Patents

Literature

67results about How to "Reduced risk of sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Container with adhesive label

ActiveCN104010943AReduce or eliminate unsuitable foldsReduce or eliminate riskContainers for flexible articlesPackaging cigaretteAdhesiveEngineering

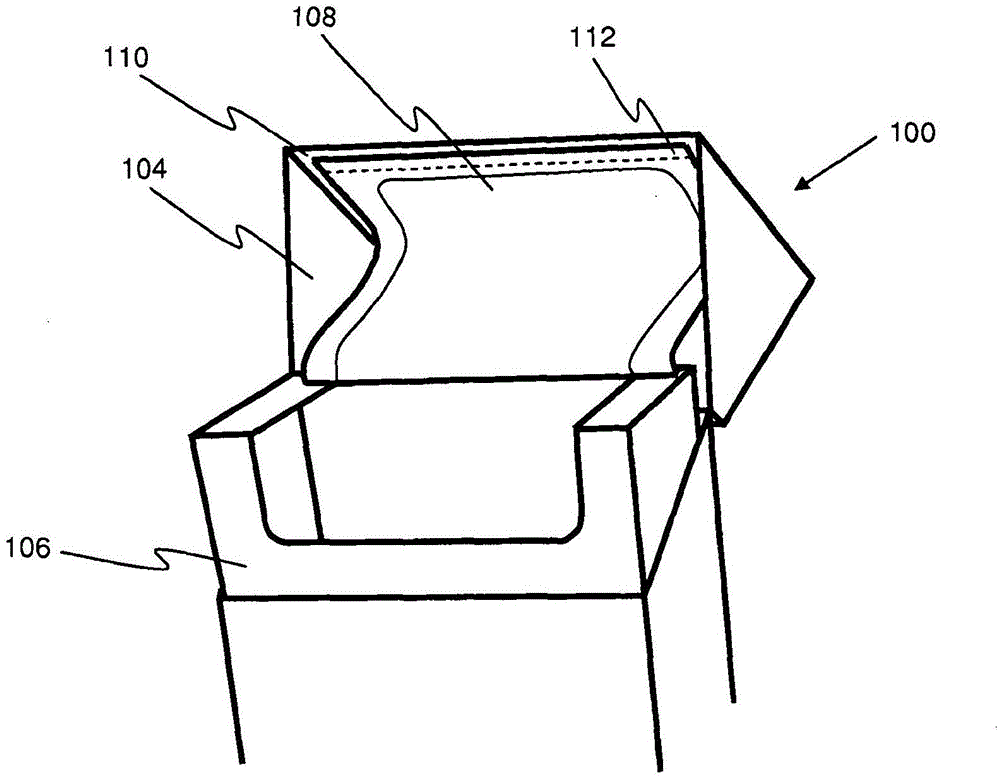

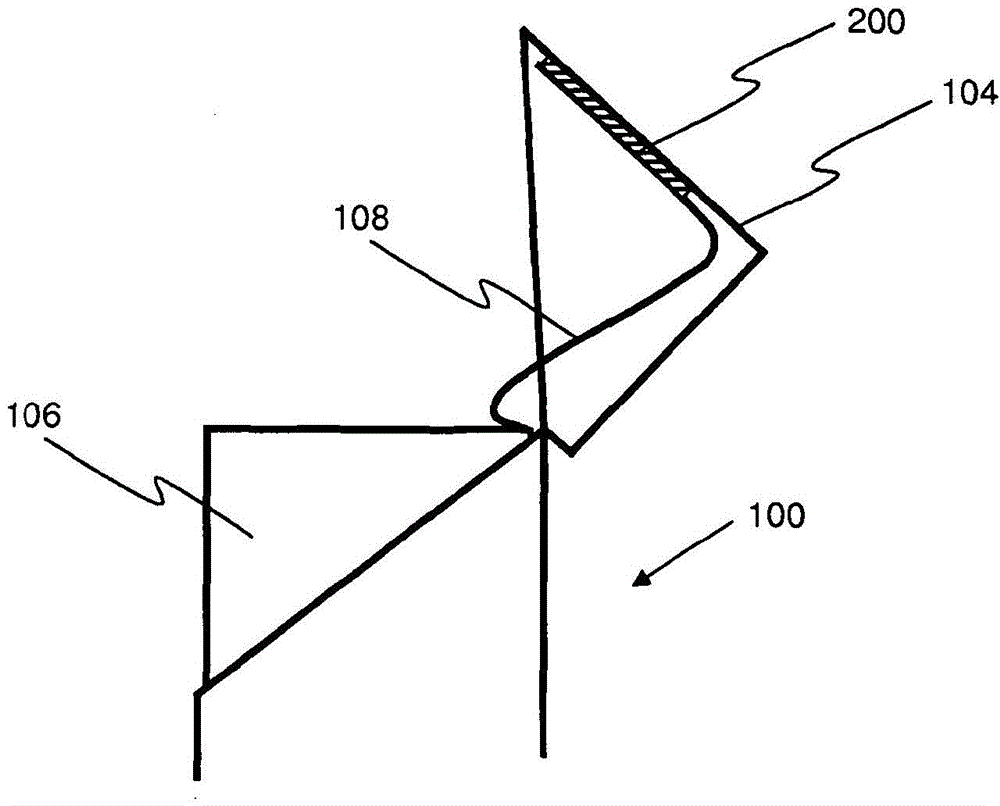

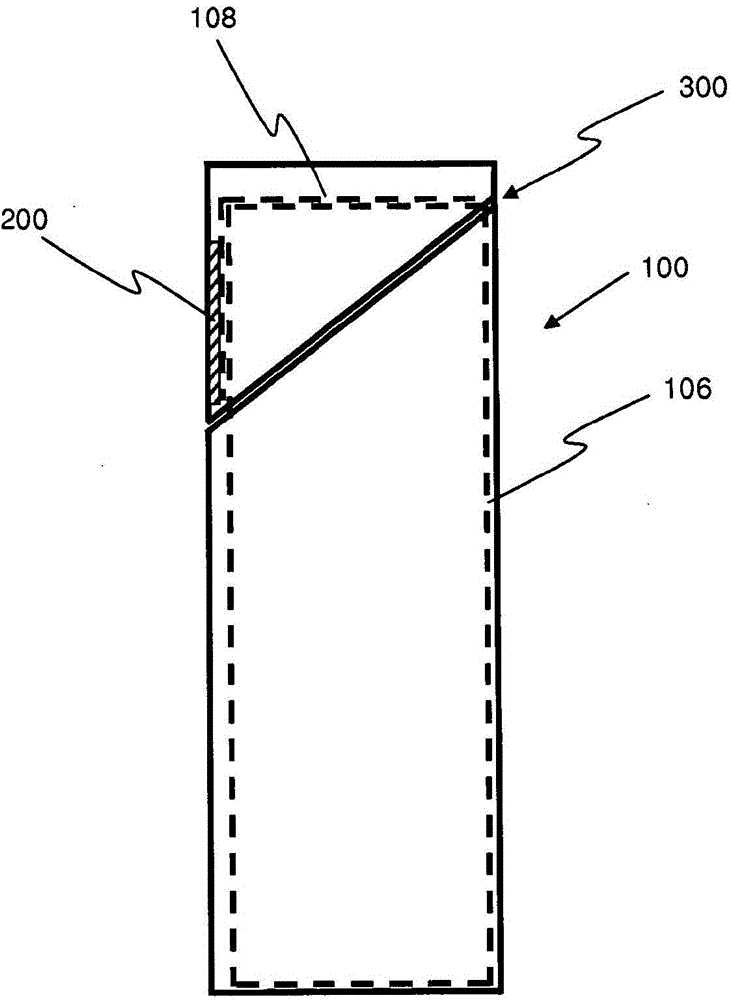

The invention relates to a container of consumer goods comprising an outer housing having a box and a lid hinged to the box. An inner package of consumer goods is disposed within the outer housing and has an access opening through which consumer goods can be removed. An adhesive label is provided with a resealable adhesive on a first portion of an inner surface of the adhesive label and an opposed outer surface of the adhesive label is permanently attached to an inner surface of a front wall of the lid of the outer housing. The outer surface of the adhesive label is permanently attached to the inner surface of the front wall of the lid of the outer housing such that the adhesive label is inwardly concave throughout movement of the lid between a closed position and the open position.

Owner:PHILIP MORRIS PROD SA

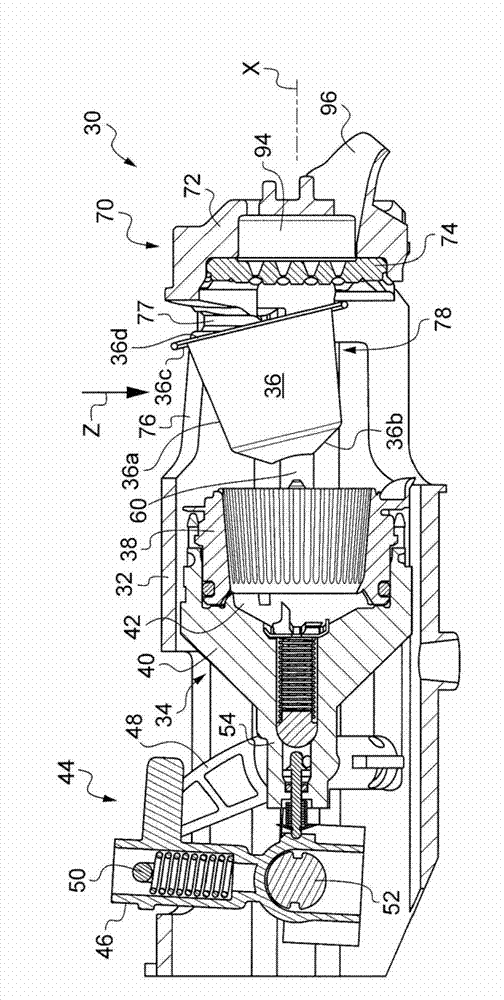

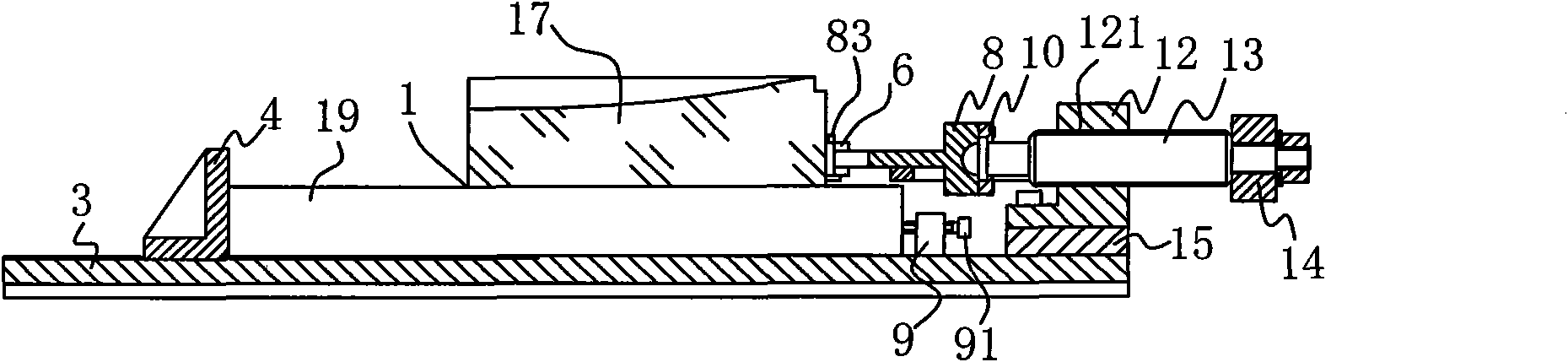

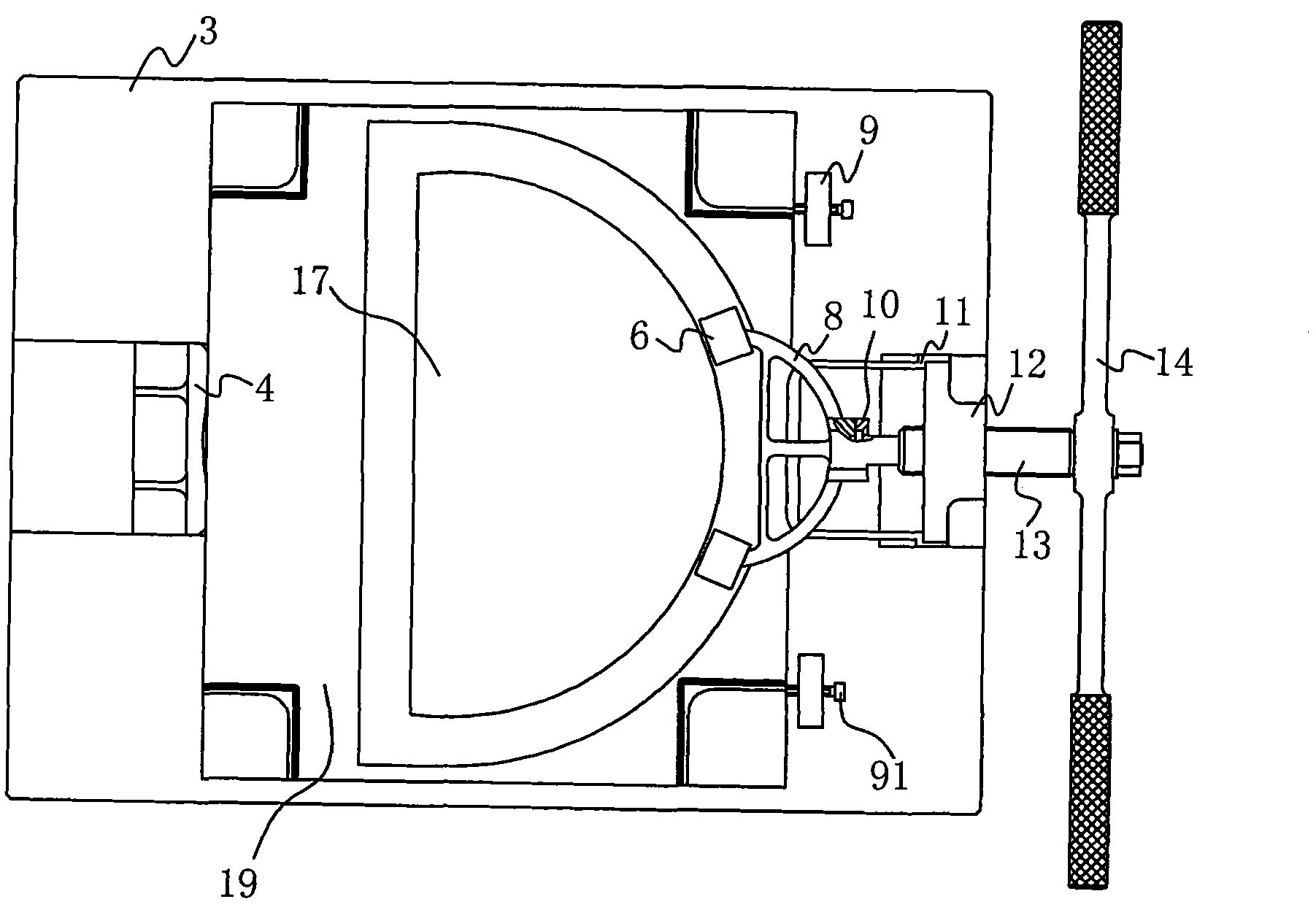

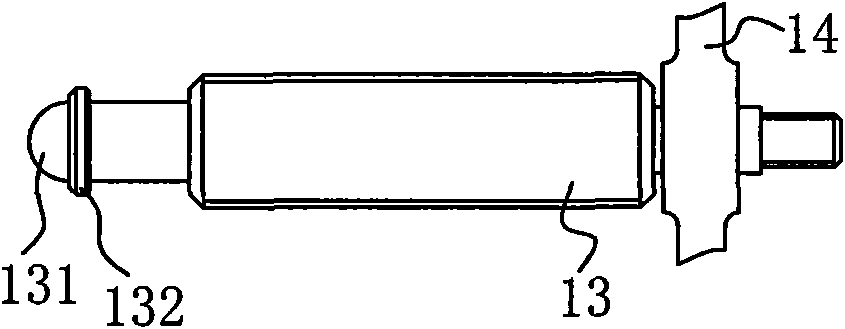

A beverage machine using ingredient capsules

InactiveCN102905584ASimple designReduced risk of cloggingBeverage vesselsTrappingAdditive ingredient

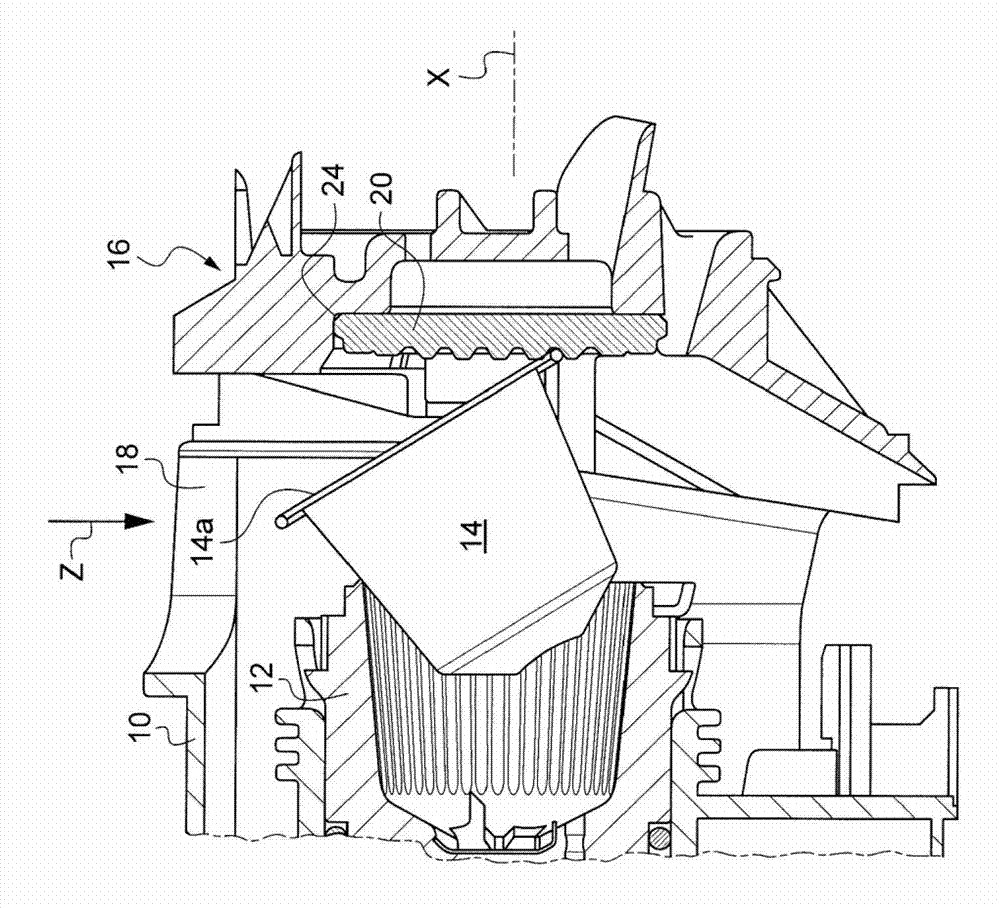

The invention concerns a beverage machine comprising a casing (32) enclosing: - a first part (34) for receiving an ingredient capsule therein, - a second part (70) having a surface (91) provided with perforating projecting members (90) facing the first part, - an opening (76) in the casing enabling the capsule to be inserted in a direction of insertion (Z) between the first and second parts, the first and second parts being movable relative to each other along a longitudinal axis (X) perpendicular to surface (91) between a first position in which first and second parts are spaced apart so that the ingredient capsule is inserted therebetween and a second position in which first and second parts are close to each other so that the capsule is in contact with the member.; The members (90) are provided in an arrangement on the surface with respect to the opening (76) so as to permanently reduce the risk of trapping of the capsule by the members during the capsule insertion.

Owner:NESTEC SA

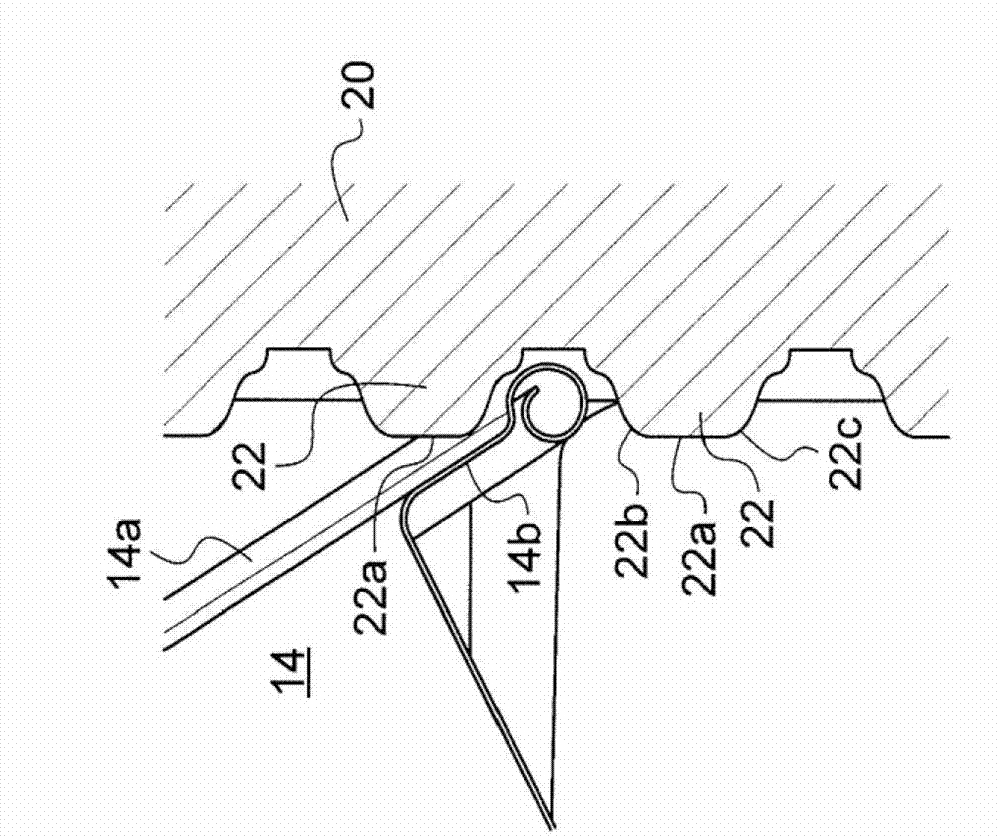

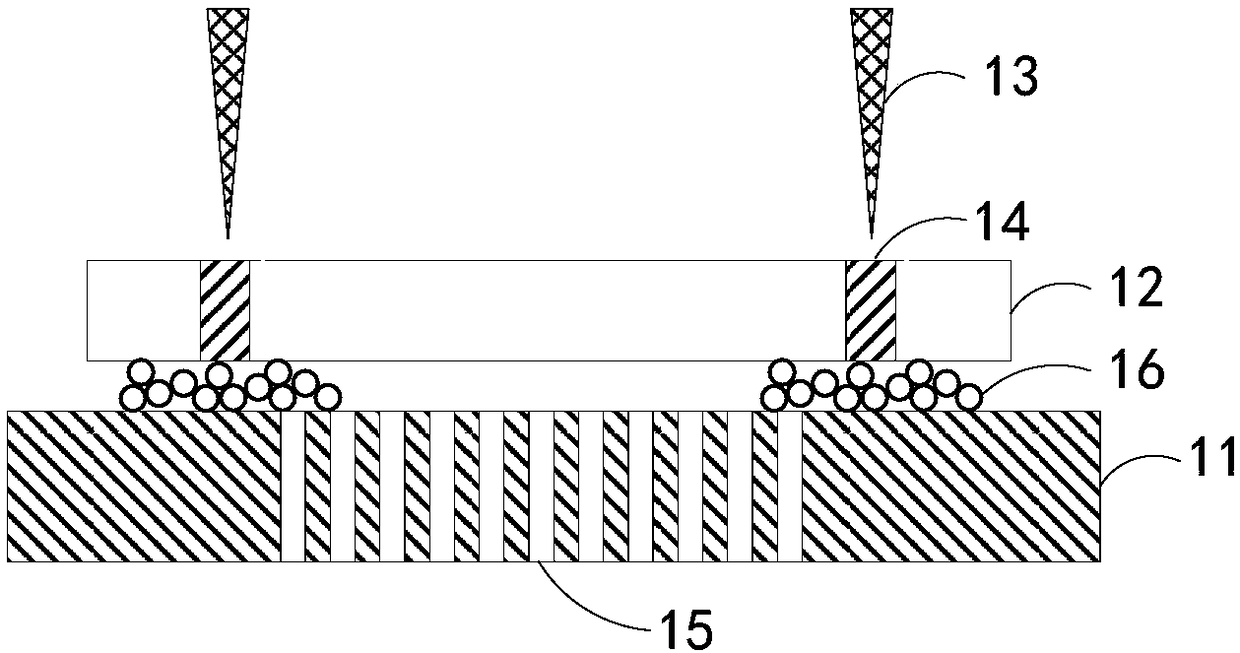

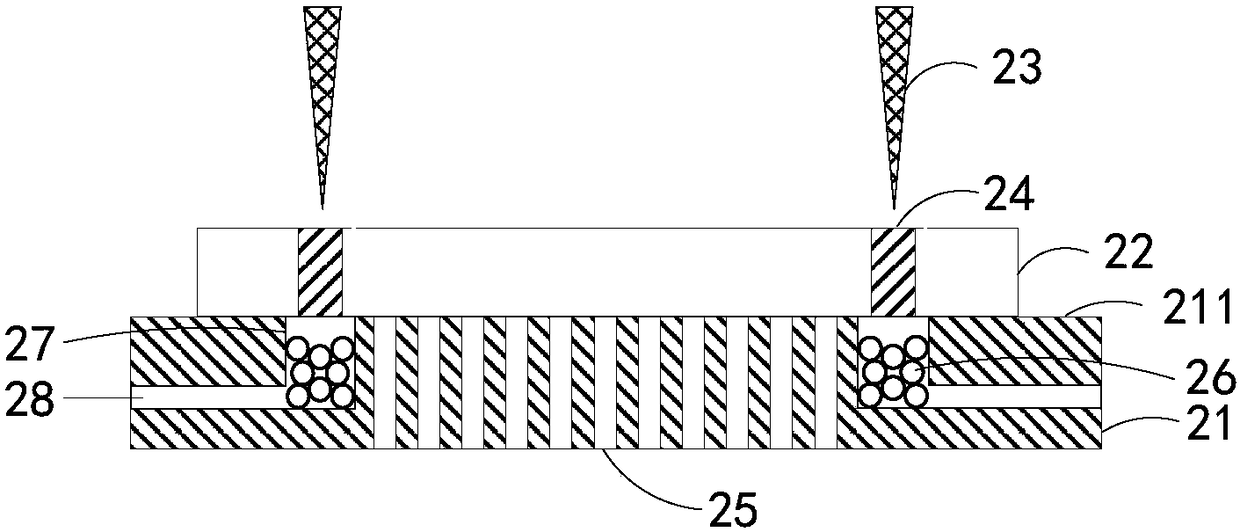

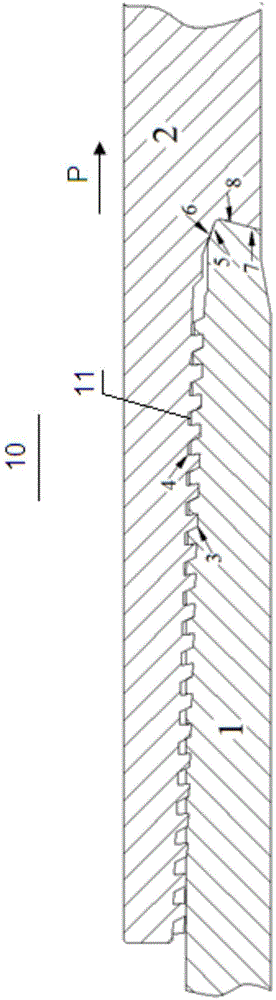

Cutting platform and cutting system

InactiveCN108453393AAvoid damageReduced risk of stickingWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses a cutting platform and a cutting system. The cutting platform comprises a platform body, a cutting groove and at least one dedusting channel, wherein the platform body comprises a first surface which is used for fixing a to-be-cut piece; the cutting groove is formed in the first surface of the platform body, and the cutting groove corresponds to a cutting line sent by a cutting device; and the at least one dedusting channel is formed in the platform body, one end of the dedusting channel communicates with the cutting groove, and the other end of the dedusting channel isconnected with a dedusting device and is used for discharging residues which are generated when the to-be-cut piece is cut by the cutting line and fall in the cutting groove. In the mode, the productquality can be increased, and the production efficiency of equipment can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

