Light diffusion member, back light assembly including the same and display device including the same

a technology of light diffusion member and back light assembly, which is applied in the direction of lighting and heating apparatus, instruments, transportation and packaging, etc., can solve the problems of generating luminance loss and affecting the base matrix material of the pet, and achieve the effect of preventing the wrinkling phenomenon reducing the manufacturing cost of the liquid crystal display device, and improving the light luminance and light diffusing efficiency of the light diffusion member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

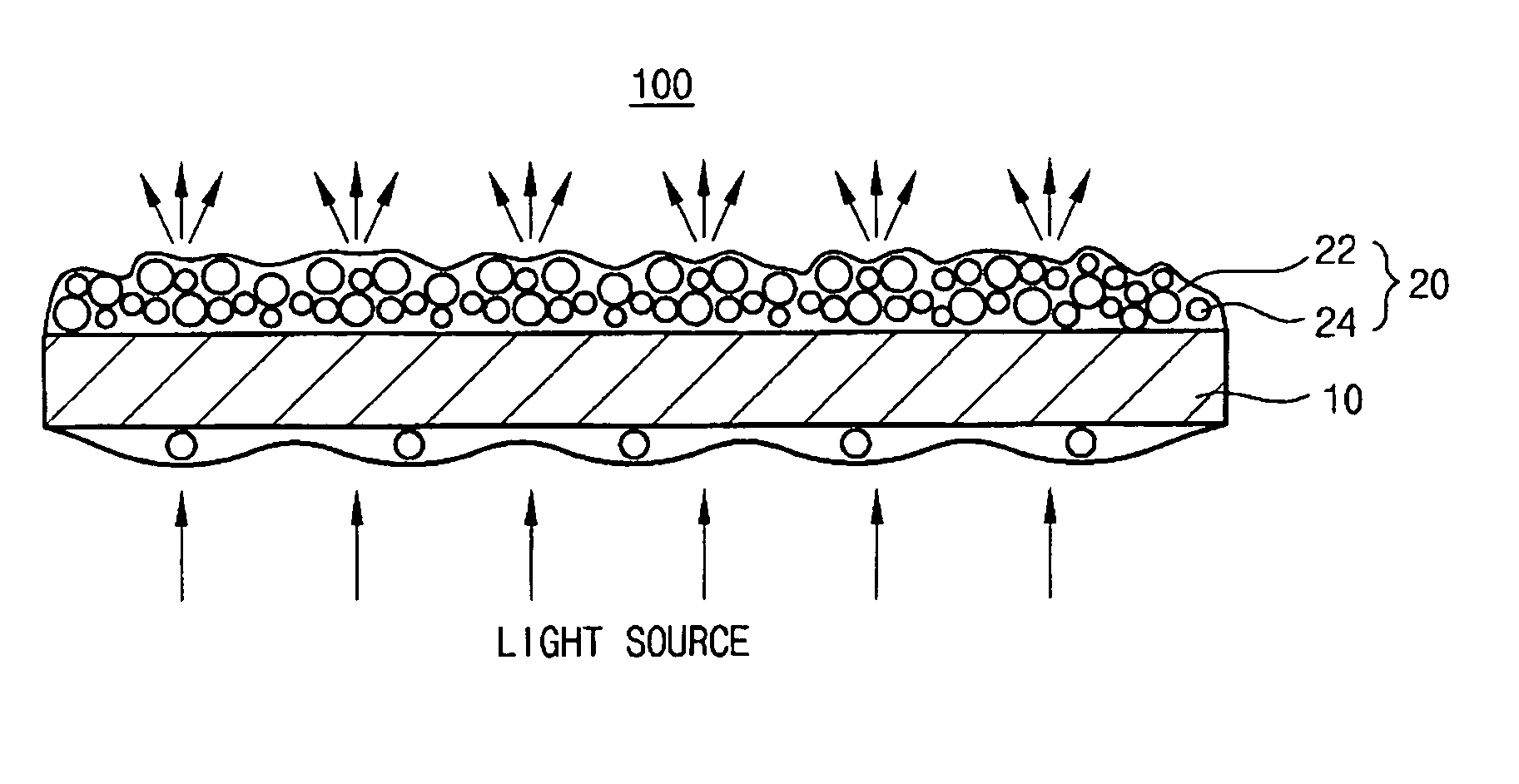

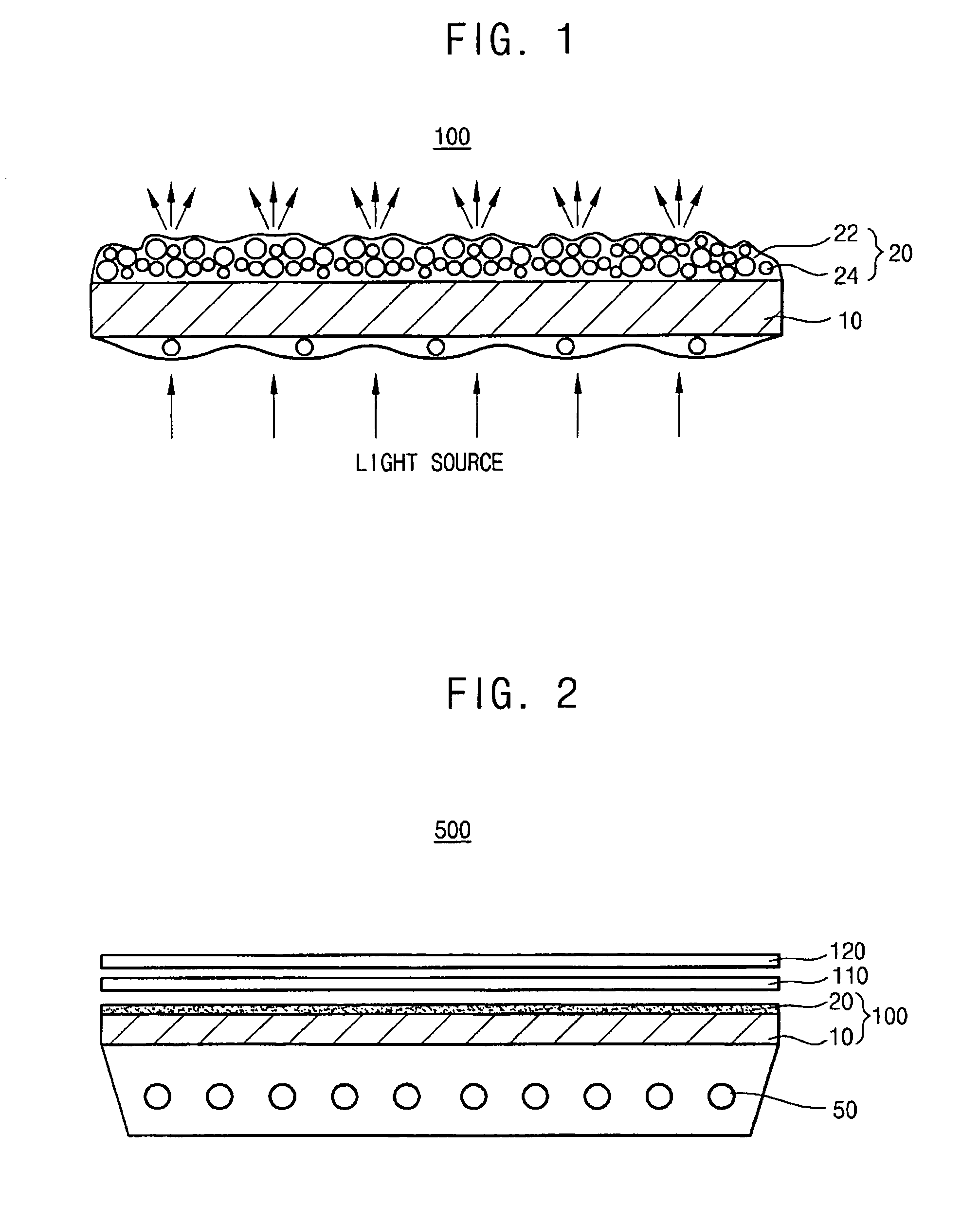

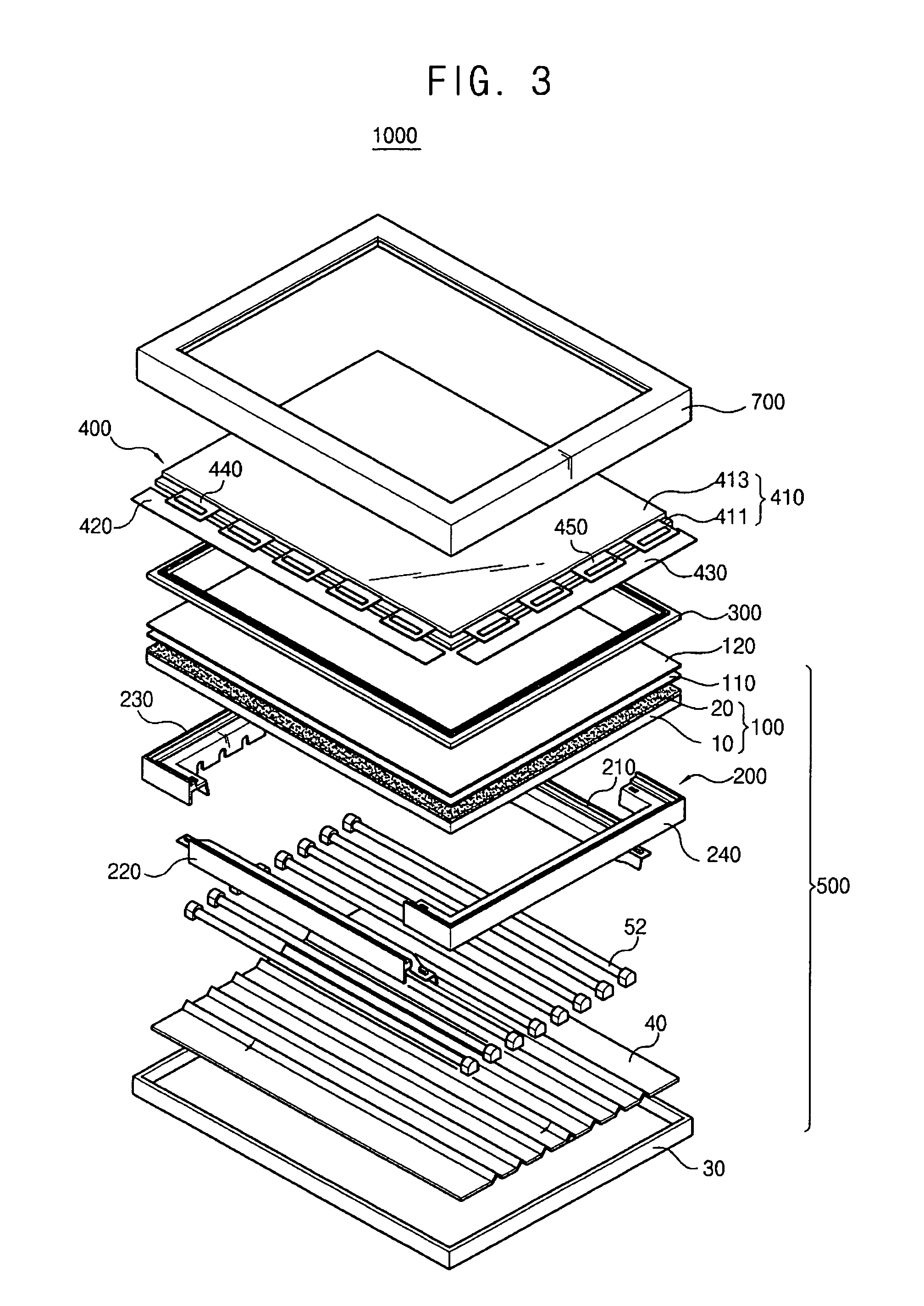

[0037]FIG. 1 is a schematic cross-sectional view showing an exemplary embodiment of a light diffusion member according to the present invention.

[0038] Referring to FIG. 1, a light diffusion member 100 includes a light diffusing body 10 and a light diffusing layer 20 formed on the light diffusing body 10. The light diffusion