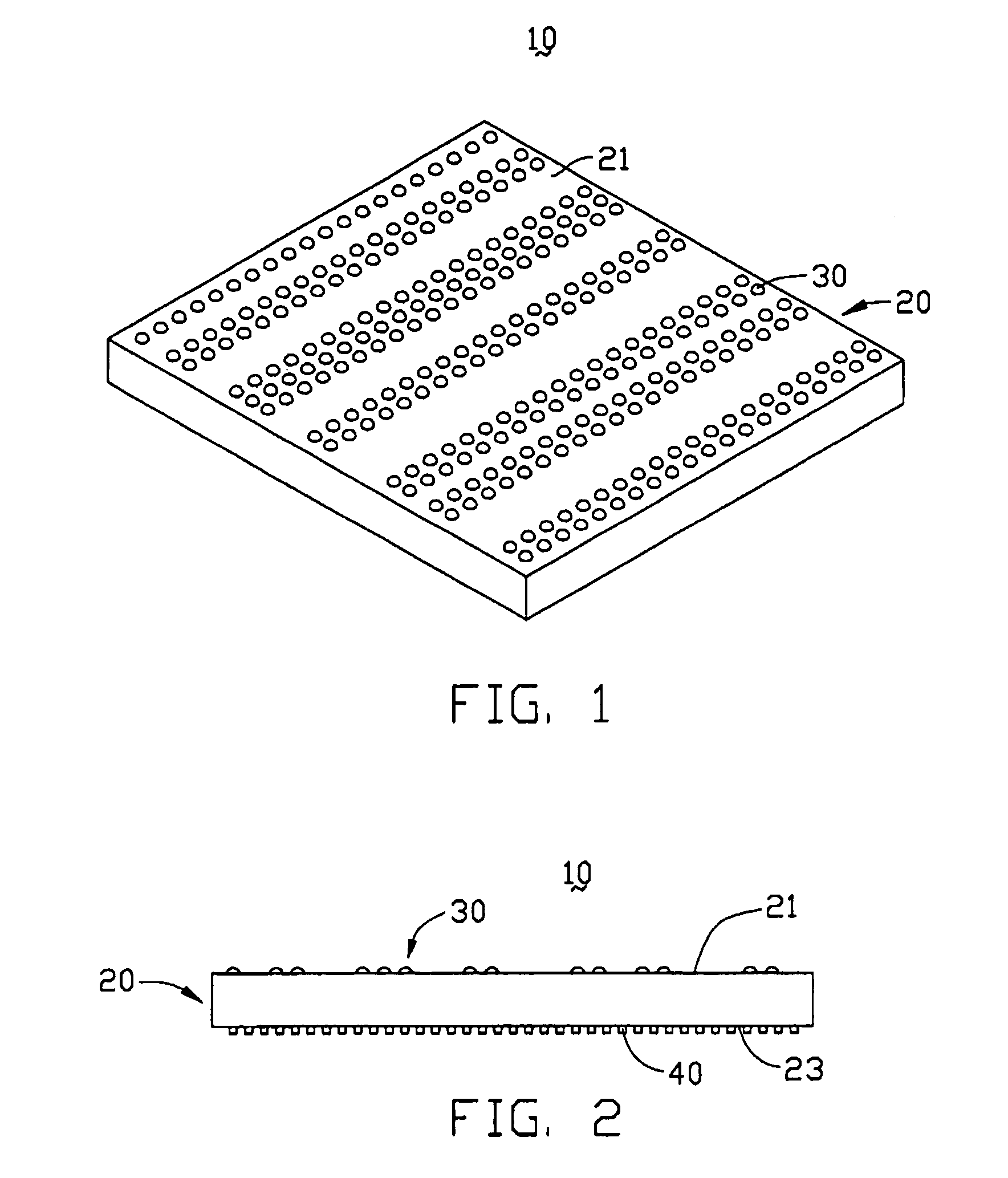

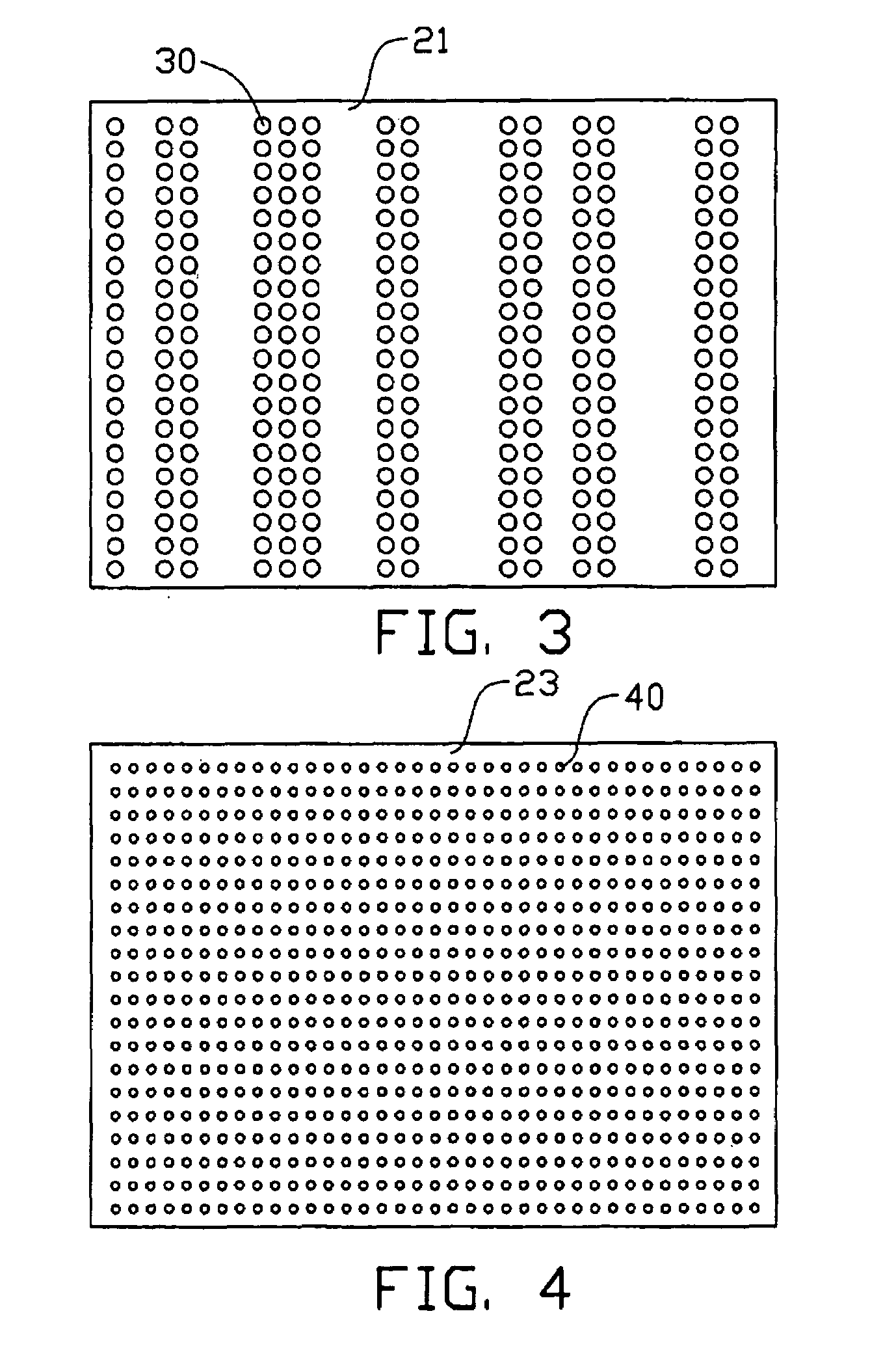

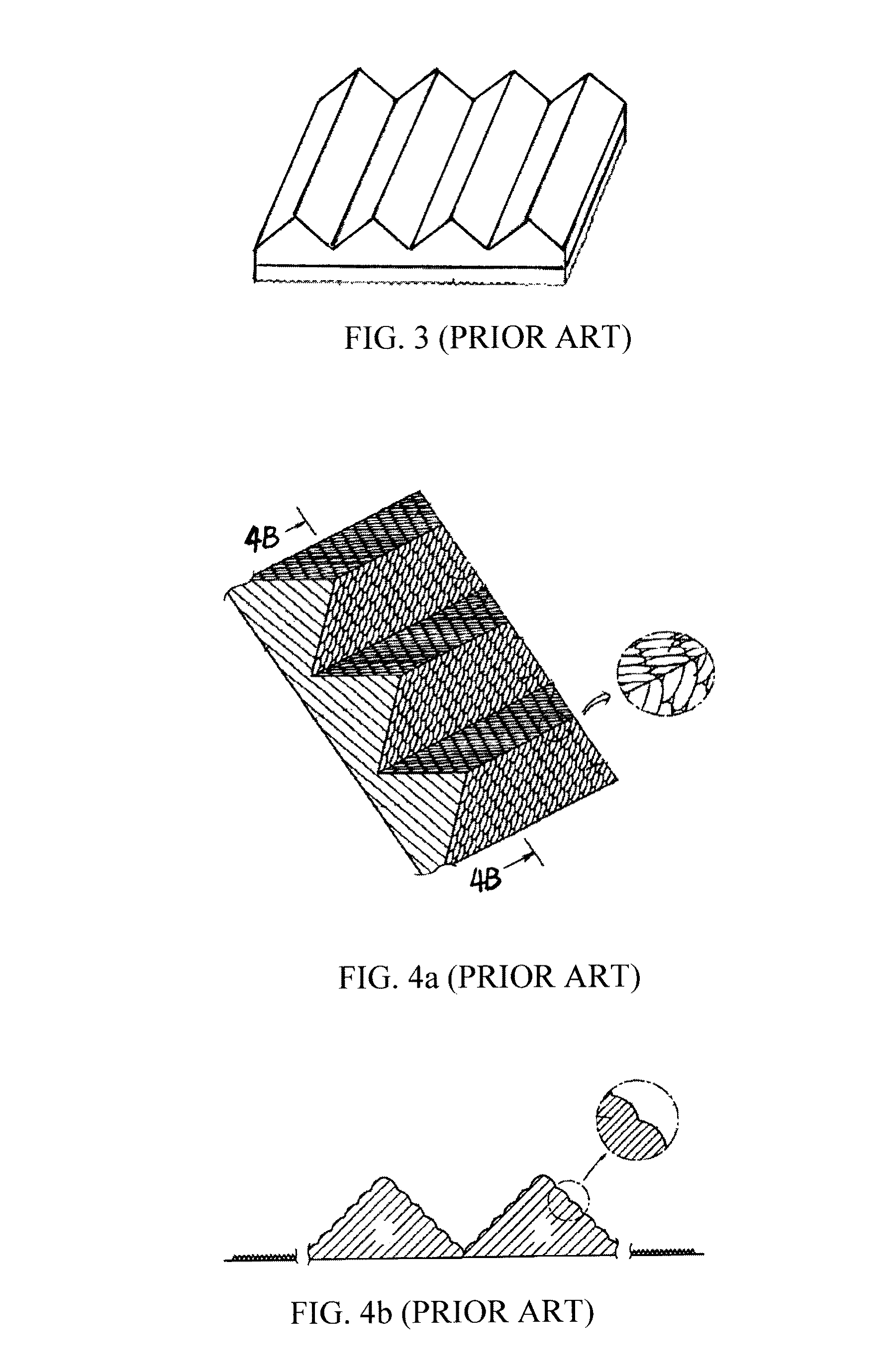

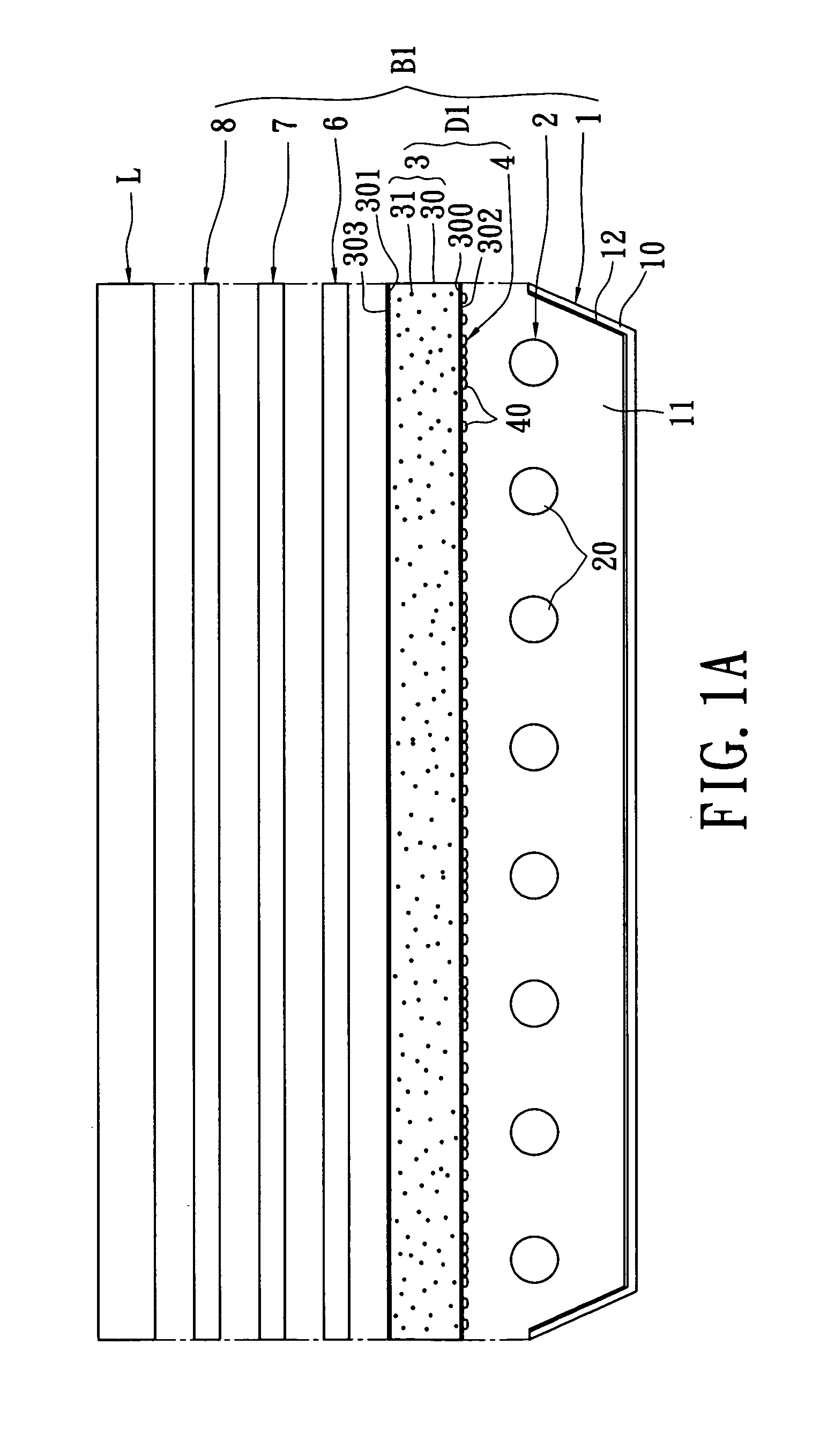

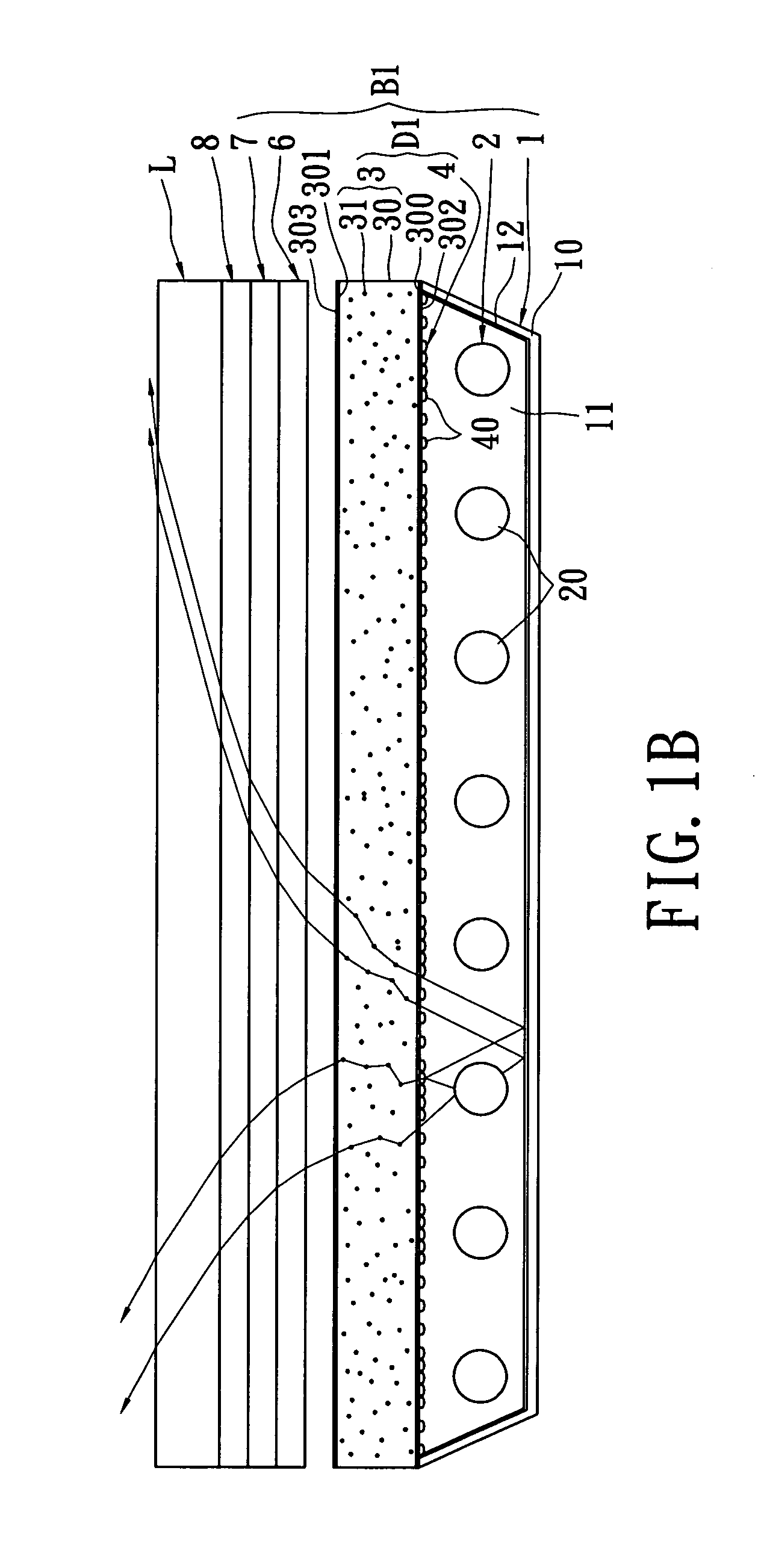

Light guide plate with diffusing protrusions

InactiveUS7014343B2Excellent light diffusionReduce brightness unevennessMechanical apparatusLight guides for lighting systemsLight guideLight beam

A light guide plate (10) includes a transparent plate (20), and a plurality of diffusing protrusions (30). The transparent plate includes an emitting surface (21), and a bottom surface (23) opposite to the emitting surface. The diffusing protrusions are distributed evenly on the emitting surface of the transparent plate, and are integrated with the transparent plate. The diffusing protrusions are hemispherical or sub-hemispherical, and a diameter of each diffusing protrusion is in the range from 10 μm˜50 μm. The light guide plate provides high emitting brightness and uniformity. The diffusing protrusions can diffuse light beams emitting from the emitting surface of the transparent plate, in order to achieve a plane light source having even brightness. The present Invention also discloses a method for fabricating the light guide plate.

