Patents

Literature

122results about How to "Improve anti-stick performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

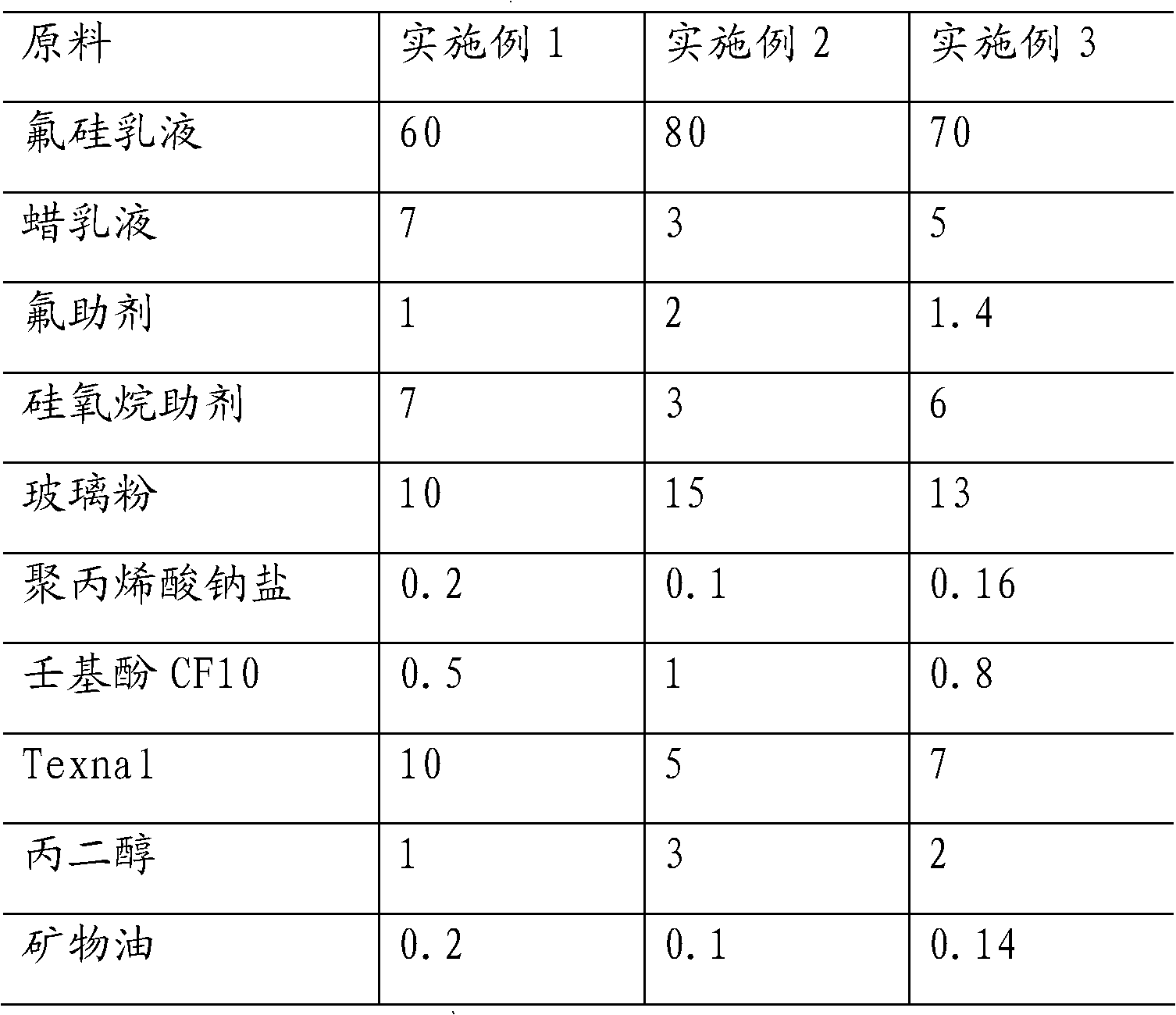

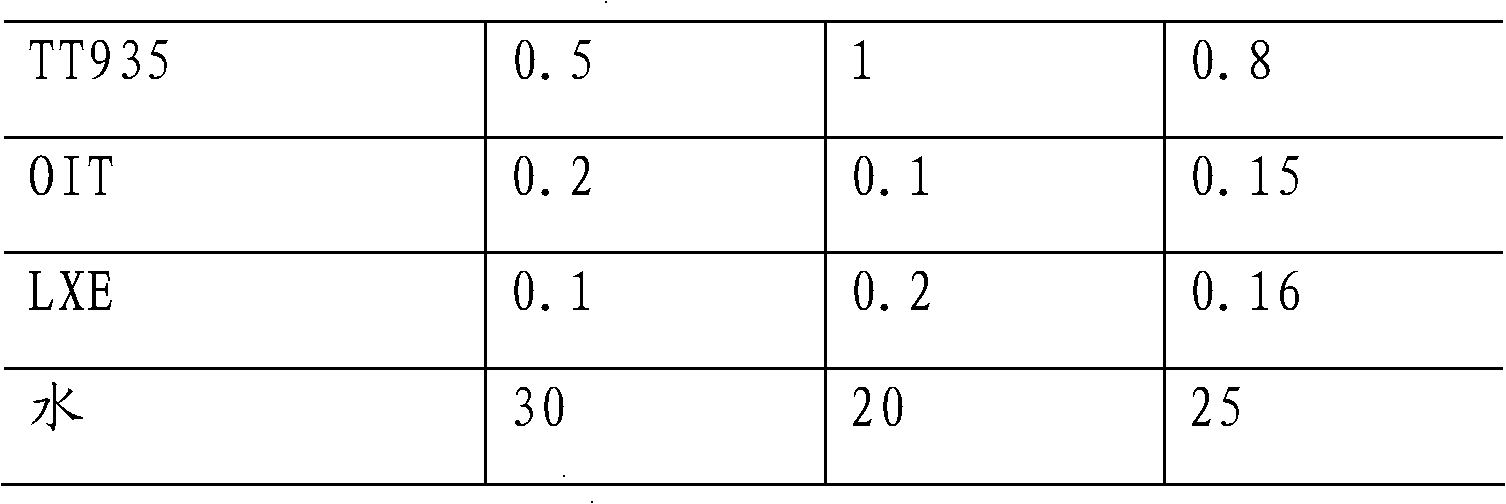

Aqueous antifouling adhesive preventing coating and production method thereof

InactiveCN102002298AHydrophobicWith anti-graffiti performanceAntifouling/underwater paintsPaints with biocidesSolventPolymer

The invention discloses an antifouling adhesive preventing coating which comprises the following components in parts by weight: 60-80 parts of polymer emulsion, 3-7 parts of water repellent agent, 1-2 parts of first adhesive preventing agent and 3-7 parts of second adhesive preventing agent, wherein the polymer emulsion is selected from one of fluorine and silicon modified acrylate emulsion, fluorine emulsion and silicon acrylic emulsion; the water repellent agent is water-soluble wax emulsion; the first adhesive preventing agent is a fluorine modified surface auxiliary agent with a water and oil repellent structure; and the second adhesive preventing agent is polyether modified hydroxyl functional polydimethylsiloxane. The invention also discloses a preparation method of the antifouling adhesive preventing coating. The coating of the invention has the performances of low surface energy, water and oil repellency, oil fouling resistance, adhesive sticker bonding prevention, and the like and has favorable antifouling adhesive preventing function and superhigh scrubbing resistance and is rapid and convenient for construction. Compared with the market sold solvent type product, the invention has the characteristic of environmental protection and can be suitable for indoor coating.

Owner:CARPOLY CHEM GRP

Slag adhesion preventing fluorine-free slag modifier for ladle refining, preparation method and using method

InactiveCN101519713AIncrease contentIncrease surface tensionProcess efficiency improvementSteelmakingPhosphor

The invention belongs to the field of steelmaking, and particularly discloses a fluorine-free slag modifier for preventing a ladle refining device from adhering slag, a preparation method and a using method. The slag modifier consists of active lime, bauxite and boric anhydride; and the slag modifier comprises the following chemical components in percentage by mass: 75 to 85 percent of CaO, 10 to 20 percent of Al2O3, 5 to 15 percent of B2O3, 0 to 8 percent of MgO, and the balance of impurities, wherein SiO2 is less than 7.0 percent, H2O is less than 0.05 percent, and the total amount of sulfur and phosphor is less than 0.01 percent. During use, in order to prevent a ladle from adhering the slag, the slag modifier is fed into the ladle in the later period of discharging steel from a steelmaking furnace, and in order to prevent an RH dip pipe or a CAS-OB dip cover and the like from dipping into the ladle device to adhere slag, the slag modifier is fed at a refining station. The slag modifier can effectively control the refining device from slag adhesion and improve the service life of a fireproof material, is favorable for reducing the contents of the sulfur, oxygen and impurities in the steel, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Manganese phosphating liquor, preparation and use thereof

InactiveCN101328583AImprove adhesionImprove corrosion resistanceMetallic material coating processesCalcium hydroxidePhosphoric acid

The invention provides a manganese phosphating solution, a preparation method thereof and an application. The compositions in percentage by mass of the manganese phosphating solution are: 5.0 to 15.0 percent of phosphoric acid, 5.0 to 20.0 percent of manganese biphosphate, 1.0 to 18.0 percent of nitric acid, 0.1 to 3.0 percent of calcium hydroxide, 0.2 to 5.0 percent of zinc oxide, 1.0 to 5.0 percent of tartaric acid and the balance being water. Water, phosphoric acid, pasty zinc oxide, nitric acid and phosphoric acid mixture, calcium hydroxide and tartaric acid are added in a reaction kettle in turn, and are stirred continuously so as to prepare the phosphating solution. The manganese phosphating solution is used in surface treatment of oil well pipe coupling. The manganese phosphating solution can be formed into a compact black crystallized phosphating film on metal surface, thereby effectively improving the abrasion resistance, thread gluing-proof property and seizure resistance of metal surface and increasing the performance of oil well pipe coupling to 4 to 10 times; moreover, the manganese phosphating solution, the preparation method thereof and the application ensure simplified operation and convenient maintenance, and can be effectively used in practical industrialized production.

Owner:BAOSHAN IRON & STEEL CO LTD

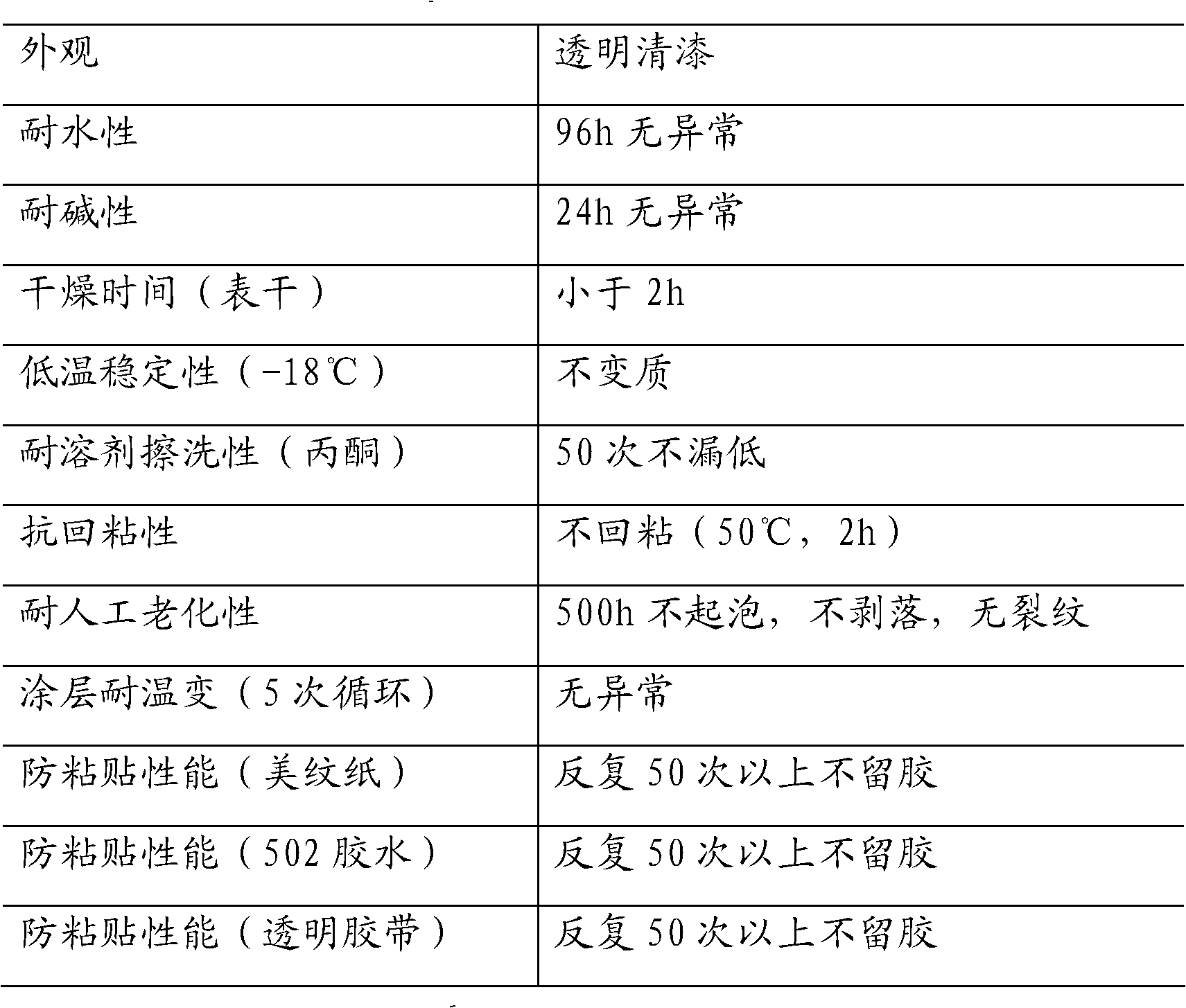

Aqueous anti-doodling and anti-affixing paint and its preparation method

InactiveCN102477249AImprove water resistanceLess water residuePolyurea/polyurethane coatingsCross-linkEmulsion

The invention relates to an aqueous anti-doodling and anti-affixing paint. The paint provided by the invention comprises a component A and a component B, wherein the component A contains, by weight, 50-70 parts of an anionic polyacrylate dispersion and 5-10 parts of a modified silane emulsion; and the component B contains, by weight, 20-25 parts of a water dispersive aliphatic polyisocyanate curing agent. The invention also relates to a preparation method of an aqueous anti-doodling and anti-affixing paint film. With the use of the polyacrylate dispersion as a base material, the aqueous anti-doodling and anti-affixing paint can have a high gloss and its scratch resistance can be improved. With the use of the water dispersive aliphatic polyisocyanate as a cross-linking agent, the paint can have excellent weatherability and yellow-stain resistance. Dual-component crosslinking and solidification can endow the paint with high surface hardness, compact film and excellent anti-doodling performance.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