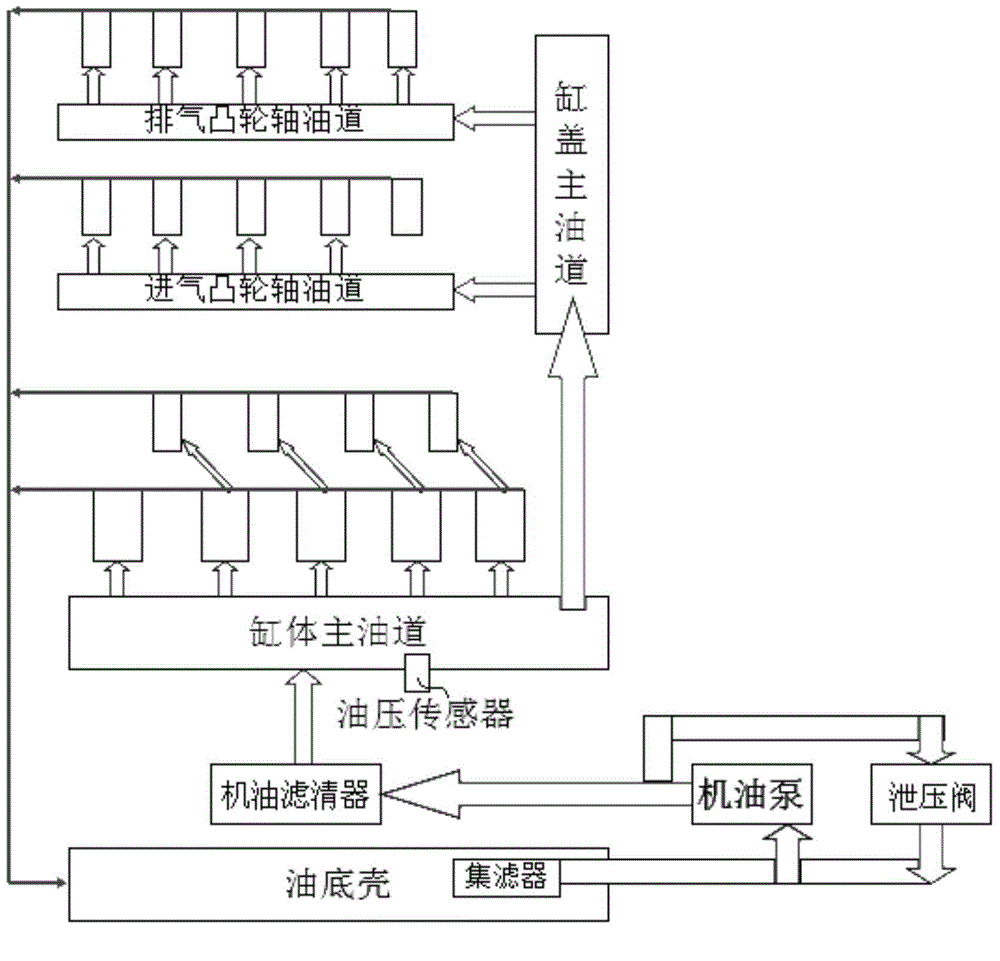

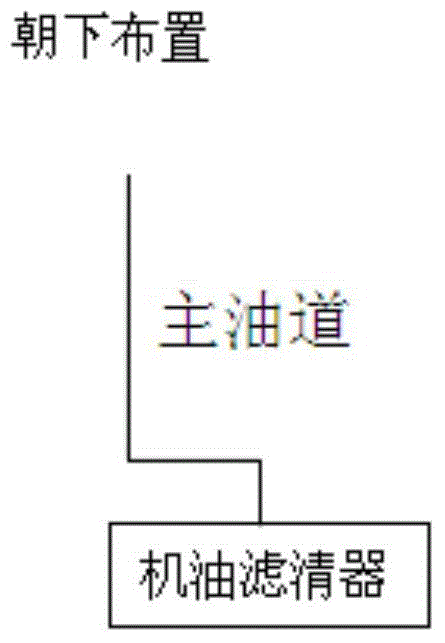

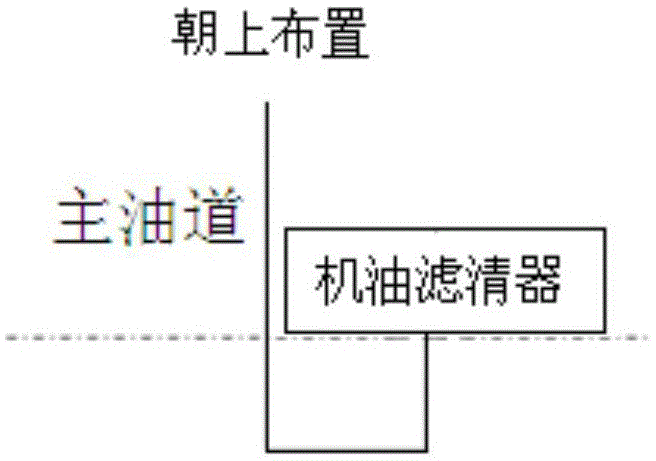

Engine oil returning structure

ActiveCN104454080AReduced risk of stickingGuaranteed cleanlinessPressure lubricationLubricant mounting/connectionCylinder blockElectromagnetic valve

The invention provides an engine oil returning structure. The engine oil returning structure comprises an oil pan, a suction filter, an engine oil pump, an engine oil filter, an electromagnetic valve, an ECU and an oil pressure sensor. Engine oil in the oil pan sequentially passes through the suction filter, the engine oil pump and the engine oil filter to enter a cylinder main oil way, the electromagnetic valve is used for connecting the engine oil filter with the oil pan, the oil pressure sensor measures the pressure of the engine oil entering the cylinder main oil way from the engine oil filter and transmits oil pressure signals to the ECU, and the ECU controls the open degree of the electromagnetic valve according to the oil pressure signals to enable the engine oil filtered through the engine oil filter to flow back to the oil pan. By means of the engine oil returning structure, it can be guaranteed that the oil pressure can better meet the practical working requirements of an engine, and the engine oil returning structure is more environmentally friendly.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

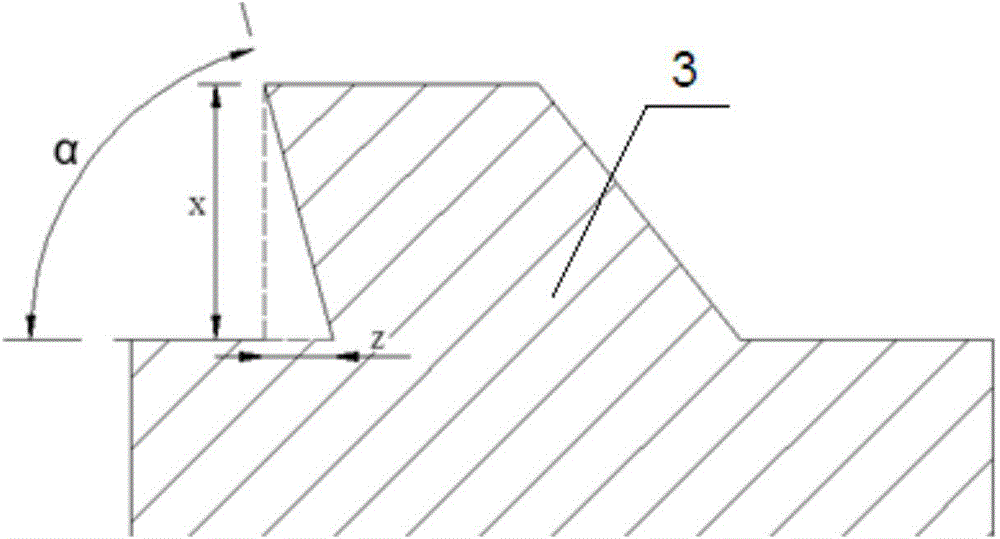

Airtight seal sleeve joint

InactiveCN104453738AGuaranteed compression performanceReduced risk of stickingDrilling rodsDrilling casingsPetroleum engineering

The invention discloses an airtight seal sleeve joint. The airtight seal sleeve joint comprises a sleeve male end and a sleeve female end, the sleeve male end is provided with an external thread, the sleeve female end is provided with an internal thread, the external thread of the sleeve male end is meshed with the internal thread of the sleeve female end, and the tooth profile of the external thread and the tooth profile of the internal thread are each of a slanting trapezoid shape. In addition, in the feeding direction of the external thread, the part, behind the external thread, of the sleeve male end is provided with a first seal face and a first retreat stop shoulder connected with the first seal face, and the first retreat stop shoulder is located at the tail end of the sleeve male end. The sleeve female end is provided with a second seal face and a second retreat stop shoulder, the second seal face is in interference fit with the first seal face, the second retreat stop shoulder is matched with the first retreat stop shoulder, and the second seal face is also connected with the second retreat stop shoulder. A gap is formed between the internal thread and the external thread. The airtight seal sleeve joint has good stretch resistance, compression resistance and torque resistance capability, better thread gluing resistance and excellent airtight seal performance and can adapt to the work environment of a three-exceeding gas field.

Owner:BAOSHAN IRON & STEEL CO LTD

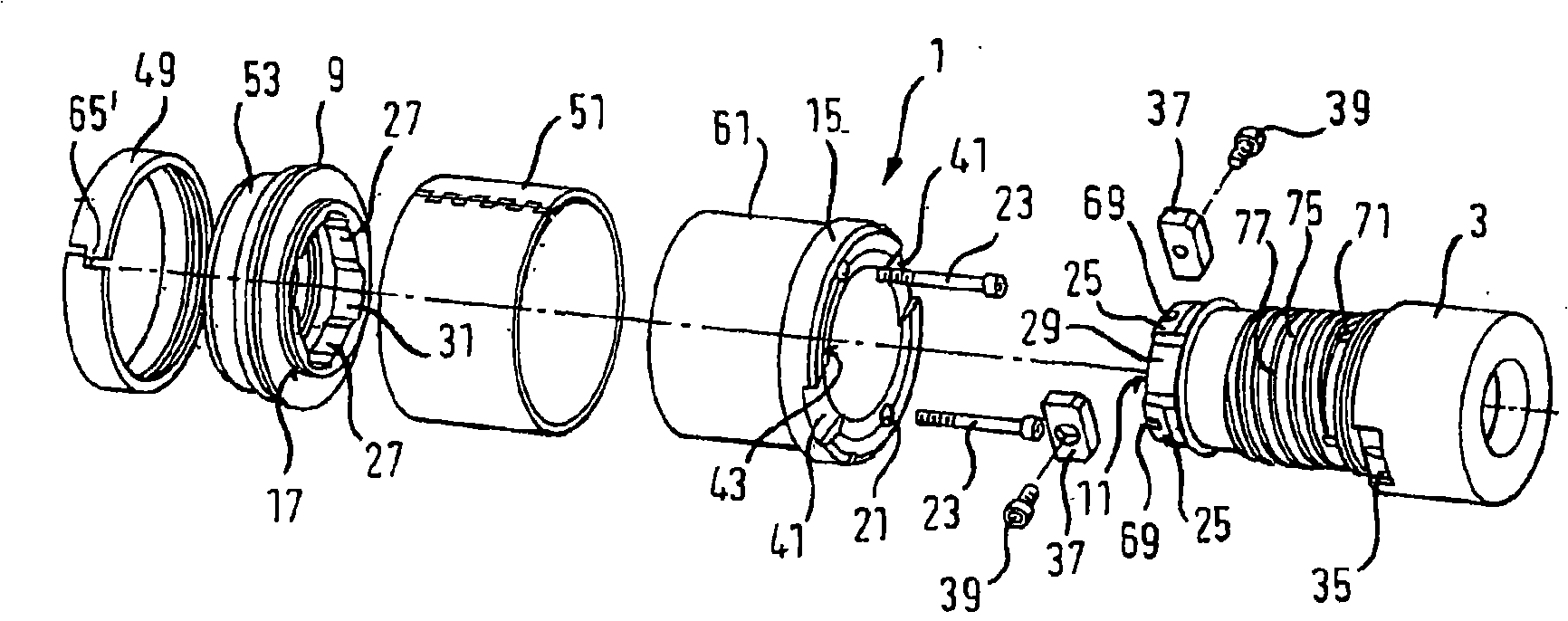

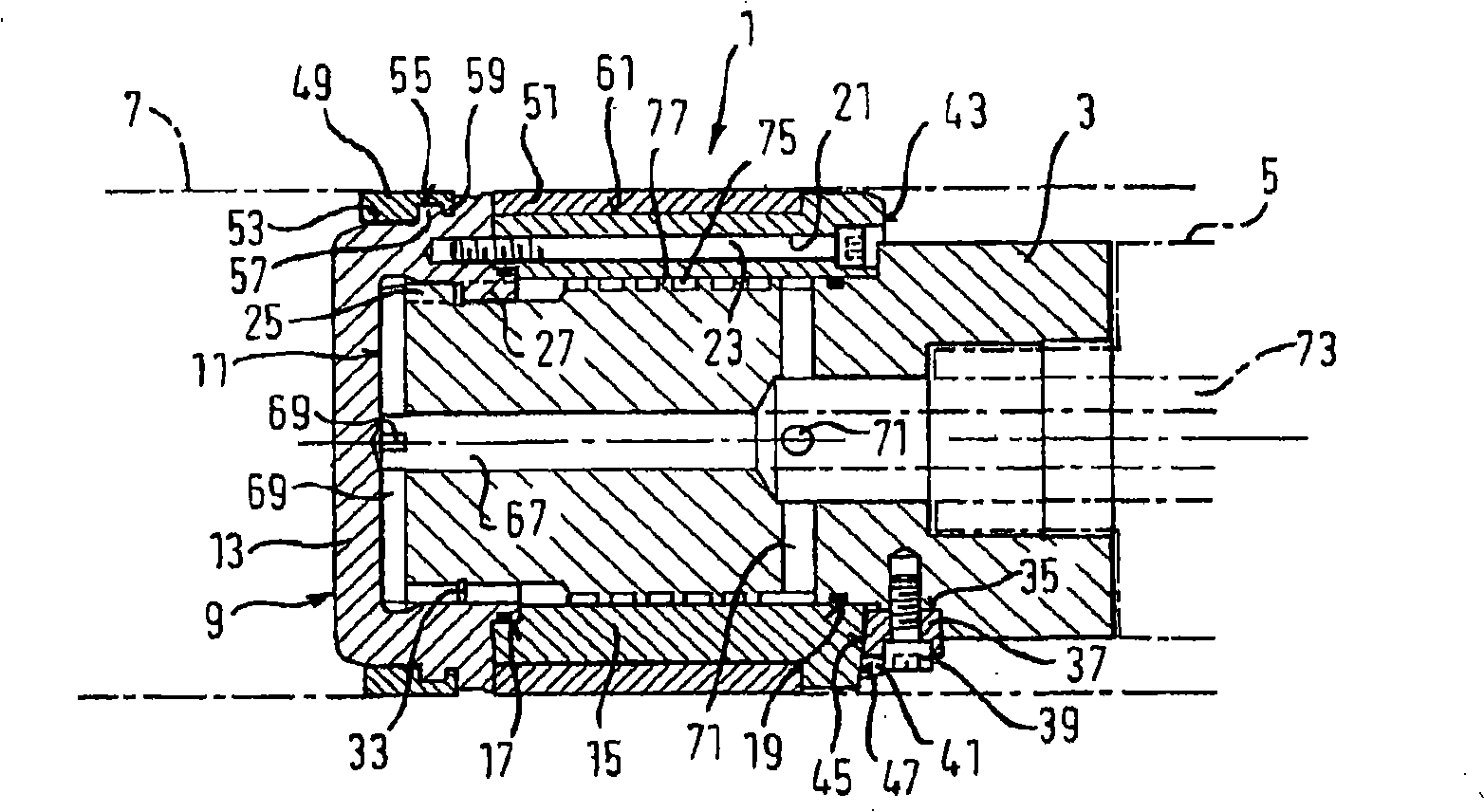

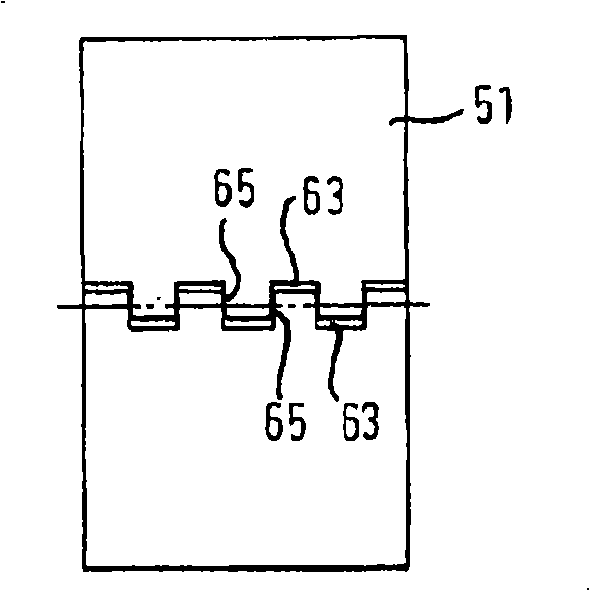

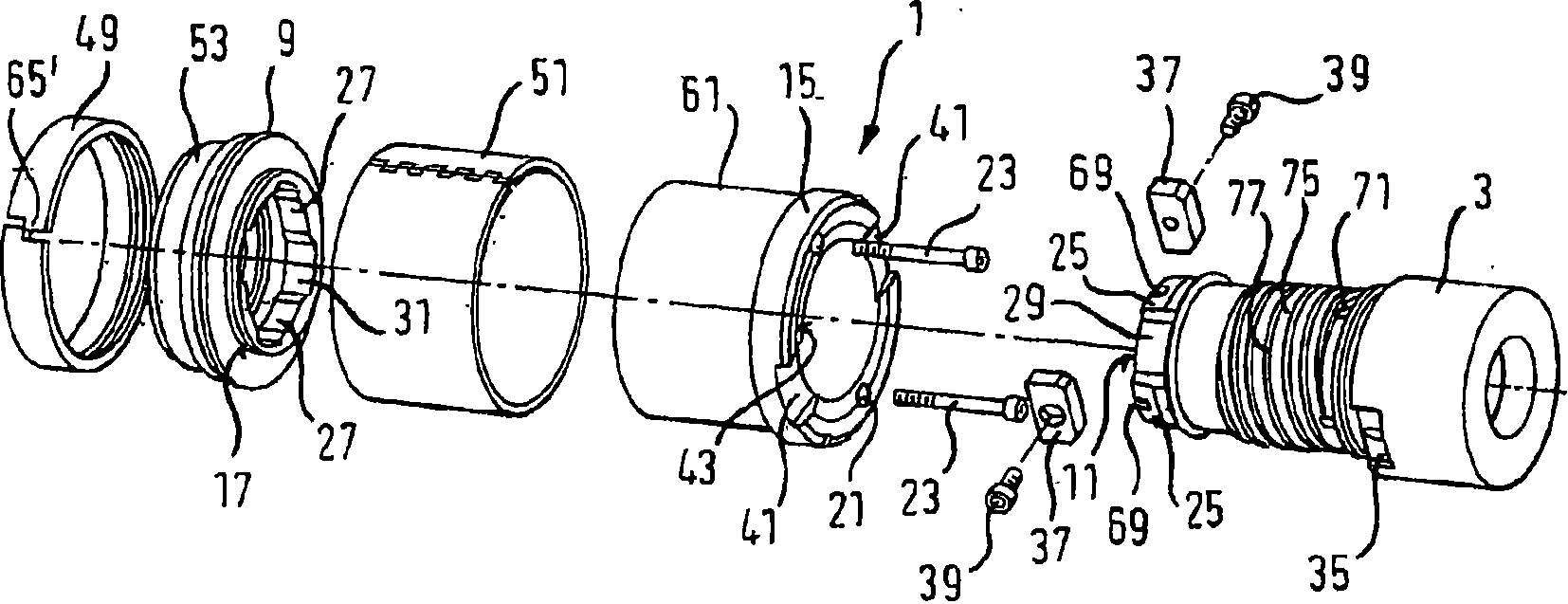

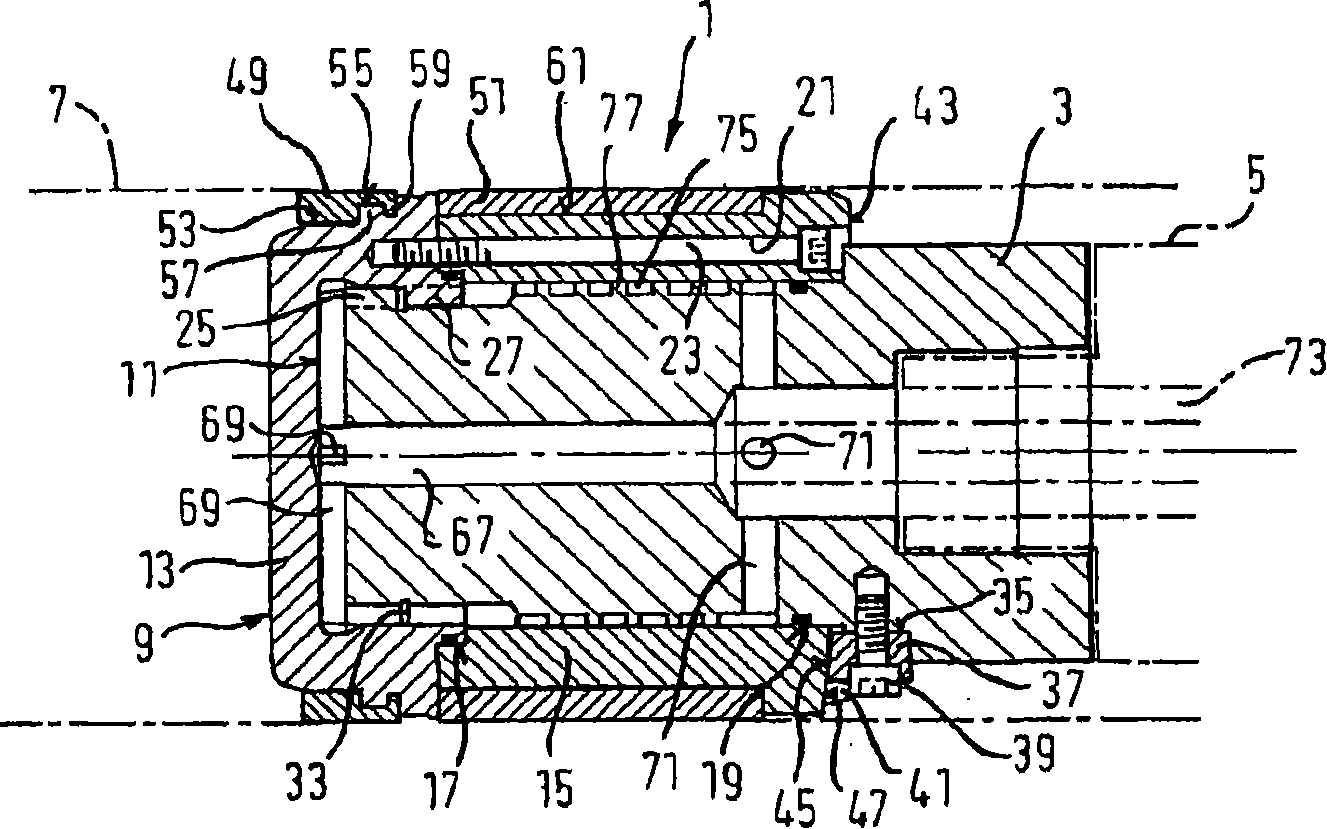

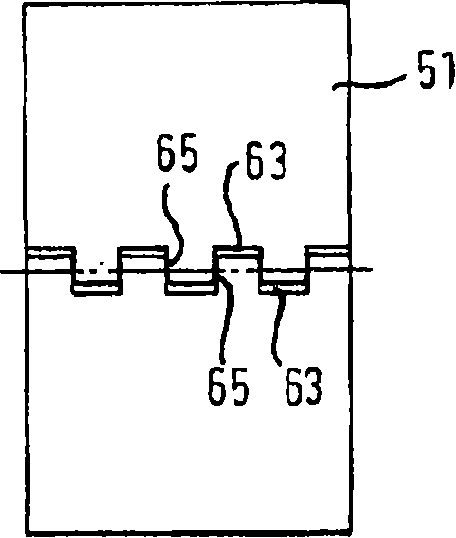

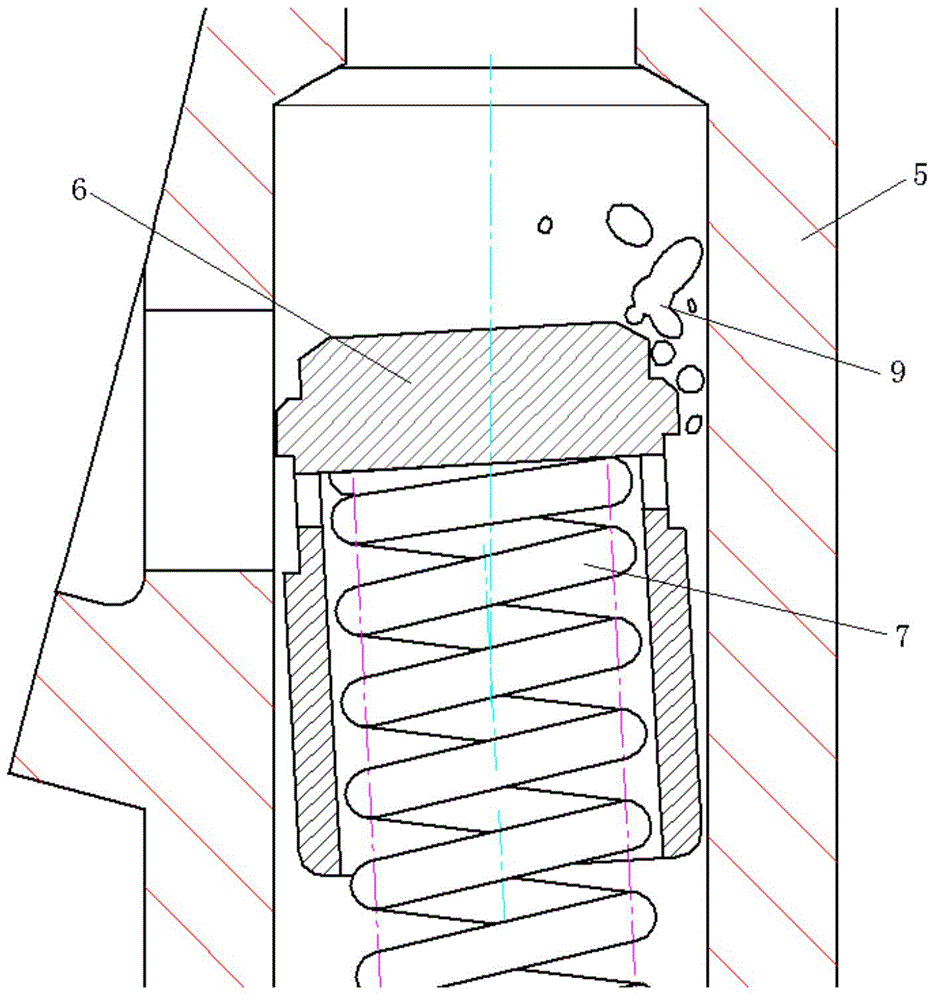

Multi-piece piston for a cold chamber casting machine

A multi-piece piston (1) is disclosed, for fixing to the high pressure side end (3) of a piston rod (5) running axially in a casting cylinder (7) of a cold chamber casting machine. The piston comprises a piston crown (9) forming a piston front face (13) on the high pressure side and a piston body (15) in the form of a bush connected to the piston crown (9) on the low pressure side. The piston body (15) can be connected to the piston crown (9) by means of fixing screws (23) to form a module. Complementary bayonet looking means (25, 27) are provided, for axial fixing of the piston (1) to the end (3) of the piston rod (5), on the piston crown (9) and the end (3).