Owner:HON HAI PRECISION IND CO LTD

Optic film and backlight module using same

InactiveUS20100046249A1Improve performanceImprove rigidityAircraft componentsMechanical apparatusComputer moduleOptical thin film

Owner:GAMMA OPTICAL +1

Optical substrates having light collimating and diffusion structures

ActiveUS8638408B2Increase brightnessImprove luminanceOptical articlesPlanar/plate-like light guidesDiffusionPrism

An optical substrate having a structured prismatic surface and an opposing structured lenticular surface. The structured lenticular surface includes shallow-curved lens structures. Adjacent shallow-curved lens structure may be continuous or contiguous, or separated by a constant or variable spacing. The lens structure may have a longitudinal structure with a uniform or varying cross section. The lenticular lenses may have a laterally meandering structure. Sections of adjacent straight or meandering lenticular lenses may intersect or partially or completely overlap each other. The lenticular lenses may be in the form of discontinuous lenticular segments. The lenticular segments may have regular, symmetrical shapes, or irregular, asymmetrical shapes, which may be intersecting or overlapping, and may be textured. The lens structure may be provided with isolated ripples, in the form of a single knot, or a series of knots.

Owner:UBRIGHT OPTRONICS CORP

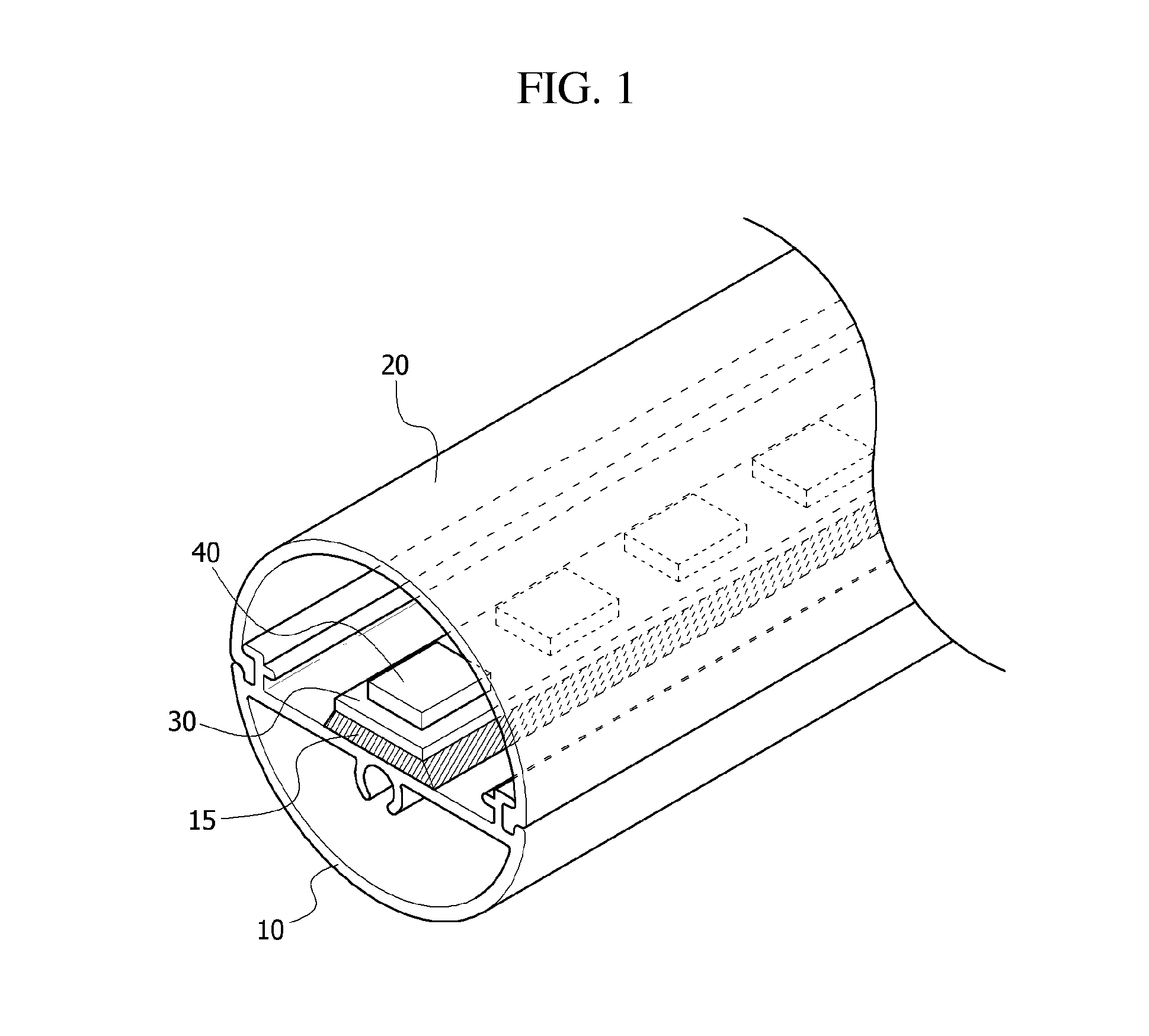

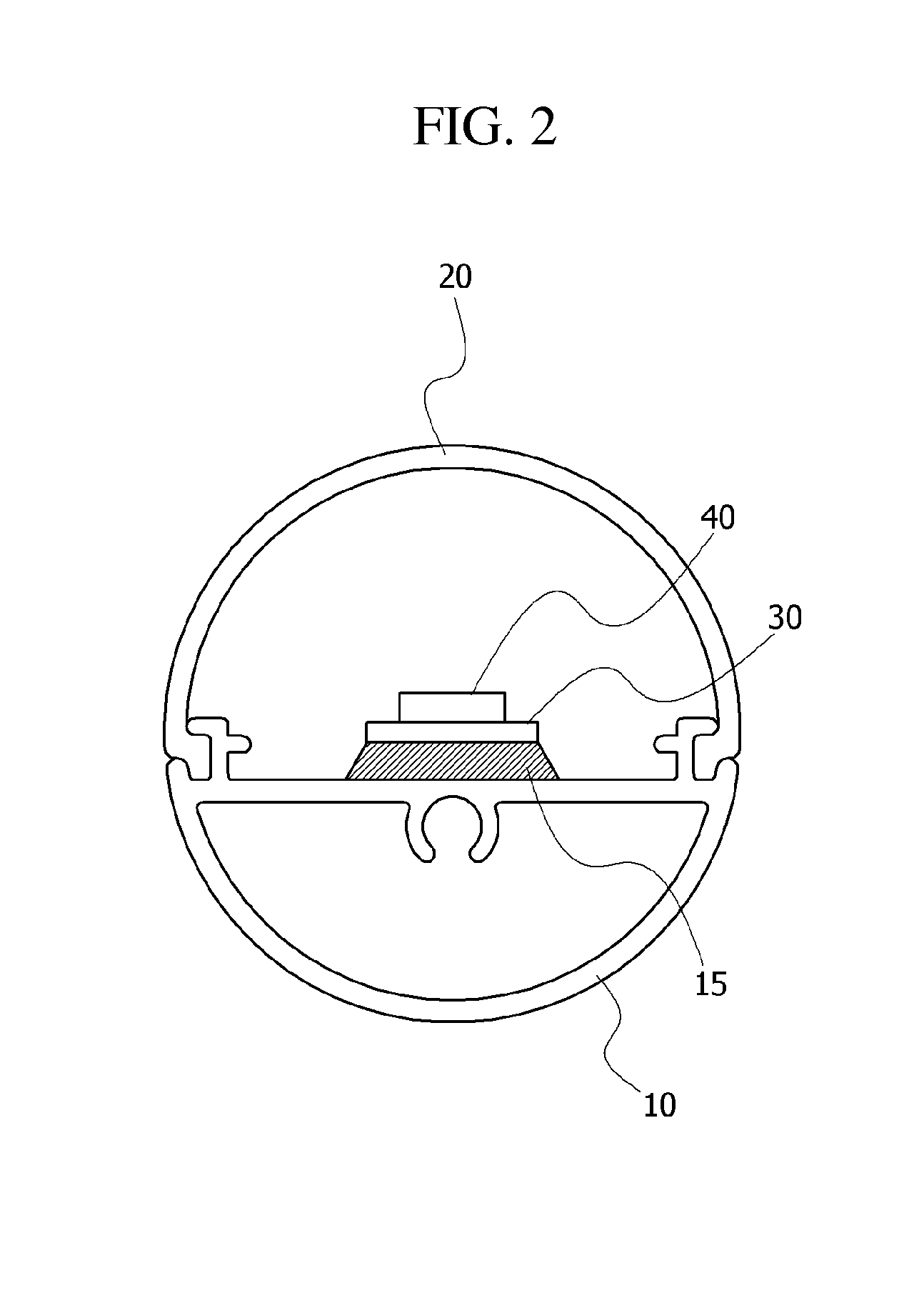

Tube-type LED illumination lamp

InactiveUS20140254145A1Improve illuminance qualityIncrease light diffusion angleElongate light sourcesLighting heating/cooling arrangementsEngineeringTubes types

A tube-type light-emitting diode (LED) illumination lamp is provided. The tube-type LED illumination lamp includes at least one printed circuit board on which at least one LED is placed, and a heat dissipation cover that has at least one seating surface on which the printed circuit board is mounted. The seating surface is obliquely formed such that each printed circuit board is mounted on each inclined surface. According to the present invention, since a light diffusion angle is increased by obliquely positioning the printed circuit board on which the LED is placed, illuminance quality of the tube-type LED illumination lamp can be improved.

