Patents

Literature

69results about How to "Good dynamic sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

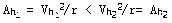

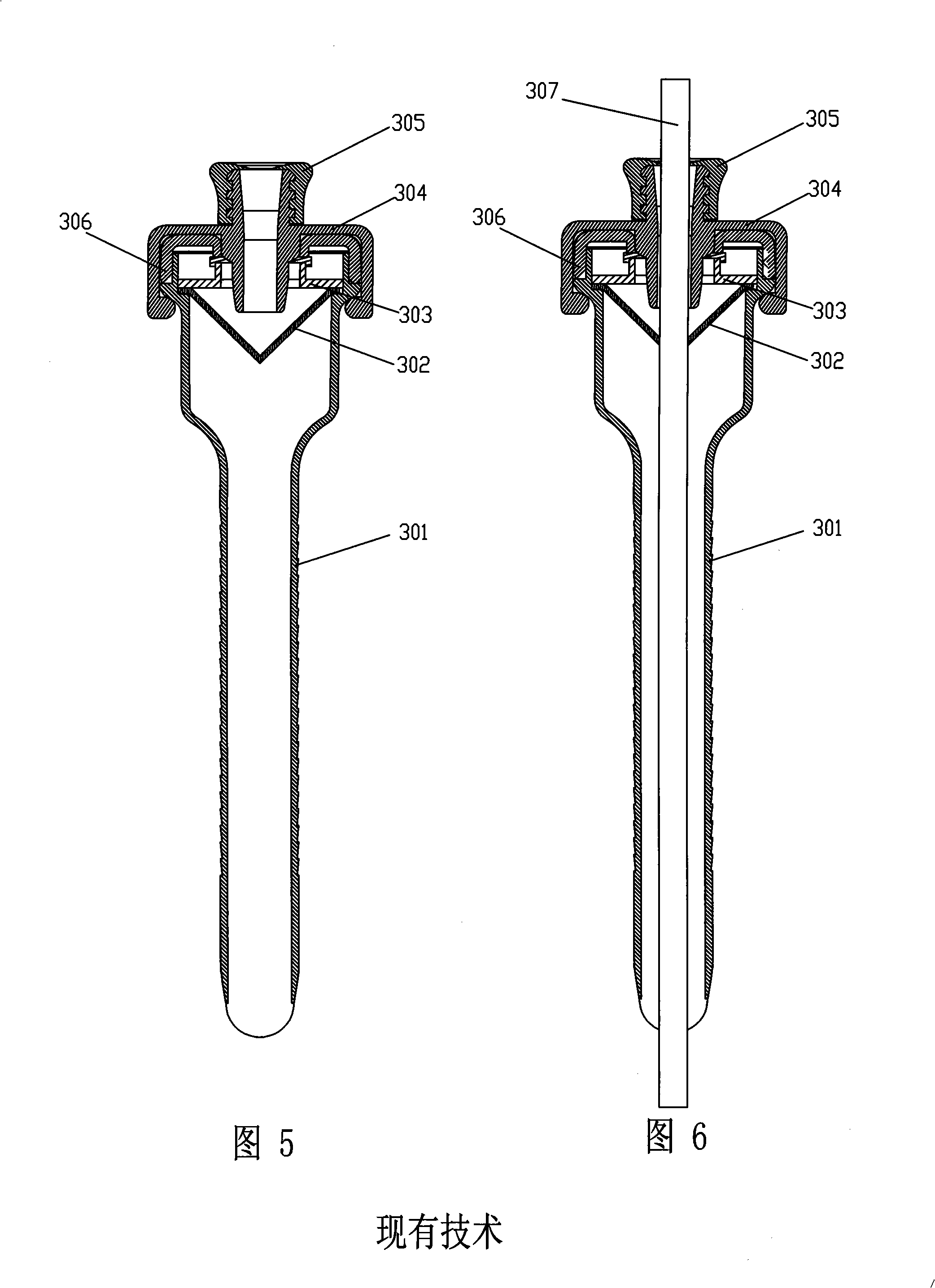

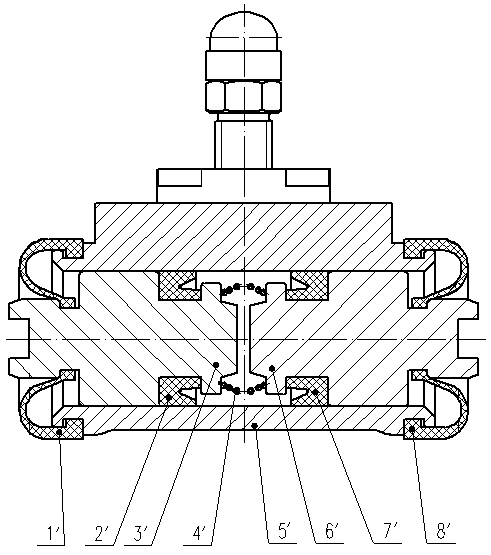

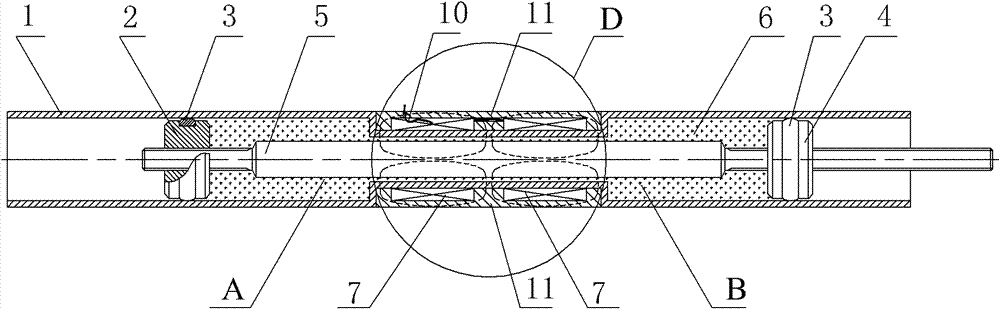

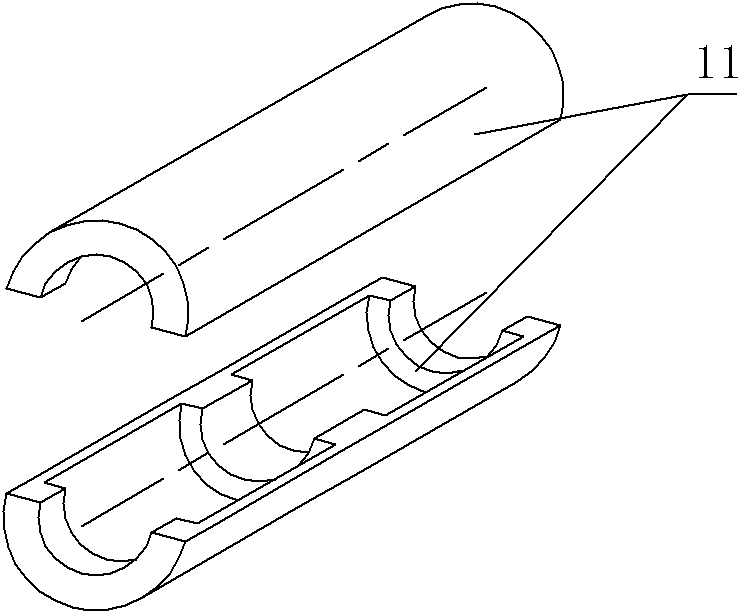

Tank-type general purpose type radial seal ring for puncture outfit and puncture outfit

