Airtight seal sleeve joint

A casing joint and gas sealing technology, which is applied in the direction of casing, pipe/pipe joint/pipe fitting, drill pipe, etc., can solve the problem that the escape of high-pressure gas and harmful gas cannot be prevented, and the mechanical properties of API standard threaded joints cannot fully meet the three requirements. It can avoid the escape of harmful or high-pressure gas, reduce the risk of galling, and achieve the effect of excellent gas sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The airtight casing joint of the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific embodiments below. However, the explanation and illustration do not constitute undue limitations on the technical solution of the present invention.

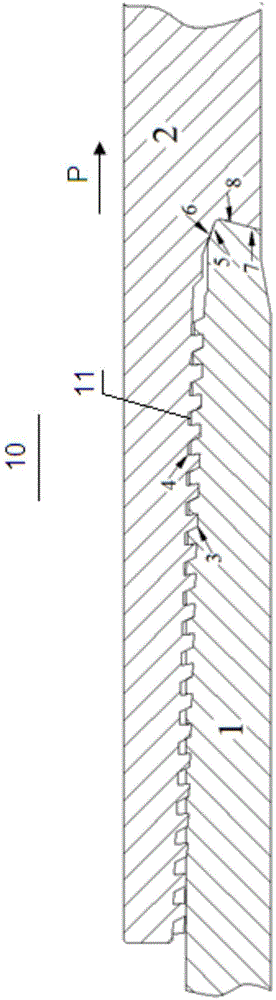

[0040] figure 1 The structure of an embodiment of the gas-tight casing joint according to the present invention is shown.

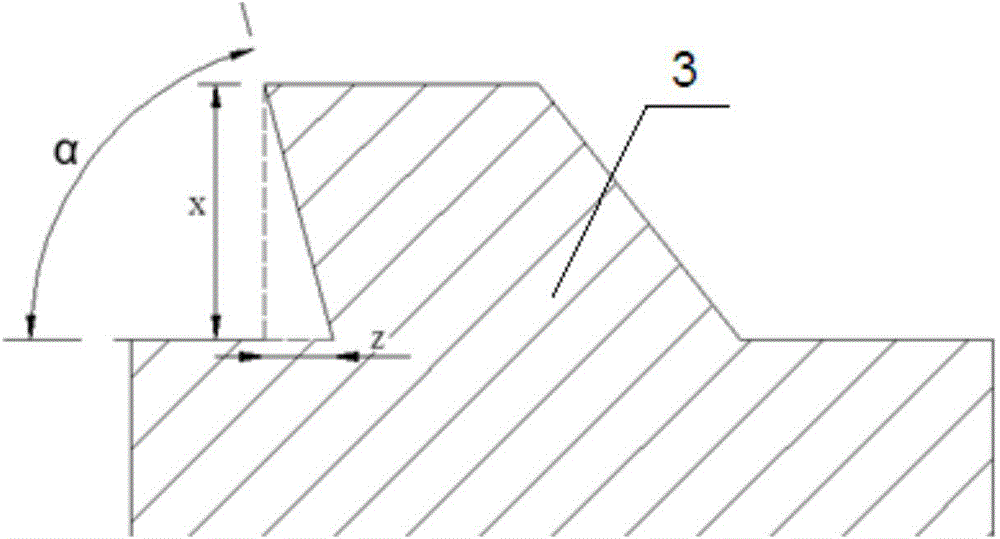

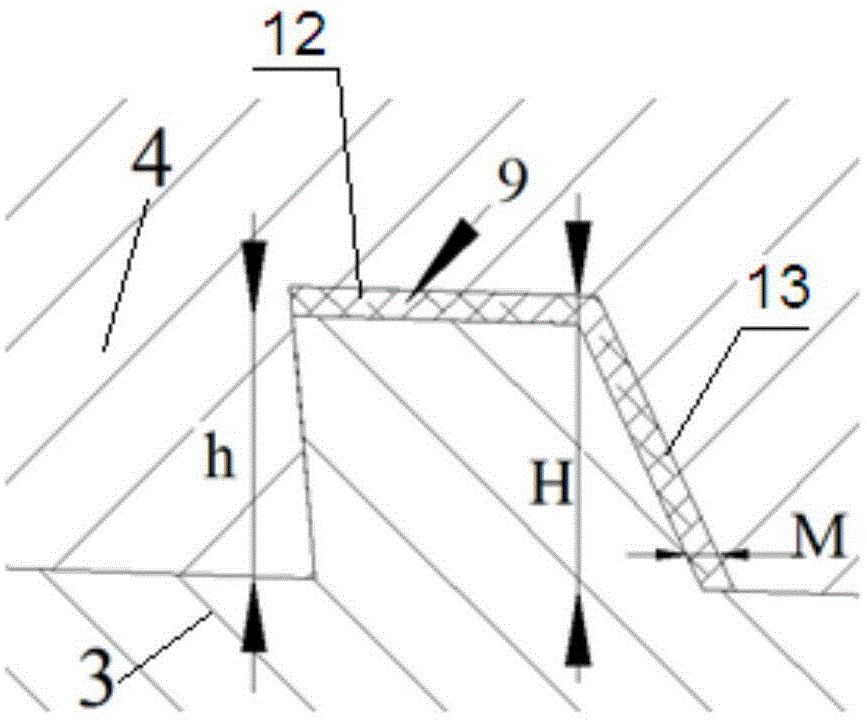

[0041] Such as figure 1 As shown, the airtight casing joint 10 in this embodiment includes a casing male end 1 and a casing female end 2, an external thread 3 is provided along the axial direction of the casing male end, and an external thread 3 is provided along the axial direction of the casing female end. An internal thread 4 is provided in the axial direction, and the external thread of the male end of the casing meshes with the internal thread of the female end of the casing. The tooth profiles of the external thread 3 and the internal thread 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com