Patents

Literature

87 results about "Prismatic surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

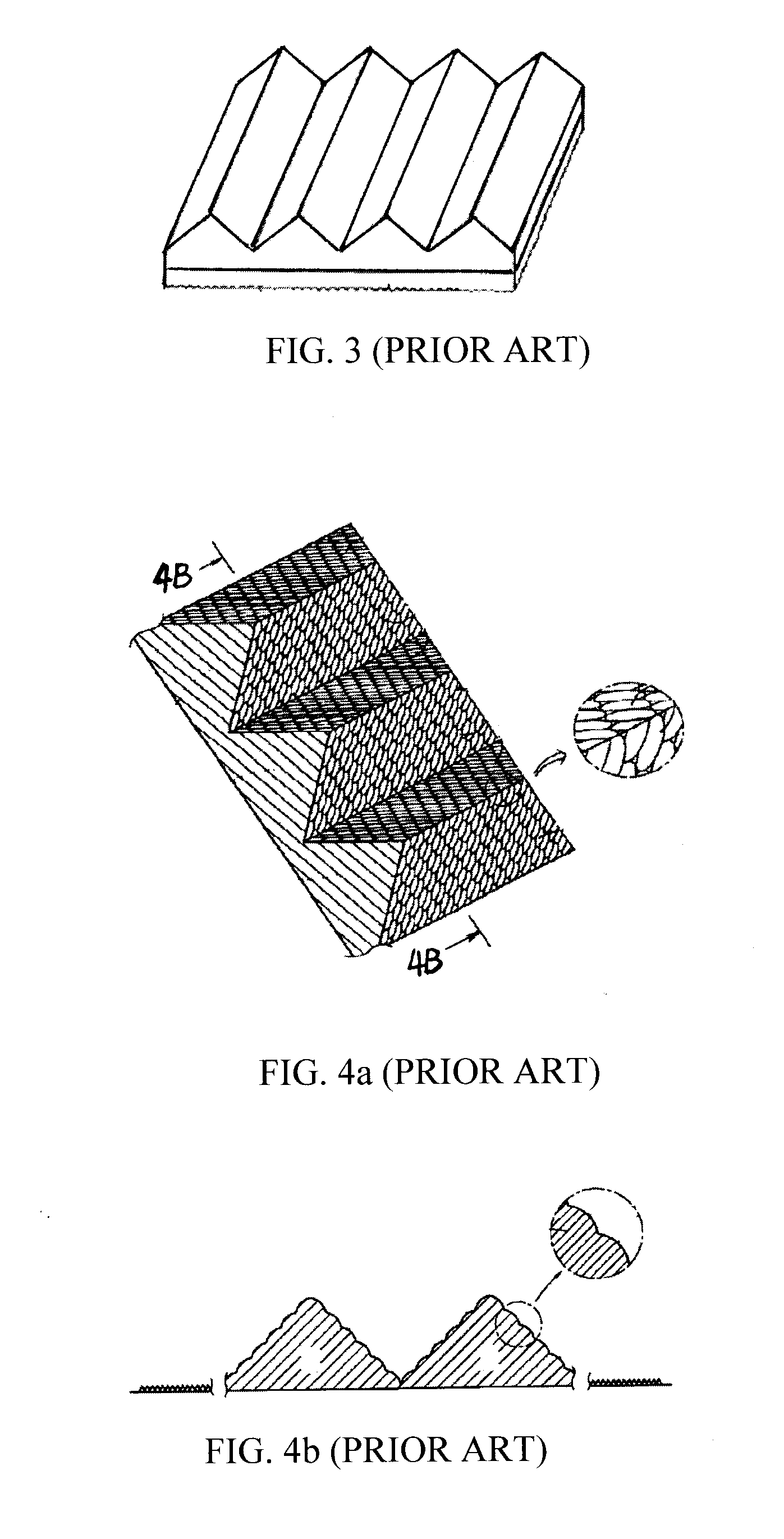

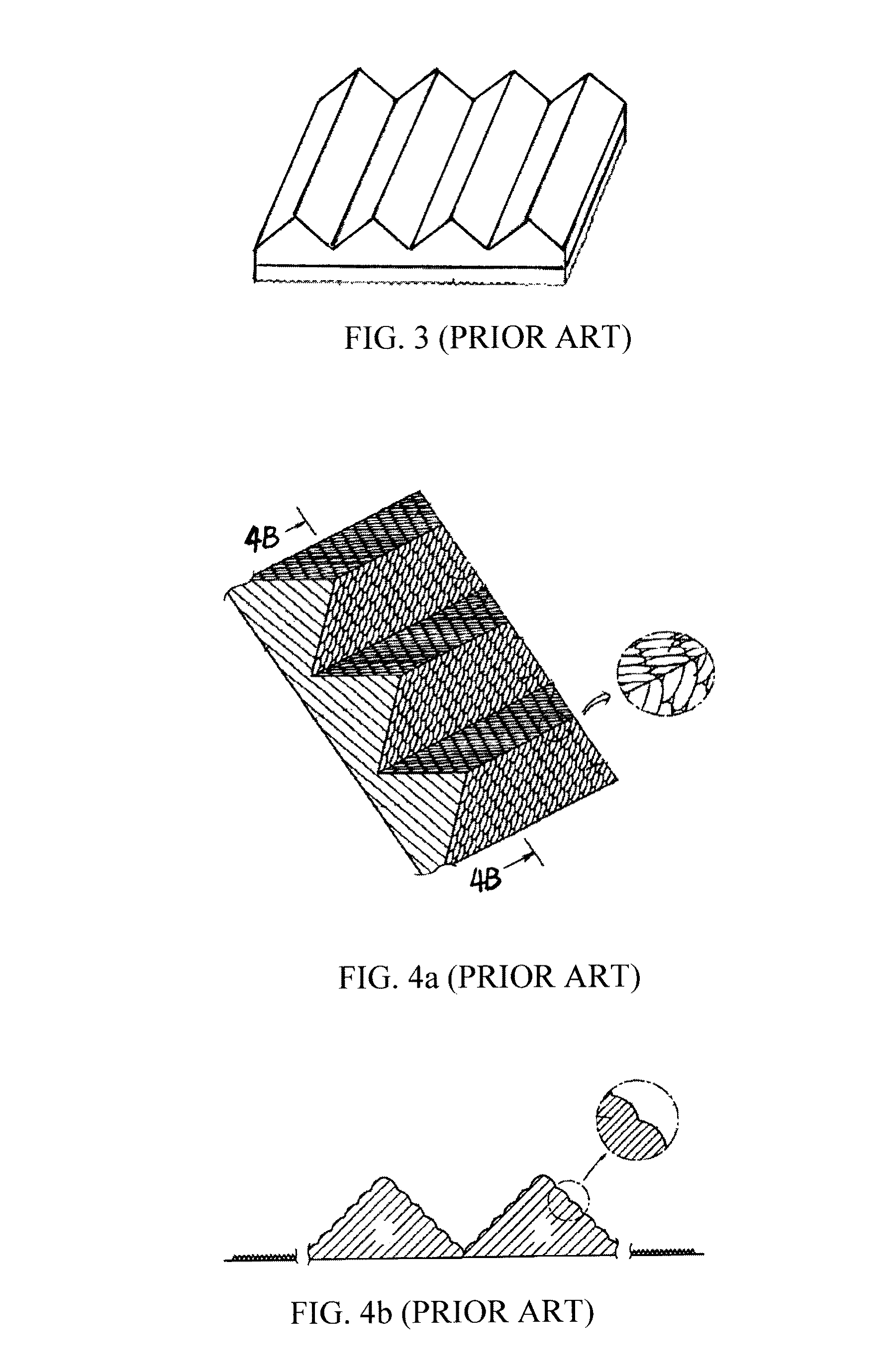

A prismatic surface is a surface generated by all the lines that are parallel to a given line and intersect a broken line that is not in the same plane as the given line. The broken line is the directrix of the surface; the parallel lines are its generators (or elements). If the broken line is closed (i.e., a closed polygon), then the surface is a closed prismatic surface.

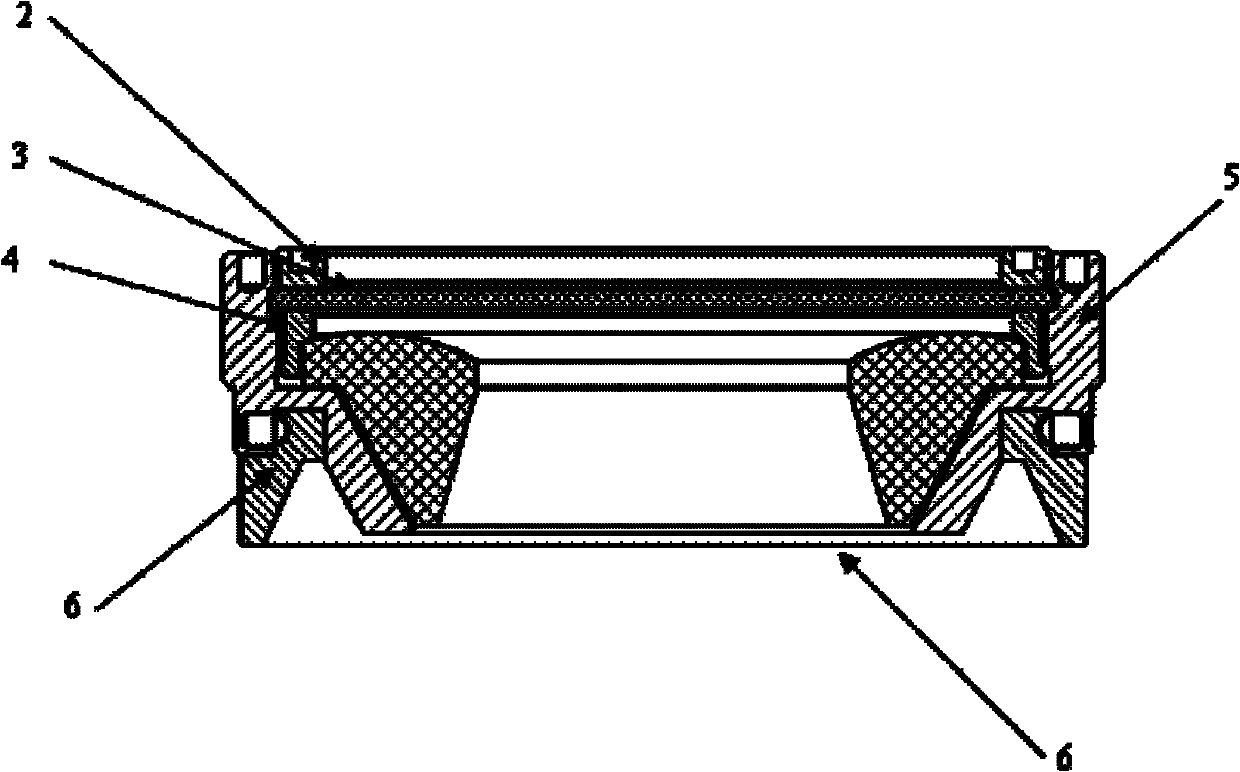

Underwater light with diffuser

InactiveUS20080130304A1Reduce the amount requiredSave resourcesNon-electric lightingPoint-like light sourcePrismOptoelectronics

The present invention is a thru-hull light for installation under the waterline of a vessel comprising a lens capable of diffusing the light broadly through the water. In a preferred embodiment, the lens is a separate, discrete component with a prismatic surface.

Owner:UNDERWATER LIGHTS USA

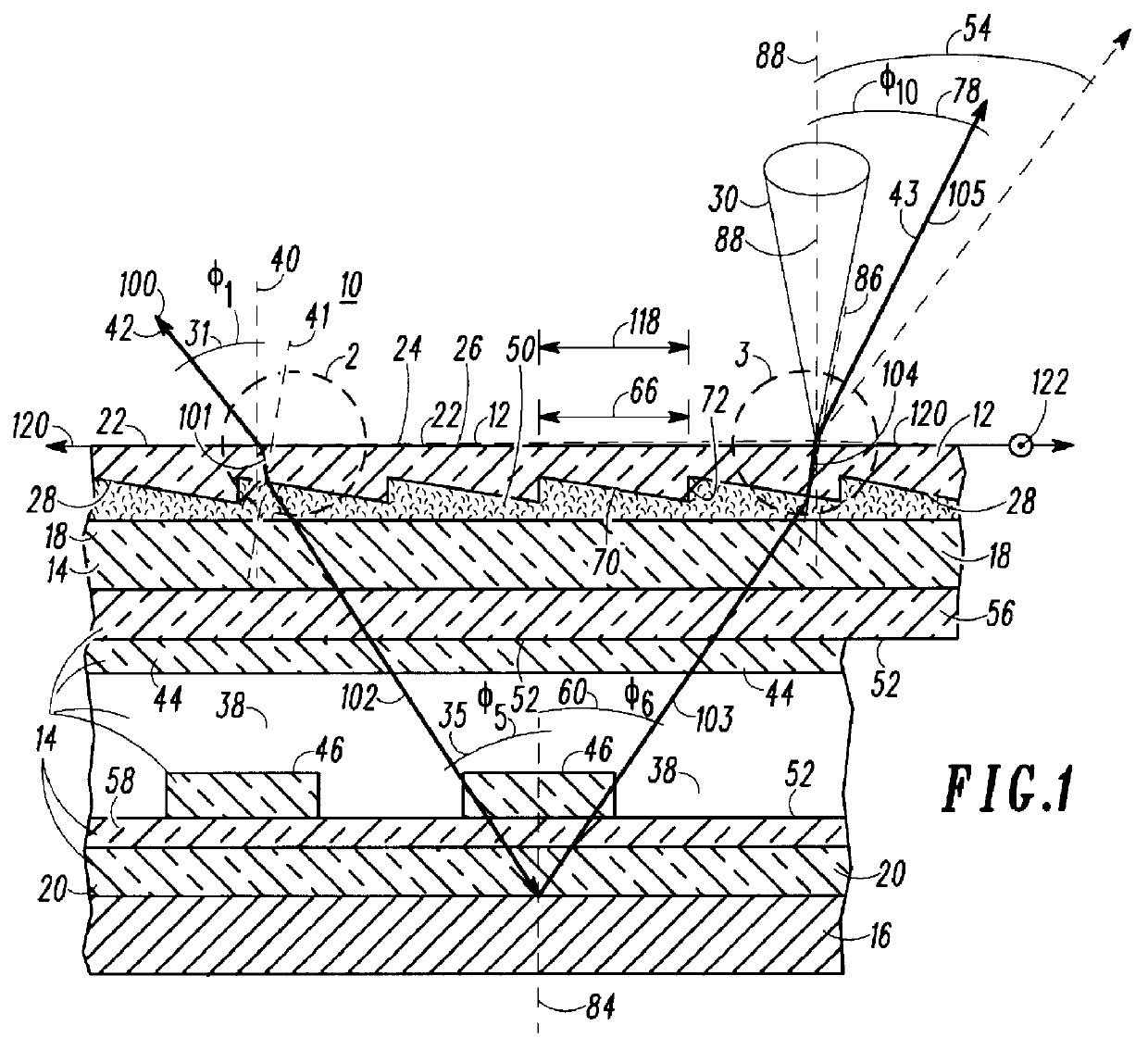

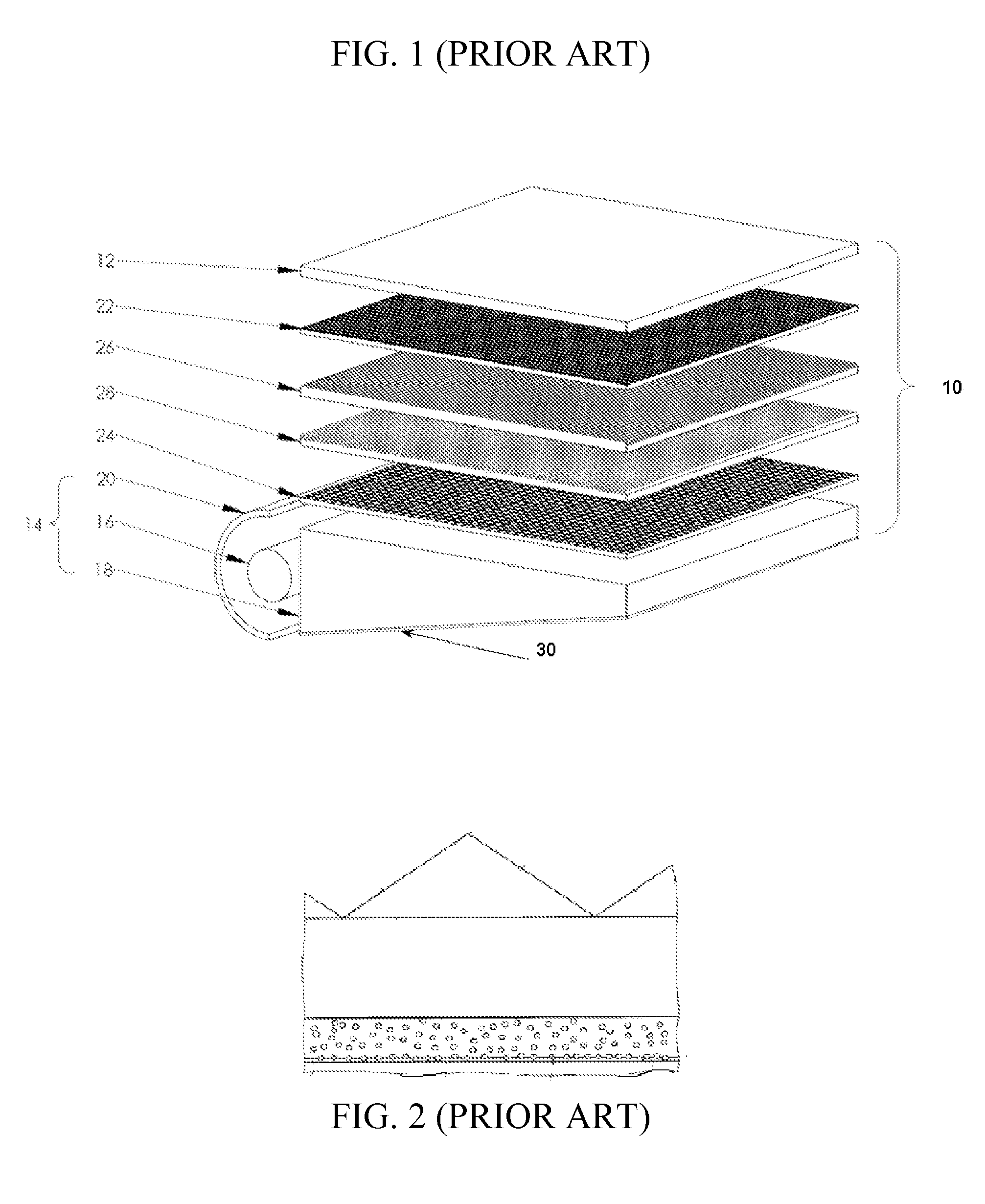

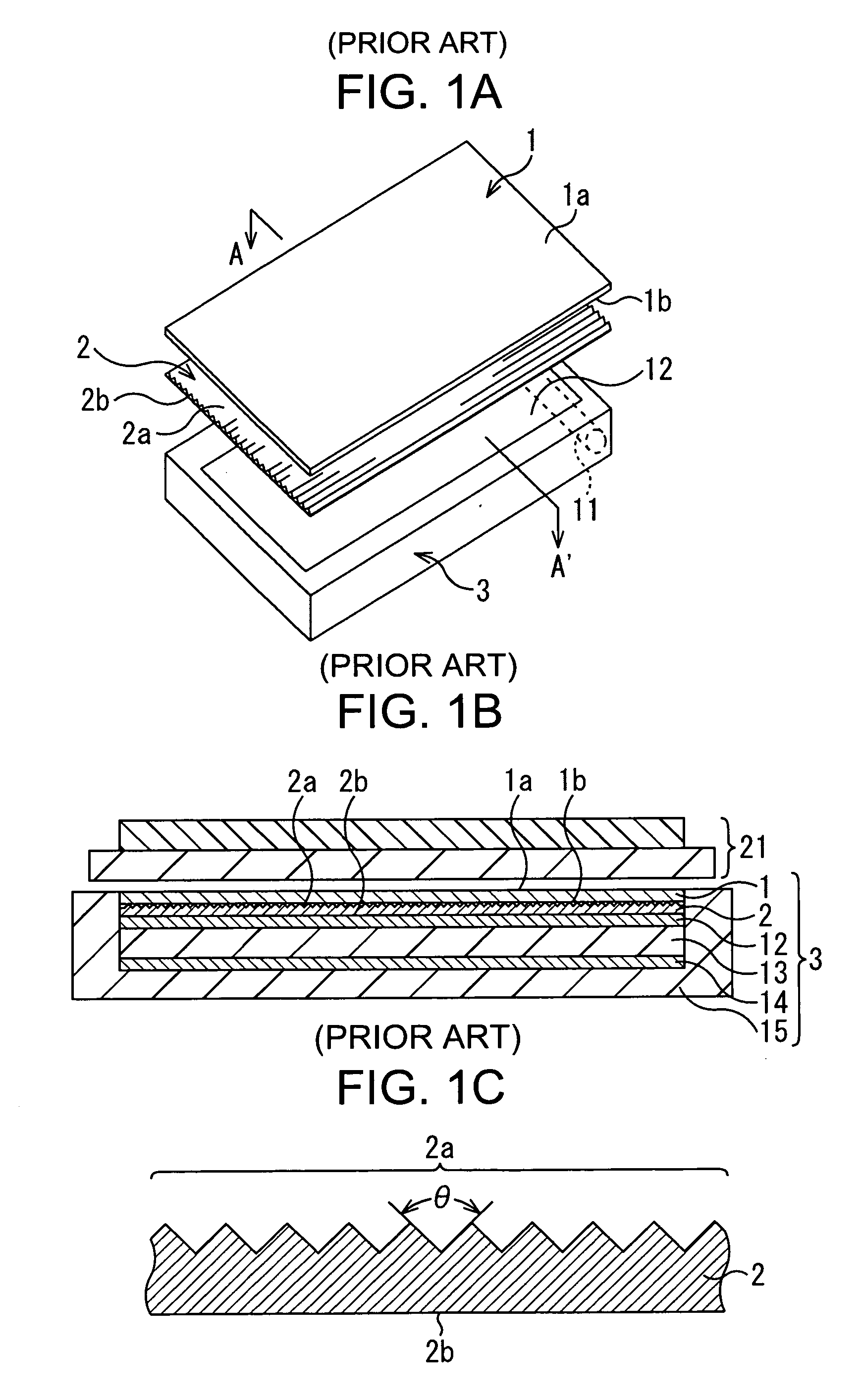

Optical display device having prismatic film for enhanced viewing

InactiveUS6166787AImprove visibilityImprove legibilityPrismsLaser detailsOptical propertyOptical interaction

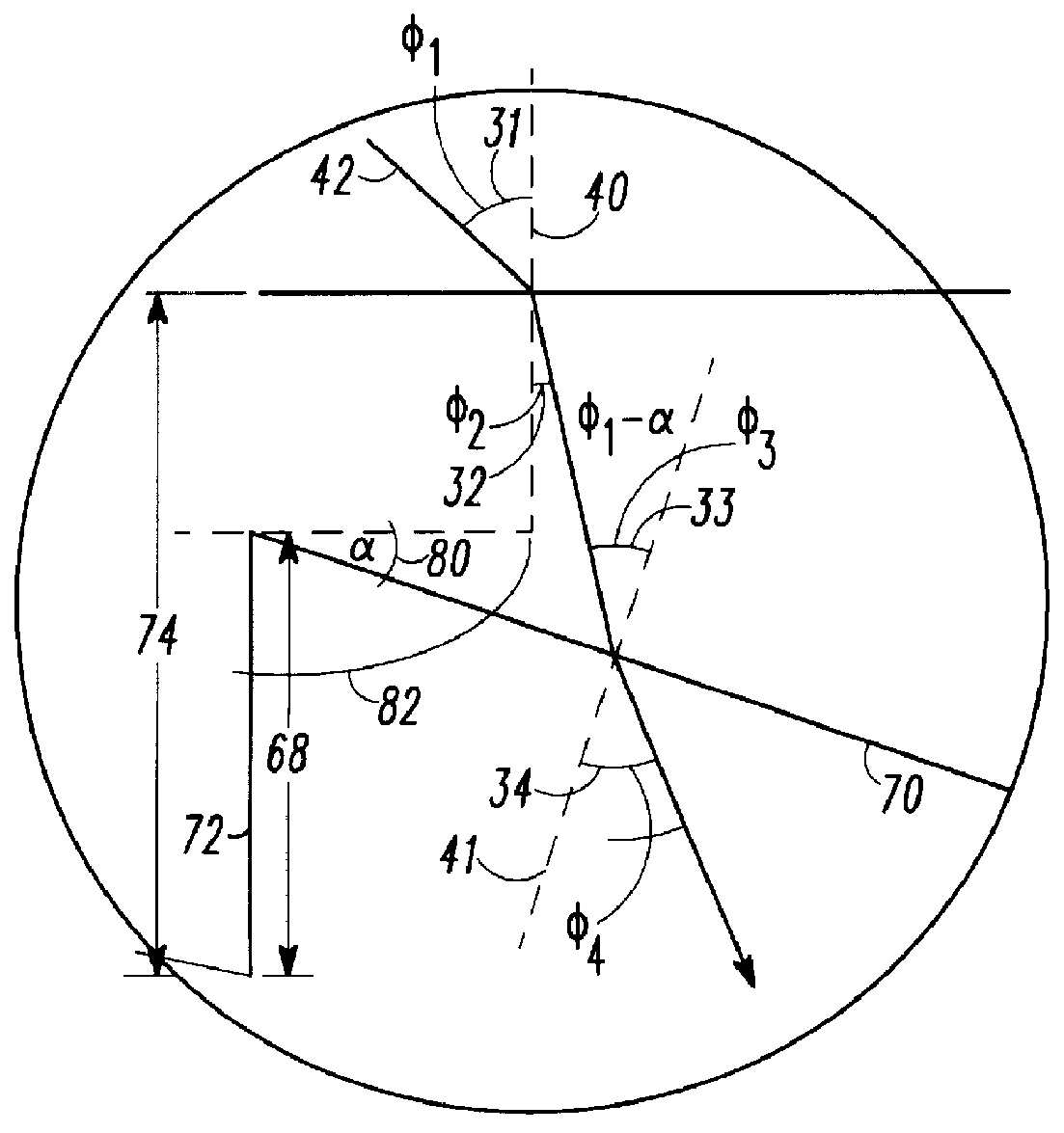

The display device includes an optical cell having a cell front with at least one cell region being capable of an optically transmissive mode and an optically nontransmissive mode with reference to the cell front. The optical cell contains an optically active material responsive to an applied electrical field such that optical properties of the material are controllably changeable. A reflector may be optically coupled to the cell. A prismatic film including a prismatic surface is optically coupled to the optical cell. The prismatic surface preferably comprises a series of prisms. The prisms have first faces and second faces intersecting the first faces. The first faces are oriented to refract light obliquely intercepting the first faces and the second faces are oriented to minimize refractive, reflective, and optical interactions of the light with the second faces. The prismatic film, the cell, and the reflector optically cooperate such that light entering a display at an incident angle is emitted from the display at an exiting angle distinct from the incident angle for viewing of the display.