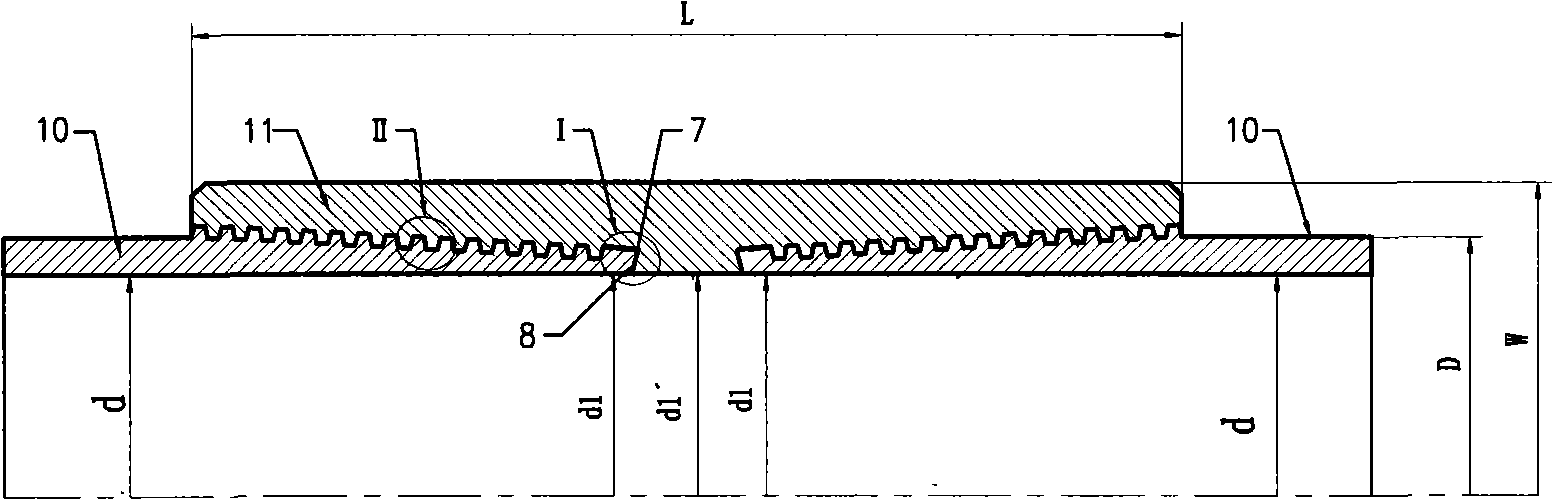

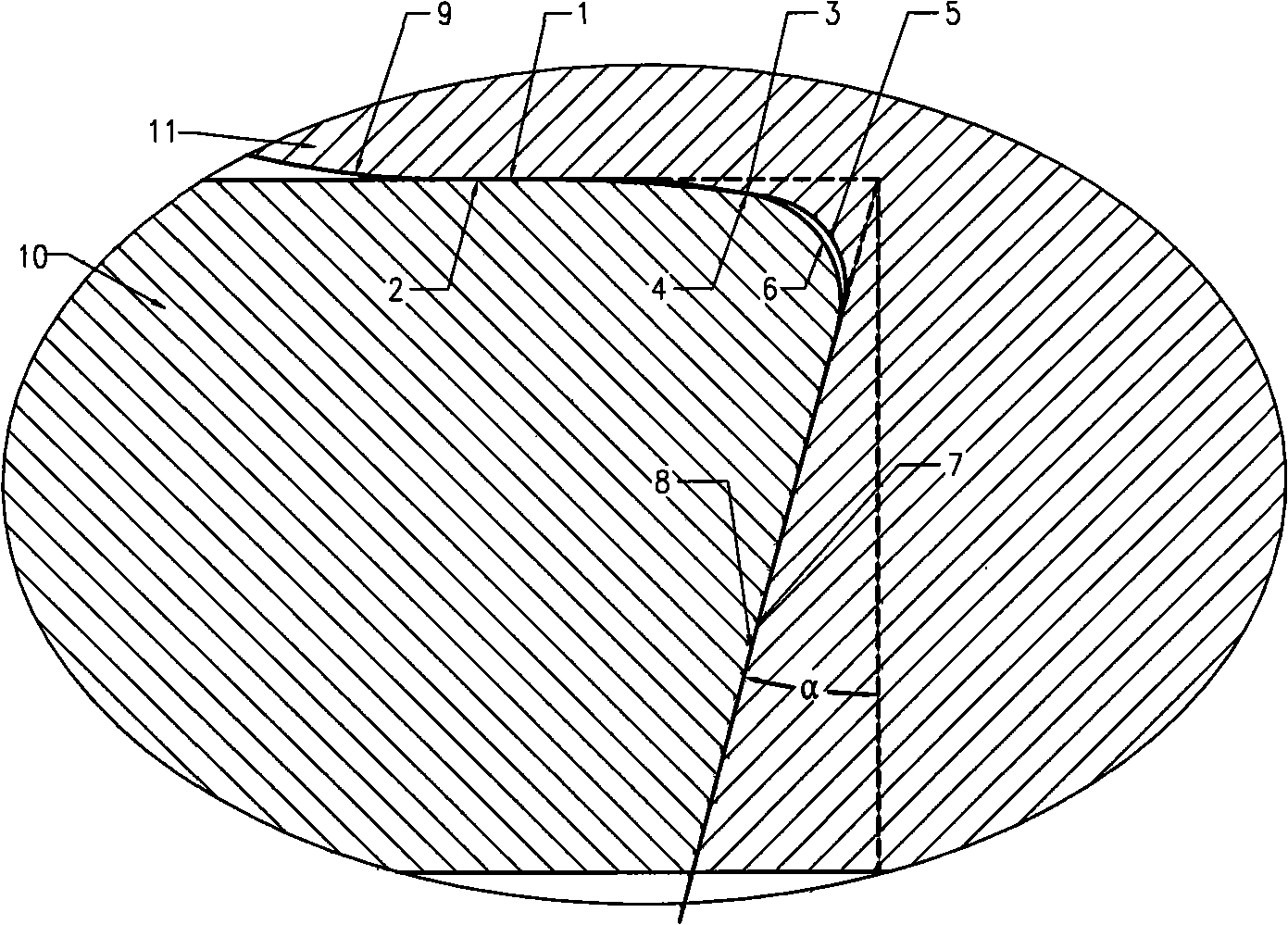

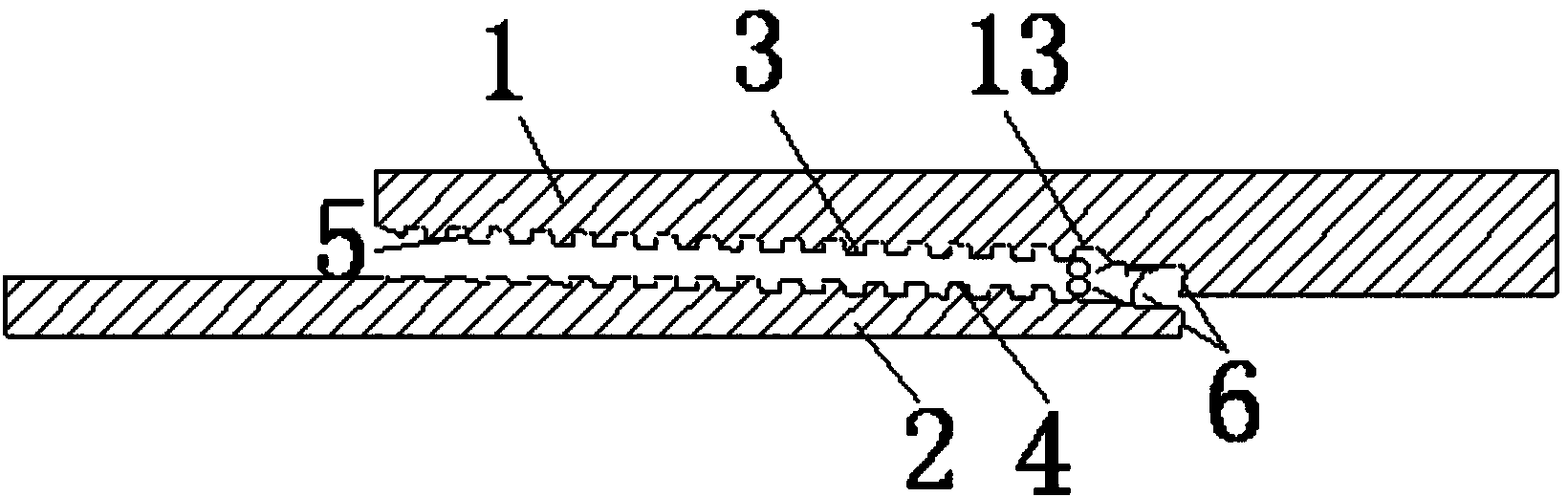

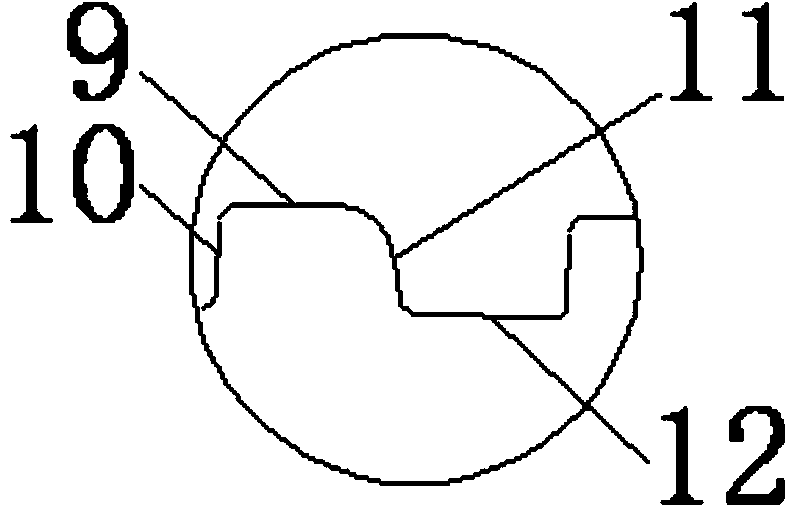

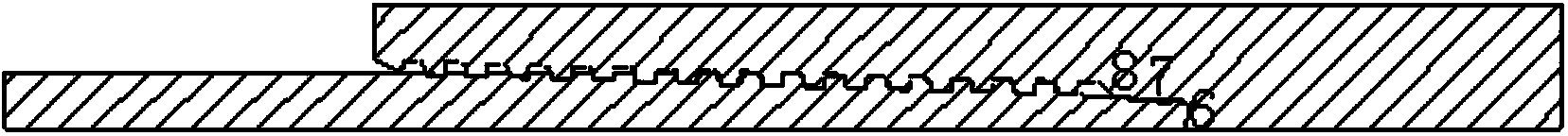

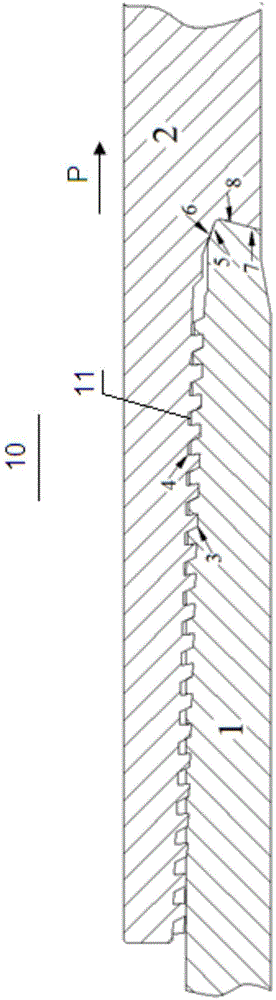

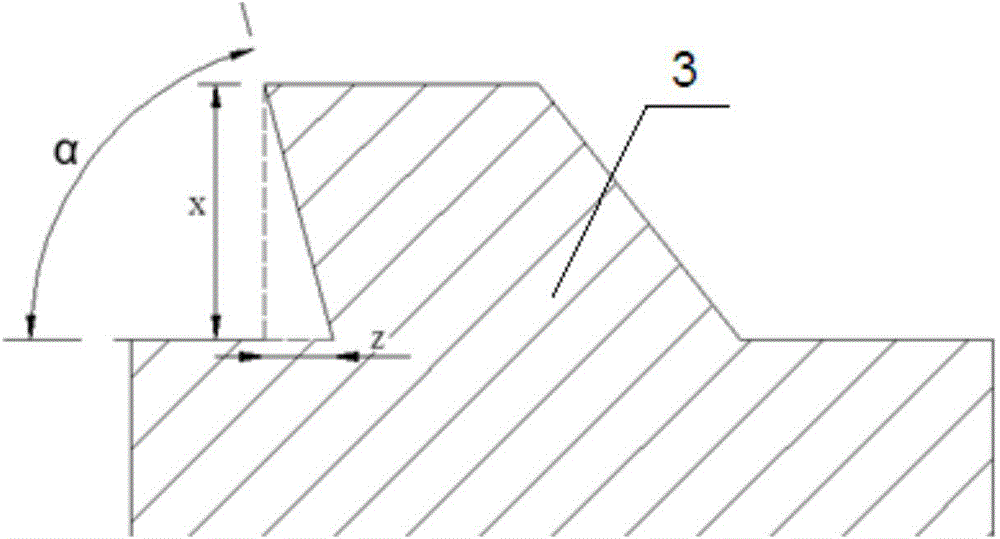

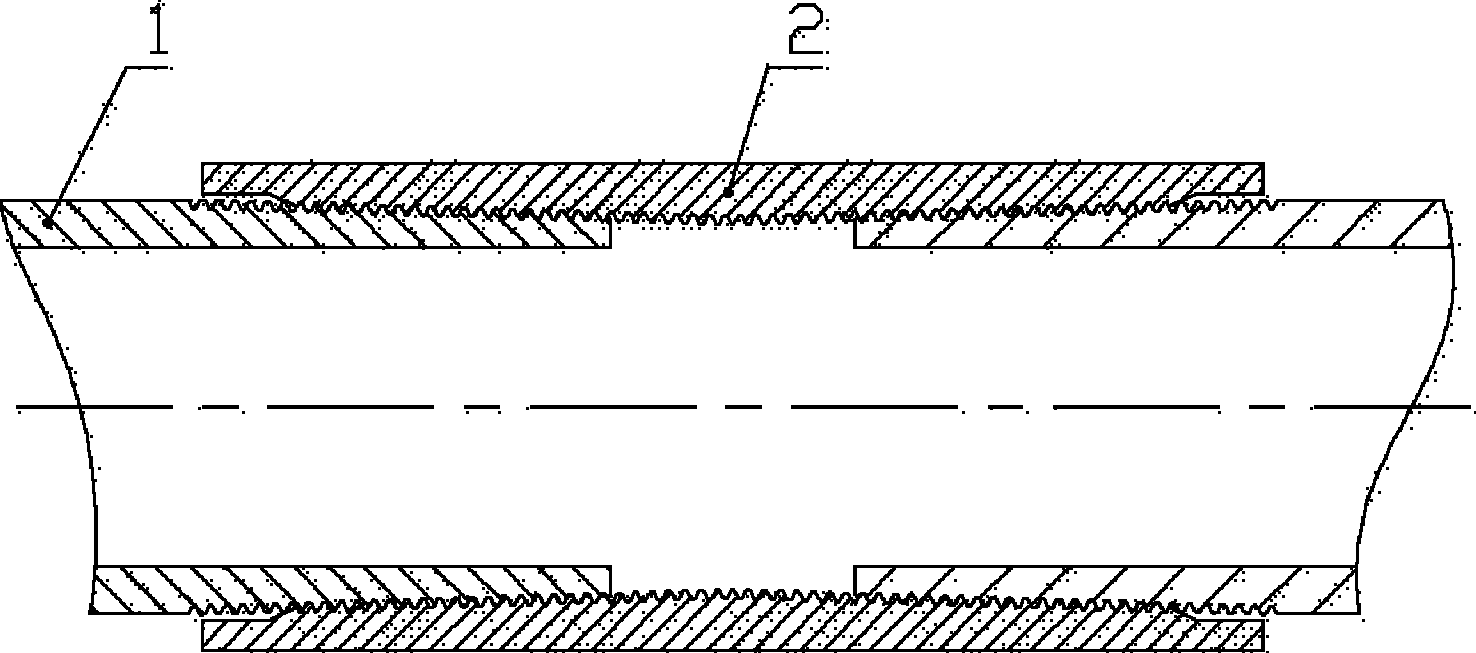

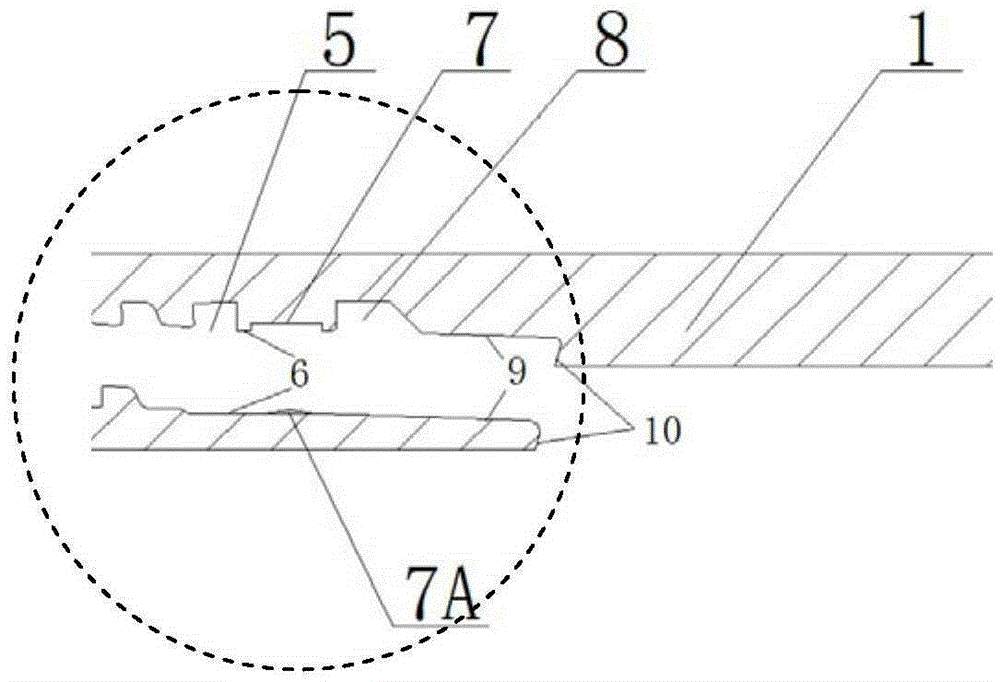

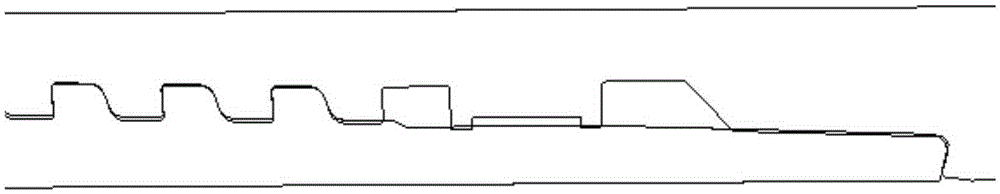

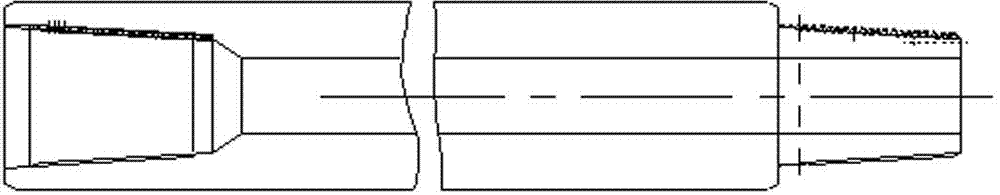

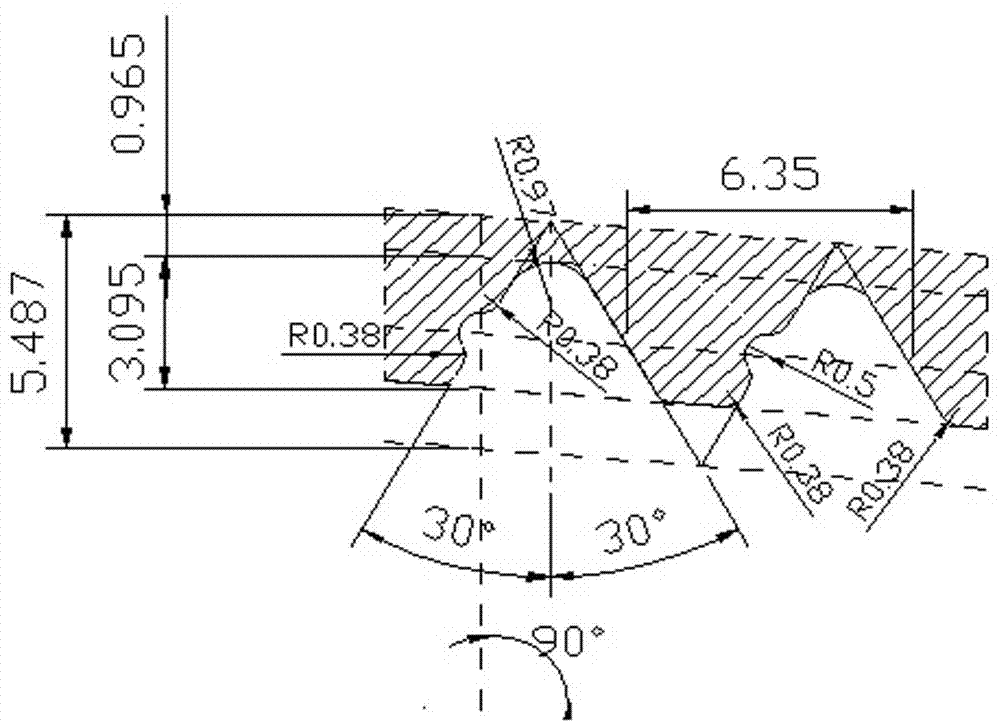

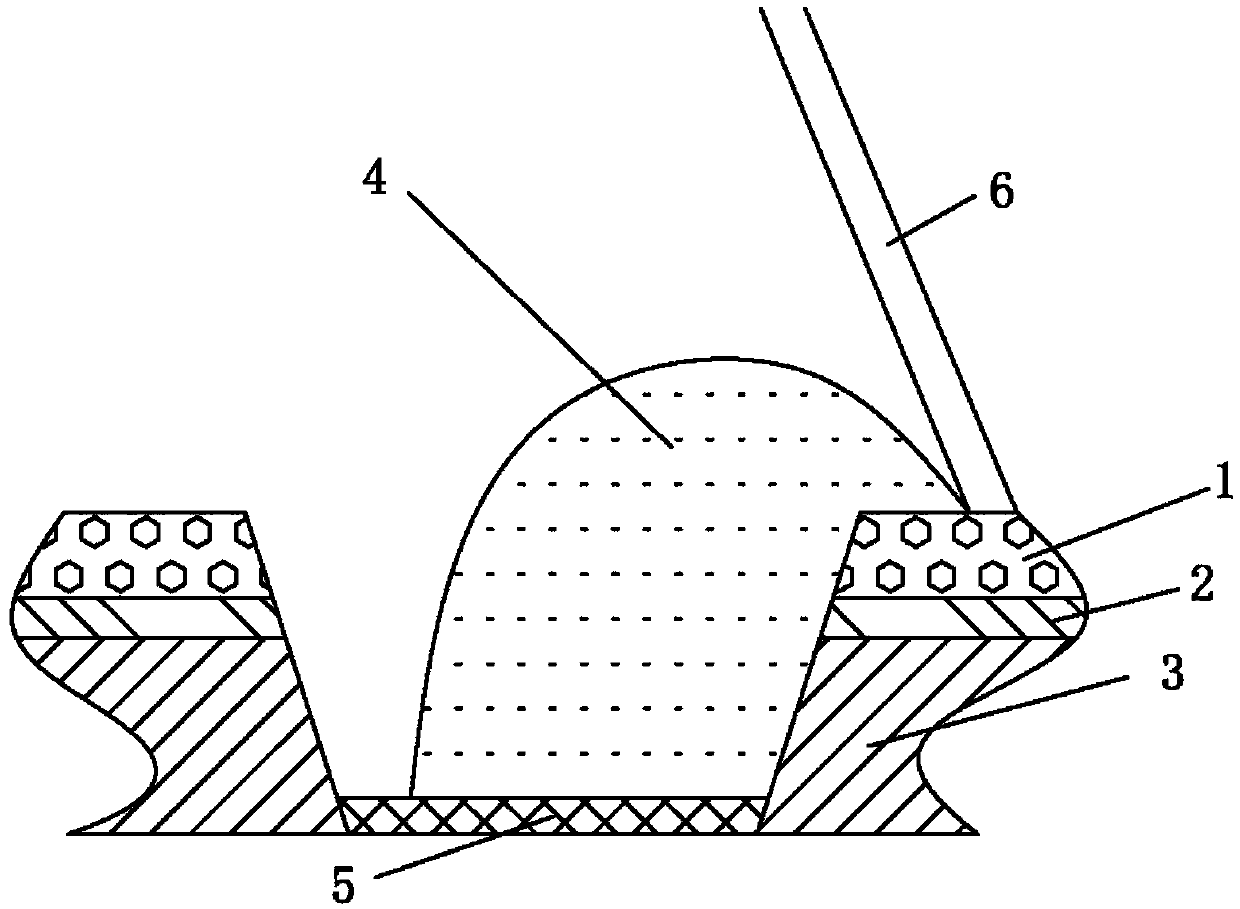

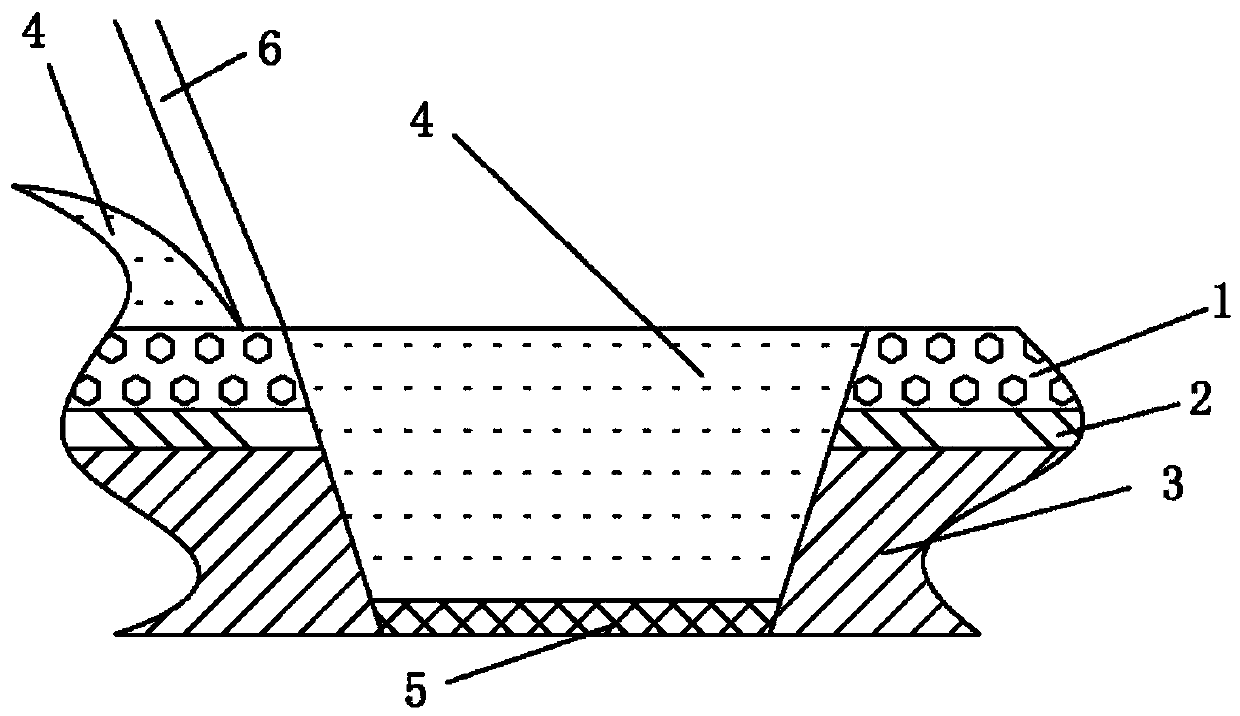

Oil conduit screwed connection structure

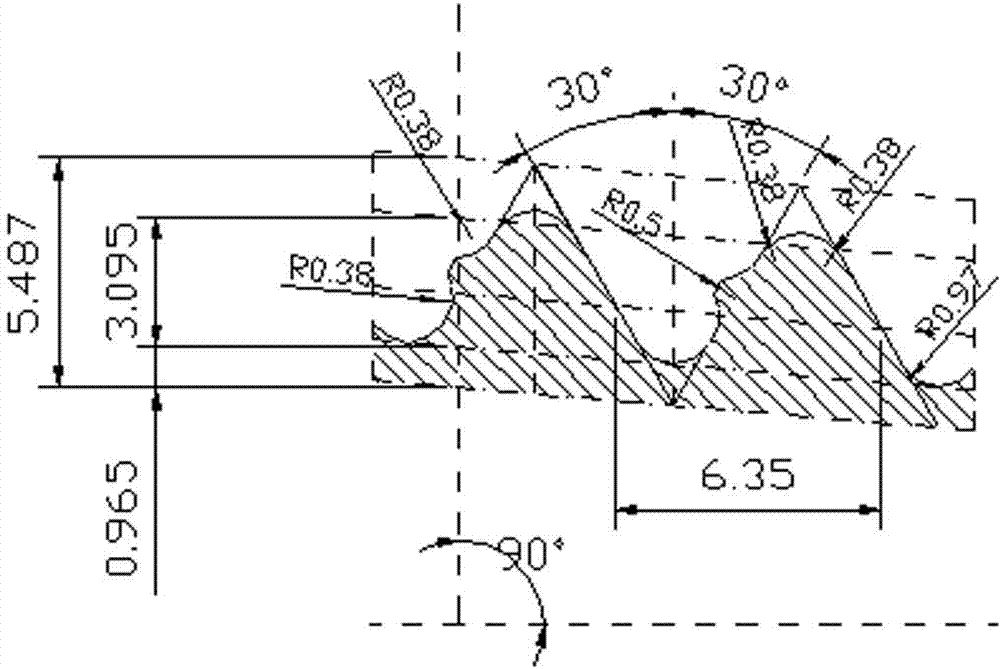

InactiveCN101307845AGood airtightnessImprove airtight performanceScrew threaded jointsInterference fitScrew thread

The invention relates to an oil pipe threaded connection structure, which is formed by screwing an oil pipe end (10) with an outer thread together with a pipe joint (11) with an inner thread. The threads adopted by the oil pipe end (10) and the pipe joint (11) are both approximate trapezoidal tapered threads; the head part of the oil pipe end (10) is provided with a circular arc surface (4); a circular conical surface (3) in interference fit with the circular arc surface is arranged on the pipe joint (11); the head part of the oil pipe end (10) is provided with an outer torque step (8); an inner torque step (7) matched with the outer torque step (8) is arranged on the pipe joint (11); the middle segment of the heat part of the oil pipe end (10) is provided with an outer cylindrical surface (2); an inner cylindrical surface (1) in interference fit with the outer cylindrical surface (2) is arranged on the pipe joint (11). The structure has the advantages of high threaded connection strength, good sealing performance, easy buckling, difficult buckling separation, good thread gluing preventing performance, strong over-torque preventing capability, etc.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

Phosphorization liquid of manganese series containing calcium

InactiveCN1687484ASignificant advantagesSignificant beneficial effectMetallic material coating processesCalcium hydroxideCopper plating