member 100 diffuses incident light from a light source 50 through a light exiting surface of the light diffusing body 10, where the light exiting surface may be a layer of the light diffusing body 10, or may simply be the outermost surface of the light diffusing body 10 that faces the light diffusing layer 20. The light diffusion member 100 includes a polymer mixture obtained by uniformly blending a first polymer and a second polymer.

[0039] Through the blending, two or more polymers having different physical properties are uniformly mixed in a predetermined mixing ratio. A complex material having a novel physical property can be prepared through the blending pr...

example 1

Manufacture of PET / PC Light Diffusing Body

[0053] 0.4 ton of chip-shaped PET and 1.6 ton of PC were put into a blending apparatus, a twin screw extruder manufactured by Killon Co., Ltd. The PET and PC were then blended at a temperature of 280° C. Then, the blended product was extruded, allowed to pass through a T-die, and then cooled in a cooling apparatus to a temperature of 30° C. The extruded and cooled light diffusing body was transported on a roll and cut to a desired size.

embodiment 2

[0054] The light diffusion member 100 according to this present embodiment includes the same components described in Embodiment 1 except utilizes a different arrangement for the light diffusing body 10. Therefore, the same reference numerals are given to the same components and repeated explanation will be omitted.

[0055] The light diffusion member 100 according to this embodiment includes a copolymer within the light diffusing body 10 having the first and the second polymers arranged as repeating units. That is, for example, instead of blending the first and second polymers to form a polymer mixture as in Embodiment 1, at least one layer of the first polymer and at least one layer of the second polymer form the light diffusing body 10. The copolymer exhibits an improved stability or uniformity of physical properties such as glass transition temperature and humidity absorbance, when compared with the polymer mixture prepared by Example 1.

[0056] The second polymer preferably has a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com