Owner:EXCO TECHNOLOGIES LTD

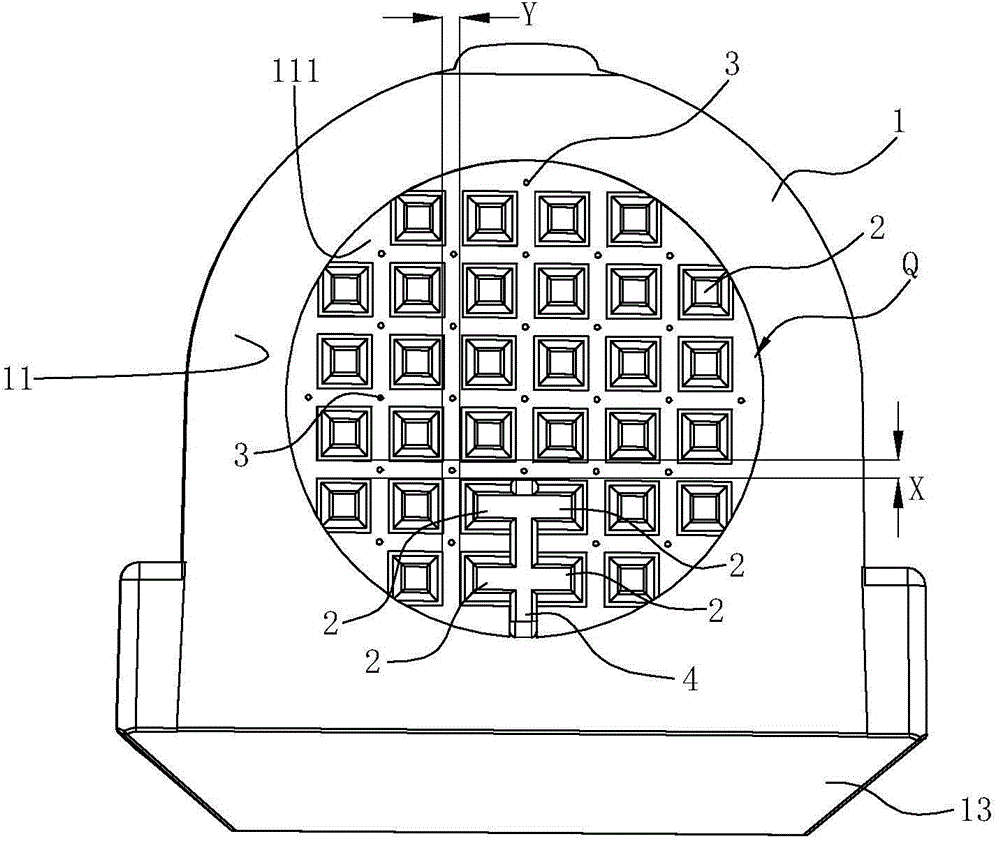

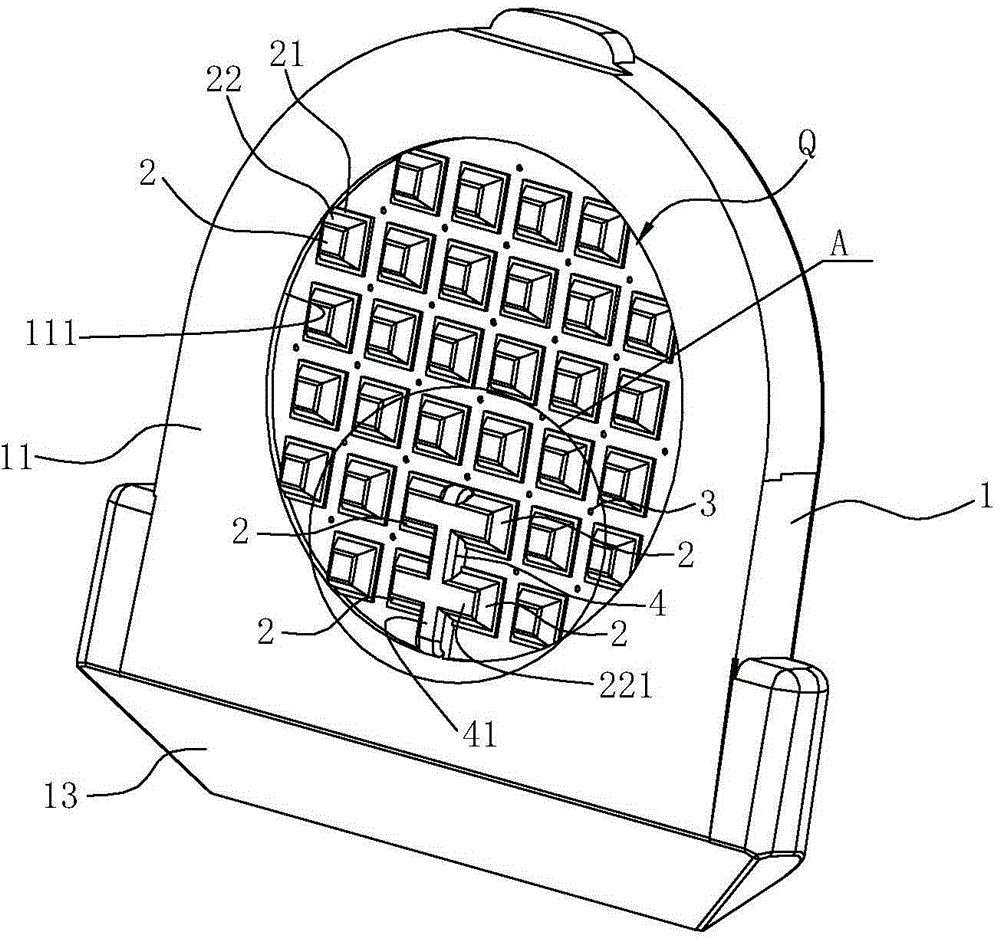

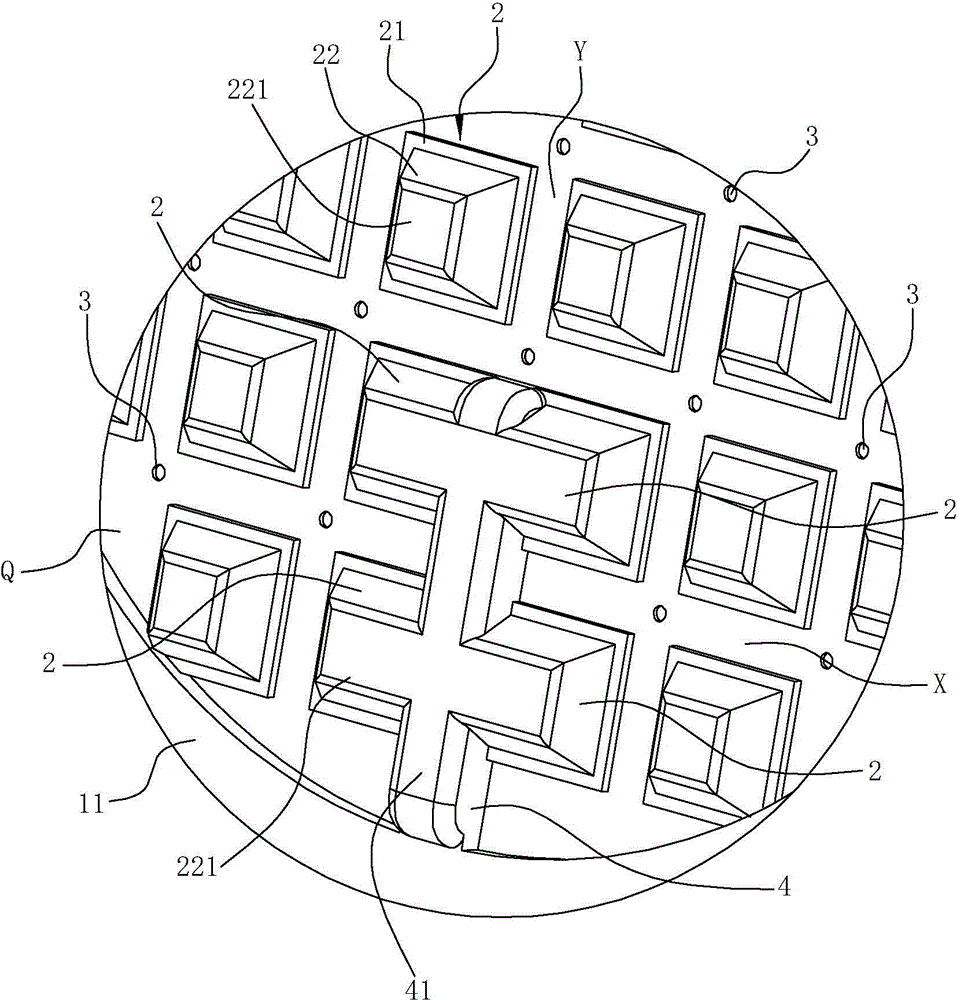

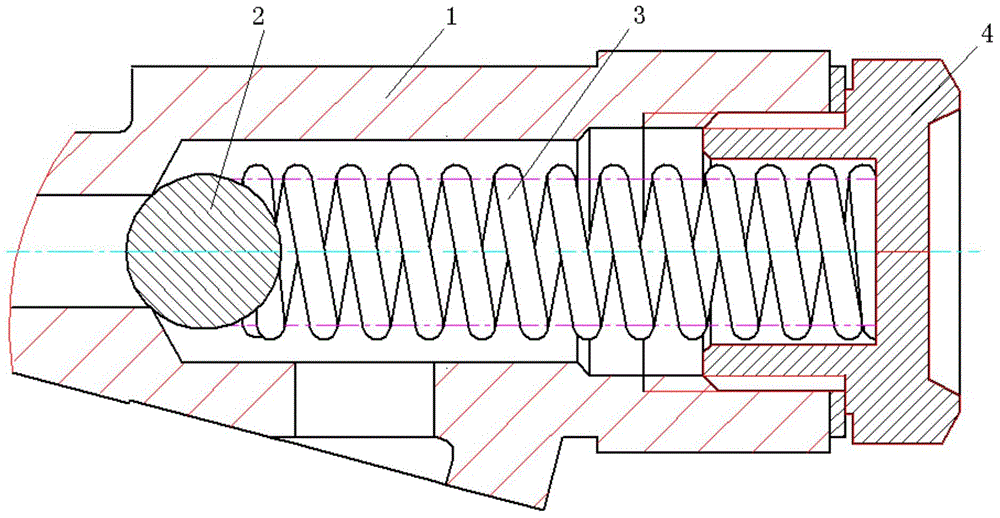

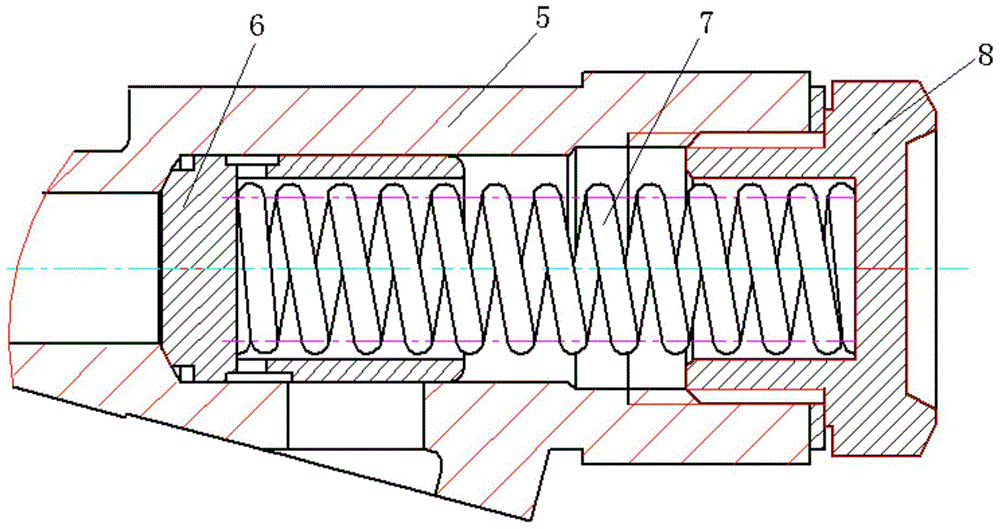

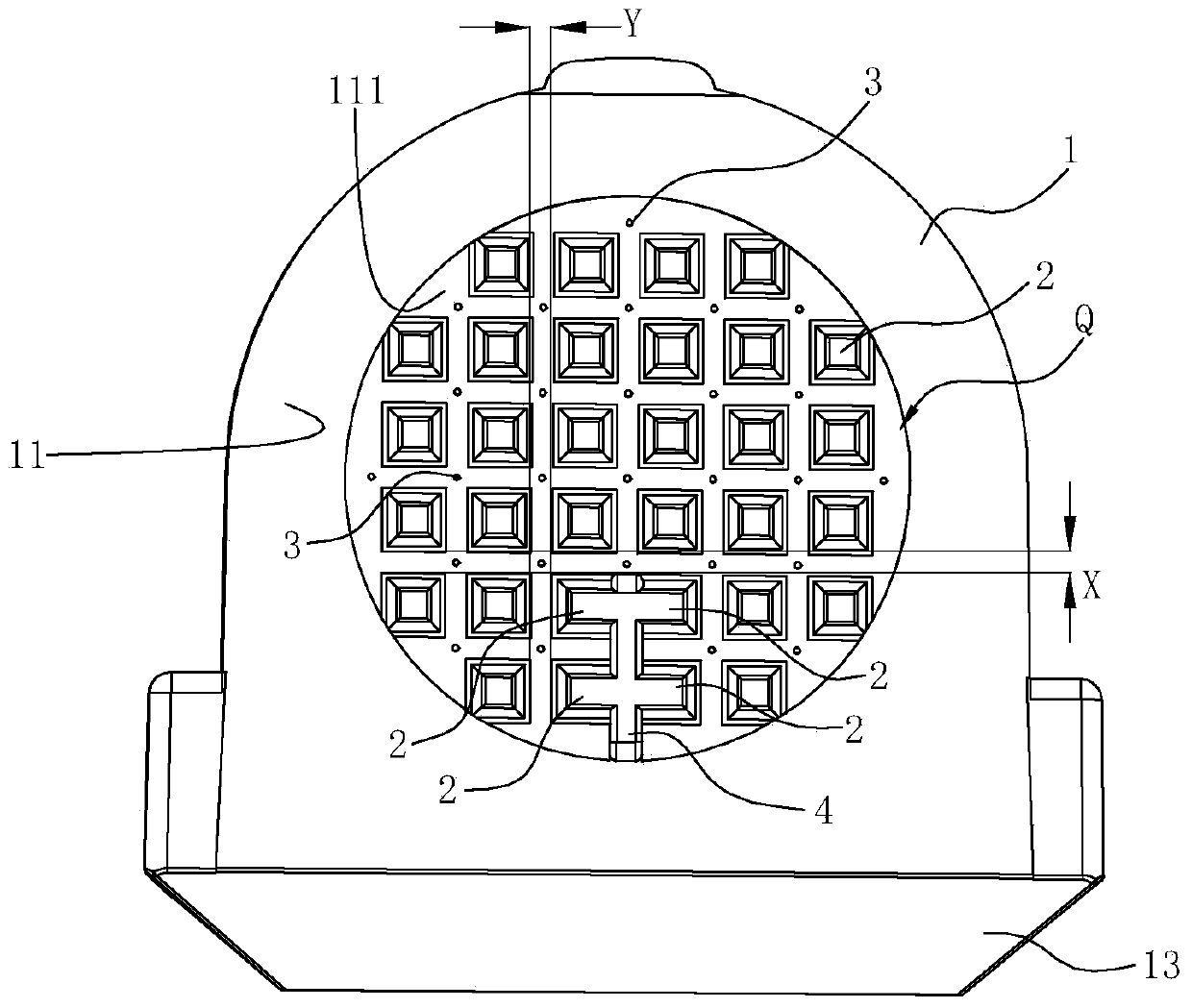

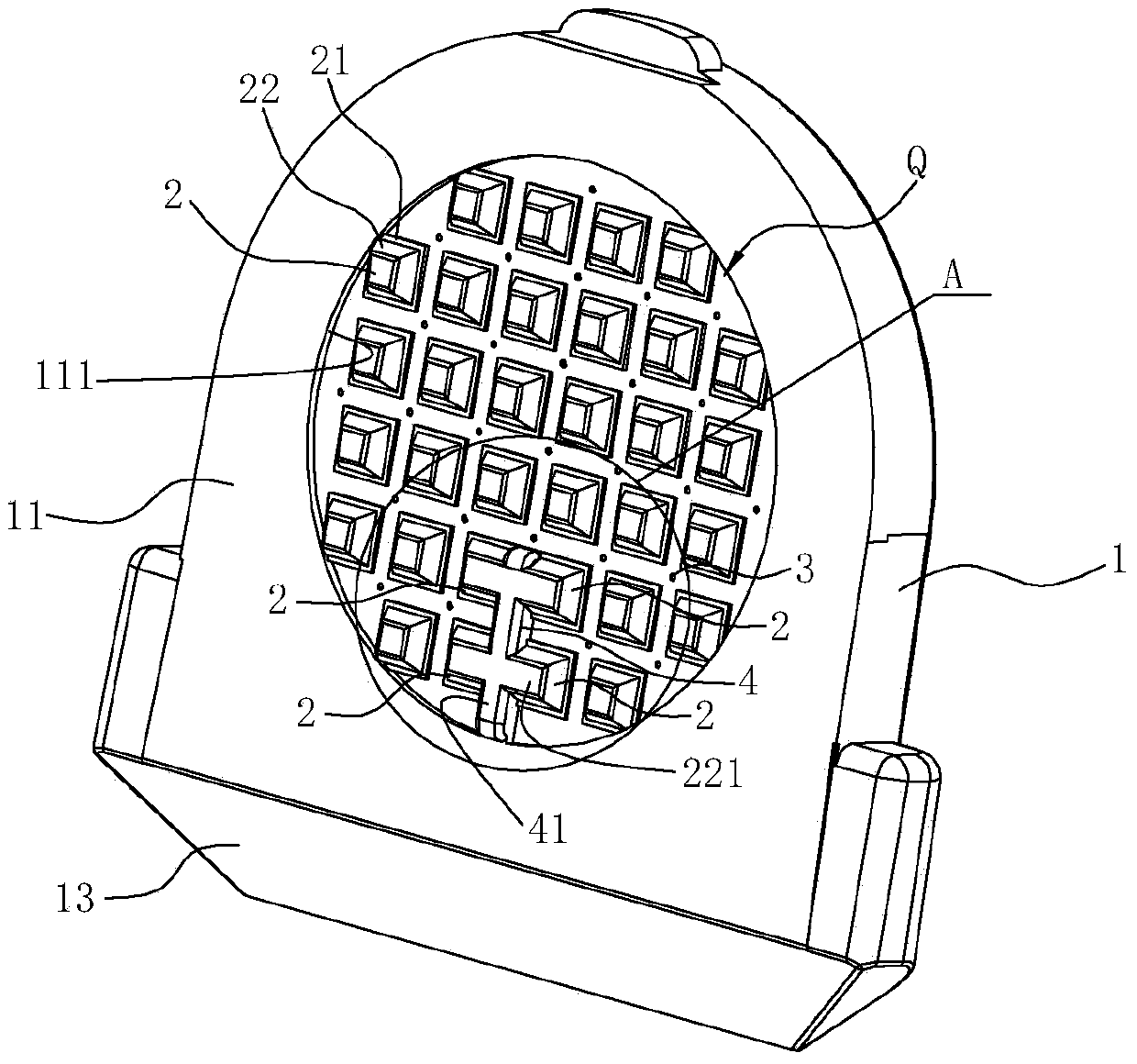

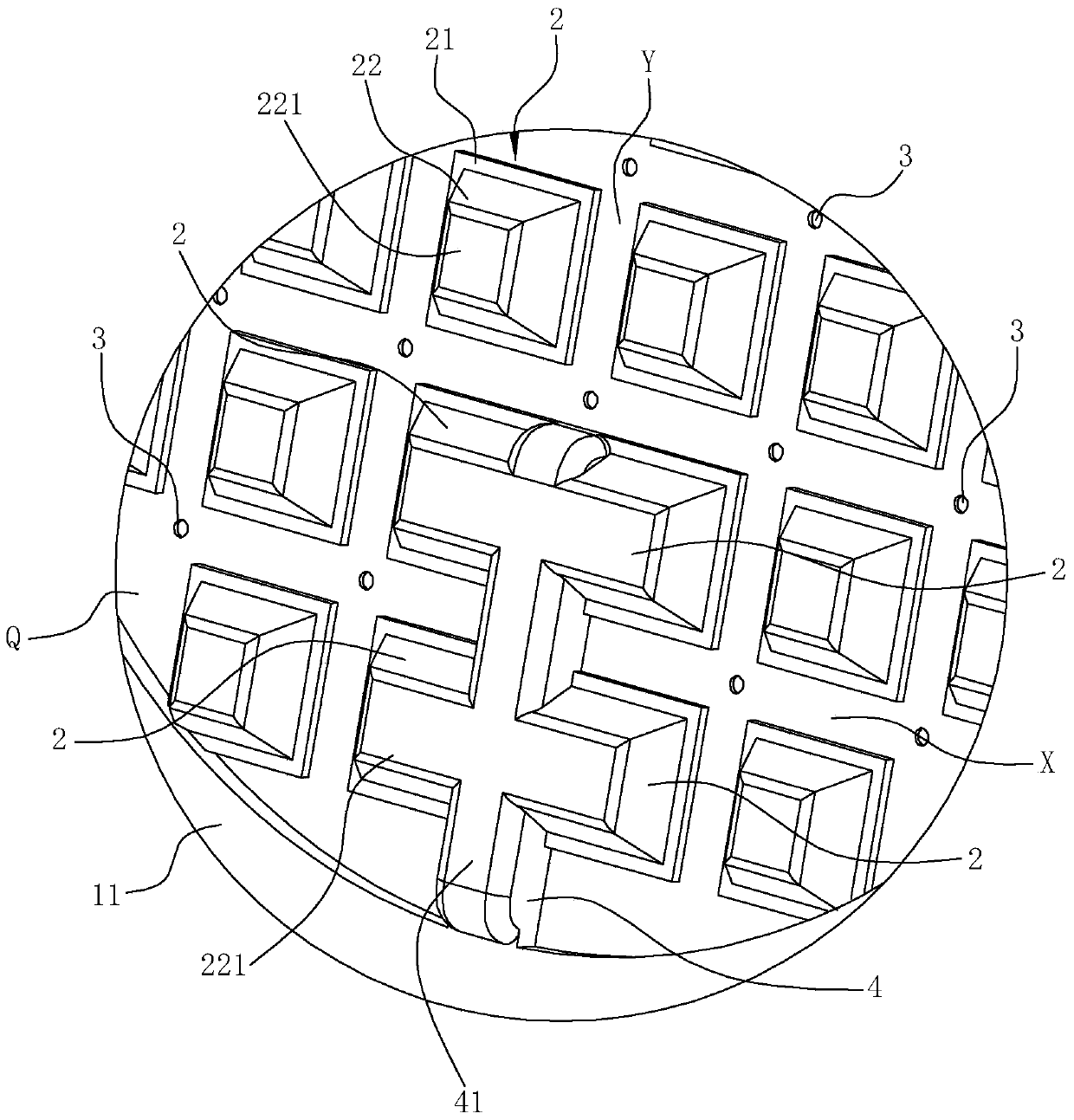

Expansion plate used for beverage brewing equipment

The invention relates to an expansion plate used for beverage brewing equipment. The expansion plate includes a plate body provided with a first end face and a second end face. The first end face of the plate body is provided with a plurality of boss parts and a plurality of beverage discharge holes throughout the plate body, the beverage discharge holes are distributed between the boss parts, and the boss parts form an expansion area on the first end face. The expansion plate is characterized in that a vertical arranged rib strip is at least arranged at the lower portion of the expansion area, and the length of the rib strip ensures blocking of the lower edge of a beverage capsule inserted in the beverage brewing equipment so that the risk that the beverage capsule gets stuck by the boss parts at an unwanted position during insertion can be lowered permanently. The beverage brewing equipment using the expansion plate can effectively ensure that the capsule does not get stuck by the boss parts on the expansion plate at the unwanted position when inserted into the beverage brewing equipment, and meanwhile the capsule can be disengaged from the expansion plate more easily.

Owner:NINGBO AAA GROUP ELECTRIC APPLIANCE

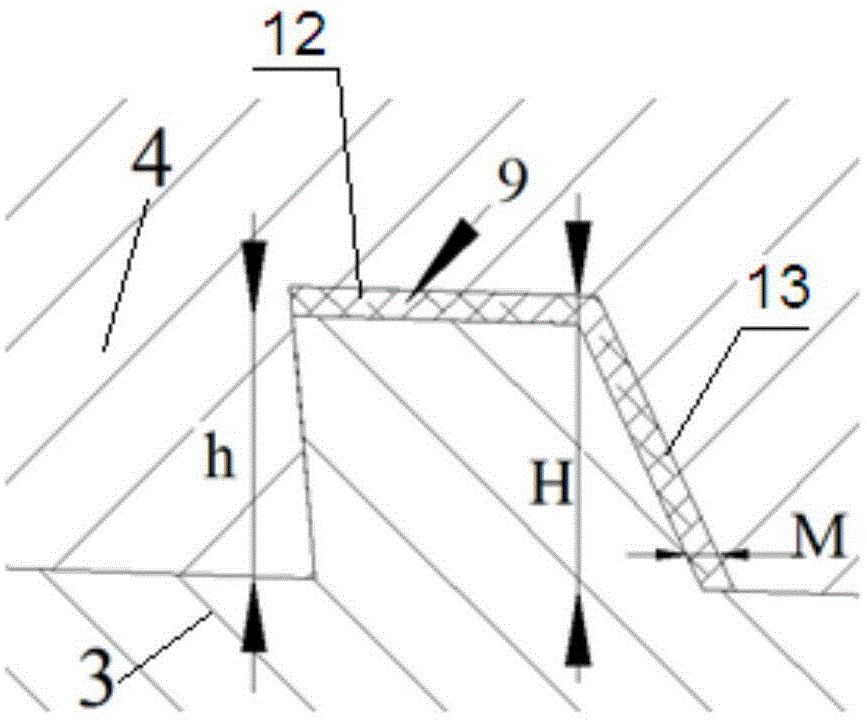

Method and tool for decementing light machine assembly parts

InactiveCN101767323AReduce the risk of stickingEasy to operateMetal-working hand toolsRoom temperatureEngineering

The invention relates to a method and a tool for decementing light machine assembly parts, comprising the following steps: 1) fixing a light machine assembly part 1 to be decemented on a decementing tool; 2) placing the light machine assembly part 1 to be decemented and the decementing tool into a high and low temperature chamber and raising temperature to 60 DEG C to 80 DEG C at constant speed in 30min then keeping the temperature for 30min; 3) opening the door of the high and low temperature chamber, slowly rotating a wrench in the high and low temperature chamber to enable a bucking bar to move leftwards until optical glass breaks away from a framing member; 4) cooling the high and low temperature chamber to room temperature and then taking out optical glass, the framing member and the decementing tool. With the method and tool of the invention, pollution of mirror surface film layer, size distortion and structural damage in the existing technology for decementing the light machine assembly parts are solved. In addition, the method and tool of the invention have the advantages of simple and convenient operation and no influence on physical property of optical elements.

