Testing apparatus for fluid resistance performance of flat plate surface

A testing device and fluid resistance technology, applied in the direction of fluid dynamics test, measuring device, testing of machine/structural components, etc., can solve the problems of inability to remove the friction of the pipe wall, complicated design, affecting the test results, etc., to eliminate friction, etc. Interference, reliable design principle, good flow field uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below Figure 1-4 And embodiment this patent is described in more detail.

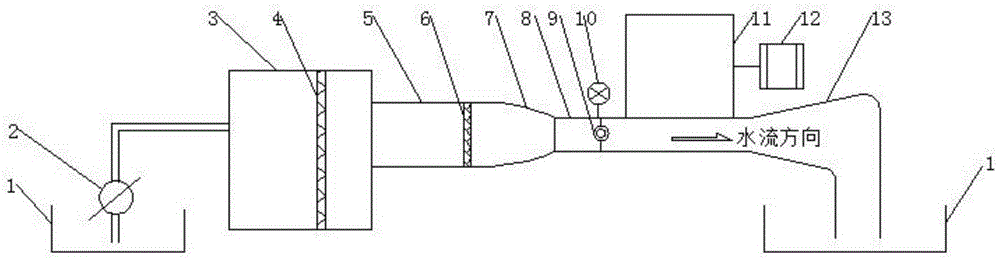

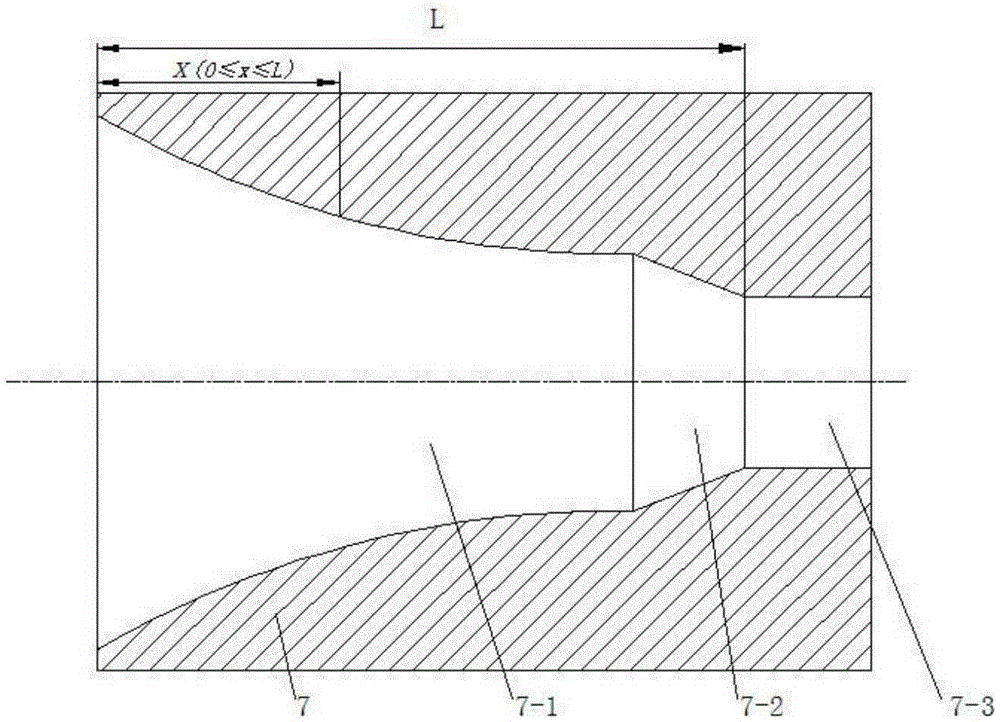

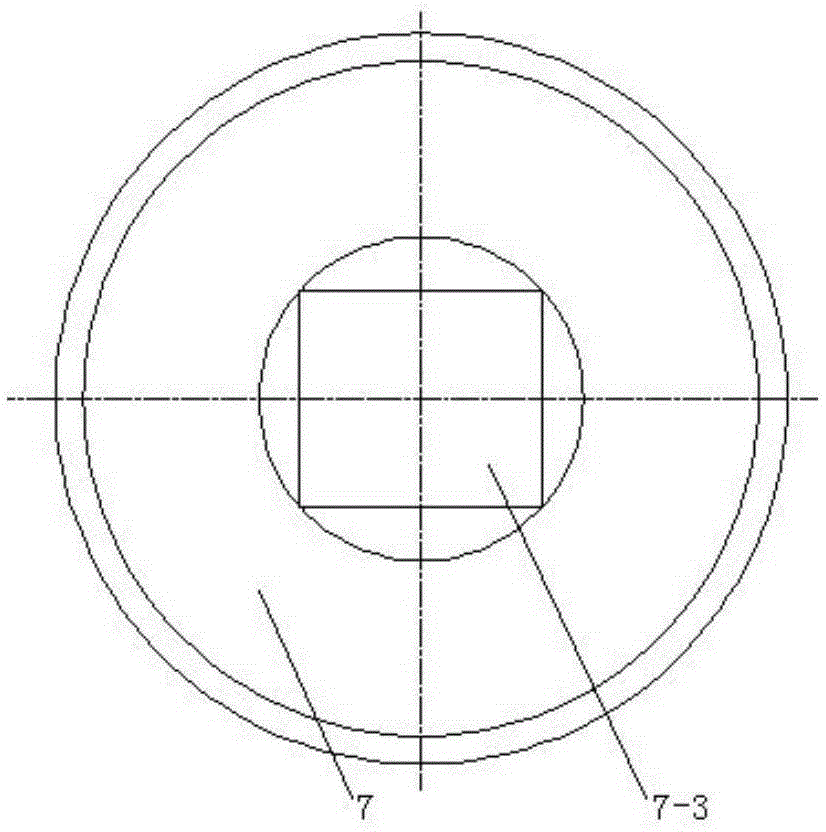

[0024] A test device for evaluating the fluid resistance performance of a flat plate surface implemented according to the present invention, such as Figure 1-4As shown, it includes water tank 1, frequency conversion pump 2, settling chamber 3, diffuser section 5, contraction section 7, working section 8, diffusion section 13, settling chamber 3, diffuser section 5, contraction section 7, working section 8, diffusion Each section of section 13 is a pipeline arranged in a horizontal direction, and each section is connected along this line to form a complete water circulation system. The test box 11 is located above the working section 8, and the test box 11 has a sealing device, a height adjuster 14, and a pressure sensor 18. The sealing device is used to seal the cover plate of the test box 11, and the height adjuster 14 is arranged on the cover plate. Power drive mechanism, height ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com