Owner:GOOGLE TECH HLDG LLC

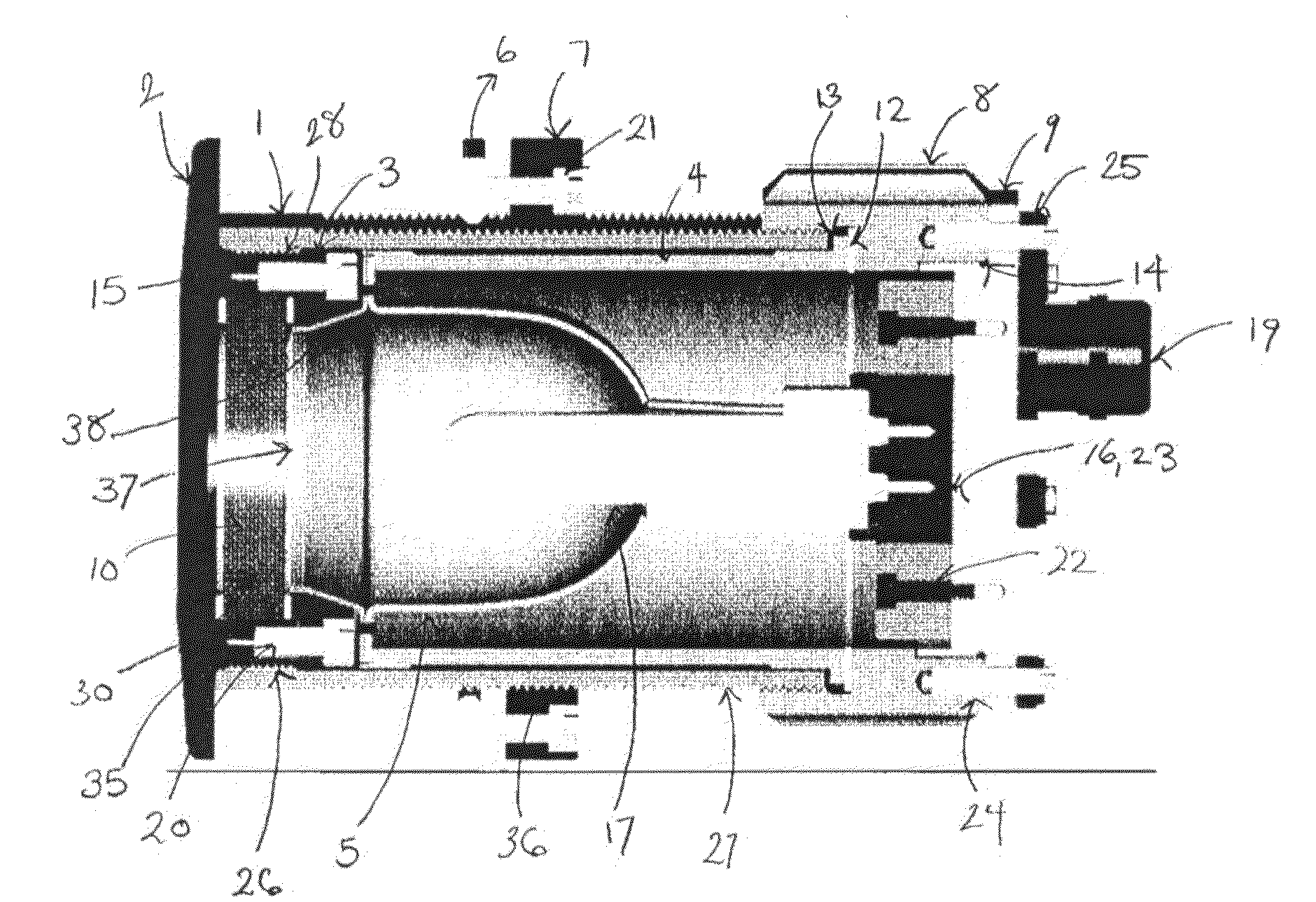

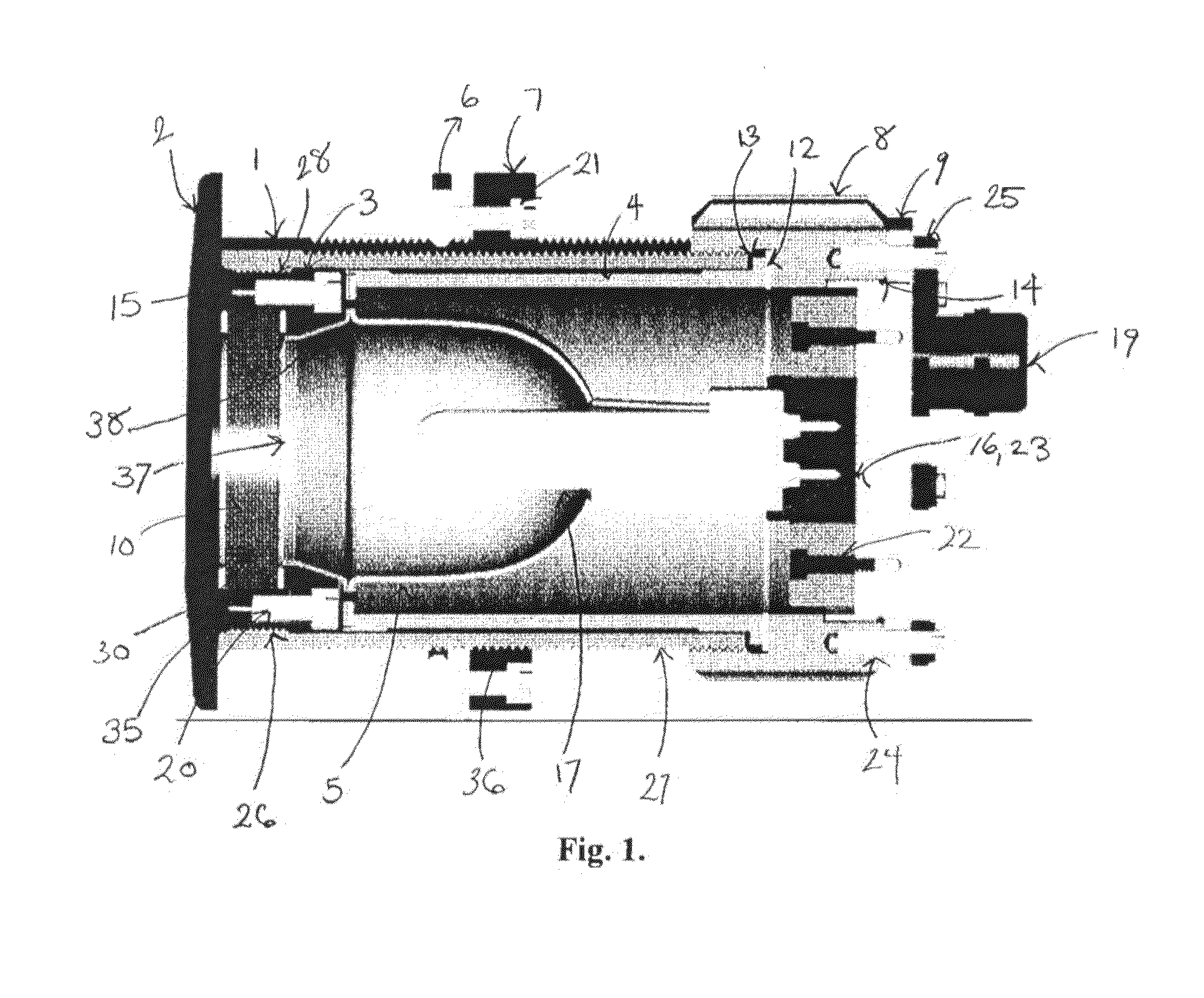

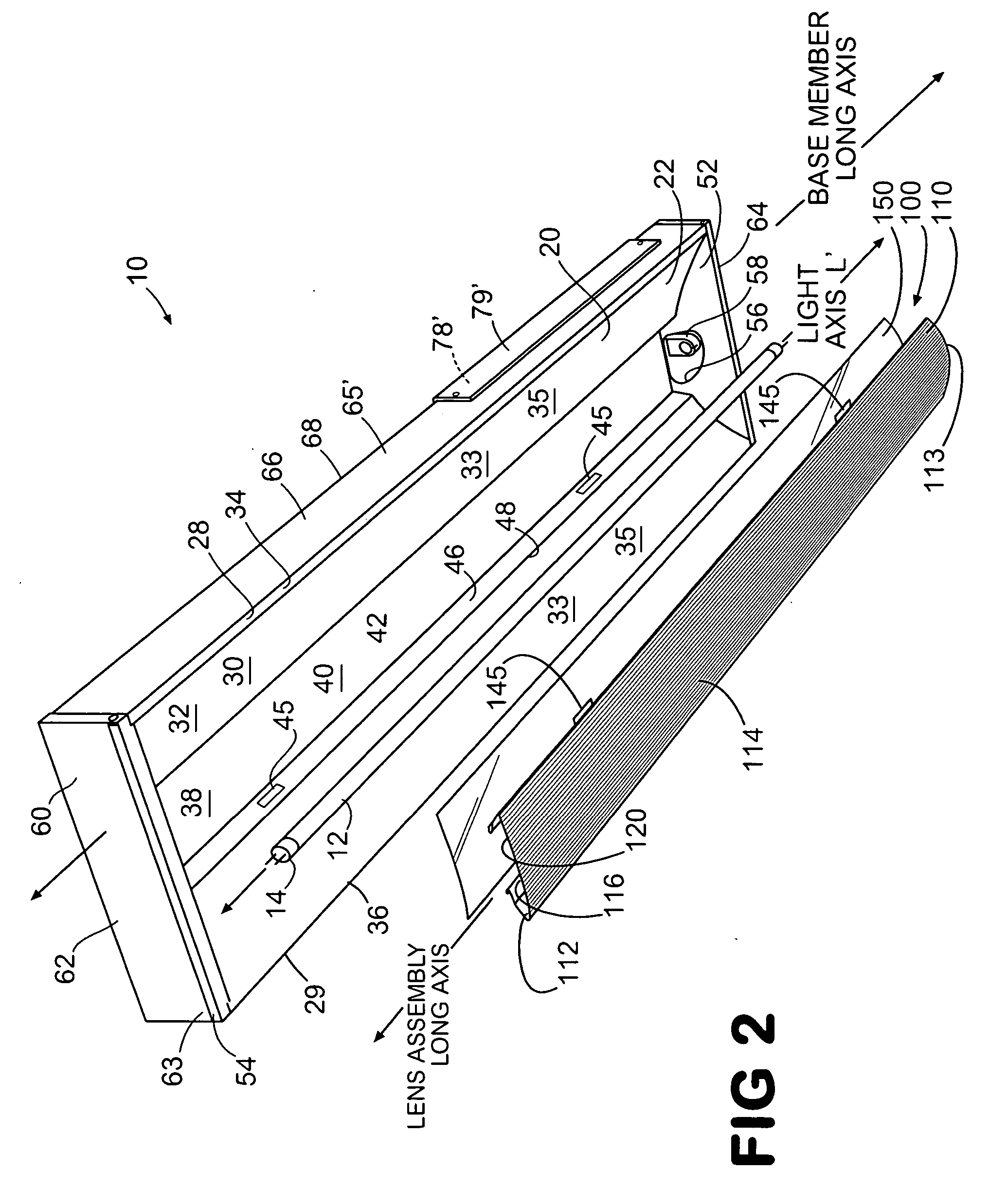

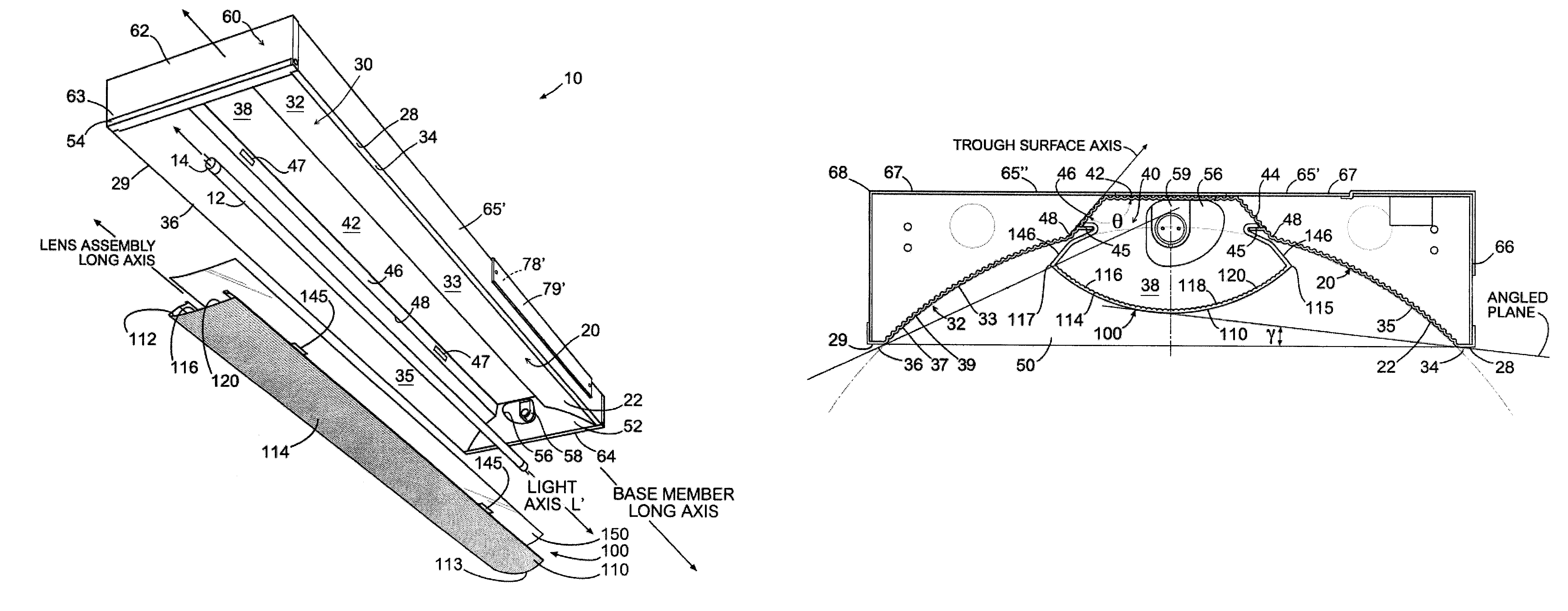

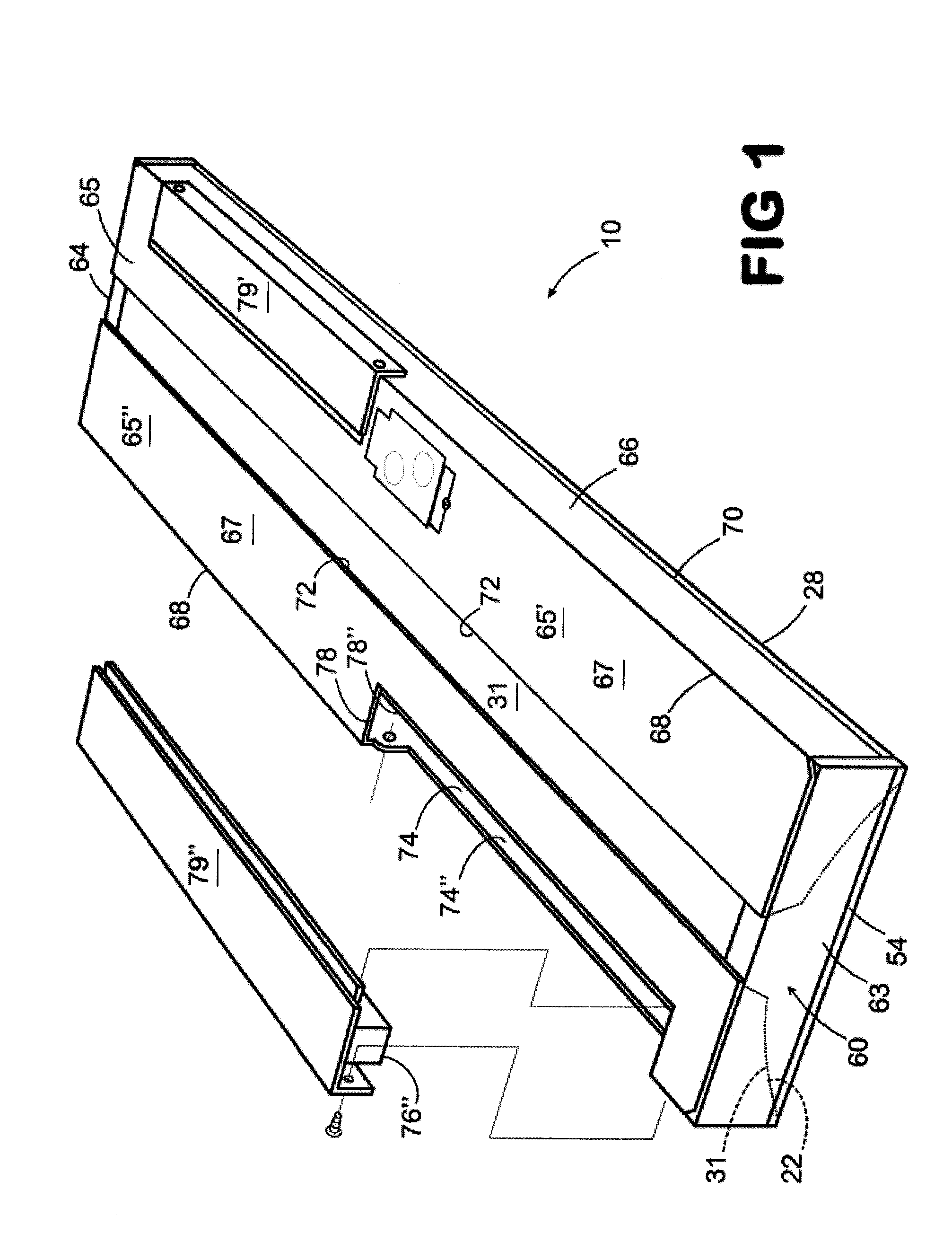

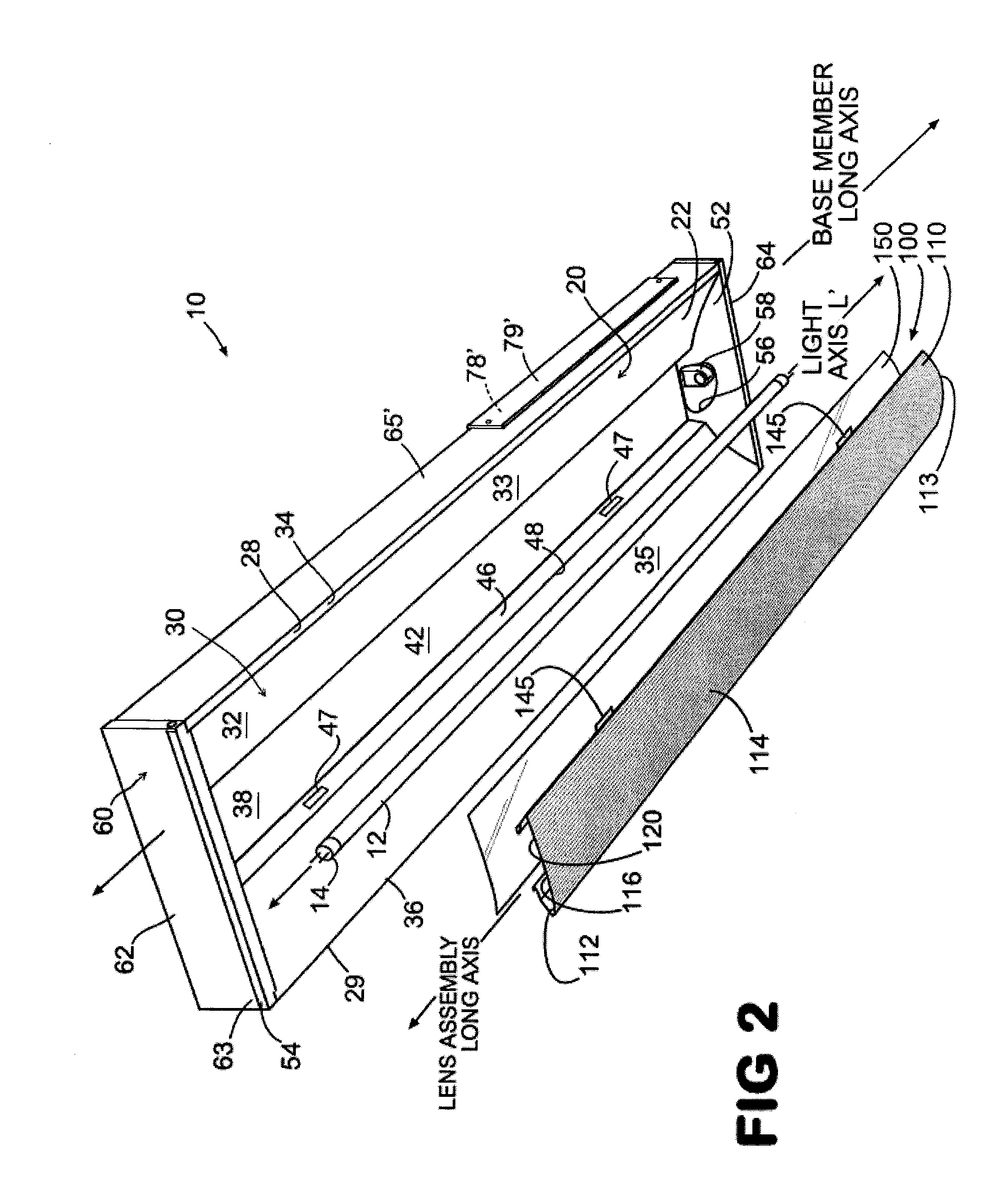

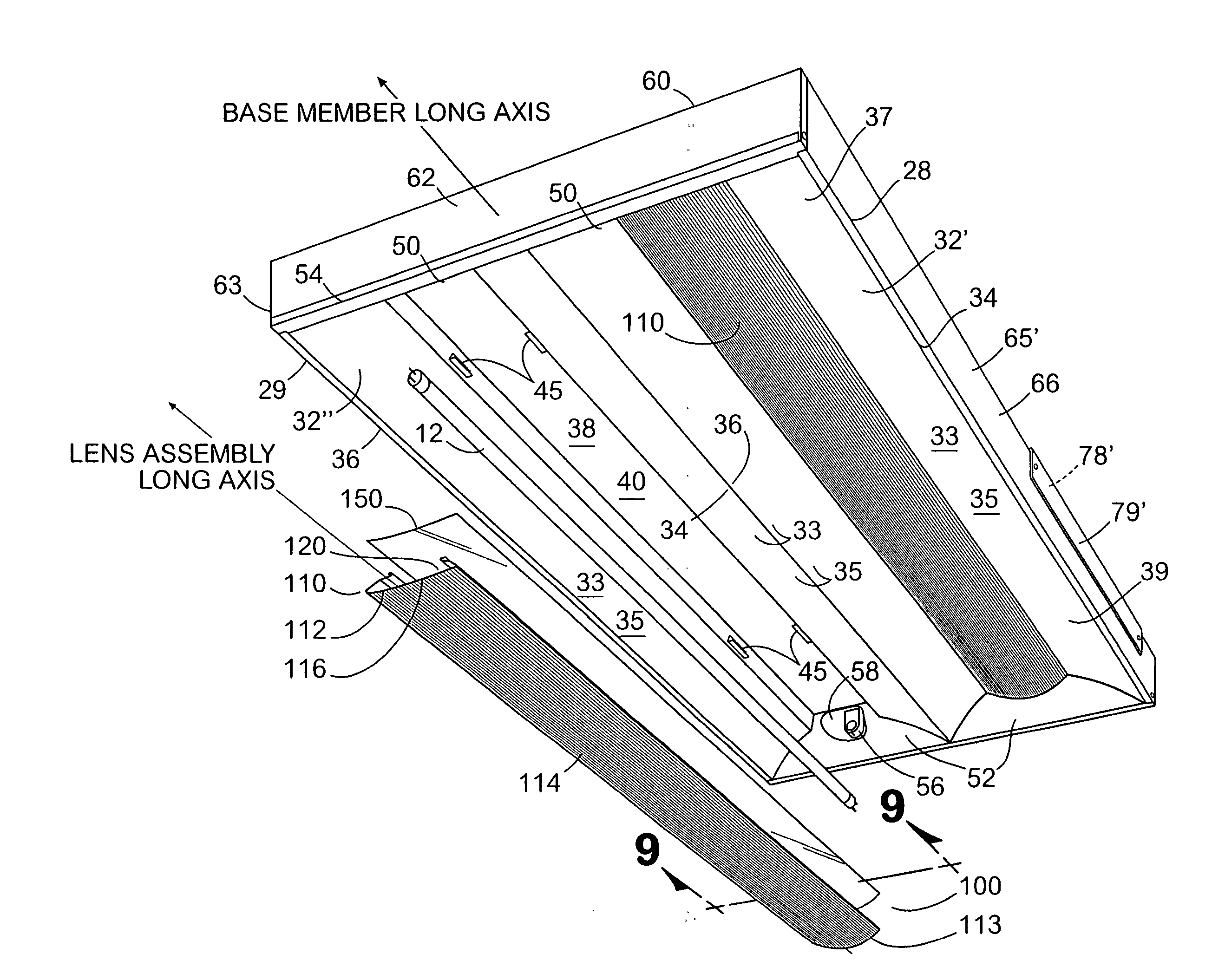

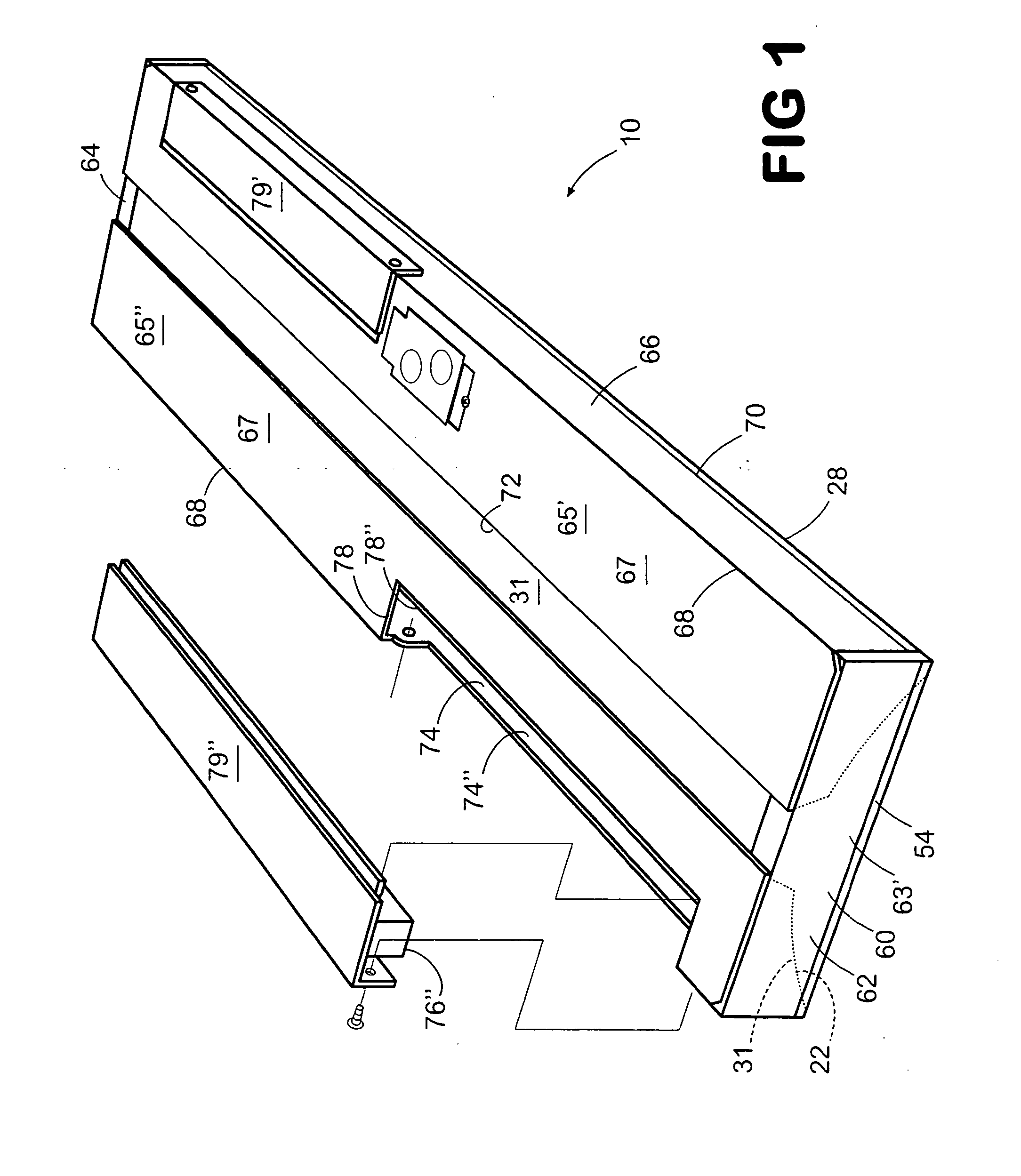

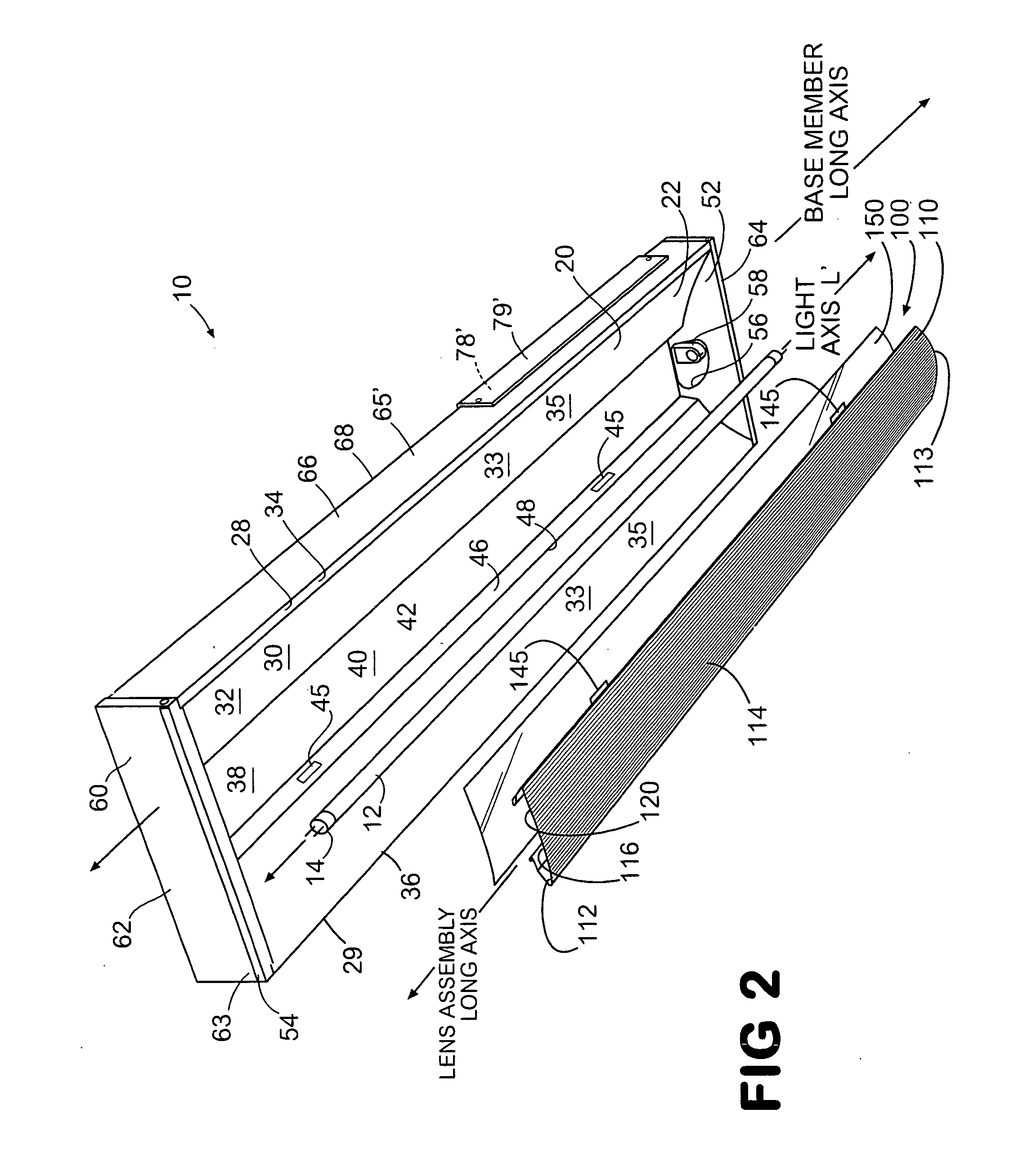

Light fixture and lens assembly for same

ActiveUS20050281023A1Effective distributionGood lookingNon-electric lightingLight source combinationsOptoelectronicsPrism

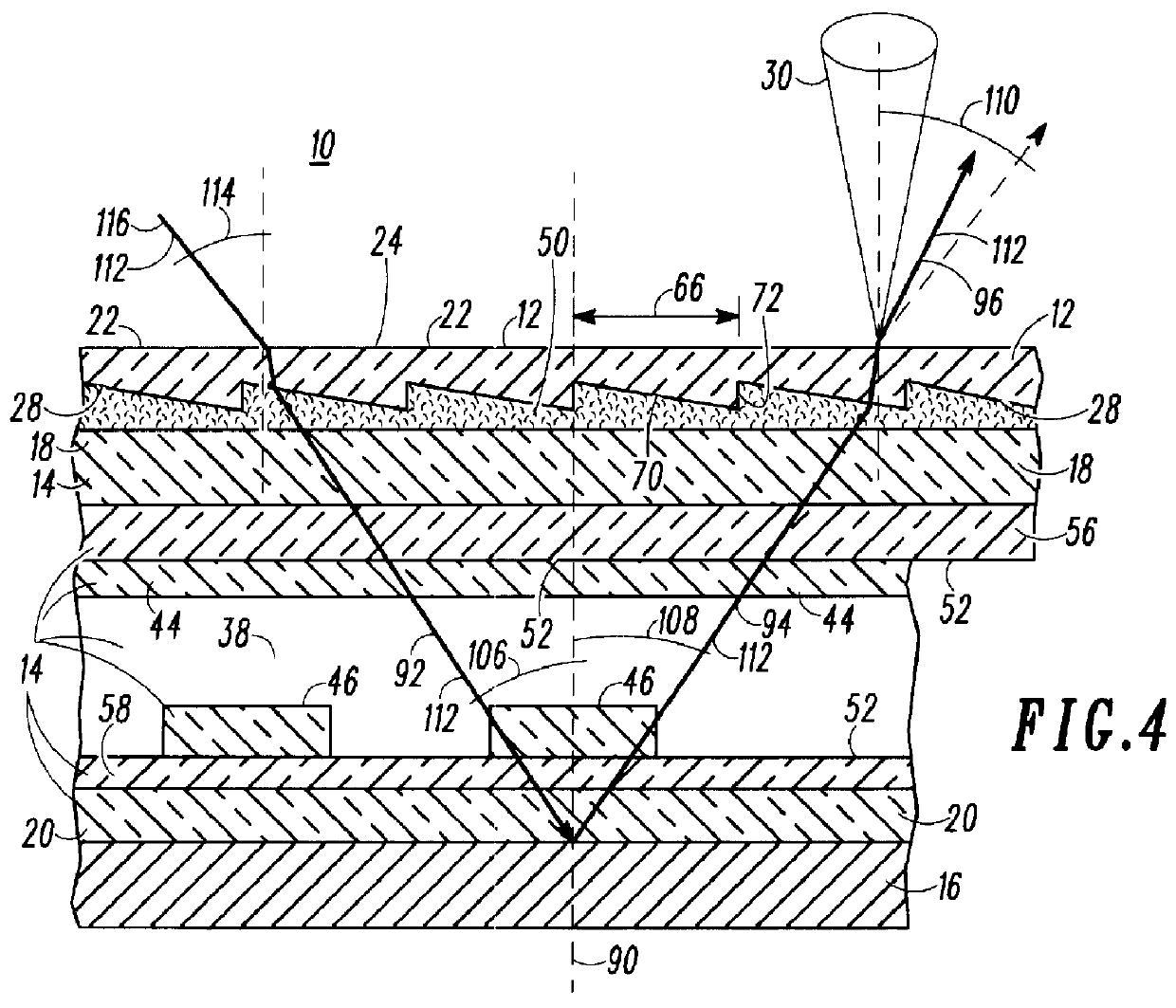

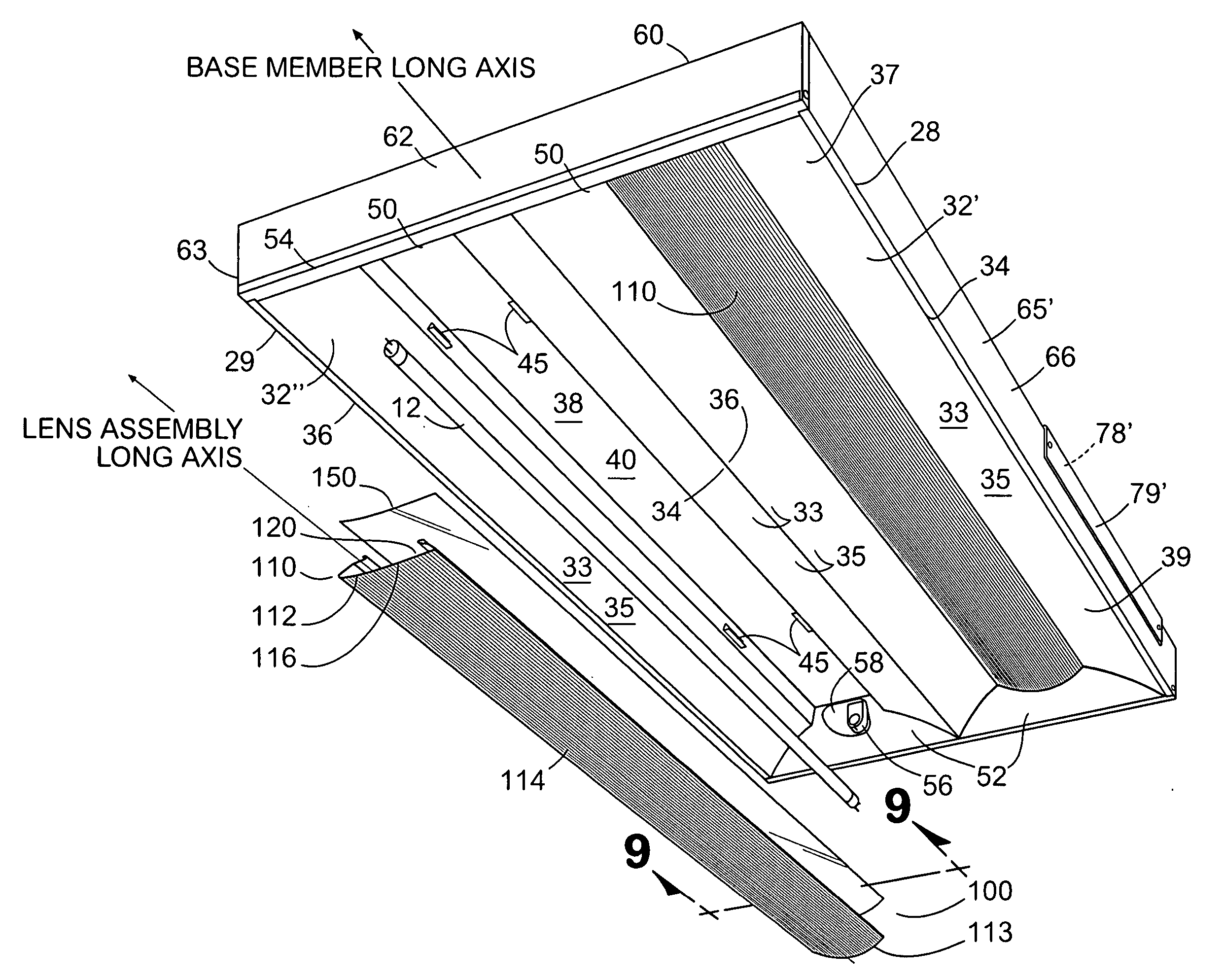

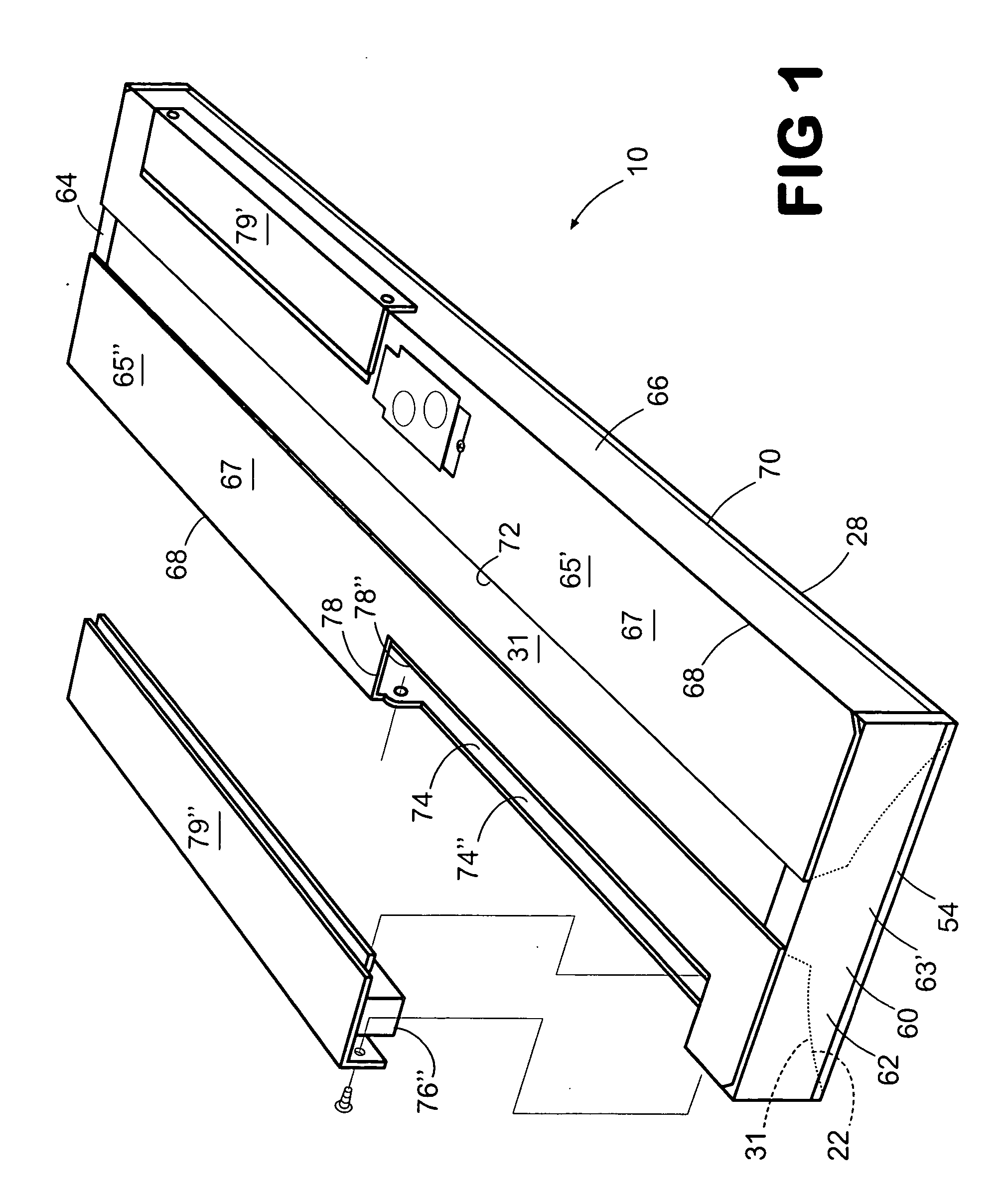

A light fixture or troffer for directing light emitted from a light source toward an area to be illuminated, including a reflector assembly within which the light source is positioned and a lens assembly detachably secured to a portion of the reflector assembly such that a lens of the lens assembly overlies the light source and such that substantially all of the light emitted from the light source passes through the lens assembly. In one example, the lens includes a curved prismatic surface that can be oriented toward or away from the underlying light source.

Owner:ABL IP HLDG

Light fixture and lens assembly for same

ActiveUS7229192B2Efficiently distributedGlare is further reducedLight source combinationsLighting support devicesPrismOptoelectronics

A light fixture or troffer for directing light emitted from a light source toward an area to be illuminated, including a reflector assembly within which the light source is positioned and a lens assembly detachably secured to a portion of the reflector assembly such that a lens of the lens assembly overlies the light source and such that substantially all of the light emitted from the light source passes through the lens assembly. In one example, the lens includes a curved prismatic surface that can be oriented toward or away from the underlying light source.

