Backlight system

A technology of backlight and light guide plate, which is applied in the direction of lighting devices, fixed lighting devices, components of lighting devices, etc., and can solve problems such as sense of difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

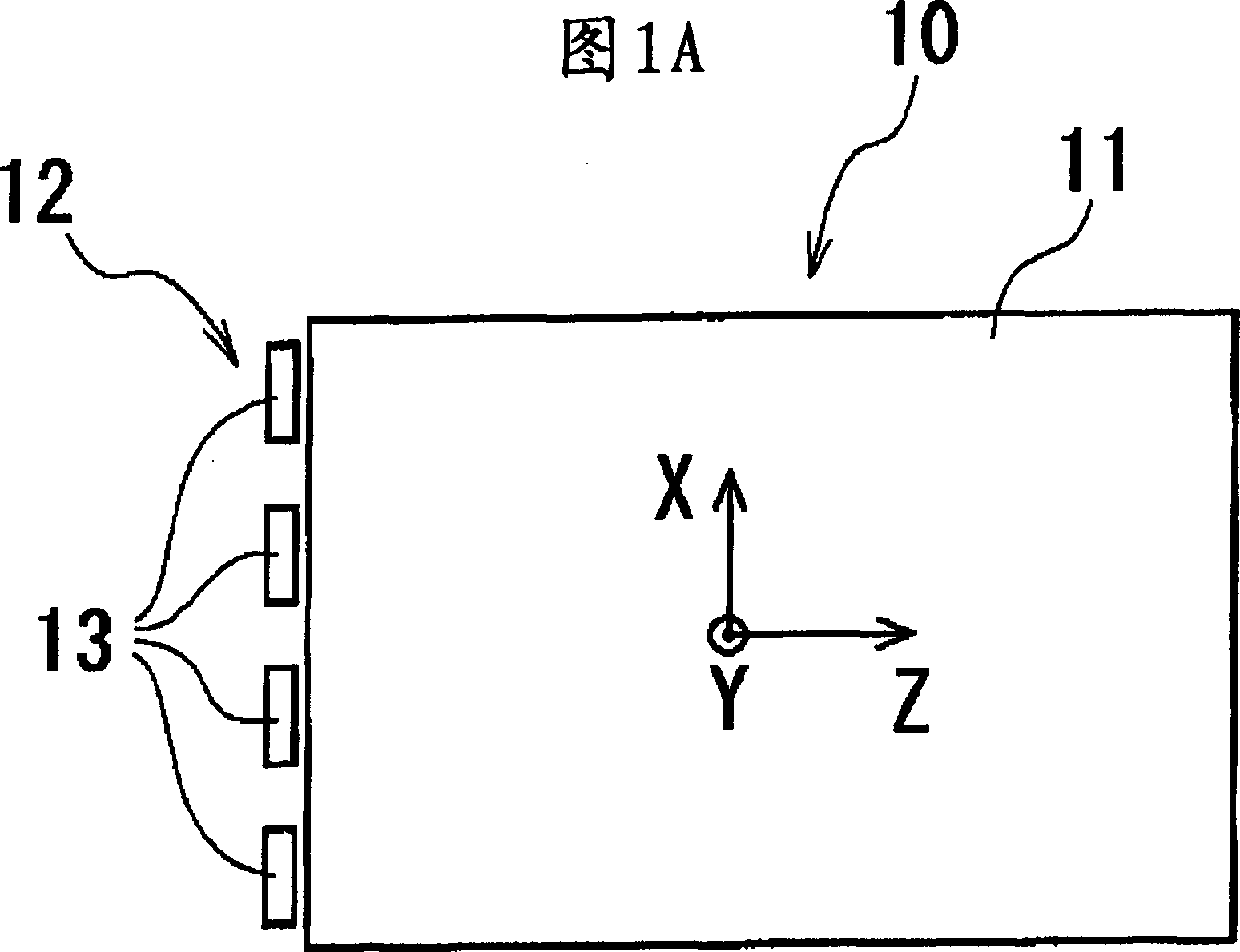

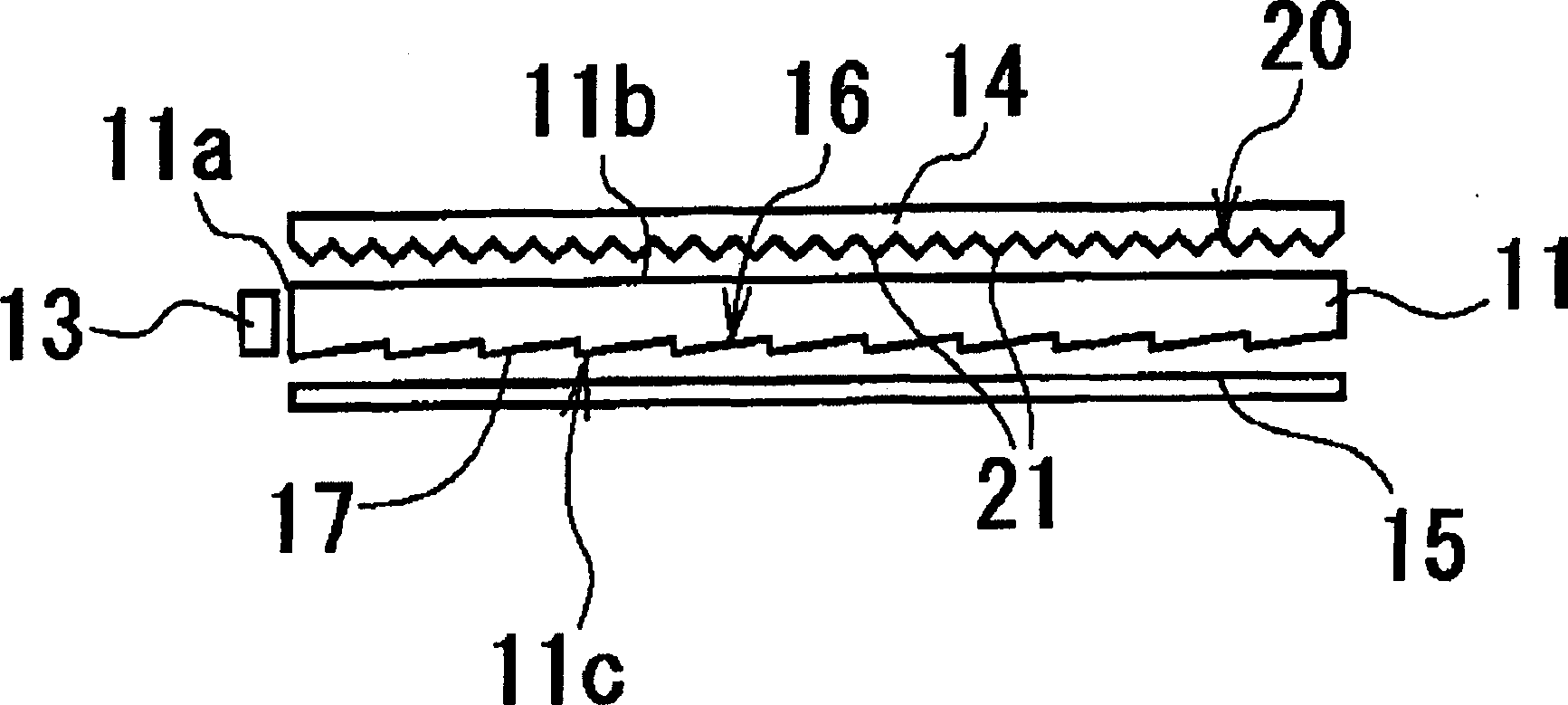

[0018] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Referring to Figure 1A and Figure 1B , shows a backlight device 10 according to an embodiment of the present invention. The backlight device 10 includes a light guide plate 11 and a light source 12 that irradiates light onto the light guide plate 11 . In the illustrated embodiment, the light source 12 is composed of a plurality of light-emitting diodes (LEDs) 13, which are close to the incident surface 11a formed on one side of the light guide plate 11, and these LEDs 13 are arranged at intervals along the incident surface 11a. .