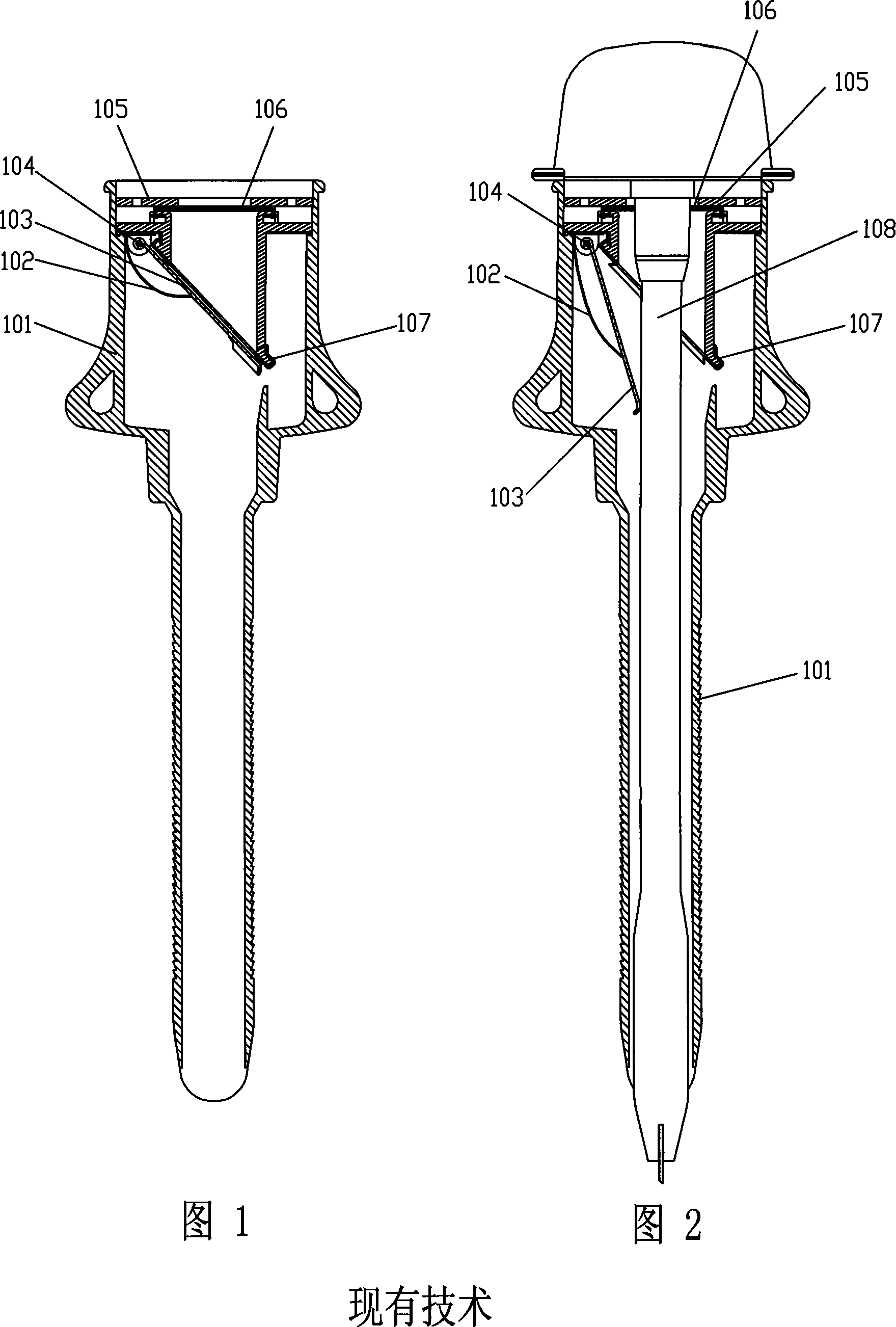

InactiveCN101480354AReduce thicknessLow movement resistanceCannulasSurgical needlesSurgical ManipulationGeneral purpose

The invention relates to a common groove radical gasket for a puncture outfit and the puncture outfit. Because the radial gasket is provided with a lithe groove, supporting zones with guide function and a through hole, the supporting zones are connected by the lithe groove, the thickness of the lithe groove is far less than the average thickness of the supporting zones, when a surgical instrument is inserted along tapered guide grooves of the supporting zones, the lithe groove is firstly distorted for holding the surgical instrument so as to achieve the sealing effect because the wall is very thin. When the surgical instrument is shaken, the supporting zones divided by the lithe groove are shaken together, and a sealing ring formed by the lithe groove always holds the surgical instrument to keep the sealing state always, thereby the best dynamic sealing effect is achieved. Especially, the lithe groove is thin, the dynamic sealing effect is good, and the kinetic resistance of the surgical instrument is little. The puncture outfit realizes the free replacement among surgical instruments with 12 mm, 10 mm, and 5 mm in diameter and is convenient for operation.