Owner:ABL IP HLDG

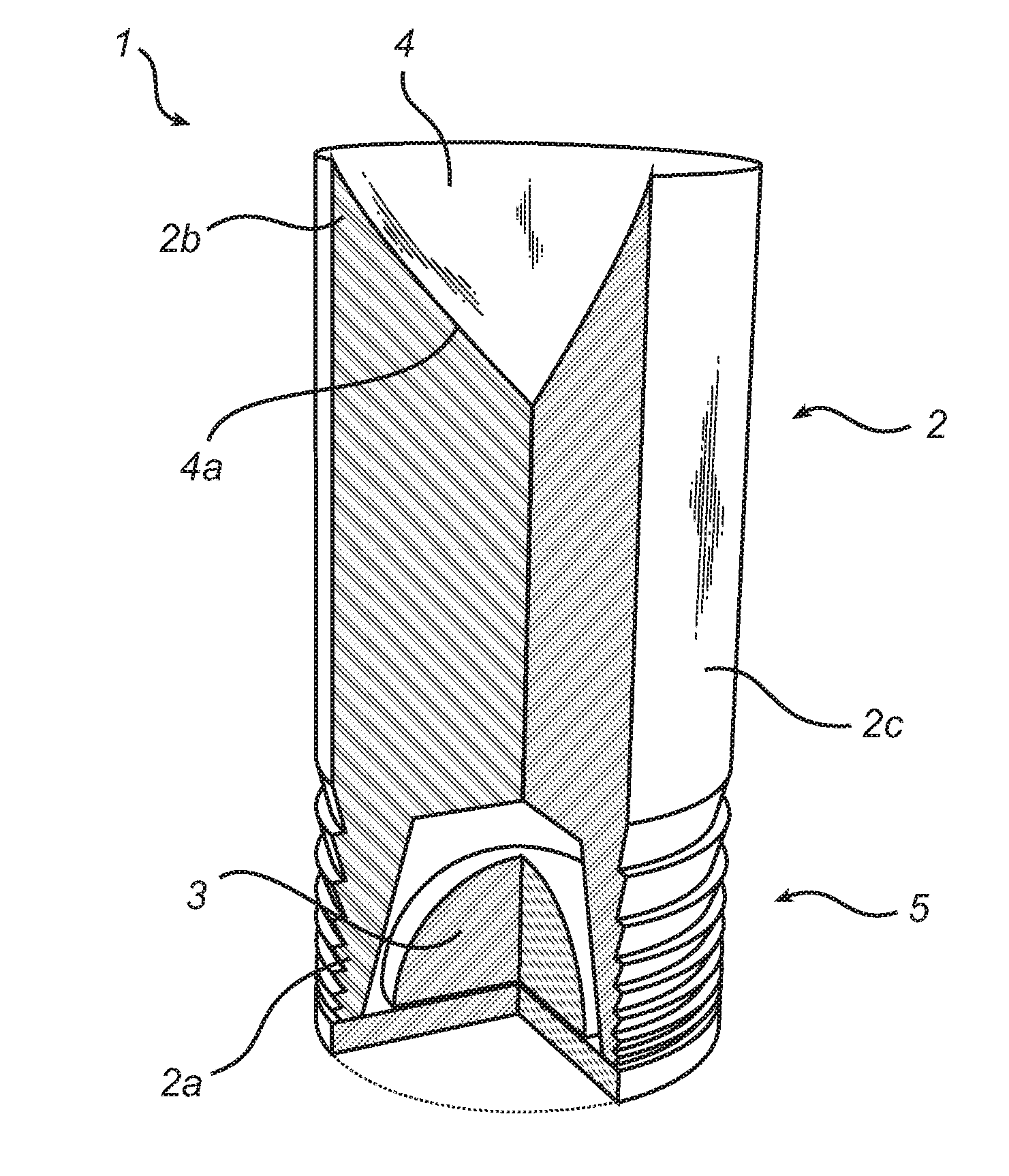

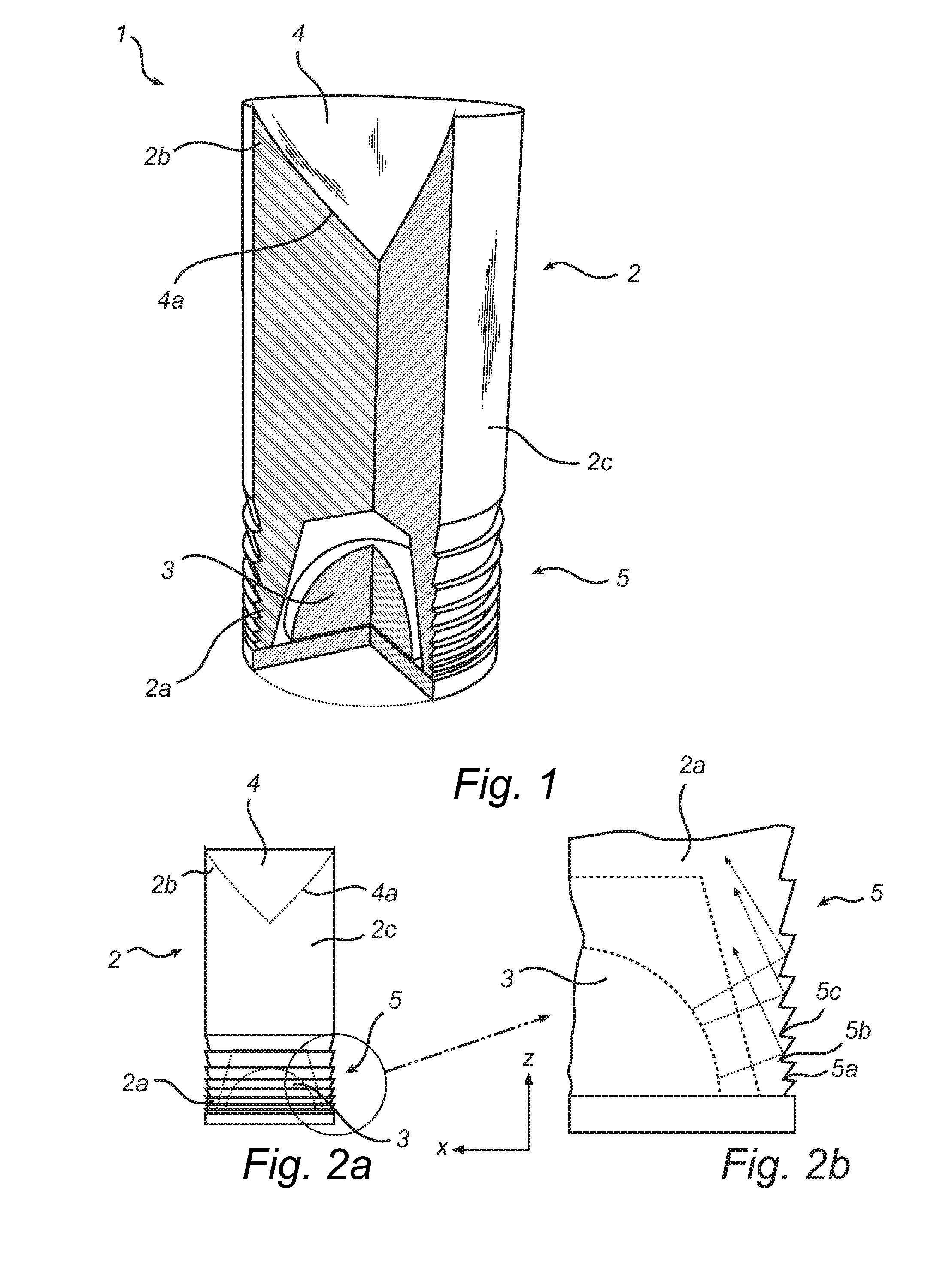

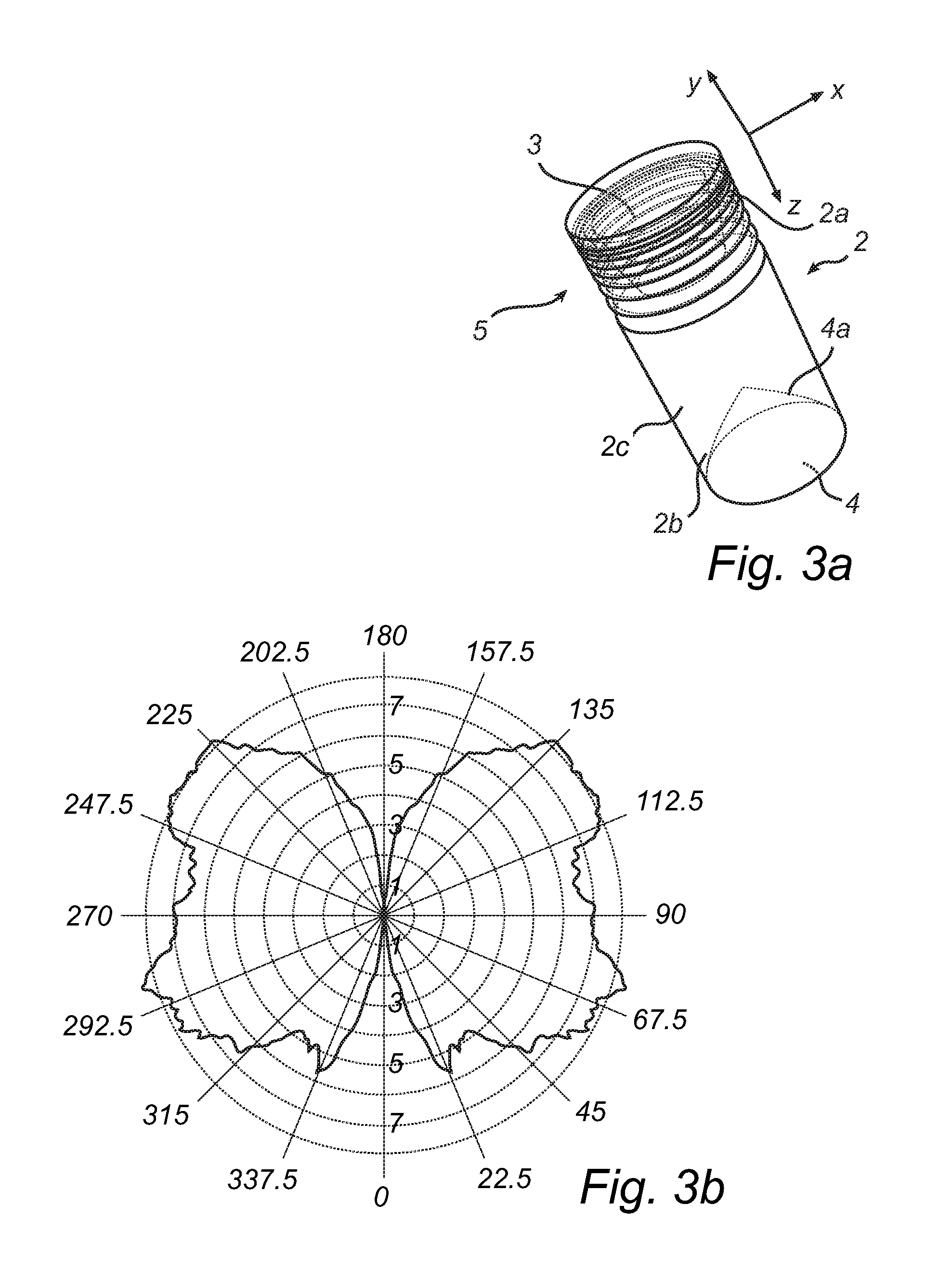

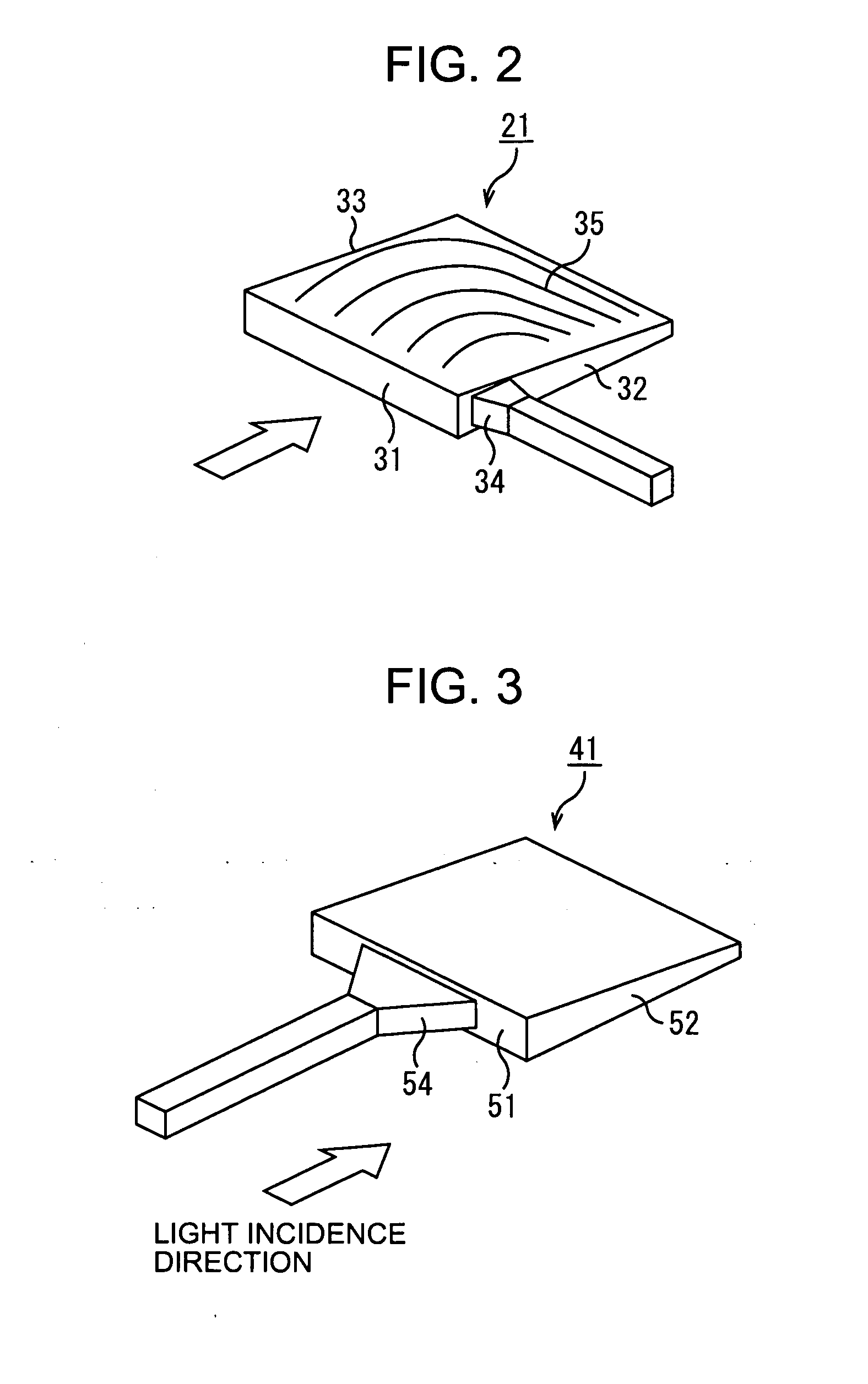

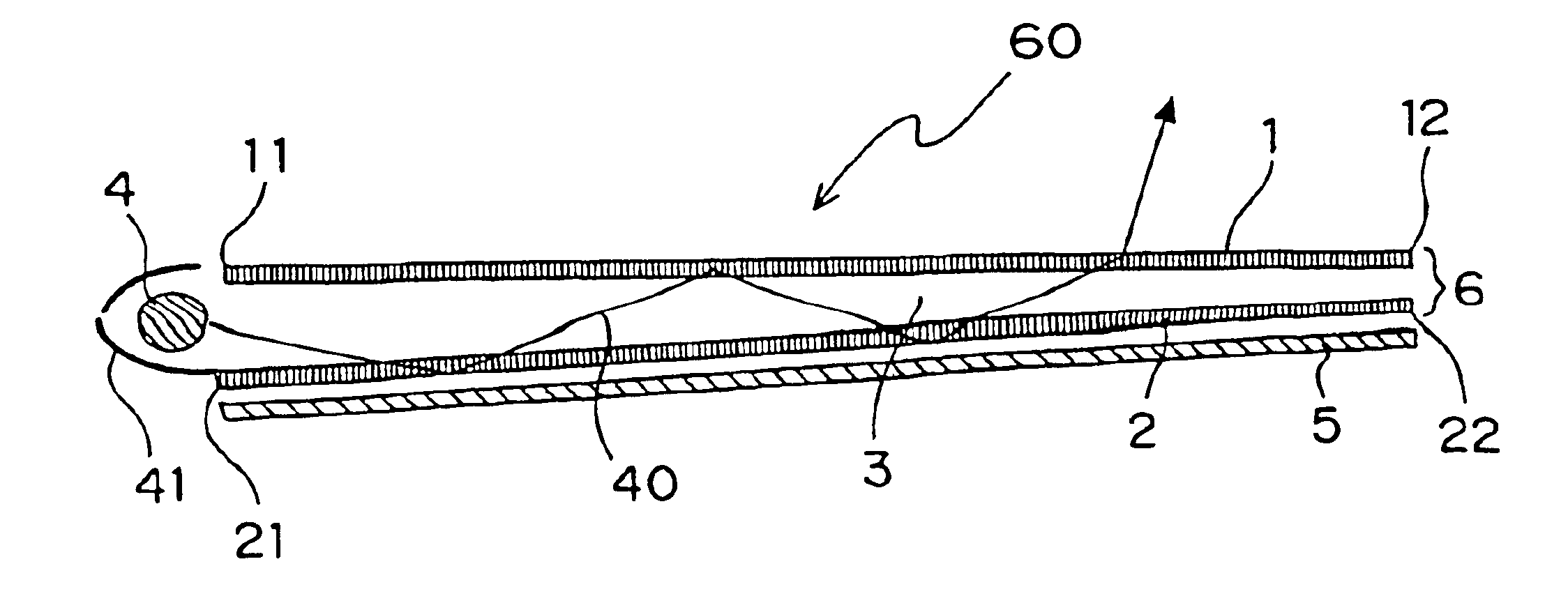

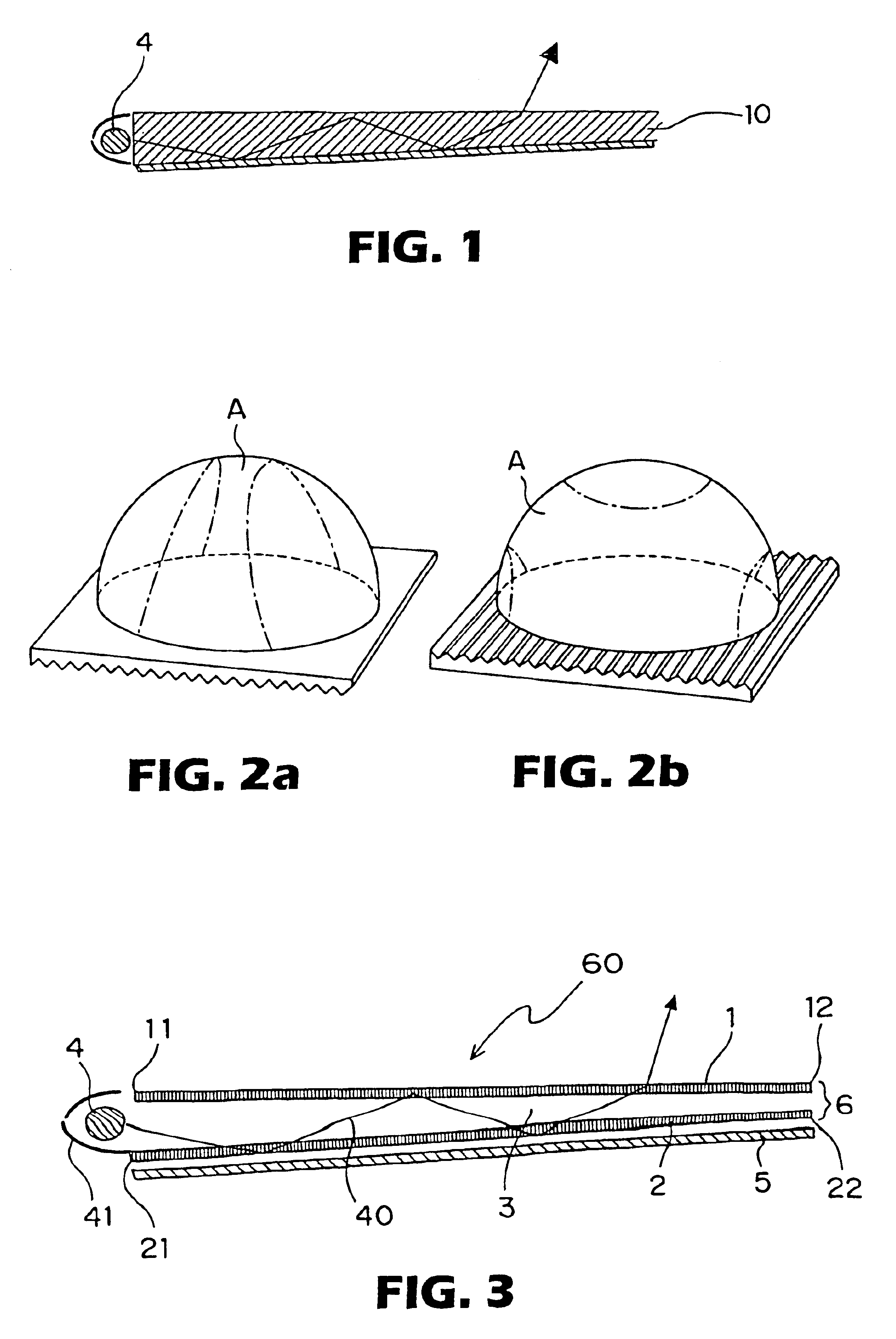

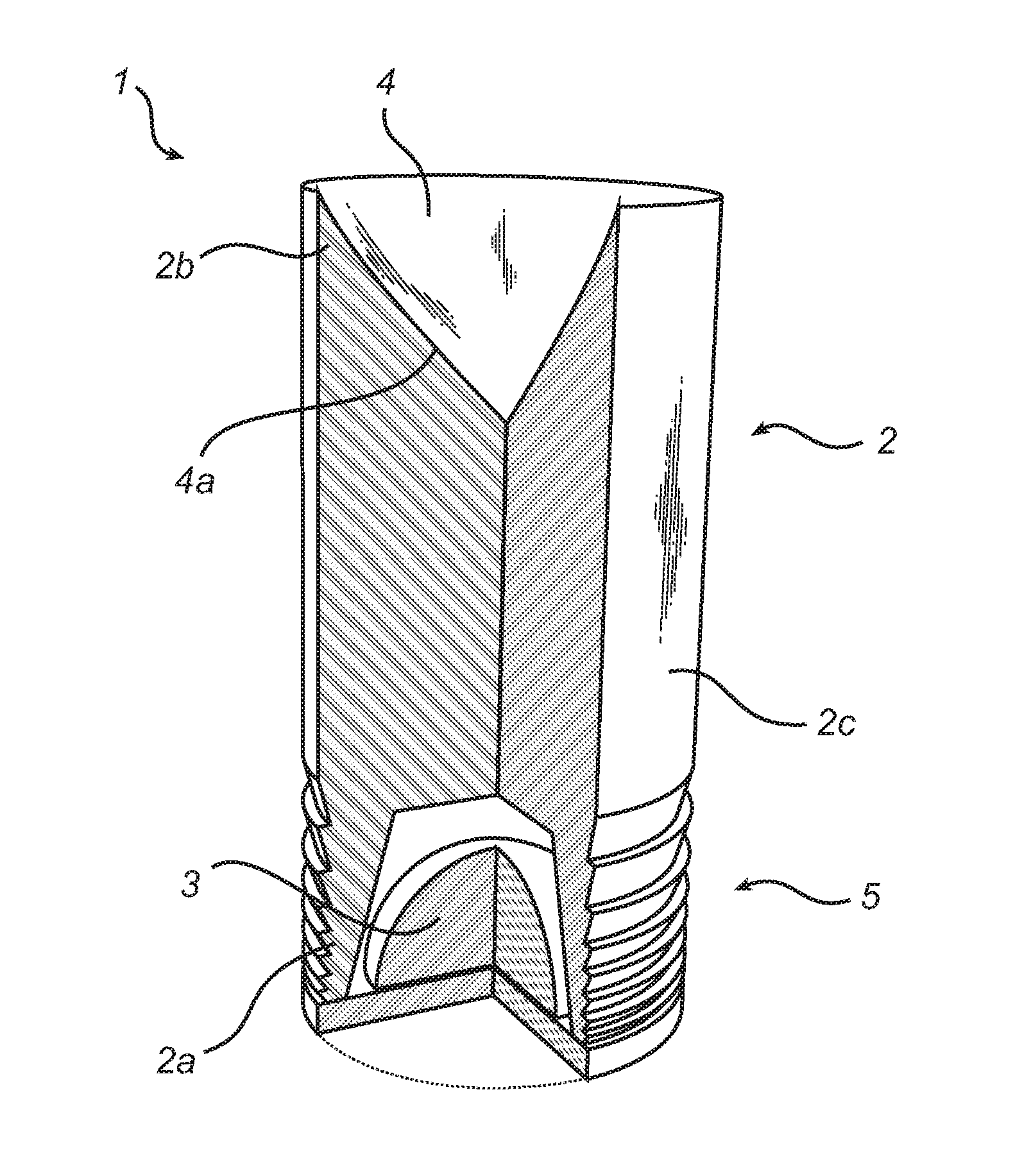

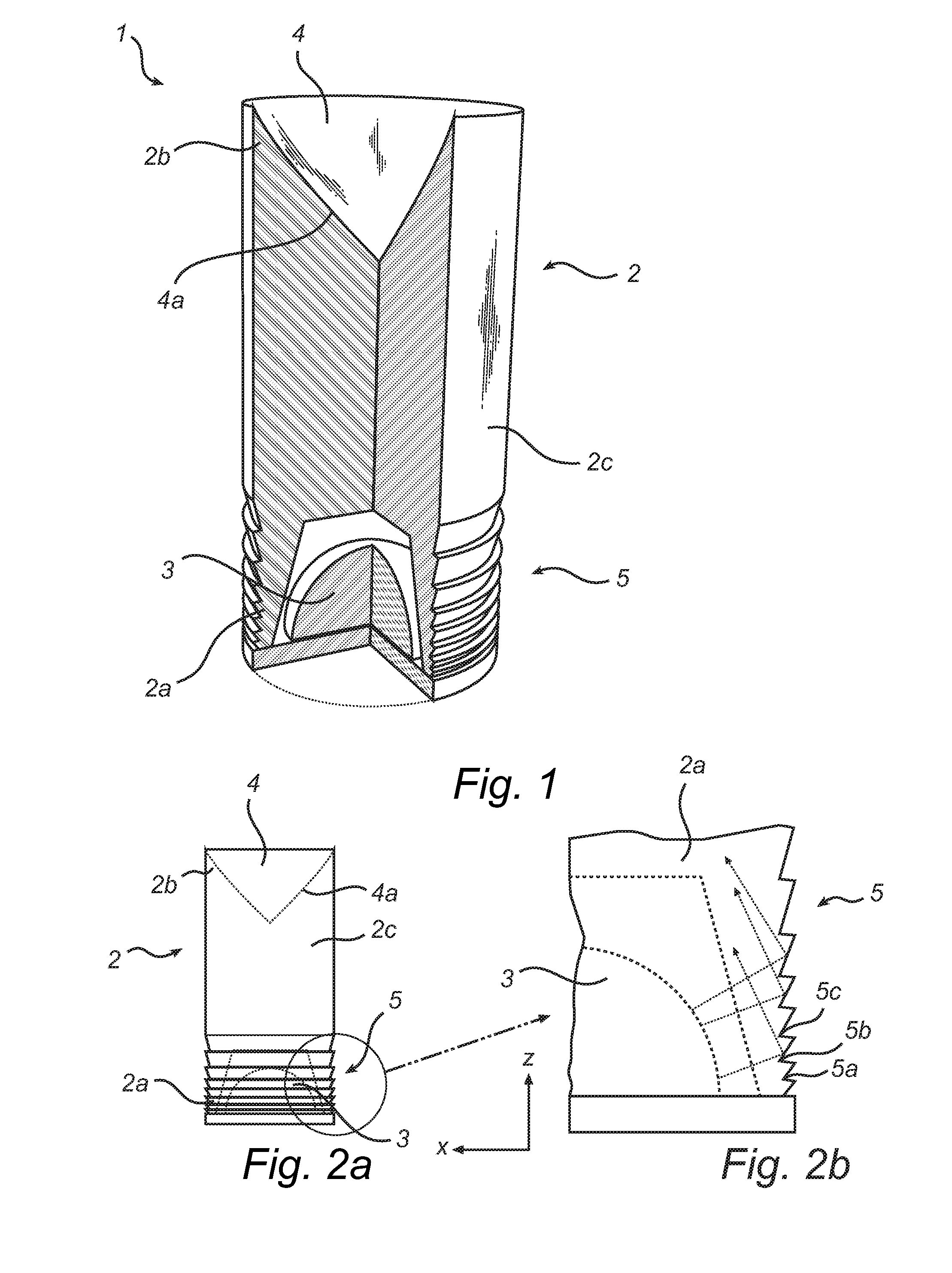

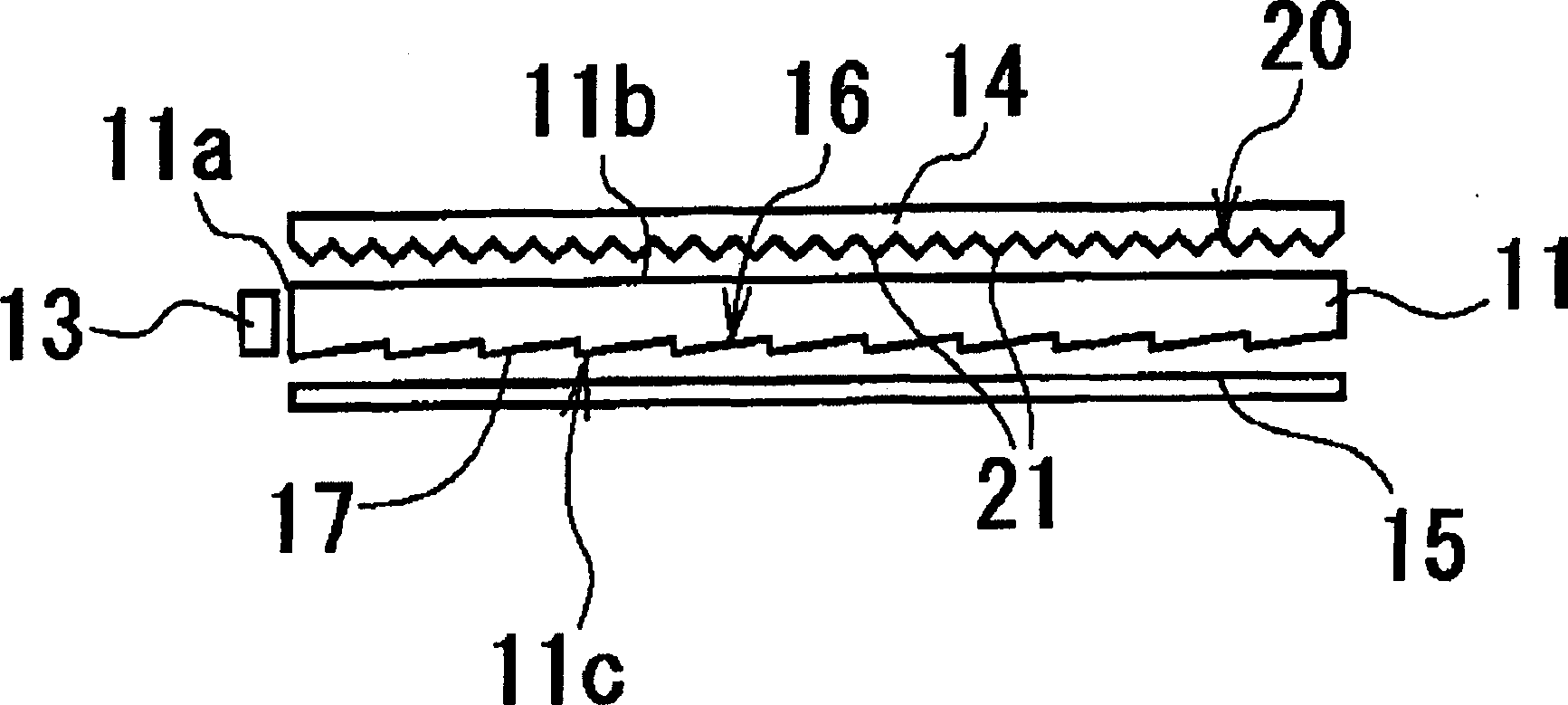

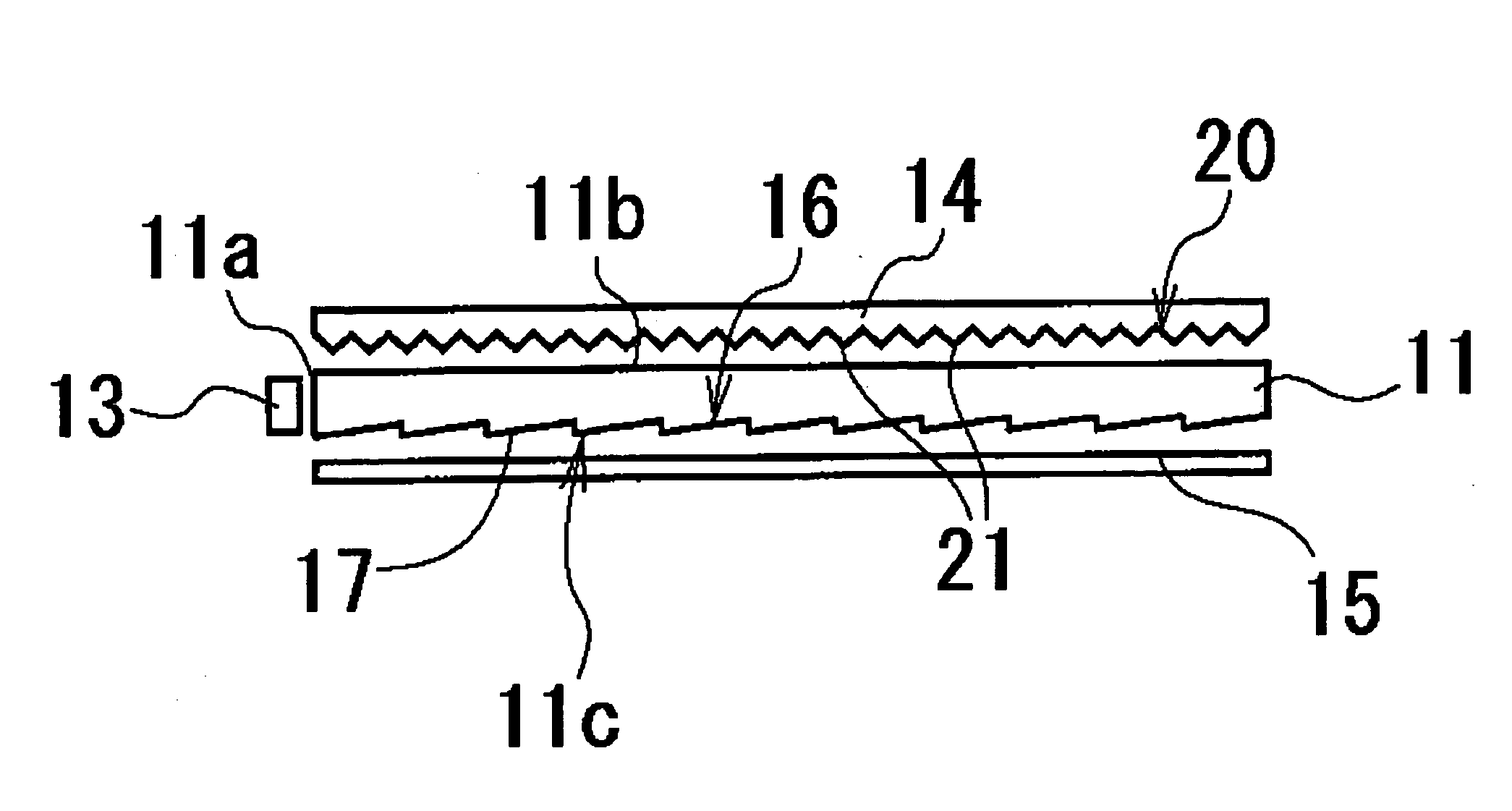

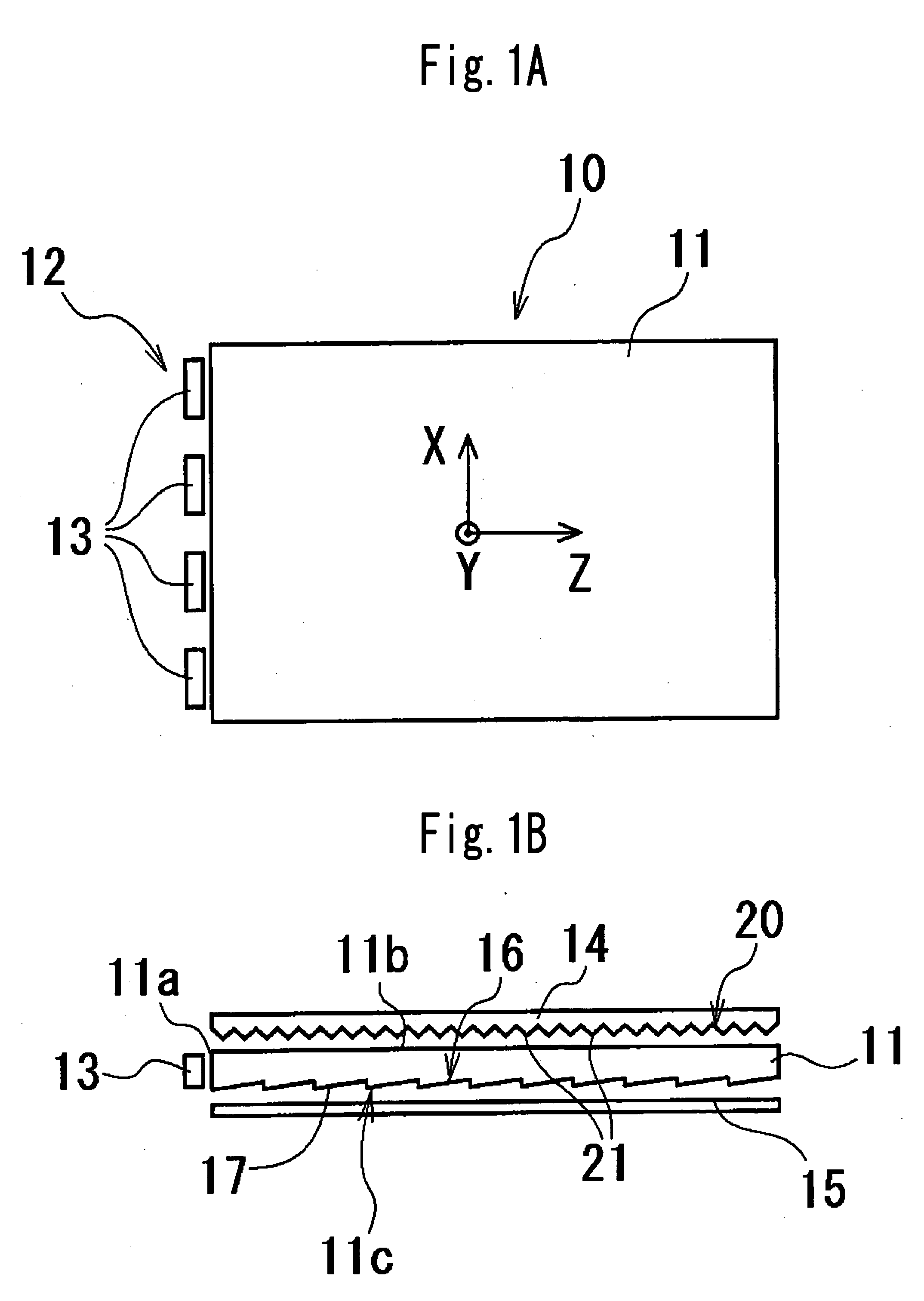

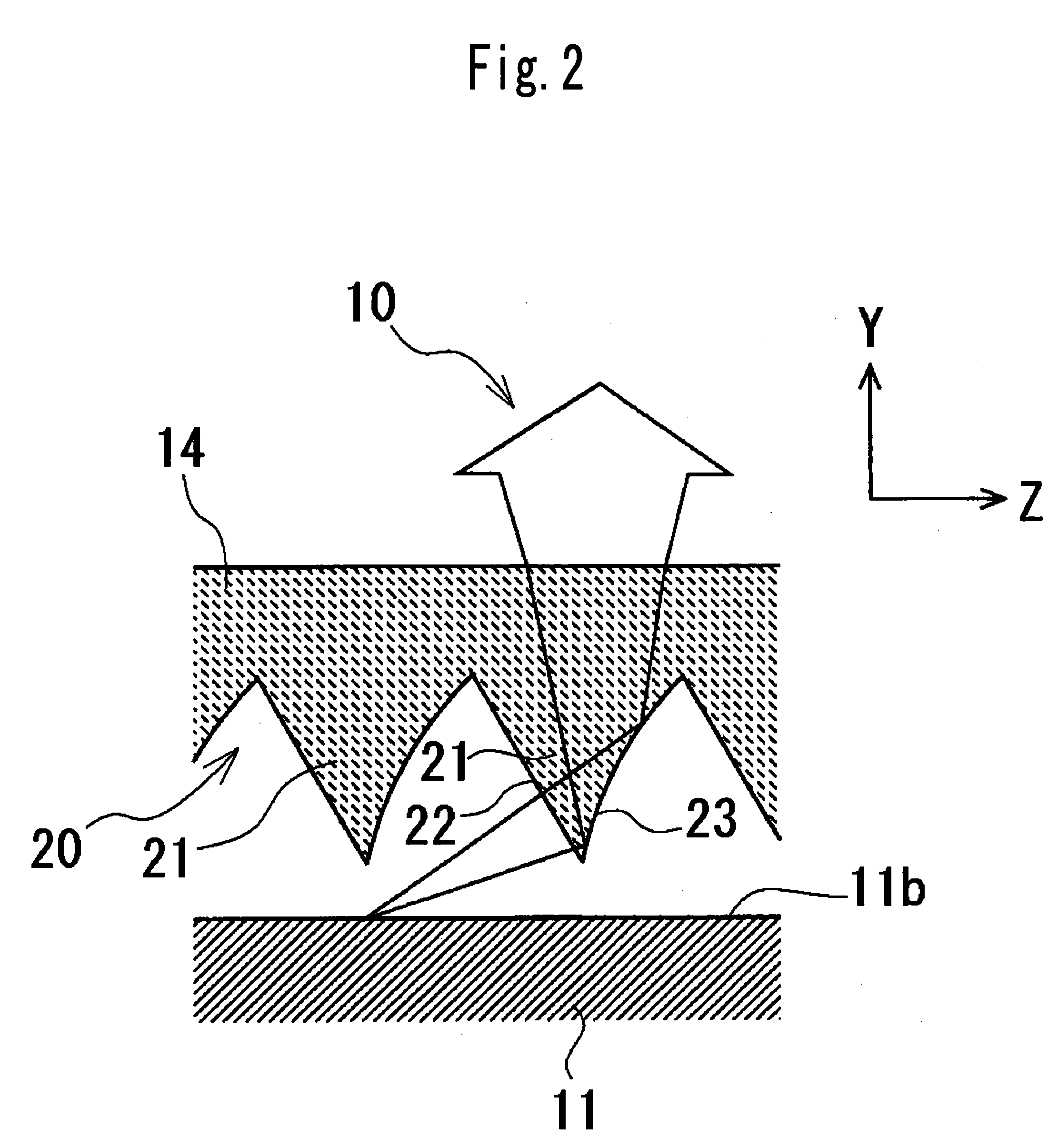

Optical element and light source comprising the same

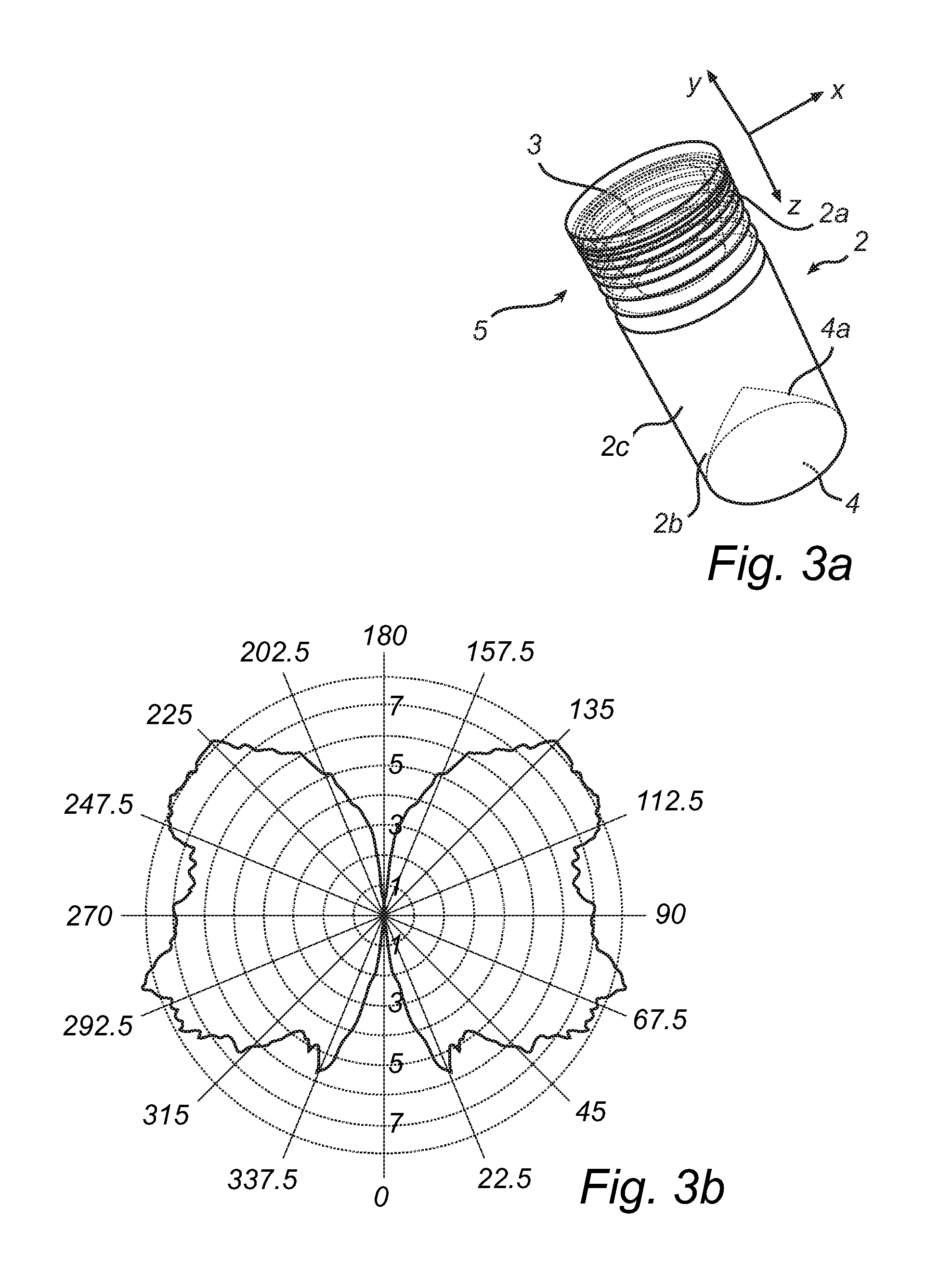

ActiveUS20110273900A1Low costEasy to manufacturePoint-like light sourceLight guides detailsLight guidePrism