The present invention relates to Mn series Ca containing phosphide solution in the domain of final chemical engineering. The main characteristic is its component and the ratio of its weight is: 20 - 31% H3PO4, 9 - 16% MnCO3, 0.5 - 4% HNO3, 0.3 - 3% CaOH and water it until 100%. The phosphating solution can make black, compact and twinkling phosphating film on the surface of metal, and there are also in the phosphating film. It also improved the capability of phosphating film. The experiment proves that: The phosphating film can enhance the wearable and anti-corrosive capability. The phosphating solution is steady and its component is suitable. It's easy to prepare the solution and cost little, and it's also passes over the process of copper-plates. It is the preparation of updates in phosphating solution belongs to manganese catalyst.

Owner:李长吉

Method for plating TC4 titanium alloy threaded surface with copper

InactiveCN106086971AImprove bindingSolve difficult technical problemsJewelleryCopper platingDistilled water

The invention relates to the technical field of metal material surface modification, in particular to a method for plating a TC4 titanium alloy threaded surface with copper. The method sequentially includes the following steps of firstly, alkaline washing, secondly, water washing, thirdly, acid pickling, fourthly, water washing, fifthly, activating treatment, sixthly, water washing, seventhly, electroplating, eighthly, cleaning, ninthly, passivating and tenthly, cleaning and drying, wherein NaOH and Na3PO4 are dissolved in distilled water, and alkaline wash used in the first step is obtained; an acid pickling solution used in the third step comprises HF, HNO3 and H20; Na2Cr2O7 and HF are dissolved in distilled water, and activate fluid used in the fifth step is obtained; and CrO3, NaCl and H2SO4 are dissolved in distilled water, and a passivating solution used in the ninth step is obtained. The method is simple in process, convenient to implement, low in cost, easy to implement and high in production efficiency; and meanwhile, a modified threaded portion has the higher plastic shearing resistance and wear resistance, and the thread sticking problem is solved.