Owner:XIAN MICROMACH TECH CO LTD

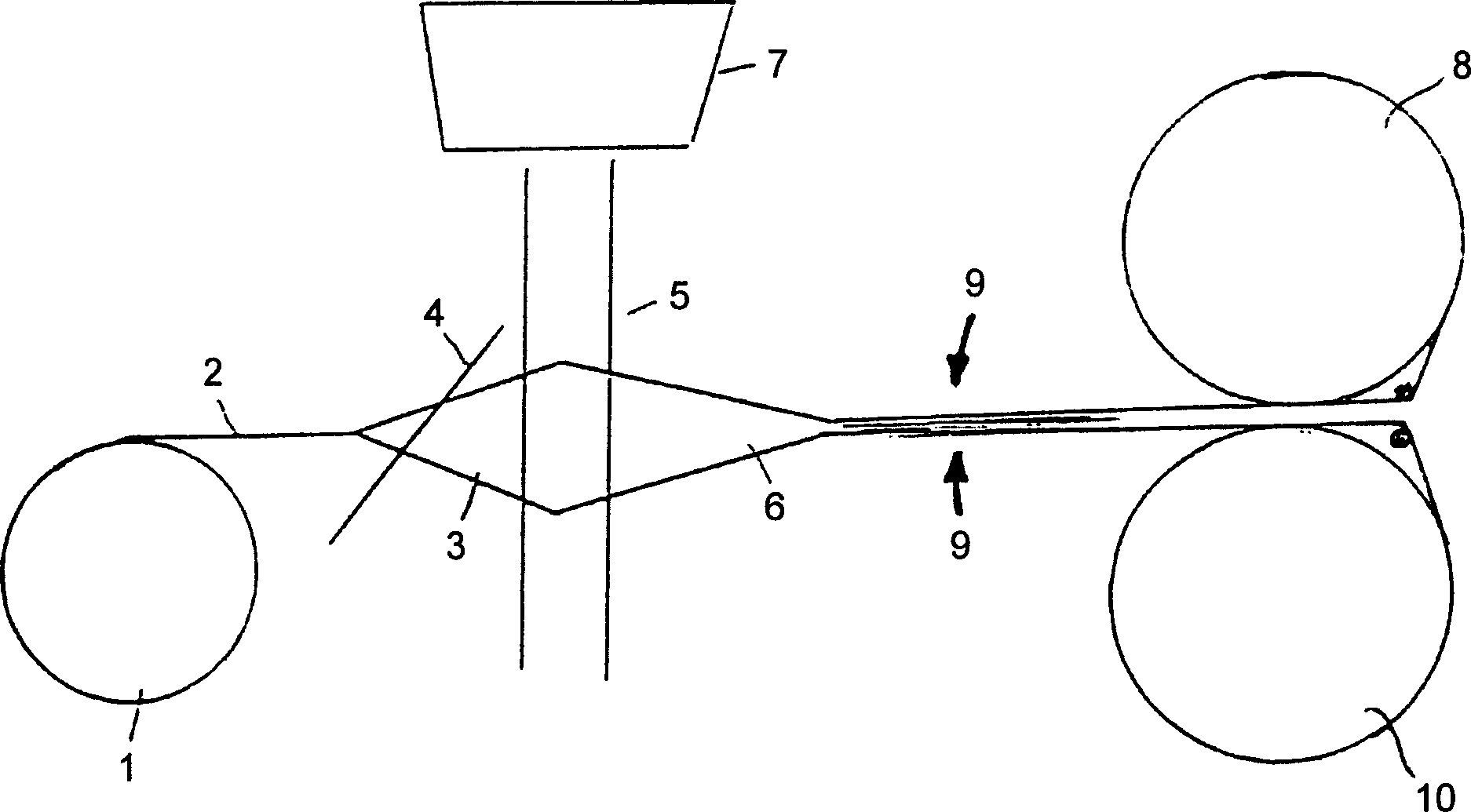

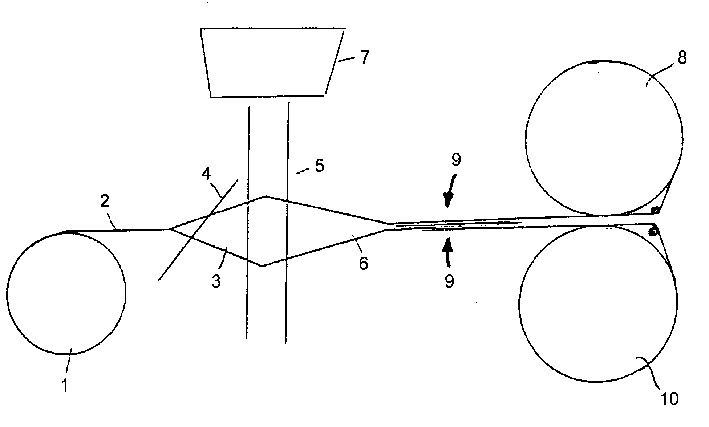

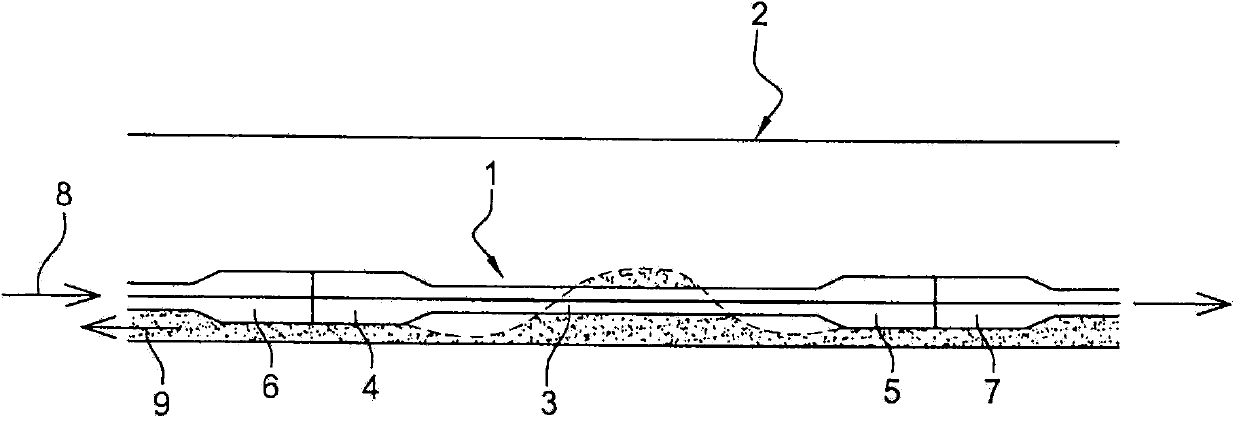

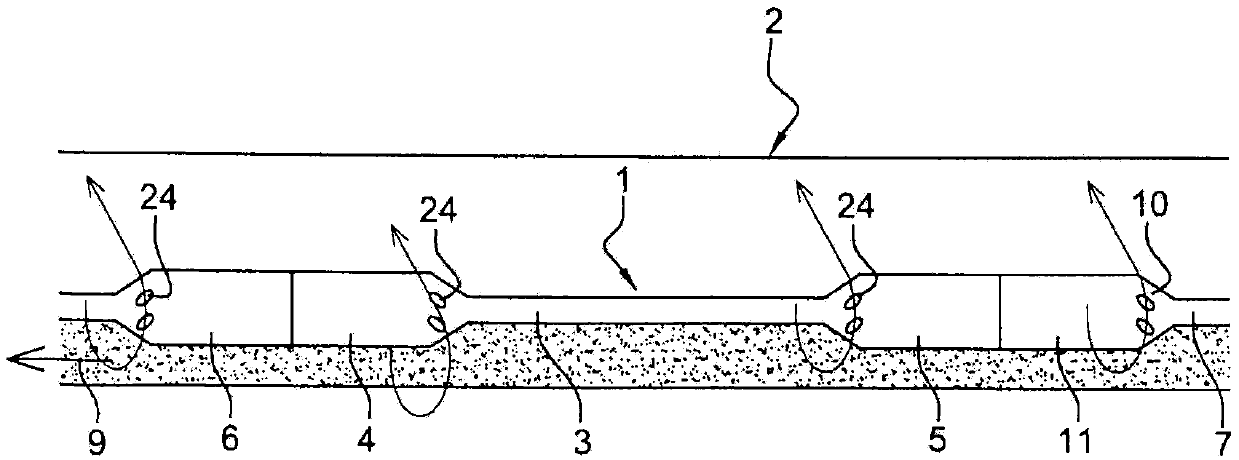

Method for producing woven fabric

The invention relates to a method for weaving single-layered and / or multi-layered woven fabric, especially airbag fabric. The inventive method is characterised in that warp threads delivered by at least two warp beams (8, 10) are interwoven.

Owner:BST SAFETY TEXTILES GMBH

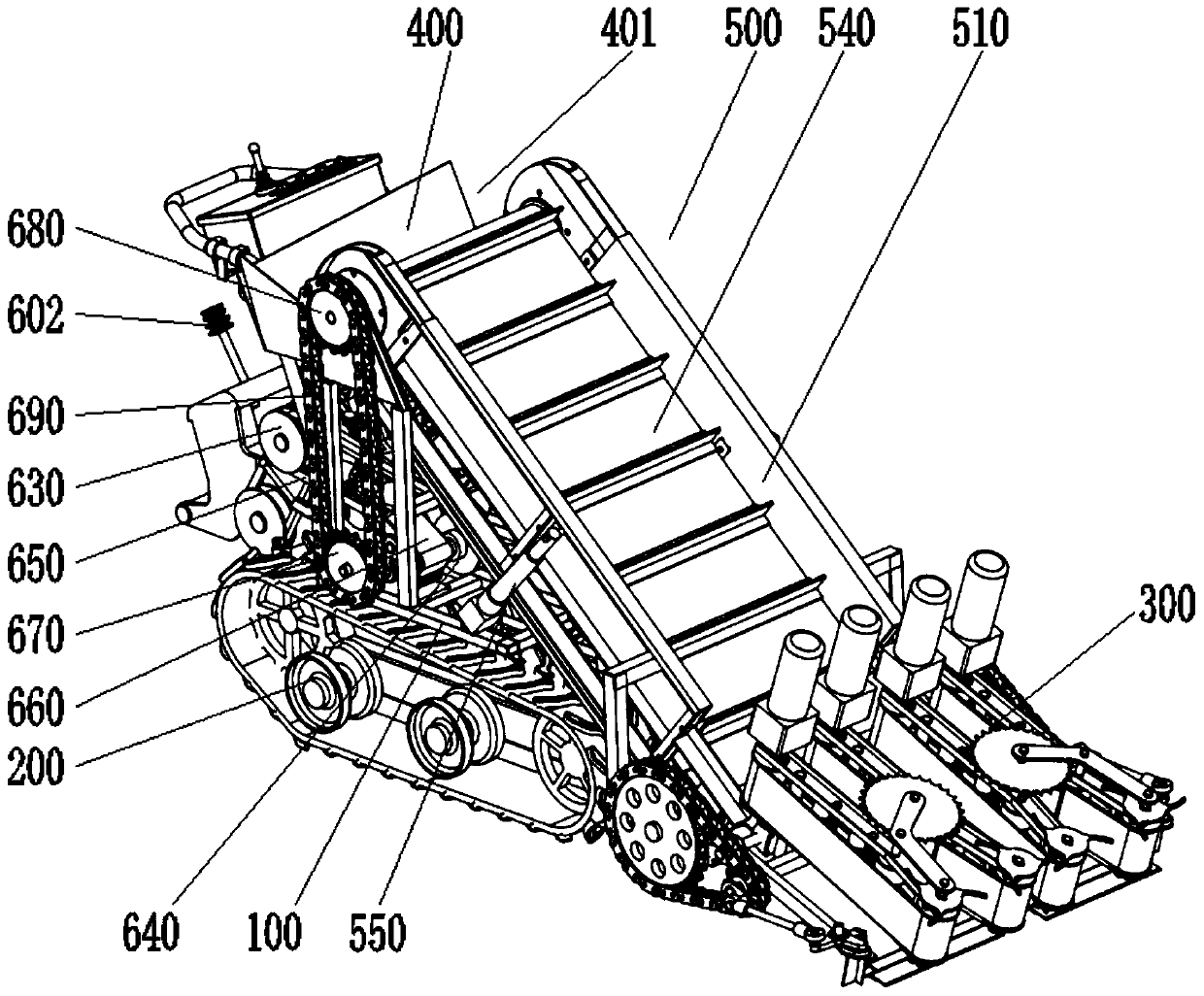

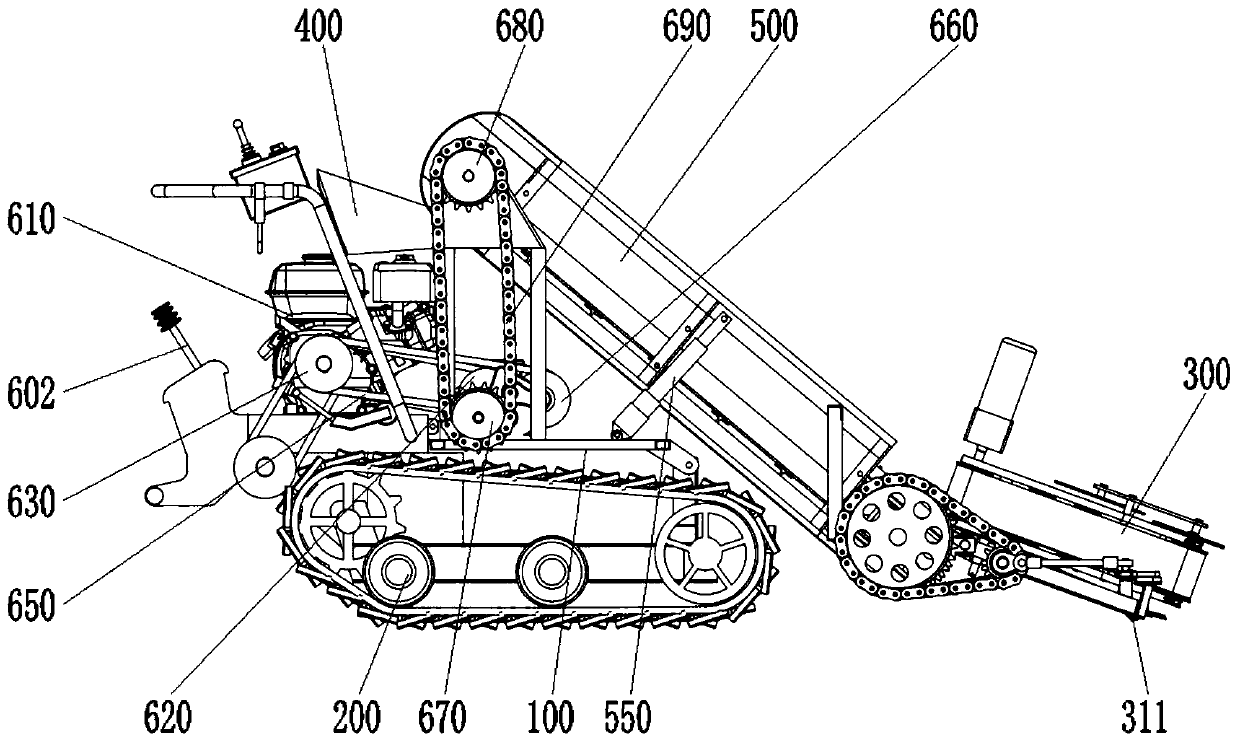

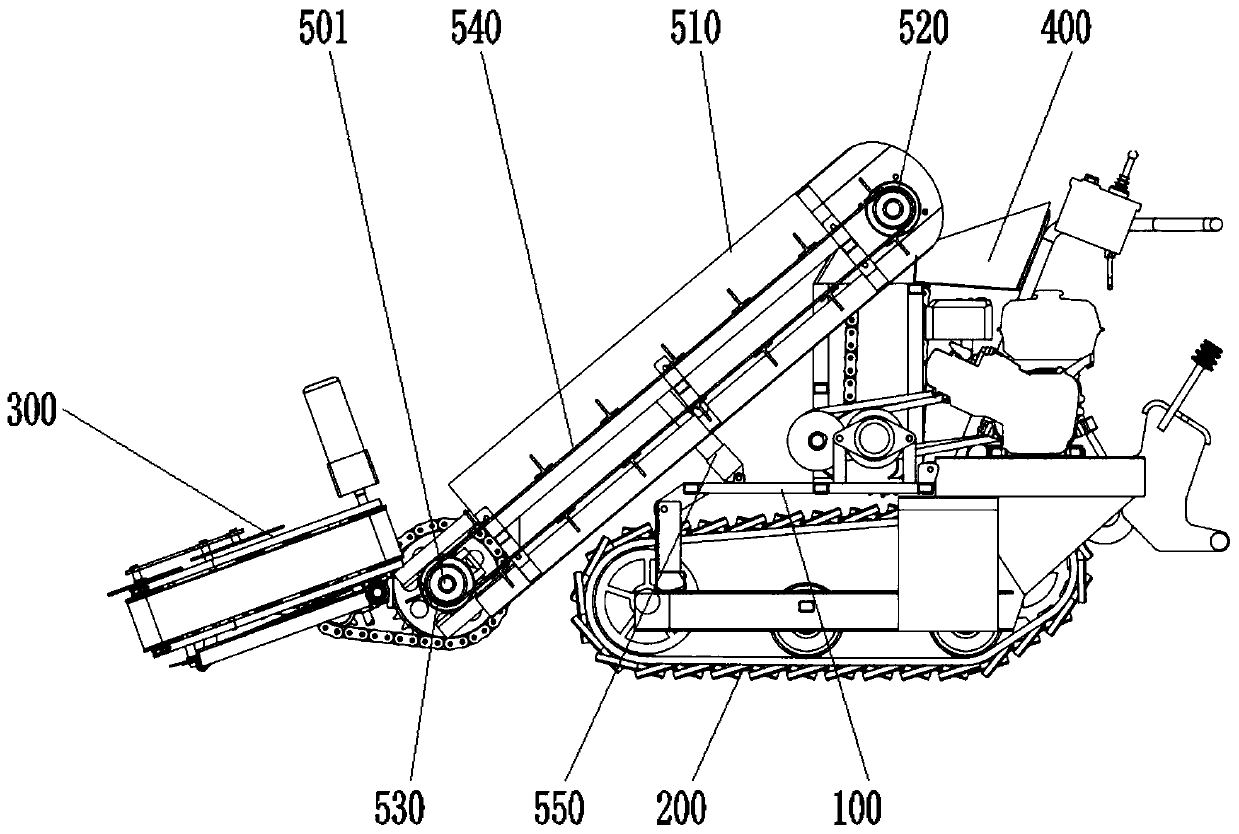

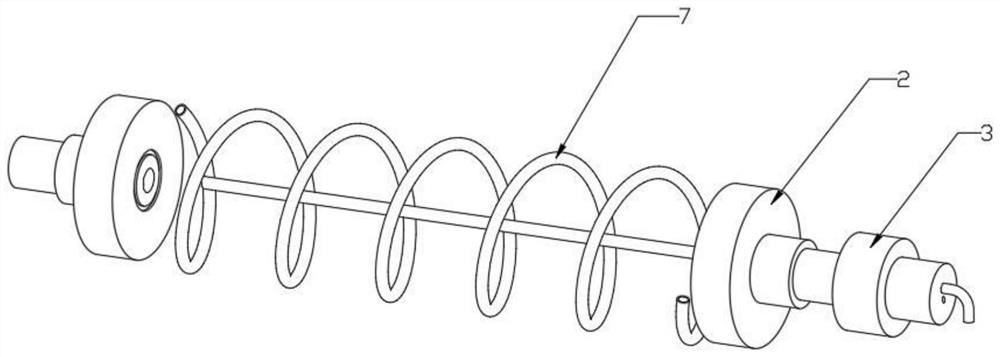

Tumorous stem mustard harvester

PendingCN110946003AReduce the chance of damageReduced risk of stickingHarvestersEngineeringMechanical engineering

The invention provides a tumorous stem mustard harvester. The tumorous stem mustard harvester comprises a rack, a walking mechanism and a cutting and conveying device. The cutting and conveying devicecomprises a rack, a vegetable leaf removal assembly, a rhizome cutting device and a flexible clamping and conveying device. The flexible clamping and conveying device comprises a first clamping and conveying part, a second clamping and conveying part and a flexible adjusting mechanism. The first clamping and conveying part and the second clamping and conveying part are arranged oppositely. A clamping and conveying channel which straightens, clamps and conveys heads is formed between the first clamping and conveying part and the second clamping and conveying part. The flexible adjusting mechanism is used for adjusting the width of the clamping and conveying channel self-adaptively according to the sizes of the heads. According to the tumorous stem mustard harvester, the tumorous stem mustard entering the clamping and conveying channel is straightened and clamped, and the width of the clamping and conveying channel is adjusted self-adaptively according to the sizes of the heads of the tumorous stem mustard. The tumorous stem mustard harvester can clamp and convey the tumorous stem mustard of different sizes, so that the tumorous stem mustard clamping and conveying reliability is improved, and the damage rate of the tumorous stem mustard in the conveying process is reduced.

Owner:CHONGQING ACAD OF AGRI SCI

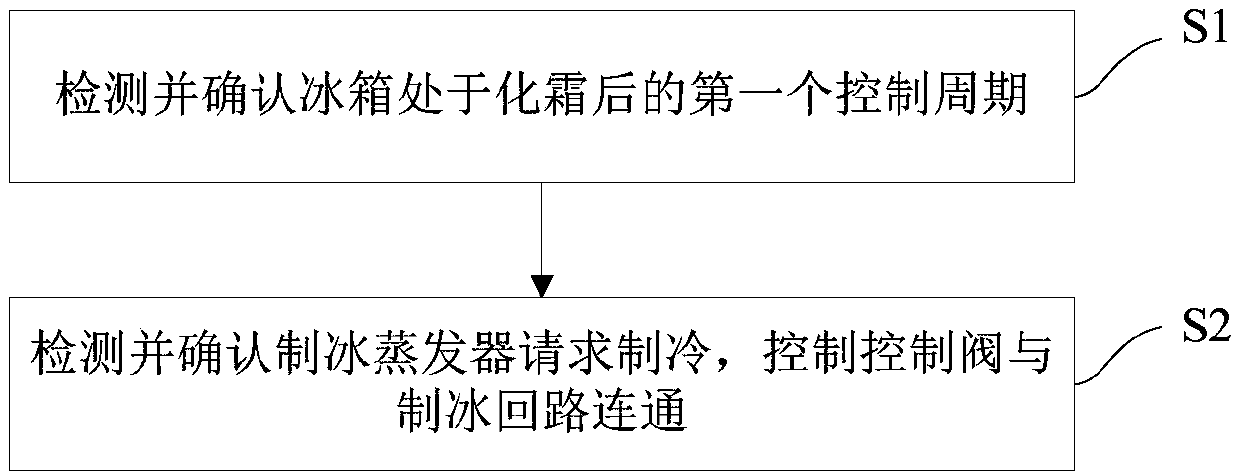

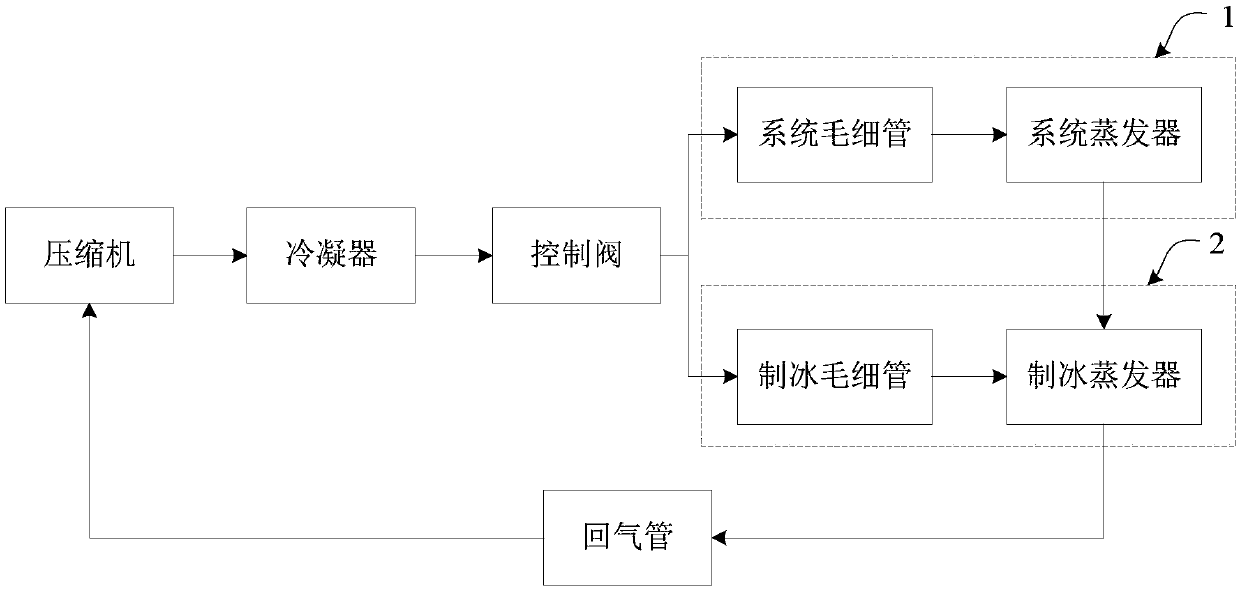

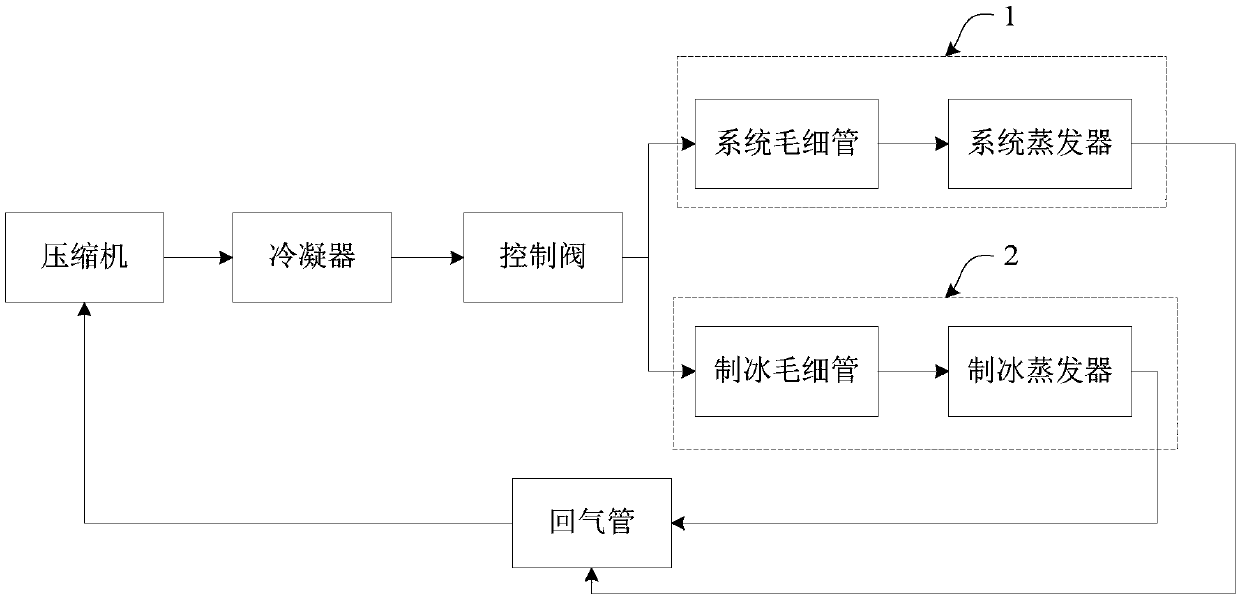

Refrigerator and control method and control device thereof

PendingCN109631487AShorten the timeReduced risk of stickingDomestic cooling apparatusLighting and heating apparatusEngineeringControl valves

The invention discloses a refrigerator and a control method and control device thereof. The method comprises the steps that the first control period that the refrigerator is in a defrosted state is detected and determined; and the fact that an ice making evaporator requests for refrigerating is detected and determined, and a control valve is controlled to communicate with an ice making circuit. According to the method, a refrigerating agent can be controlled to be preferentially introduced into the ice making circuit after the refrigerator is defrosted, therefore, the time that an ice making chamber is in a high-temperature state due to defrosting is effectively shortened, the risk of ice block adhesion caused by ice block melting and re-icing after melting is reduced, and ice blocks can be stored at high quality for a long term.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