Owner:KUMHO ELECTRIC INC

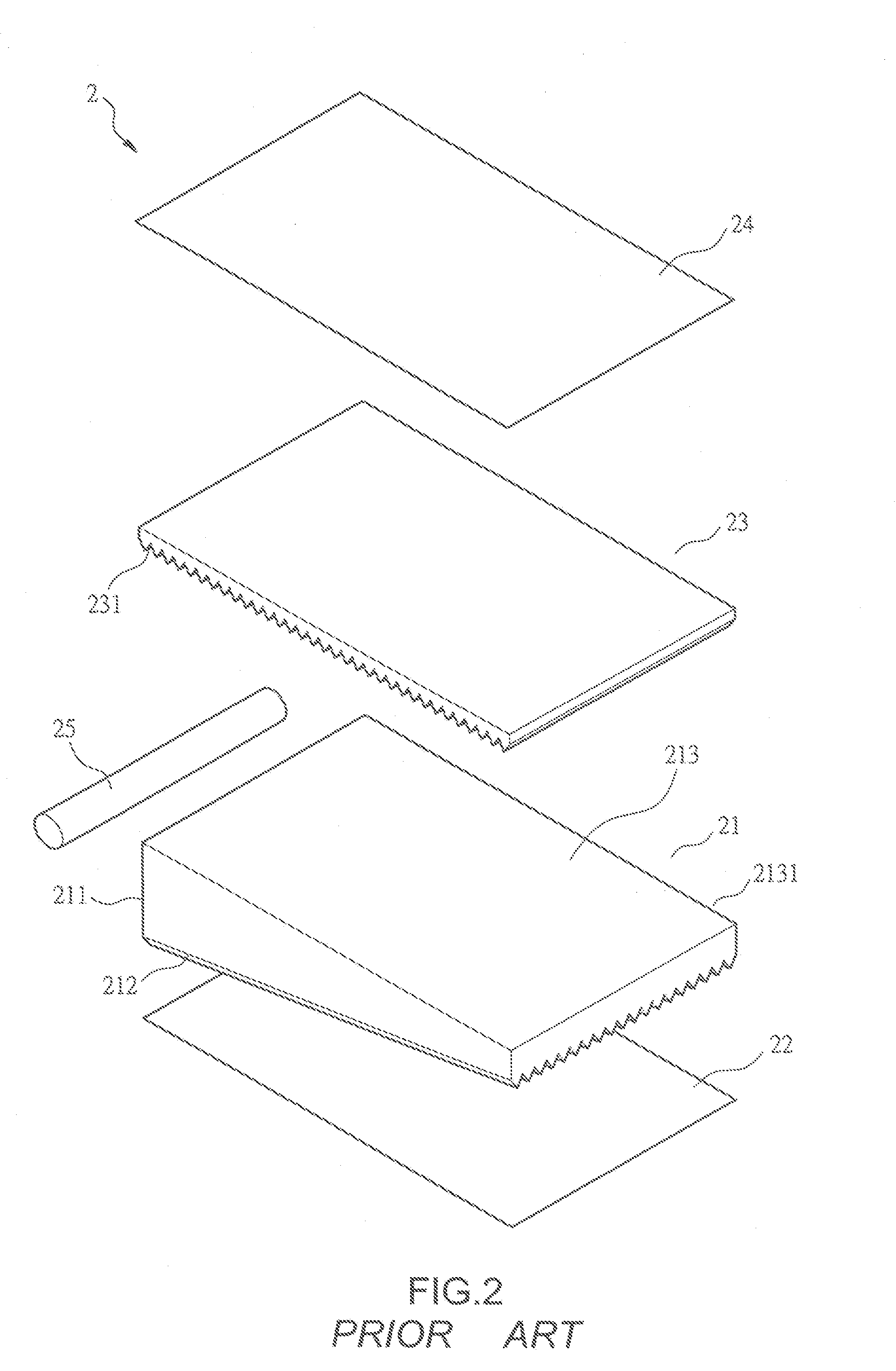

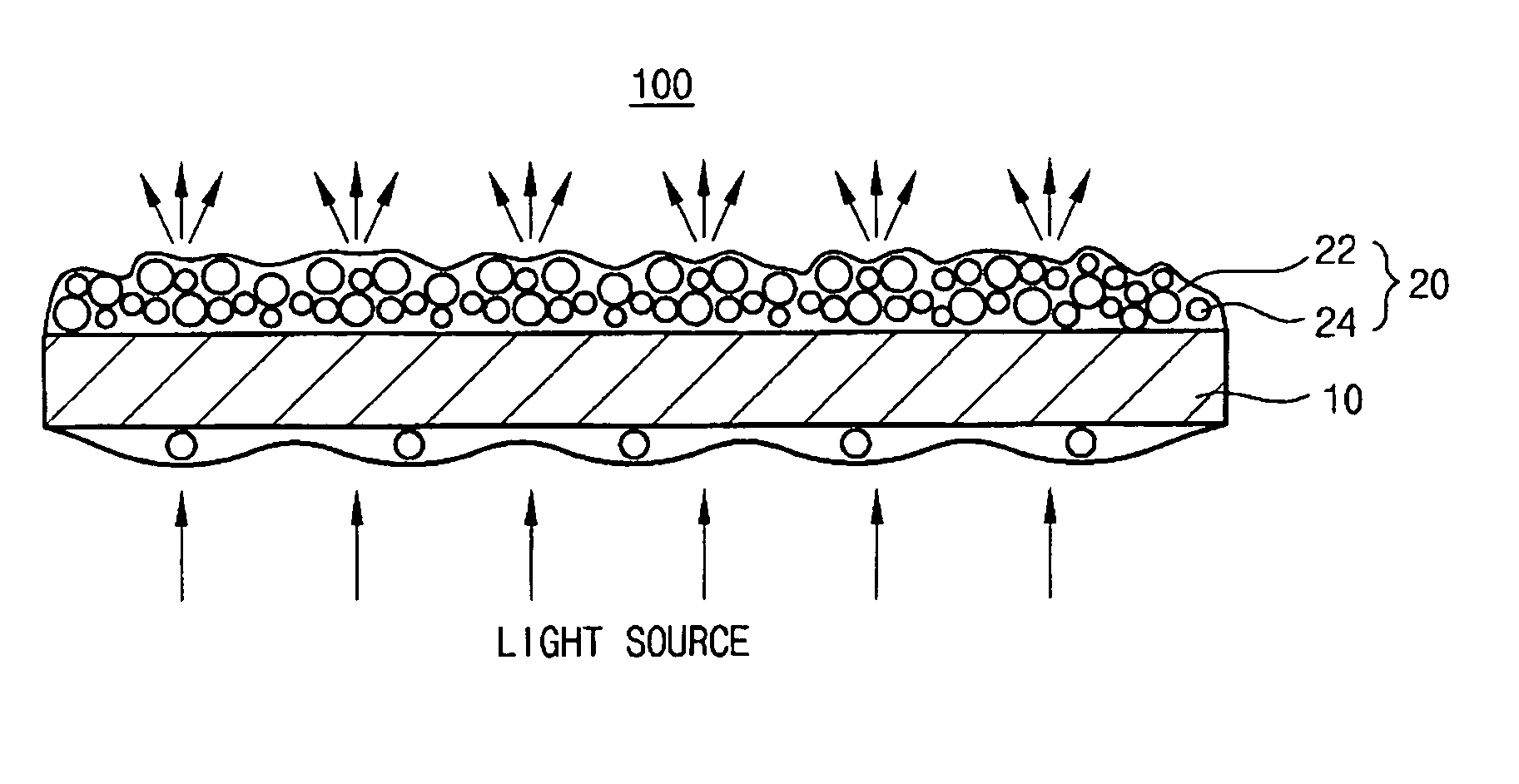

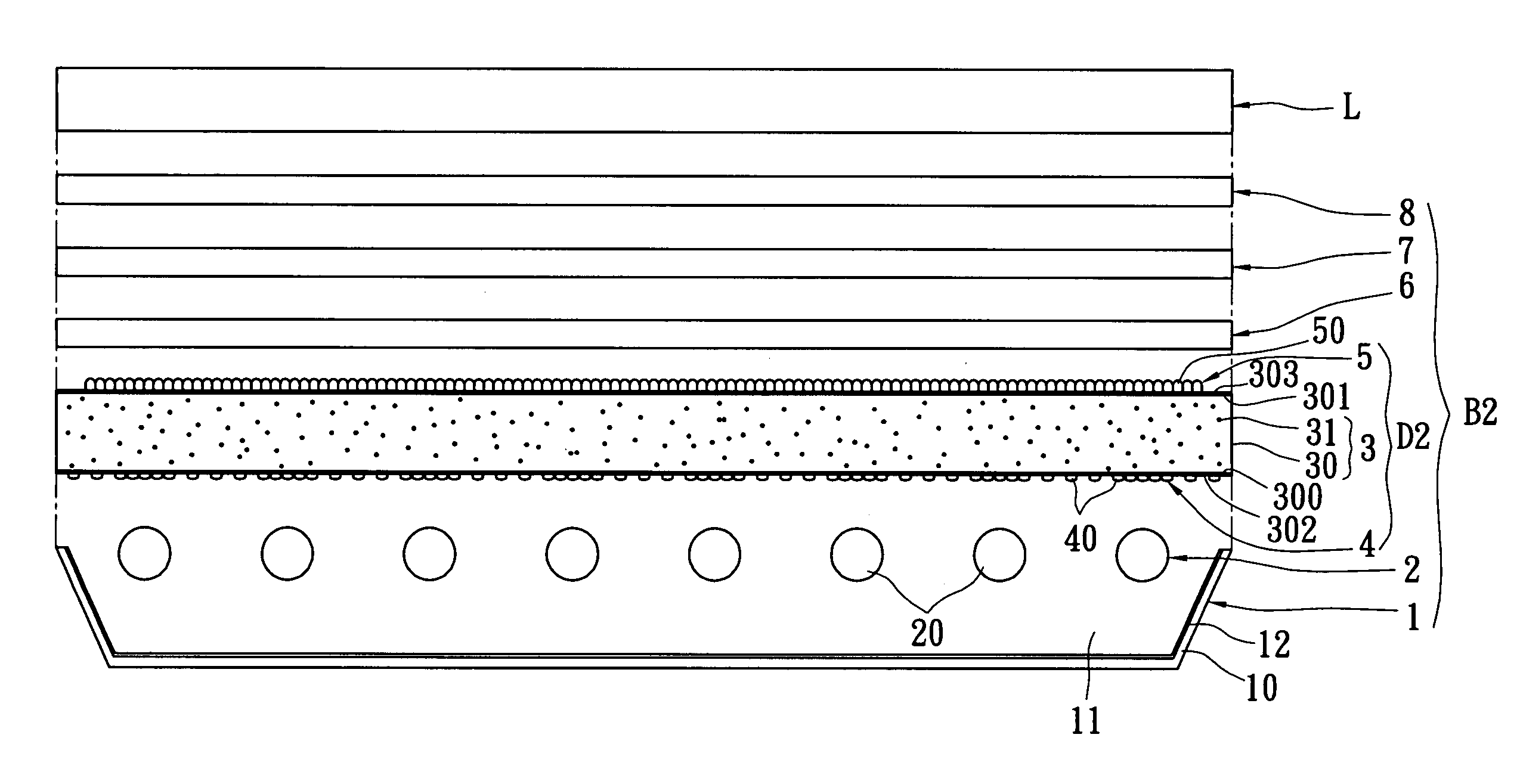

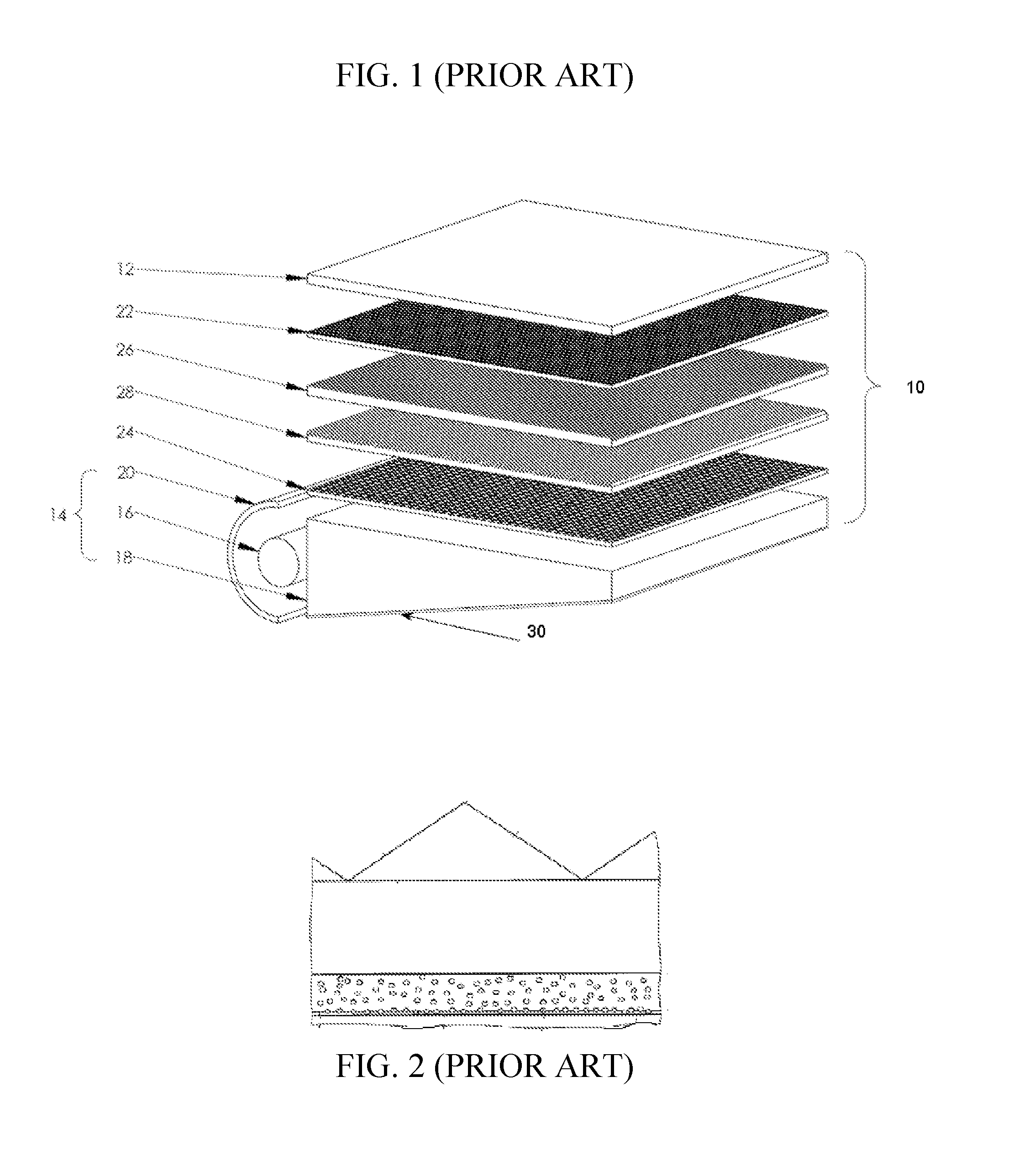

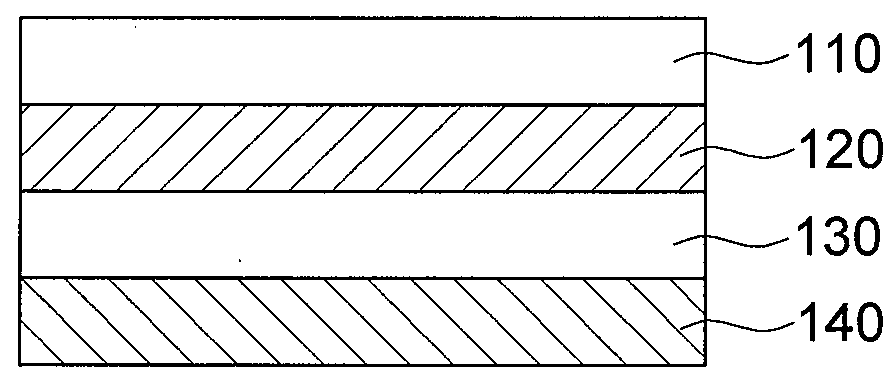

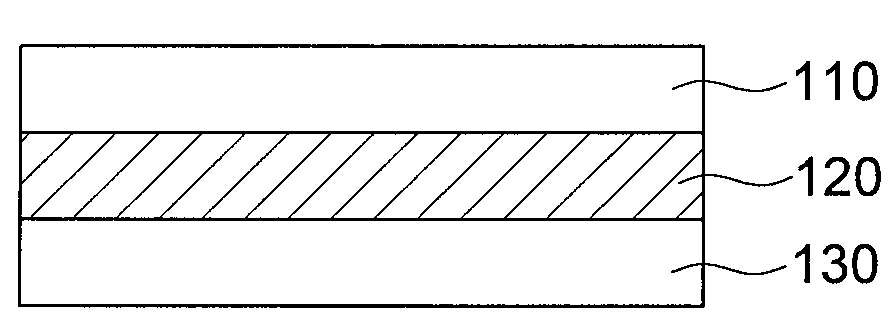

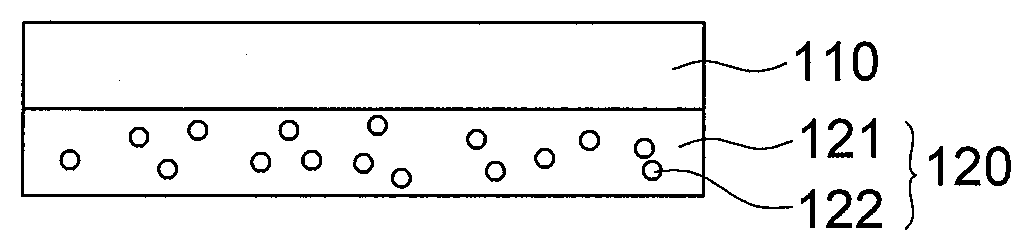

Compound diffusion plate structure, backlight module, and liquid crystal display

ActiveUS8040461B2Increase brightnessReduce power consumptionIlluminated signsNon-linear opticsDiffusionExit plane

A liquid crystal display, comprising: a liquid crystal display panel and a backlight module. The backlight module comprising: a reflection unit, a light emitting unit, and a compound diffusion plate structure. The light emitting unit has a plurality of light emitting components installed within the installation space of the reflection unit. The compound diffusion plate structure is placed on one side of the light emitting unit, comprising: a body unit and a printing micro diffusion unit. The body unit has a main layer, and a plurality of micro diffusion particles formed inside the body unit, allowing light to diffuse within the body unit. The printing micro diffusion unit has a plurality of convex lens units formed on a light entrance plane or a light exit plane of the body unit by means of printing.