Owner:XIAN TECHNOLOGICAL UNIV

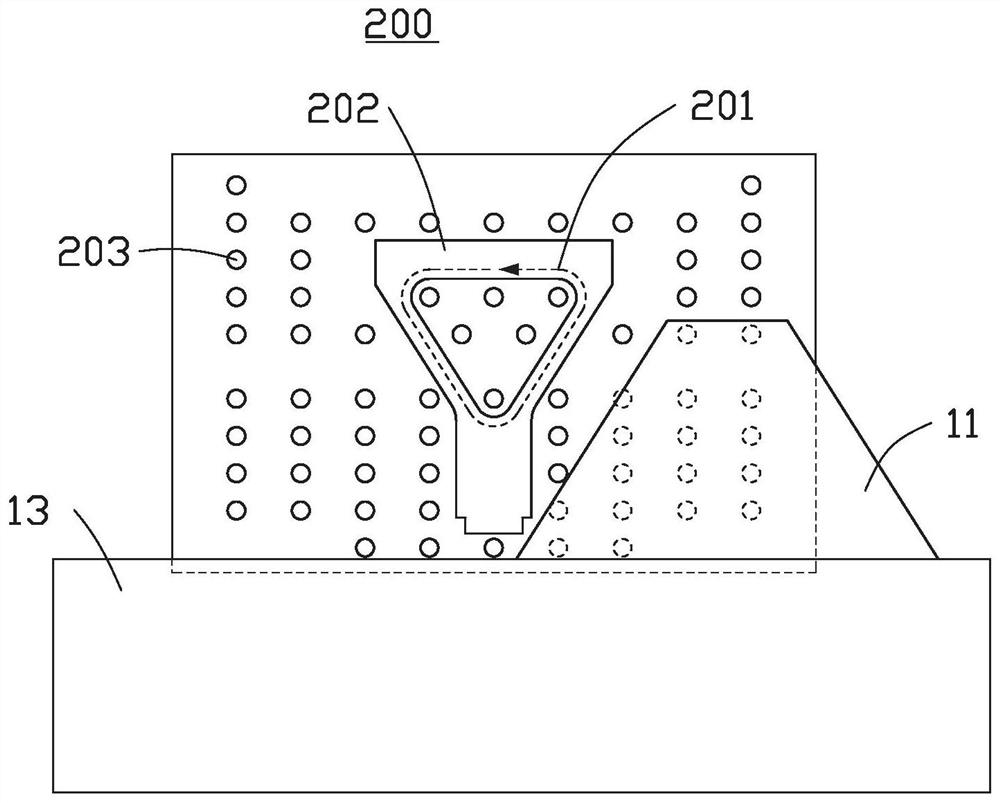

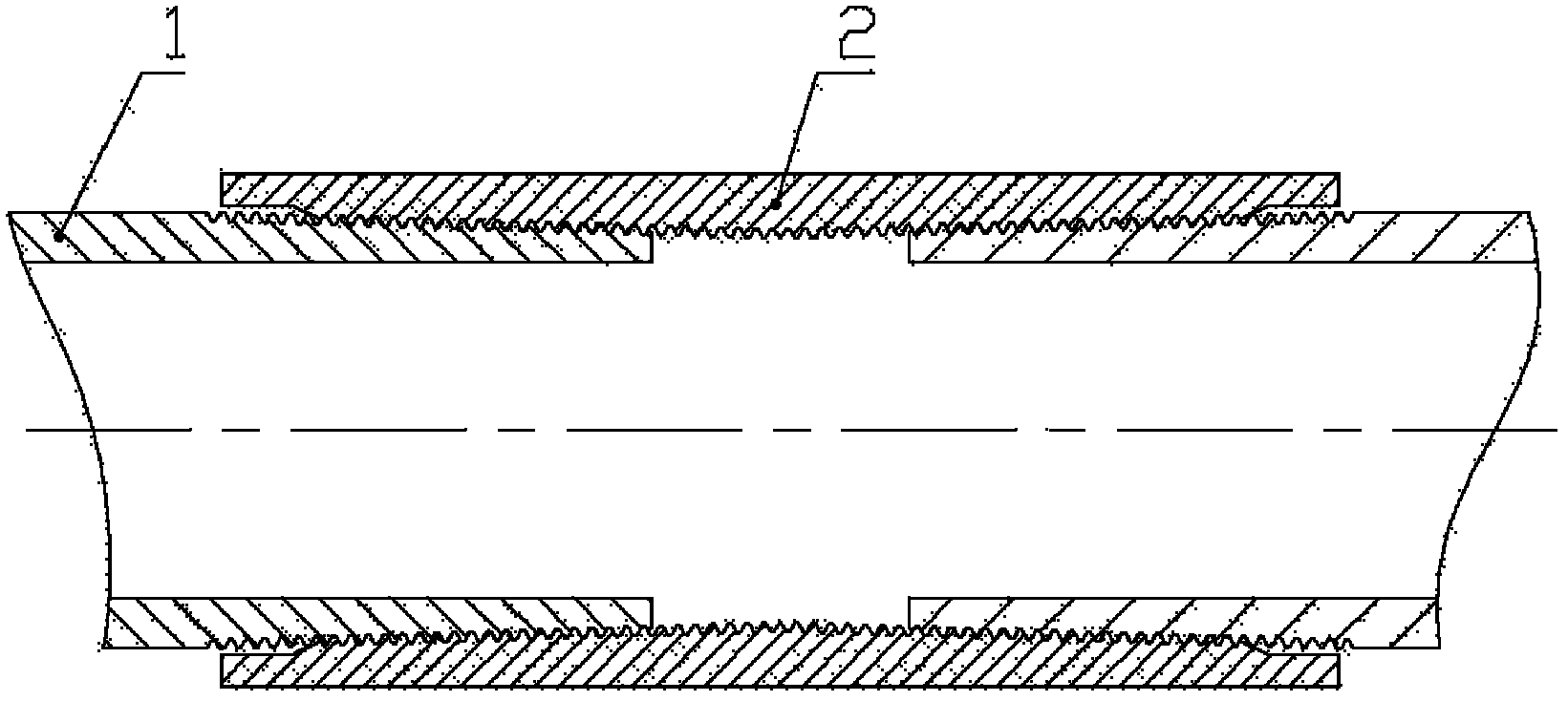

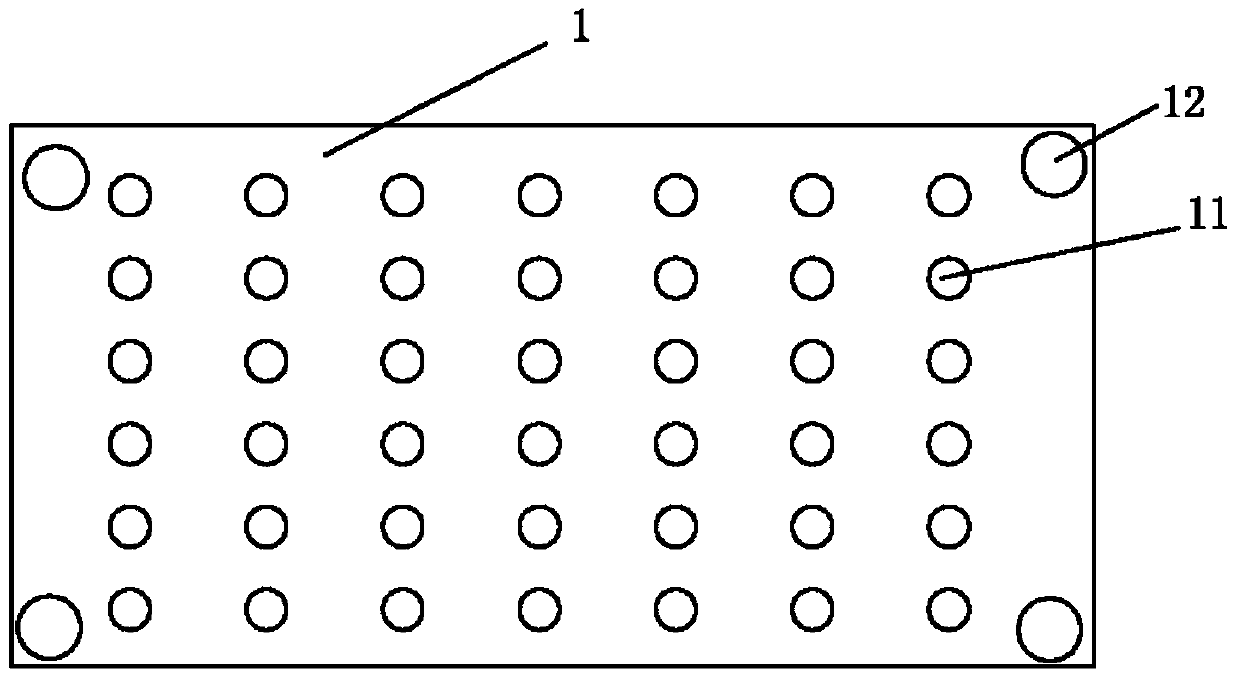

Tab structure, application of tab structure, preparation method and preparation device of tab structure

PendingCN112103455ASimple structural designImprove anti-stick performanceFinal product manufactureSecondary cellsIsosceles trapezoidMechanical engineering

The invention discloses a tab structure, application of the tab structure, a preparation method and a preparation device of the tab structure. The tab structure comprises an electrode plate and a tabbody, the tab body is of an isosceles trapezoid structure, and the angle between the waist edge of the tab body and the edge of the electrode plate body is greater than or equal to 80 degrees and lessthan or equal to 85 degrees. The tab body is adjusted into the isosceles trapezoid, and the angle between the waist edge of the tab body and the electrode plate is limited, so that the design of thetab structure is optimized, and the anti-sticking performance of the tab body is improved; the tab structure has an important significance for improving the forming integrity of the battery electrodeplate and the consistency of the battery cell, and meanwhile has high applicability in the aspect of sheet laser forming.

Owner:ZHONGTIAN ENERGY STORAGE TECH

Method for preparing surface coating of high chrome steel

The invention discloses a method for preparing surface coating of high chrome steel. The method comprises the following steps: degreasing, cold washing, weak corrosion, weak corrosion plus nickel plating, cold washing, copper-tin alloy plating, cold washing, passivation, cold-hot washing and molybdenum soaking. Nickel is pre-plated on the high chrome steel, and the copper-tin alloy is plated on the nickel plated surface. Compared with the prior art, the method has the advantages of improving the anti-bonding property of an oil casing connector, realizing the whole shackle of the oil casing connector, and ensuring the service performance of the oil casing in high chrome steel.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Water-soluble environmentally-friendly gravure ink and preparation method thereof

The invention discloses water-soluble environmentally-friendly gravure ink, which is characterized by being prepared from the following raw materials in percentage by weight: 5-50 percent of liquid water-soluble resin, 5-70 percent of water-soluble pigment, 5-40 percent of water, 1-5 percent of latent solvent and 0.1-25 percent of aid. The invention further discloses a preparation method of the water-soluble environmentally-friendly gravure ink. In the water-soluble environmentally-friendly gravure ink, tap water can be taken as a diluting agent, so that cost is saved for a printing enterprise; and the ink has high printing adaptability, high friction resistance, high waterproofness and high adhesion, is noncorrosive on an inking roller, and can be directly washed with water. When the water-soluble environmentally-friendly gravure ink is used for printing, tap water can be directly used for diluting, the product generality is relatively high, and the water-soluble environmentally-friendly gravure ink is mainly applied to printing processes of paper, plastic films, aluminum foils and the like.