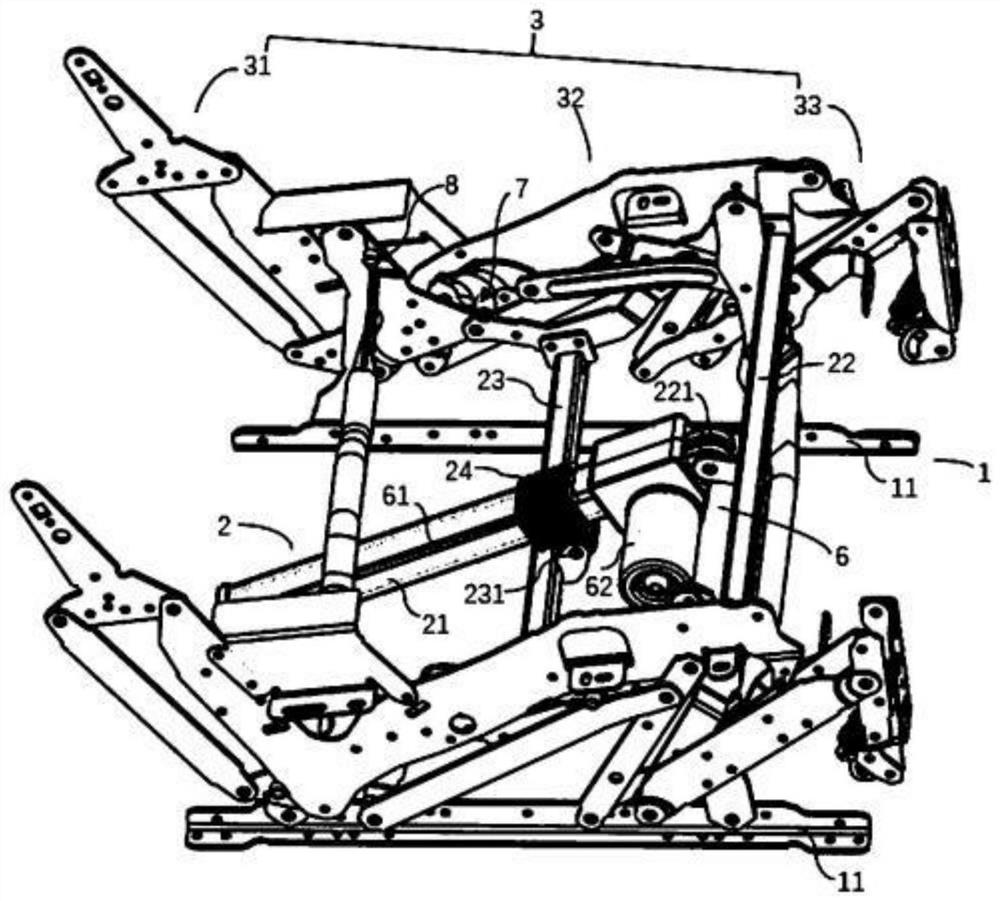

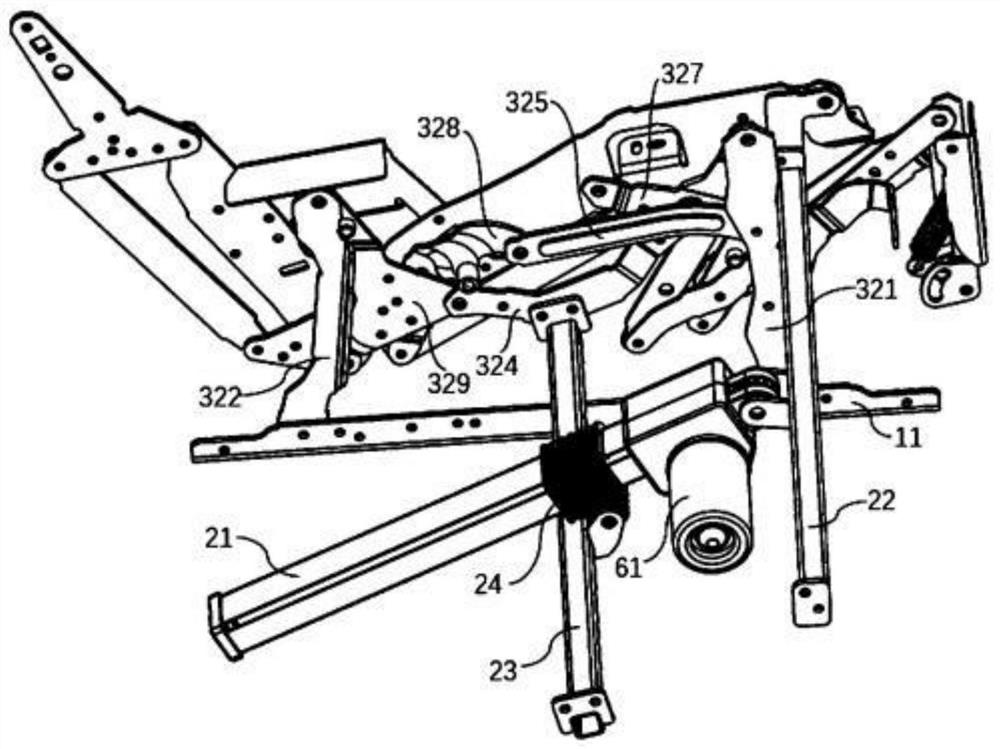

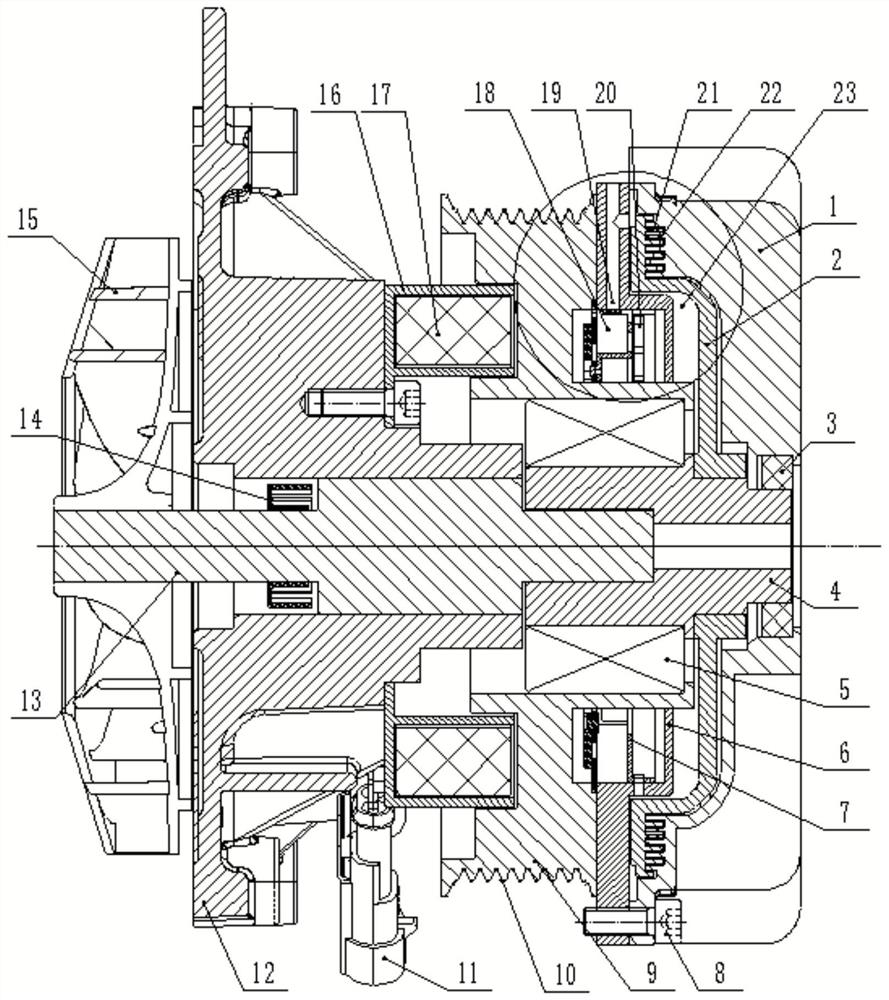

Novel motor-driven mechanical stretching device

PendingCN112545236AGuaranteed linkage functionSimple structureSofasCouchesElectric machineryLinkage (mechanical)

The invention discloses a novel motor-driven mechanical stretching device. The improved novel motor-driven mechanical stretching device comprises a left side component and a right side component whichare symmetrical, the left side component comprises a leg stretching mechanism, a seat plate linkage mechanism and a backrest mechanism, the seat plate linkage mechanism comprises a front mounting piece, one end of the front mounting piece is pivoted to the front portion of a bottom connecting rod, the other end of the front mounting piece is pivoted with a first front rotating piece, the middle of the front mounting piece is pivoted with a second front rotating piece, the other end of the second front rotating piece is pivoted with a side connecting rod piece, the front end of the side connecting rod piece is pivoted with the middle of the first front rotating piece, the rear end of the side connecting rod piece is pivoted with a rear rotating piece which is pivoted with a rear mounting piece, the other end of the rear mounting piece is pivoted to the rear end of the bottom connecting rod, and the rear rotating piece and the front rotating piece I are pivoted with an assembling side plate simultaneously. The problems that an existing seat plate linkage mechanism is complex in structure, large in number of parts, high in manufacturing cost and high in clamping stagnation risk are solved.

Owner:沙剑波

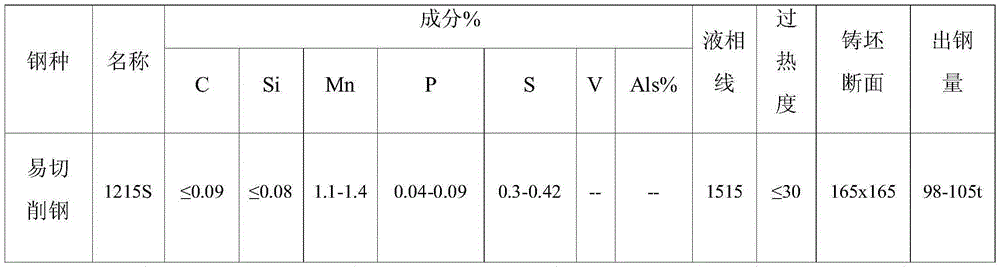

Special continuous casting crystallizer function protecting material for sulfur free-cutting steel and preparation method thereof

The invention discloses a special continuous casting crystallizer function protecting material for sulfur free-cutting steel and a preparation method thereof. The protecting material comprises the following chemical components in percentage by weight: 30.2-40.2% of SiO2, 17.0-27.0% of CaO, Li2O not more than 3.5%, 9.3-18.3% of Al2O3, 2.5-8.5% of K2O+Na2O2, 2.0-7.0% of F-, MgO not more than 8.5%, and Fe2O3 not more than 2.0%. The vitrification tendency of slag films is high due to lower binary alkalinity; the lubrication can be guaranteed; the bonding risk is reduced; and the heat stability and the chemical stability of the protecting material in the melting process are improved.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP +1

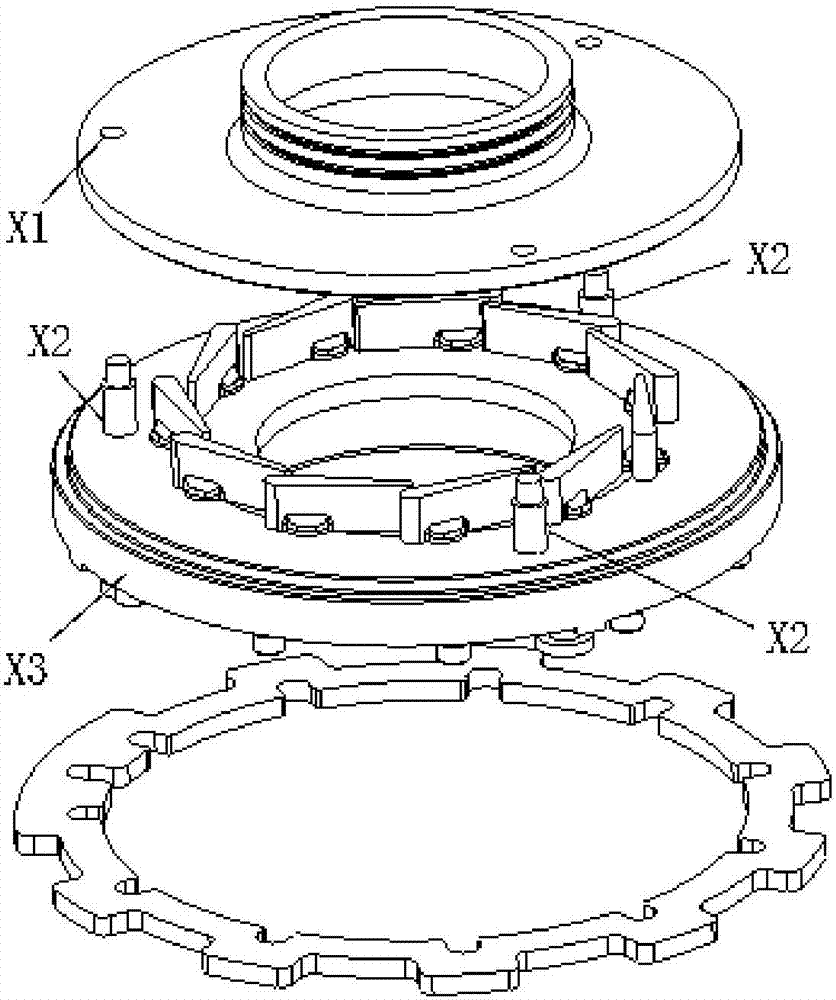

Variable nozzle ring component for effectively preventing blade from clamping stagnation

PendingCN106939828AEliminate High Temperature StuckReduced risk of stickingInternal combustion piston enginesStatorsRocker armLow speed

The invention discloses a variable nozzle ring component for effectively preventing a blade from clamping stagnation. The variable nozzle ring component for effectively preventing a blade from clamping stagnation is a turbocharger accessory. A turbine end of the turbocharger comprises a turbine housing, a turbine and the variable nozzle ring component. The variable nozzle ring component comprises a blade guard plate, a spacer pin, the blade, a mounting disk, a rigging pin, a synchronizing ring and an adjusting rocker arm. The blade guard plate is located between the turbine housing and the blade; the spacer pin, the blade and the rigging pin are assembled on the mounting disk, the synchronizing ring is fixed on the mounting disk through the rigging pin, the adjusting rocker arm is connected with the synchronizing ring, and the adjusting rocker arm is assembled with a shaft tail end of the blade. The variable nozzle ring component can reduce the high-temperature clamping stagnation risk of a nozzle blade by means of adjusting a design structure of the spacer pin and the blade guard plate, and simultaneously can reduce a design value of the blade clearance and improve the low-speed performance.

Owner:奕森科技(江苏)有限公司

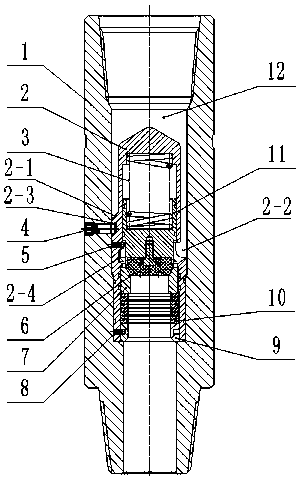

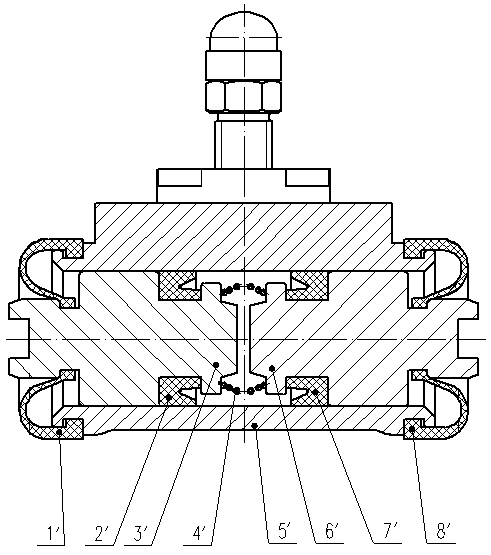

Mud splash-proof valve for oil drilling

The invention discloses a mud splash-proof valve for oil drilling. A shell is in a circular pipe shape, and an overall valve element is supported on a second step of an inner hole; a valve element body is in a cylinder shape with the lower end open, four steps are sequentially machined in a cylinder from bottom to top, and a valve seat is mounted on the upward cylinder wall of the first step in anattached mode; and during pump starting, mud enters the upper inner hole of the shell from an upper drilling tool, and enters a deceleration groove shaped like the Chinese character 'chuan' through three flow channels shaped like the Chinese character 'nian' to form an even and stable mud flow to enter the cylinder of the valve element body, and thus the valve element ascends to the upper parts of the flow channels shaped like the Chinese character 'nian' and an opening in the cylinder along with a piston. A soft-to-hard sealing pair is formed between the valve element and the valve seat, thus the sealing reliability is improved, the valve seat is supported through a supporting pin, a supporting seat and a strong spring, machining and mounting processes are simplified, and the product cost is lowered.

Owner:东营市创元石油机械制造有限公司

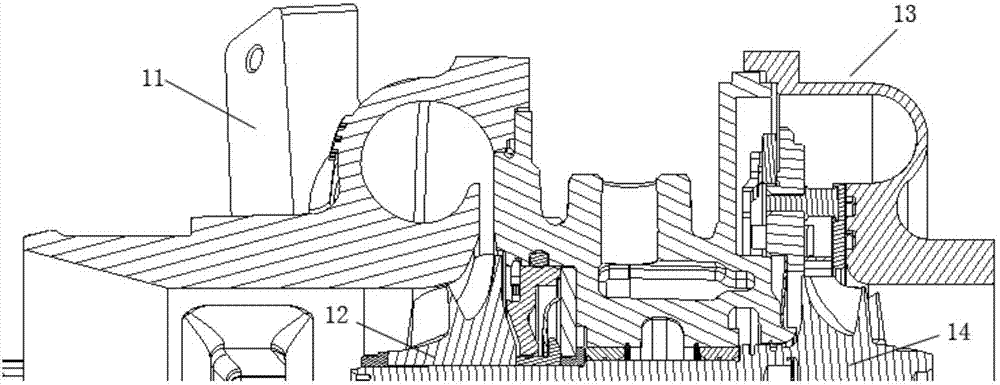

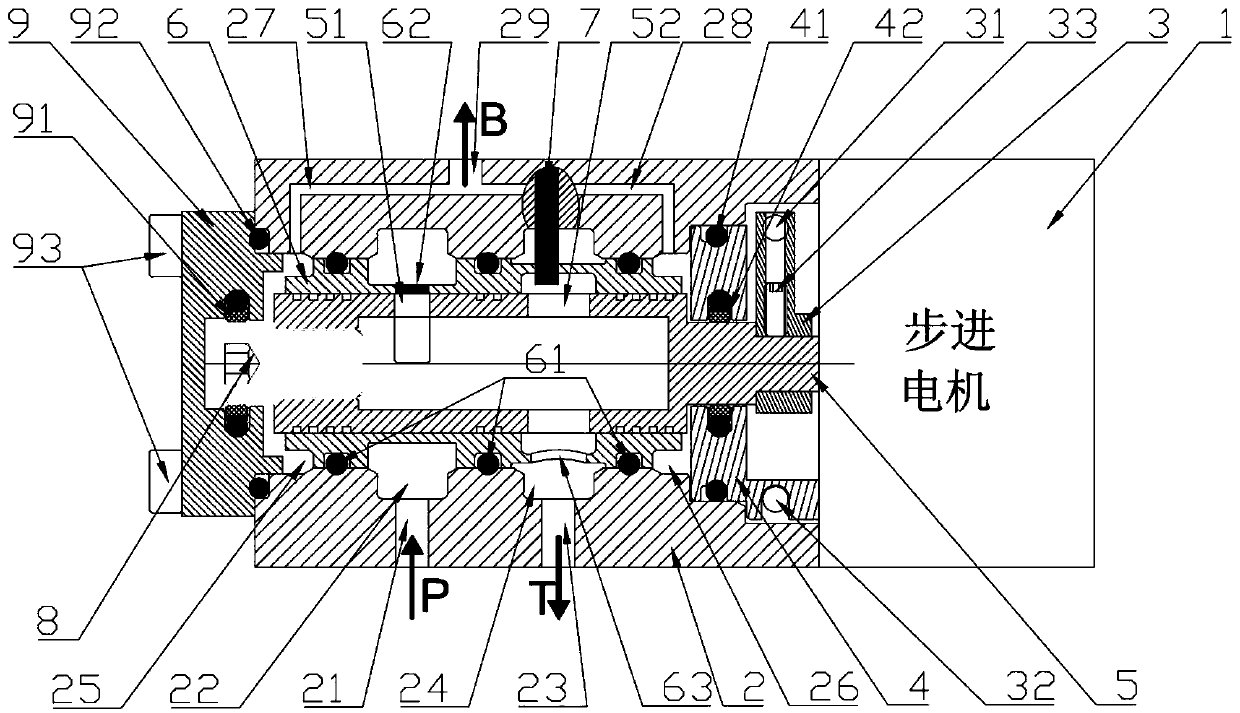

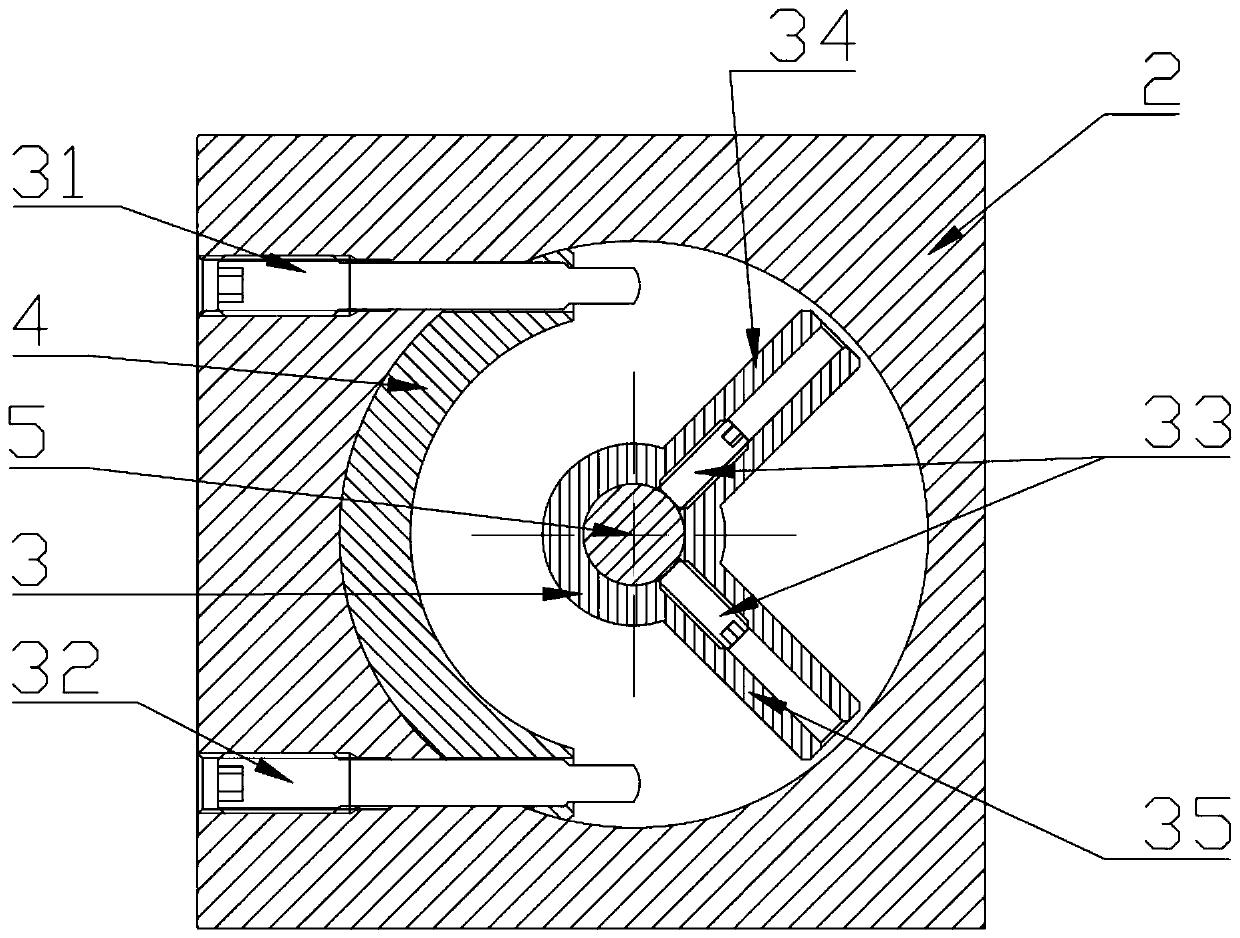

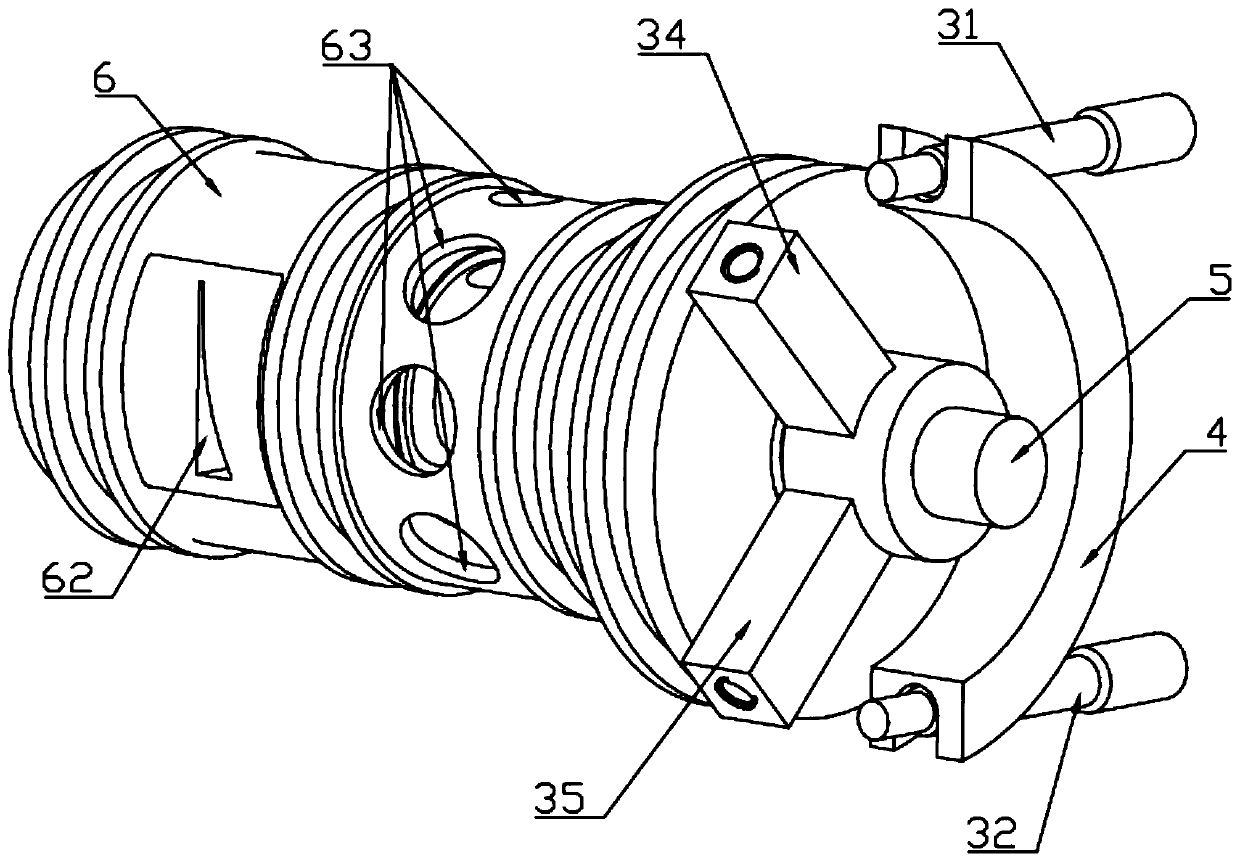

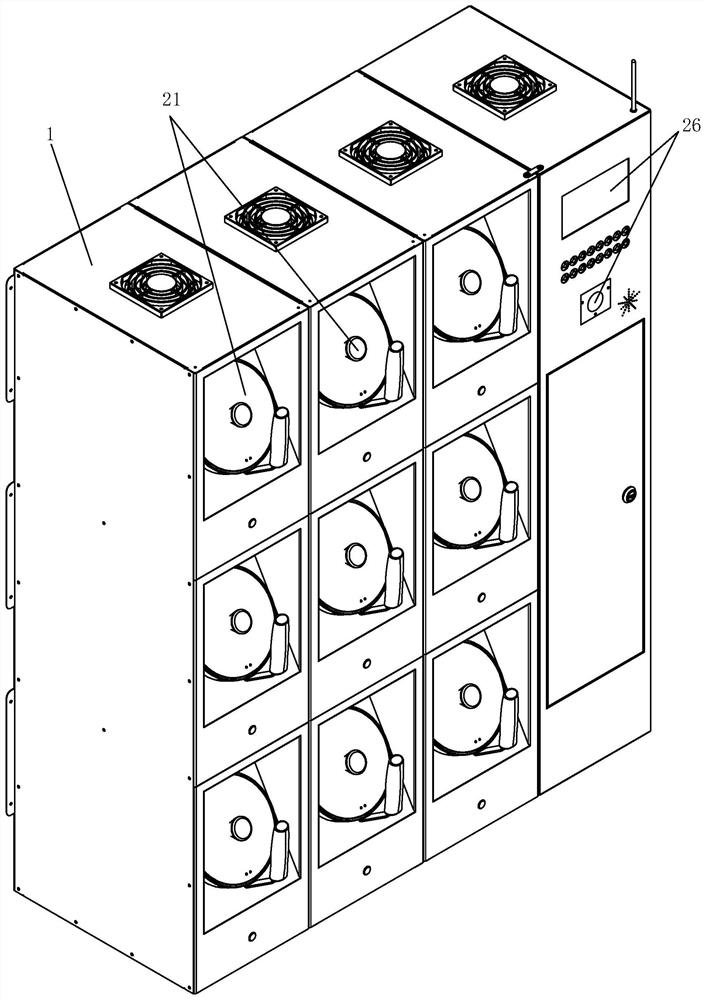

High-reliability fuel metering device driven by stepping motor

ActiveCN110579252AReduced risk of stickingSimplify complex structuresIndirect mass flowmetersAviationMotor drive