Owner:ENTIRE TECH CO LTD

Optical substrates having light collimating and diffusion structures

ActiveUS20160341883A1Increase brightnessImprove luminanceMechanical apparatusOptical articlesCurve shapeEngineering

This invention discloses a method of forming an uneven structure on a substrate. Use a hard tool to penetrate into a mold to cut a first trench and a second trench in an order on a surface of a mold, wherein the hard tool has a smoothly-curved shape such that the transverse width of each of the first trench and the second trench increases as the penetrating depth of the hard tool increases, wherein when each of the first trench and the second trench marches along a first direction, the penetrating depth of the hard tool is controlled by repeating moving the hard tool up and down to cut the mold such that the transverse width of each of the first trench and the second trench varies according to the controlled penetrating depth of the hard tool, wherein the first trench and the second trench completely overlap with each other with no space therebetween. Then, use the surface of the mold to emboss a thin film on a substrate.

Owner:UBRIGHT OPTRONICS CORP

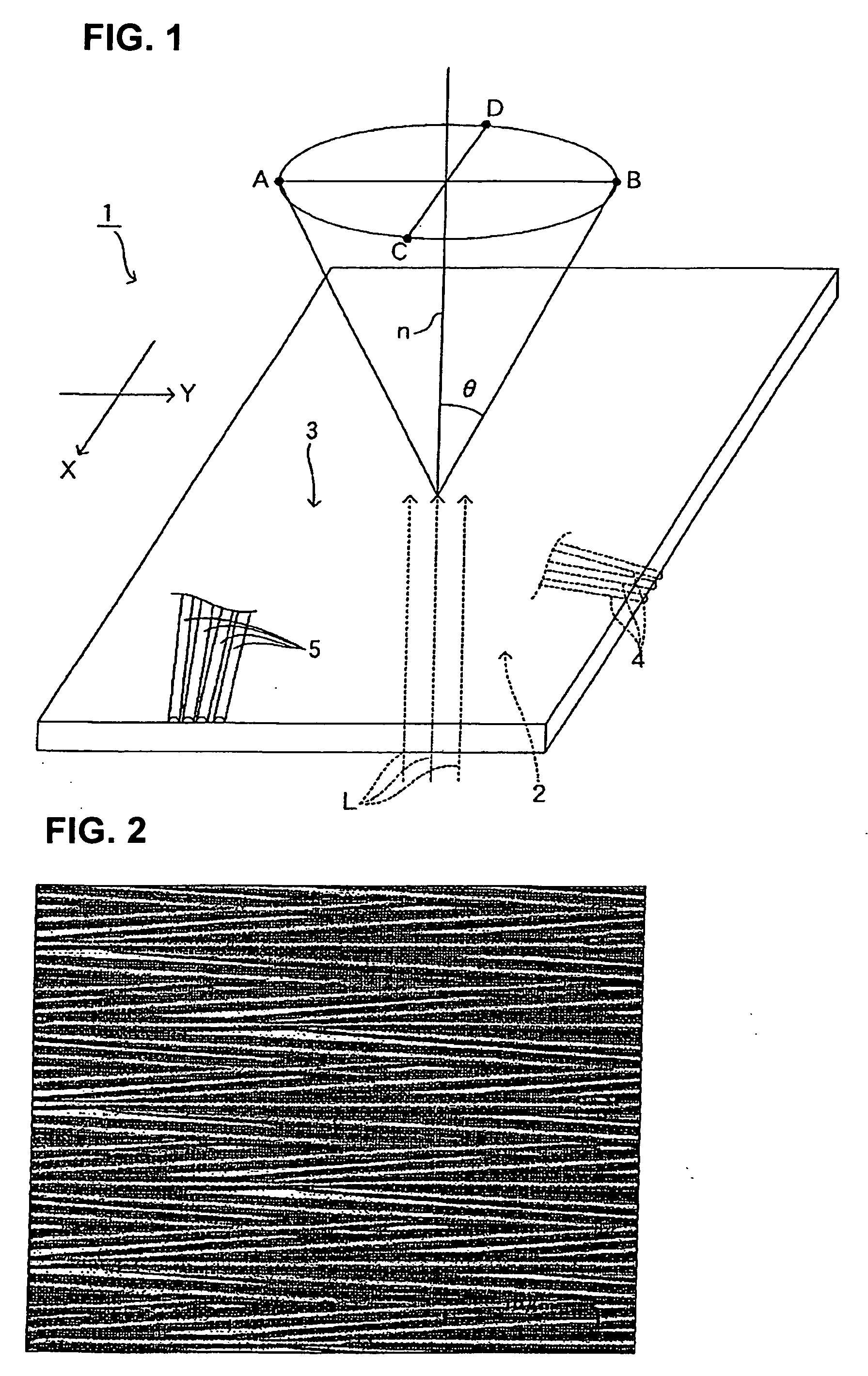

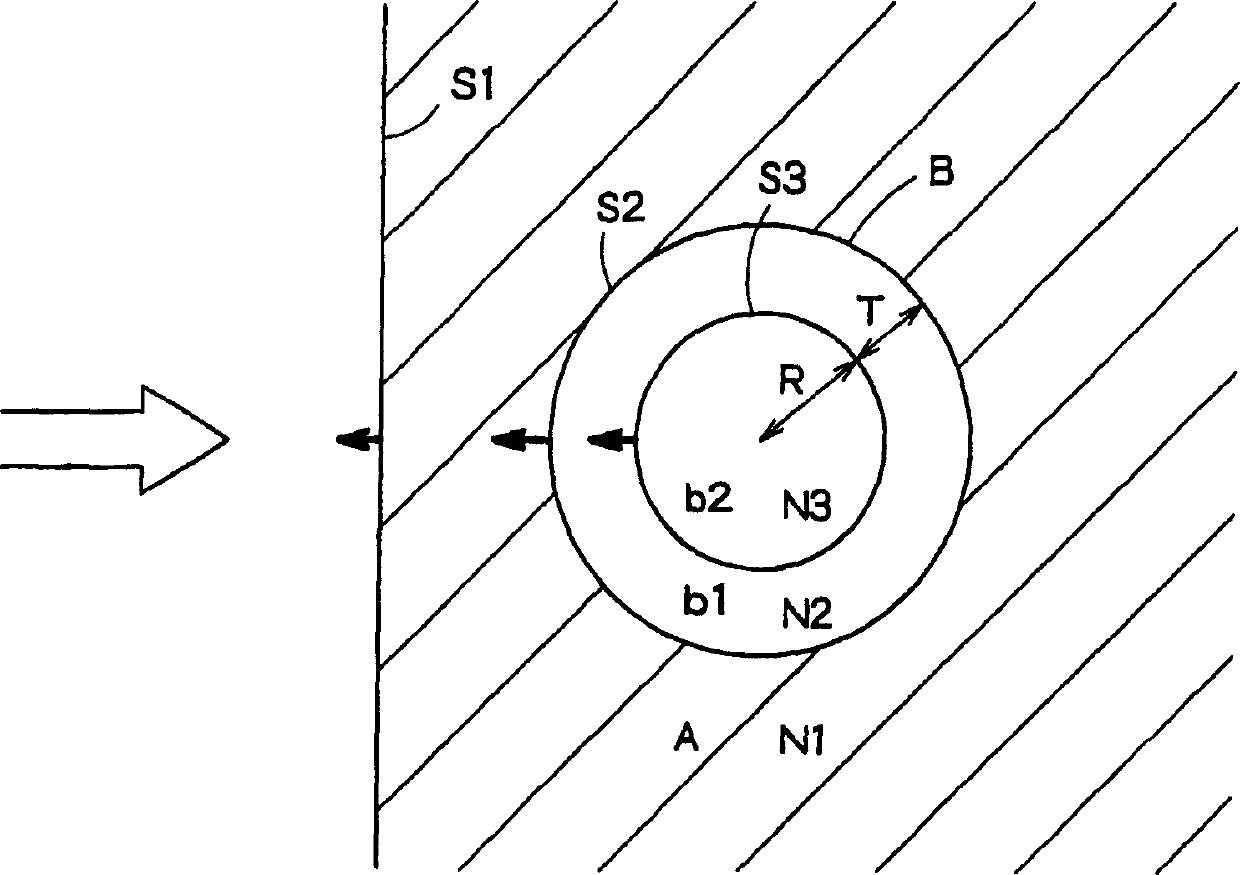

Optical film and method for producing same

InactiveUS20090123698A1Excellent light diffusionGood light diffusion effectSilicaDiffusing elementsOptical transmittanceSolvent

Disclosed is a method for producing an optical film composed of a transparent resin and a metal oxide, which film has high light transmittance and light diffusion property even it is formed thin. Also disclosed is such an optical film. Specifically disclosed is a method for producing an optical film having a total light transmittance of not less than 70% and a haze value of not less than 20%, which comprises a step (A) wherein a metal compound to form a metal oxide through a sol-gel reaction is subjected to a sol-gel reaction in a solvent; a step (B) for providing a solution containing a transparent resin as a solute; a step (C) for mixing the mixture obtained in the step (A) with the solution obtained in the step (B); and a step (D) wherein the mixture obtained in the step (C) is applied or spread over a substrate or container and then heated for evaporating the solvent, thereby forming a film thereon.