Owner:江苏云合新材料科技有限公司

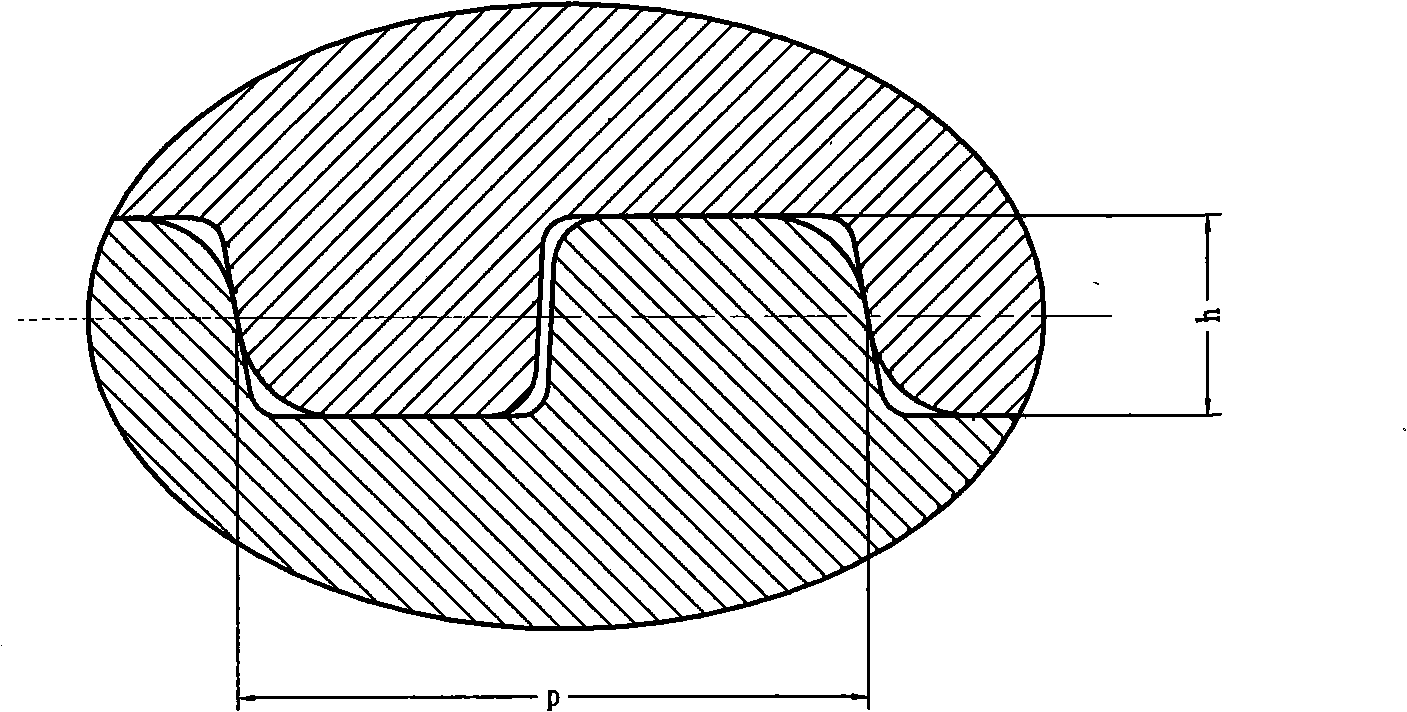

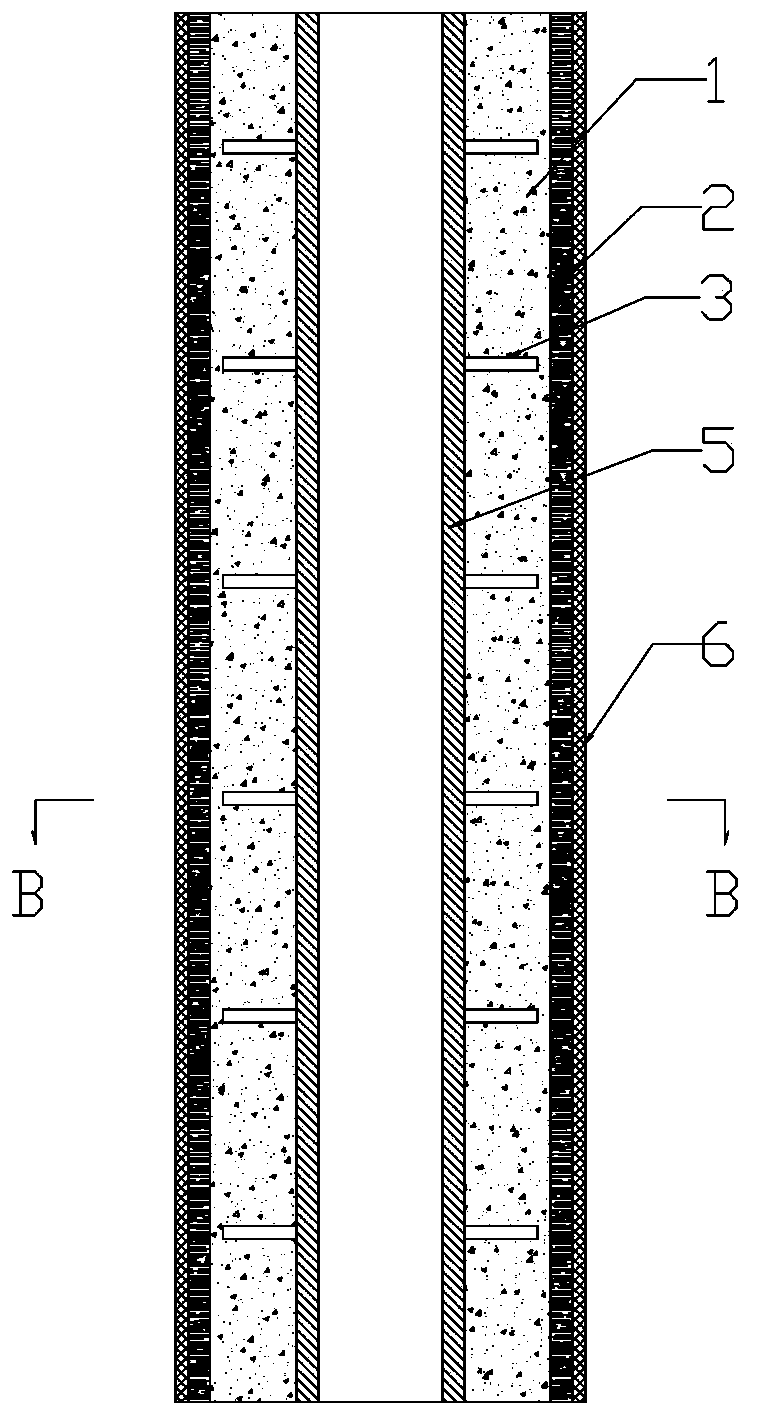

Multistage sealing anti-sticky buckle type thread for titanium alloy oil casing

InactiveCN103527110AImprove airtight reliability performanceReduced stress stateDrilling rodsDrilling casingsButtressCoupling

The invention relates to a multistage sealing anti-sticky buckle type thread for a titanium alloy oil casing. The multistage sealing anti-sticky buckle type thread comprises an oil casing coupling and an oil casing tube end, the oil casing coupling is provided with a standard API buttress internal thread which is sequentially connected with a tool withdrawal groove, a cone surface to cone surface first stage sealing structure, a cylinder surface to cylinder surface second stage sealing structure and a negative angle torque circular bead, wherein the cone surface to cone surface first stage sealing structure and the cylinder surface to cylinder surface second stage sealing structure are in transition through chambering, and the negative angle torque circular bead is connected with the standard API buttress internal thread through a transitional angle. The multistage sealing anti-sticky buckle type thread for the titanium alloy oil casing has the advantages that two stages of metal sealing and one negative angle torque circular bead sealing are added based on the improved buttress thread, the reliability of the air tightness of a thread connector is improved through the design of multistage sealing, meanwhile, the stress state of the thread connector is reduced by changing a thread parameter, the performance of an anti-sticky buckle is improved, and machining and detecting are convenient.

Owner:XIAN SANHUAN TECH DEV GENERAL

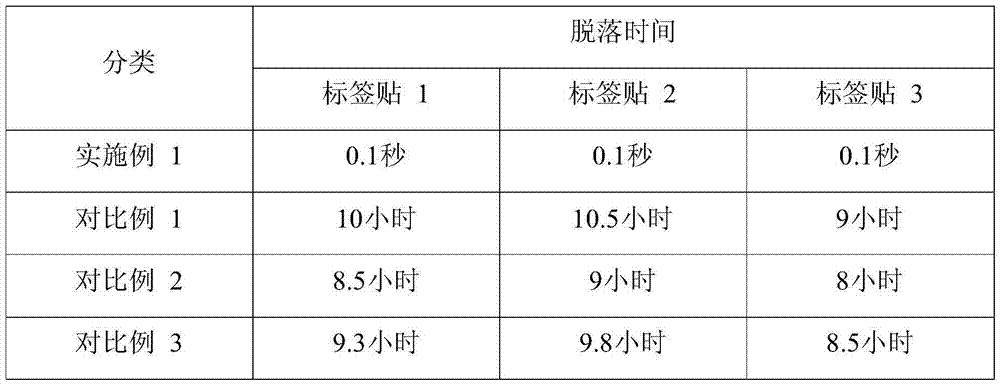

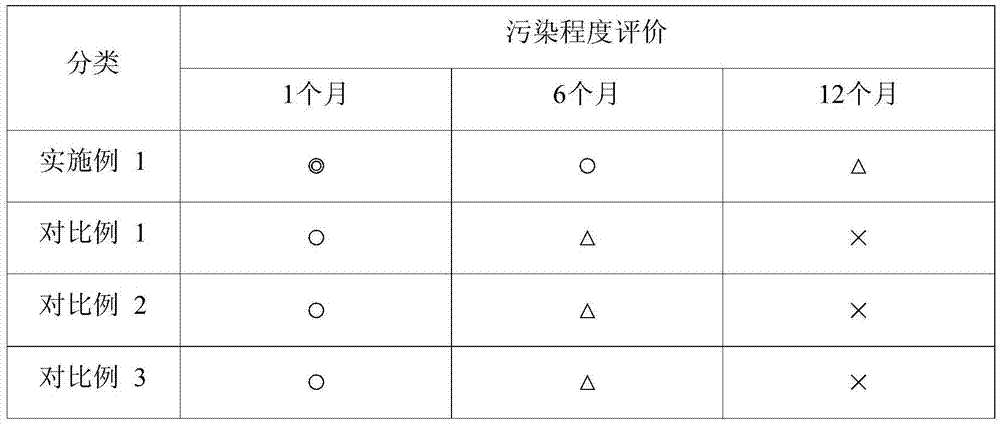

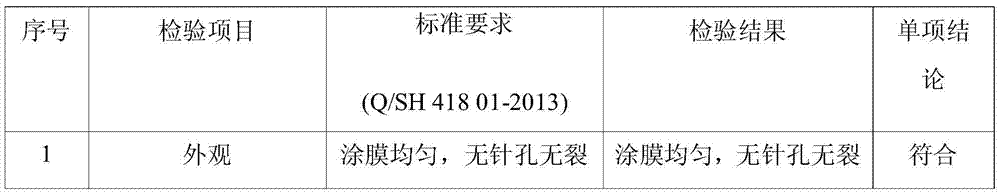

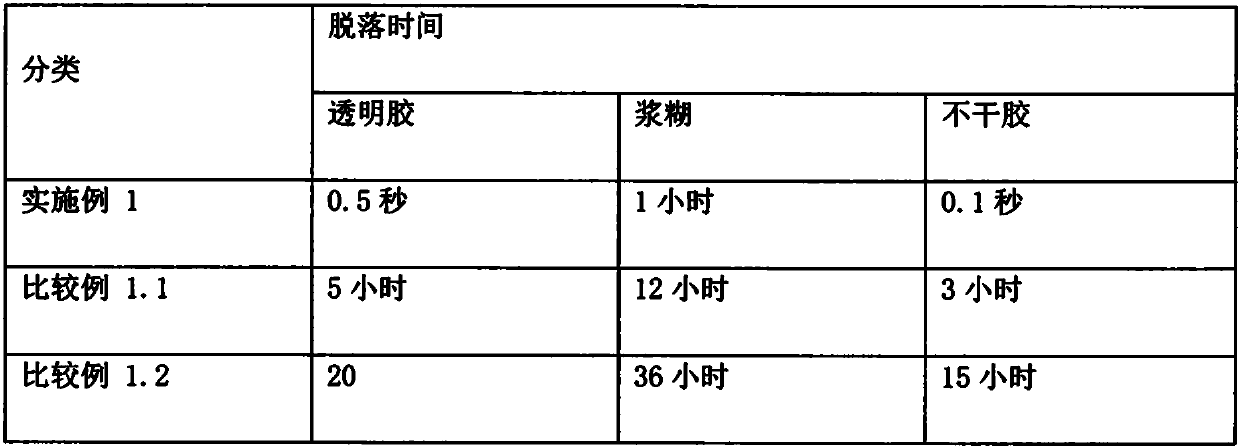

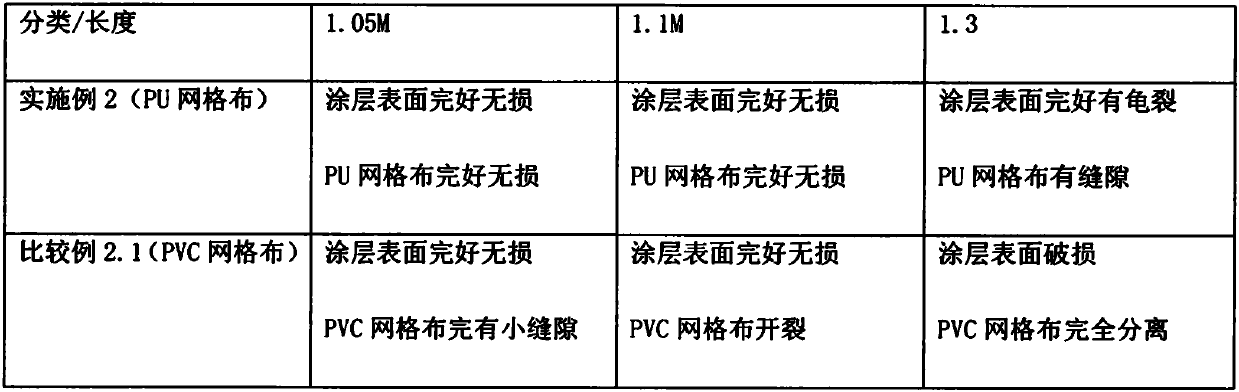

Anti-sticking coating and anti-sticking patch

ActiveCN105440938AImprove anti-stick performanceGood antifoulingAntifouling/underwater paintsPaints with biocidesAcrylic resinVinyltriethoxysilane

The invention relates to a coating, in particular to an anti-sticking coating. The anti-sticking coating comprises the following components by weight percent: 10 to 30 percent of resin I, 10 to 30 percent of acrylic resin, 5 to 10 percent of 3-vinyltriethoxysilane, 5 to 10 percent of diphenyldichlorosilane, 1 to 5 percent of photocatalyst, 5 to 10 percent of silicon dioxide, 1 to 10 percent of additives and 20 to 50 percent of solvent. The invention also provides an anti-sticking patch. The surface of the anti-sticking patch is coated with the anti-sticking coating. The anti-sticking coating and the anti-sticking patch are not only good in anti-sticking performance, but also capable of improving the attractiveness of various facilities, and also relatively good in antifouling performance and abrasion resistance.

