Anti-stuck pressure relief system for engine lubricating oil

A lubricating oil and anti-seize technology, which is used in the control of lubricant pressure, the installation/connection of lubricant purification devices, lubricating parts, etc. Stability, poor durability and other problems, to avoid failure, prevent excessive compression, reduce the risk of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

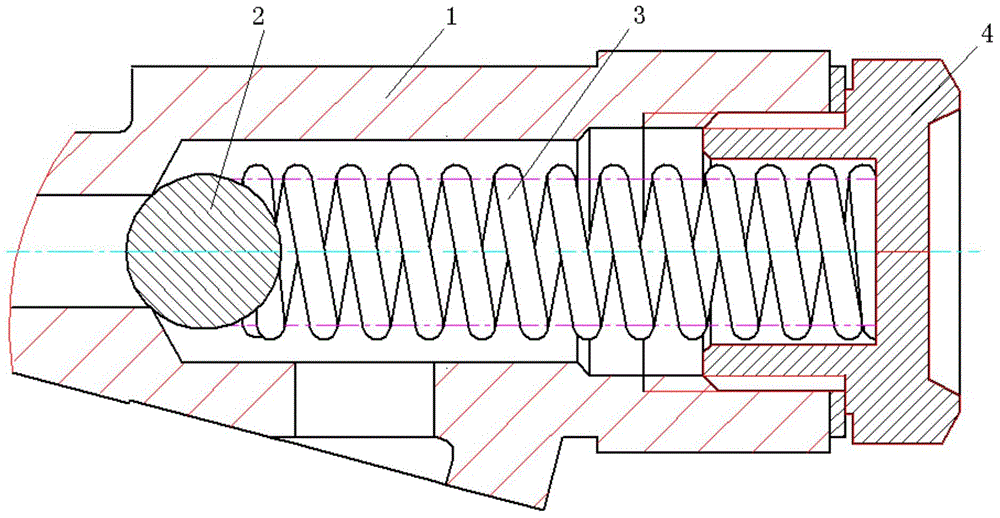

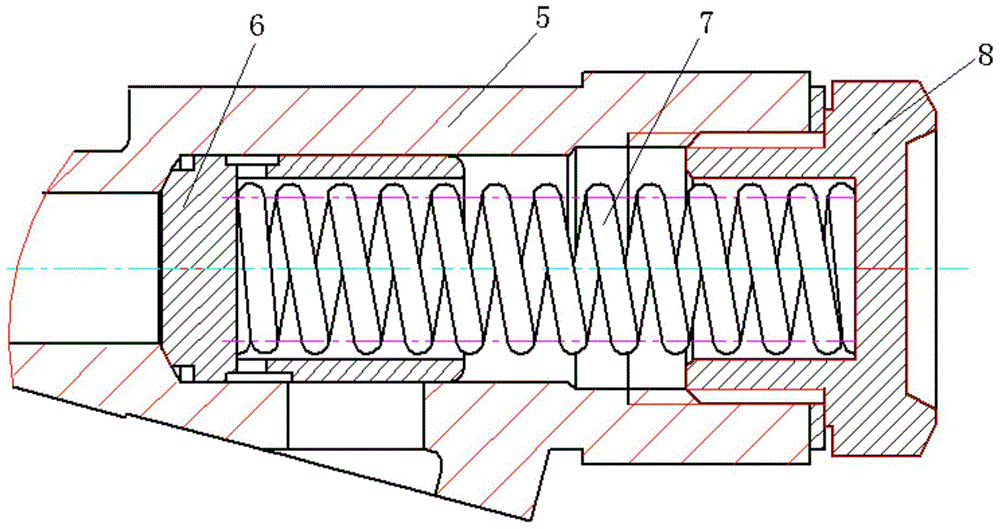

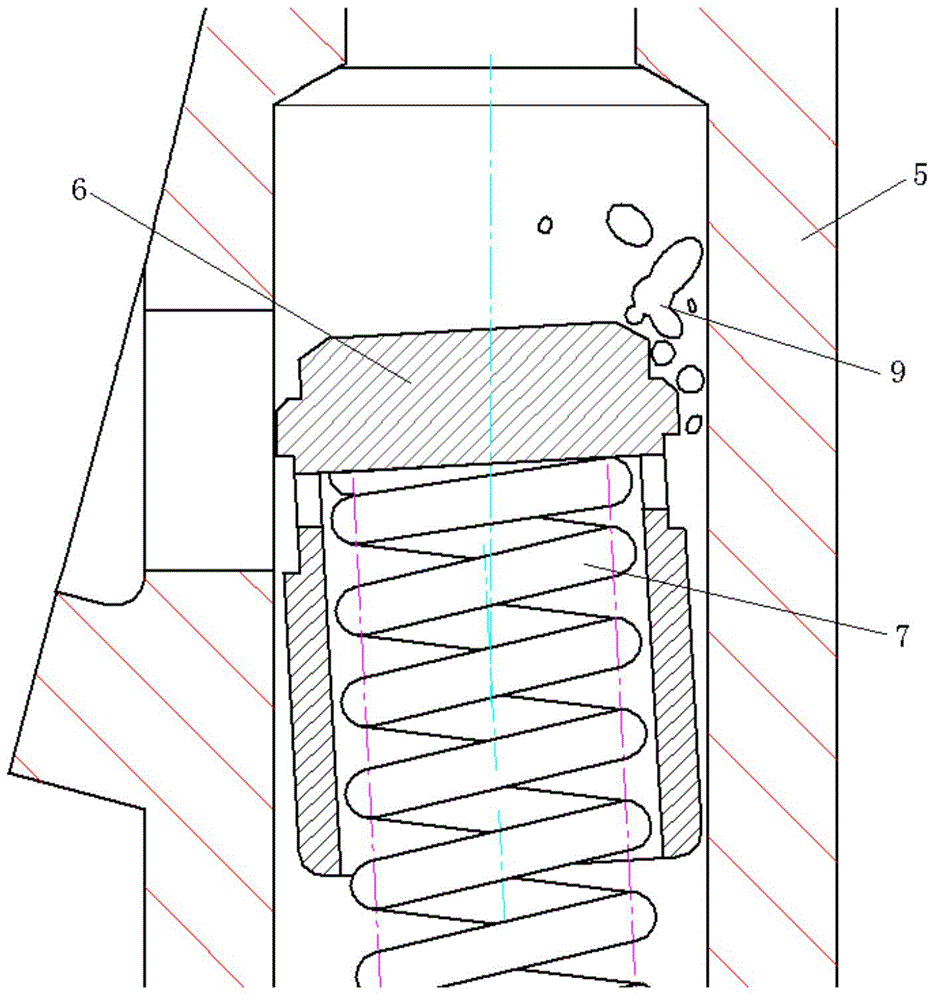

[0029] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0030] Because the pressure resistance of the lubrication system needs to be considered comprehensively, the oil filter can only filter out 60% of the impurities in the oil passing through the filter paper, and the relatively fine impurities that cannot be filtered still exist in the lubrication system, and these impurities are mostly iron impurities. , This kind of impurity is small in size and high in hardness, and it is easy to accumulate in the side clearance of the plunger of the plunger pressure limiting valve, causing wear and sticking of the plunger. Moreover, not all the oil in the system is filtered by the oil filter. The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com