Owner:MITSUI CHEM INC

Dental curable composition and composite resin using the same

ActiveUS8476338B2Excellent light diffusionHigh transparencyImpression capsOther chemical processesInorganic particleRefractive index

The present invention provides a dental curable composition exhibiting both excellent light diffusion and excellent transparency, and having high mechanical strength and surface smoothness and gloss after polishing as a cured product as well as good handling properties as a paste. The present invention is a dental curable composition including: a polymerizable monomer (A) having a refractive index of 1.52 to 1.58 after polymerization; inorganic particles (B) having a refractive index of 1.43 to 1.50; and inorganic particles (C) having a refractive index of 1.52 to 1.58. The inorganic particles (B) are aggregates of inorganic fine particles having an average primary particle size of 2 to 50 nm, and the content of the inorganic particles (B) is 0.1 to 10% by weight.

Owner:KURARAY NORITAKE DENTAL

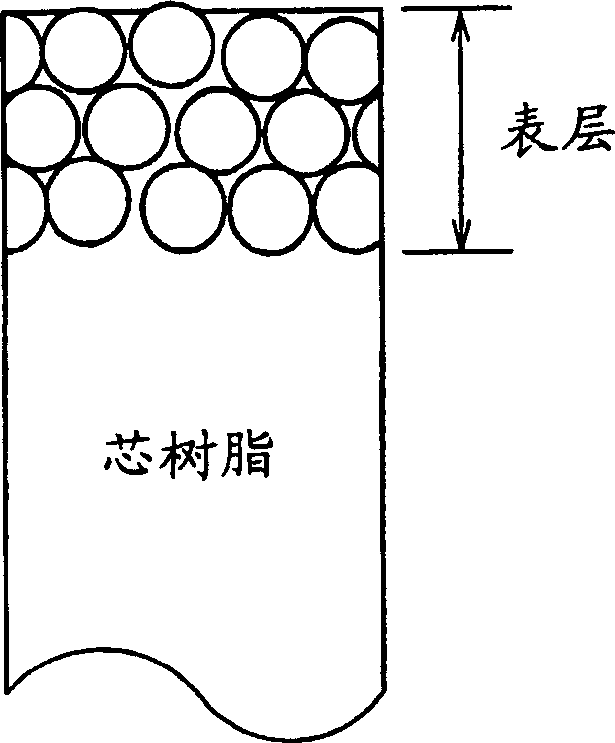

Light diffusing agent, light diffusing sheet, and nonglare sheet

InactiveCN1576901AHigh transparencyLight loss is smallPrismsDiffusing elementsDiffusionRefractive index

Provided is a light diffusion sheet that has high diffusing efficiency and can obtain an excellent image bright with high contrast without dull colors and blur by reducing the unnecessary scattered light, and can realize a high quality image. This is a light diffusion agent to be used by dispersing in a transparent base material, consists of particles and the skin layers covering them, and satisfies the conditional equations (I) and (II). Conditional equation (I): N1 G02B 5 / 02 2 10 2 2004 / 6 / 28 1576901 2005 / 2 / 9 1289924 2006 / 12 / 13 2006 / 12 / 13 2006 / 12 / 13 Dai Nippon Printing Co., Ltd. Japan Honda Makoto gong haijun zhang zhicheng 72001 The Company Ltd. of the Chinese Patent Agency (Hong Kong) Zi Building 22, Yingjun Centre, No.23, Gangwan Road, Hong Kong Wanzi Japan 2003 / 6 / 27 185322 / 03

