V8 type gray cast iron cylinder body casting pouring method

A pouring method and technology of gray cast iron, applied in the direction of mold, core, mold composition, etc., can solve problems such as easy occurrence of foaming, shrinkage cavity, long core preparation cycle, and difficulty in venting cylinder head surface, etc., to achieve The effect of increasing demoulding efficiency, shortening the preparation cycle, and eliminating the time and cost of retraining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

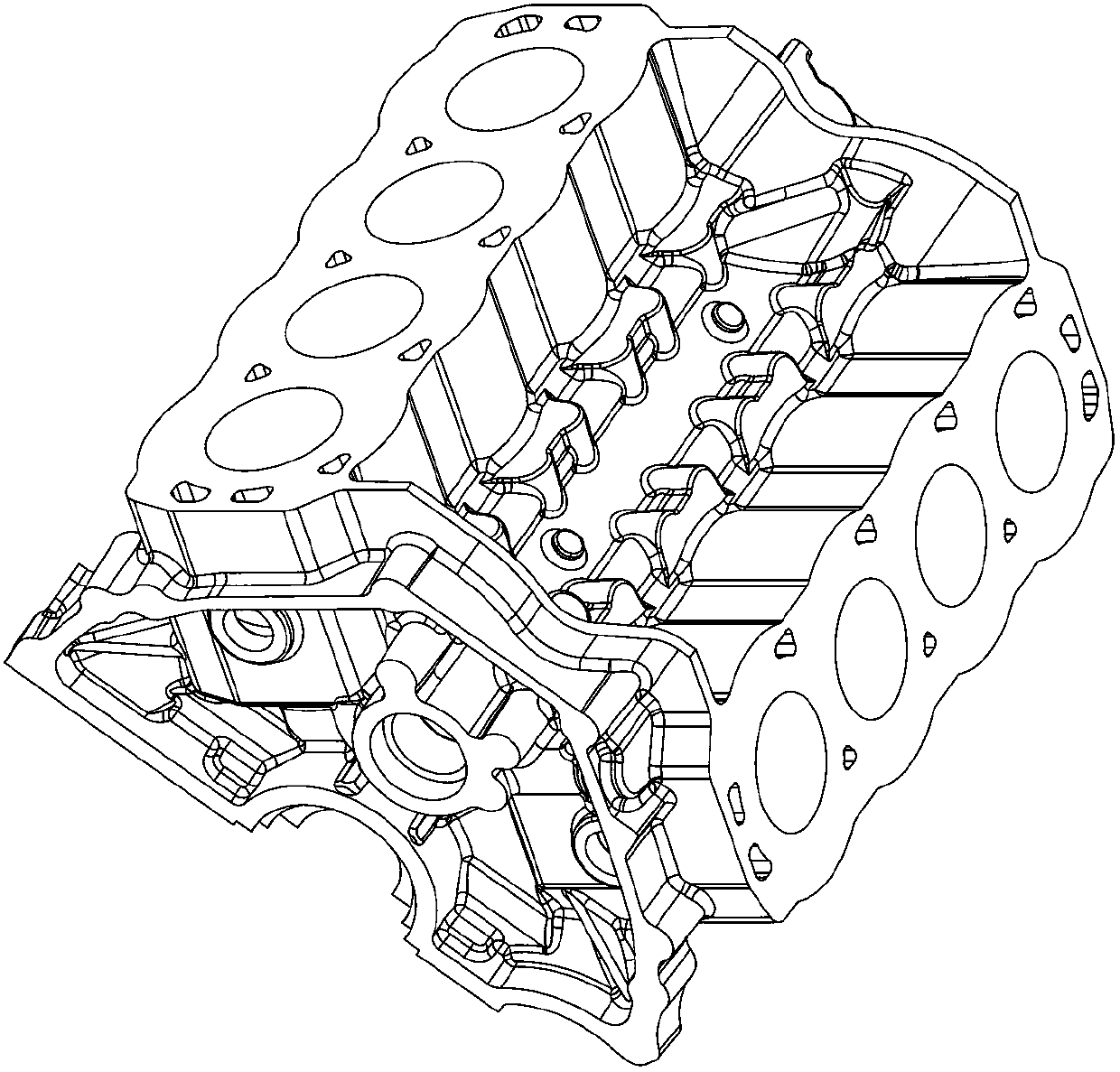

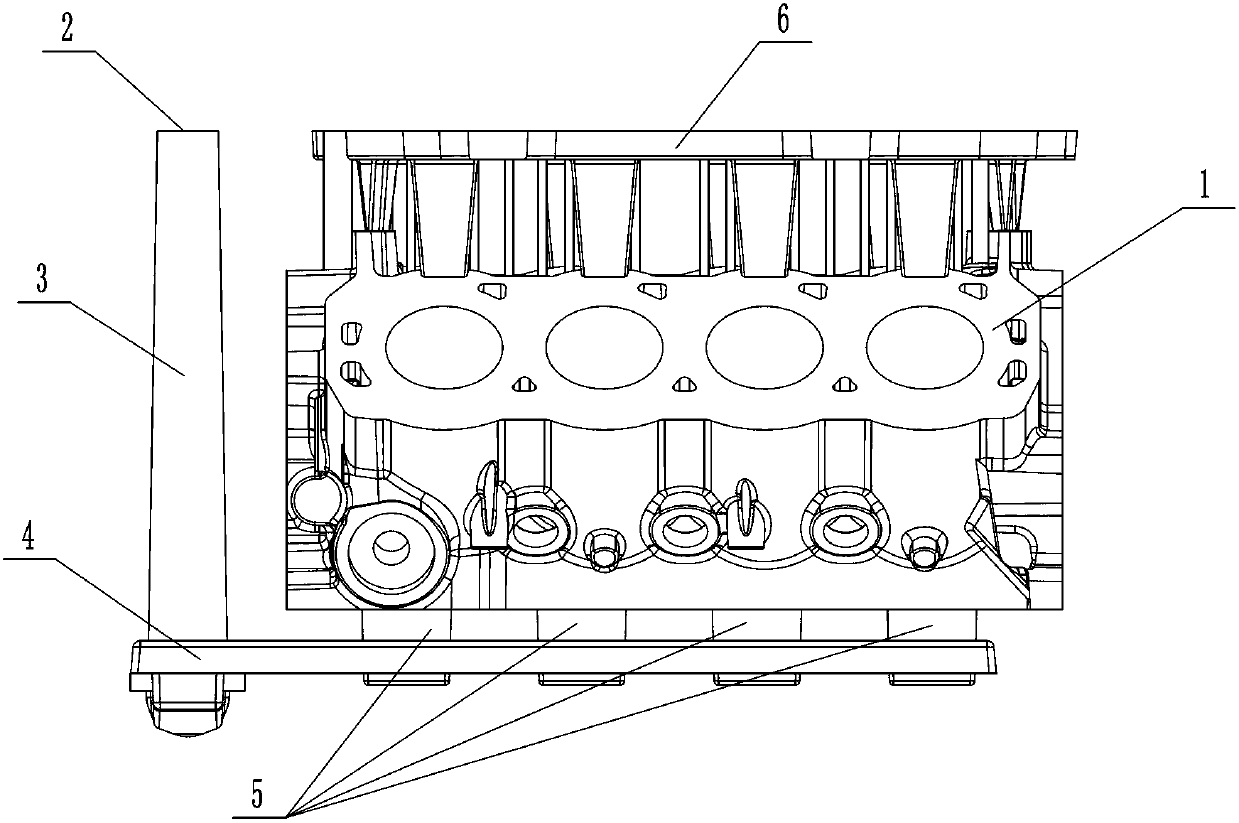

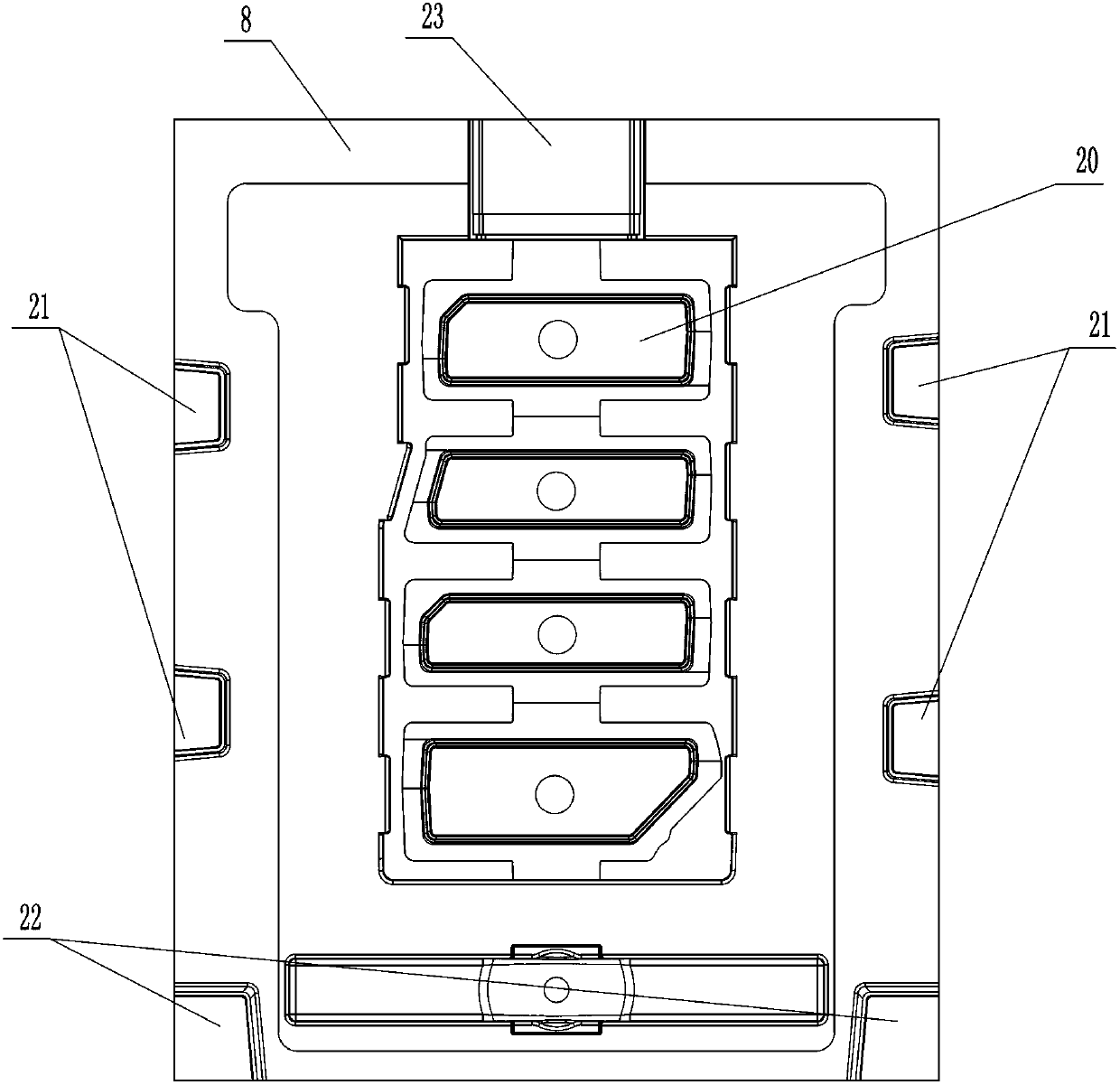

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a casting method of V8 gray cast iron cylinder castings is carried out by core casting, including the following technical measures:

[0027] 1) Set the pouring position of the casting: set the cavity 1 of the V8 cylinder body horizontally, and the part corresponding to the machine foot of the cavity 1 of the V8 cylinder body is located at the bottom;

[0028] 2) Set up the gating system: the gating system includes the outer gate 2, the sprue 3, the runner 4 and the inner gate 5, and its technical feature is: the outer gate 2 is located at the center of the entire gating system In the upper part, there are two runners 4, the two runners 4 are parallel to each other, and the two runners 4 are located below the machine foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com