Owner:BEIJING BOYUEJIECHUANG ENVIRONMENTAL ENG

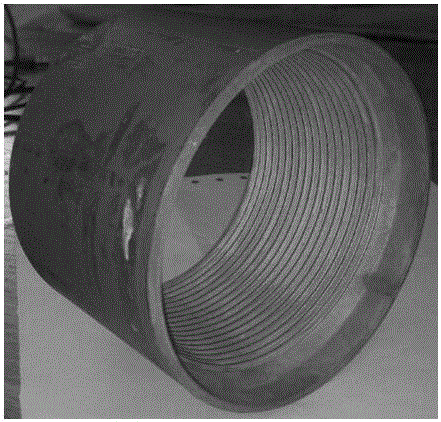

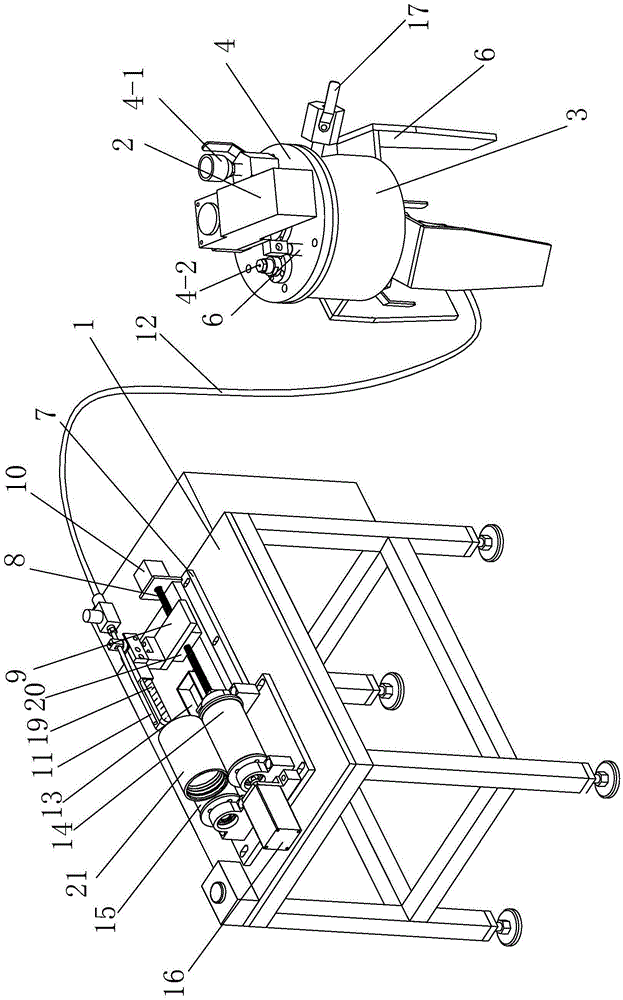

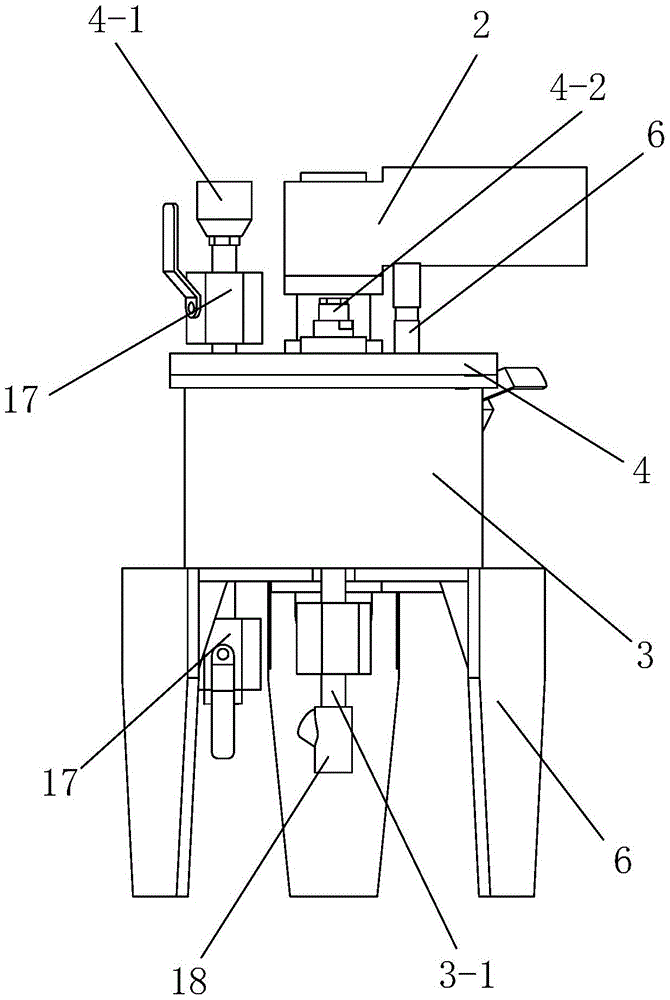

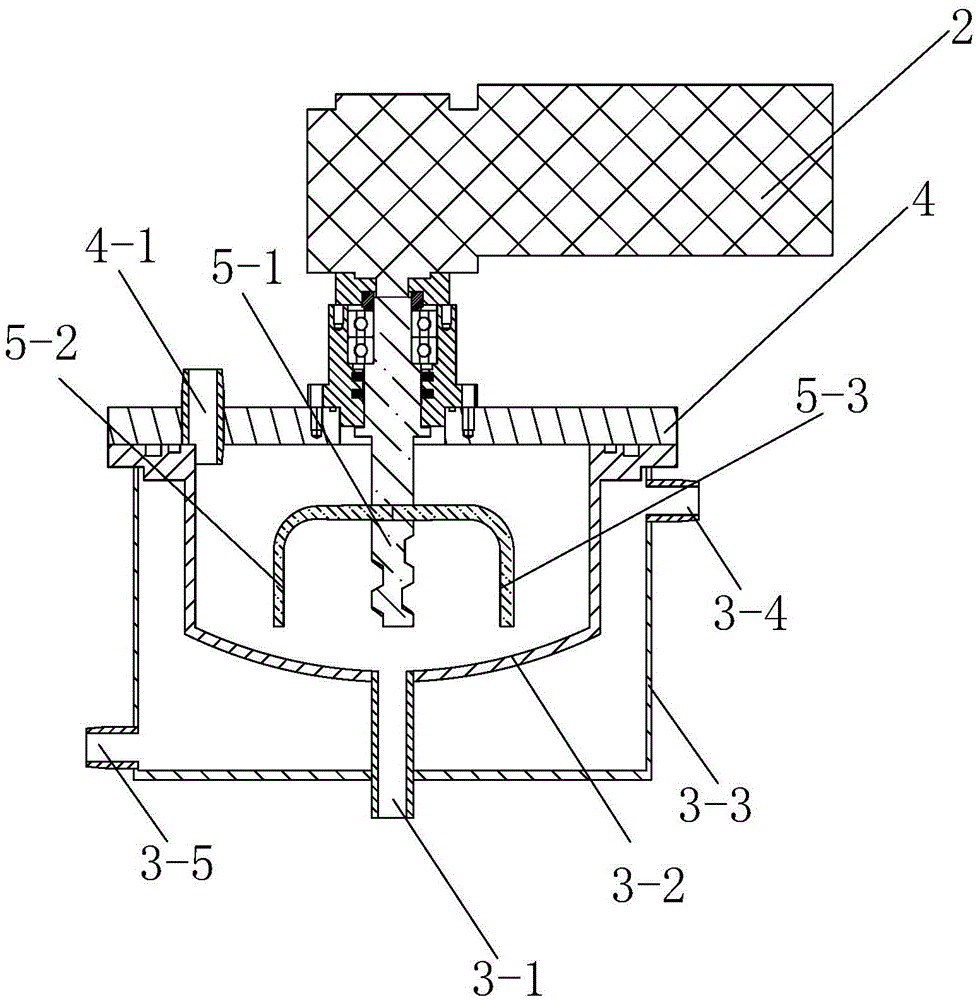

Device and method for coating inner wall of oil casing coupling with anti-friction nano coating

InactiveCN105583126ASimple structureNovel and reasonable designLiquid surface applicatorsCoatingsCouplingReciprocating motion

The invention discloses a device for coating the inner wall of an oil casing coupling with an anti-friction nano coating. The device for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises a storage mechanism, a feeding mechanism and a workpiece rotating mechanism. The storage mechanism comprises a stirring kettle and a first driving motor. The feeding mechanism comprises a base, a lead screw, a moving block and a second driving motor. A dripping pipe and a coating brush are arranged on the moving block. The workpiece rotating mechanism comprises a driving roller, a driven roller and a third driving motor. The invention further discloses a method for coating the inner wall of the oil casing coupling with the anti-friction nano coating. The method for coating the inner wall of the oil casing coupling with the anti-friction nano coating comprises the following steps that firstly, a workpiece is rotated; secondly, the anti-friction nano coating is evenly stirred; thirdly, the nano coating is brushed while the coating brush moves in a reciprocating mode; and fourthly, drying is conducted. According to the device and method for coating the inner wall of the oil casing coupling with the anti-friction nano coating, the design is novel and reasonable, the device can be obtained conveniently, and the method can be implement conveniently; the application range is wide, and the using effect is good; an oil casing coupling workpiece can be coated with the coating rapidly, and the purpose of improving the viscidity resistance of the oil casing coupling is achieved finally.

Owner:XIAN UNIV OF SCI & TECH

Airtight seal sleeve joint

InactiveCN104453738AGuaranteed compression performanceReduced risk of stickingDrilling rodsDrilling casingsPetroleum engineering

The invention discloses an airtight seal sleeve joint. The airtight seal sleeve joint comprises a sleeve male end and a sleeve female end, the sleeve male end is provided with an external thread, the sleeve female end is provided with an internal thread, the external thread of the sleeve male end is meshed with the internal thread of the sleeve female end, and the tooth profile of the external thread and the tooth profile of the internal thread are each of a slanting trapezoid shape. In addition, in the feeding direction of the external thread, the part, behind the external thread, of the sleeve male end is provided with a first seal face and a first retreat stop shoulder connected with the first seal face, and the first retreat stop shoulder is located at the tail end of the sleeve male end. The sleeve female end is provided with a second seal face and a second retreat stop shoulder, the second seal face is in interference fit with the first seal face, the second retreat stop shoulder is matched with the first retreat stop shoulder, and the second seal face is also connected with the second retreat stop shoulder. A gap is formed between the internal thread and the external thread. The airtight seal sleeve joint has good stretch resistance, compression resistance and torque resistance capability, better thread gluing resistance and excellent airtight seal performance and can adapt to the work environment of a three-exceeding gas field.

Owner:BAOSHAN IRON & STEEL CO LTD

Modified graphene composite namometer coating and preparation method and application thereof

InactiveCN109135494AImprove anti-friction performanceImprove wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsOrganic solventGraphene

The invention relates to a modified graphene composite namometer coating and a preparation method and application thereof. The coating comprises film-forming resin, a curing agent, an organic solvent,a dispersing agent and nanometer lubricating filler. The preparation method comprises the steps of preparation of graphene oxide suspension liquid, preparation of modified graphene, preparation of aresin solution and preparation of the graphene composite namometer coating. The modified graphene composite namometer coating is extremely high in wear resistance, and the anti-galling capacity of a threaded connector of an oil delivery pipe is greatly improved. The preparation process is simple, the solidification speed is high, the cost is low, convenience is brought to construction, and no pollution to the environment is caused.

Owner:DONGHUA UNIV

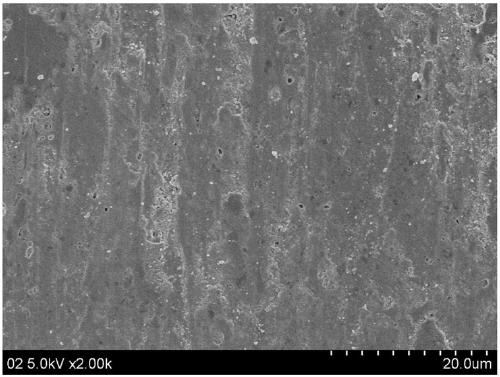

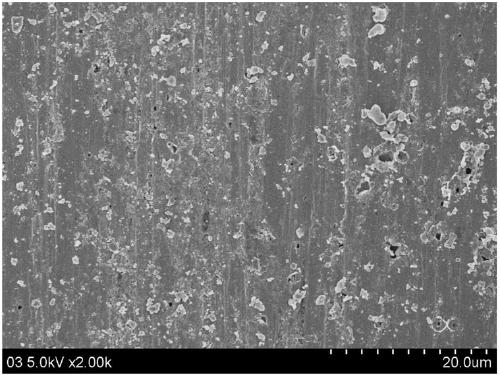

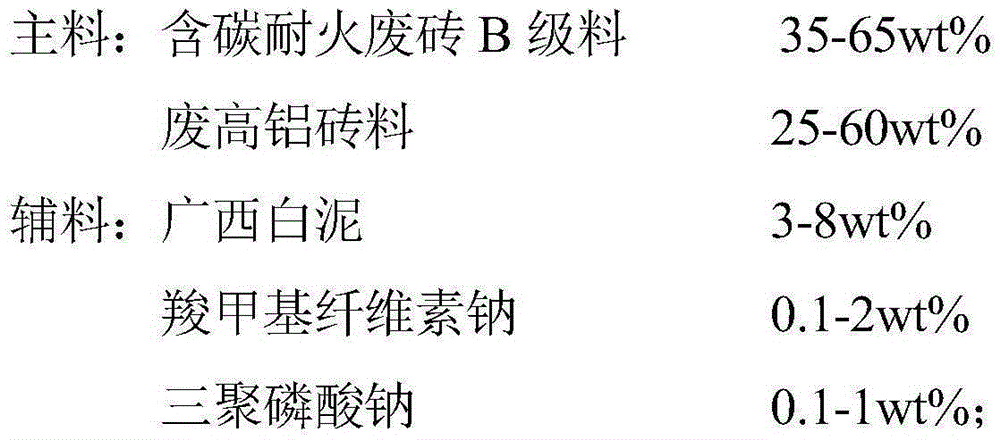

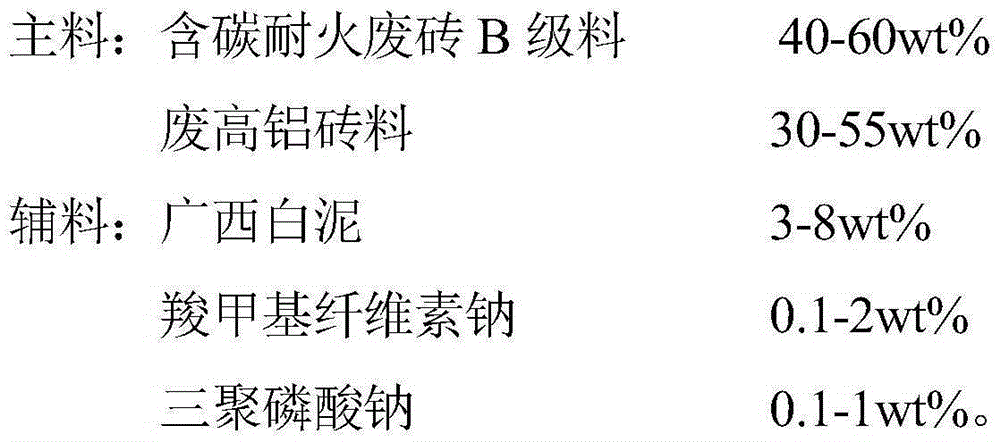

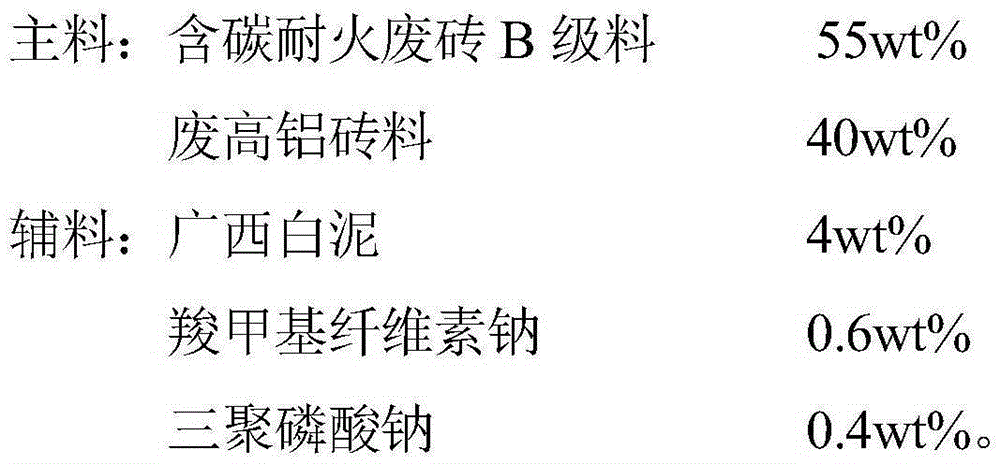

Anti-sticking slag gunning material for hot-metal bottle

The invention discloses an anti-sticking slag gunning material for a hot-metal bottle. The anti-sticking slag gunning material comprises the following components in percentages by weight: 35wt% to 65wt% of carbonic fire-retardant waste brick B-level material, 25wt% to 60wt% of waste high-alumina brick material, 3wt% to 8wt% of Guangxi white mud, 0.1wt% to 2wt% of sodium carboxymethylcellulose and 0.1wt% to 2wt% of sodium tripolyphosphate. The preparation process of the anti-sticking slag gunning material for the hot-metal bottle disclosed by the invention is simple, anti-sticking slag treatment construction can be carried out under cold and hot conditions of equipment, and the material can be used immediately after the construction is finished. The anti-sticking slag gunning material has the characteristics of simple construction, excellent anti-sticking slag performance, high sintering strength, low cost and the like, and is significant in economic benefit and social benefit.

Owner:WUGANG REFRACTORY CO LTD

Abrasion-resistant erosion-resistant burning-stick preventing coating for aluminum alloy guide rail, and preparation method and application of abrasion-resistant erosion-resistant burning-stick preventing coating

ActiveCN109628871AHigh bonding strengthHigh densityMolten spray coatingThermal sprayingAlloy substrate

The invention relates to the field of thermal spraying coatings, in particular to an abrasion-resistant erosion-resistant burning-stick preventing coating for an aluminum alloy guide rail, and a preparation method and application of the abrasion-resistant erosion-resistant burning-stick preventing coating. The abrasion-resistant erosion-resistant burning-stick preventing coating for the aluminum alloy guide rail contains a metal ceramic layer, wherein the metal ceramic layer is prepared from the following components in percentage by mass: 10-20% of Co, and 80-90% of tungsten carbide ceramic. Cobalt and tungsten carbide mixed powder is adopted as a raw material to be sprayed onto the surface of an aluminum alloy substrate through a supersonic flame to form the metal ceramic layer, thus theabrasion-resistant erosion-resistant burning-stick preventing coating for the aluminum alloy guide rail is obtained, the coating is uniform and dense, erosion resistance, abrasion resistance and high-temperature high-speed flame flow burning-adhesive resistance of the guide rail can be improved, service performance of the guide rail is further improved, the maintenance and repair operation frequency of the guide rail is decreased, the maintenance and repair operation difficulty of the guide rail is lowered, and the comprehensive combat capability is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

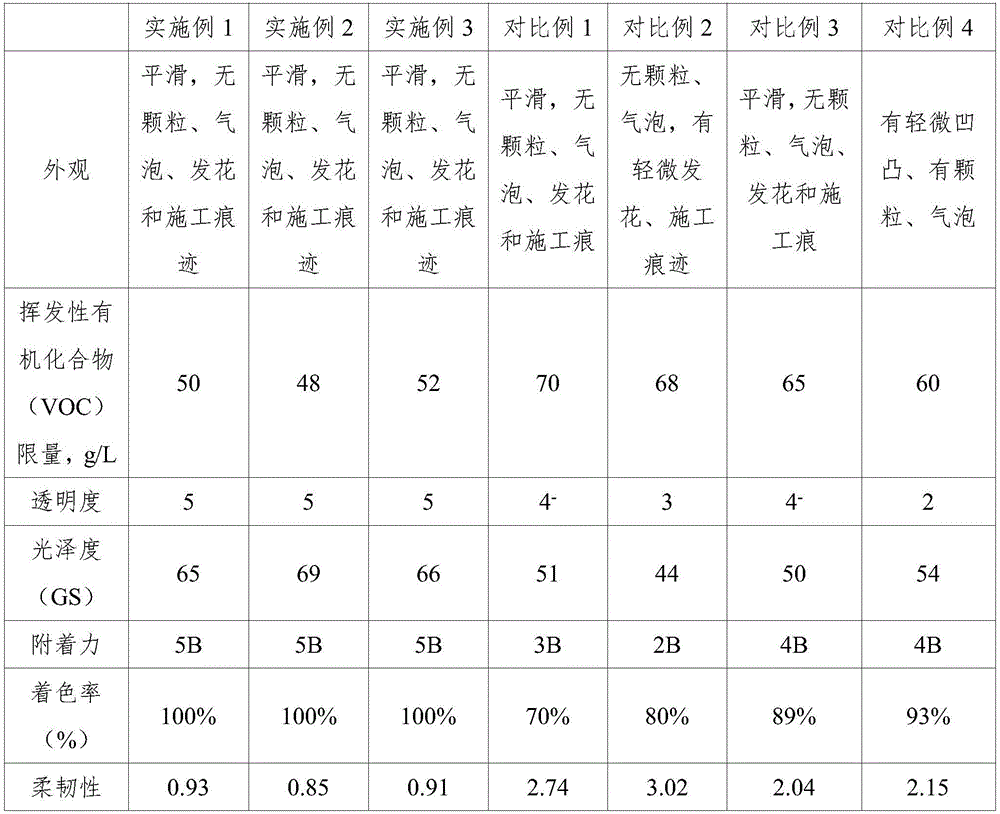

Water-soluble silk-screen printing ink and preparation method thereof

The invention belongs to the field of chemical coatings and particularly relates to water-soluble silk-screen printing ink and a preparation method thereof. The water-soluble silk-screen printing ink is mainly prepared from waterborne polyurethane resin, waterborne acrylic resin, white paste, a crosslinking agent, a leveling agent, tripropylene glycol ether and a thickener, wherein the white paste is mainly prepared from titanium dioxide, a dispersant, a wetting agent, an antifoaming agent and deionized water, and the particle size of the white paste is 3-4 mu m. A formula of the water-soluble silk-screen printing ink is reasonably and scientifically matched, all components cooperate to enhance adhesion, coloring rate, flexibility, sweat resistance and corrosion resistance of a water-soluble silk-screen printing ink coating, a printed product painted with the coating has the effects that the printed product has transparent and bright surface, is glossy and do not fade or peel off after long-term usage, and the water-soluble silk-screen printing ink has low content of VOCs (volatile organic compounds) and heavy metals, is healthy and environment-friendly and meets the requirements of modern people.

