Novel drum brake wheel cylinder structure

A technology for drum brakes and wheel cylinders, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., and can solve the problem of the small matching length between the outer cylindrical surface of the piston and the cylindrical surface of the inner hole of the wheel cylinder, and the problem that the piston and the inner hole of the wheel cylinder Wear and tear, cup sealing deterioration and other problems, to achieve the effect of reducing the risk of sticking, good dynamic sealing performance, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

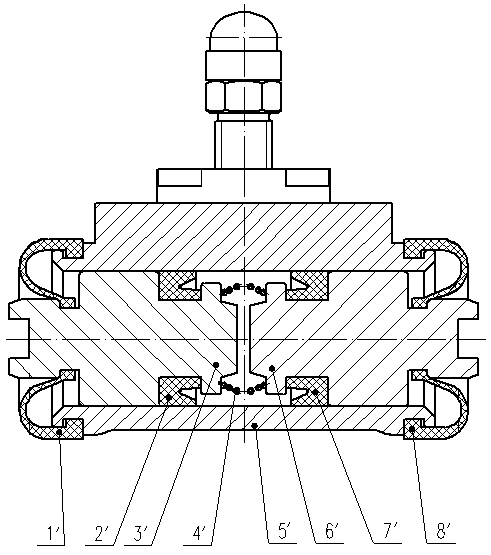

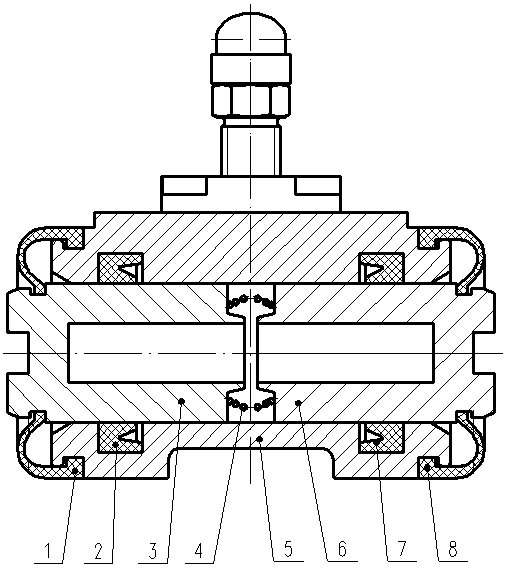

[0013] The present invention is made up of sealing function part one 1, leather cup one 2, wheel cylinder piston one 3, wheel cylinder spring 4, wheel cylinder 5, wheel cylinder piston two 6, leather cup two 7, sealing function part two 8, wheel cylinder piston One 3 and wheel cylinder piston two 6 are respectively assembled on both sides of the cylinder hole of wheel cylinder 5, the wheel cylinder 5 is in clearance fit with wheel cylinder piston one 3 and wheel cylinder piston two 6 respectively, and the sealing function part one 1 is respectively connected with the wheel cylinder piston One 3 is connected with the wheel cylinder 5, the sealing function part 2 8 is respectively connected with the wheel cylinder piston 2 6 and the wheel cylinder 5, there are two leather cup installation grooves in the inner hole of the wheel cylinder 5, the leather cup 1 2 and the leather cup 2 7 are respectively installed On the leather cup installation groove of wheel cylinder 5, wheel cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com