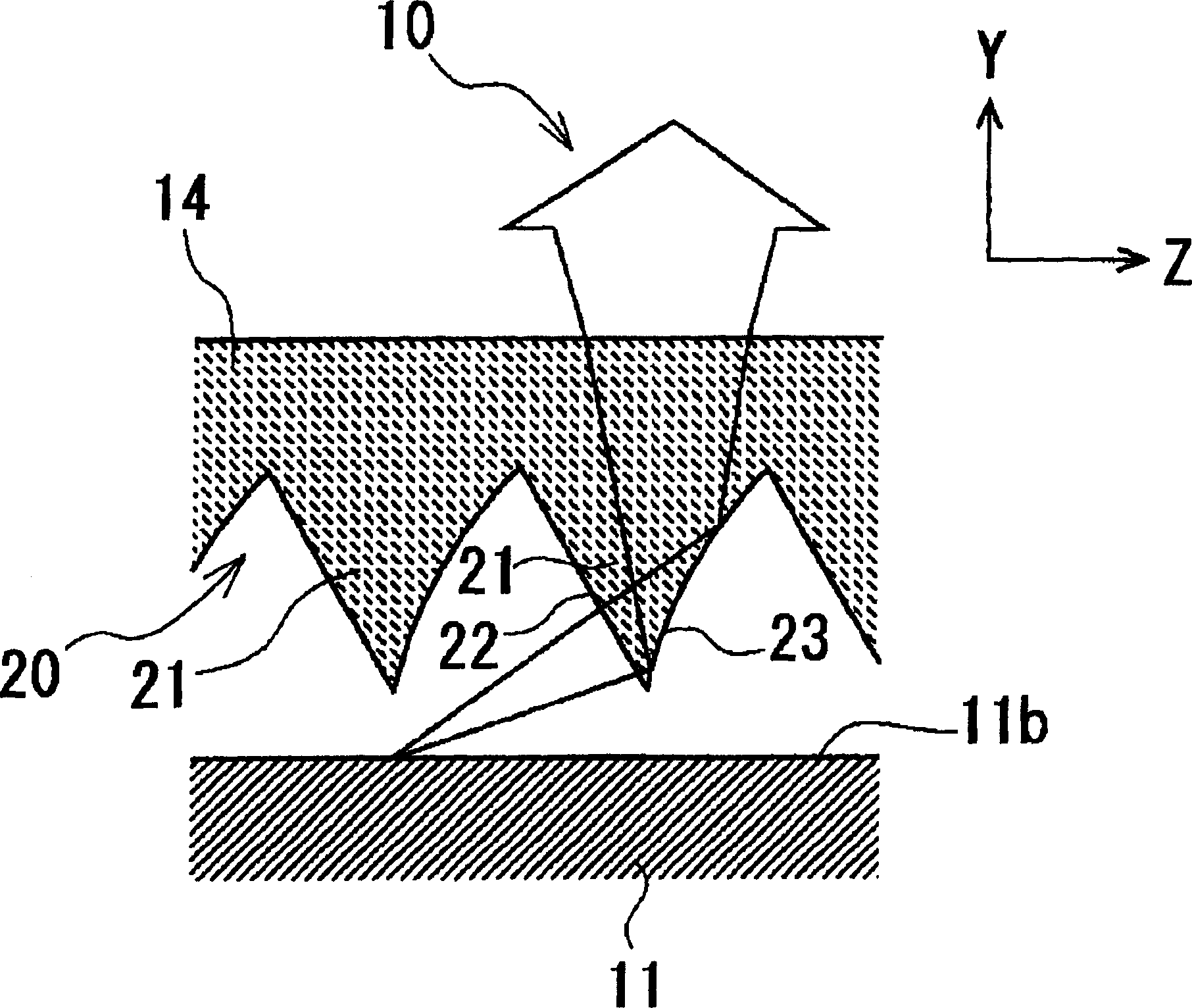

[0019] In addition, the prism plate 14 is disposed opposite to and close to the upper surface 11 b of the light guide plate 11 , and the reflection plate 15 is disposed opposite to and close to the lower surface 11 c of the light guide plate 11 .

[0020] In addition, in FIG. 1A, X represents the width direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com