Owner:周星 +1

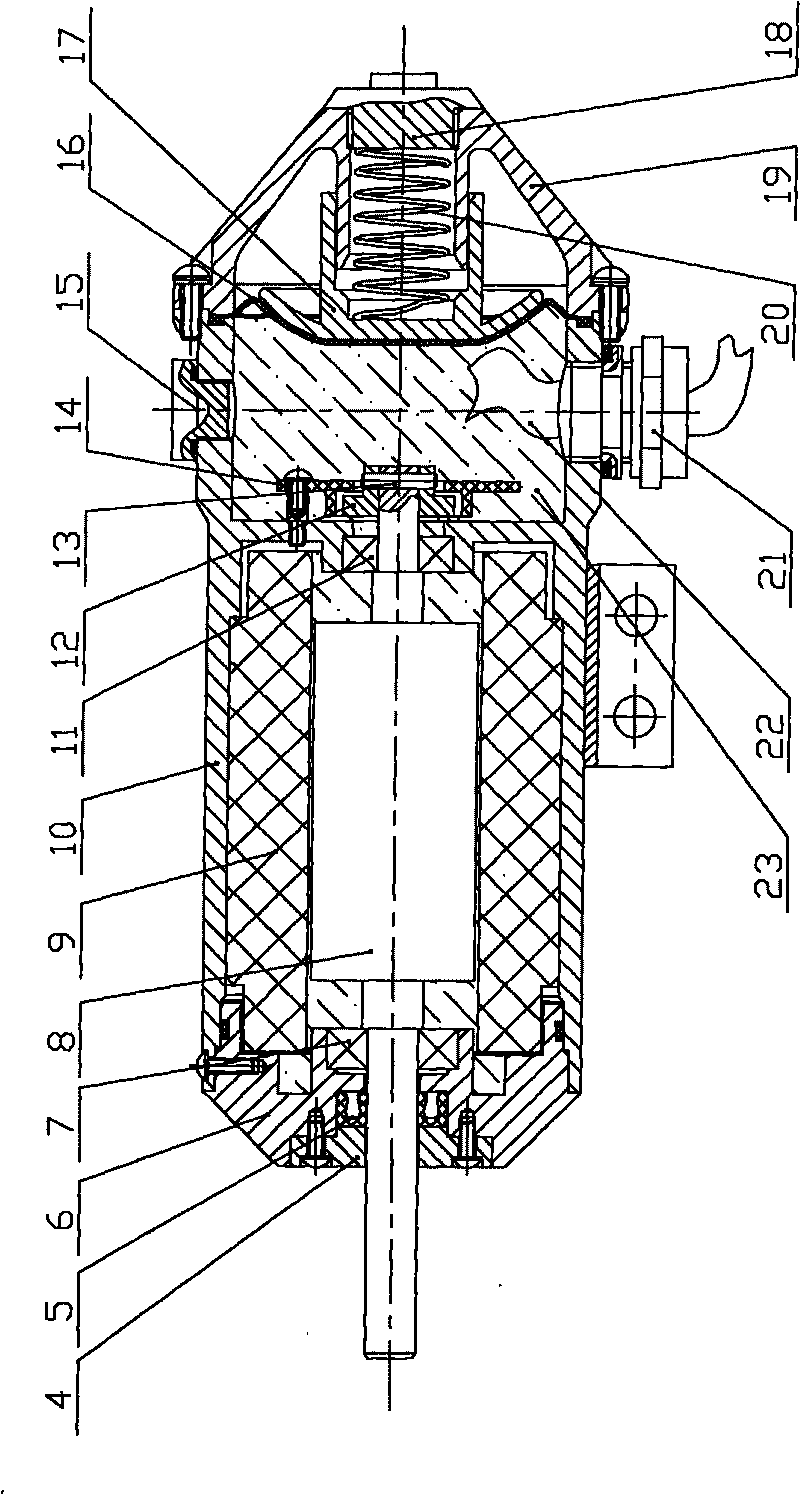

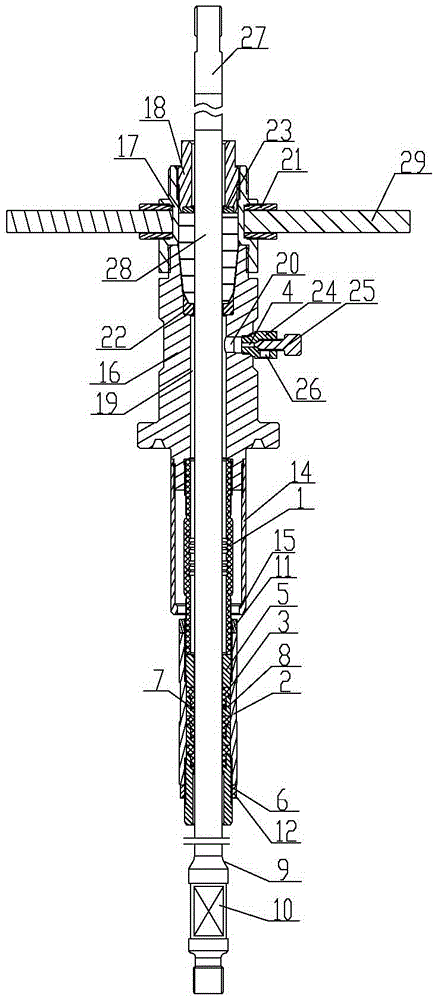

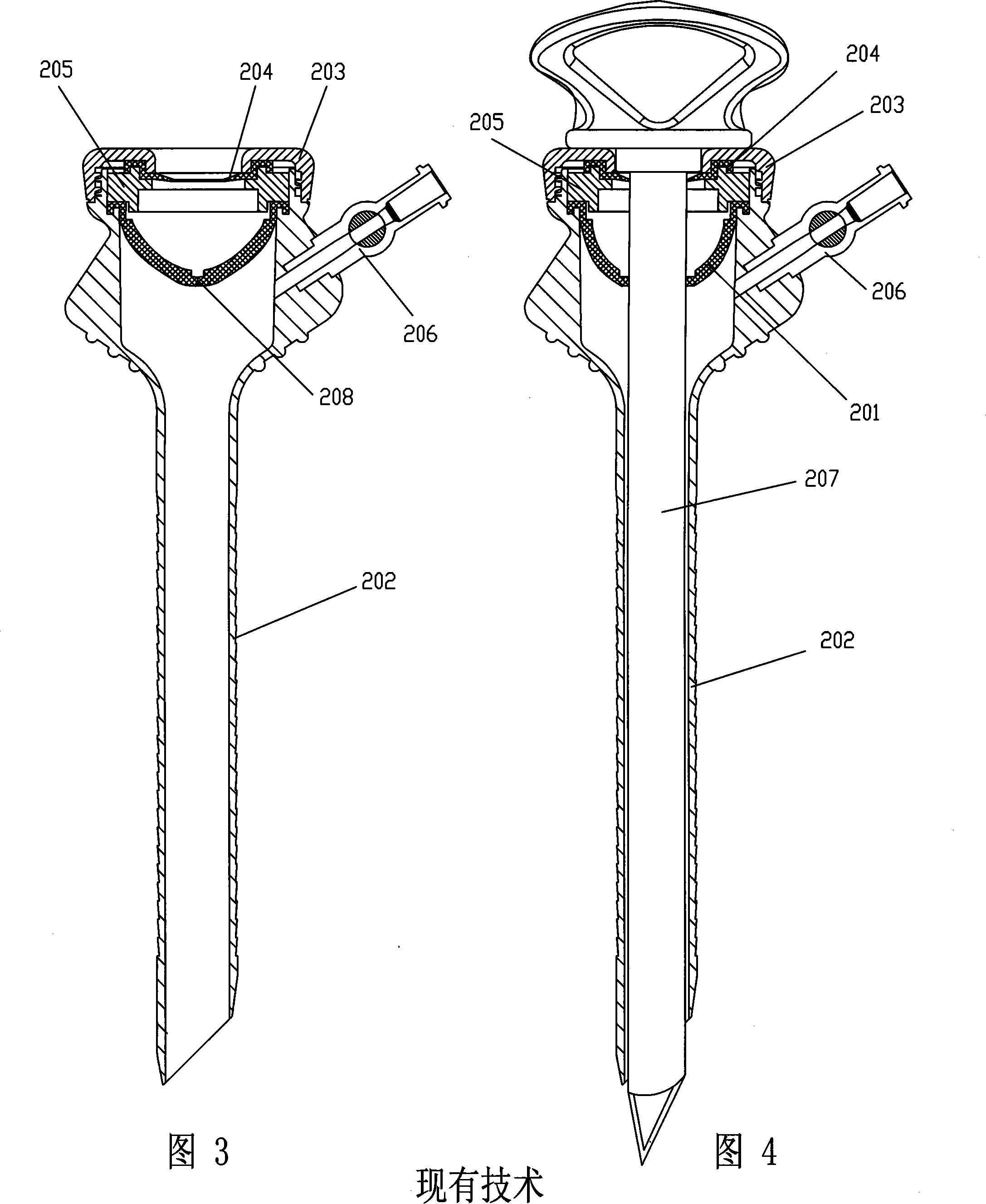

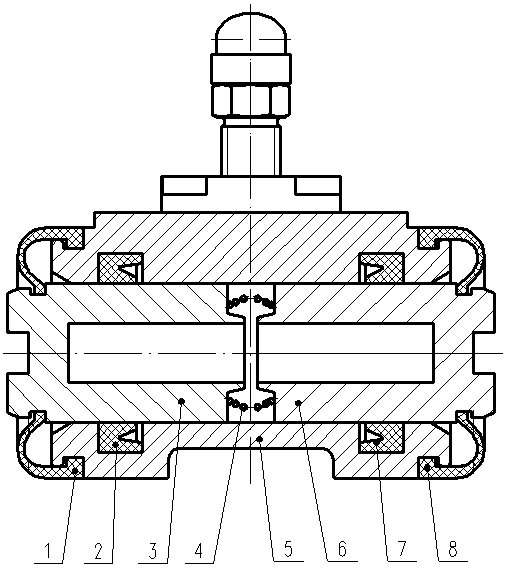

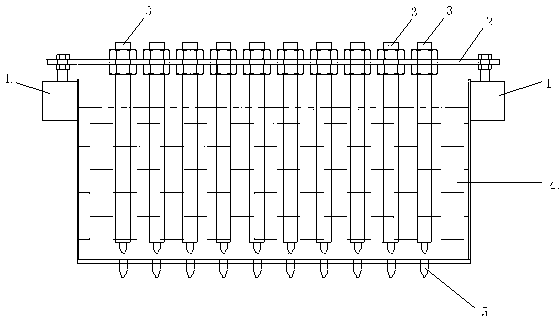

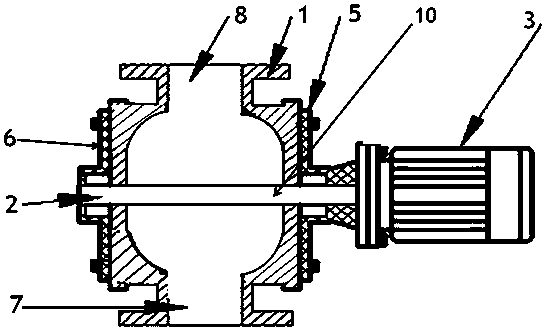

High-reliability puncture outfit

ActiveCN101474089ALow movement resistanceFit closelySuture equipmentsInternal osteosythesisEngineeringBearing surface

The invention relates to a high reliability puncture outfit. As a mounting bracket of a retaining valve is provided with a bearing surface which is matched with the funnel surface of the retaining valve, the bearing surface of the mounting bracket clings to the funnel surface structure of the retaining valve; when a surgery instrument is in and out in the retaining valve, as the bearing surface is inosculated and matched with the shape of the funnel surface, the bearing surface can effectively regulate the shape of the funnel surface, improves the inosculating situation of the incision of the retaining valve, prevent the occurrence of the skull patch phenomenon and increases the sealing effect after the surgery instrument is extracted. In addition, as a radial sealing ring with a flexible deforming slot is specially designed in the puncture outfit, the puncture outfit of the invention also realizes the random change of the surgery instrument with the 10mm to 5mm of diameter, not only has good moving seal effect, but also the surgery instrument has small kinetic resistance.