The invention discloses a high-reliability fuel metering device driven by a stepping motor, wherein the device is used for metering fuel in fuel pump regulators of a gas turbine and an aero-engine. Tobe specific, a stepping motor drives a rotary metering valve to act and thus a shielding area of a circumferential hole of the metering valve is changed, thereby realizing metering of the fuel flow of the metering valve. The device has advantages of novel and simple structure, great easiness in processing and assembling, simple and flexible controlling, and high reliability. The metering valve adopts a circumferential hole design, a radial oil inlet-outlet design and a balanced oil return path design, thereby eliminating the axial force of the valve element of the valve, effectively reducingthe motion resistance moment of the valve element, reducing the clamping stagnation risk of the valve, and improving the dynamic response characteristic and reliability of the metering valve. According to the invention, the angular phase position of the valve element of the metering valve is locked through the holding torque of the stepping motor; the interferences on the valve controlling by external disturbances of mechanical vibration, valve hydraulic force and motor current fluctuation and the like can be resisted; and the robustness and reliability of the fuel metering device can be greatly improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

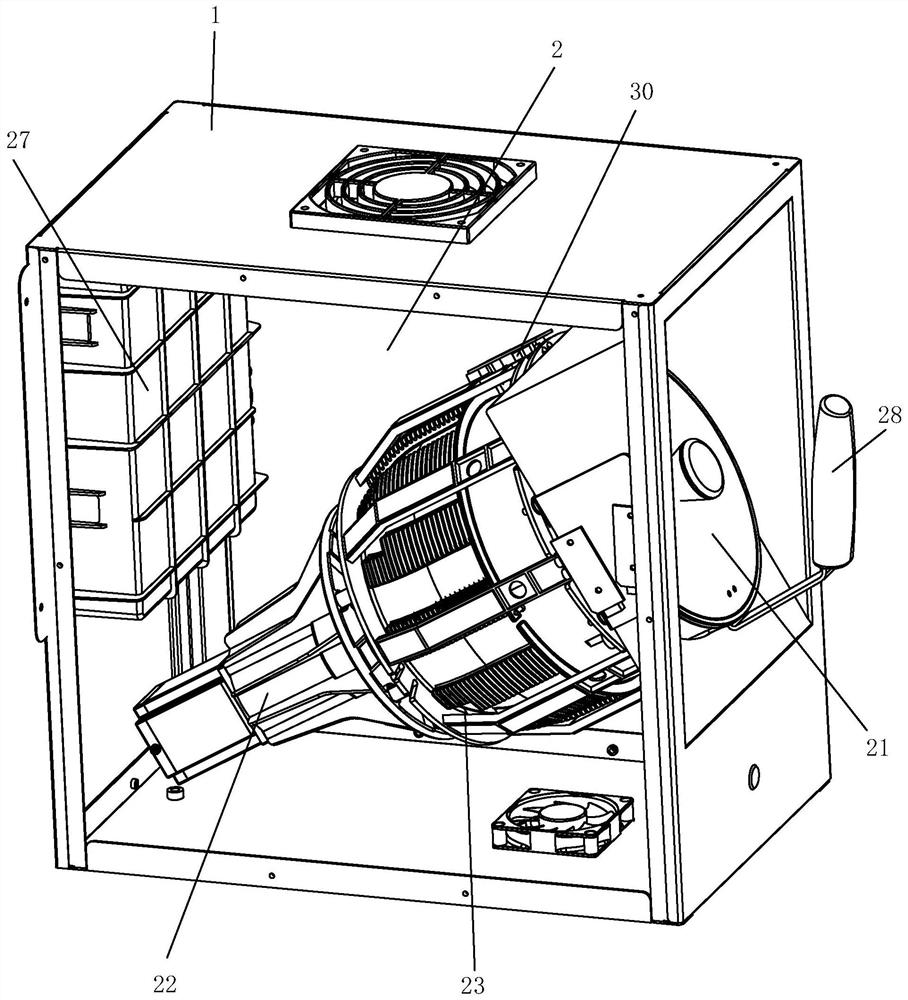

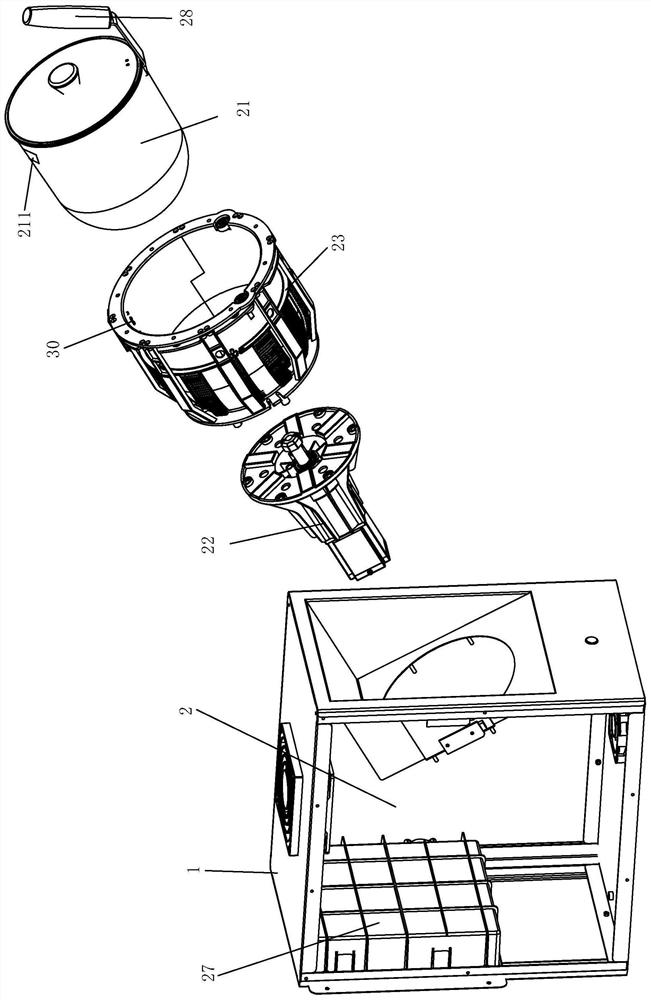

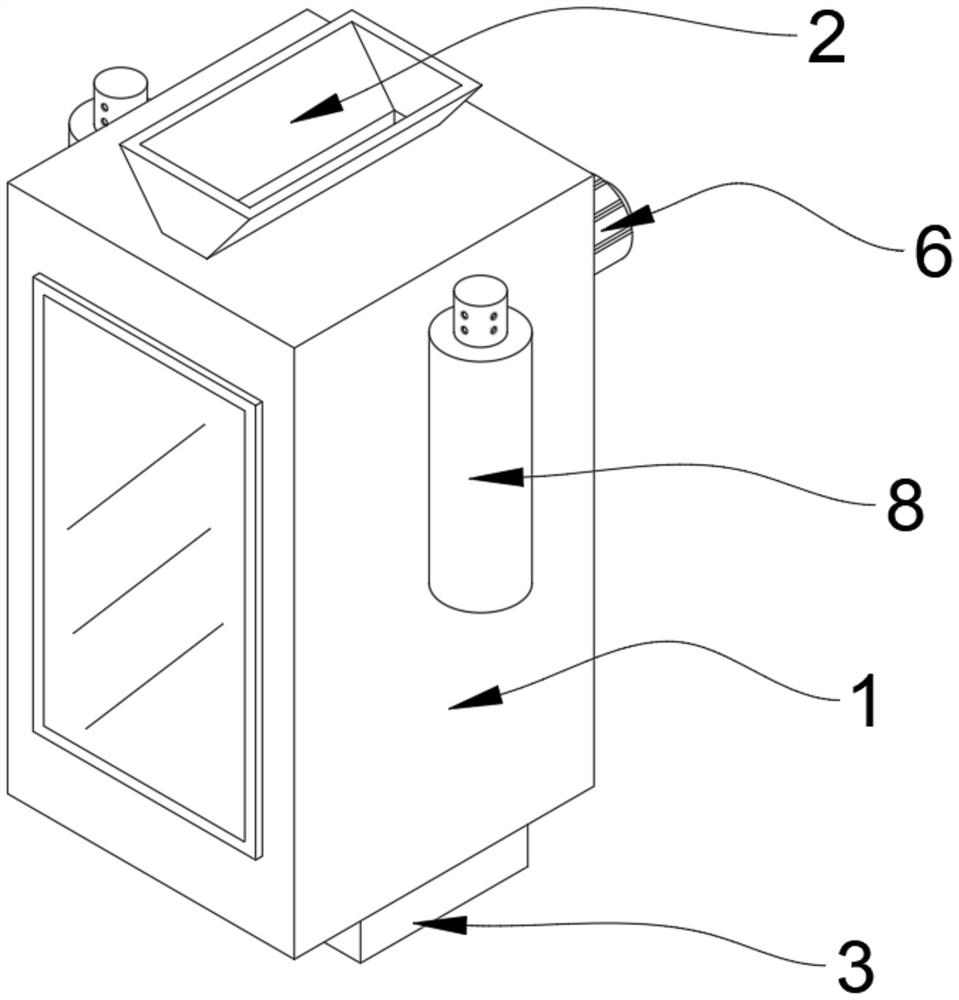

Automatic cooker

PendingCN113662424AHeating evenly and fullyReduce the risk of stickingWarming devicesTime-controlled ignitorsPhysicsCooker

The invention discloses an automatic cooker which comprises a rack. A containing cavity is formed in the rack, a frying pan, a heating mechanism and a driving mechanism used for driving the frying pan to turn forwards and backwards are arranged in the containing cavity, and the frying pan is obliquely arranged in the containing cavity. According to the automatic cooker, by arranging the driving mechanism for driving the frying pan to turn forwards and backwards, when the automatic cooker cooks food materials, the driving mechanism drives the frying pan to turn forwards and backwards according to preset conditions so that the food materials in the frying pan turn forwards and backwards along with the frying pan, a condition that only one side of the food materials is heated is avoided, and the food materials are heated uniformly. The frying pan is obliquely arranged in the containing cavity so that when the food materials are turned forwards and backwards to a certain height in the frying pan, the food materials fall back to the bottom of the frying pan through the dead weight of the food materials, the stir-frying action of people during cooking of the food materials is simulated, the food materials are fully stir-fried and uniformly and fully heated, and meanwhile, the risk that the food materials stick to the pan is reduced; and the quality of dishes is improved.

Owner:深圳贝乐威科技有限公司

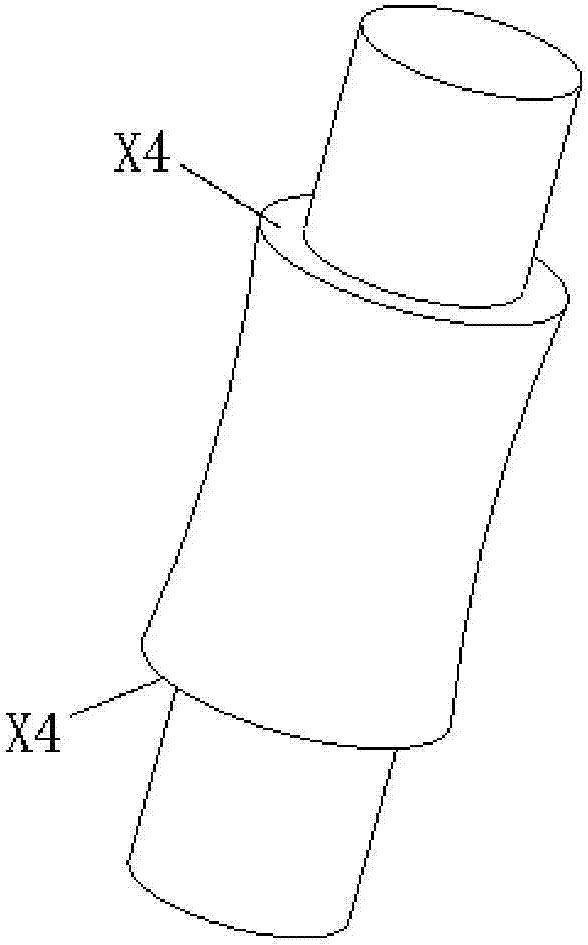

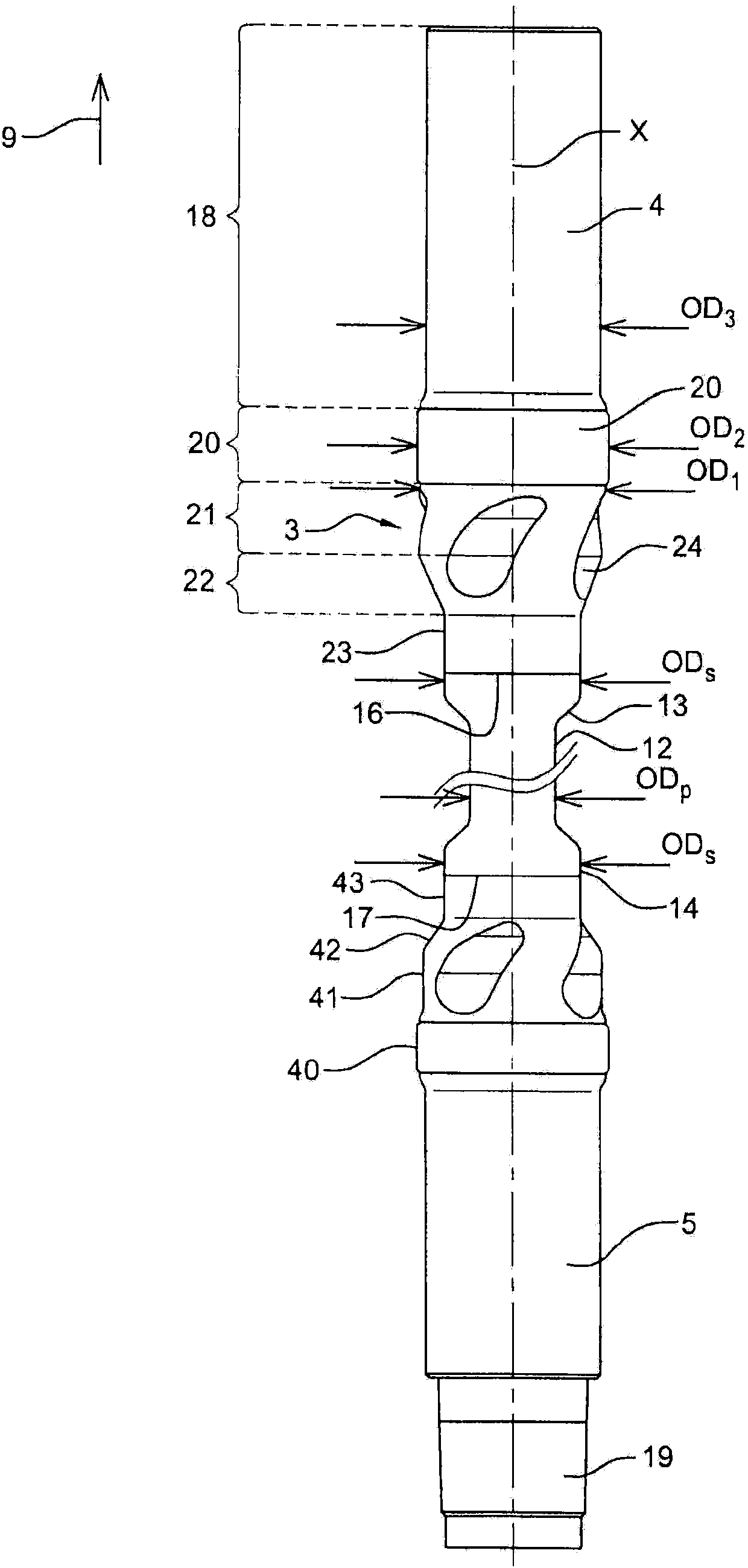

Drill string element with fluid activation area

ActiveCN103797209AReduce axial loadReduce wearDrilling rodsCleaning apparatusEngineeringBiological activation

A tubular drill string element (3) is provided. The tubular drill string element (3) comprises a substantially cylindrical body (12) and two connectors (4, 5). Each connector is arranged at an end of the body and provided with a threaded portion (18, 19) suitable for being connected to a complementary element. At least one of the two connectors is provided with a lifting surface (22) suitable for engaging with a lifting tool of the element with a view to the assembly of same in a drill string. The tubular drill string element (3) is characterized in that the lifting surface has a non-circular transverse section forming an activation area (24) for a drilling fluid.

Owner:VALLOUREC DRILLING PROD FRANCE

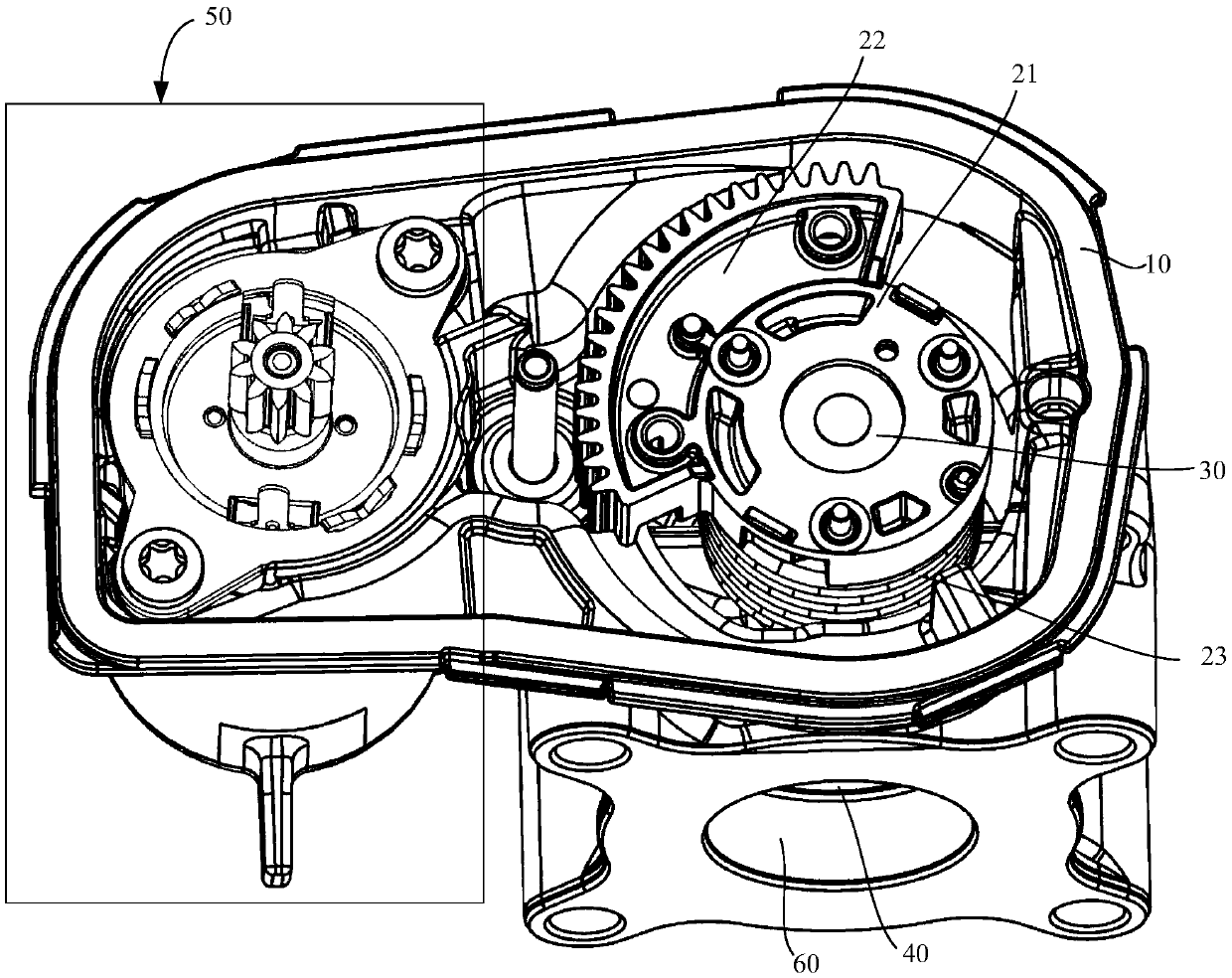

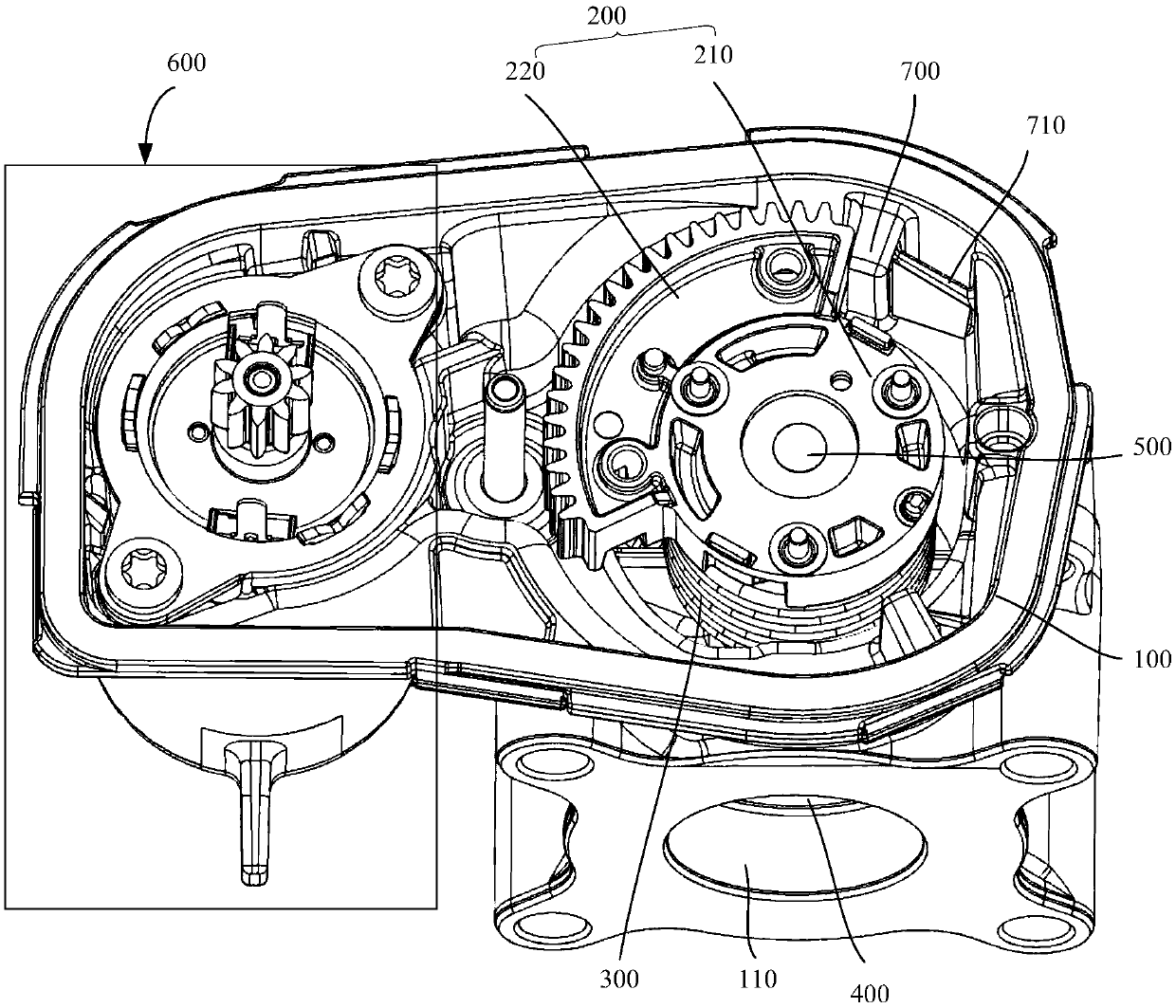

Waste gas recirculation valve

InactiveCN109611244AReduced risk of stickingEliminate the risk of out-of-tolerance leaksExhaust gas recirculationMachines/enginesExhaust fumesTorsion spring

The invention provides a waste gas recirculation valve. The waste gas recirculation valve comprises a shell, and a transmission mechanism, a torsional spring and a limit mechanism which are arranged in the shell. A shell air path is formed in the shell. A valve is arranged on the shell air path. The transmission mechanism is used for driving the valve to move so as to regulate the flow rate of gasin the shell air path. The torsional spring is connected with the transmission mechanism and used for driving the transmission mechanism to reset to a target position through a reset torsional braid,and the reset torsion of the torsional spring in the target position is 0. The limit mechanism is used for stopping the transmission mechanism from resetting to the target position when the torsionalspring drives the transmission mechanism to reset in the specified direction, so that the reset torsion of the torsional spring is greater than 0 when the torsional spring is stopped by the limit mechanism. The risk of clamping stagnation between the valve and the shell air path under high and low temperature conditions is effectively lowered.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

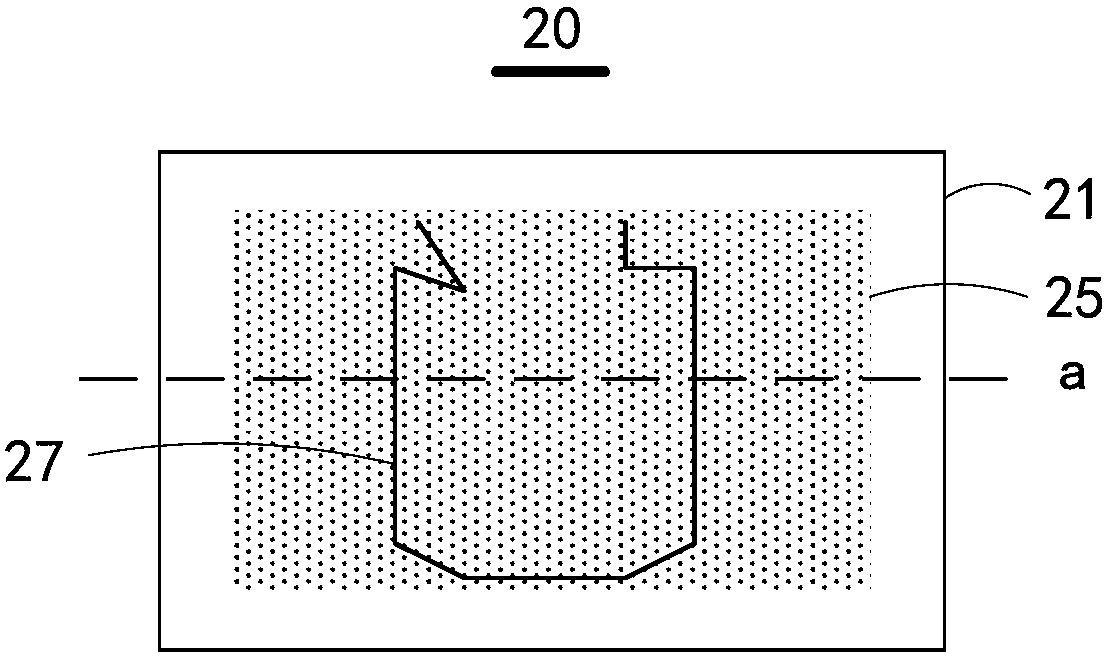

Multi-piece piston for a cold chamber casting machine

A multi-piece piston (1) is disclosed, for fixing to the high pressure side end (3) of a piston rod (5) running axially in a casting cylinder (7) of a cold chamber casting machine. The piston comprises a piston crown (9) forming a piston front face (13) on the high pressure side and a piston body (15) in the form of a bush connected to the piston crown (9) on the low pressure side. The piston body (15) can be connected to the piston crown (9) by means of fixing screws (23) to form a module. Complementary bayonet looking means (25, 27) are provided, for axial fixing of the piston (1) to the end (3) of the piston rod (5), on the piston crown (9) and the end (3).