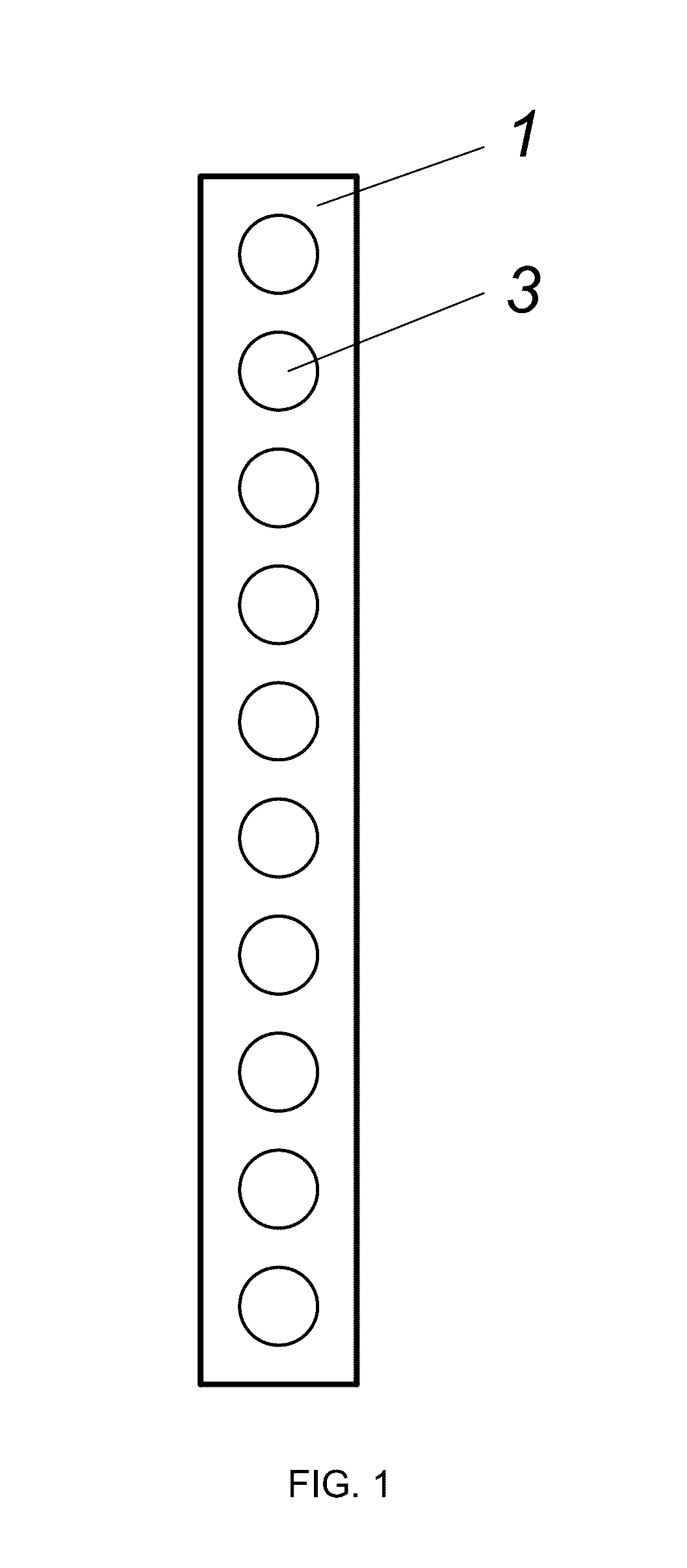

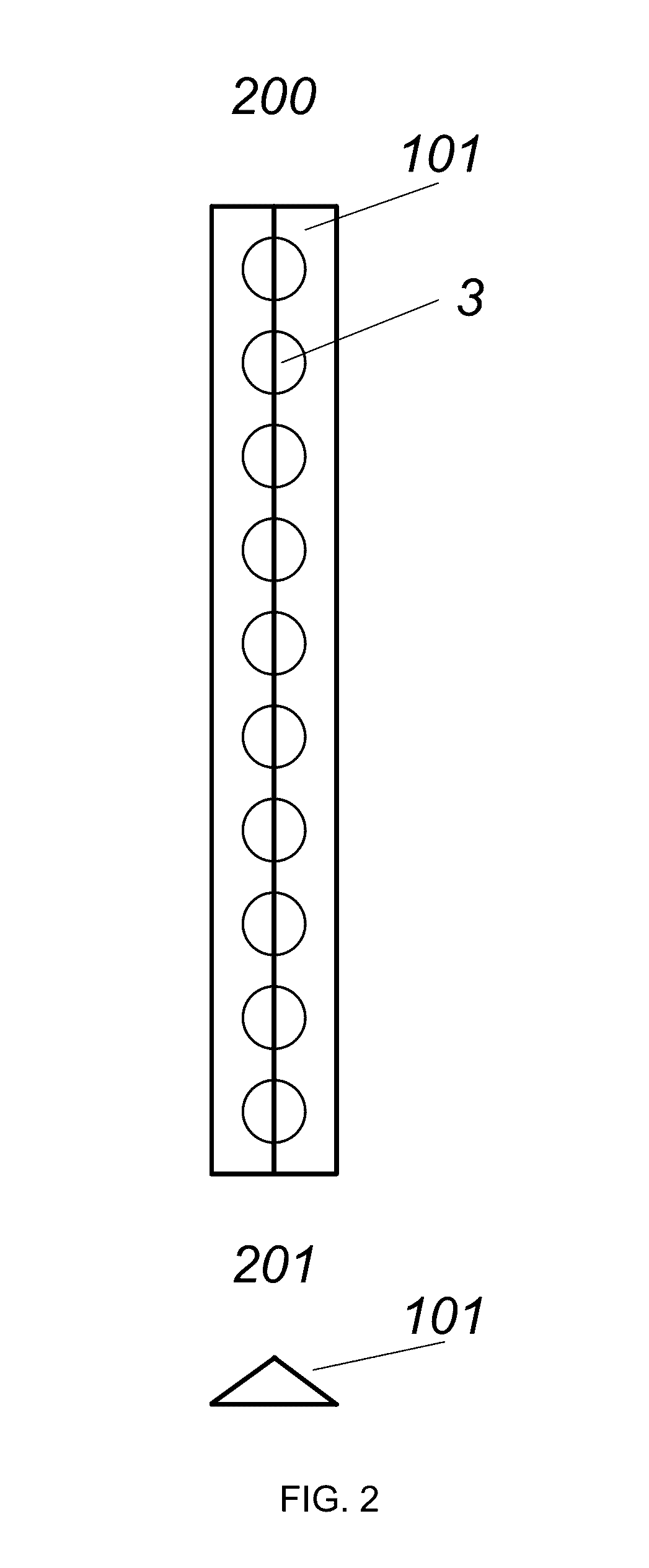

The present invention relates to an optical element including a light guide, into which light from one or more light-emitting diodes in a light unit arranged at one end of the light guide is injected, and a reflector arranged at the other end of the light guide capable of reflecting light incident on the reflector. The light guide further includes a prismatic surface comprising a plurality of prisms, each prism being arranged at an angle to an axial direction of the light guide, for guiding the light emitted from the light unit towards the output end of the light guide. The present invention also relates to a light source including an optical element according to the present invention, the light source being arranged for retrofitting into a luminaire employing an incandescent light source.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