Owner:ZHONGSHAN YONGHUI CHEM

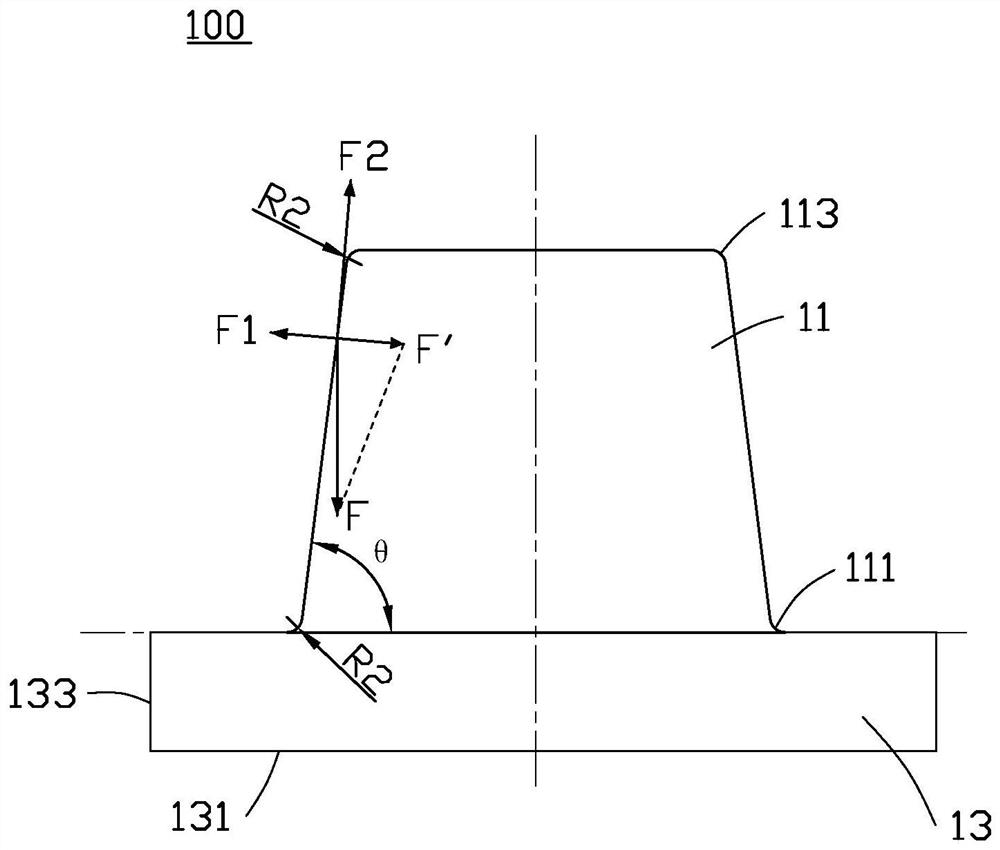

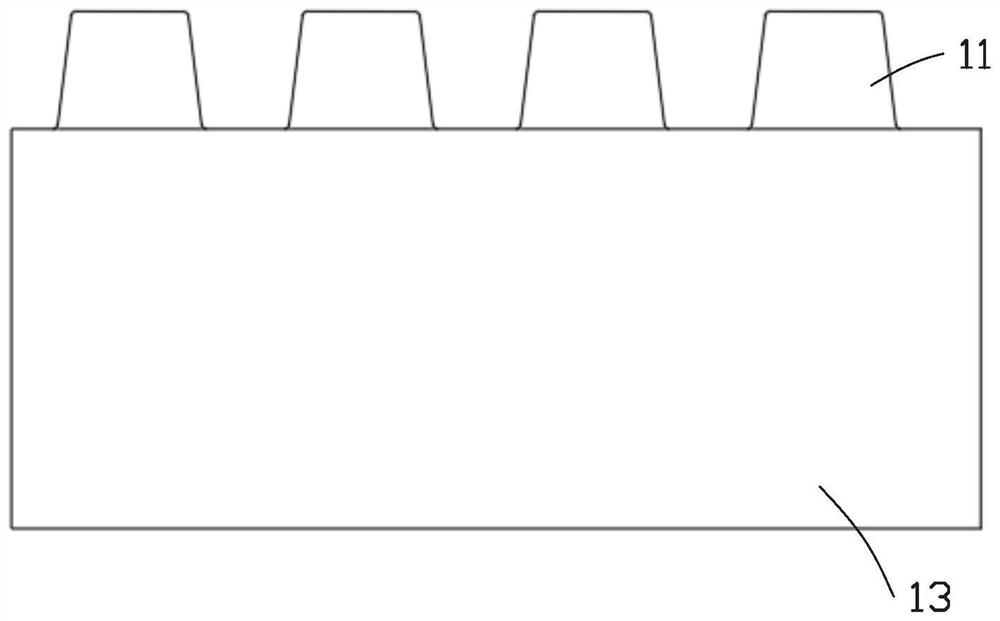

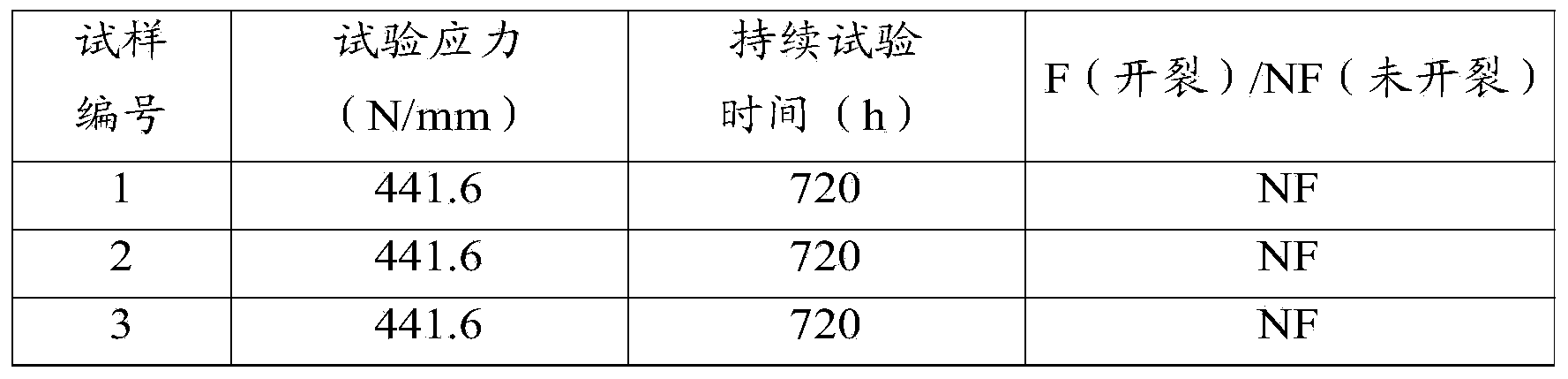

Control method for improving anti-sticking performance and connection strength of round thread oil pipe and bushing

ActiveCN102678064AImprove anti-stick performanceImprove connection strengthDrilling rodsDrilling casingsCouplingOil and natural gas

The invention discloses a control method for improving the anti-sticking performance and connection strength of a round thread oil pipe and a bushing, which belongs to the technical field of improvement on the performance of API (American Petroleum Institute) round thread oil pipe and bushing entities in the petroleum and natural gas industry. The method comprises the following steps of: comprehensively controlling the yield strength of the oil pipe, the bushing and a coupling material; controlling the parameters of inner and outer threads; and controlling the coupling surface treating quality, wherein the inner and outer threads are specifically a coupling inner thread and a bushing outer thread. By comprehensively controlling the yield strength, the inner and outer thread parameters and the like of the oil pipe, the bushing and the coupling material, the anti-sticking performance of an API round thread is improved, the connection strength is improved greatly, the underground sealing reliability and strength reliability of the API round thread oil pipe and a bushing joint are enhanced, and safety in use of the API round thread oil pipe and the bushing is ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Slag adhesion resistant material for slag tank and preparation method of slag adhesion resistant material

The invention provides a slag adhesion resistant material for a slag tank and a preparation method of the slag adhesion resistant material. The slag adhesion resistant material is prepared from the following raw materials in percentage by weight: 70-90wt% of superfine slag powder, 6-30wt% of additive and 1-3wt% of binder (total 100%). The preparation method comprises the following steps of mixingthe superfine slag powder, the additive and the binder with formula amounts, adding water, and performing uniform stirring and mixing to obtain the slag adhesion resistant material. Compared with theprior art, the slag adhesion resistant material provided by the invention is low in cost by adopting blast furnace slag as a main raw material, is ground with the granularity being 300-400 meshes, isuniformly mixed with the additive and the binder to control the viscosity of the slurry, is strong in adhesion with the slag tank, short in solidification time, high in refractoriness and good in slagadhesion resistance effect, can realize a target of overturning the tank for more than or equal to 3 times after spraying the slag tank for one time. Meanwhile, the use of the superfine slag powder is broadened and the resource additional value is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Rapid buckling threaded structure for expansion pipe in large expansion rate and machining and preparing method

InactiveCN105422019AEnough thicknessImprove distortionDrilling rodsDrilling casingsEngineeringScrew thread

The invention provides a rapid buckling threaded structure for an expansion pipe in the large expansion rate. A direct connection threaded structure is adopted, and the threaded connector comprises an expansion pipe female buckle and an expansion pipe male buckle; the expansion pipe female buckle is sequentially provided a low-conicity single-hook-type female thread, tool withdrawal grooves, cylindrical surface sealing segments, a first-stage sealing groove and / or a second-stage sealing groove, conical surface sealing segments and negative-angle torque shoulders from the end to the interior; the expansion pipe male buckle is sequentially provided negative-angle torque shoulders, conical surface sealing segments, cylindrical surface sealing segments and a single-hook-type male thread from the end to the interior; the threaded connector adopts a double-channel multi-stage sealing structure, and particularly adopts a double-channel sealing mode of a third-stage sealing structure before expansion and a second-stage sealing structure after expansion. According to the rapid buckling threaded structure for the expansion pipe in the large expansion rate, the high-leakproofness property of the threaded connector deformed in the large expansion rate are achieved by adopting the optimized double-channel multi-stage sealing structure; meanwhile, the mutual buckling and buckling speed is increased through the optimal design on the thread pitch and the thread form, and therefore rapid buckling of the thread is achieved; in addition, machining and detecting are easy.

Owner:中国石油集团石油管工程技术研究院 +1

Dual-tooth-form gas-tight thread

ActiveCN103696704AImprove torsion resistanceFunction increaseDrilling rodsDrilling casingsHorizontal wellsWell drilling

The invention relates to a connecting sealing structure for a petroleum drilling tool, in particular to a dual-tooth-form gas-tight thread. The dual-tooth-form gas-tight thread is characterized in that an inner thread is provided with a concave-arc sealing surface; an outer thread is provided with a convex-arc sealing surface; the convex sealing surface is an elliptic arc, parabolic arc or spline-shaped convex-arc sealing surface; the convex-arc sealing surface of the outer thread is meshed with the concave-arc sealing surface of the inner thread. The connecting sealing structure has the advantages that 1, a joint is high in connecting strength, can be matched with a tube body at equal strength, is even higher than the tube body at certain times, and is suitable for deep wells and super deep wells; 2, the bending resistance grade is 3+, so that the connecting sealing structure is suitable for deviated wells, large-displacement wells and horizontal wells; 3, buckling can be performed easily and rapidly without causing any error, so that the connecting sealing structure is suitable for drilling operation in severe environments of deserts, sea and the like; 4, the anti-sticking performance is high, and buckling and detachment can be performed without damaging the threads; 5, the excessive torque resistance is high.

Owner:山西环界石油钻具制造股份有限公司

Thread gluing resistant combination coating layer of threaded connection sleeve and preparation method of thread gluing resistant combination coating layer

InactiveCN104947058AWear-resistantSelf-lubricatingVacuum evaporation coatingSputtering coatingStress concentrationDlc coating

The invention discloses a thread gluing resistant combination coating layer of a threaded connection sleeve and a preparation method of the thread gluing resistant combination coating layer. The preparation method IS characterized in that the preparation method comprises the steps of preparing a DLC (Diamond Like Carbon) coating layer on an external thread surface and preparing a Cu (copper) coating layer on an internal thread surface; the external thread surface is coated with the DLC coating layer by utilizing ion beam assisted magnetron sputtering; the DLC coating layer has the characteristics of wear resistance, self-lubrication, and low possibility of deformation; the internal thread surface is coated with the Cu coating layer by utilizing an electroplate method; and the Cu coating layer has the characteristics of low hardness and good malleability, thereby significantly releasing stress concentration generated by the sleeve in a loading and unloading processes or in a working process. With the ingenious combination of the wear resistance and the deformation of the different coating layers on the internal thread surface and the external thread surfaces of an oil and gas well sleeve, the phenomenon of thread gluing caused by too big contact stress can be inhibited obviously, the thread gluing resistance of a screw thread is improved greatly, and the technical requirements of ISO13679 (International Standardization Organization 13679) on a screwing on / off test for the connection threads of the oil and gas well pipe are met.