Owner:DAI NIPPON PRINTING CO LTD

Fiber optic tapestry

Owner:LIGORANO NORA +1

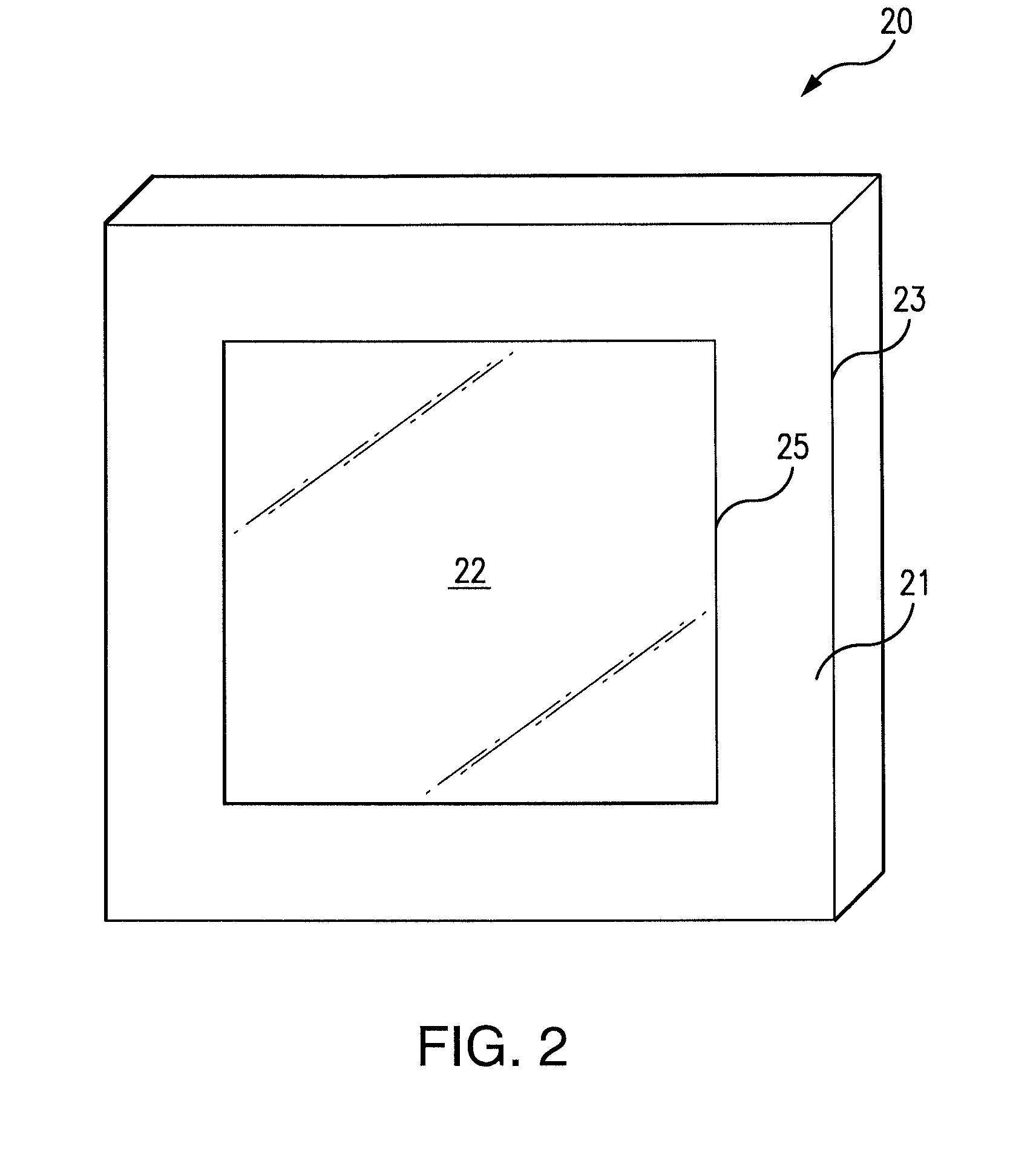

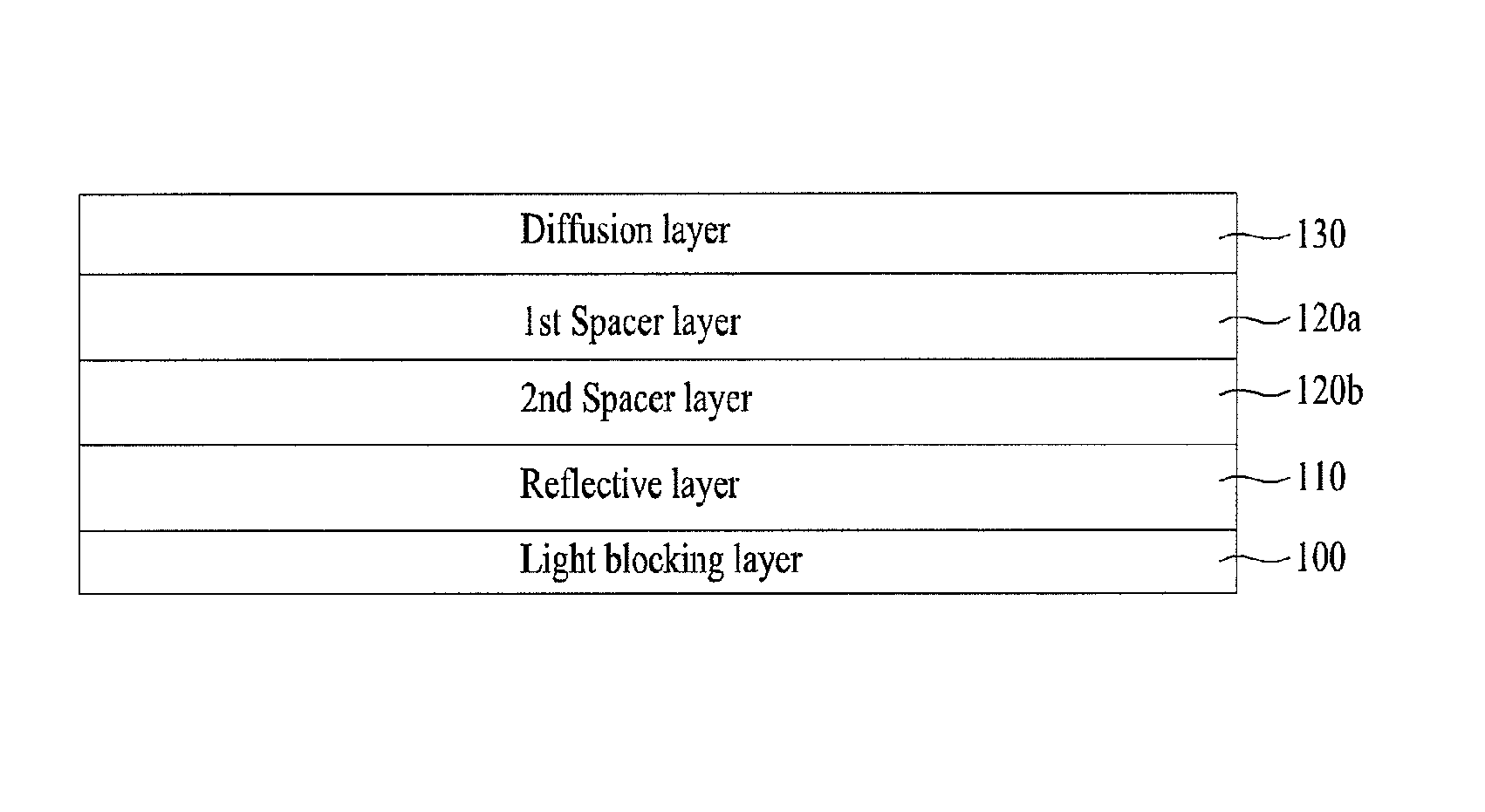

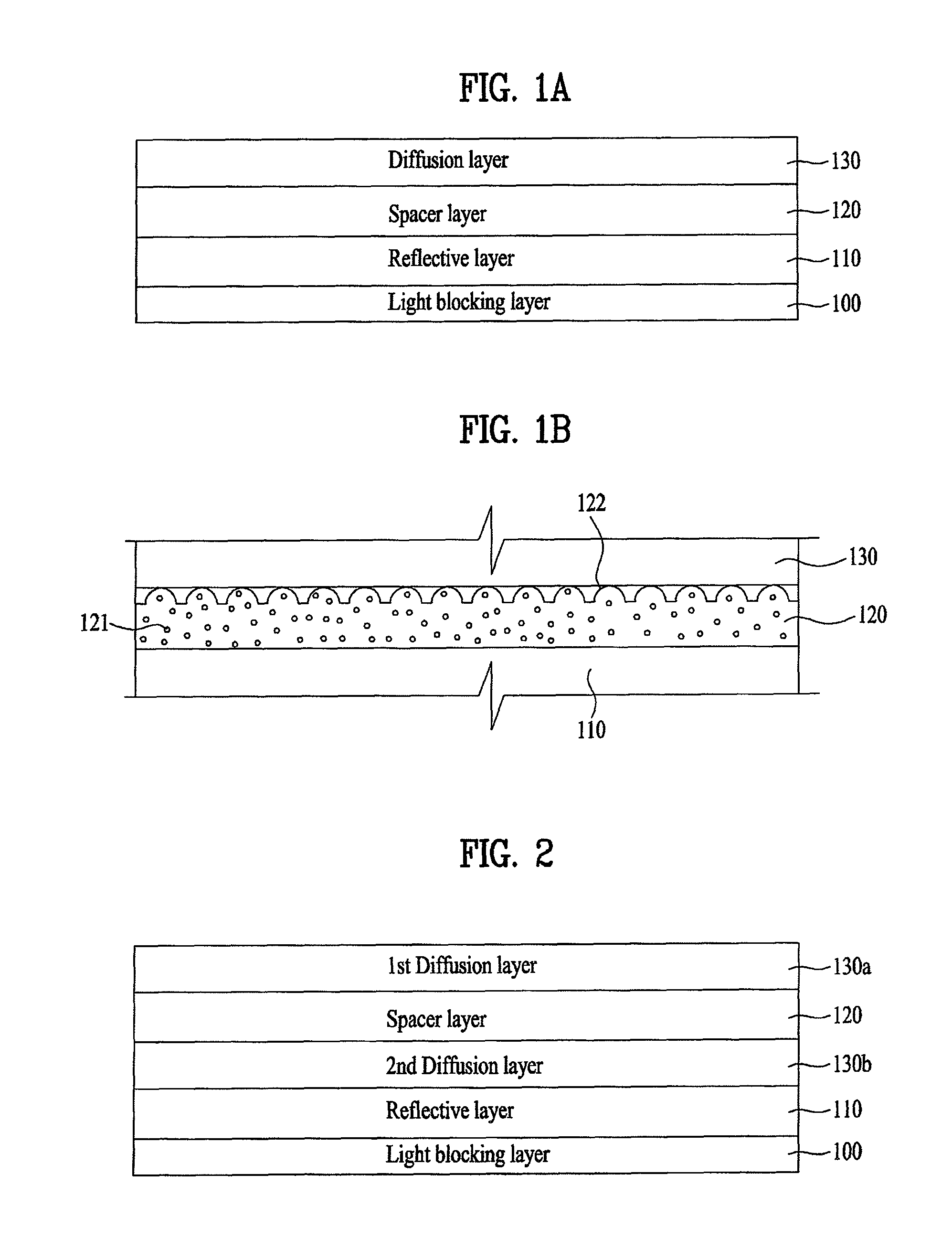

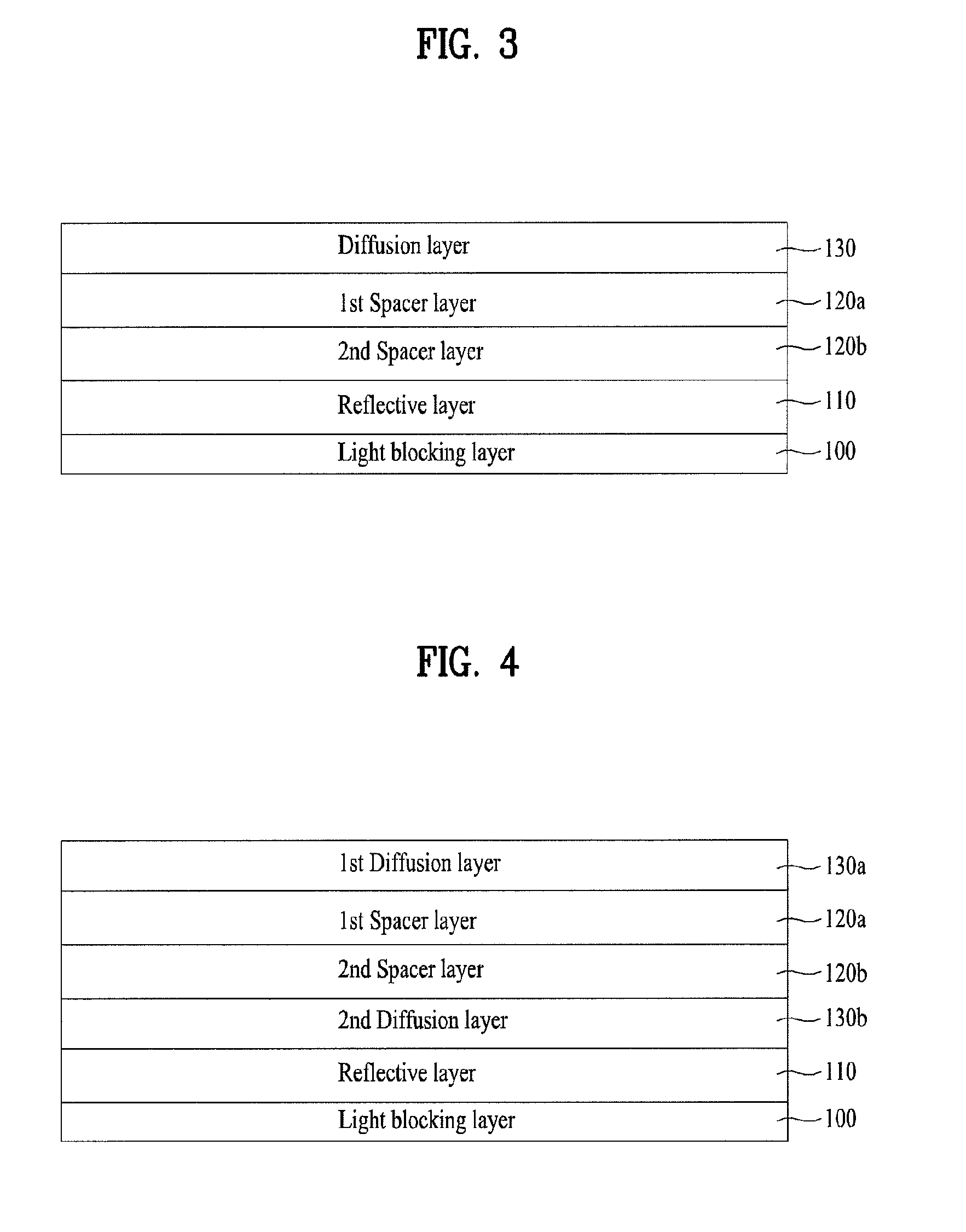

Reflective type screen using a spacer layer

A reflective type screen using a spacer layer and that includes a light blocking layer blocking an incident light, a reflective layer formed on the light blocking layer to reflect the incident light, a diffusion layer formed on the reflective layer to diffuse the incident light, and at least one spacer layer formed between the reflective layer and the diffusion layer to have a refractive index differing from that of an adjacent layer to refract the incident light.

Owner:LG ELECTRONICS INC

Optical film and display device comprising the same

ActiveUS20160033693A1Improved side visibilityImprove visibilityDiffusing elementsPolarising elementsDisplay devicePolarizer

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com