Oil conduit screwed connection structure

A threaded connection and oil pipe technology, applied in the direction of threaded connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of unsatisfactory thread sealing performance, poor sealing performance of gas medium, eddy current, etc. Good sealing performance and stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0021] The main specifications of tubing used in oil fields are 2-3 / 8″ (60.32mm), 2-7 / 8″ (73.02mm), 3-1 / 2″ (88.90mm), 4″ (101.60mm), (114.30mm ), etc., the 2-7 / 8″ specification is the most commonly used. The following specific instructions take the oil pipe with the commonly used specification 2-7 / 8″ (73.02×5.51mm) and the steel grade is P110 as an example, and the special threaded connection design for the oil pipe The characteristics are described:

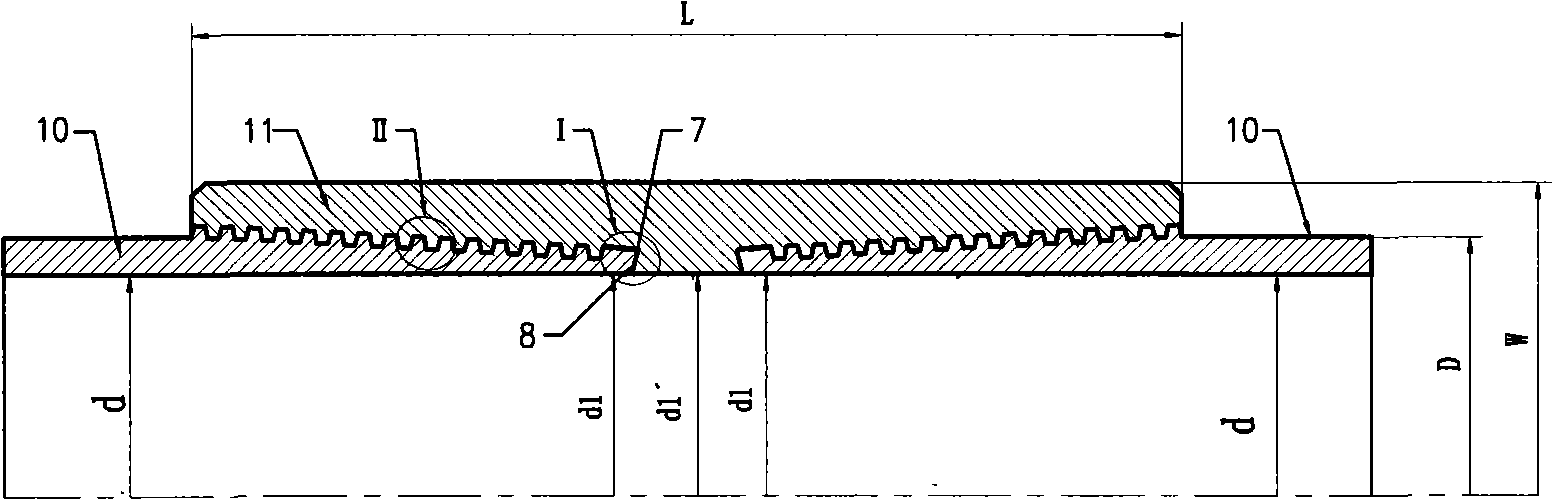

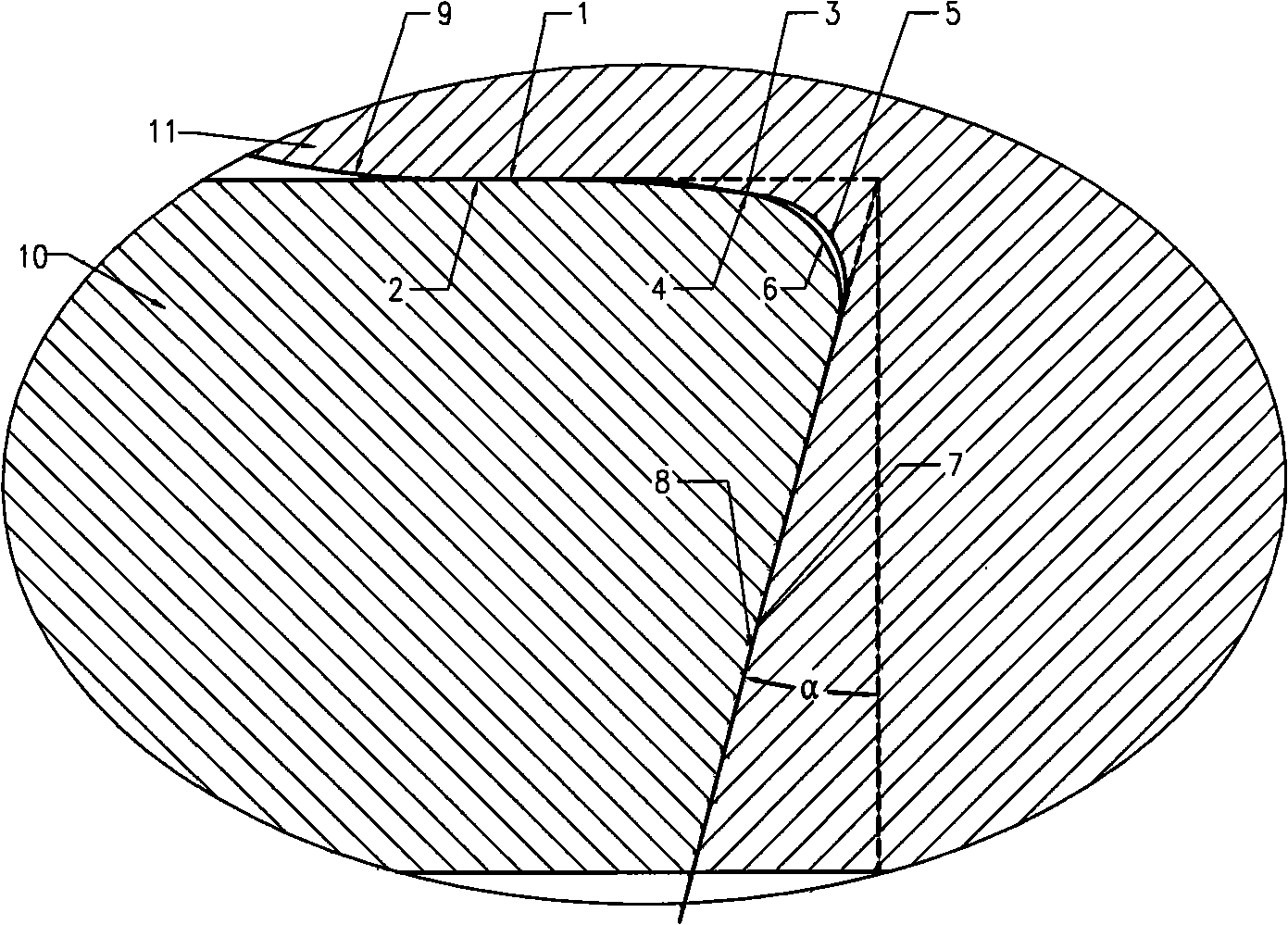

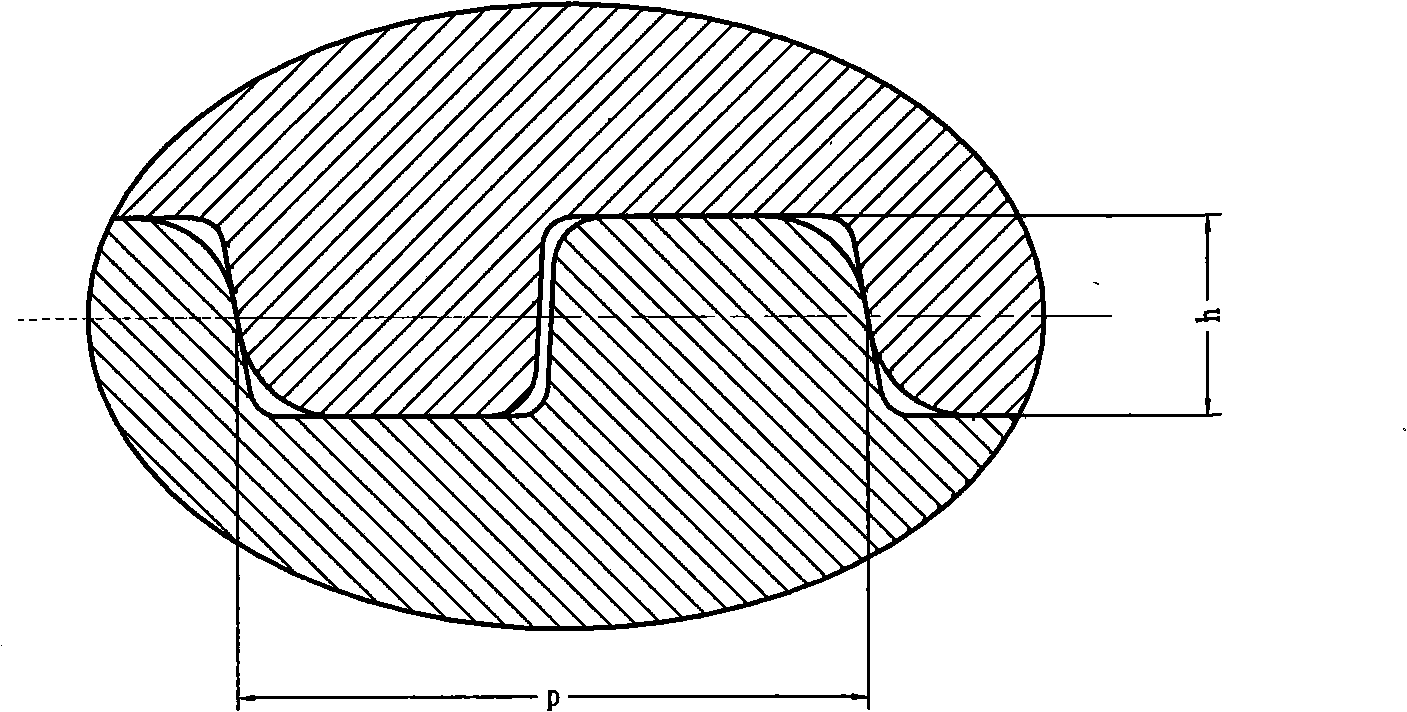

[0022] As shown in Figures 1 to 4, an oil pipe threaded connection structure is formed by screwing an oil pipe end 10 with an external thread and a pipe joint 11 with an internal thread. It is a non-API standard partial trapezoidal tapered thread. The head of the oil pipe end 10 is provided with an arc surface 4 with R=6mm, and the pipe joint 11 is provided with a 1:8 conical surface with an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com