Owner:XI AN JIAOTONG UNIV

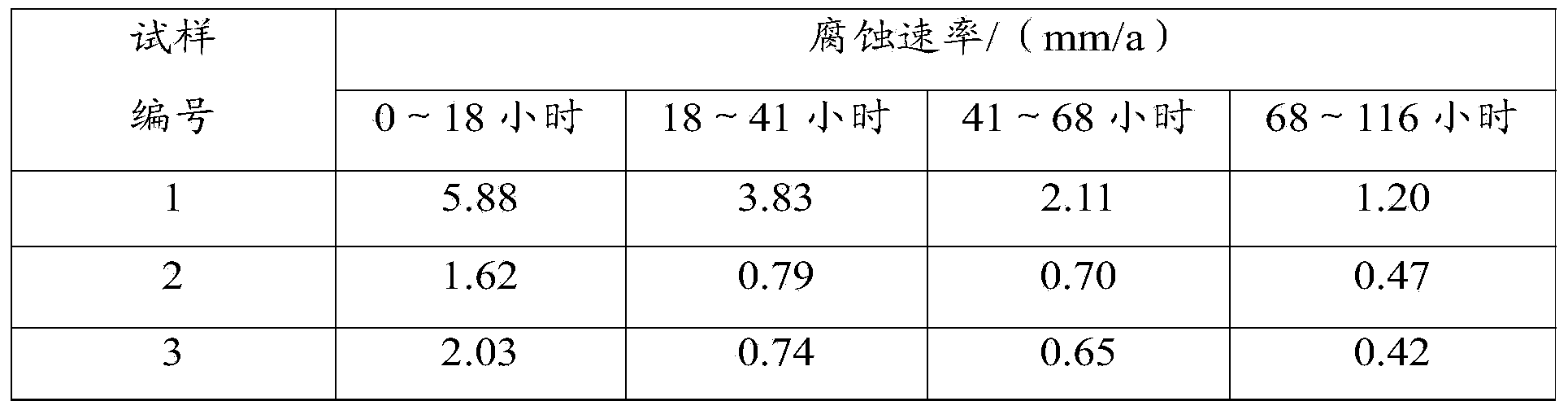

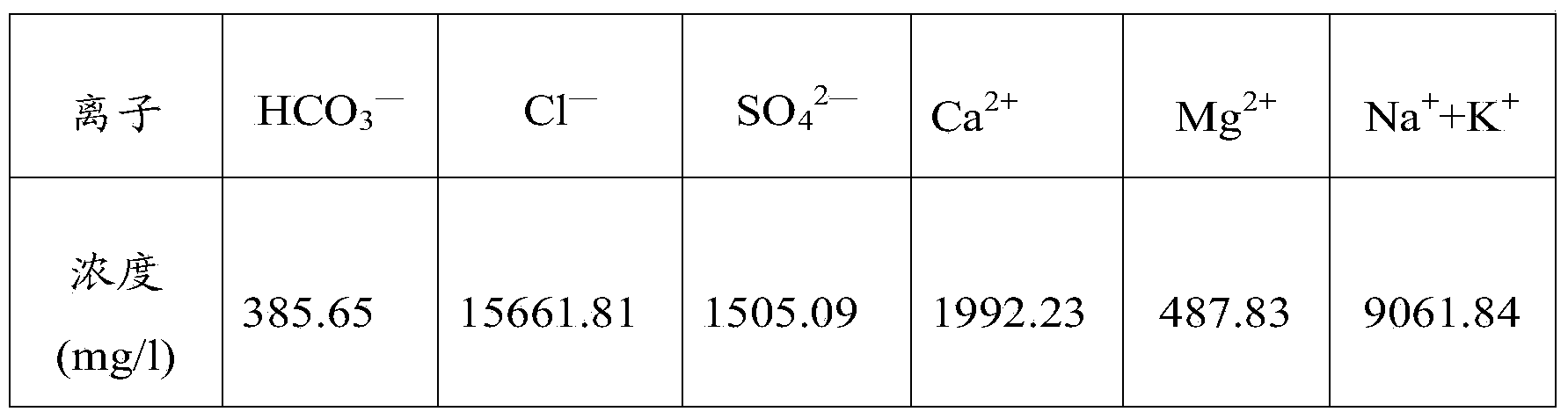

Method of improving corrosion resistance of oil tube

InactiveCN103834915AImprove corrosion resistanceImprove mechanical propertiesCorrosion preventionSolid state diffusion coatingNitrogenOxygen ions

The invention provides a method of improving corrosion resistance of an oil tube. The method comprises the following steps: (1) pre-cleaning; (2) card mounting; (3) pre-heating; (4) nitrogen-carbon-yttrium ion penetrating; (5) ion activating; (6) oxygen ion penetrating; (7) post-cleaning; (8) ion stabilizing, and (9) oil immersing. The method disclosed by the invention can carry out controllable ion penetrating (PIP) treatment on the oil tube to form multiple compound penetrating layers on the surface of the oil tube, so that good mechanical performance is achieved and service life of the oil tube is prolonged while the corrosion resistance is improved, and therefore, the method has good practical application effect.

Owner:四川中久红宇科技有限公司 +1

Environment-friendly water-based ink

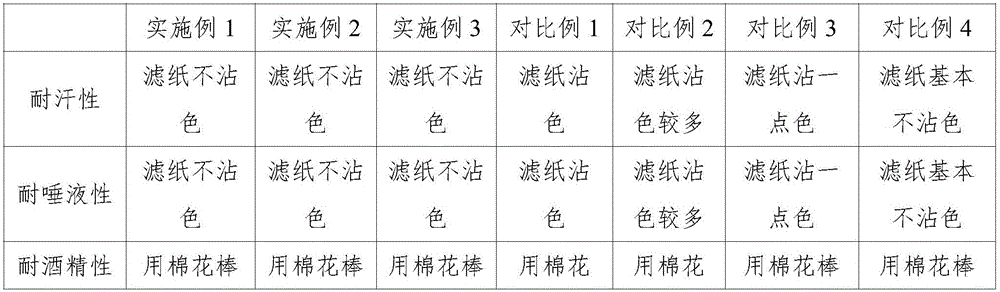

The invention discloses an environmentally friendly water-based ink. The components include 65.0-79.0% of a self-crosslinking water-based resin, 0-20.0% of a resin-free water-based color paste, 0.05-0.3% of a defoamer, and a pH regulator by weight. 0.1‑0.5%, wetting agent 0.1‑0.5%, titanium dioxide 0.5‑1.0%, associative polyurethane thickener 0.1‑0.6%, cosolvent 1.0‑5.0%, bactericide 0.05‑0.2%, and deionized water. Compared with the existing technology, the water-based ink and its color dilute the adhesion between the gold oil and the PVC film layer, and the anti-sticking performance, water resistance, and alcohol resistance of the ink layer are all improved, and there is no back-sticking after printing and rewinding storage Phenomenon, the transfer printing network is clear, the color is full, the gravure printing is on the PVC film, compared with the natural one, there is no color difference, and the construction is simple.

Owner:郑荣

Coating method for titanium alloy oil pipe coupling

ActiveCN104174577AImprove wear resistanceImprove anti-stick performancePretreated surfacesEpoxy resin coatingsCouplingPull-off

The invention discloses a coating method for a titanium alloy oil pipe coupling. The method comprises the steps as follows: firstly, cleaning the oil pipe coupling; secondly, configuring molybdenum disulfide coating, preparing a molybdenum disulfide solution and enabling the viscosity of the molybdenum disulfide solution to range from 31 to 33 Pa.s; thirdly, conducting spraying, to be specific, spraying the molybdenum disulfide solution to the oil pipe coupling through utilizing an air atomizing spray gun with a container or adopting a continuous circulating solution pump pressurizing flow system; fourthly, solidifying, to be specific, putting the oil pipe coupling, subjected to the spraying, into a curing device for curing, and controlling the temperature in the curing device to be 195-205 DEG C; fifthly, testing, performing a gluing-pulling test on oil pipe coupling coating, judging the qualified degree of the oil pipe coupling coating through judging the thickness of the coating pulled off. According to the method, molybdenum disulfide is sprayed onto the titanium alloy oil pipe coupling to form a molybdenum disulfide coating on the surface of the coupling, so that the wearing resistance of a titanium alloy oil pipe joint is improved, and besides, the sticky buckling resistance property is improved accordingly.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Noctilucent anti-sticking coating and noctilucent anti-sticking urban landscape patch

InactiveCN110819192AExcellent night scene beautification effectGood antifouling effectFireproof paintsAntifouling/underwater paintsChemistryPhotocatalysis

The invention relates to a coating, and concretely relatse to a noctilucent anti-sticking coating and a noctilucent anti-sticking urban landscape patch. The noctilucent anti-sticking coating comprises15 wt% of rare earth aluminate type persistent phosphor, 10 wt% of nano-silica, 15 wt% of acrylic resin, 5 wt% of vinyltriethoxysilane (VTEOS), 5 wt% of diphenyldichlorosilane, 1-5 wt% of a photocatalyst, 10 wt% of an additive and 35-40 wt% of a solvent. The surface of the noctilucent anti-sticking urban landscape patch is coated with the noctilucent anti-sticking coating. The noctilucent anti-sticking coating and the noctilucent anti-sticking urban landscape patch have good night scene beautifying effect, good pattern decorating effect and excellent anti-sticking, wear-resisting and attractive decorating effects.

Owner:BEIJING BOYUEJIECHUANG ENVIRONMENTAL ENG

Vanadium-containing molten iron slag pan anti-sticking agent and slag sticking prevention method

InactiveCN111154931AReduce operating costsReduce sheddingManufacturing convertersRecycling and recovery technologiesSteelmakingDolomite

The invention belongs to the technical field of metallurgical steelmaking, and particularly relates to a vanadium-containing molten iron slag pan anti-sticking agent and a slag sticking prevention method. The anti-sticking agent comprises lime powder, light calcined dolomite, carbon silica, a molten iron ladle castable and water. The raw materials are cheap and easy to obtain, the operation cost of steel slag sticking prevention can be reduced, the anti-sticking agent has high refractoriness, good slag resistance and good capability of reacting with steel slag, and the slag sticking probability can be effectively reduced.

Owner:HEBEI IRON AND STEEL

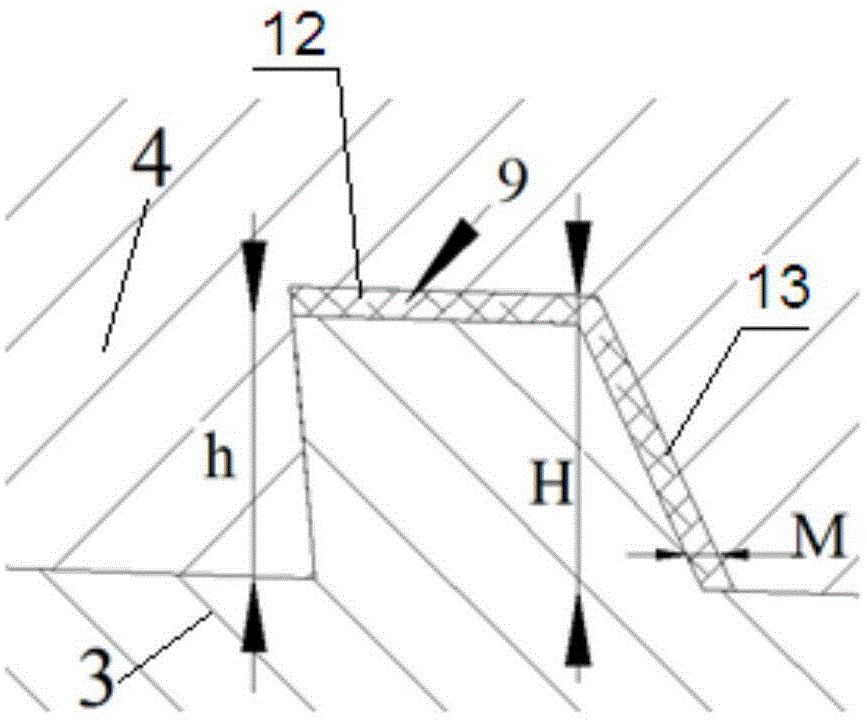

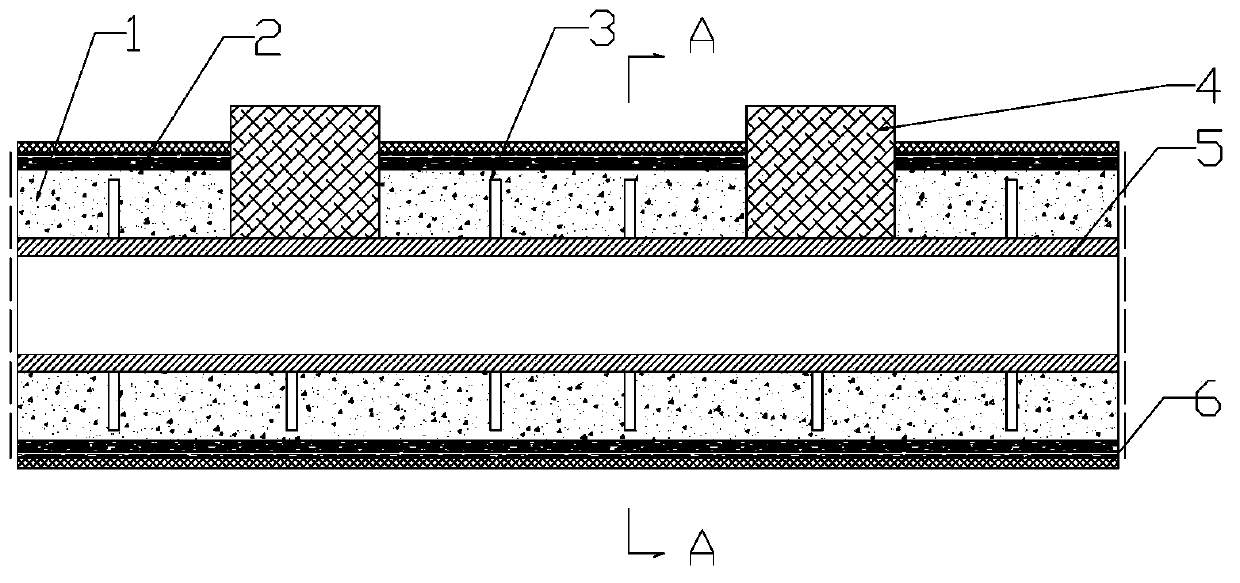

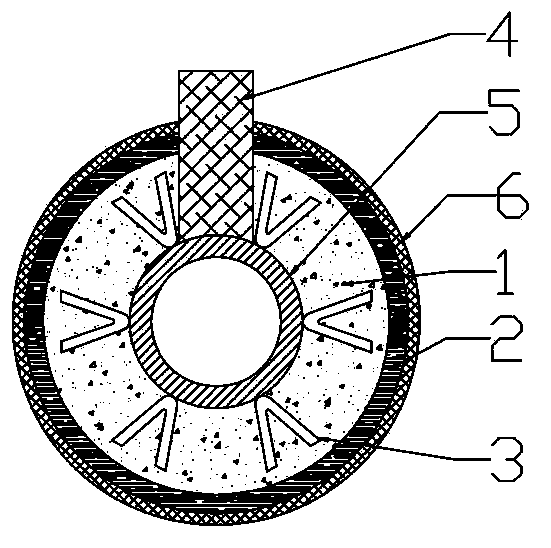

Furnace beam and vertical column fire-resistant thermal insulation lining structure of walking beam furnace for heating high-temperature oriented silicon steel and manufacturing method of structure

The invention discloses a furnace beam and vertical column fire-resistant thermal insulation lining structure of a walking beam furnace for heating high-temperature oriented silicon steel. The furnace beam and vertical column fire-resistant thermal insulation lining structure comprises a metal pipe forming a foundation of a furnace beam or a vertical column, wherein heat-resistant cushion blocks are arranged on the metal pipe forming the foundation of the furnace beam at intervals along the axis direction, metal anchoring parts are uniformly distributed on the outer wall of the metal pipe along the axial direction and the peripheral direction, a fire-resistant insulating layer is formed to cling to the outer wall of the metal pipe in a pouring manner and is combined with the metal anchoring parts, and the fire-resistant insulating layer is sequentially covered by a slag-bonding prevention layer and an anti-oxidation coating. As the heat preservation and slag-bonding prevention double-layer structure and the design of appropriate thickness are adopted by the furnace beam and vertical column fire-resistant thermal insulation lining structure of the walking beam furnace, the integrality of a thermal insulation lining is improved, and the comprehensive usability of the thermal insulation lining is improved.

Owner:武汉钢铁有限公司

LED lamp molding printing process

ActiveCN109659419AAvoid stickingEqual amount of glueNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveEngineering

The invention relates to the technical field of LEDs, in particular to an LED lamp molding printing process. The LED lamp comprises an LED base, the LED base is provided with a plurality of cavities,and each cavity is fixed with an LED chip. The printing process comprises the following steps of: (1) designing a tape film, wherein the tape film is provided with a plurality of through holes, one surface of the tape film is coated with an adhesive layer, the adhesive is applied to the base to allow the through holes to face the cavities of the LED base; (2) injecting fluorescent glue into the cavities; (3) performing blade coating at the surface of the tape film by employing a scraper; and (4) stripping off the tape film. The tape film is attached to the LED base to prevent the fluorescent glue from pasting to the base; the scraper is employed to scrape the overflowing fluorescent glue on the tape film into the cavities of the LED base to facilitate even glue amount of the cavities so asto display an even luminance effect.

Owner:东莞市谷麦光学科技有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com