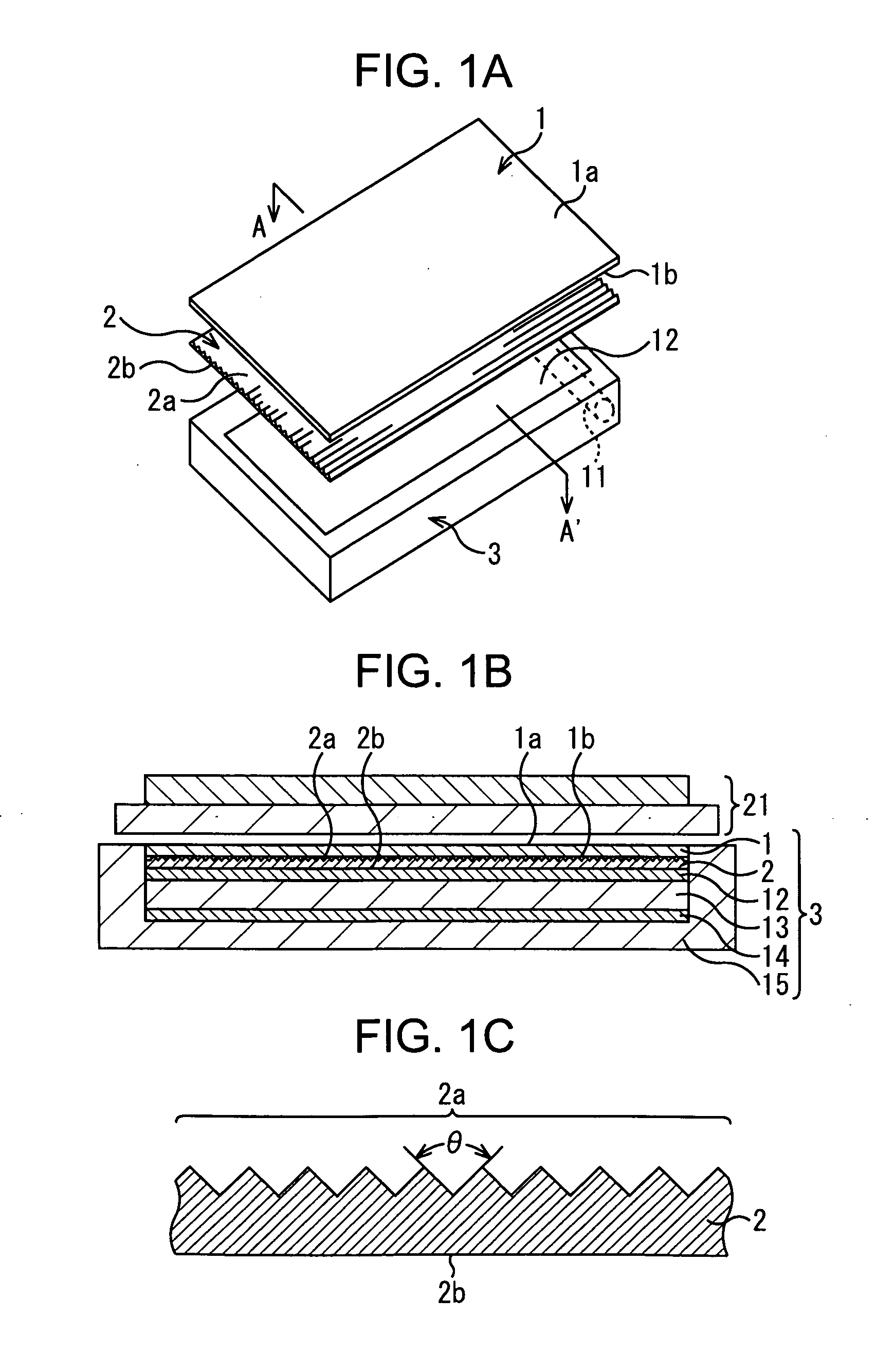

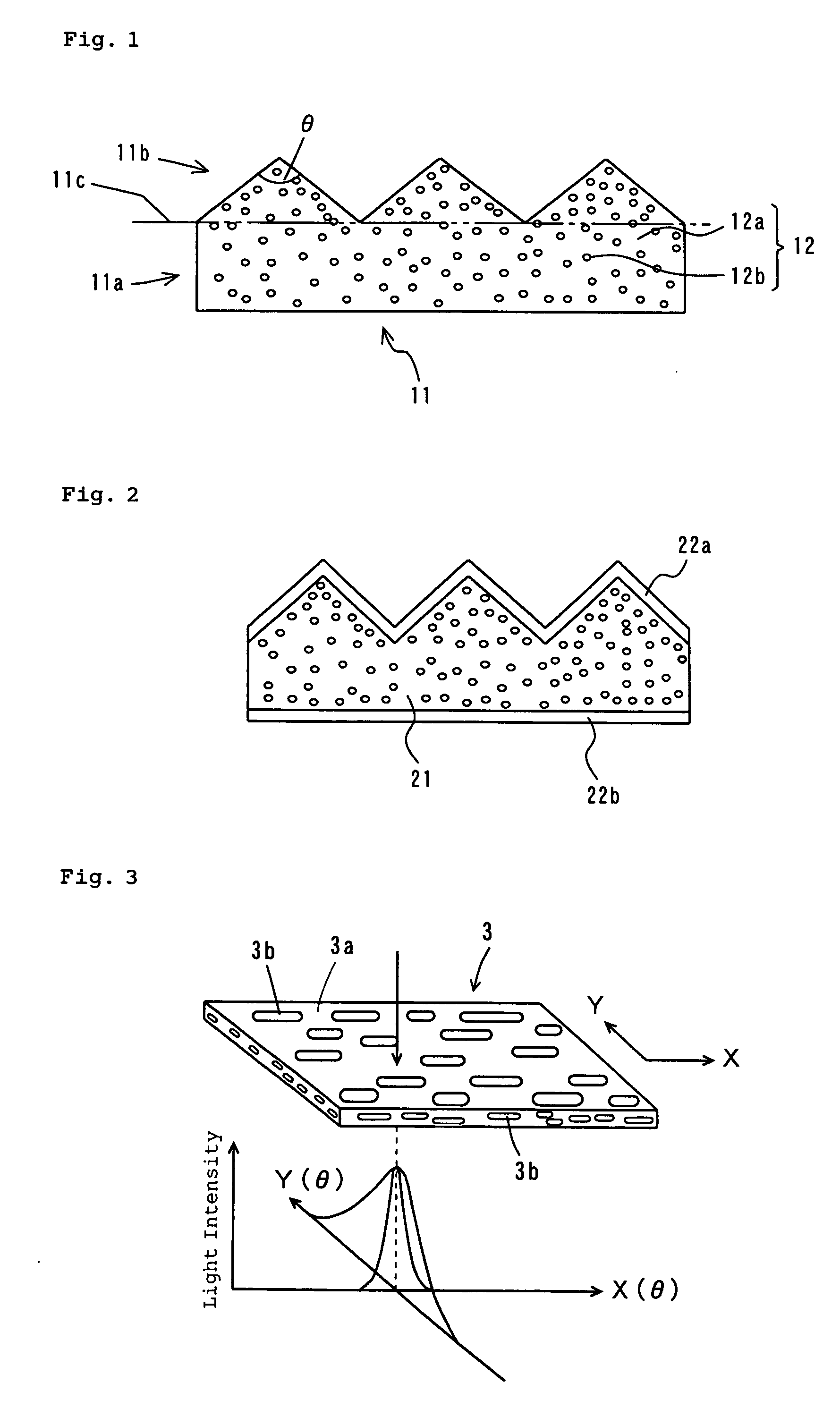

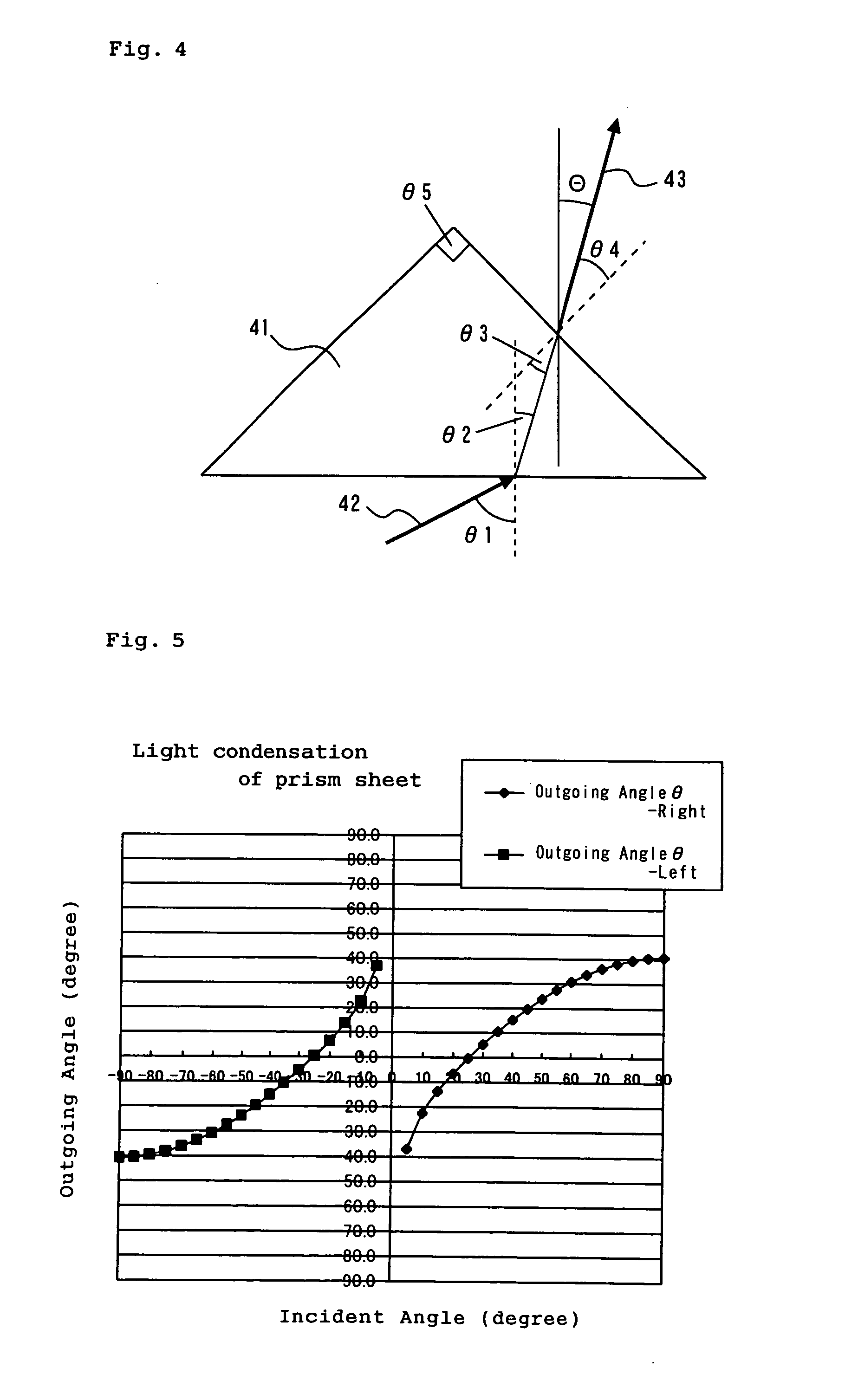

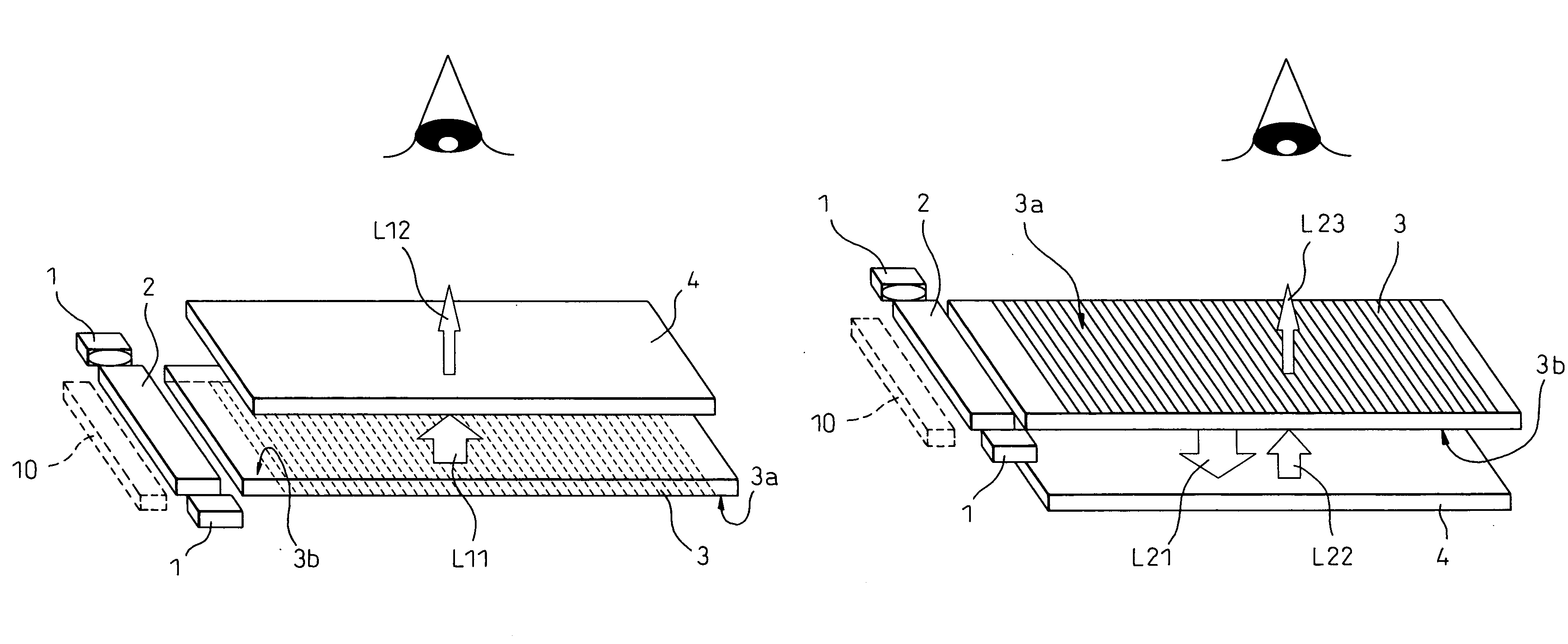

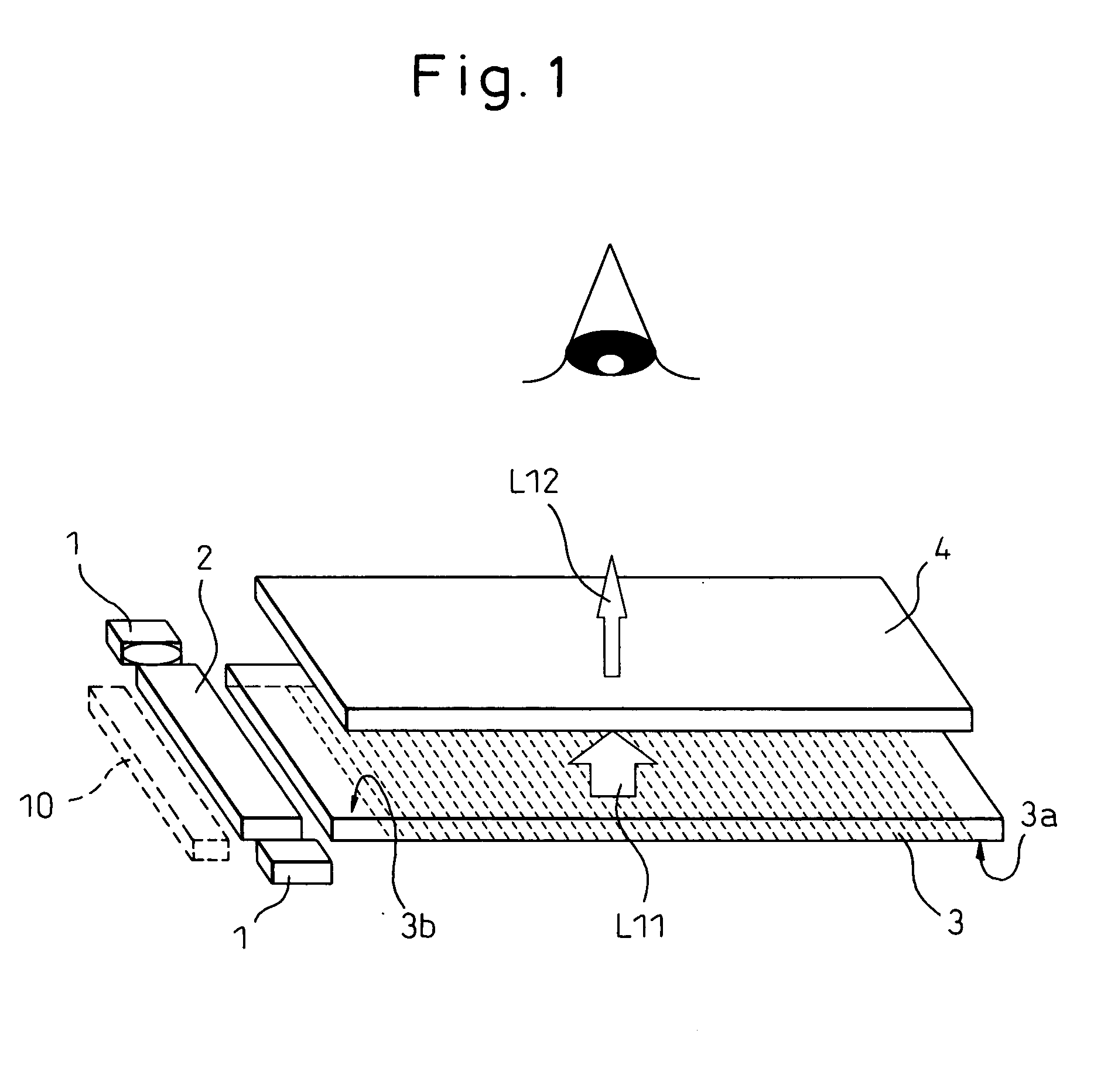

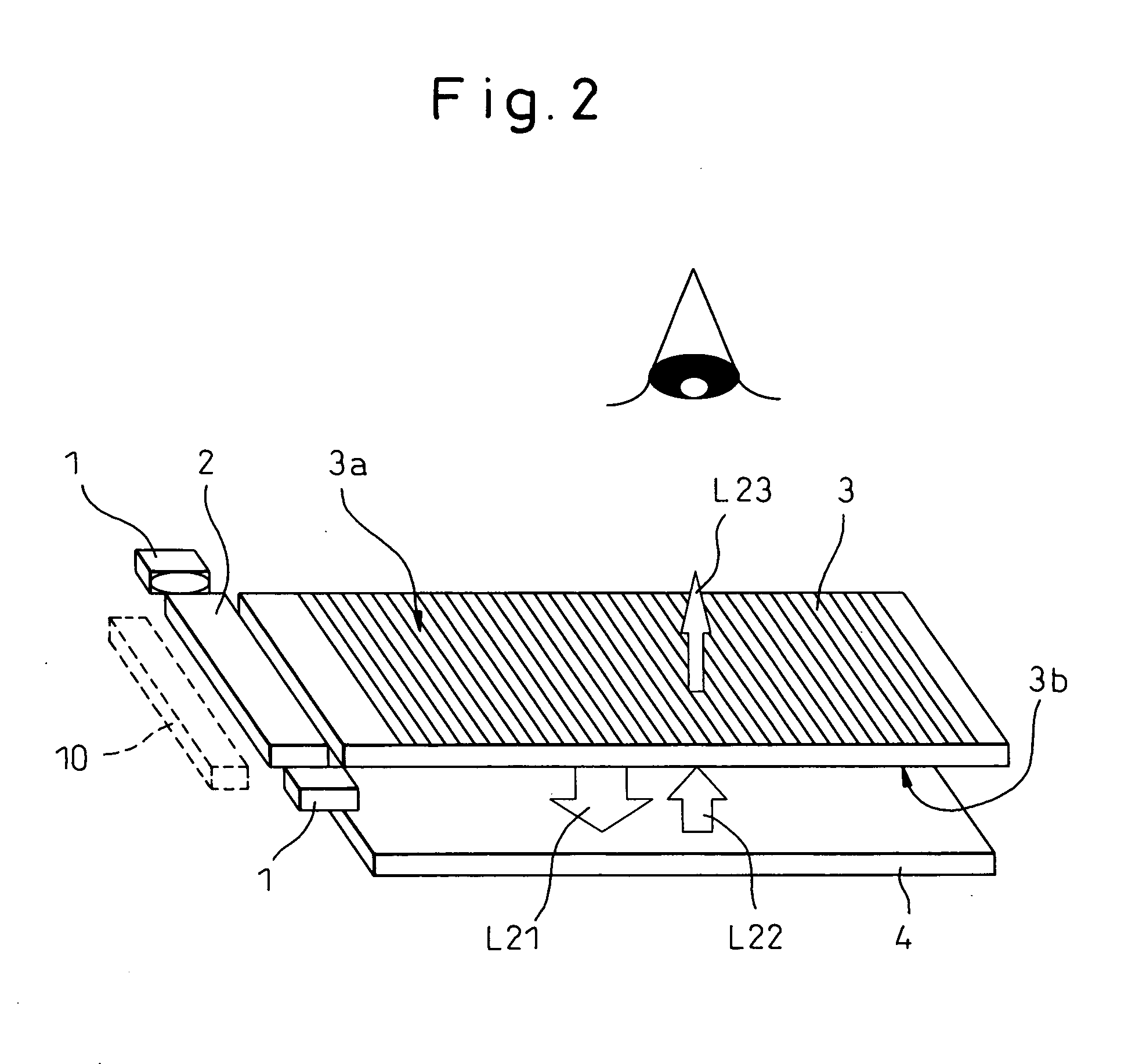

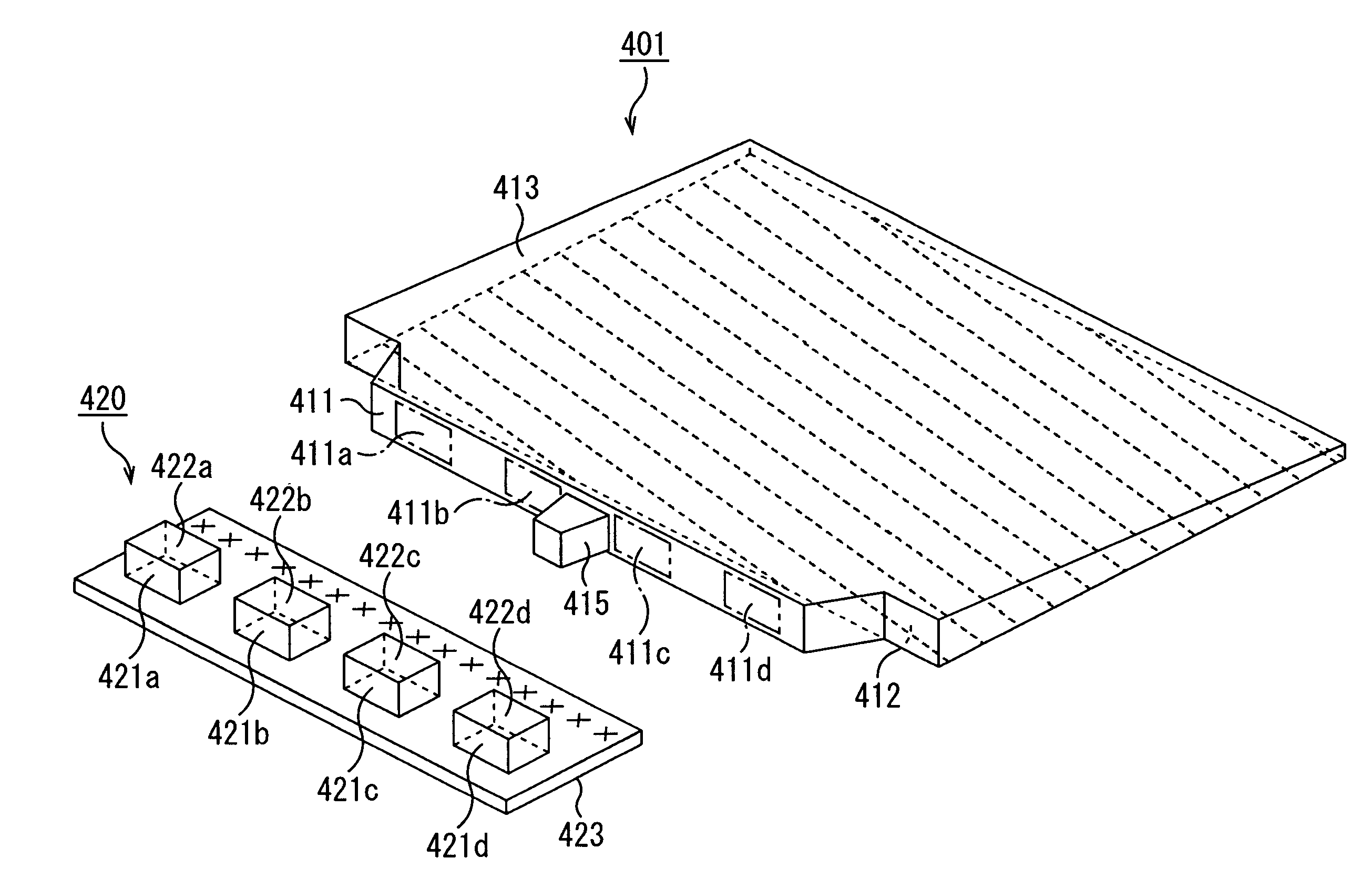

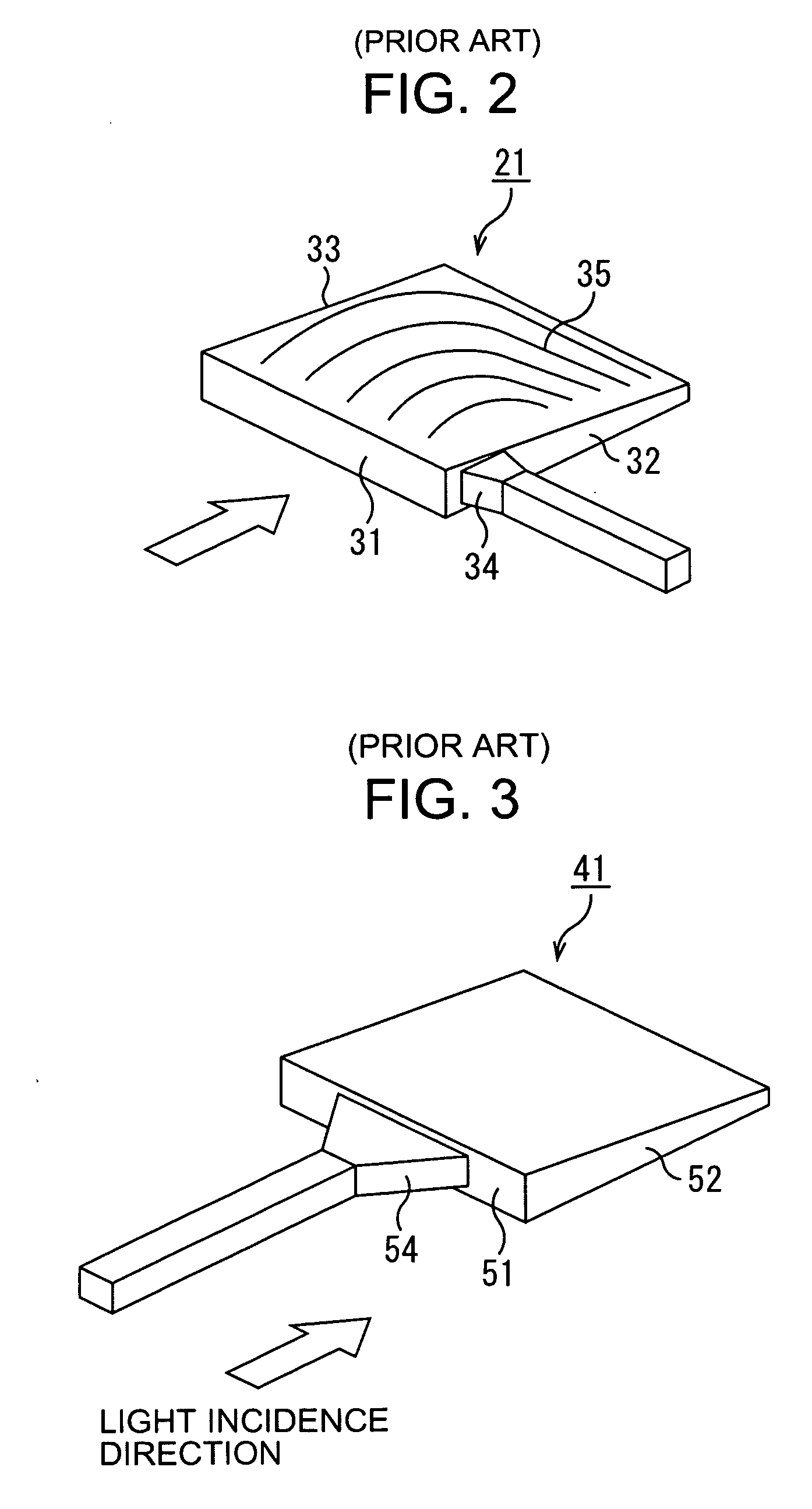

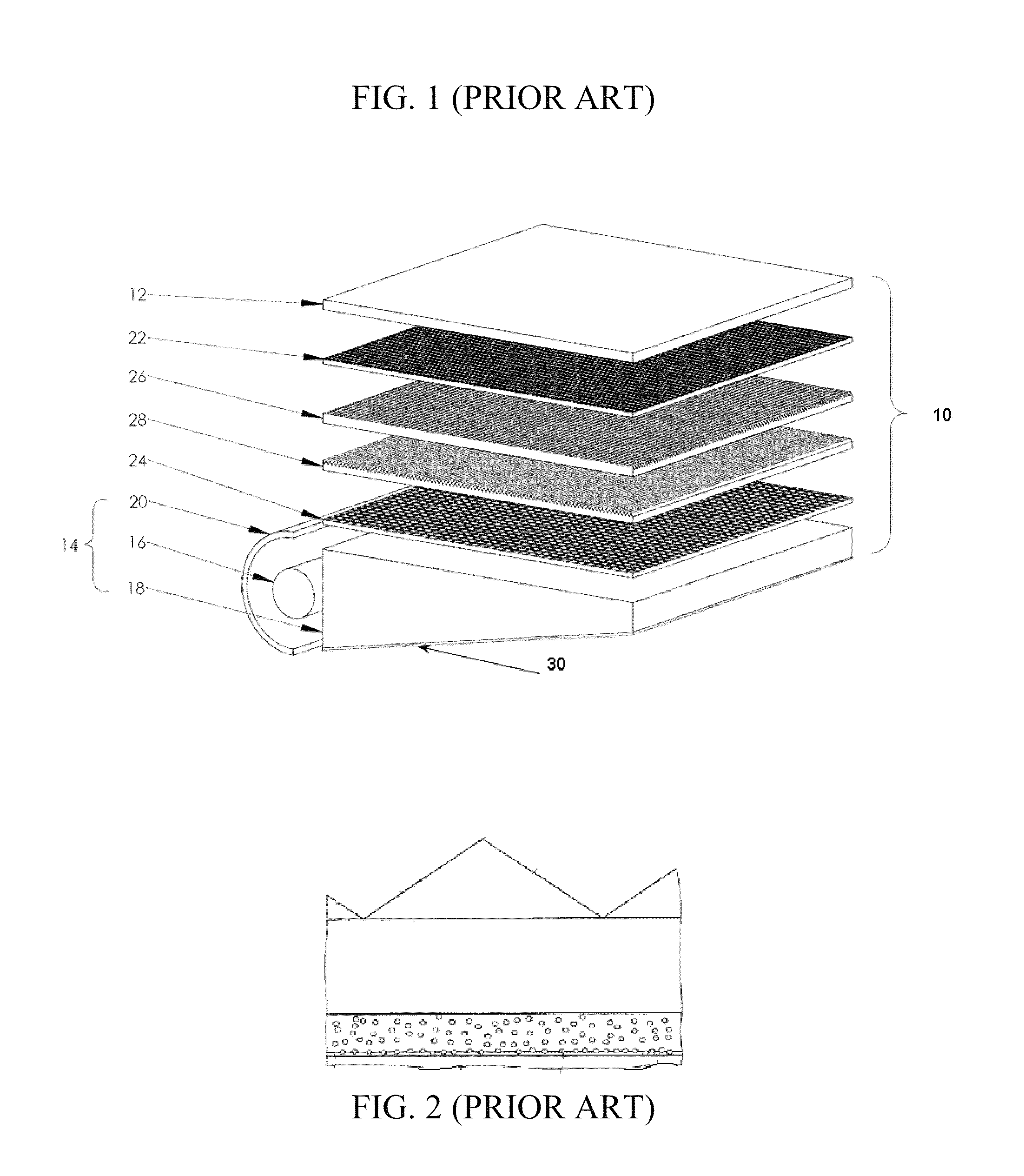

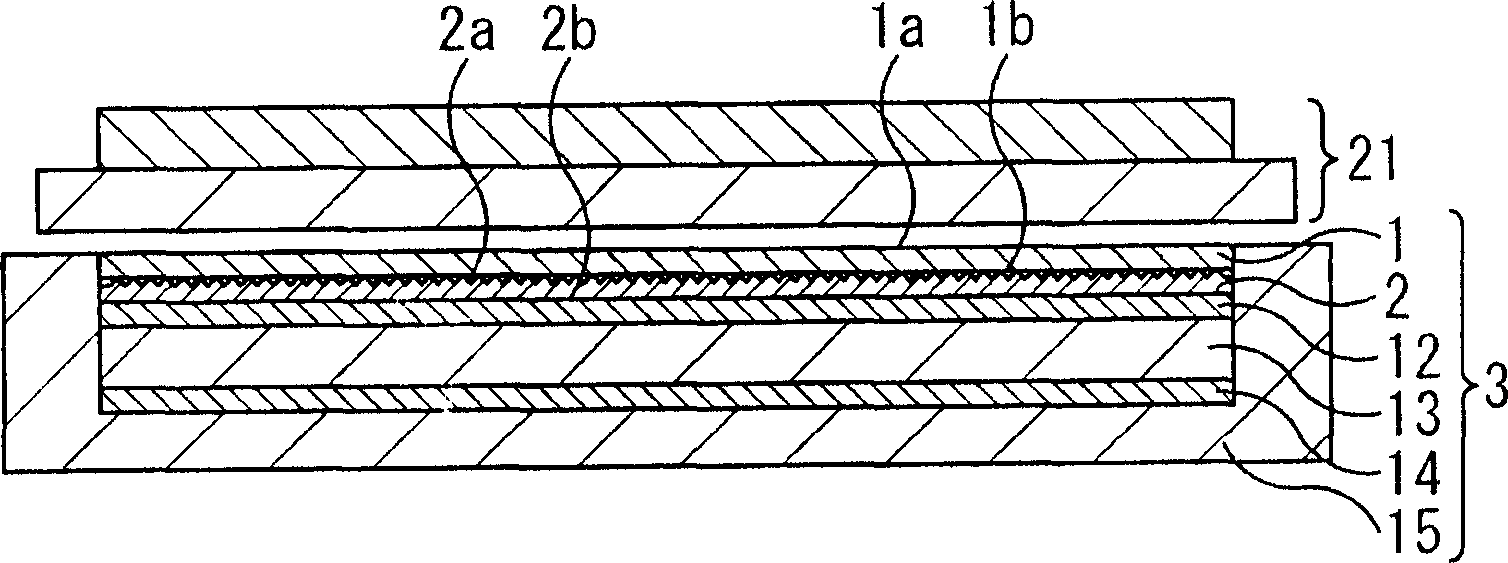

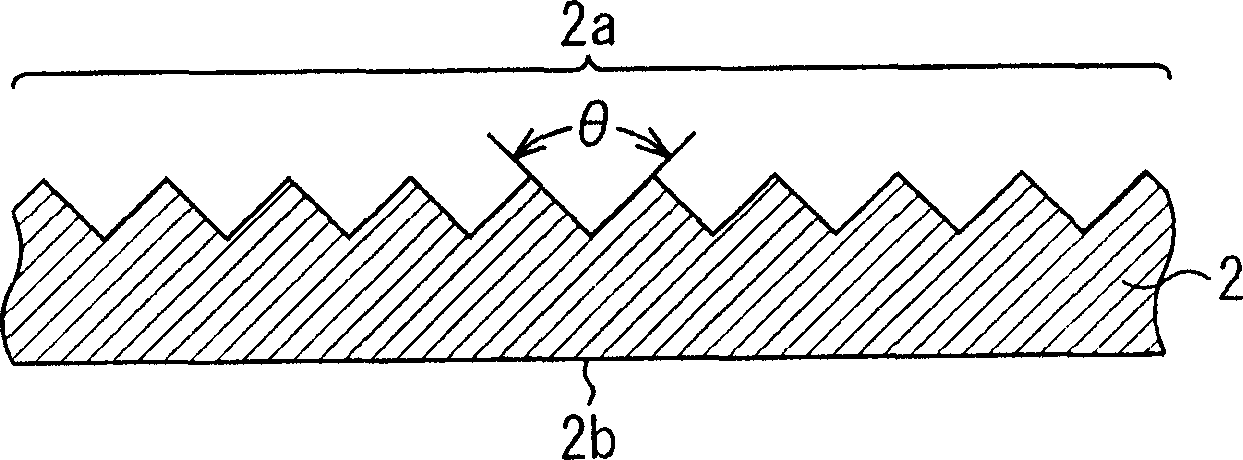

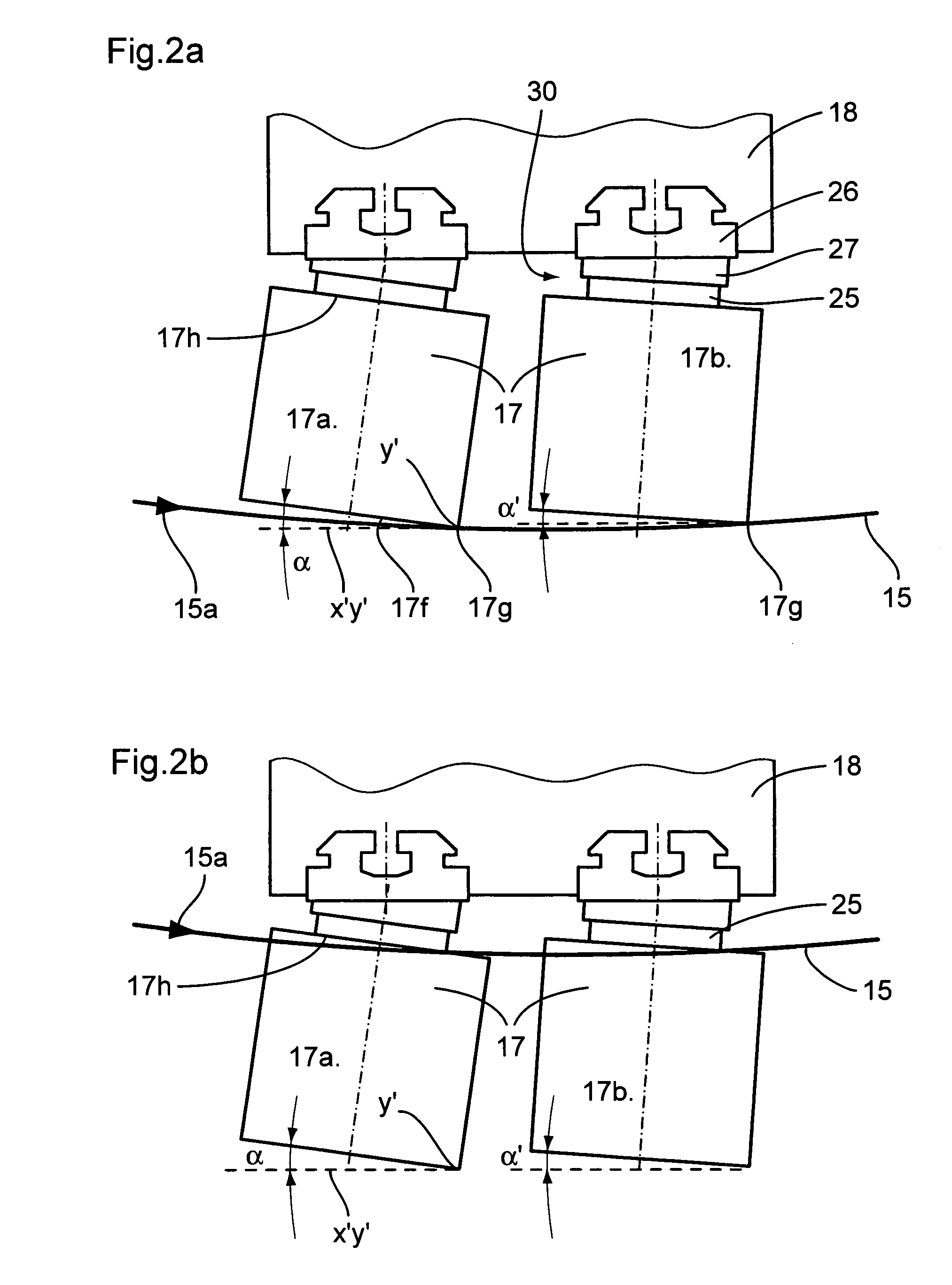

Back light, light guiding plate, method for manufacturing diffusion plate and light guiding plate, and liquid crystal display device

InactiveUS20060268568A1Reduce the number of partsEasy to manufactureShow cabinetsMechanical apparatusDiffusionControl layer

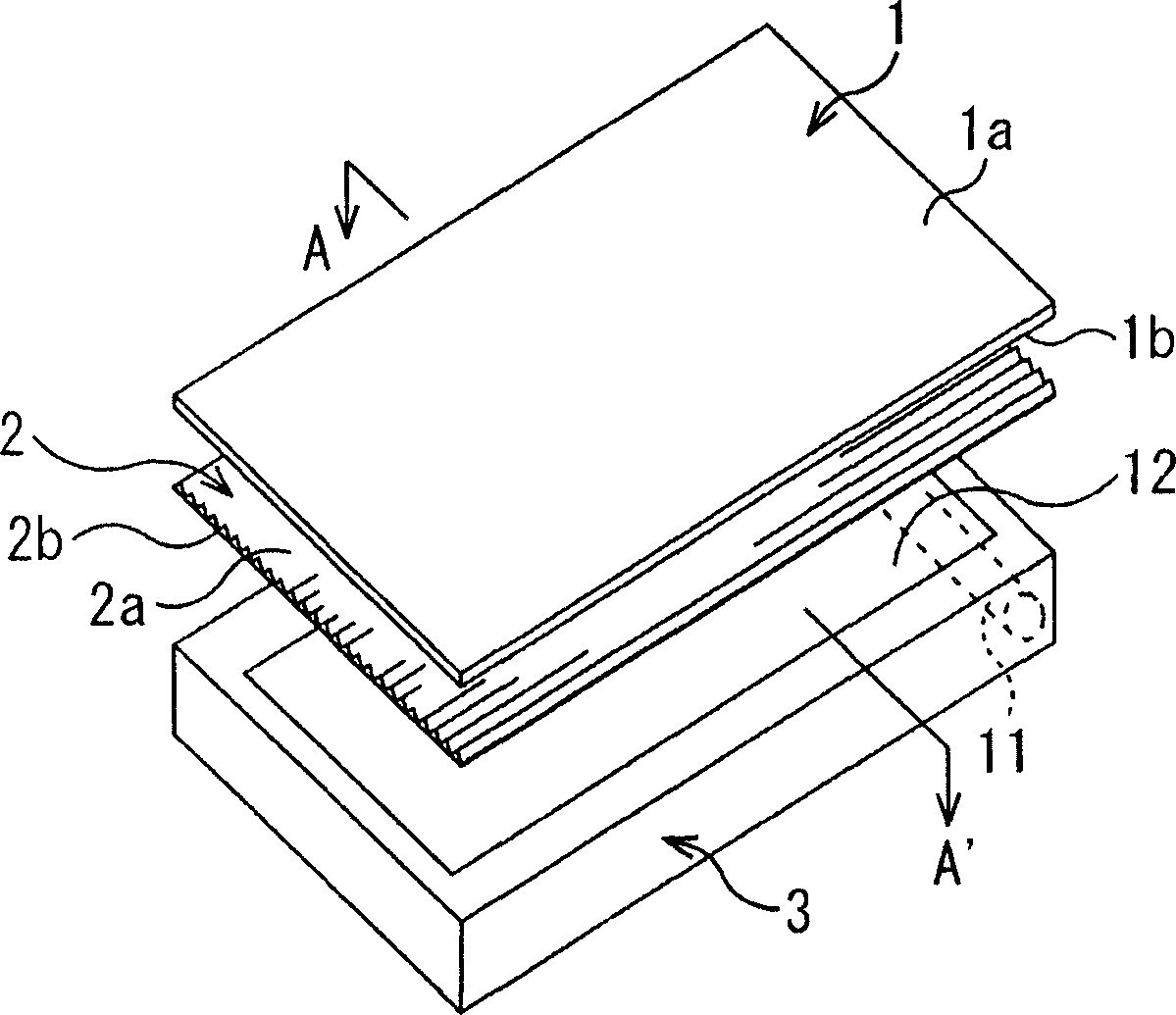

The present invention relates to a backlight and a light guide plate, a method of manufacturing a diffuser and the light guide plate, and to a liquid crystal display apparatus, all enabling a cost reduction by reducing the parts count and curtailing unnecessary manufacturing processing. A diffuser 261 has a light distribution layer 181 including a prismatic surface wherein stripe grooves or asperities are arrayed in parallel with each other, a diffusion layer 182 containing diffusion elements 191 for diffusing incident light, and a light incidence control layer 271 including a prismatic surface wherein stripe grooves or asperities are arrayed in parallel on a side of fluorescent tubes 131. The diffusion layer 182 is formed from the same resin, and only the diffusion elements 191 are formed from a different resin. The prism of the light incidence control layer 271 is optimized so as to enhance the proportion, to light being reflected without entering the light incidence control layer 271, of light re-entering other parts of a surface of the light incidence control layer 271, in order to guide incident light toward the diffusion layer 182 efficiently. The present invention is applicable to a backlight of a liquid crystal display apparatus.

Owner:SONY CORP

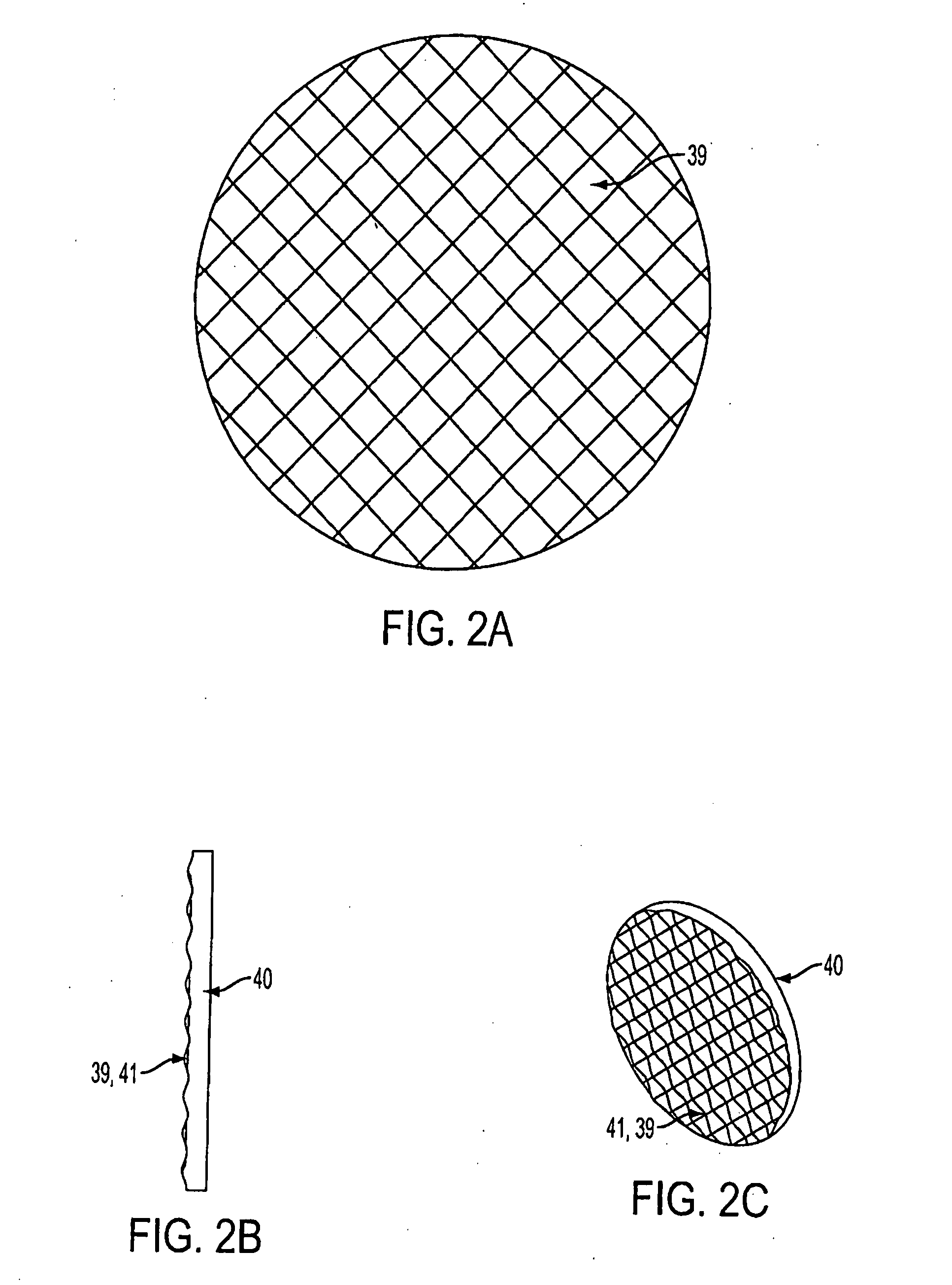

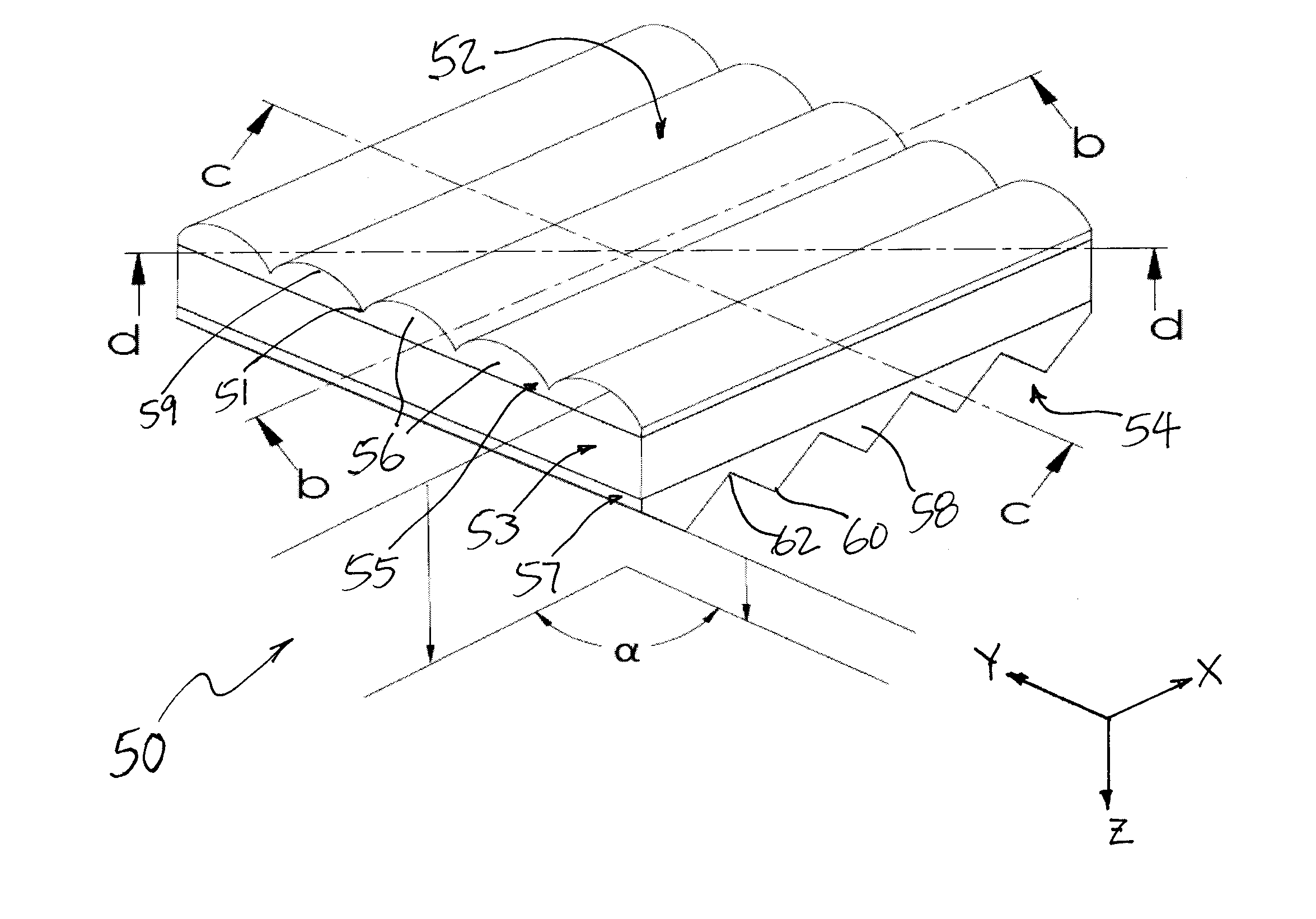

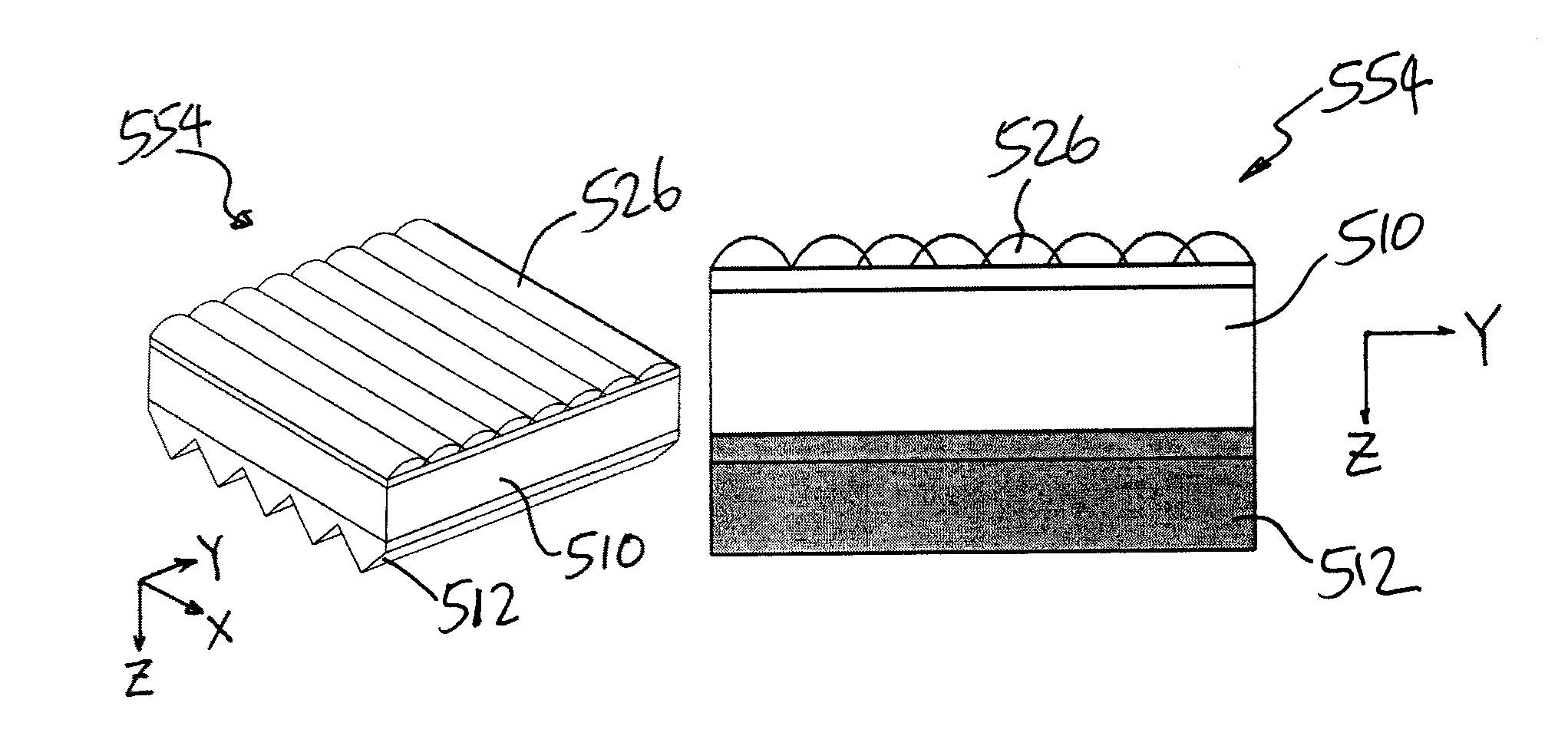

Optical substrates having light collimating and diffusion structures

ActiveUS20110234580A1Reduce certain undesired optical effectReduce brightnessOptical articlesPlanar/plate-like light guidesDiffusionPrism

An optical substrate having a structured prismatic surface and an opposing structured lenticular surface. The structured lenticular surface includes shallow-curved lens structures. Adjacent shallow-curved lens structure may be continuous or contiguous, or separated by a constant or variable spacing. The lens structure may have a longitudinal structure with a uniform or varying cross section. The lenticular lenses may have a laterally meandering structure. Sections of adjacent straight or meandering lenticular lenses may intersect or partially or completely overlap each other. The lenticular lenses may be in the form of discontinuous lenticular segments. The lenticular segments may have regular, symmetrical shapes, or irregular, asymmetrical shapes, which may be intersecting or overlapping, and may be textured. The lens structure may be provided with isolated ripples, in the form of a single knot, or a series of knots.

Owner:UBRIGHT OPTRONICS CORP

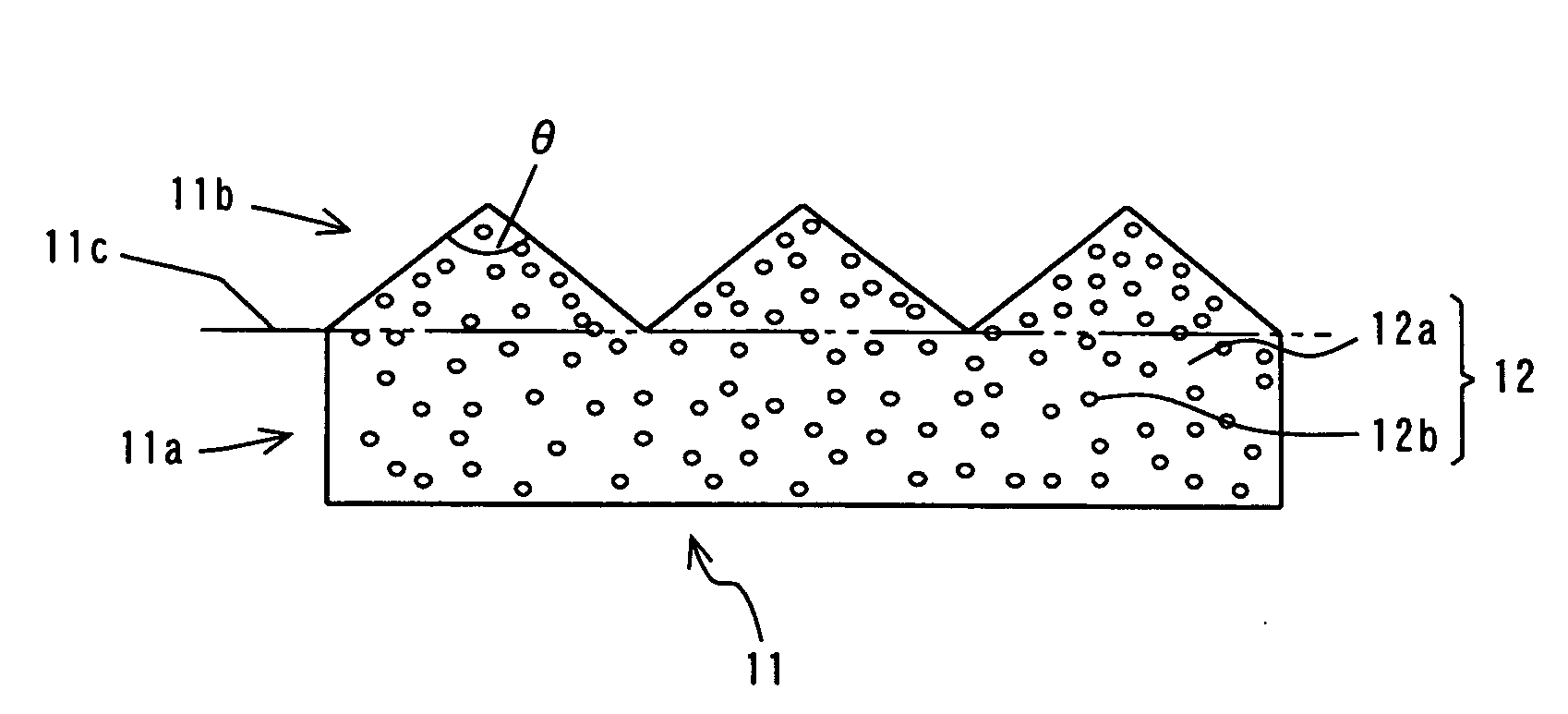

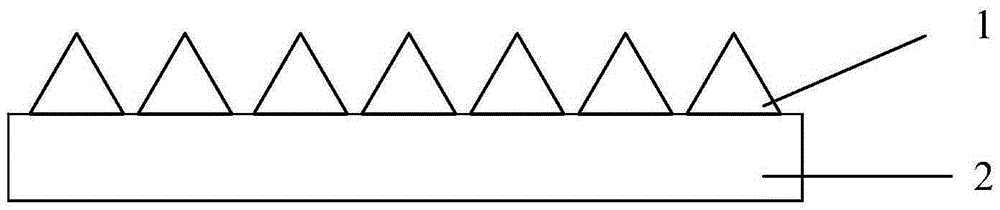

Optical sheet

InactiveUS20080310171A1Increase brightnessAvoid it happening againOptical light guidesRefractorsOptoelectronicsPrism

An optical sheet comprises a continuous phase comprising a transparent material and a dispersed phase dispersed in the continuous phase, and has a first surface and a second surface. At least one of the first surface and the second surface forms a prismatic surface of a prism portion constituting portion of the sheet, and the prism portion has a plurality of prism units, each having a triangular cross-section, formed regularly in a longitudinal and / or width direction of the sheet.

Owner:DAICEL CHEM IND LTD

Light fixture and lens assembly for same

ActiveUS20050281024A1Effective distributionGood lookingNon-electric lightingLight source combinationsOptoelectronicsPrism

A light fixture or troffer for directing light emitted from a light source toward an area to be illuminated, including a reflector assembly within which the light source is positioned and a lens assembly detachably secured to a portion of the reflector assembly such that a lens of the lens assembly overlies the light source and such that substantially all of the light emitted from the light source passes through the lens assembly. In one example, the lens includes a curved prismatic surface that can be oriented toward or away from the underlying light source.

Owner:ABL IP HLDG

Prismatic light-guide plate and illumination device that enable the provision of good-quality planar light source

InactiveUS20070230216A1Little deterioration in brightnessHigh densityDiffusing elementsOptical light guidesHigh densityLight guide

A prismatic light-guide plate has a prismatic surface, which is provided with a plurality of prisms that reflect light that is incident from a light-incident end thereof, and an emission surface opposite to the prismatic surface, which completely reflects the light that is incident thereto to propagate the same, and which also emits emitted light that is reflected from the prisms. The prismatic light-guide plate has scattering portions provided in a region of the emission surface that emits the emitted light at a high density, for scattering the emitted light and broadening an angle of view of light.

Owner:FUJITSU LTD

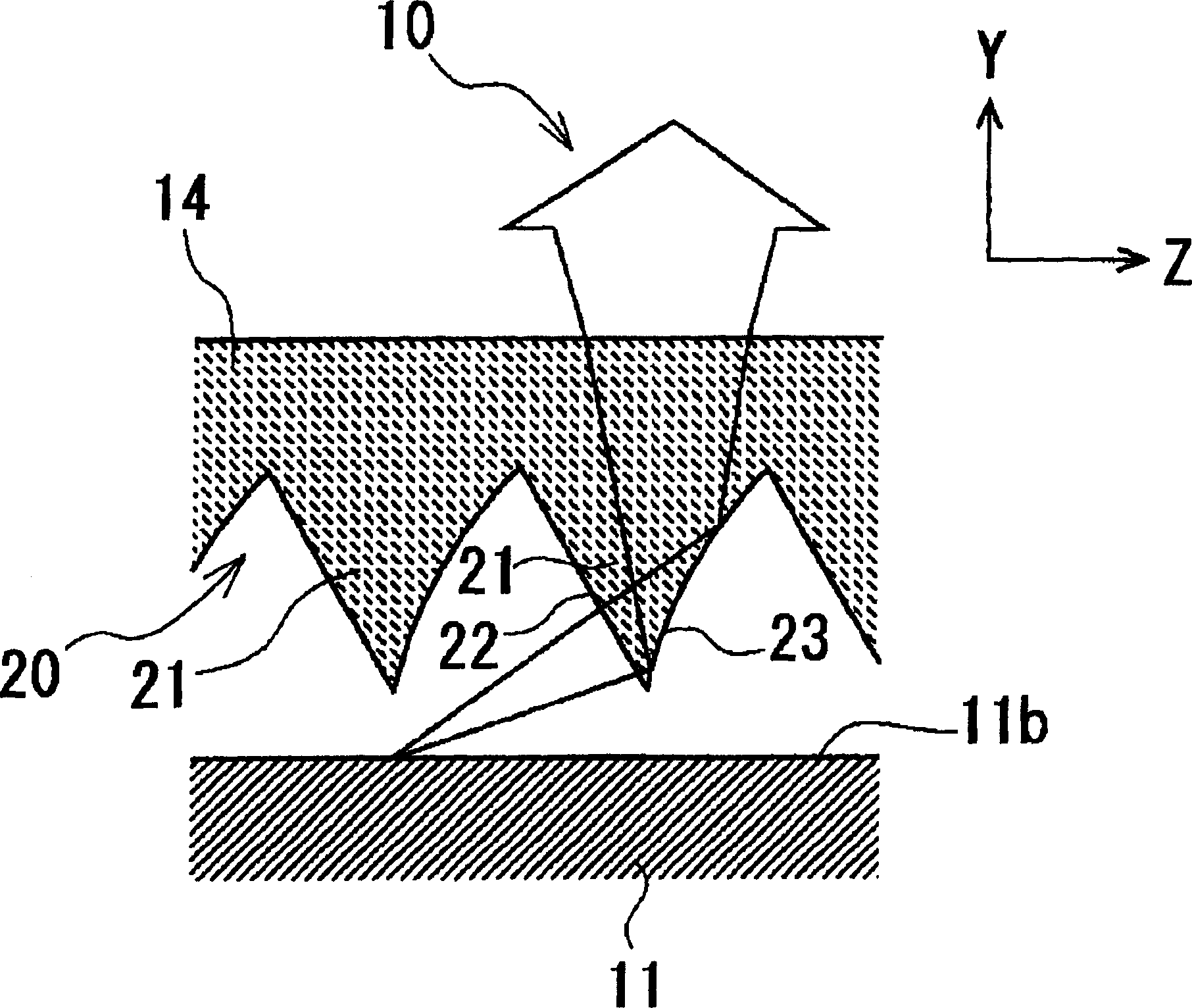

Hollow surface illuminator

InactiveUS6809892B2Reduce the weight of the unitReduce weightPrismsMechanical apparatusEngineeringPrism

A light-conducting unit which can effectively balance the light-leaking effect and the light-propagation effect of the prismatic films forming the light-conducting space, and satisfy the requirements to reduce the weight of the unit is disclosed. A light-conducting unit comprising the first prismatic film and the second prismatic film, each having two major surfaces, one of which is a prismatic surface, and the other of which is a flat surface, said prismatic surface carrying prisms arranged substantially parallel to each other, wherein said two prismatic films are arranged so that the first edges of said prismatic films are positioned to form an opening, a light-conducting space is formed between said prismatic films, and the height of said light-conducting space does not substantially increase from said opening to the remote edges of the prismatic films opposing said opening, and the major surface of said first prismatic film which faces outside said light-conducting space is a light-emitting surface, and the arrangement of the both prismatic films and the directions of the prisms of the both prismatic films in relation to the incident direction of light are defined under the specific conditions.

