Arm rest and work equipment

A boom and frame structure technology, used in fire rescue, construction, cranes, etc., can solve the problems of complex molds, high-strength steel booms with heavy weight and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

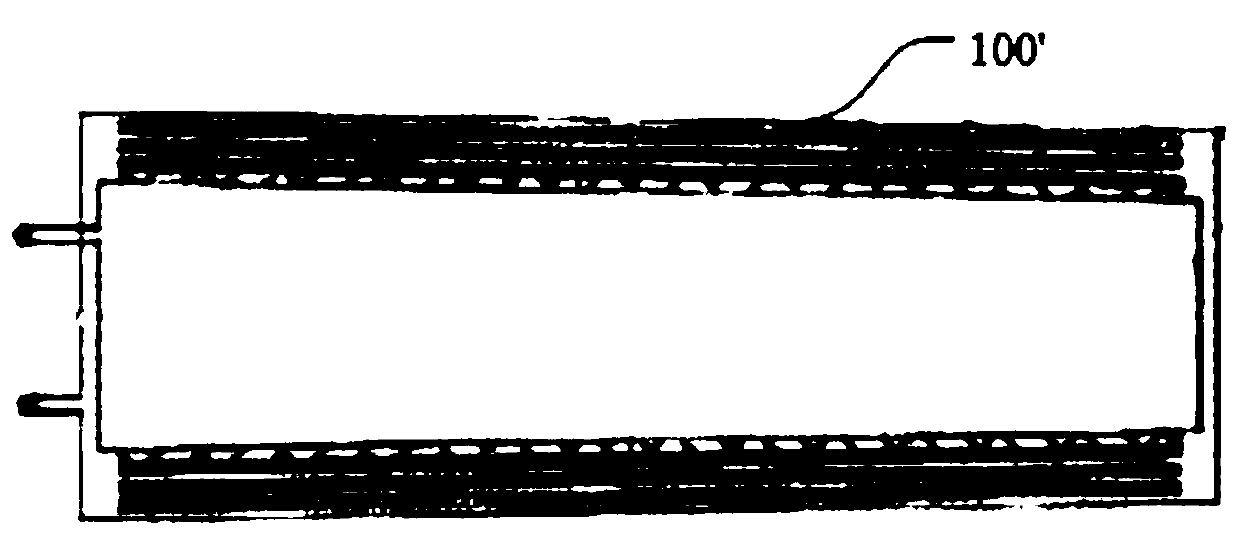

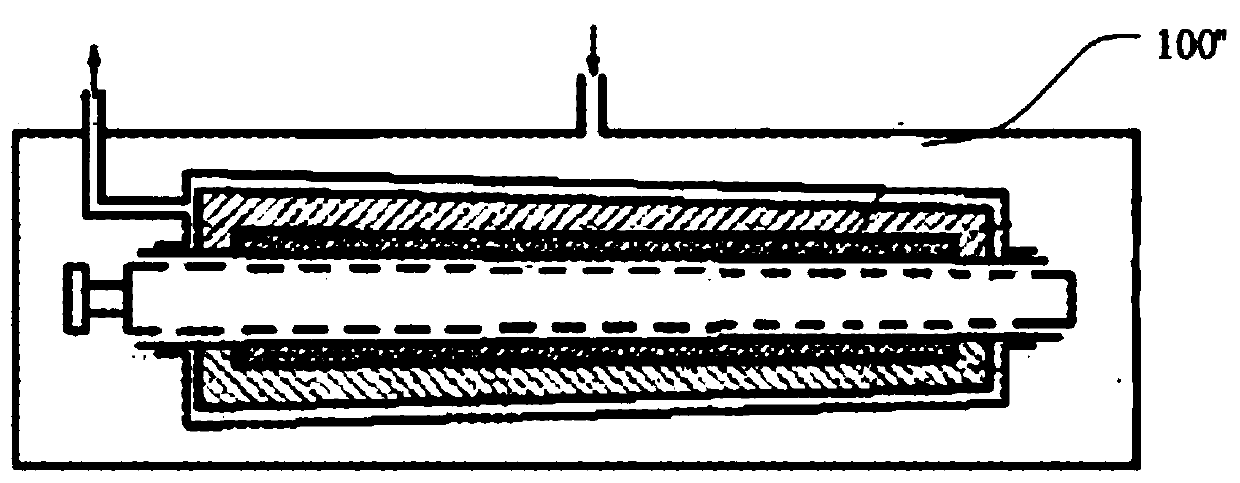

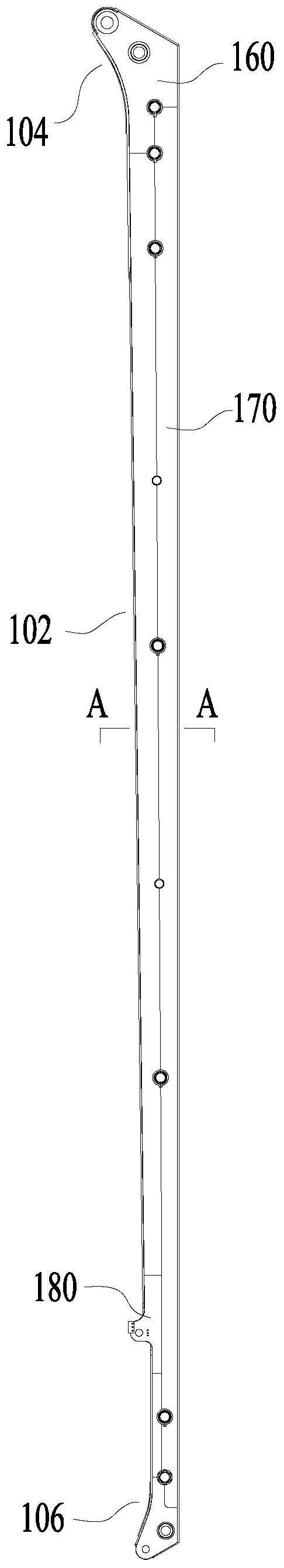

[0048] Such as image 3 and Figure 4 As shown, the present embodiment provides a boom 100, which has a frame structure, and the boom 100 includes: a top board 110, a bottom board 120, a first side board 130 and a second side board 140, and the bottom board 120 is spaced from and opposite to the top board 110 Set, the second side plate 140 and the first side plate 130 are spaced apart and opposite to each other; wherein, one side of the first side plate 130 is provided with a first bent portion 134, at least a part of the first bent portion 134 is connected to the top plate 110 Fitting and splicing each other, the other side of the first side plate 130 opposite to the first bending portion 134 is provided with a second bending portion 136, at least a part of the second bending portion 136 is bonding and splicing with the bottom plate 120; the second One side of the side plate 140 is provided with a third bending portion 144, at least a part of the third bending portion 144 is...

Embodiment 2

[0051] Such as image 3 , Figure 6 , Figure 7 and Figure 8 As shown, this embodiment provides a boom 100 . In addition to the technical features of the above-mentioned embodiments, this embodiment also includes the following technical features:

[0052] The first bending portion 134 and the second bending portion 136 are integrally formed with the first side plate 130 respectively; the third bending portion 144 and the fourth bending portion 146 are integrally formed with the second side plate 140 respectively.

[0053] In this technical solution, both ends of the first side plate 130 are respectively bent to form the first bent portion 134 and the second bent portion 136 , which improves the forming efficiency of the first side plate. Similarly, the two ends of the second side plate 140 are respectively bent to form the third bent portion 144 and the fourth bent portion 146 , which improves the forming efficiency of the second side plate 140 . Therefore, the productio...

Embodiment 3

[0055] Such as Figure 4 As shown, this embodiment provides a boom 100 . In addition to the technical features of the above-mentioned embodiments, this embodiment also includes the following technical features:

[0056] The arm frame 100 further includes: a first rib 138 disposed on the first side plate 130 and located between the first bending portion 134 and the second bending portion 136 ;

[0057] The second rib 148 is disposed on the second side plate 140 and located between the third bending portion 144 and the fourth bending portion 146 .

[0058] In this embodiment, the first rib plate 138 and the first side plate 130 are integrally configured, and the second rib plate 148 and the second side plate 140 are also integrally configured, which can not only strengthen the first side plate 130 and the second side plate 140 The structural strength can also simplify the structure and simplify the processing technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com