Owner:EXCO TECHNOLOGIES LTD

Anti-stuck pressure relief system for engine lubricating oil

ActiveCN104879185AAvoid failureReduced risk of stickingLubricant mounting/connectionLubrication pressure controlSteel ballEngineering

The invention relates to an anti-stuck pressure relief system for engine lubricating oil. The system comprises a main oil duct, a first pressure limiting valve oil duct, a second pressure limiting valve oil duct, a steel ball type pressure limiting valve, a plunger type pressure limiting valve and a bolt provided with a magnet, wherein one end of the first pressure limiting valve oil duct and one end of the second pressure limiting valve oil duct are connected with the main oil duct; the plunger type pressure limiting valve is arranged at the other end of the first pressure limiting valve oil duct; the steel ball type pressure limiting valve is arranged at the other end of the second pressure limiting valve oil duct; a bolt hole is formed in one side wall of the first pressure limiting valve oil duct; the bolt provided with the magnet is matched and connected with the bolt hole through threads. The steel ball type pressure limiting valve and the plunger type pressure limiting valve are simultaneously used in the lubricating system and are connected in parallel, and the opening pressure of the steel ball type pressure limiting valve is set to be larger than that of the plunger type pressure limiting valve.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Breakout plates for beverage brewing equipment

The invention relates to a breakout plate for beverage brewing equipment, comprising a plate body with a first end surface and a second end surface, the first end surface of the plate body has a plurality of bosses and a plurality of bosses arranged between the bosses A beverage discharge hole that runs through the plate body, and a plurality of said bosses form a burst area on the first end surface, which is characterized in that: at least one vertical rib is provided at the lower part of the burst area, the said The length of the ribs ensures the blocking of the lower edge of the beverage capsule inserted into the beverage brewing device in order to permanently reduce the risk of the beverage capsule being caught by the boss in an undesired position during insertion of the beverage capsule. The brewing device using the breakout plate can effectively ensure that the capsule is not stuck in an undesired position by the protrusion on the breakout plate during insertion into the device, and it is also more conducive to the detachment of the capsule relative to the breakout plate.

Owner:NINGBO AAA GROUP ELECTRIC APPLIANCE

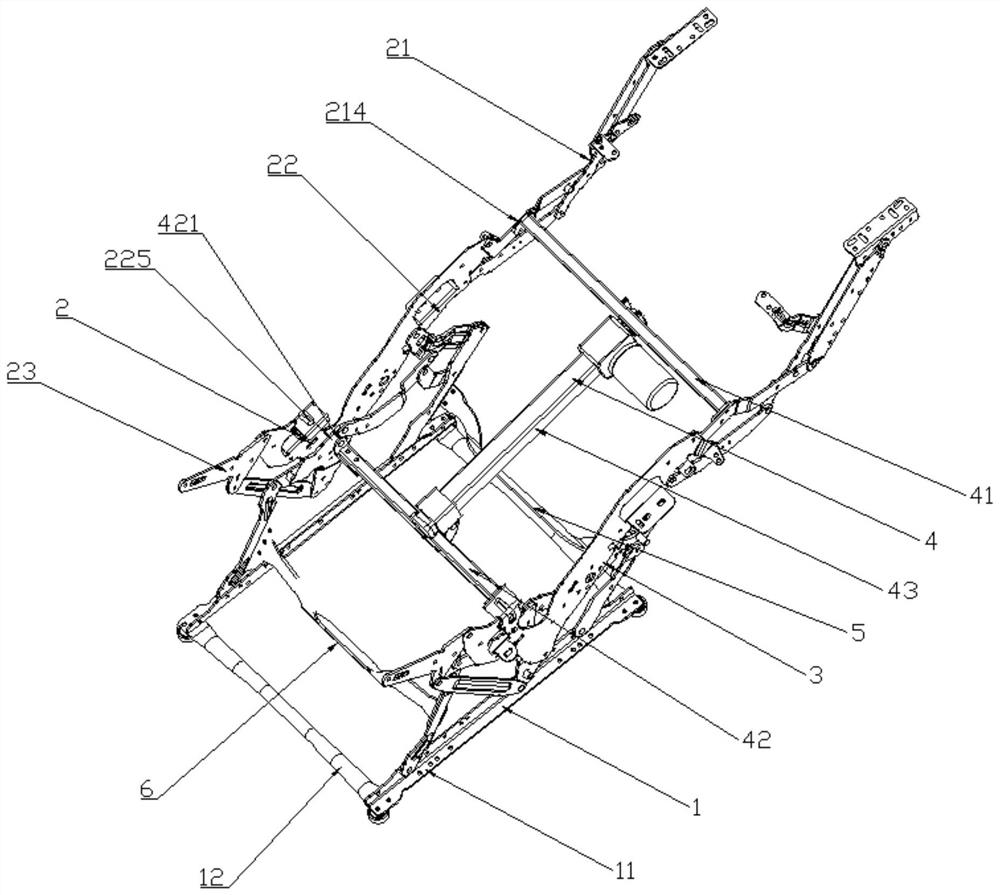

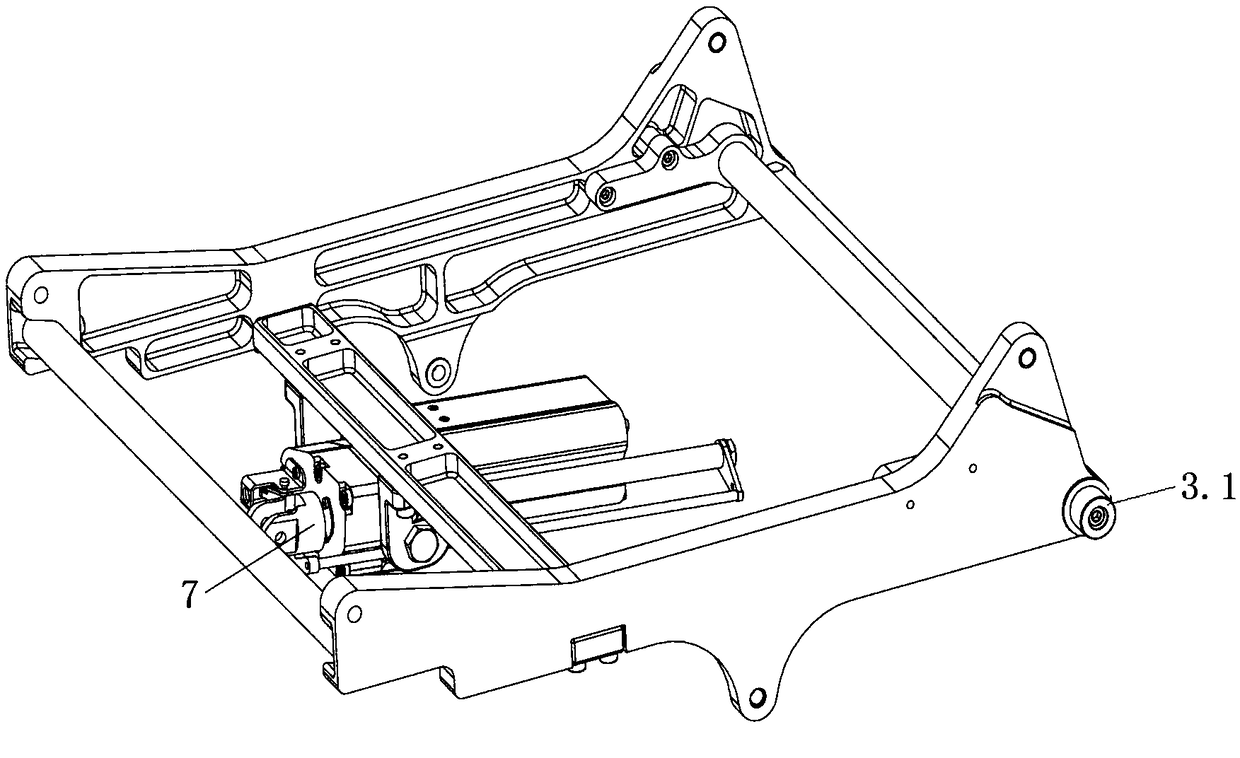

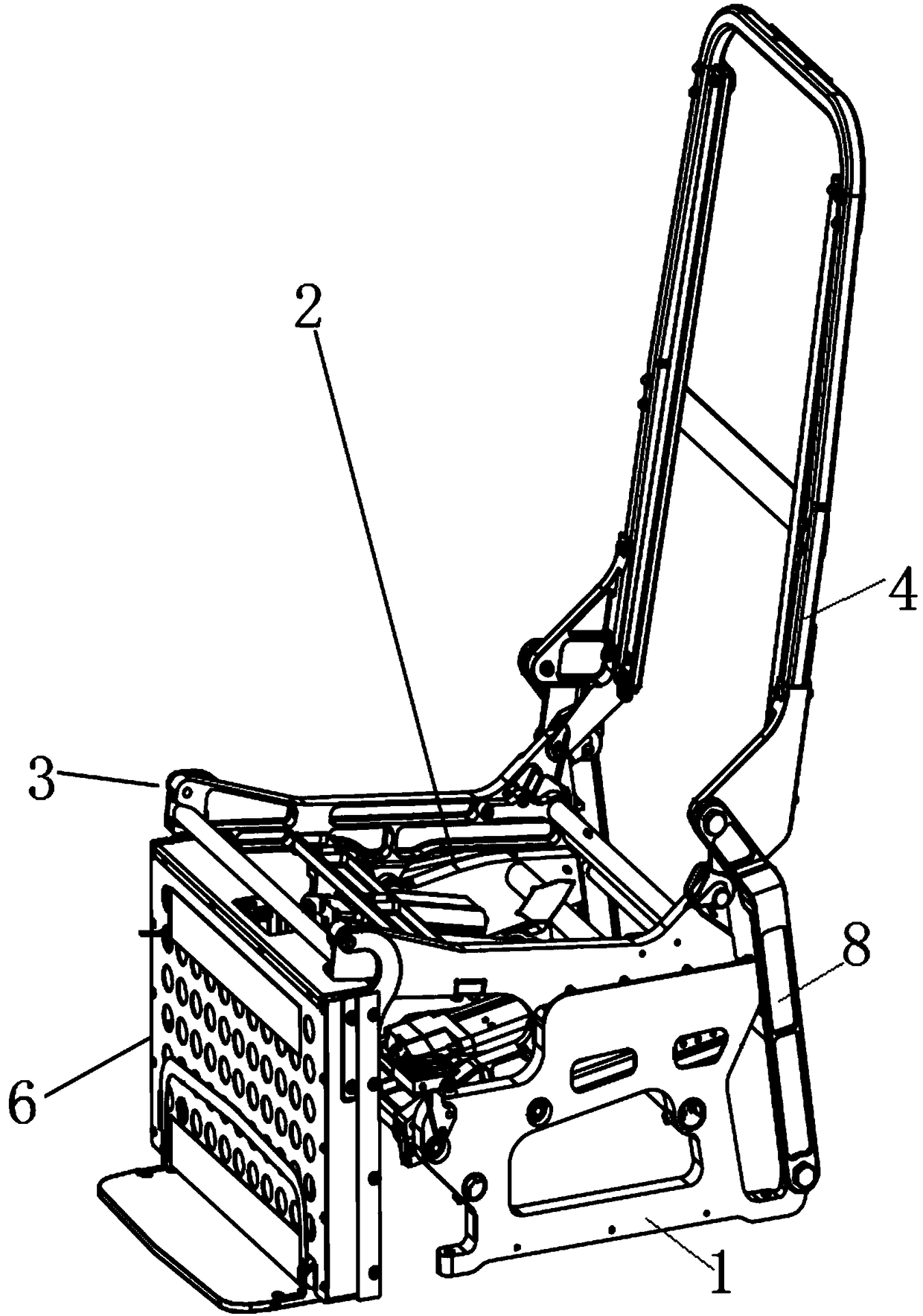

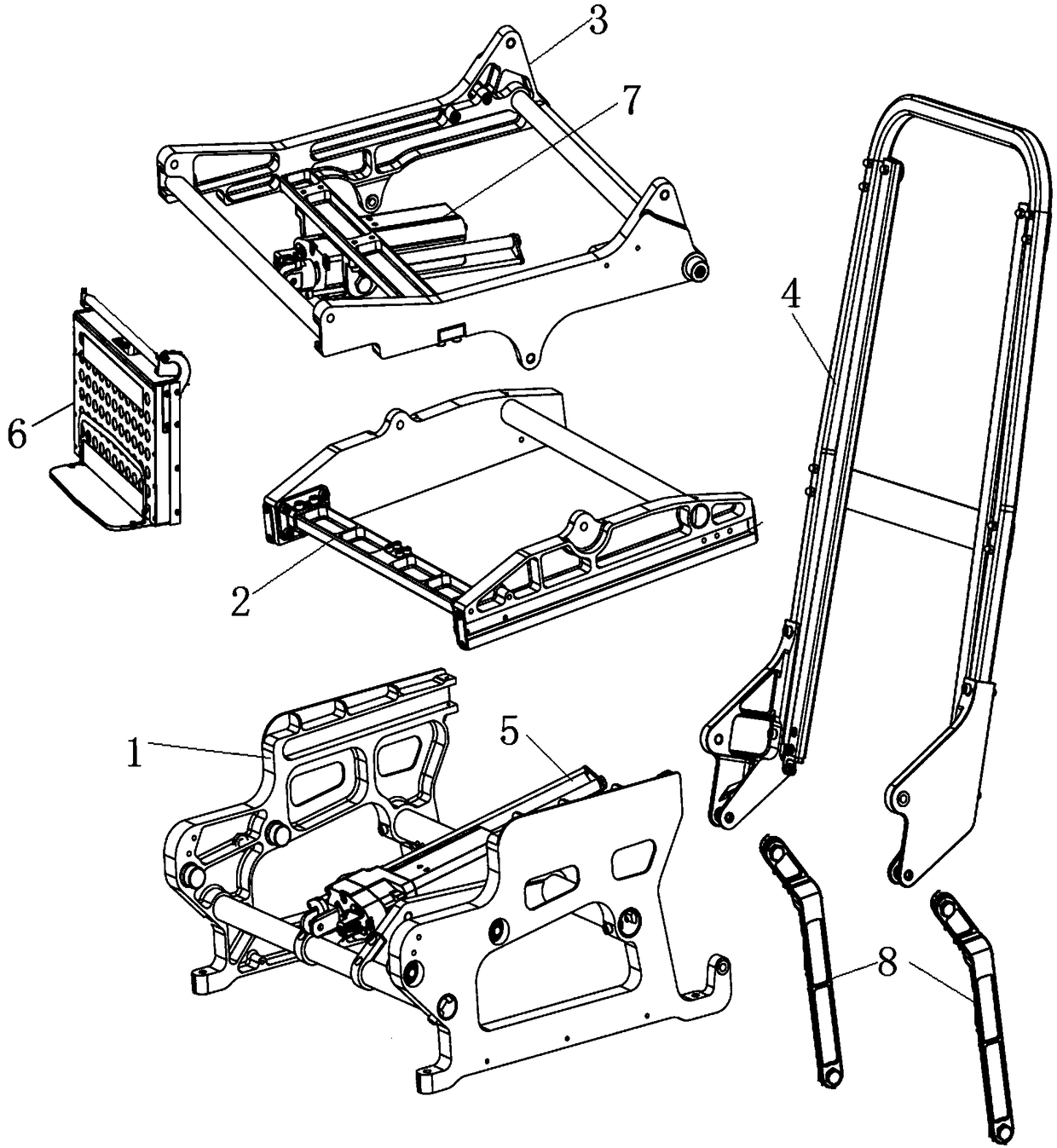

Frame structure of full-flat air seat

The invention discloses a frame structure of a full-flat air seat, which comprises a fixed frame component, a traction frame component, a bottom plate component, a backrest component and a first telescopic component; the traction frame component is slidably arranged in the fixed frame component; the bottom plate component is slidably arranged in the fixed frame component and hinged to the upper part of the traction frame component; the bottom of the backrest component is hinged above the rear end of a seat plate component; the upper end of a support rod component is hinged with the bottom of the rear end of the fixed frame component, the upper end of the support component is hinged with the bottom of the backrest component, and the hinge point between the support component and the backrestcomponent is positioned above the hinge point between the backrest component and the seat plate component; one end of the first telescopic component is fixedly arranged on the fixed frame component,and the other end of the first telescopic component is fixedly arranged on the traction frame component. The seat can realize the electric full-flat or resetting of the chair, has the advantages of simple structure and light weight, and can improve the overall reliability of the seat frame.

Owner:湖北航宇嘉泰飞机设备有限公司

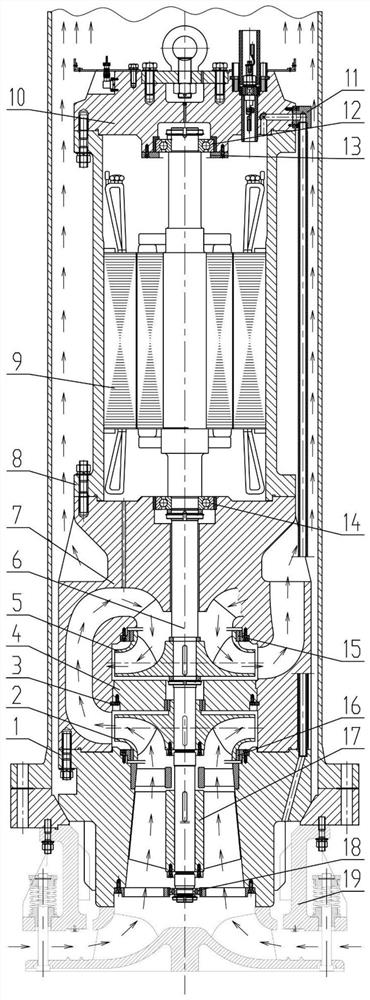

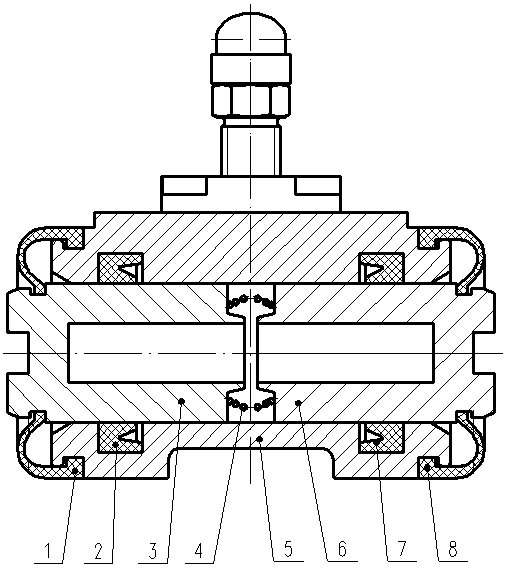

Split type electric control silicone oil clutch water pump

PendingCN112943439AImprove responsivenessReduced risk of stickingCoolant flow controlPump componentsImpellerDrive shaft

The invention discloses a split type electric control silicone oil clutch water pump, wherein a clutch part is rigidly connected with and fixed to a shaft connecting bearing of a water pump part through a driven shaft, the clutch water pump aims to change an original stacking type assembly manner, the risk of clamping stagnation of a driving part and a driven part is reduced, separation coupling response time can be optimized, the speed of an impeller is corrected more accurately, engine oil consumption is better reduced, the requirement of an engine cooling system is met, and the service life of parts of the cooling system is prolonged.