Owner:3M INNOVATIVE PROPERTIES CO

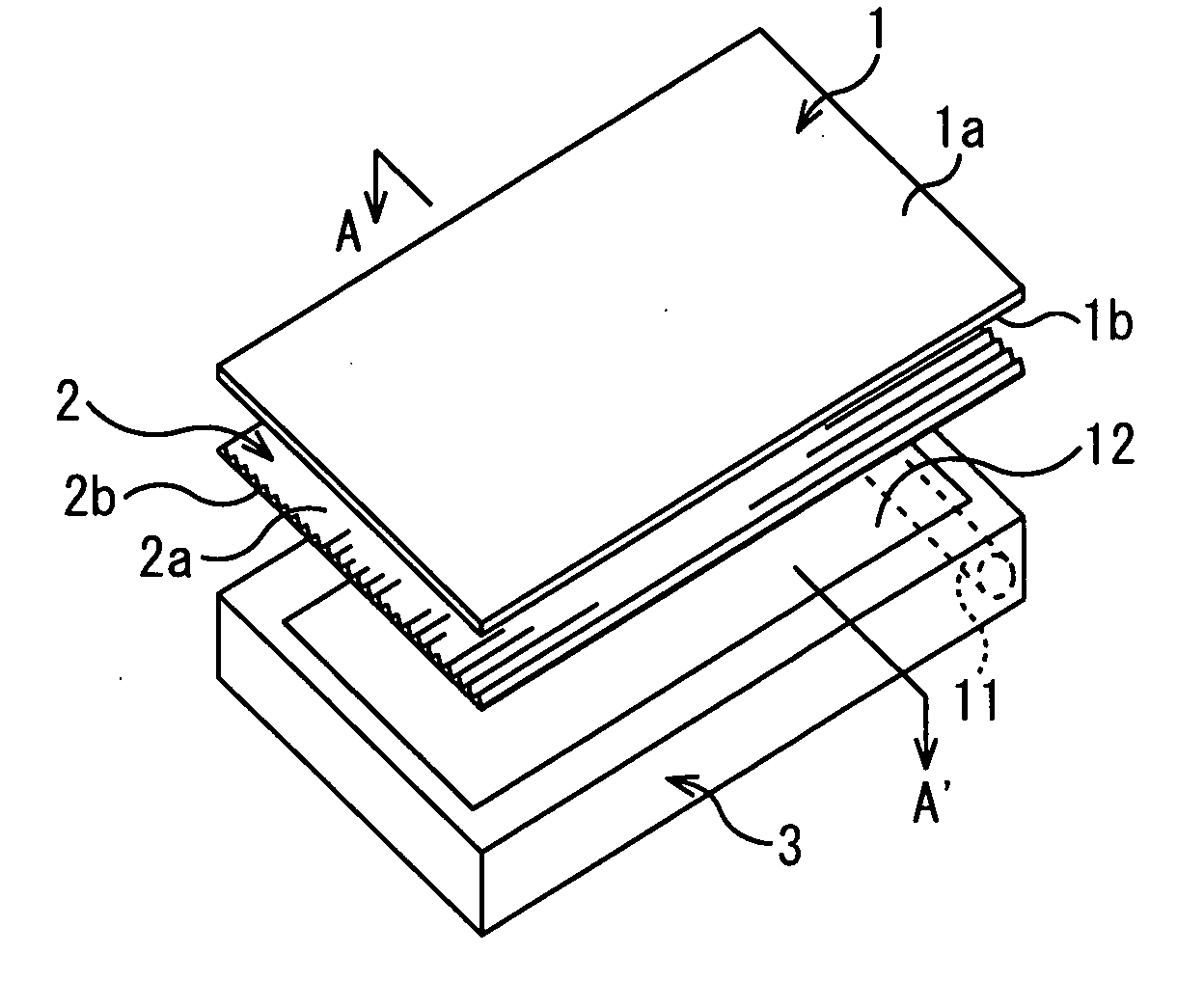

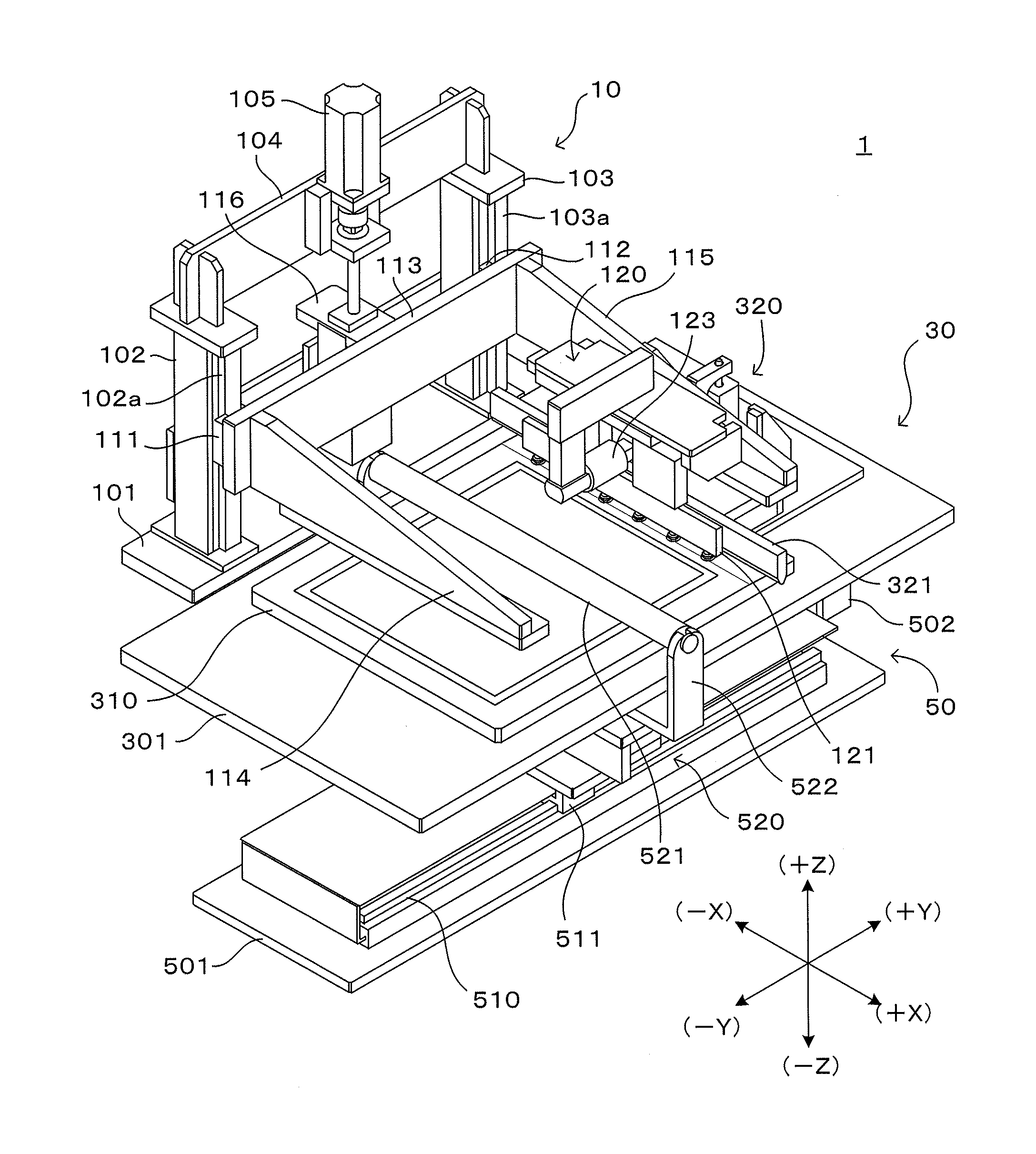

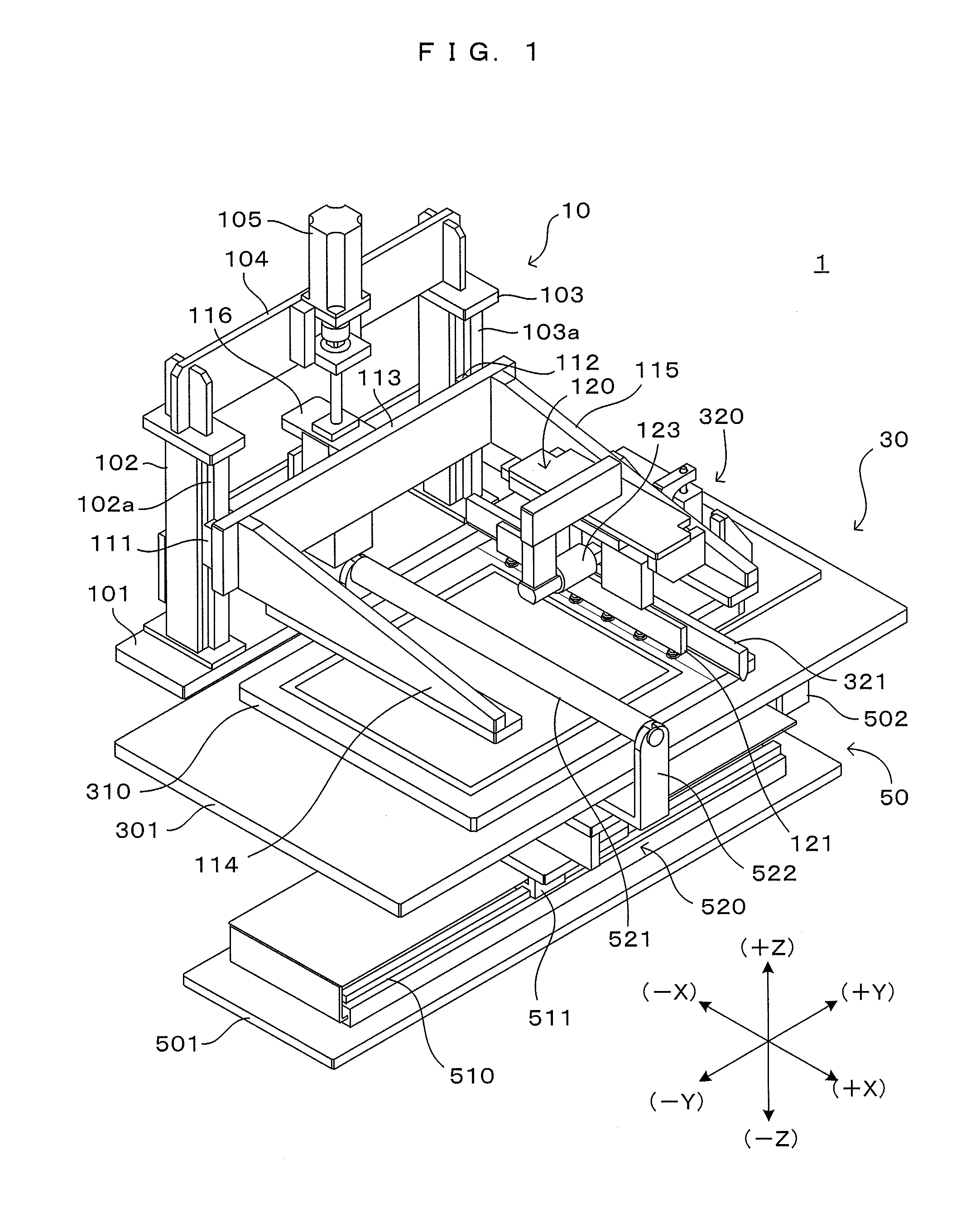

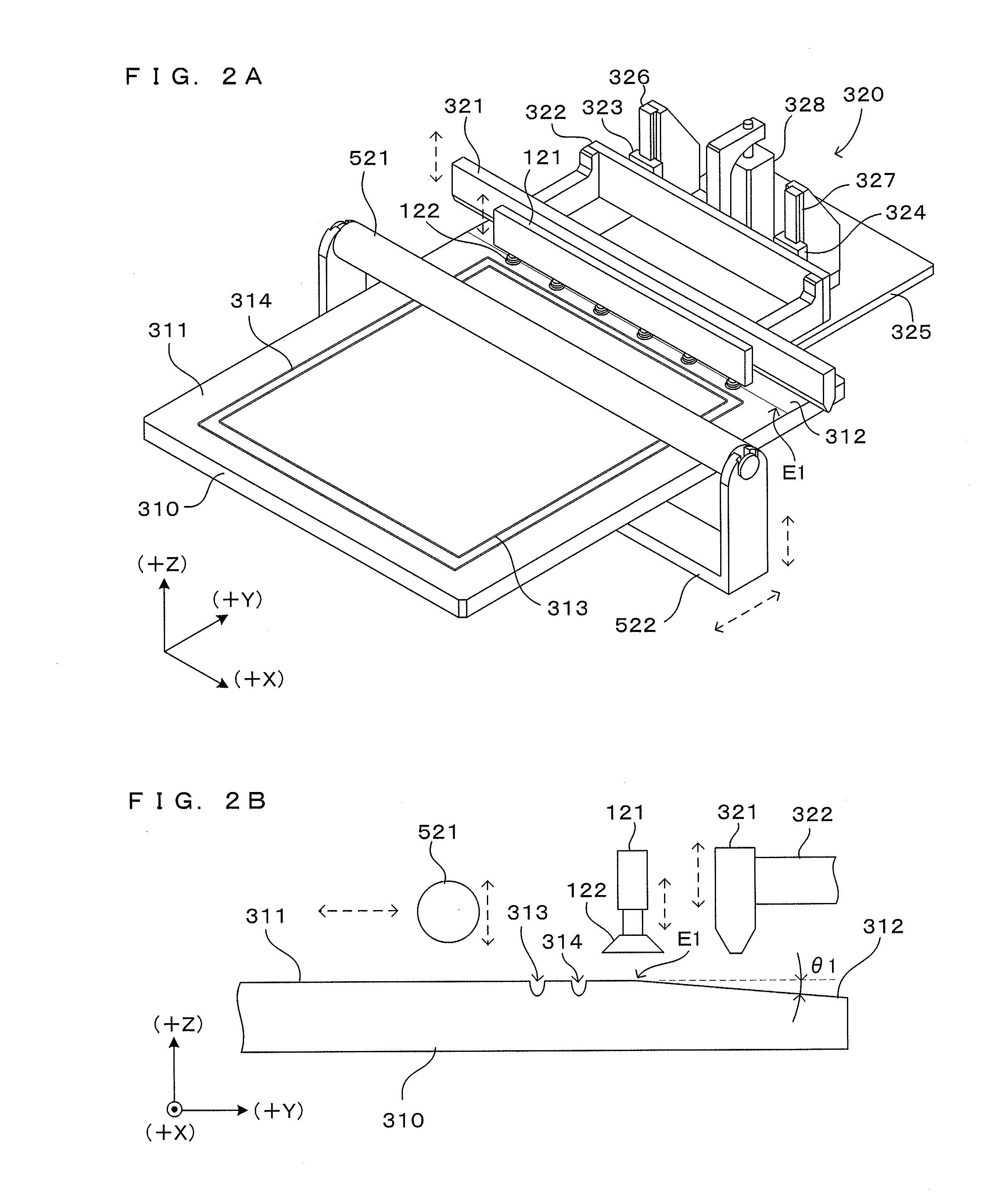

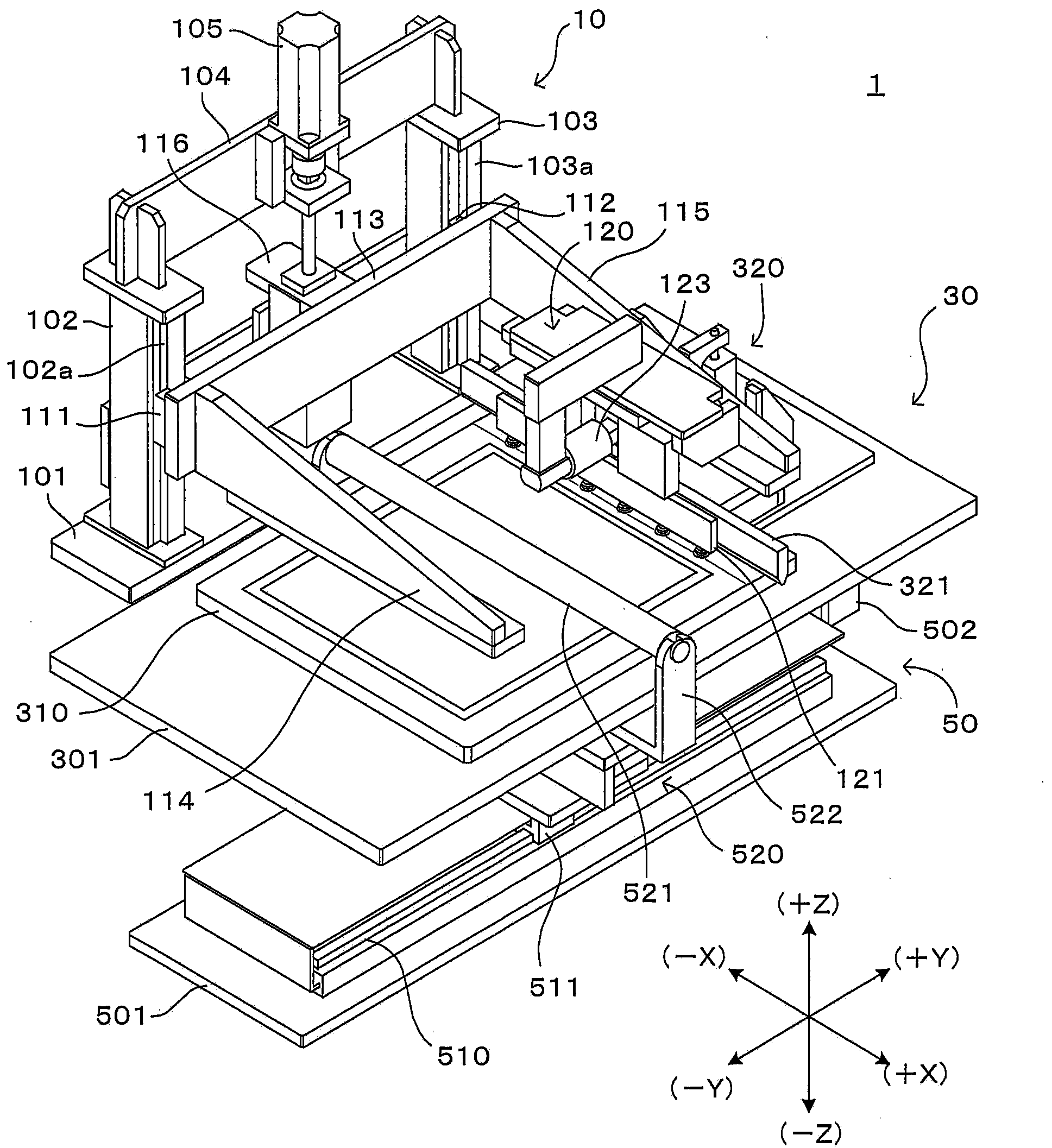

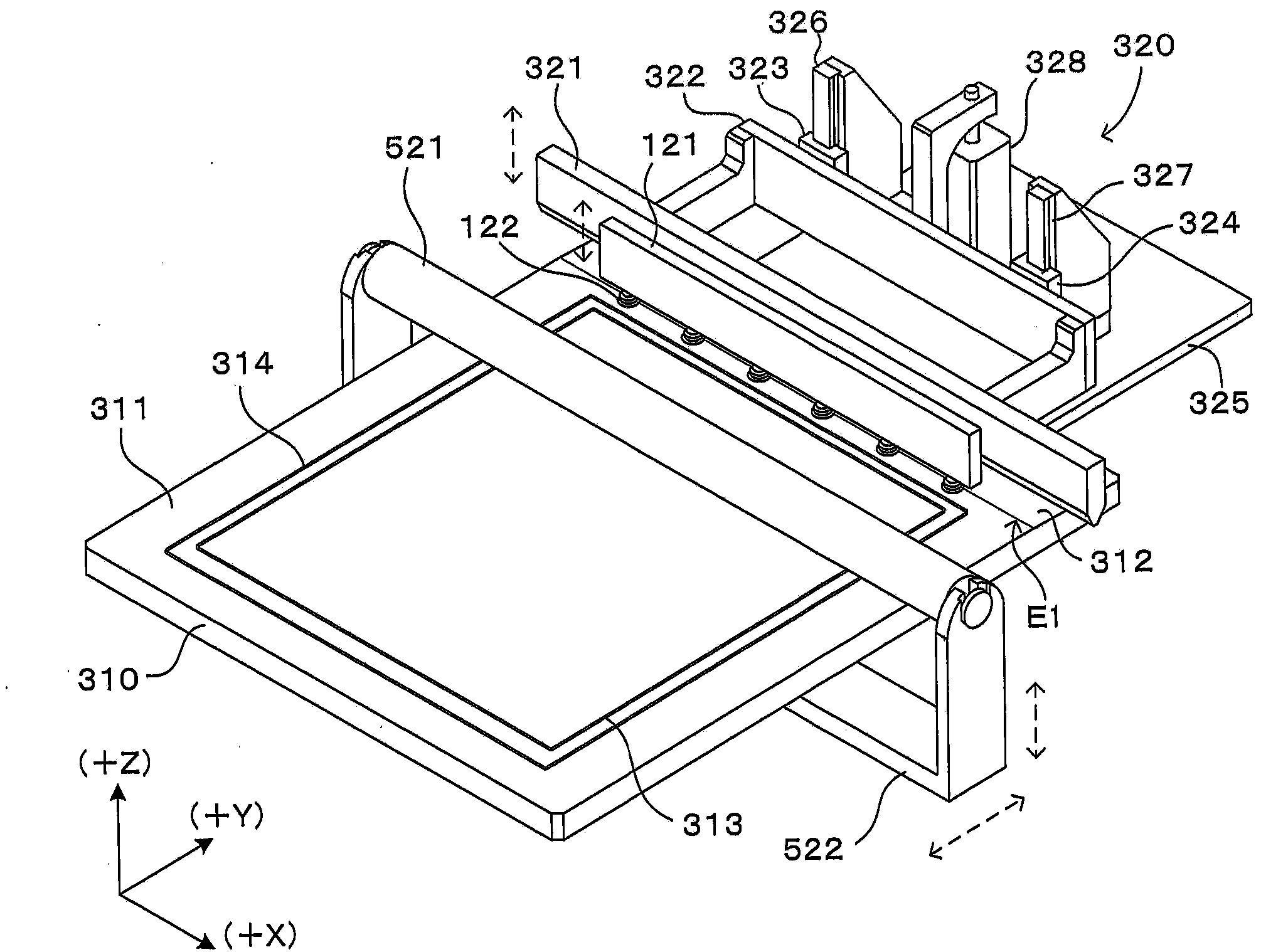

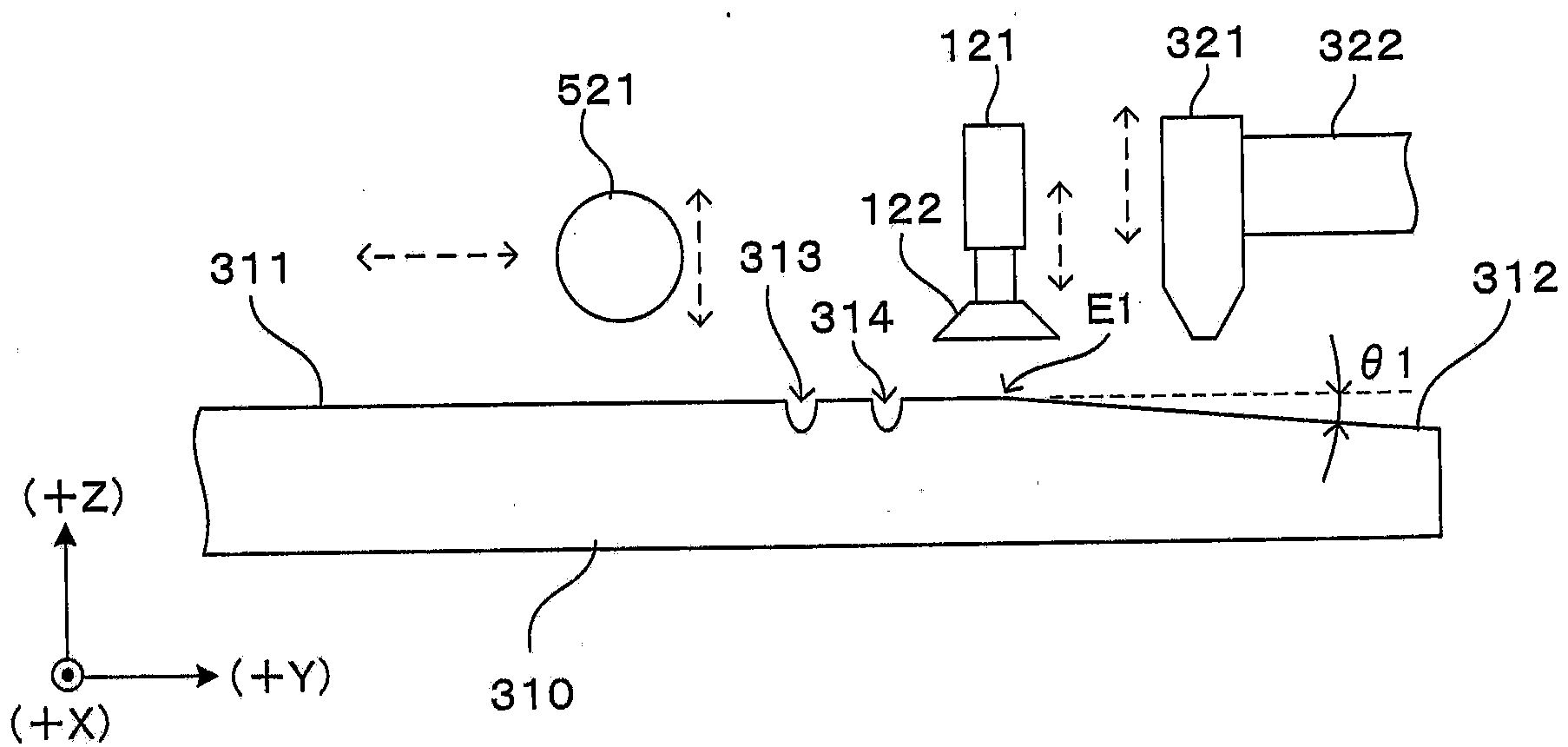

Detaching apparatus and detaching method

InactiveUS20140209250A1Avoid damageChange speedLayered productsLaminationEngineeringMechanical engineering

In a detaching apparatus, a detachment starter bends one end part of a first plate-like body into a cylindrical or prismatic surface in a direction opposite to a second plate-like body, thereby forming a single and straight boundary line between an adhering region and a detached region. A separator increases a distance between a first holder holding the first plate-like body and a second holder holding the second plate-like body to separate the first and second plate-like bodies.

Owner:DAINIPPON SCREEN MTG CO LTD

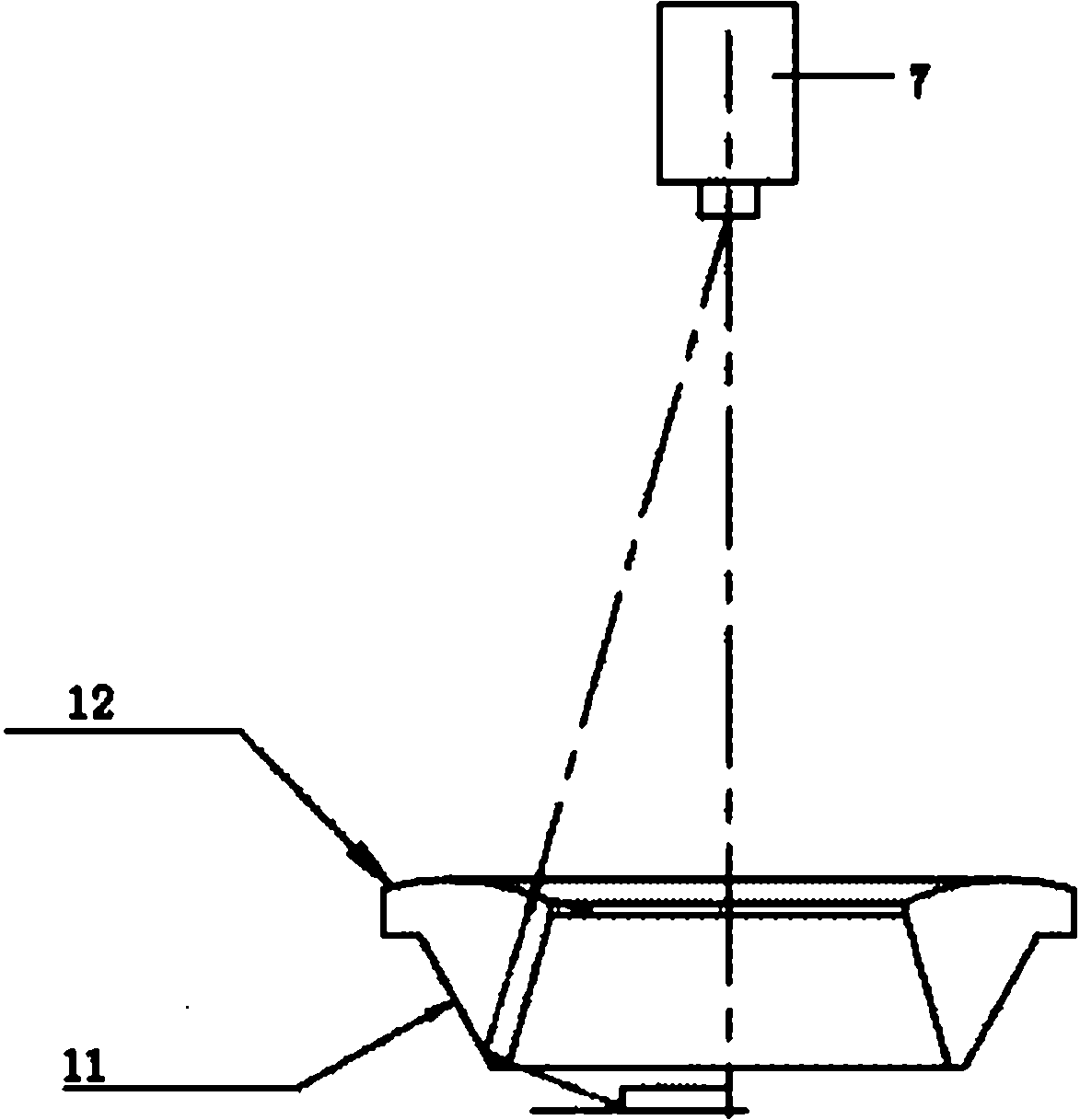

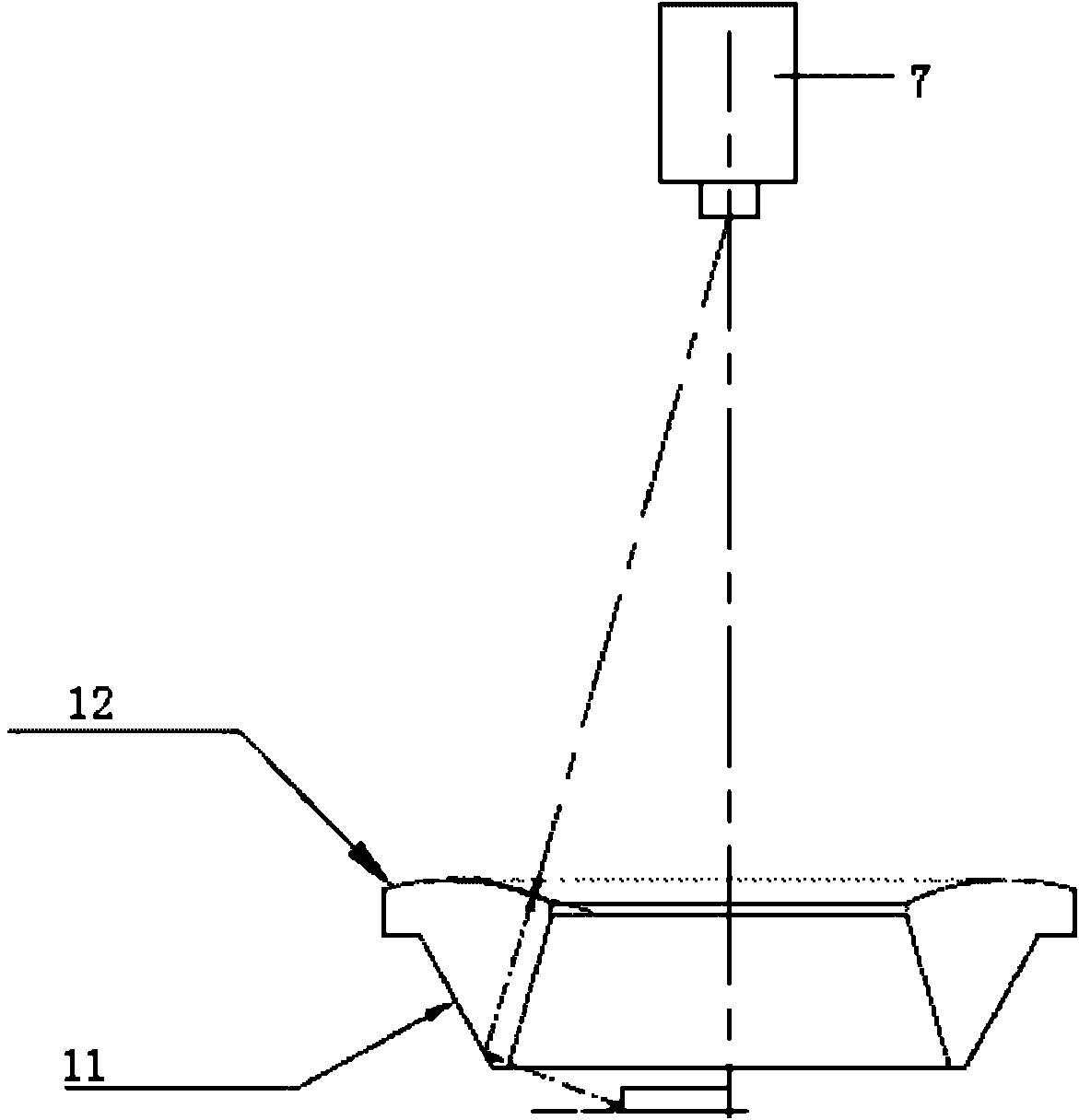

Reflective amplified type coin detection device

The invention provides a reflective amplified type coin detection device, comprising an annular refracting prism, an annular convex lens and a camera. The upper circumference of the annular refracting prism is larger than the lower circumference of the annular refracting prism; prismatic surfaces are the corresponding slopes to form an inclined annular shape with big top part and small bottom part; the annular convex lens is arranged along the upper circumference of the annular refracting prism; lens surfaces of the annular convex lens face to the prismatic surfaces of the annular refracting prism; the coin is arranged at the center below the annular refracting prism; a side image of the coin is refracted to the annular convex lens via the prismatic surface of the annular refracting prismand zoomed; the camera is vertically arranged above the center of the annular convex lens and is positioned above the coin to shoot the image zoomed by the annular convex lens; and the annular refracting prism and the annular convex lens are compounded into a composite annular prism. The coin detection device has simple structure; an image collecting system consisting of the prism, the convex lens and the camera has high image forming precision and good definition; and the rolled words on the edge of the coin can be detected by shooting the image by the camera; and the detection is convenientand quick.

Owner:江苏科思机电工程有限公司

Optical element and light source comprising the same

ActiveUS8602621B2Low costEasy to manufacturePoint-like light sourceLight guides detailsLight guidePrism

The present invention relates to an optical element including a light guide, into which light from one or more light-emitting diodes in a light unit arranged at one end of the light guide is injected, and a reflector arranged at the other end of the light guide capable of reflecting light incident on the reflector. The light guide further includes a prismatic surface comprising a plurality of prisms, each prism being arranged at an angle to an axial direction of the light guide, for guiding the light emitted from the light unit towards the output end of the light guide. The present invention also relates to a light source including an optical element according to the present invention, the light source being arranged for retrofitting into a luminaire employing an incandescent light source.

Owner:KONINK PHILIPS ELECTRONICS NV

Backlight and light guide plate, method of manufacturing diffuser and light guide plate, and liquid crystal display apparatus

Owner:SONY CORP

Detaching apparatus and detaching method

ActiveCN103963421ASuppression offsetEfficient strippingLamination ancillary operationsLaminationEngineeringMechanical engineering

Owner:DAINIPPON SCREEN MTG CO LTD

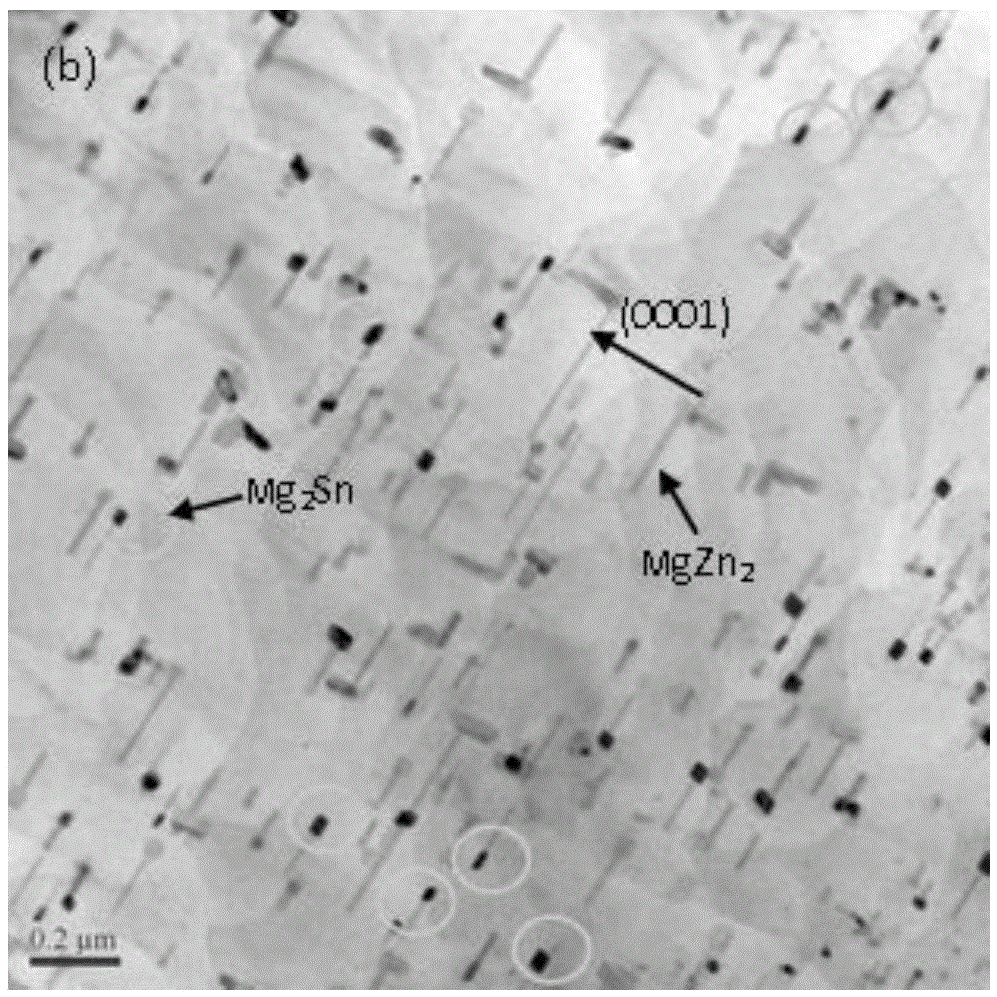

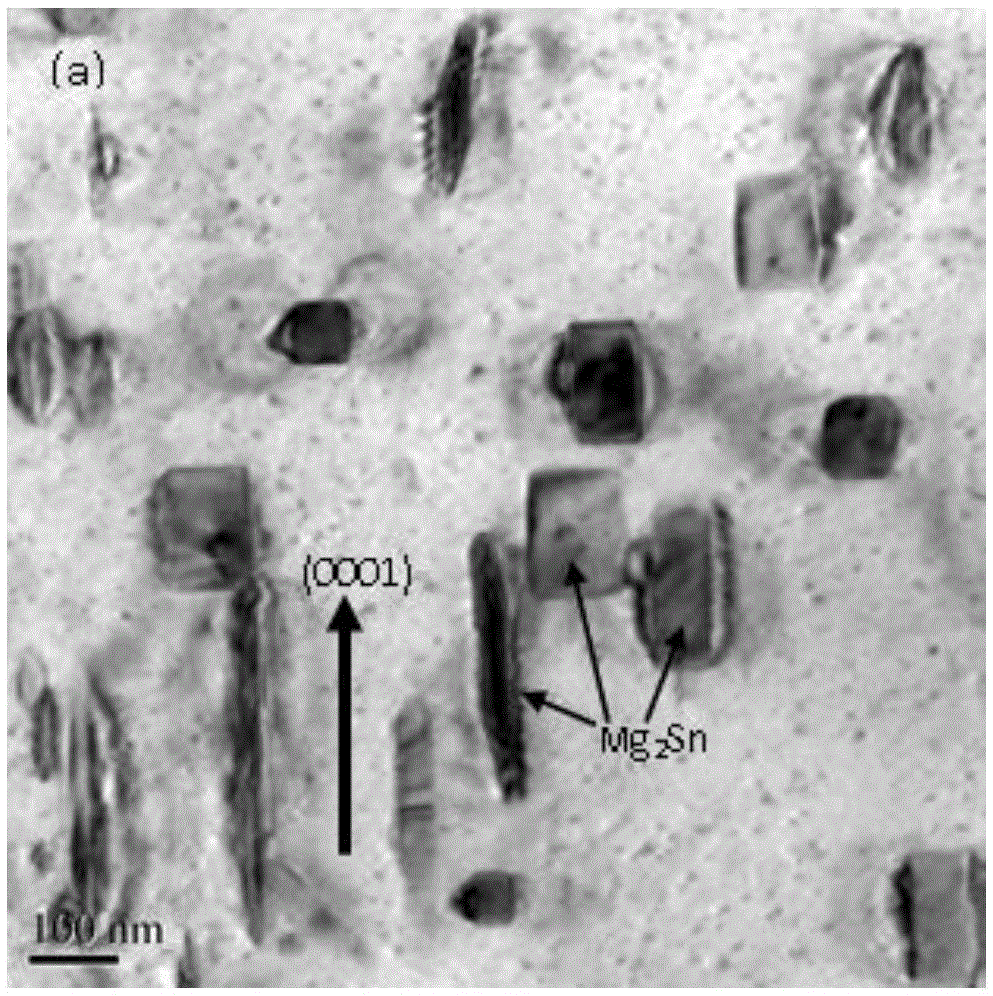

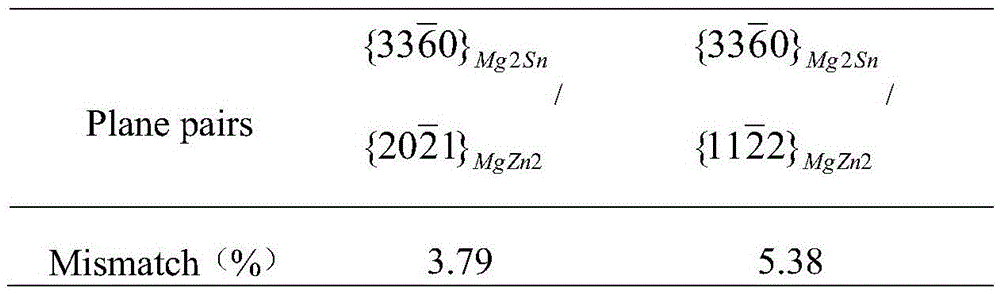

High-strength magnesium alloy and method for preparing high-strength magnesium alloy by inducing orientation of precipitated phase to change

The invention discloses high-strength magnesium alloy. The high-strength magnesium alloy is prepared from, by weight, 2.0%-5.0% of tin, 0.5%-5.0% of zinc, 0-0.15% of inevitable impurities and the balance magnesium. The high-strength magnesium alloy has the Mg2Sn precipitated phase which is precipitated along the conical surface or the prismatic surface of the magnesium. A method for preparing the high-strength magnesium alloy by inducing the orientation of the precipitated phase to change comprises the following steps that a, smelting is conducted; b, alloy is homogenized; and C, heat treatment is conducted on an extruded bar. According to the method for preparing the high-strength magnesium alloy by inducing the orientation of the precipitated phase to change, the high-strength magnesium alloy is prepared by adding the alloy element Zn for achieving aging precipitation of MgZn2 in advance, the Mg2Sn precipitated phase is not completely parallel to the base plane any more, and a second phase which is precipitated along the conical surface or the prismatic surface of the magnesium is obtained, so that the orientation relationship between the Mg2Sn precipitated phase and a magnesium matrix is changed, and the strength of the magnesium alloy is improved.

Owner:CHONGQING ACADEMY OF SCI & TECH

Optical substrates having light collimating and diffusion structures

ActiveUS8638408B2Increase brightnessImprove luminanceOptical articlesPlanar/plate-like light guidesDiffusionPrism

An optical substrate having a structured prismatic surface and an opposing structured lenticular surface. The structured lenticular surface includes shallow-curved lens structures. Adjacent shallow-curved lens structure may be continuous or contiguous, or separated by a constant or variable spacing. The lens structure may have a longitudinal structure with a uniform or varying cross section. The lenticular lenses may have a laterally meandering structure. Sections of adjacent straight or meandering lenticular lenses may intersect or partially or completely overlap each other. The lenticular lenses may be in the form of discontinuous lenticular segments. The lenticular segments may have regular, symmetrical shapes, or irregular, asymmetrical shapes, which may be intersecting or overlapping, and may be textured. The lens structure may be provided with isolated ripples, in the form of a single knot, or a series of knots.

