Production process for purification column used for water purifier

A production process and purification column technology, applied in the field of purification column production process, can solve the problems of irregular circumferential angle of the circular tube, uneven thickness of the cylindrical tube wall, etc. The effect of sequential welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] [Example 1] The production process of type I purification column

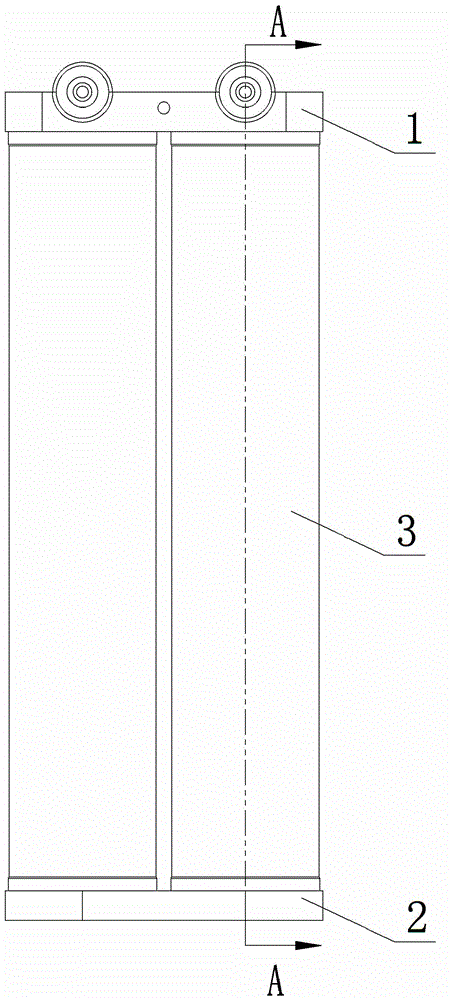

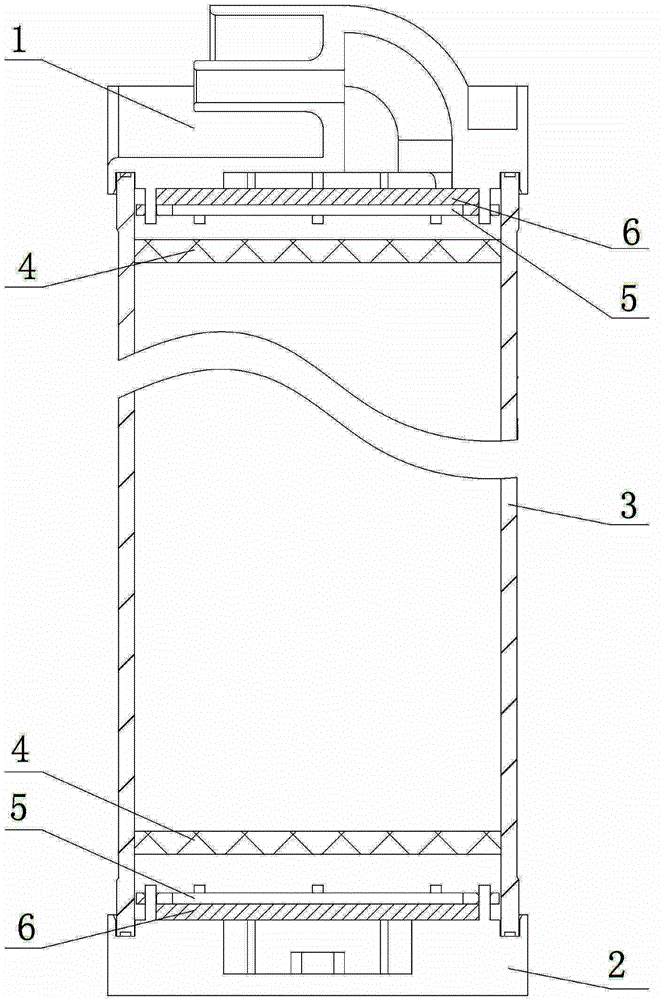

[0034] Such as figure 1 and 2 The type I purification column shown comprises an upper end cap 1, a lower end cap 2, one or more purification cartridges 3, a filter screen 4 arranged in the purification cartridge 3, and the purification cartridge 3 is installed between the upper end cap 1 and the lower end cap 2 In between, the microporous filter 6 is welded in the groove of the upper end cover 1 or the lower end cover 2 through the filter press ring 5, and the described production process includes the following steps:

[0035] S1. Stamping: Cut the 120-mesh filter with a stamping die;

[0036] S2. Injection molding: The upper end cover 1, the lower end cover 2, the purification cylinder 3, the filter screen 4, and the filter plate pressure ring 5 are respectively injection molded, and the process parameters of each component injection molding are as follows:

[0037] a. Purification column 3, the raw ...

Embodiment 2

[0049] [Example 2] The production process of type I purification column

[0050] Type I purification column comprises an upper end cap 1, a lower end cap 2, one or more purification cartridges 3, a filter screen 4 arranged in the purification cartridge 3, and the purification cartridge 3 is installed between the upper end cap 1 and the lower end cap 2, The microporous filter sheet 6 is welded in the groove of the upper end cover 1 or the lower end cover 2 through the filter sheet pressure ring 5, and the described production process includes the following steps:

[0051] S1. Stamping: Cut the 130-mesh filter with a stamping die;

[0052] S2. Injection molding: The upper end cover 1, the lower end cover 2, the purification cylinder 3, the filter screen 4, and the filter plate pressure ring 5 are respectively injection molded, and the process parameters of each component injection molding are as follows:

[0053] a. Purification cylinder 3, the raw material is mixed PP, the inj...

Embodiment 3

[0065] [Example 3] The production process of type II purification column

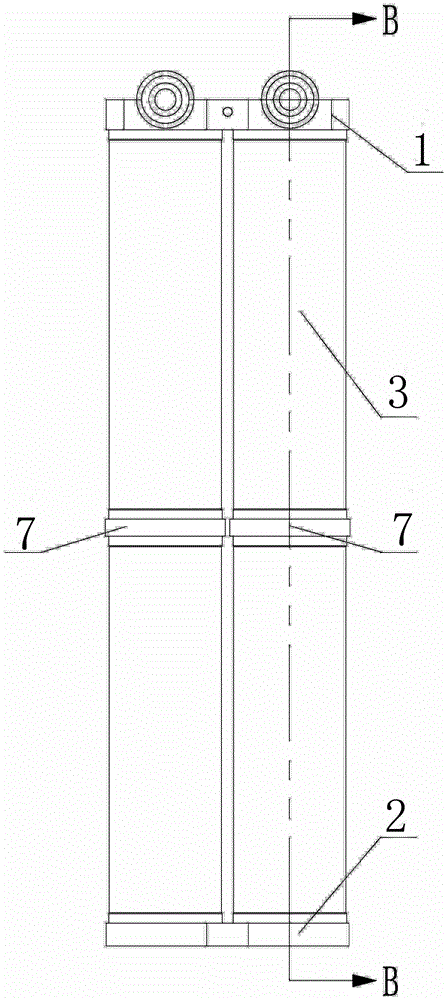

[0066] Such as image 3 and 4 As shown, the type II purification column includes an upper end cover 1, a lower end cover 2, a purification column body 3 connected with a connecting ring 7, a filter screen 4 arranged in the purification column body 3, and the purification column body 3 is installed on the upper end cover 1 and the lower end Between the covers 2, the microporous filter 6 is welded in the groove of the upper end cover 1 or the lower end cover 2 through the filter press ring 5, and the production process of the type II purification column includes the following steps:

[0067] S1. Stamping: Cut the 150-mesh filter screen with a stamping die;

[0068] S2. Injection molding: The upper end cover 1, the lower end cover 2, the purification cylinder 3, the connecting ring 7, the filter screen 4, and the filter plate pressure ring 5 are respectively injected into molding, and the process paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com