Owner:周星 +1

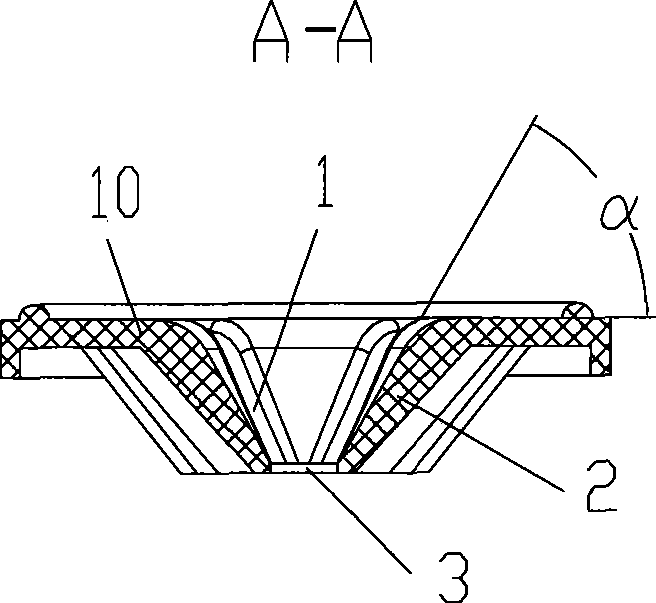

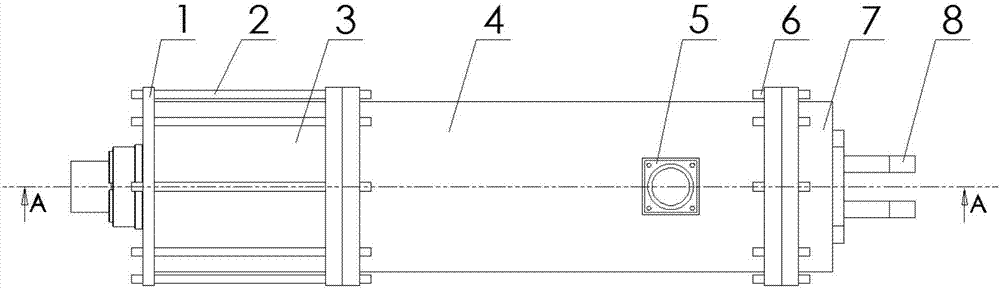

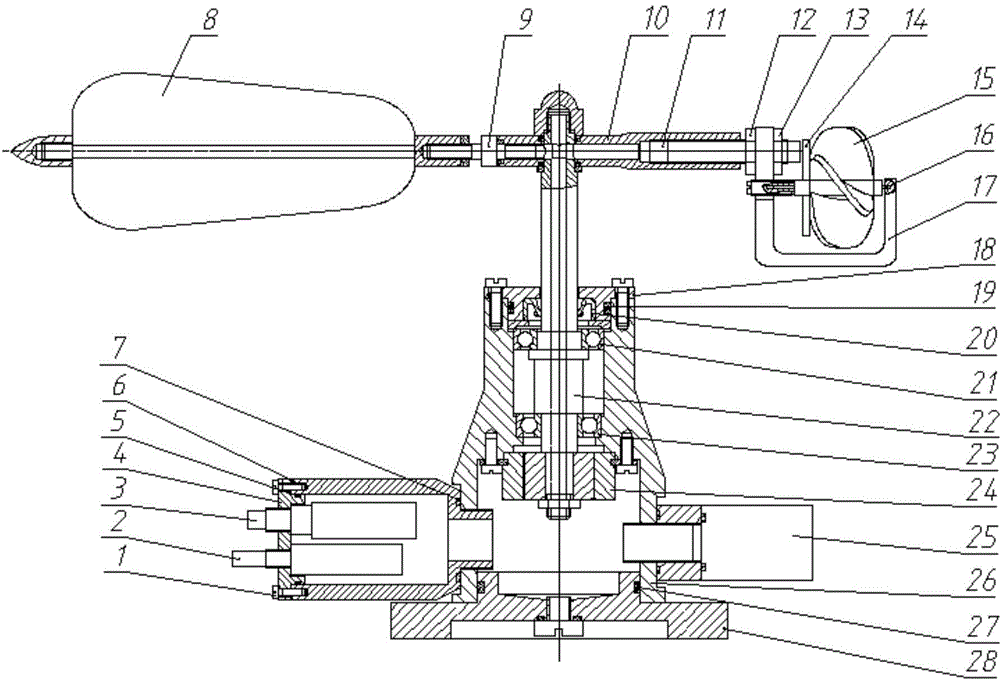

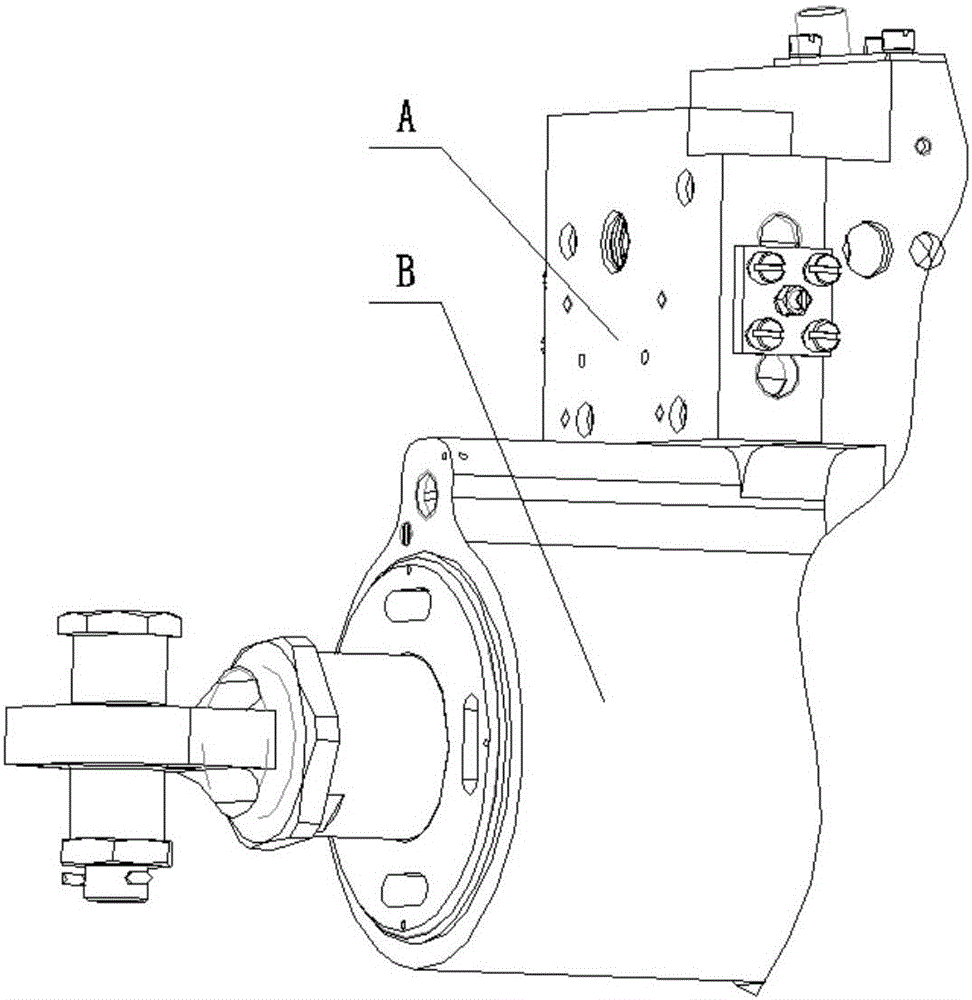

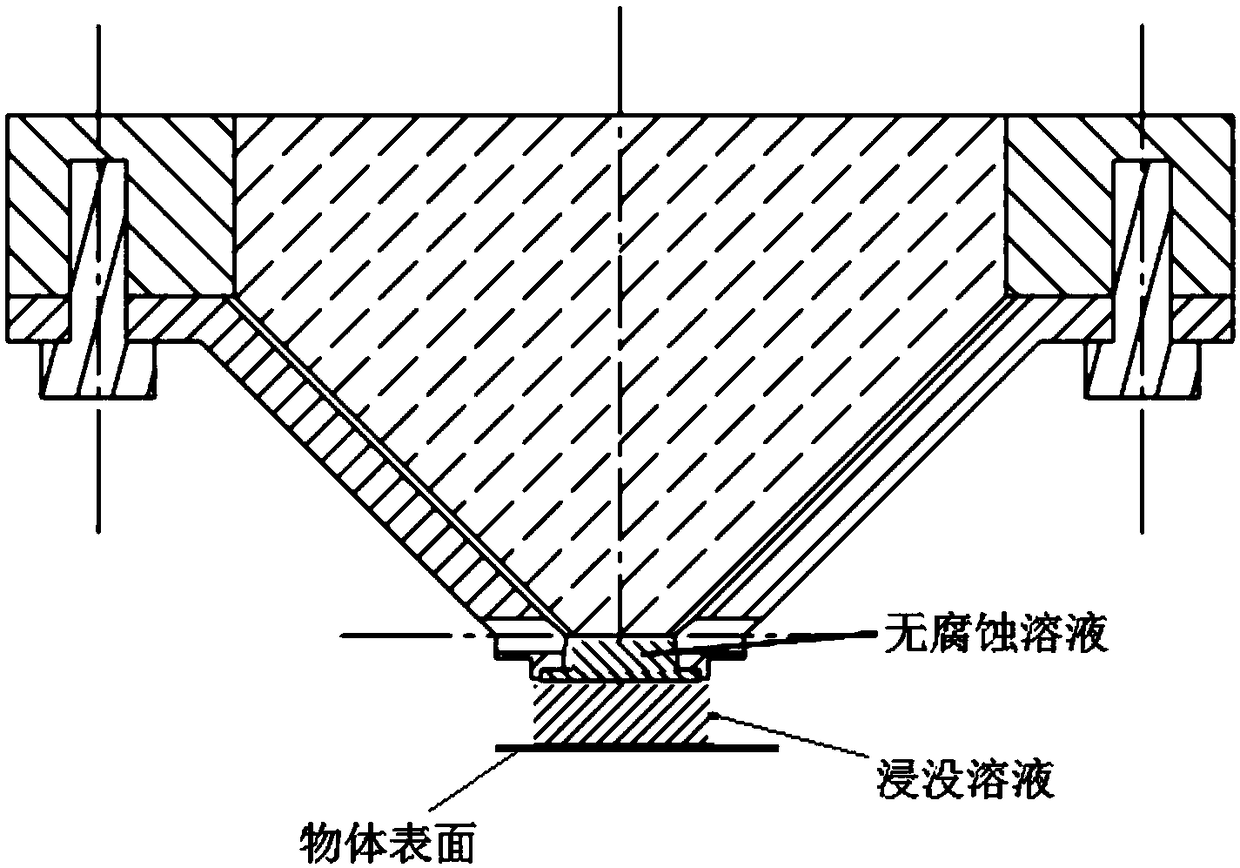

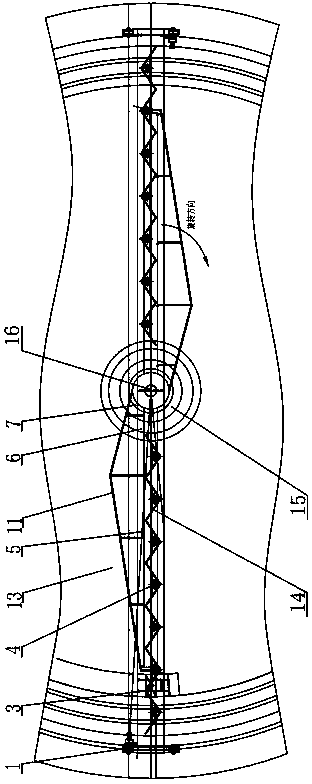

Slurry pulsator

The invention relates to a mud pulse generator, which mainly comprises a rotating pulse head, a pulse head supporting seat, a main shaft supporting mechanism, a main shaft assembly, a controlling and buffering mechanism, a solenoid valve assembly, a balancing piston mechanism, a pulse generator casing body and a pressure bearing electrode assembly. By matching the impeller and the rotor of the rotating pulse head as well as the flow passage and the area of the pulse head supporting seat, not only the mud pulse generator has higher adaptability, but also the quality of the pulse signals is improved; the main shaft assembly, the controlling and buffering mechanism and the solenoid valve assembly all adopt hidden structures and the key mechanisms can work in the hydraulic oil inside the casing body, so that the reliability of the mud pulse generator is improved; dynamic seal is only adopted between the bearing nut of the stator of the pulse head supporting seat and the main shaft. The balanced pressure difference between the inside and the outside of the casing body can be basically maintained through the balancing piston mechanism. Therefore, the dynamic sealing performance is good, and the service cycle is long. The mud pulse generator has the advantages of simple structure and low processing and use cost.