Owner:UBRIGHT OPTRONICS CORP

Back light, light guiding plate, method for manufacturing diffusion plate and light guiding plate, and liquid crystal display device

InactiveCN1860405AReduce in quantityMeet the light distribution performanceElongate light sourcesDiffusing elementsDiffusionLiquid-crystal display

The present invention relates to a backlight and a light guide plate, a method of manufacturing a diffuser and the light guide plate, and to a liquid crystal display apparatus, all enabling a cost reduction by reducing the parts count and curtailing unnecessary manufacturing processing. A diffuser 261 has a light distribution layer 181 including a prismatic surface wherein stripe grooves or asperities are arrayed in parallel with each other, a diffusion layer 182 containing diffusion elements 191 for diffusing incident light, and a light incidence control layer 271 including a prismatic surface wherein stripe grooves or asperities are arrayed in parallel on a side of fluorescent tubes 131 . The diffusion layer 182 is formed from the same resin, and only the diffusion elements 191 are formed from a different resin. The prism of the light incidence control layer 271 is optimized so as to enhance the proportion, to light being reflected without entering the light incidence control layer 271 , of light re-entering other parts of a surface of the light incidence control layer 271 , in order to guide incident light toward the diffusion layer 182 efficiently. The present invention is applicable to a backlight of a liquid crystal display apparatus.

Owner:SONY CORP

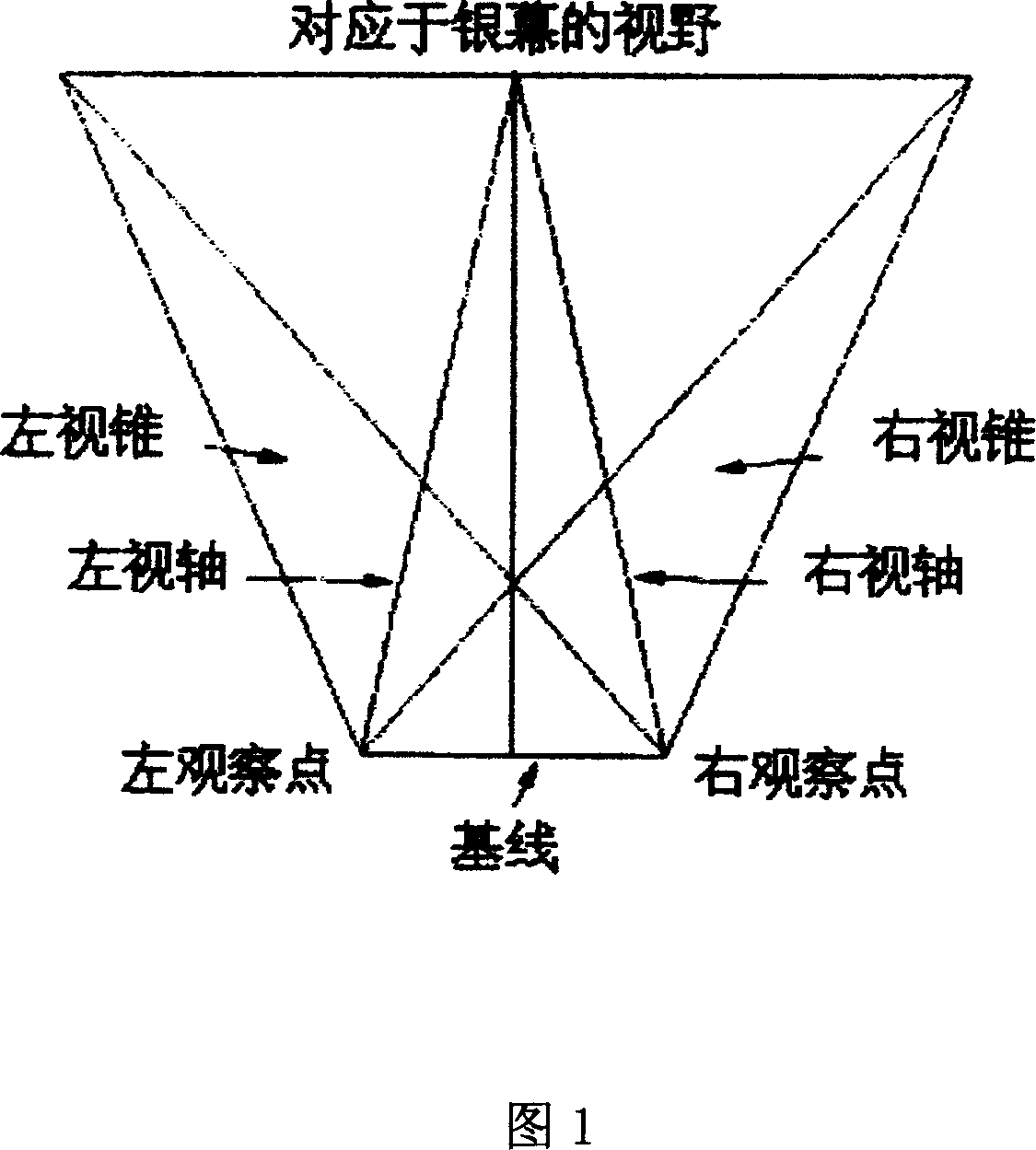

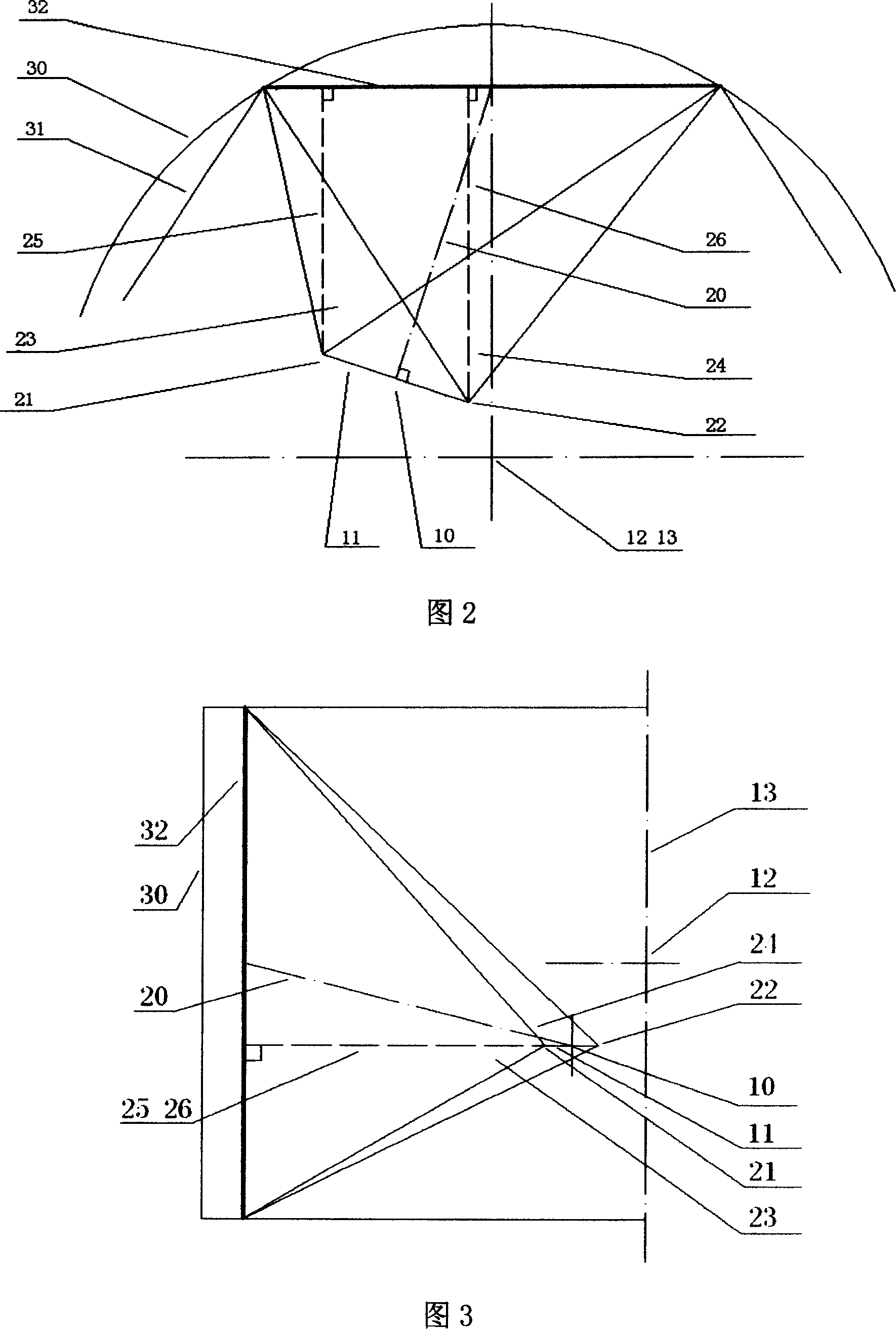

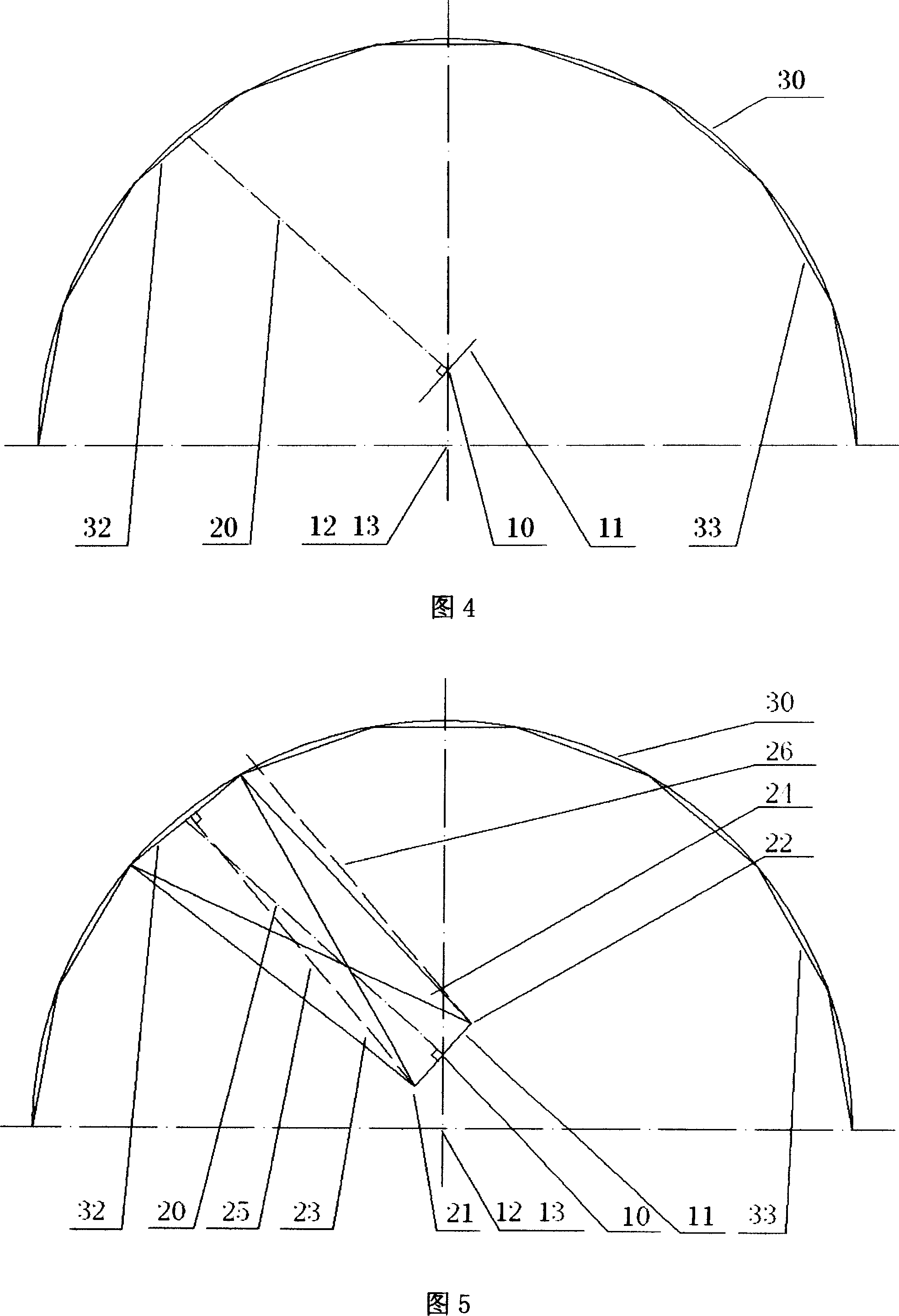

Manufacturing method for 3D cineorama image

InactiveCN101000460AAdapting to changes in the best viewing pointFrequent rotation and positioning operationsAnimationStereoscopic photographyCamera lensParallax

A method for preparing 3D cineorama image of ring screen includes using prismatic surface with N numbers of rectangular surfaces to approximately replace cylindrical surface (CS) in 3-D software, deflecting base point representing optimum viewing point from center of CS and from axle, setting up N pairs of playing up camera lens and using 2XN numbers of camera lens to simultaneously play up each frame in 3-D scene to from CS stereo-image with parallax effect and in corresponding to left and right eyes then forming ring-screen 3D cineorama image with continuous dynamic effect.

Owner:钟明

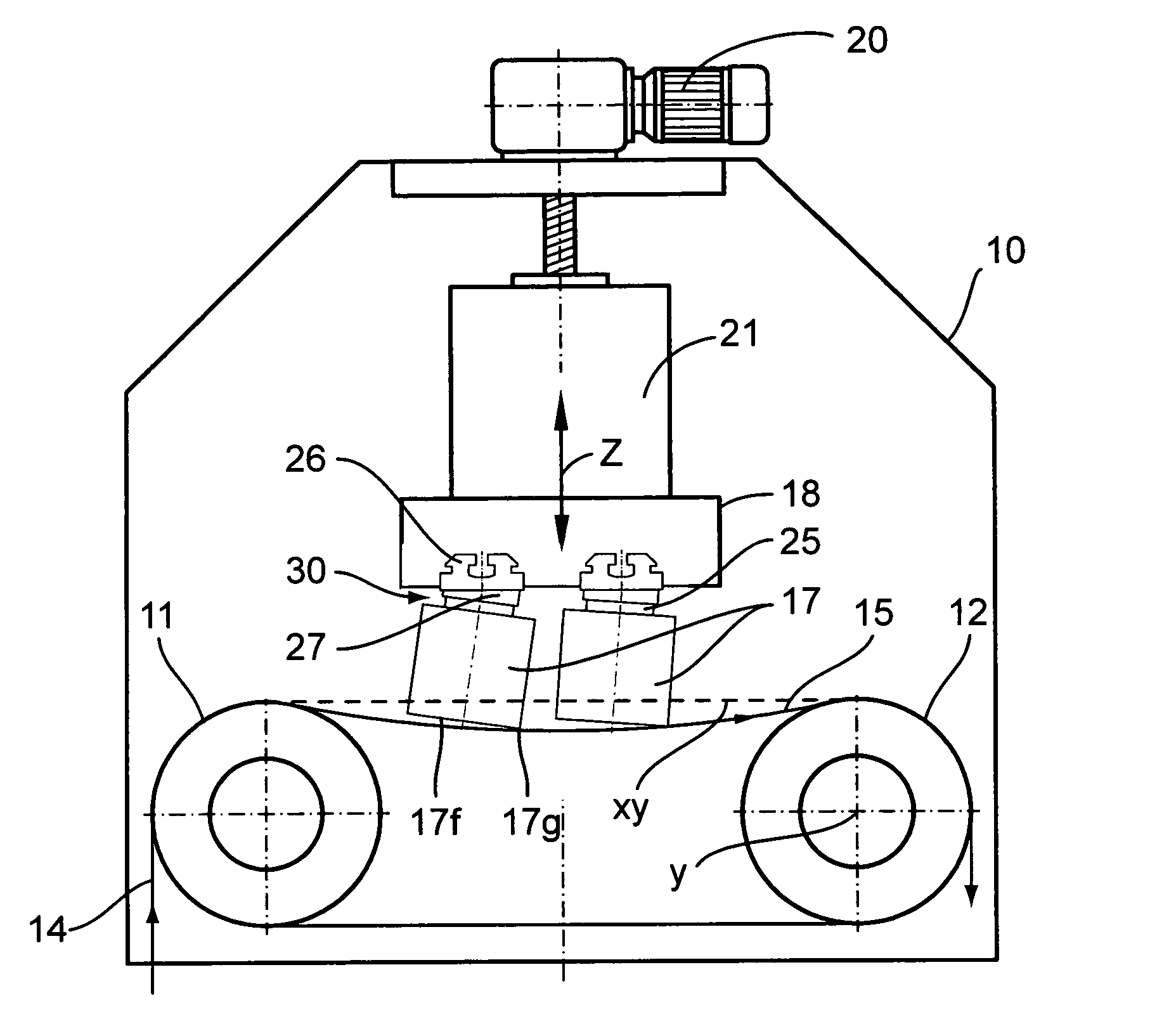

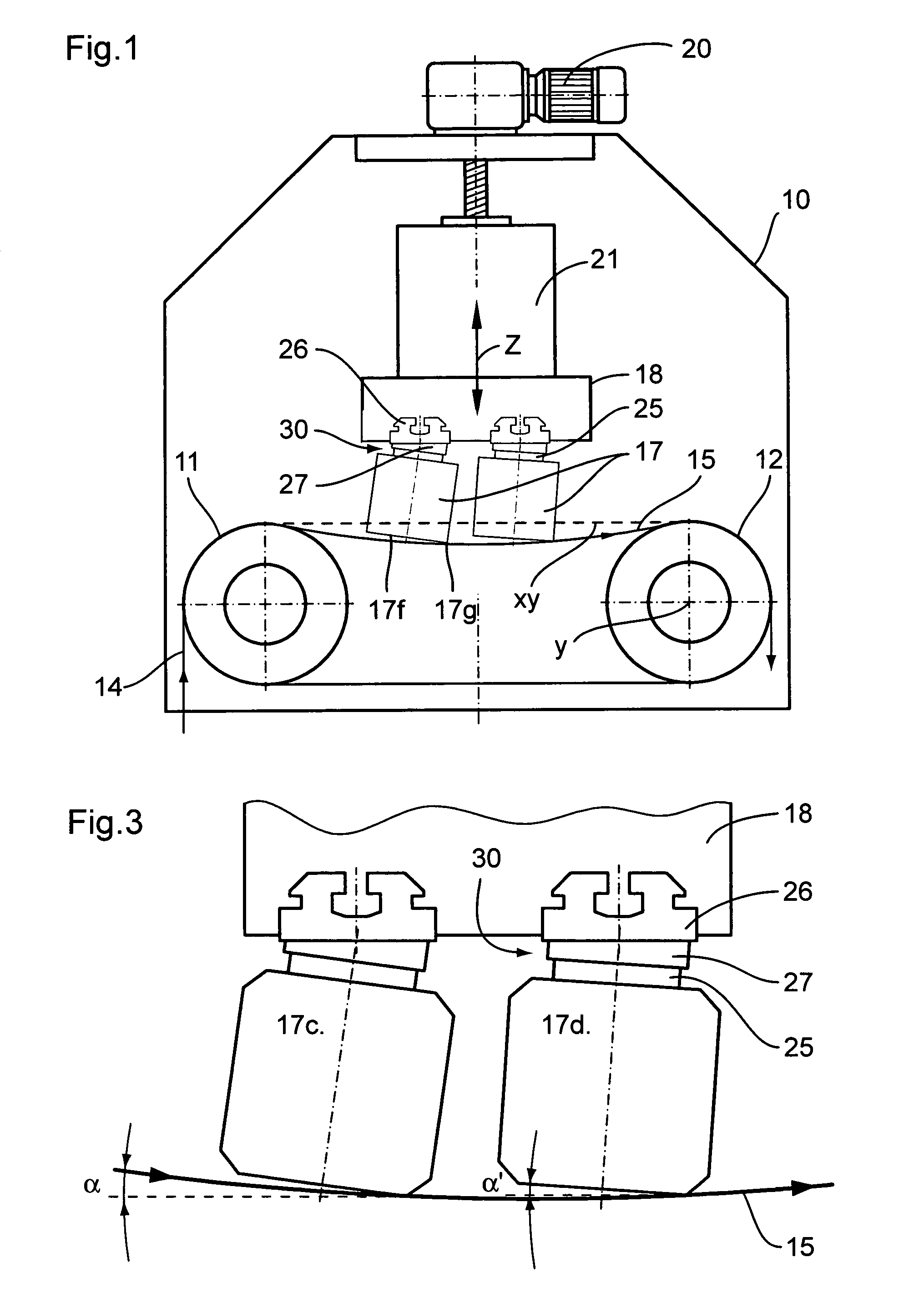

Wire sawing process and device

InactiveUS6981495B2Prevent penetrationAvoid typingMetal sawing devicesGrinding machinesEngineeringWire saw

In the sawing process and device according to the invention, the pieces to be sawed are mounted on at least one support table and caused to bear against a layer of wires. Inclination structure in the form of wedges or pieces for angular adjustment by pivoting and blocking, are provided to mount the pieces obliquely with angles of inclination between one of their prismatic surfaces and a horizontal working plane. There is thus obtained a precise beginning of sawing with sawed slices of equal thickness and a careful end of cutting without chipping.

Owner:APPLIED MATERIALS SWITZERLAND

Backlight system

A backlight system comprising a light-guiding plate having a light-entrance surface, an upper surface, and a lower surface, a light source disposed to face the light-entrance surface, a reflecting sheet disposed to face the lower surface of the light-guiding plate, a prismatic sheet disposed to face the upper surface of the light-guiding plate, and a micro-prismatic mechanism provided on the lower surface of the prismatic sheet, the micro-prismatic mechanism including a plurality of projection-like prismatic parts extending parallel to the light-entrance surface of the light-guiding plate and disposed at intervals in a generally perpendicular direction to the light-entrance surface, each prismatic part having a pair of prismatic surfaces, of each pair of prismatic surfaces, at least the prismatic surface on the side further from the light source forming into a curved surface.

Owner:CITIZEN ELECTRONICS CO LTD

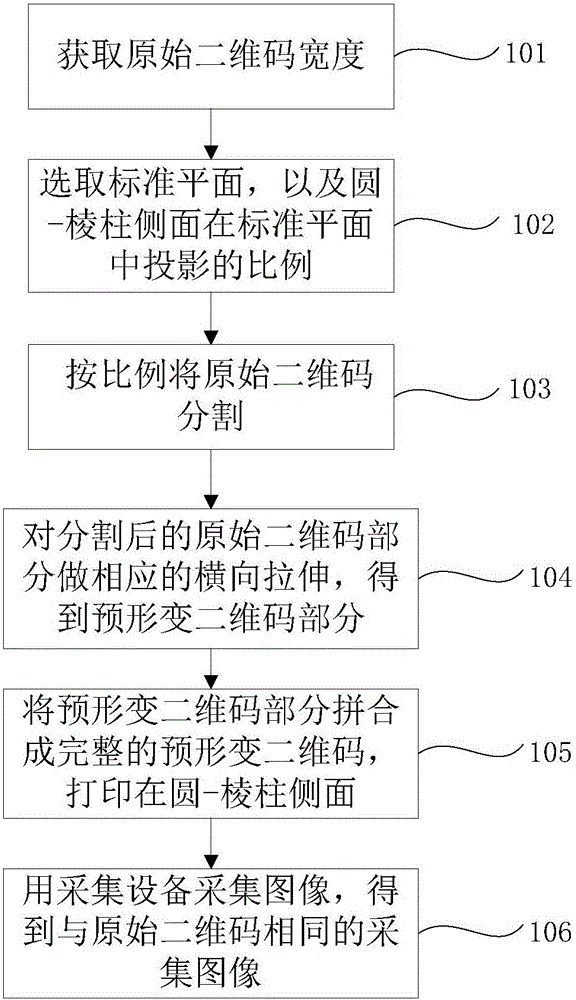

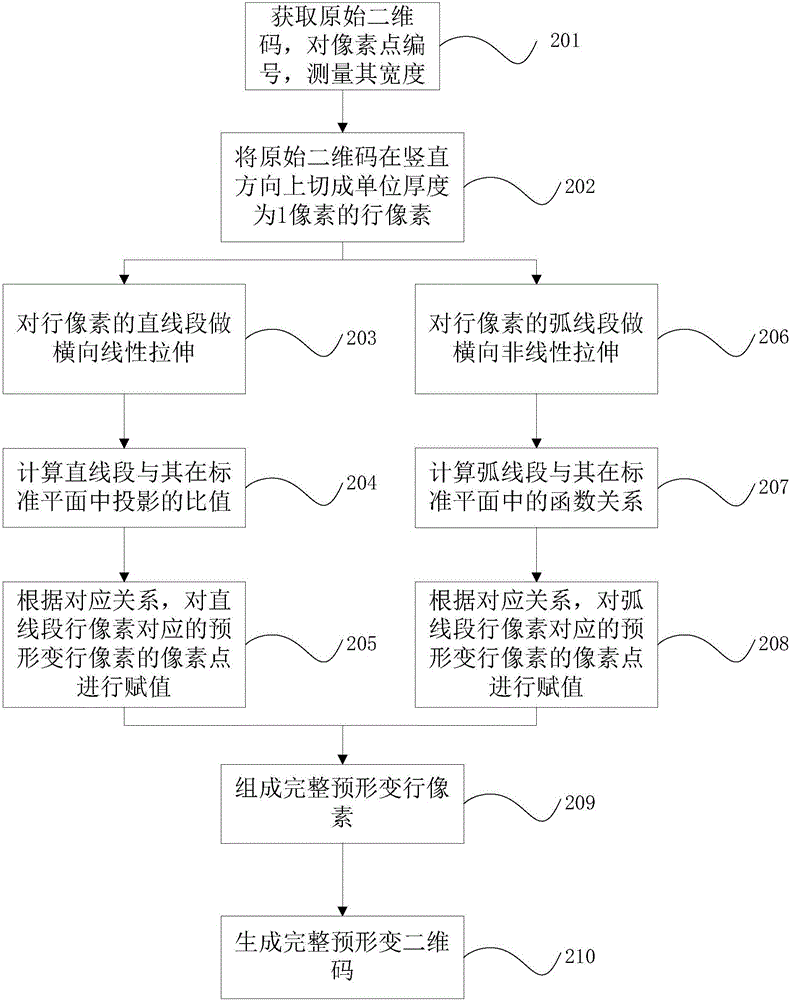

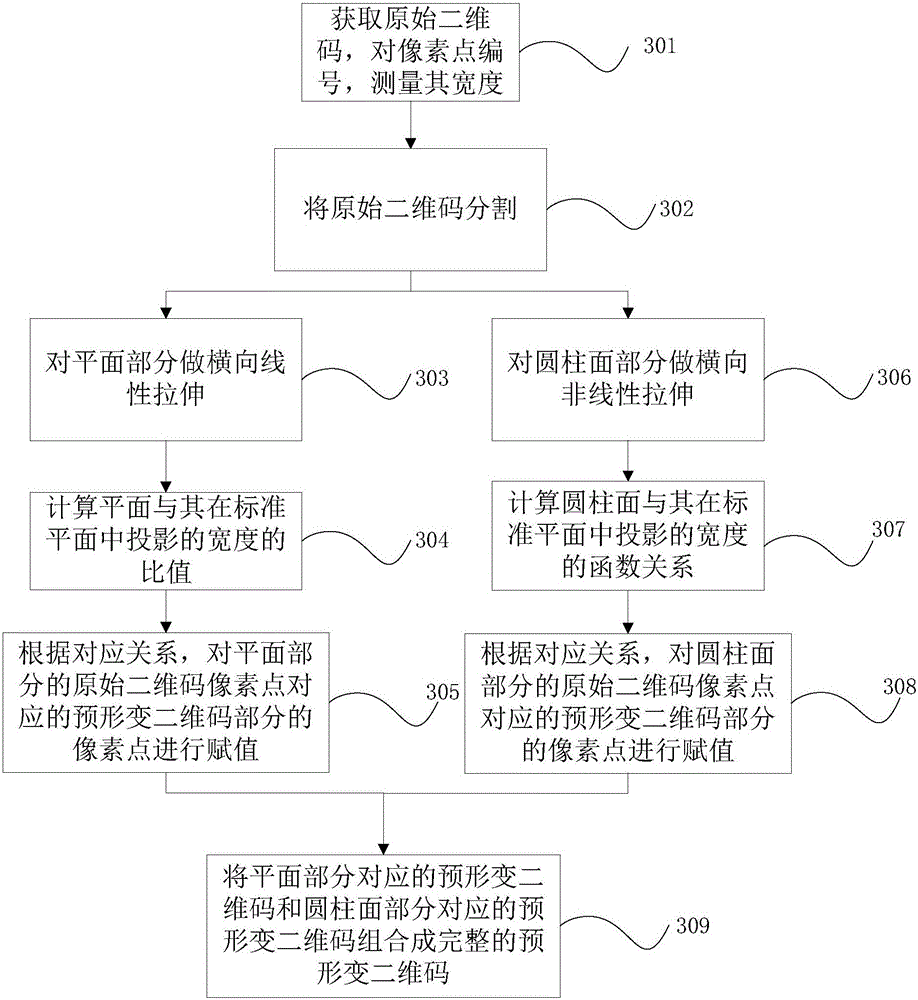

Method for generating and collecting two dimension code on surface of cylinder-prism assembly

The invention discloses a method for generating and collecting a two dimension code on a surface of a cylinder-prism assembly. An original two dimension code is segmented according to a ratio of a prismatic surface and a cylindrical surface; a part, corresponding to the prismatic surface, of the two dimension code is subjected to transverse linear stretching operation; a pre-deformed two dimension code part of the prismatic surface is obtained; a part, corresponding to the cylindrical surface, of the two dimension code is subjected to transverse non-linear stretching operation; a pre-deformed two dimension code part of the cylindrical surface is obtained; a whole pre-deformed two dimension code is assembled and printed on a corresponding position of a surface of the cylinder-prism assembly; a collecting device is used for subjecting the whole pre-deformed two dimension code to image collecting operation along a direction perpendicular to a standard surface; a collected image corresponding to the whole pre-deformed two dimension code is obtained, the collected image is as same as the original two dimension code, the two dimension code can be collected and identified while a decoding module of current code scanning software remains unchanged, a range of application occasions of the two dimension code is expanded, and specifically the two dimension code can be applied to commodities having cylinder-prism assembly surfaces.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

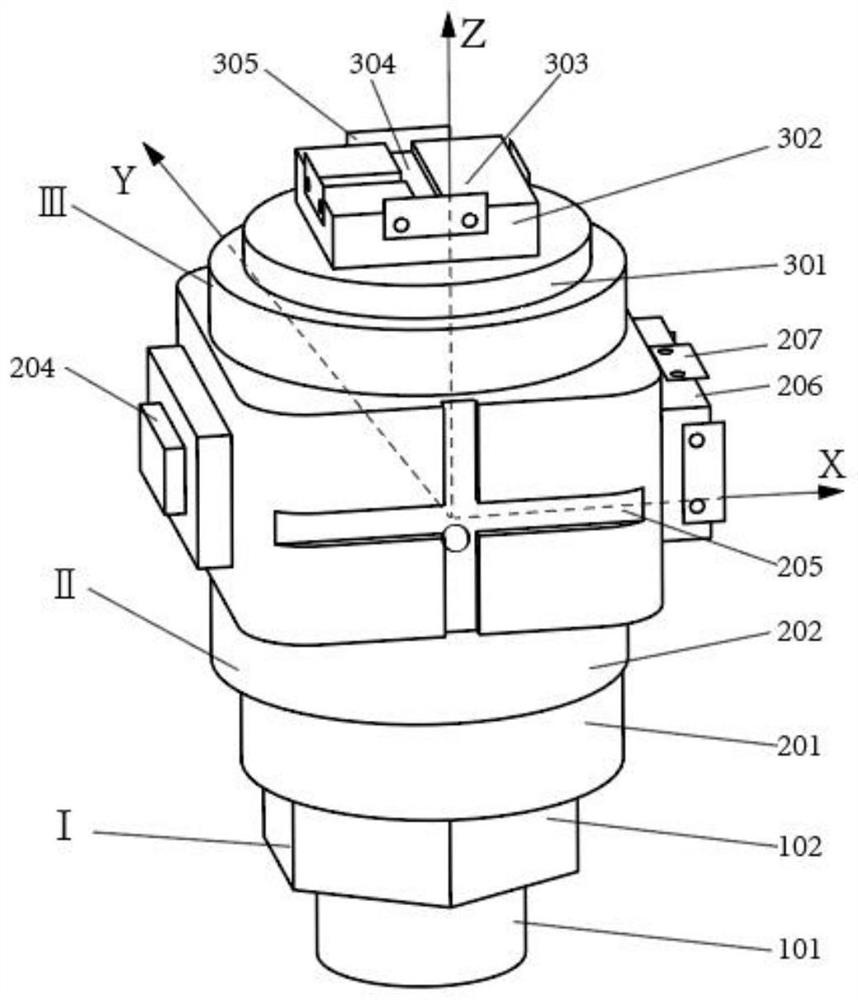

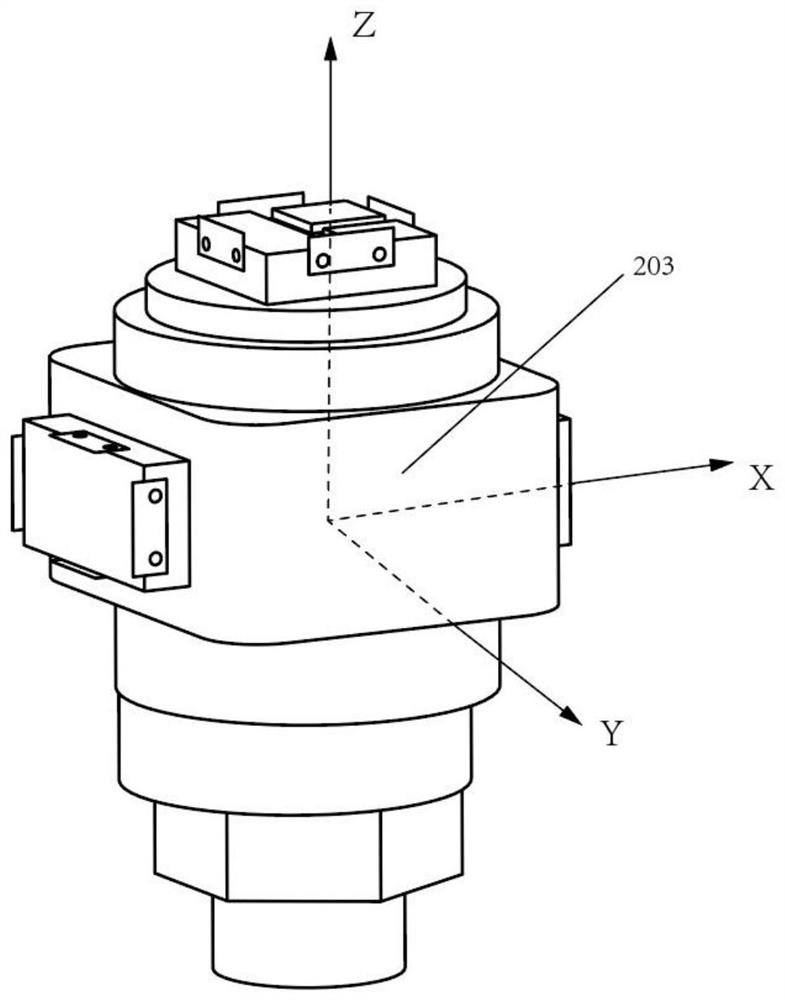

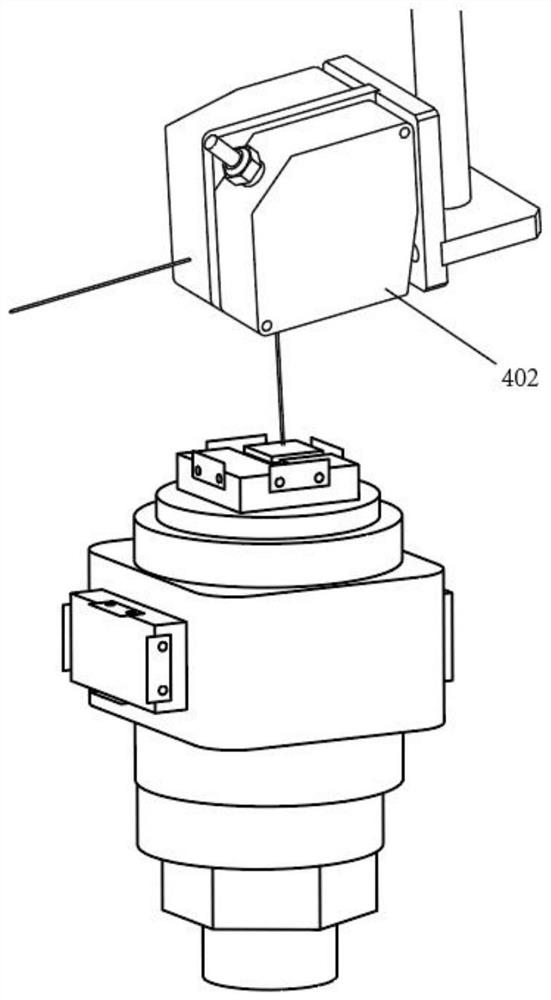

Orthogonal point laser double-measuring-head pose calibration test piece

The invention discloses an orthogonal point laser double-measuring-head pose calibration test piece, which comprises three shaft sections: a clamping shaft section, a horizontal measuring head calibration shaft section and a vertical measuring head calibration shaft section; the clamping shaft section comprises a clamping prism surface and a positioning cylindrical surface; the horizontal measuring head calibration shaft section comprises a calibration cylindrical surface, a calibration eccentric cylindrical surface, and a peripheral alignment plane, a boss type stepped surface, a cross-shapedgroove and a peripheral calibration boss which are distributed according to a calibration station sequence; the vertical measuring head calibration shaft section comprises a circular ring type stepped surface, a top calibration boss, a top alignment plane and a T-shaped groove; in the calibration process, the test piece can satisfy calibration and calibration of the horizontal measuring head andthe vertical measuring head in an orthogonal coordinate system; compared with a single-measuring-head pose calibration test piece, the test piece can effectively improve the measurement range, and reduces pitching and deflection errors in a point laser measuring head installation process and calibration errors of coordinate systems of the two measuring heads by using multiple characteristic surfaces for calibration.