Owner:SUZHOU RISING AUTO PARTS

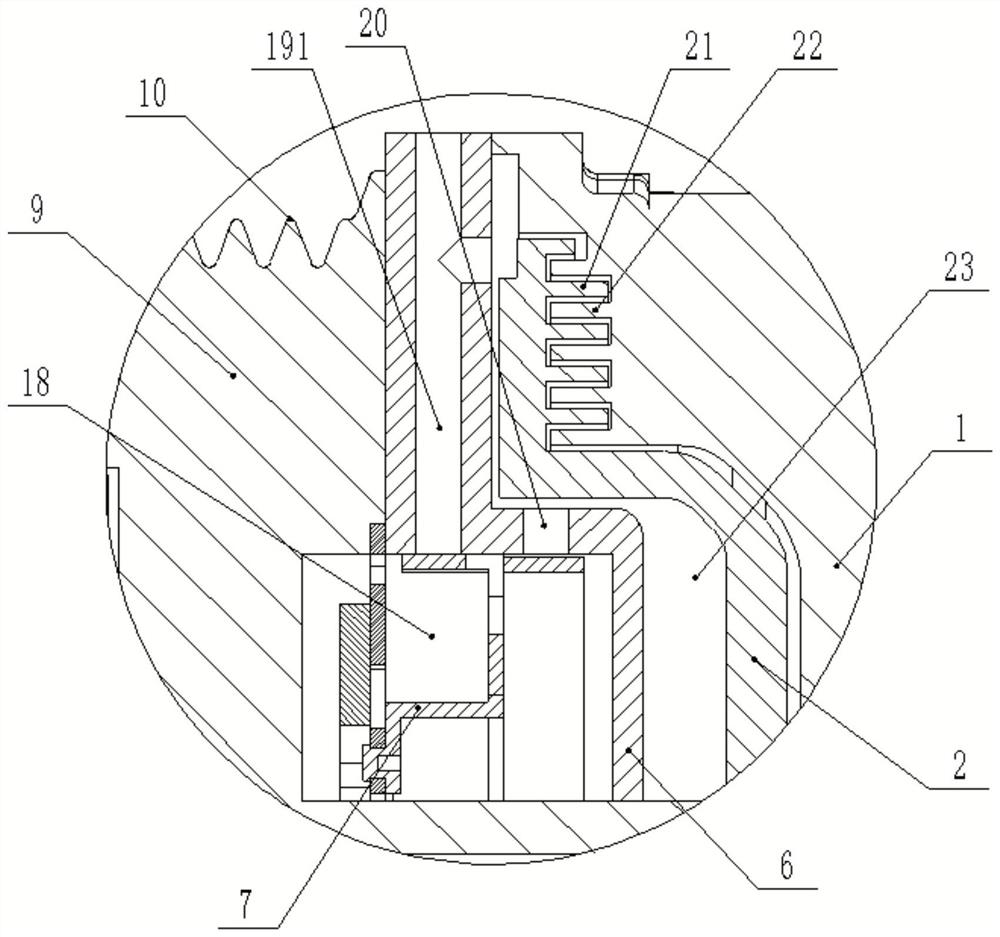

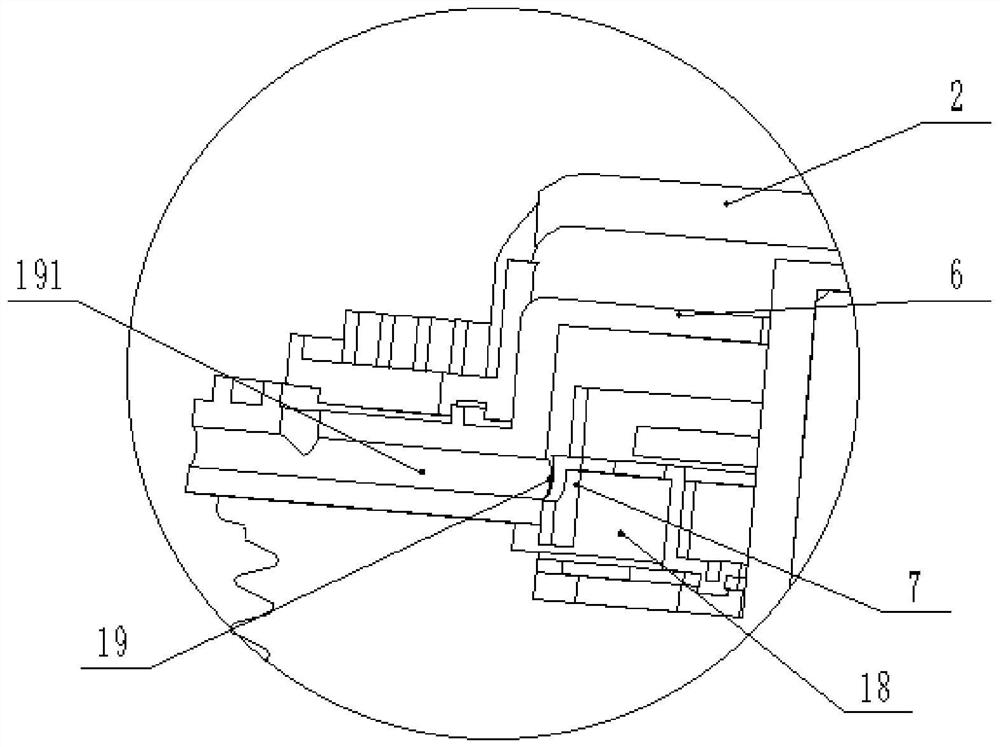

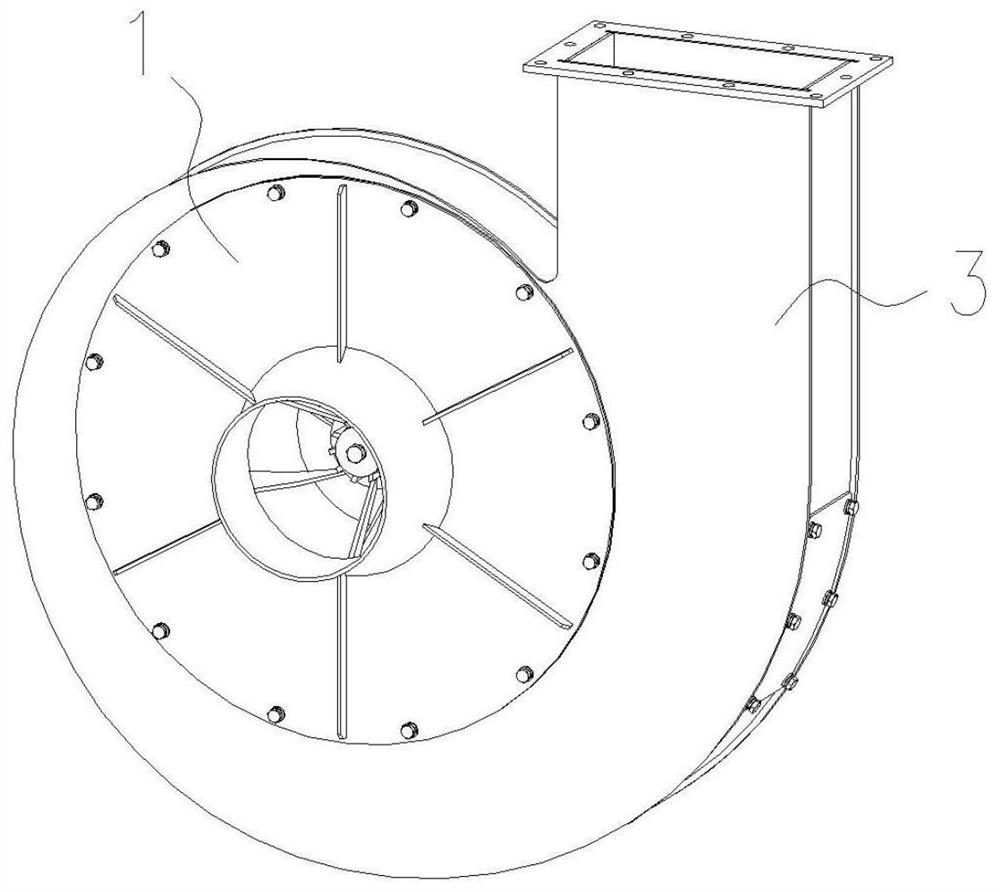

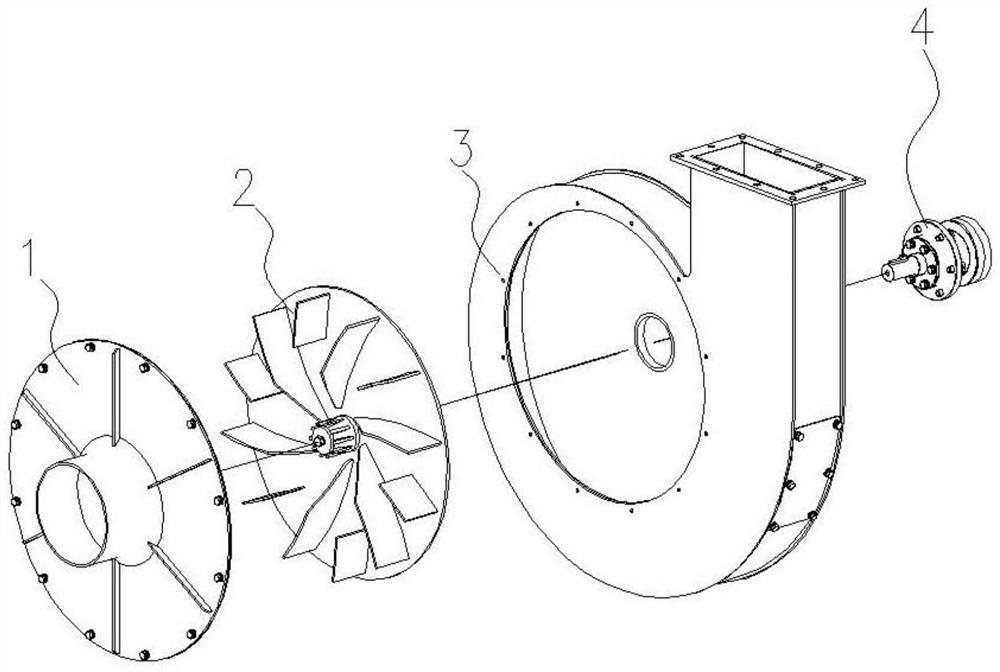

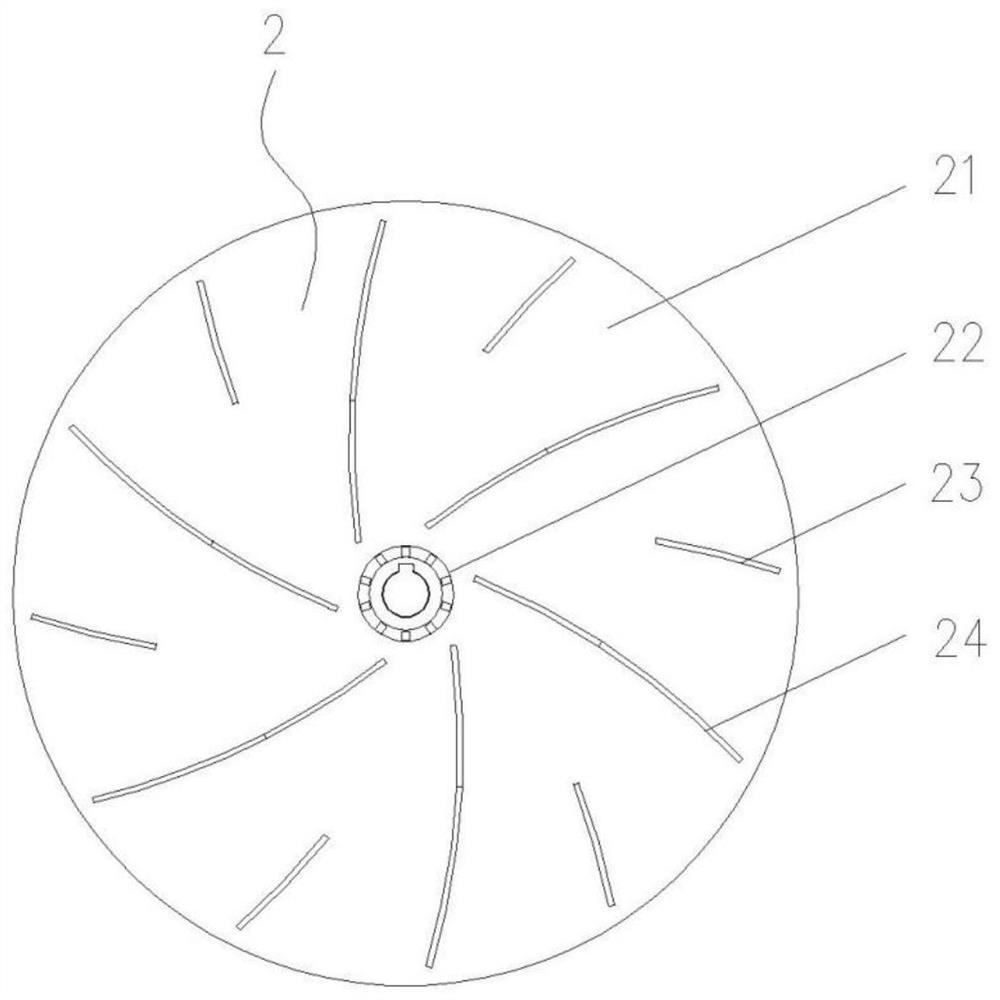

Volute type centrifugal fan

PendingCN113565770AImprove crushing effectIncrease the gapPump componentsPump installationsStructural engineeringKnife blades

The invention relates to a volute type centrifugal fan. The volute type centrifugal fan comprises a volute, an air inlet cover, an impeller and a power assembly. The cover plate is provided with a stationary knife cutterhead, the stationary knife cutterhead comprises a blade fixing ring and a plurality of blades, the plurality of blades are uniformly distributed, the two ends of each blade are connected with the cover plate and the blade fixing ring correspondingly, the cutting edge of each blade is outwards inclined, and the impeller, an output shaft, the blade fixing ring and an air inlet pipe are coaxial; and the blade fixing ring sleeves an impeller shaft in a gap, a plurality of long blades are arranged on the other face, corresponding to the cover plate, of an impeller disc, are evenly distributed around the impeller shaft and spirally spread along the outer side of the impeller shaft, and inclined edges are arranged at the ends, close to the impeller shaft, of the plurality of long blades and correspond to the cutting edges of the blades of the stationary knife cutterhead. The cutting edges of the blades and the inclined edges of the long blades form gap shearing edges. According to the technical scheme, the inclined edges of the blades relatively move at a high speed relative to the blades of the stationary knife cutterhead, and when the gaps of the shearing edges are smaller, garbage is sheared to be smaller, and the crushing effect of the centrifugal fan is better.

Owner:FUJIAN LONGMA ENVIRONMENTAL SANITATION EQUIP

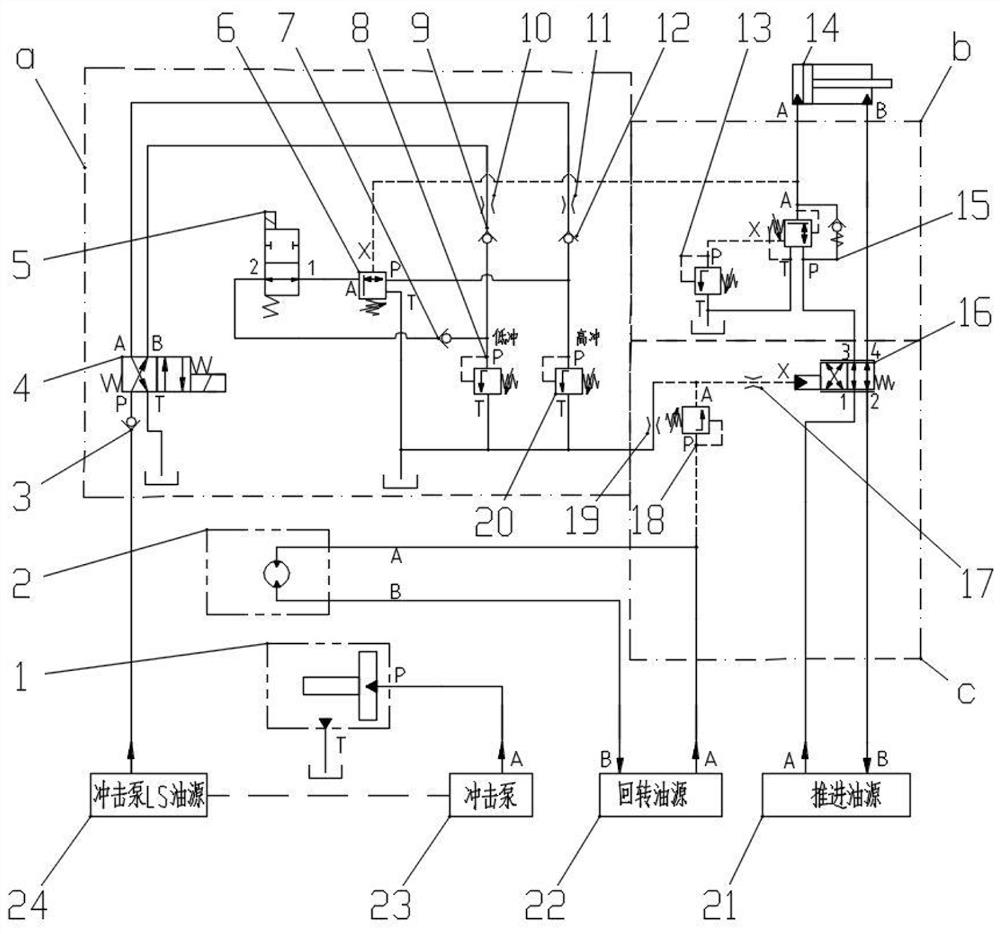

Hydraulic control system of rock drill

ActiveCN112727818ARealize regulationRealize functionServomotor componentsServomotorsProportional controlThermodynamics

The invention belongs to the technical field of rock drilling equipment. A hydraulic control system of a rock drill comprises a propelling pressure control unit, wherein the propelling pressure control unit comprises a propelling oil source, a propelling oil cylinder, a proportional anti-jamming reversing valve, a propelling pressure reducing valve and a propelling overflow valve, and an oil outlet port A and an oil return port B of the propelling oil source are connected with a rodless cavity and a rod cavity of the propelling oil cylinder through the proportional anti-jamming reversing valve separately; the propelling pressure reducing valve is arranged on an oil path between the rodless cavity of the propelling oil cylinder and the proportional anti-jamming reversing valve; and the propelling overflow valve is connected with an external control port of the propelling pressure reducing valve. According to the invention, through a simple and reliable hydraulic control principle of adjusting a propelling pressure to be matched with an impact pressure, the functions of automatically adjusting an impact power along with the propelling pressure and preventing idling can be realized; and a forced high-impact function is set according to actual requirements, and the feeding speed and direction of the propelling oil cylinder can be automatically and proportionally controlled according to the change of the resistance of a rotary motor, so that an automatic and proportional anti-jamming function is realized.

Owner:中铁工程装备集团隧道设备制造有限公司

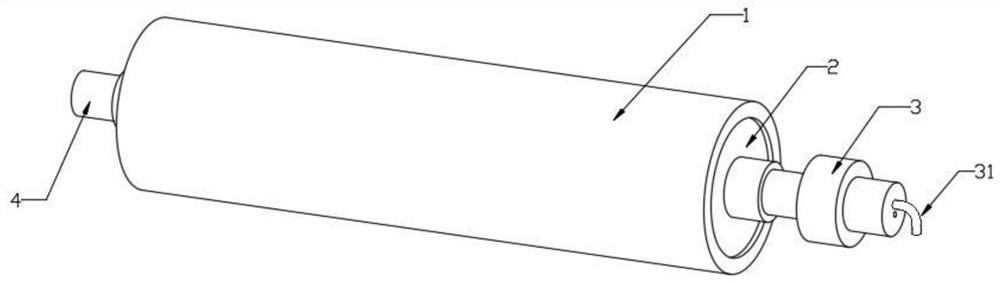

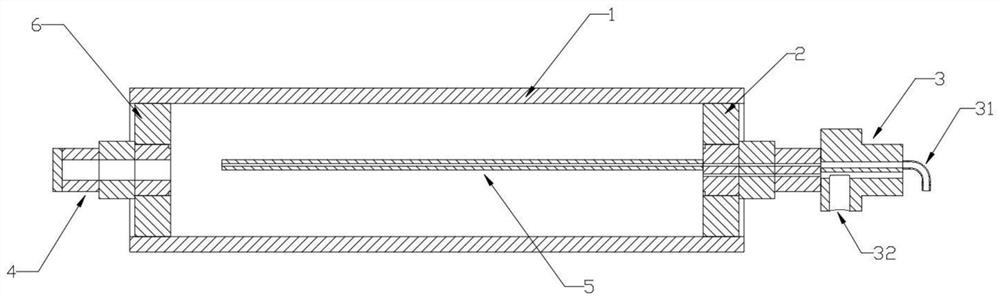

Guide roller water-cooling circulating device for continuous cast rolling

PendingCN111872138AOvercome the defects of non-circulationQuality assuranceGuiding/positioning/aligning arrangementsWork cooling devicesChrome platingWater pipe

The invention discloses a guide roller water-cooling circulating device for continuous cast rolling. The guide roller water-cooling circulating device comprises a hollow roller, the two ends of the hollow roller are provided with a right end shaft head and a left end shaft head correspondingly, a water inlet pipeline and a water return pipeline are arranged in the right end shaft head, and the right end of the right end shaft head is connected with a two-way rotating joint; and a water inlet and a water return port are formed in the two-way rotating joint, the water inlet is connected with aninlet of the water inlet pipeline, the water return port is connected with an outlet of the water return pipeline, an outlet of the water inlet pipeline is connected with a water inlet shaft core, andthe water inlet shaft core extends into the hollow roller. According to the guide roller water-cooling circulating device, the structure of a water-cooling guide roller is simplified, the water-cooling guide roller is formed by modifying a scrapped cold roller, the roller surface made of materials is high in hardness and resistant to abrasion, chromium electroplating is not needed, the use cost is greatly reduced, the temperature of the improved roller surface is reduced to 40-50 DEG C from original 90-120 DEG C, the cooling speed of a cast-rolled plate is greatly increased, and the plate surface temperature is reduced to 75-85 DEG C from original 130-140 DEG C.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

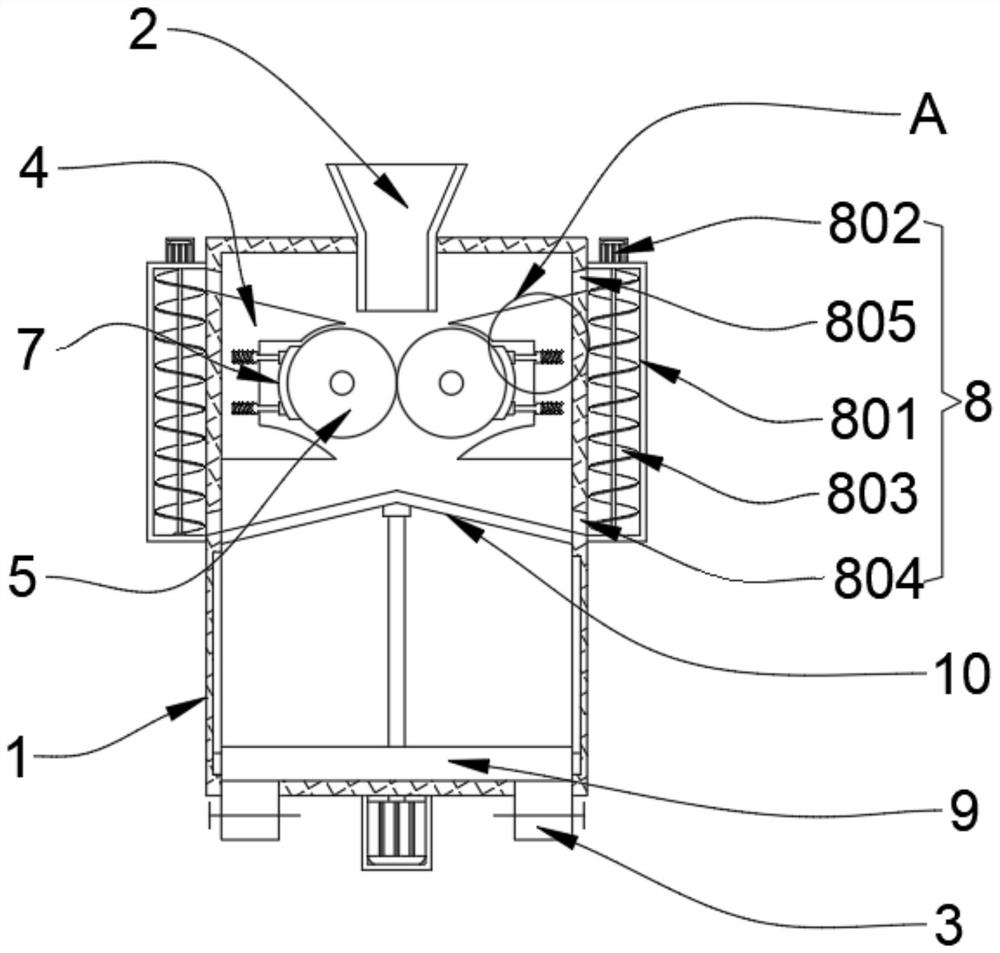

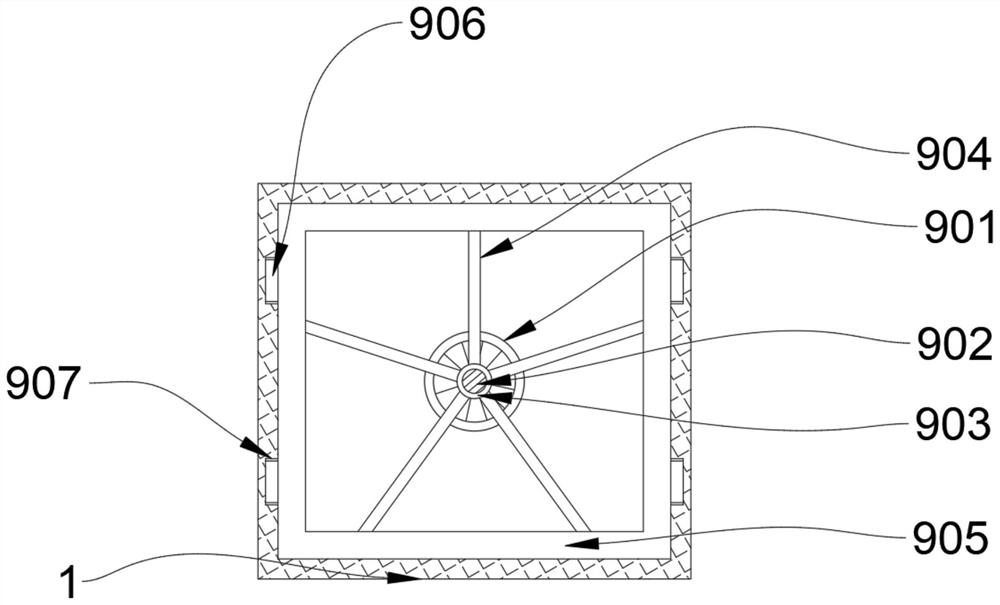

Clay mineral crushing device

PendingCN114768929AImprove the crushing effectReduce the risk of stickingHollow article cleaningGrain treatmentsMining engineeringClay soil

The invention discloses a clay mineral crushing device, and relates to the field of clay processing. The device comprises a box body, a feeding hopper and a discharging port, a cleaning mechanism is arranged in a flow guide base, a filter screen is installed in the middle of the inner side of the box body, a scraping assembly is arranged on the lower portion of the interior of the box body, and lifting mechanisms are arranged on the upper portions of the two sides of the box body. It is guaranteed that the cleaning brush clings to the surface of the crushing roller all the time, the situation that normal crushing work of the crushing roller is hindered is reduced, and the crushing effect of the crushing roller is improved; according to the clay crushing device, through the arrangement of the crushing mechanism and the cooperative use of the scraping assembly, the risk that clay is attached to the inner wall of the box body is prevented, resource waste is reduced, through the arrangement of the filter screen and the lifting mechanism, the crushed clay can be thoroughly screened and guided into the box body again to be crushed again, and the crushing effect of the device is effectively guaranteed; and the crushing efficiency is greatly improved.

Owner:广西中煤科技发展有限公司

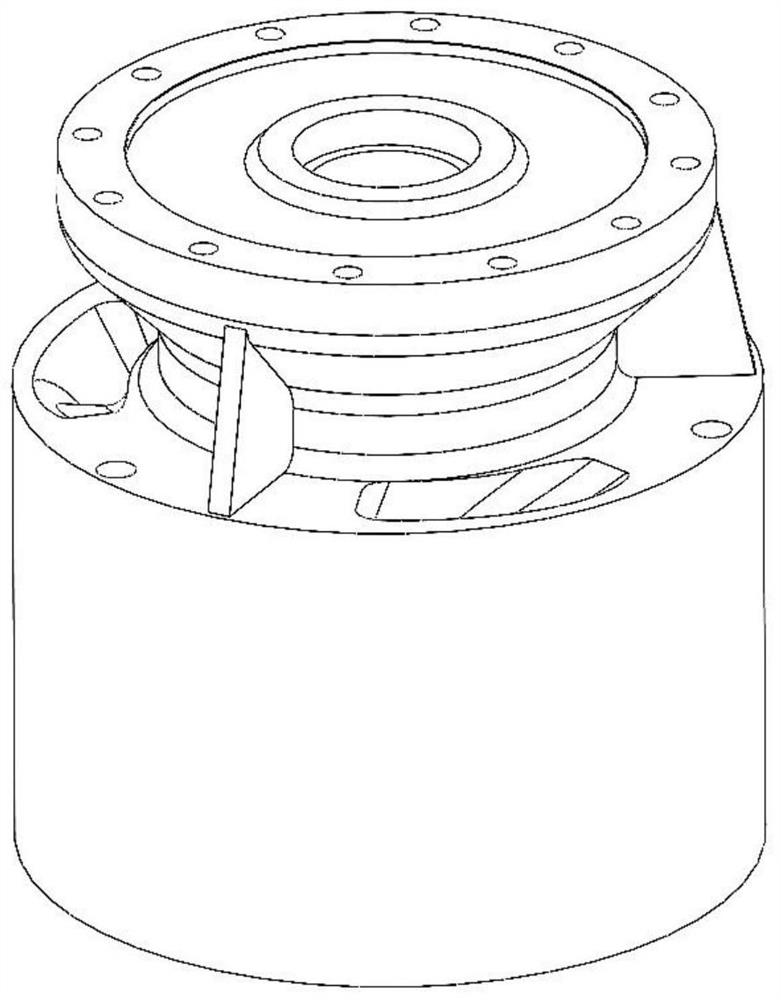

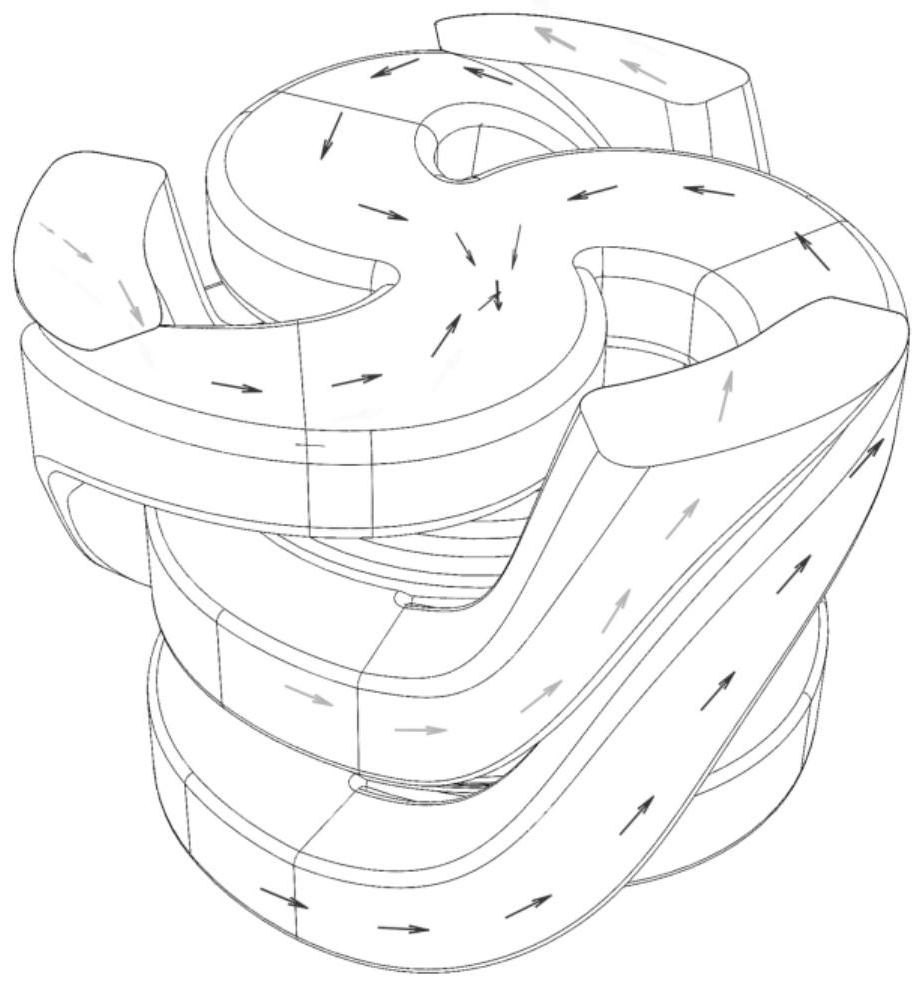

Low-temperature in-tank pump without balance mechanism

PendingCN112682330AWon't movePrecise positioningPump componentsRadial flow pumpsImpellerBalancing machine

The invention relates to a low-temperature in-tank pump without a balance mechanism. The low-temperature in-tank pump without the balance mechanism comprises a spiral flow guide body, a rotating shaft and an inducer, wherein the spiral flow guide body is of a columnar structure; a cavity is arranged in the spiral flow guide body and is configured to accommodate a first-stage impeller and a secondary impeller; blades of the first-stage impeller and blades of the secondary impeller are arranged back to back; a first through hole and a plurality of overflow channels are further formed in the spiral flow guide body; the cavity is in fluid communication connection with the overflow channels; the rotating shaft penetrates through the first through hole; the first-stage impeller and the secondary impeller are annularly arranged on the rotating shaft in a sleeving mode; the first end of the rotating shaft is fixedly connected with a motor; the second end of the rotating shaft is a free end; and the inducer is annularly arranged at the second end of the rotating shaft in a sleeving mode and is configured to induce fluid to enter the spiral flow guide body. According to the low-temperature in-tank pump without the balance mechanism provided by the invention, the device is free of the balance mechanism, has the advantages of few friction pairs, simple bearing positioning and the like, is more suitable for conveying low-temperature easy-to-gasify media, and can be beneficial to greatly reducing the clamping stagnation risk of a pump rotor.

Owner:CNOOC GAS & POWER GRP +1

Novel drum brake wheel cylinder structure

InactiveCN109027065AExtended service lifeGuaranteed OrientationBrake actuating mechanismsActuatorsWheel cylinderMechanical engineering

The invention relates to a novel drum brake wheel cylinder structure, and belongs to the technical field of automobile braking. A first wheel cylinder piston and a second wheel cylinder piston are assembled on the two sides of a wheel cylinder hole respectively, and a wheel cylinder is in clearance fit with the first wheel cylinder piston and the second wheel cylinder piston. A first sealing function piece is connected with the first wheel cylinder piston and the wheel cylinder separately, and a second sealing function piece is connected with the second wheel cylinder piston and the wheel cylinder separately. Two leather cup mounting grooves are formed in an inner hole of the wheel cylinder, the first leather cup and the second leather cup are arranged in the leather cup mounting grooves of the wheel cylinder respectively, and a wheel cylinder spring is installed between the first wheel cylinder piston and the second wheel cylinder piston. The first wheel cylinder piston and the secondwheel cylinder piston are provided with outer cylindrical surfaces. The novel drum brake wheel cylinder structure has the advantages that the structure is novel, the axial matching length of the wheel cylinder pistons and the wheel cylinder hole is increased, the guide performance of the wheel cylinder hole to the wheel cylinder pistons is kept, and the eccentric abrasion phenomenon of the wheelcylinder pistons in the braking process is relieved, so that the higher the roughness grade of the outer surfaces of the wheel cylinder pistons is, the better the dynamic sealing performance of the wheel cylinder pistons is.

Owner:JILIN DONGGUANG AOWEI AUTOMOBILE BRAKE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com