Owner:WESTERN DRILLING KELAMAYI DRILLING TECH INST

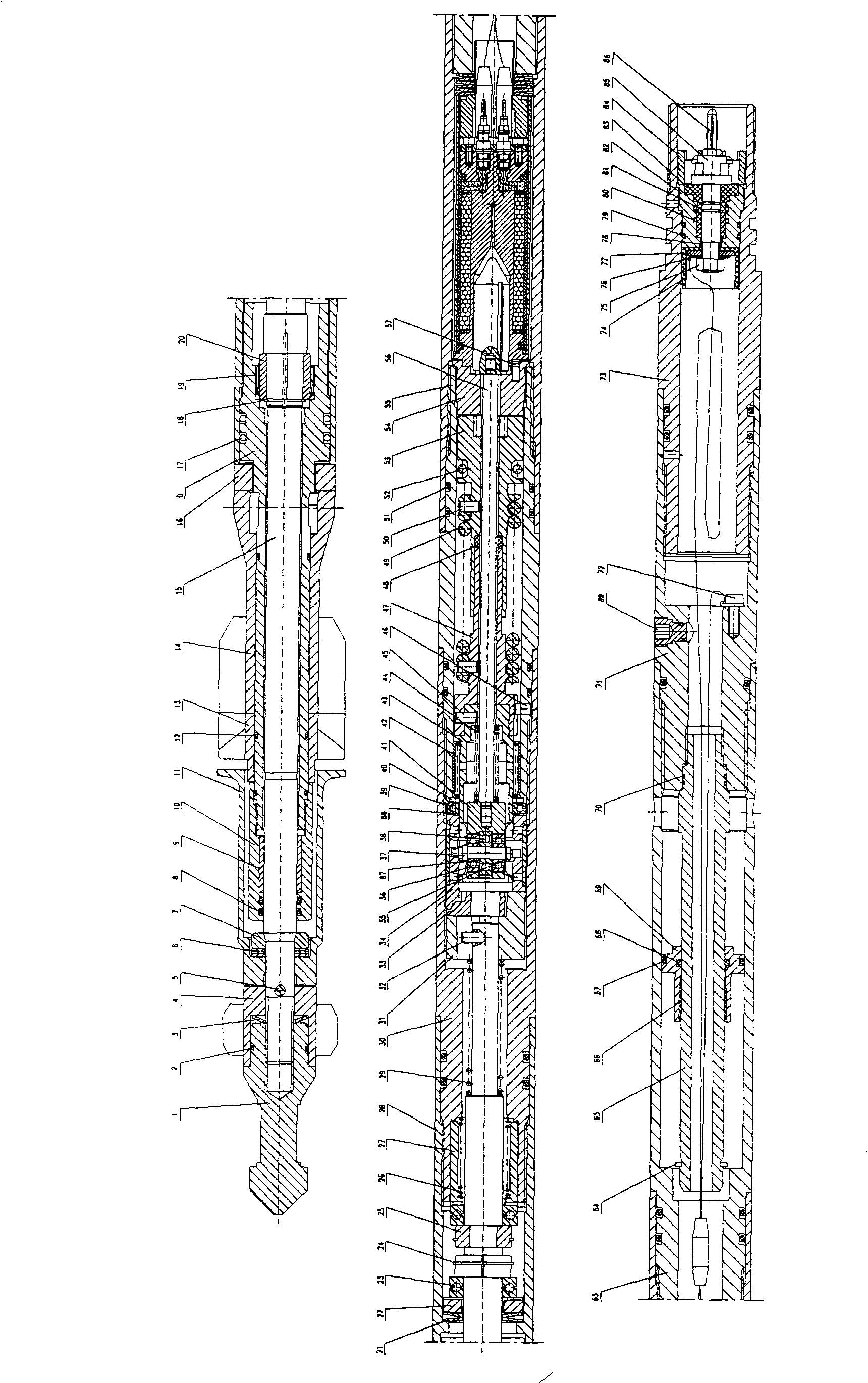

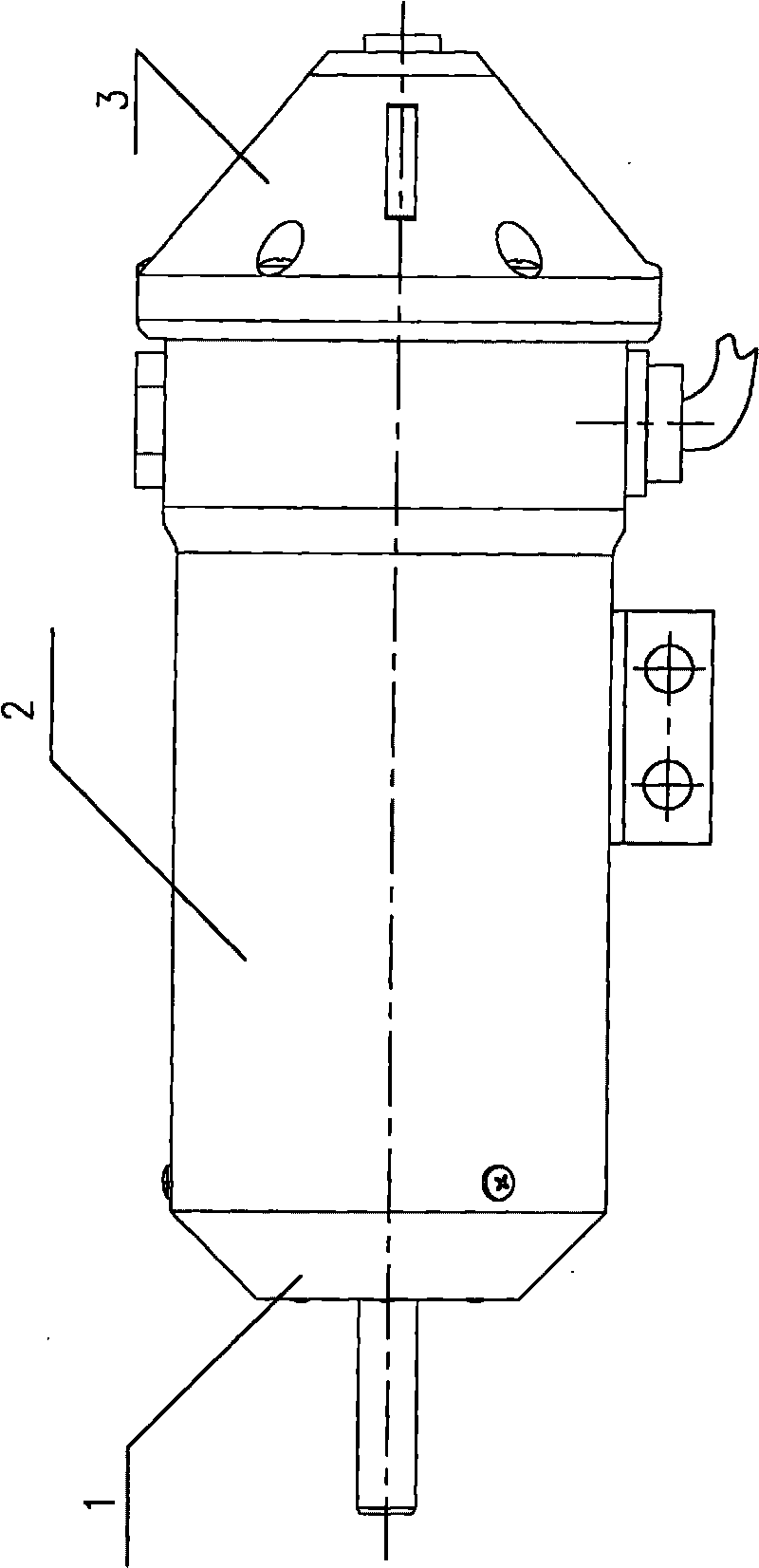

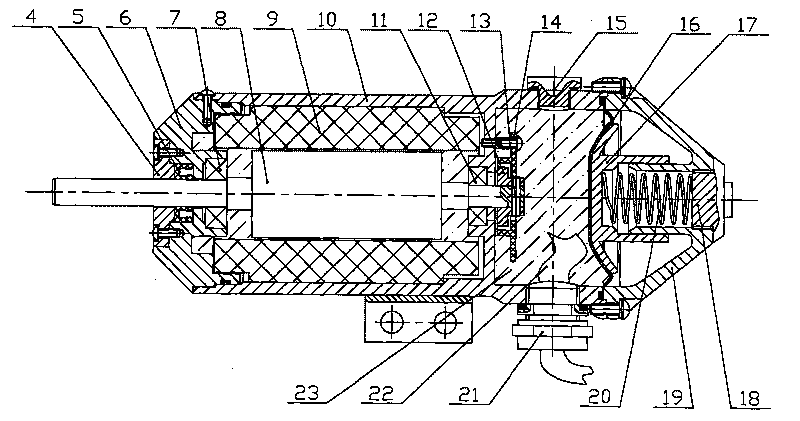

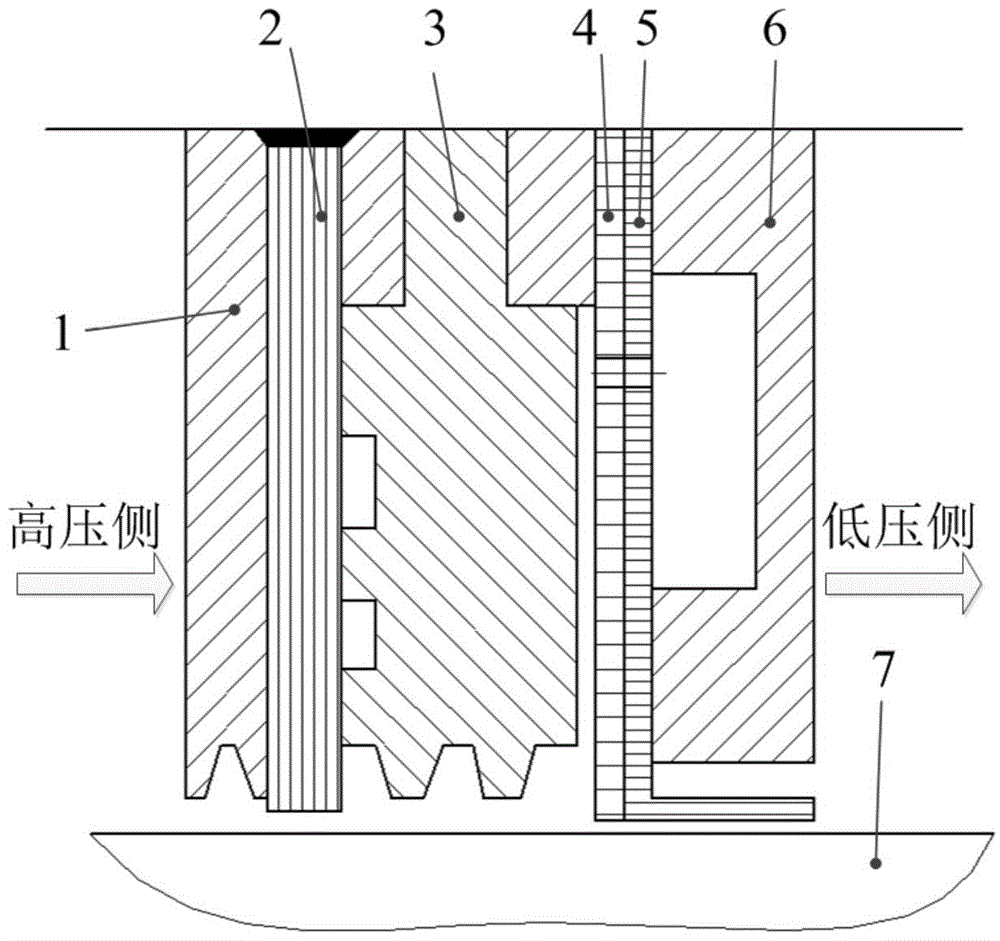

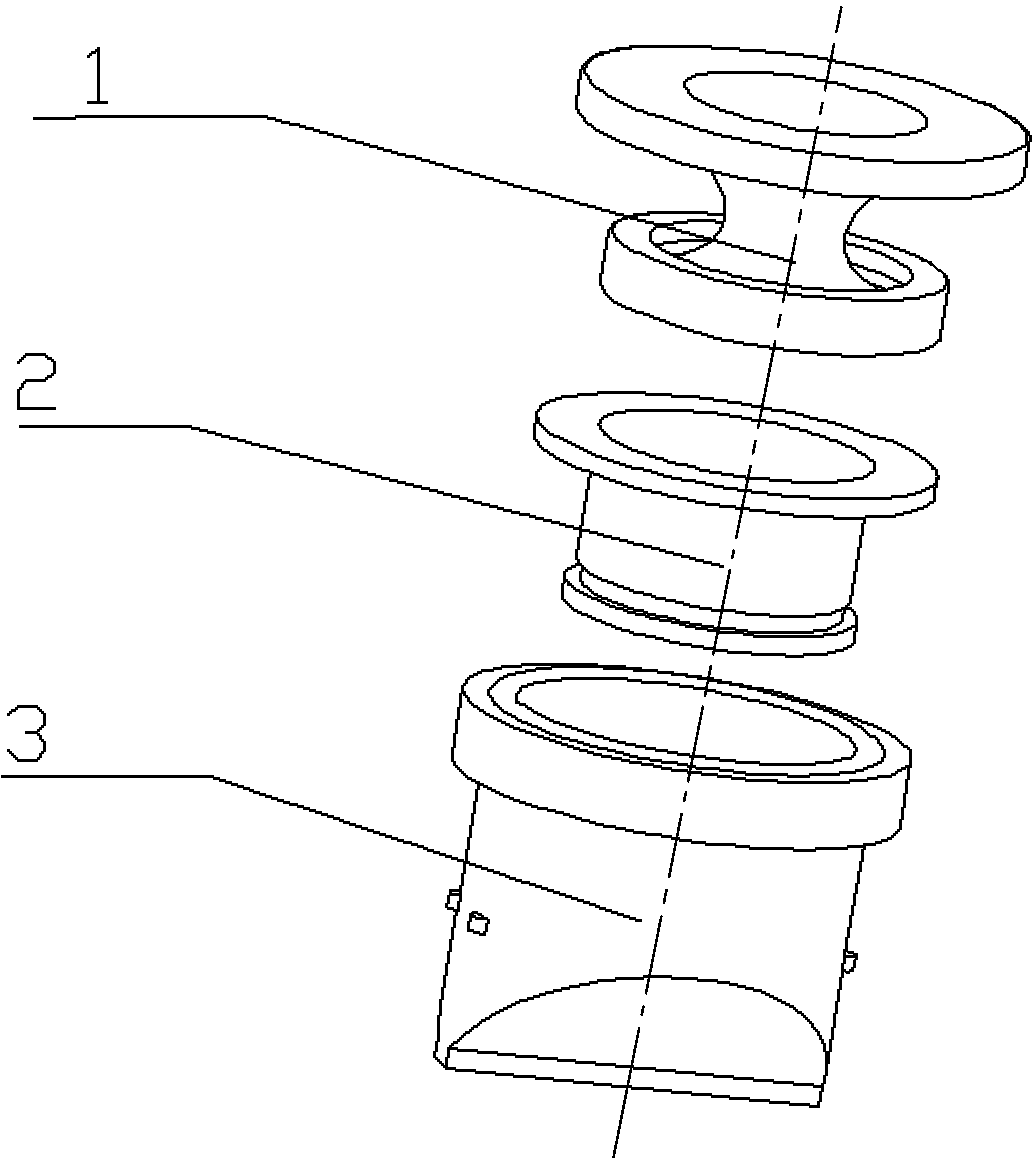

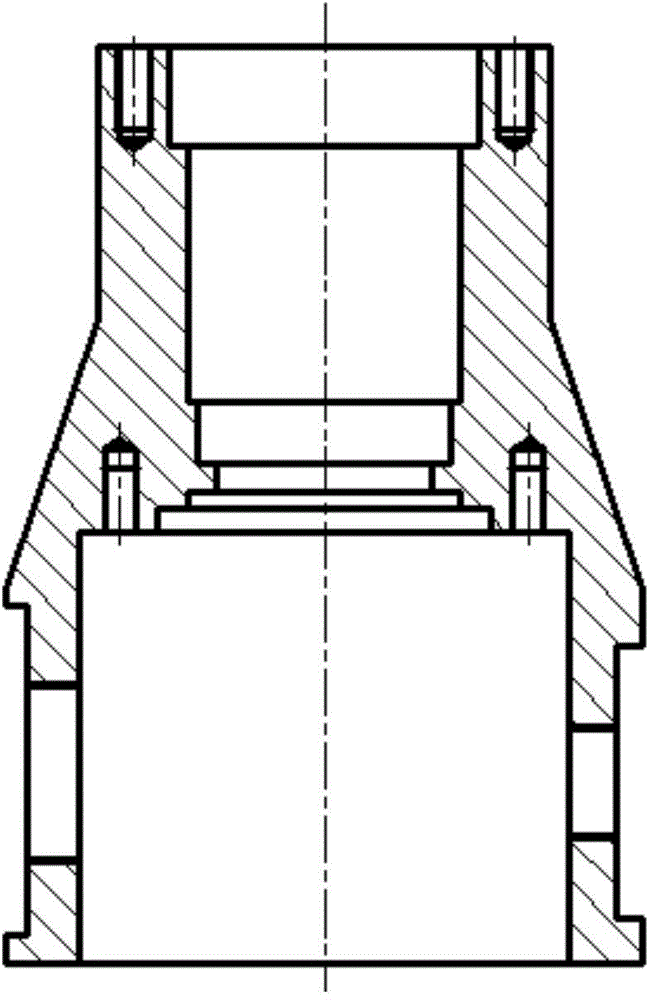

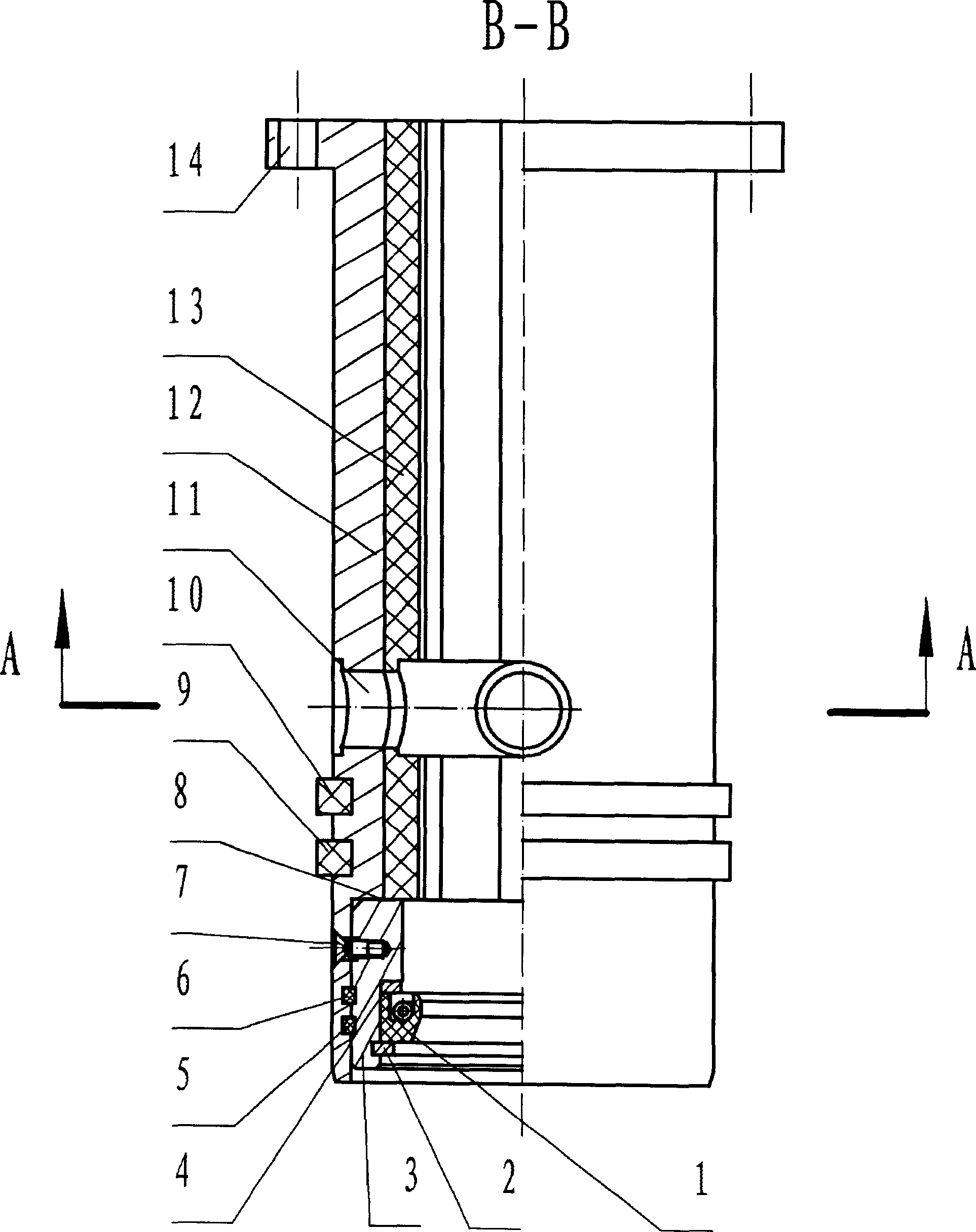

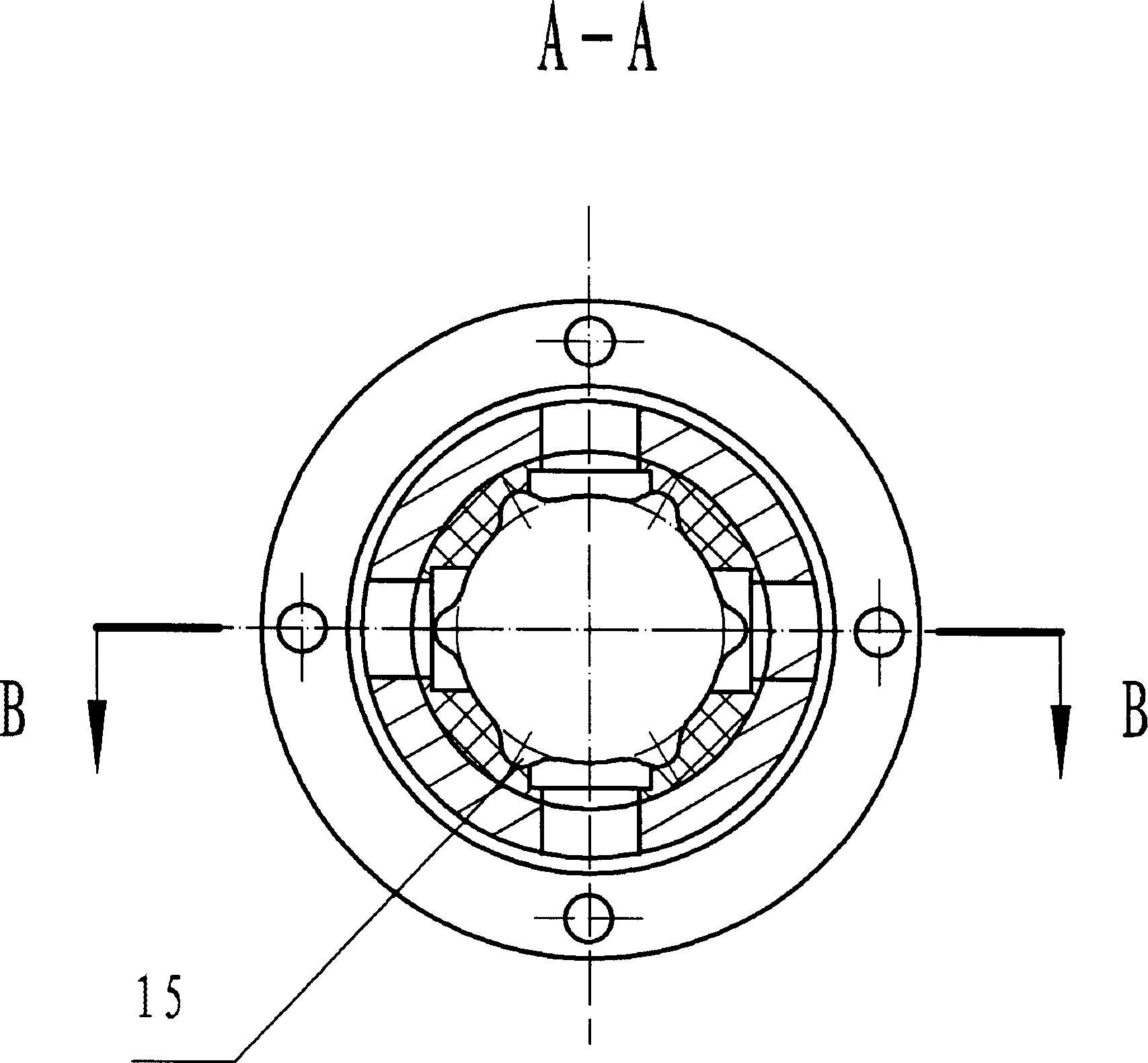

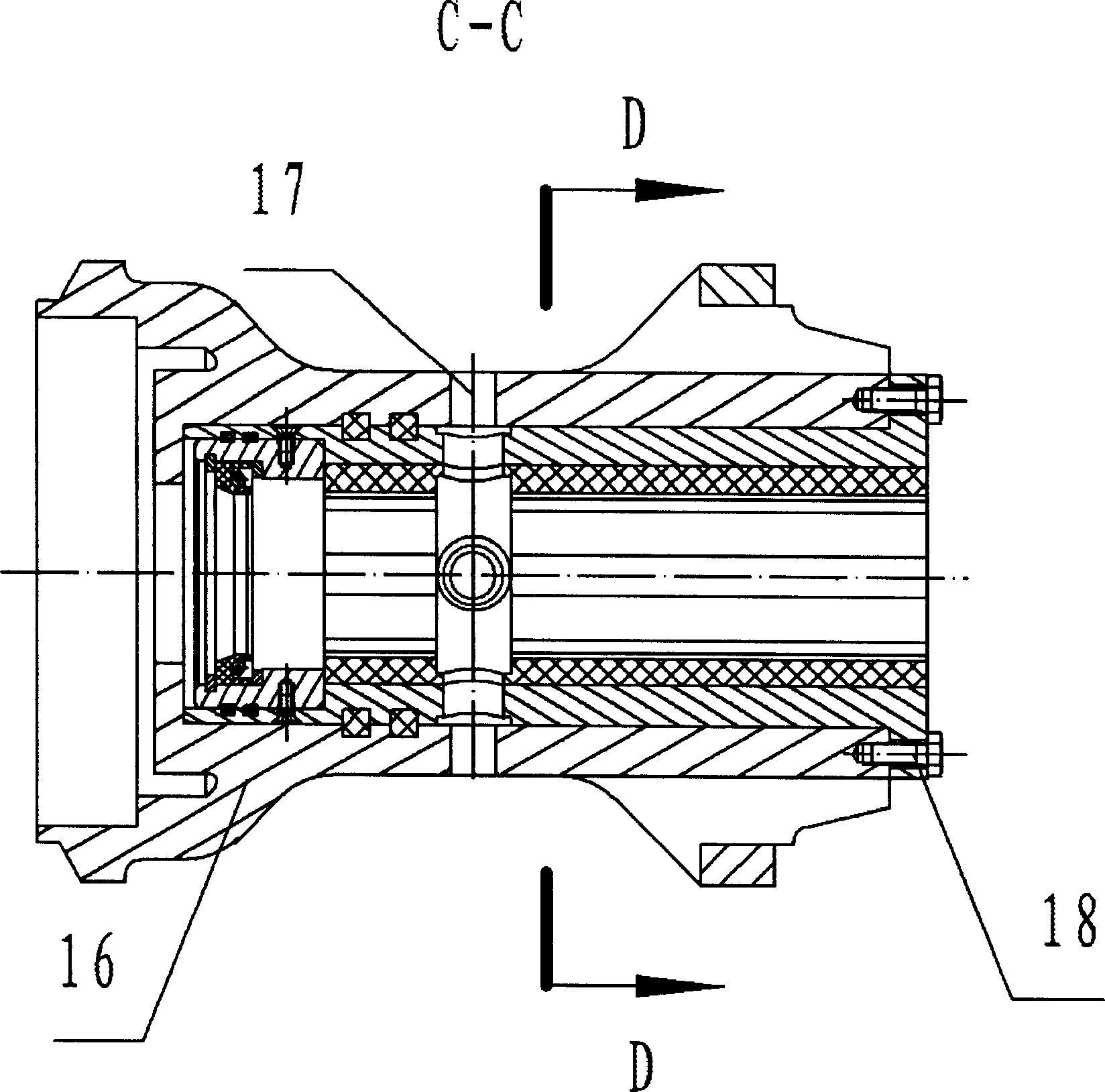

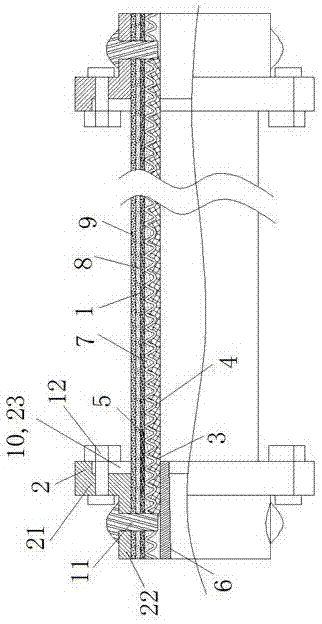

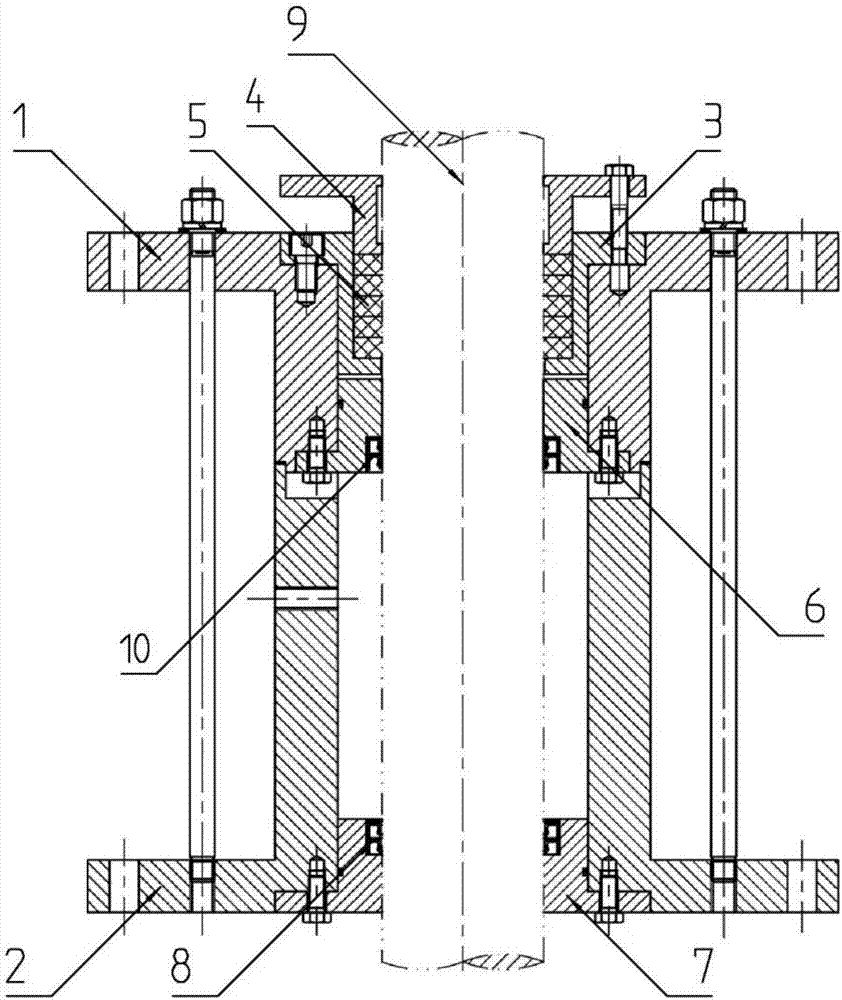