Owner:SICHUAN UNIV

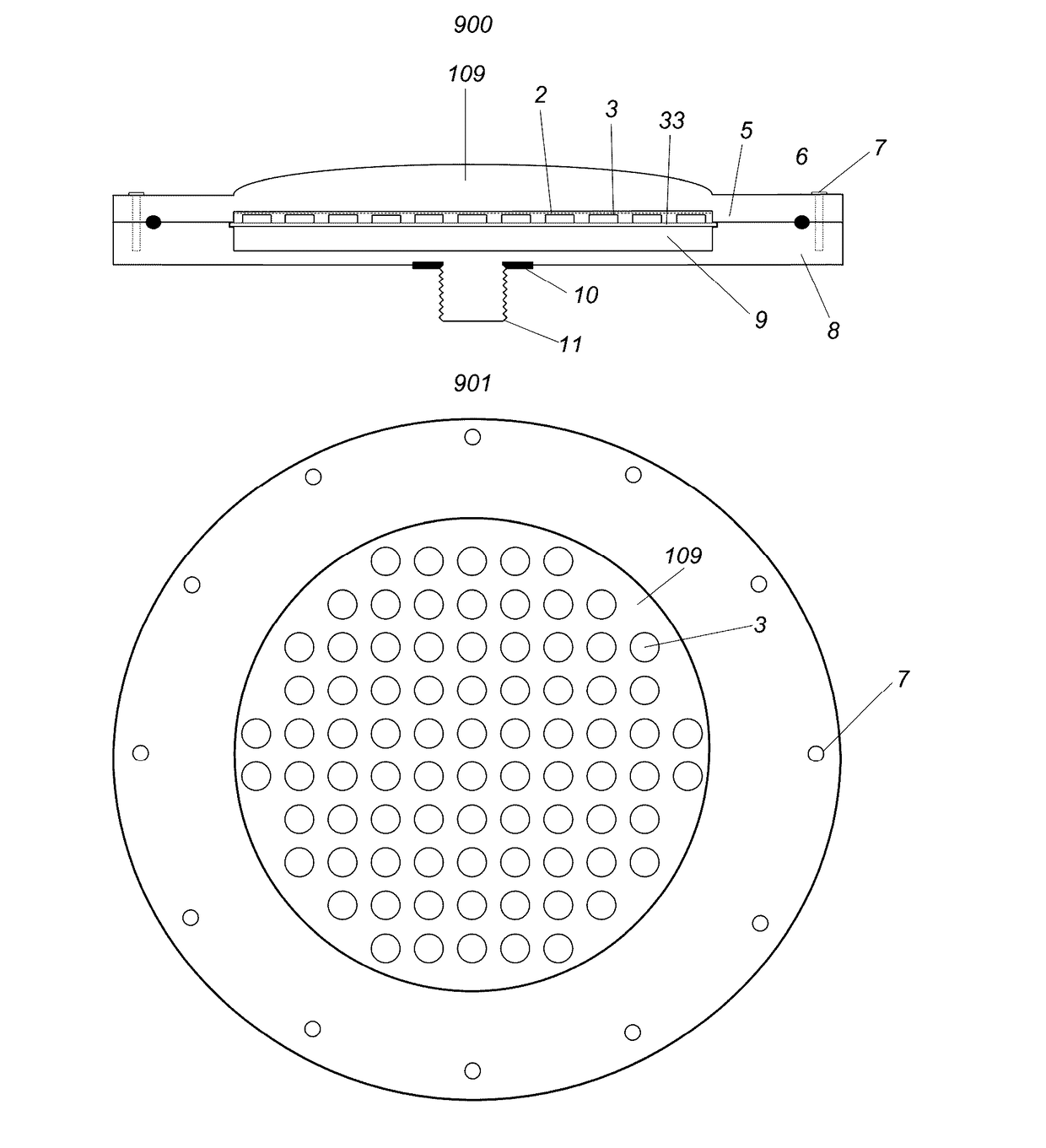

Diffractive and prismatic OLED wireless and LED wireless underwater pool light sources

InactiveUS20170167717A1Increase humidityPlanar light sourcesElectrical apparatusPrismLight-emitting diode

The systems and methods described herein relate to wireless solid-state semiconductor illumination devices, such as organic light emitting diodes (OLEDs), and / or light emitting diodes (LEDs), configured in arrays capable of generating light via a diffractive transmission layer and prismatic surfaces for illumination purposes. The OLEDs, or LEDs, can be deployed in arrays yielding a variety of geometrical configurations such as linear arrays, square arrays, pentagonal arrays, hexagonal arrays, octagonal arrays, other polygonal arrays, and arrays approaching a circular configuration. One of the features of these solid-state semiconductor (OLED and LED) illumination arrays is that they are driven by immediately adjacent battery power sources, they are wireless, and can controlled remotely.

Owner:E Z WIRELESS LED LIGHT CO

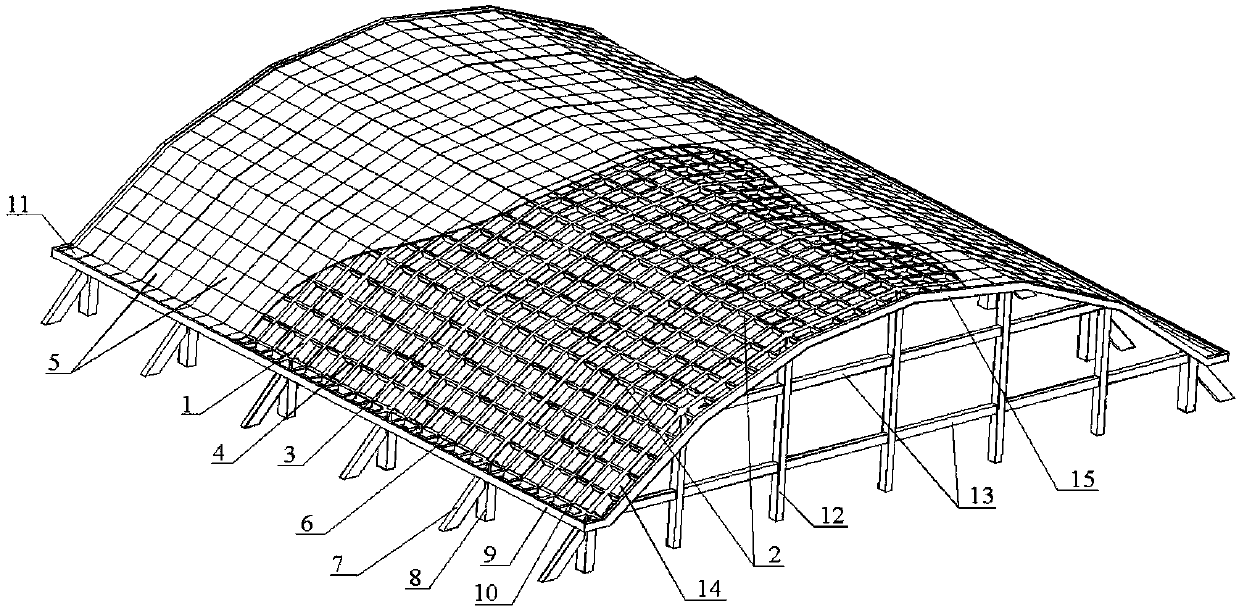

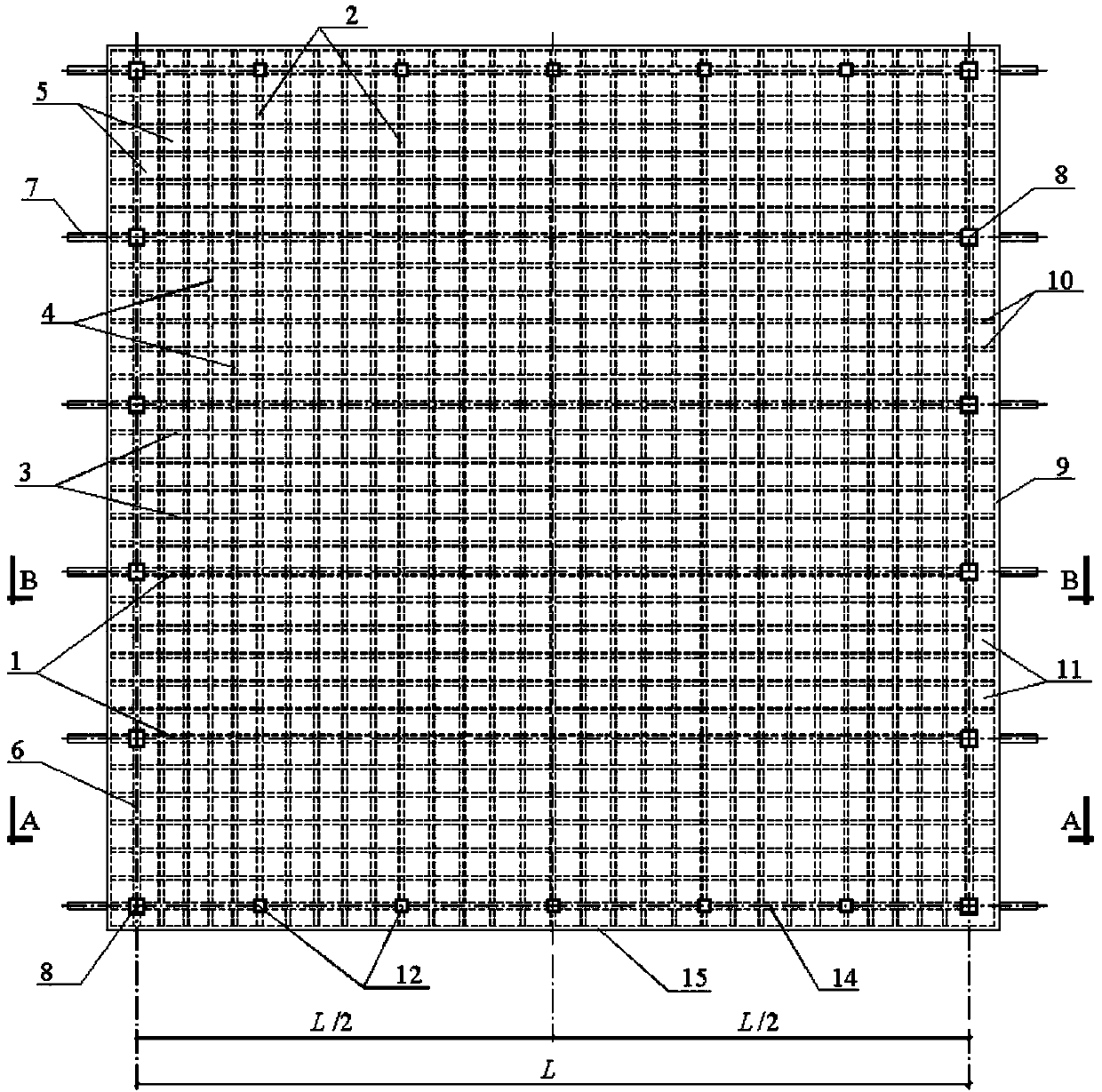

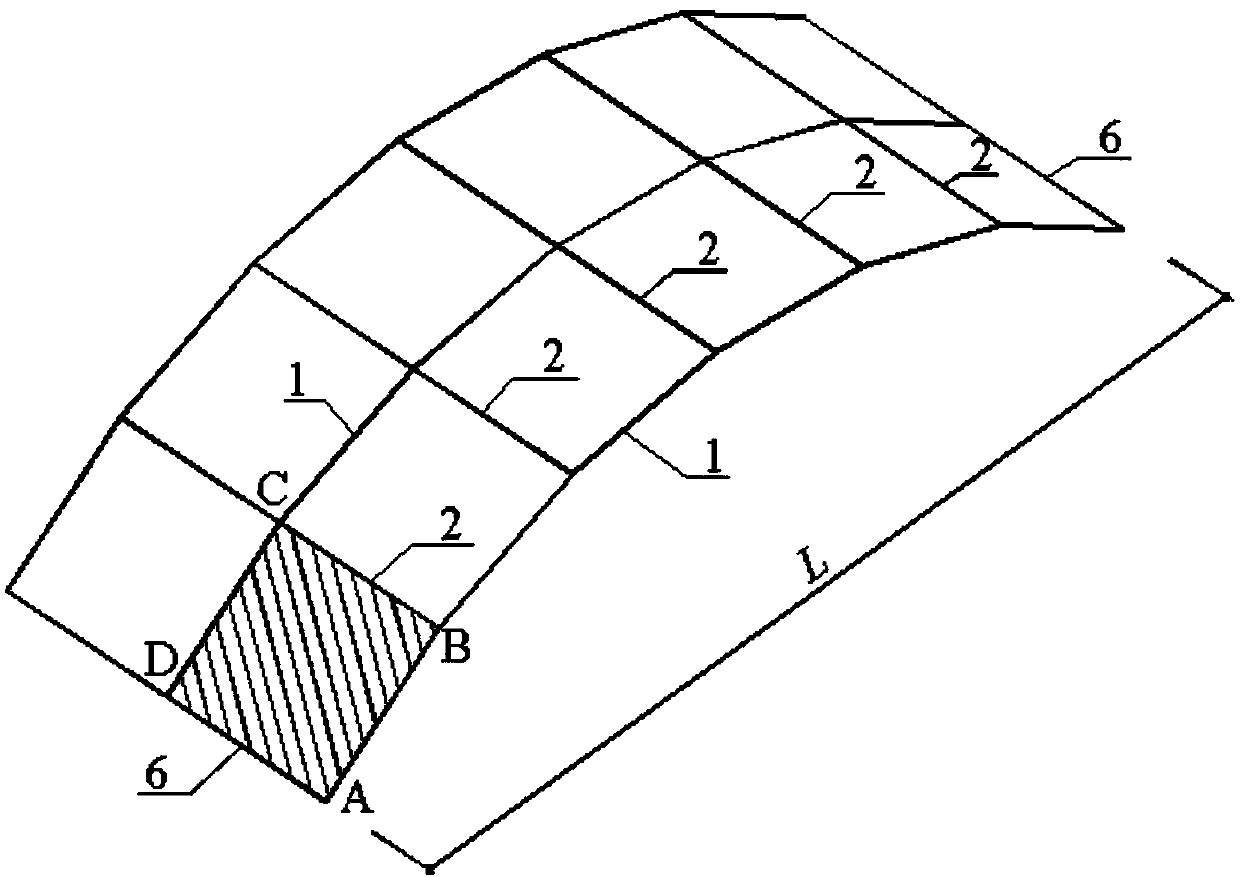

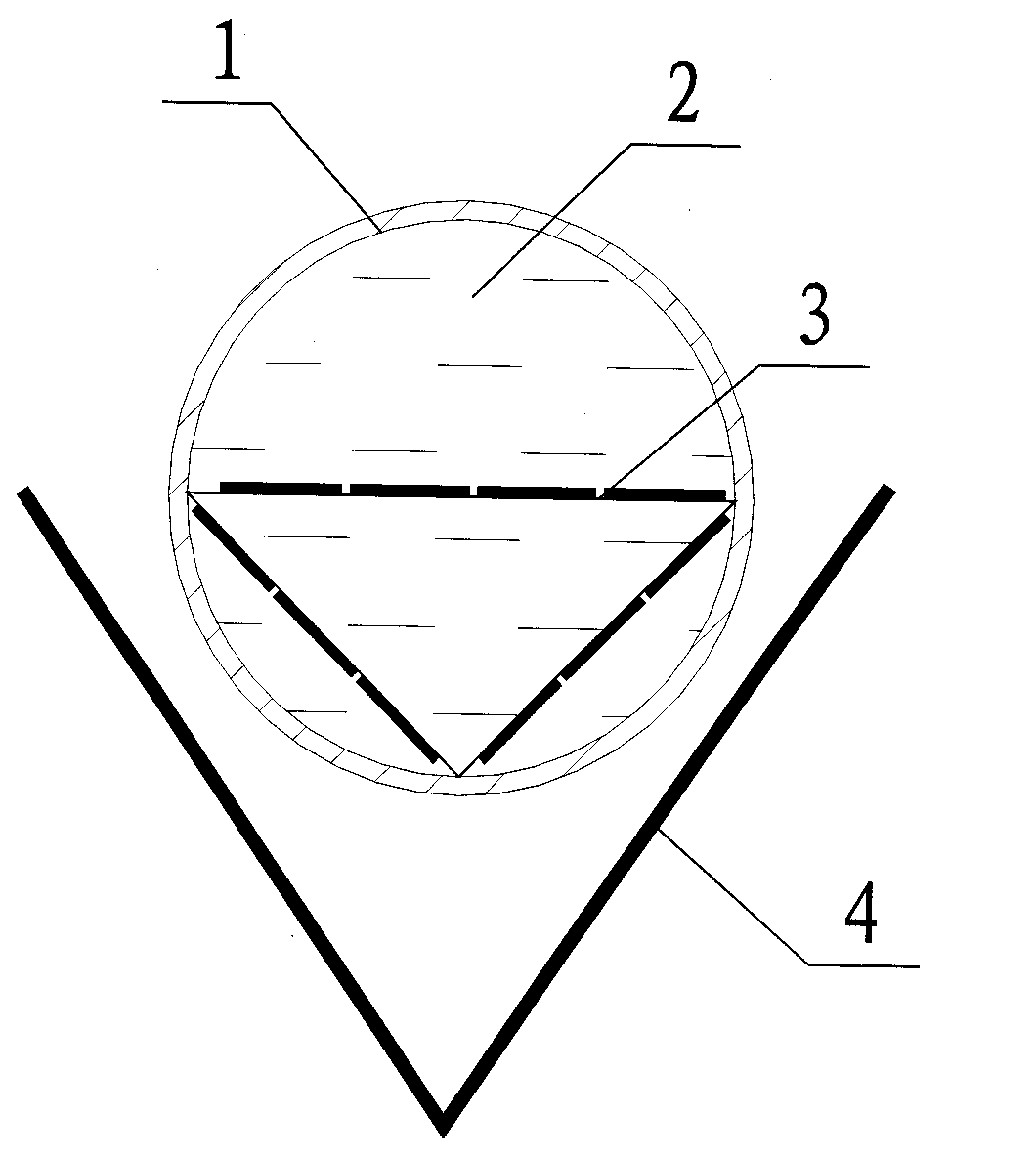

Long-span concrete prismatic surface arch reticulated shell roof structure and manufacturing method thereof

PendingCN107893500AGuarantee the construction qualityAvoid design difficultiesBuilding roofsArchitectural engineeringStructural engineering

The invention discloses a long-span concrete prismatic surface arch reticulated shell roof structure and a manufacturing method thereof. The prismatic surface of the structure is internally connectedto a round curve face, after a giant cylindrical bearing grid is formed by a main folding arch and a regression line beam, dense rib flat plates are divided in the giant grid, roof slope toes are supported on a side frame beam, after a gutter is formed to bear roof thrust by cooperating with the side frame beam, the thrust is transmitted to an anti-thrust structure composed of an inclined rod anda side frame column, and a roof end is supported on a gable wall frame. Manufacturing of the structure can adopt a total cast-in-place concrete mode or prefabricated method. The long-span concrete prismatic surface arch reticulated shell roof structure is applied to roofs of buildings such as warehouses, convention and exhibition and auditoriums, and has the advantages of being good in durability,high in rigidness, high in bearing capacity, low in construction cost and the like.

Owner:GUIZHOU UNIV

Backlight system

A backlight system comprising a light-guiding plate having a light-entrance surface, an upper surface, and a lower surface, a light source disposed to face the light-entrance surface, a reflecting sheet disposed to face the lower surface of the light-guiding plate, a prismatic sheet disposed to face the upper surface of the light-guiding plate, and a micro-prismatic mechanism provided on the lower surface of the prismatic sheet, the micro-prismatic mechanism including a plurality of projection-like prismatic parts extending parallel to the light-entrance surface of the light-guiding plate and disposed at intervals in a generally perpendicular direction to the light-entrance surface, each prismatic part having a pair of prismatic surfaces, of each pair of prismatic surfaces, at least the prismatic surface on the side further from the light source forming into a curved surface.

Owner:CITIZEN ELECTRONICS CO LTD

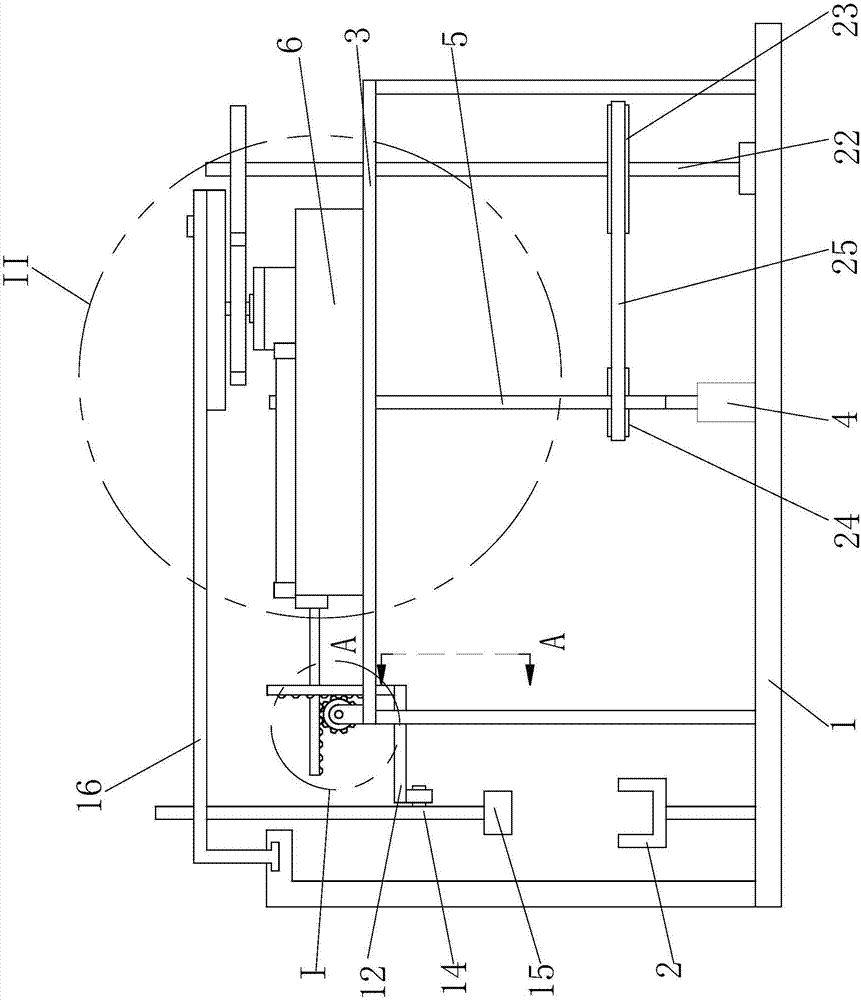

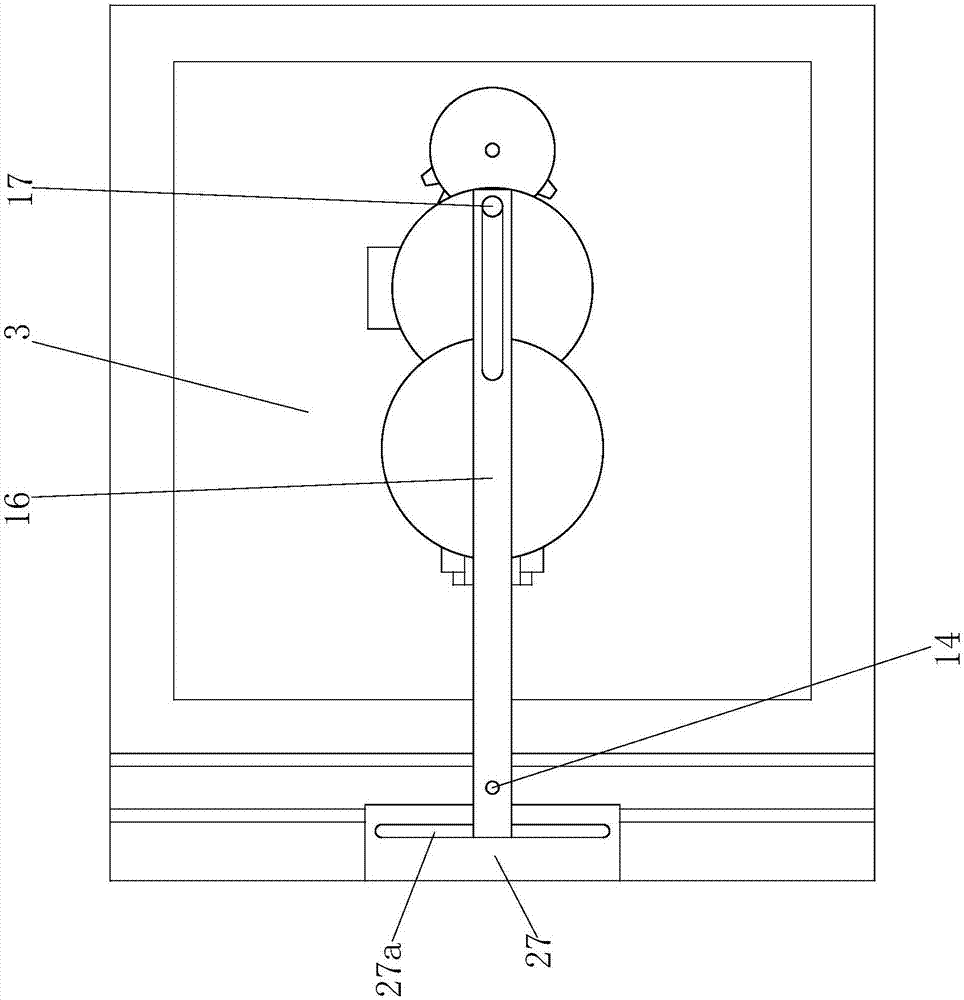

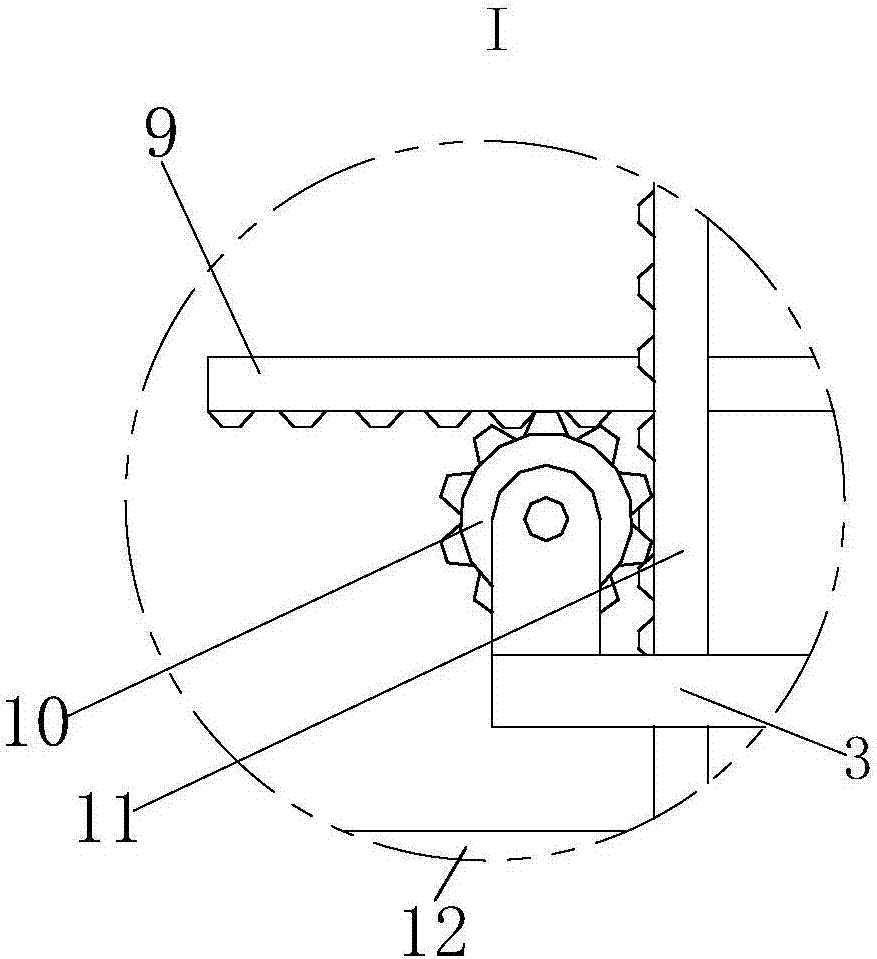

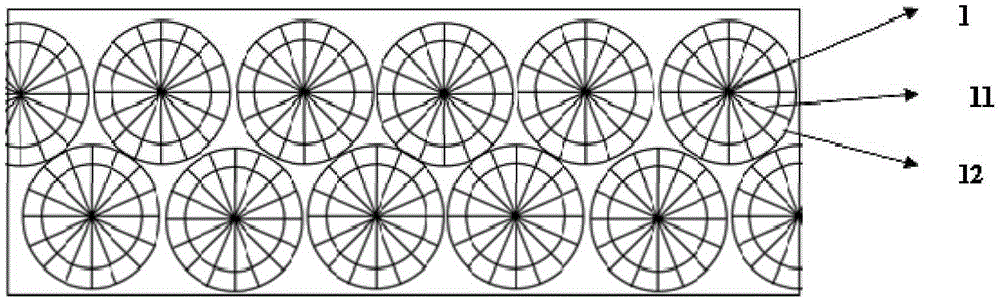

Automatic forging device for square tubes

ActiveCN107088639AAchieve the effect of fully automatic forgingHigh degree of automationPower hammersHammer drivesEngineeringMechanical engineering

The invention relates to an automatic forging device for square tubes. The automatic forging device for square tubes comprises a bottom plate, wherein a fixed rack, a placement table and an L-shaped limiting rack are correspondingly fixedly mounted on the bottom plate respectively from right to left; and a motor is mounted on the bottom plate and is connected with a central shaft which is matched with the fixed rack through a bearing. A disc which rotates eccentrically is matched with a transverse plate rack, a rotating plate rotates intermittently, while a forging hammer is controlled to move vertically in a reciprocating manner, the forging hammer further can intermittently move linearly to feed in the front-back direction, and the effect of completely and automatically forging a whole prismatic surface of a square tube can be achieved. Moreover, the forging effect is good.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

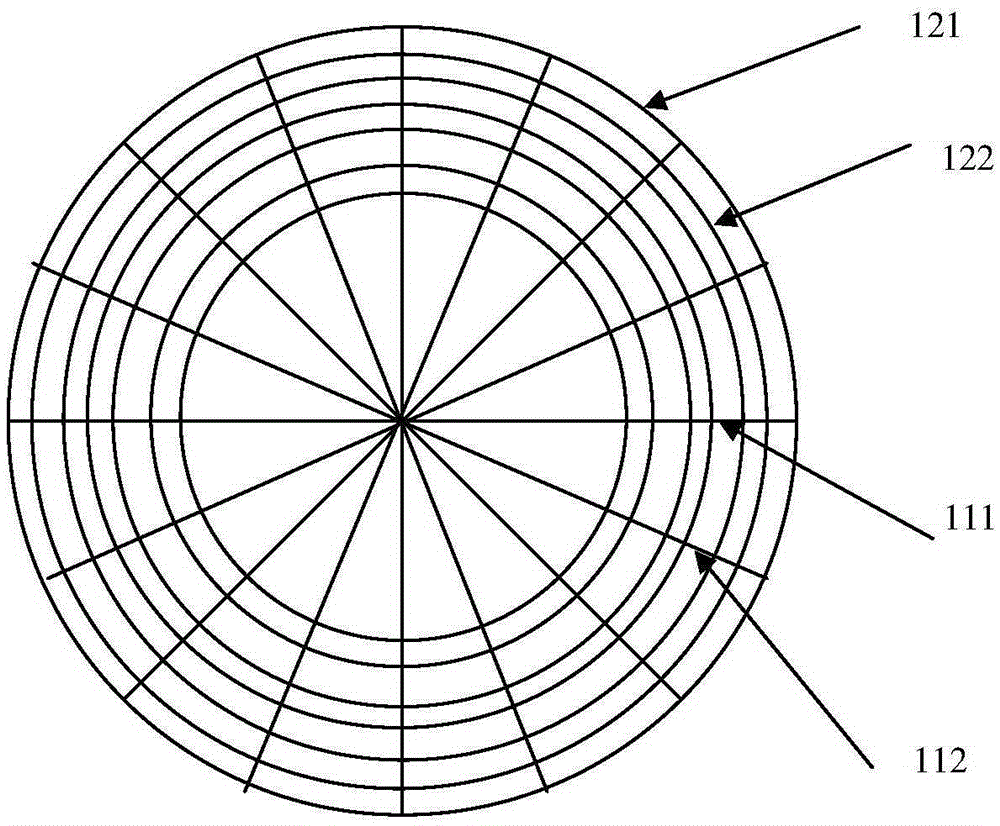

Brightening film

ActiveCN106773237AAvoid Light Interference PhenomenaGood light uniformityNon-linear opticsLiquid-crystal displayNewton's rings

The invention relates to the field of liquid crystal display back light modules technique, and particularly relates to a brightening film and a method for its production. The invention provides a brightening film, so as to overcome the defect that an existing brightening film is prone to the Moore effect and the Newton ring. The invention comprises a substrate and a prism structure layer, wherein the prism structure layer is bonded to the base material layer, and the prism structure layer is composed of repeating units including a first prism structure unit and a second prism structural unit; the first prism structure unit is a group of concentric prismatic rays; the second prism structure unit is a group of concentric prismatic rings; the second prism structure unit intersects the first prism structure unit. A group of concentric prismatic rays includes a number of prismatic rays. A group of concentric prismatic rings includes a number of prismatic rings. The invention can improve the brightness gain and have the anti-interference effect, and can reduce the Newton ring phenomenon and the Moore effect.

Owner:NINGBO CHANGYANG TECH

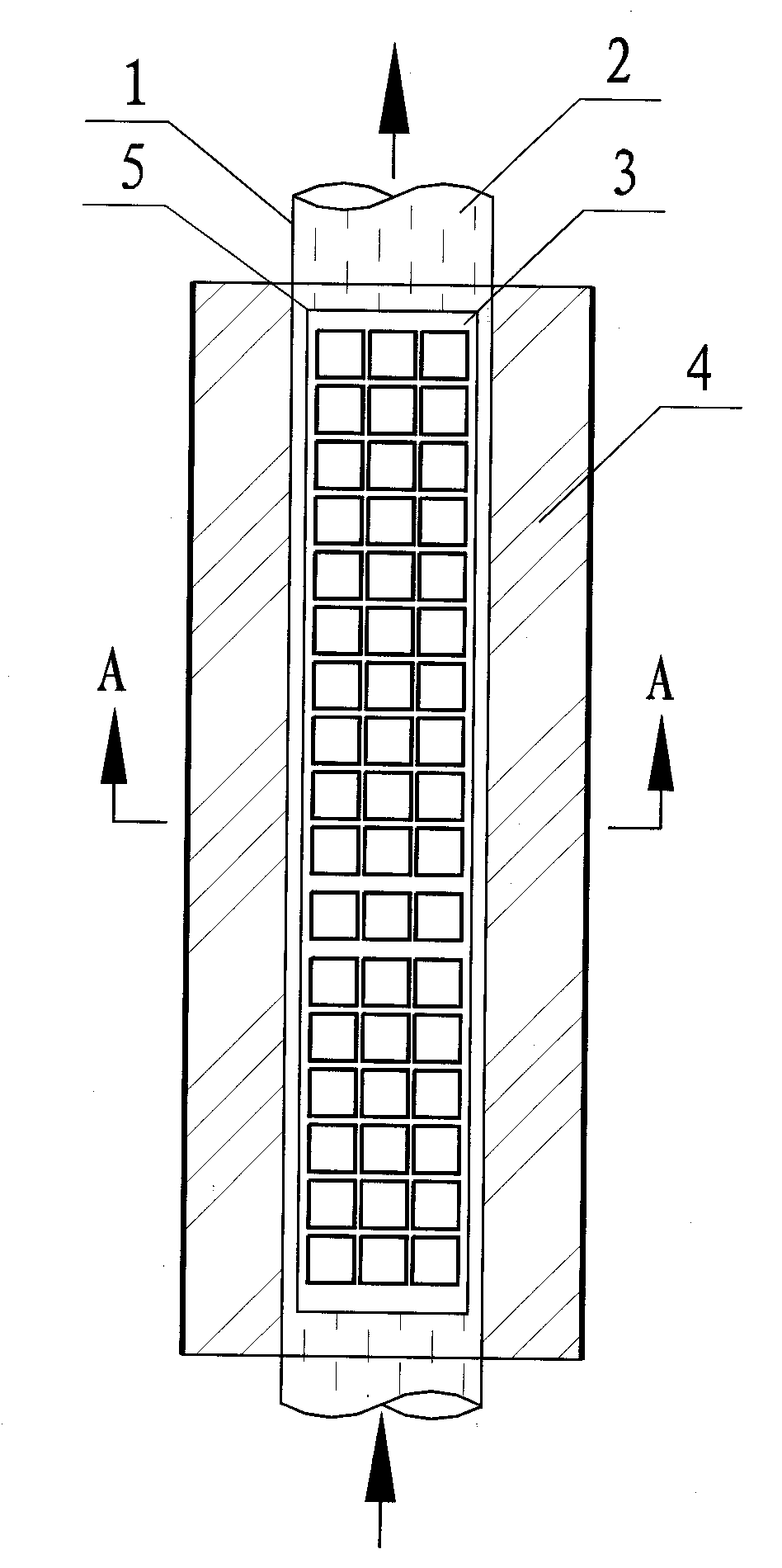

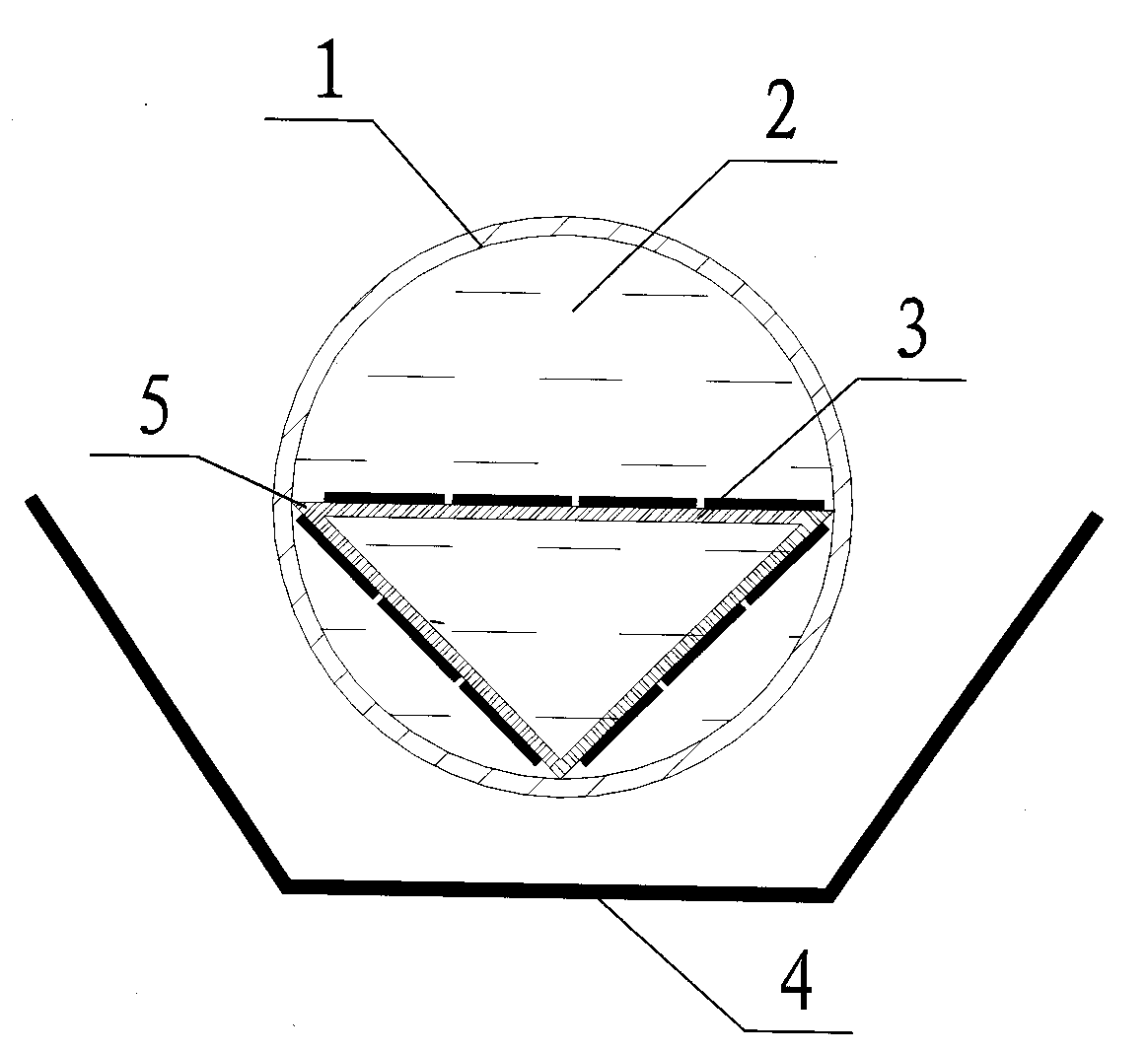

Photovolatic concentrating receiver with secondary baffle board

InactiveCN101789460ATake advantage ofImprove cooling effectPhotovoltaicsPhotovoltaic energy generationSolar batteryPrismatic surface

The invention discloses a photovolatic concentrating receiver with a secondary baffle board, comprising a light-transmitting tube, a battery assembly, insulated liquid and a secondary baffle board. The secondary baffle board is arranged above or below the light-transmitting tube; and the battery assembly forms a prismatic shape and is arranged in the light-transmitting tube in which the insulated liquid is arranged. In the invention, primary light-focusing light which is arranged around focus spots and is not irradiated on the battery assembly is reflected into the light-transmitting tube by using the secondary baffle board and the battery assembly which is arranged in the light-transmitting tube and forms a prismatic surface can fully receive partial light-focusing light, so that full utilization of the light-focusing light can be realized. Meanwhile, the insulated liquid flowing through the light-transmitting tube can effectively cool a solar battery and is beneficial to ensuring the high-efficiency work of the solar battery.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com