Integrated stainless steel-carbon steel composite tube and preparation process and coating process thereof

A stainless steel, one-piece technology, applied in the field of pipelines, can solve problems such as poor pressure bearing capacity, poor corrosion resistance and resistance to external damage, unreliable connection between the composite layer and the base layer, easy separation of the base layer and the inner lining, etc., to ensure the resistance High pressure, excellent performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

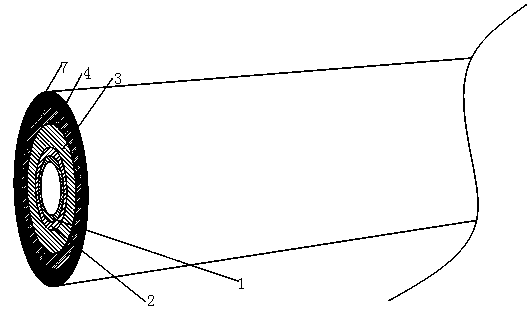

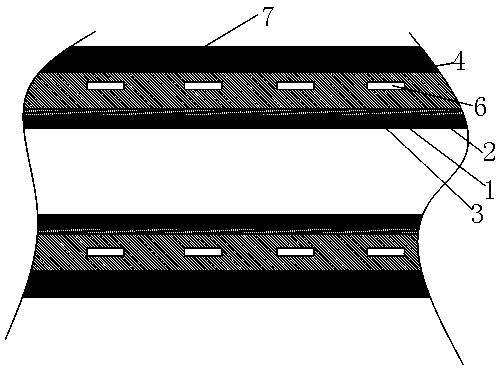

[0040] Such as Figures 1 to 3 As shown, this embodiment provides an integrated stainless steel-carbon steel composite pipe, which includes a four-layer structure, which is a stainless steel layer 1, a stainless steel-carbon steel mixed layer 2, and a carbon steel layer 3 from the inside to the outside. , Epoxy resin layer 4, specifically, the stainless steel layer is made of pure stainless steel, the carbon steel layer is made of pure carbon steel, and the stainless steel-carbon steel mixed layer is made of stainless steel and carbon steel through metallurgical melting At the same time, the mixed layer of stainless steel and carbon steel forms an integrated structure with the stainless steel layer and the carbon steel layer respectively, that is, the stainless steel-carbon steel mixed layer is composed of a part of the stainless steel layer and a part of the carbon steel layer. That is, the stainless steel-carbon steel mixed layer is composed of a part of the stainless steel ...

Embodiment 2

[0059] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the one-piece stainless steel-carbon steel composite pipe includes a four-layer structure, which is followed by a stainless steel layer, a stainless steel-carbon steel mixed layer, a carbon steel layer, and a stainless steel layer from outside to inside. The epoxy resin layer, correspondingly, the epoxy resin layer is located on the inner wall of the pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com