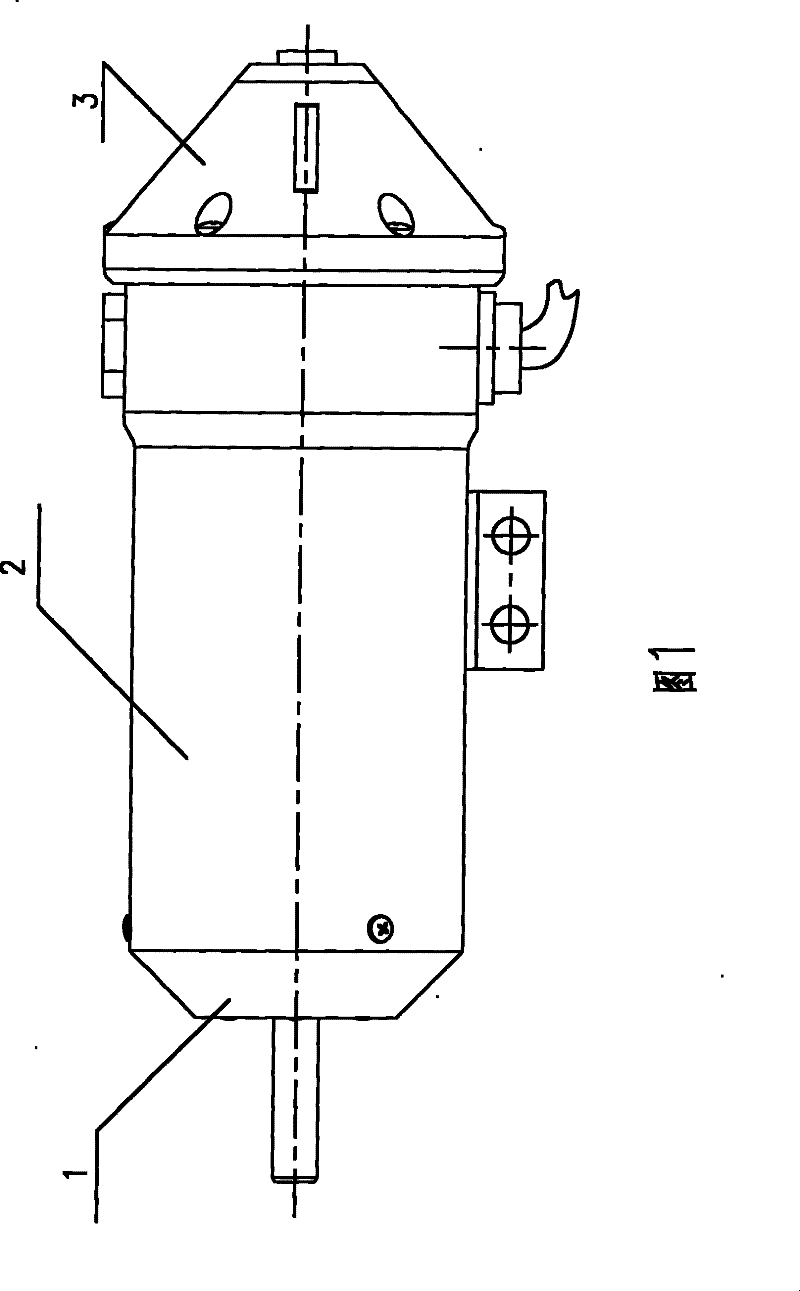

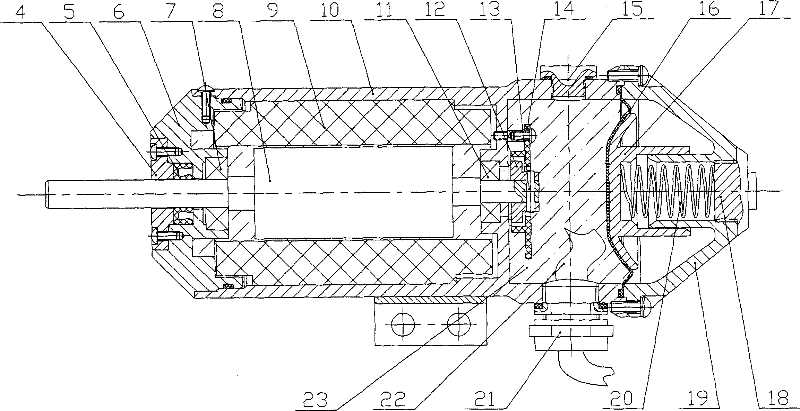

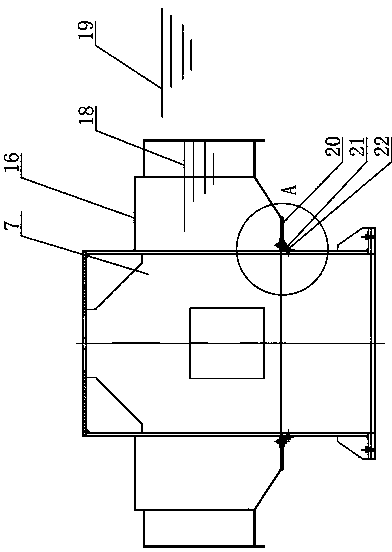

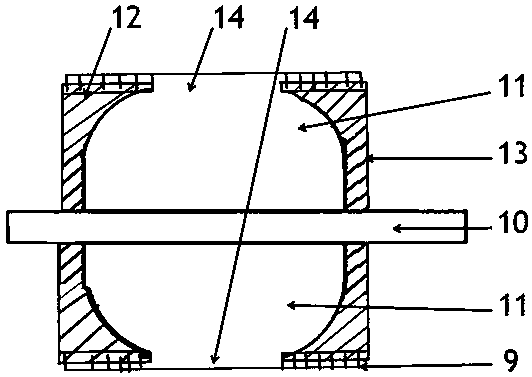

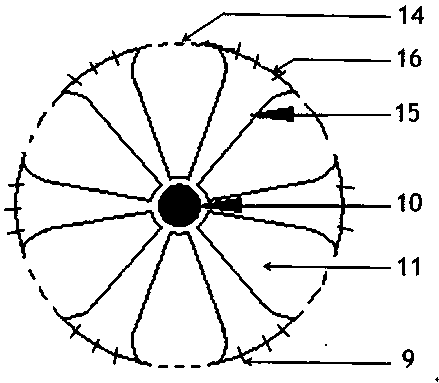

Compensated underwater brushless DC motor structure and assembly method thereof

InactiveCN101752937AImprove reconfigurabilityEasy maintenanceStructural associationSupports/enclosures/casingsUnderwaterEngineering

The invention relates to a compensated underwater brushless DC motor structure and an assembly method thereof. The motor structure comprises a motor end cover subassembly (1), a motor main body (2) and a compensator device (3), wherein the motor end cover subassembly (1) is positioned at the front end of the motor main body (2) and is fixedly connected with the motor main body (2) via bolts, the compensator device (3) is positioned at the tail of the motor main body (2) and connected with the motor main body (2) via bolts, and the compensator device (3) comprises a compensator skin (16), a compensator gland bush (17), a motor tail hood (19), a compensator spring (20) and a compensator screw cap (18). The motor structure has modularized design characteristic, the compensator device and the motor main body can be separated, and different compensator devices can be correspondingly adjusted or replaced for meeting different work environmental requirements so that the motor structure has the advantages of simple and compact structure, convenient assembly and debugging, and safe and reliable working and easy maintenance.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

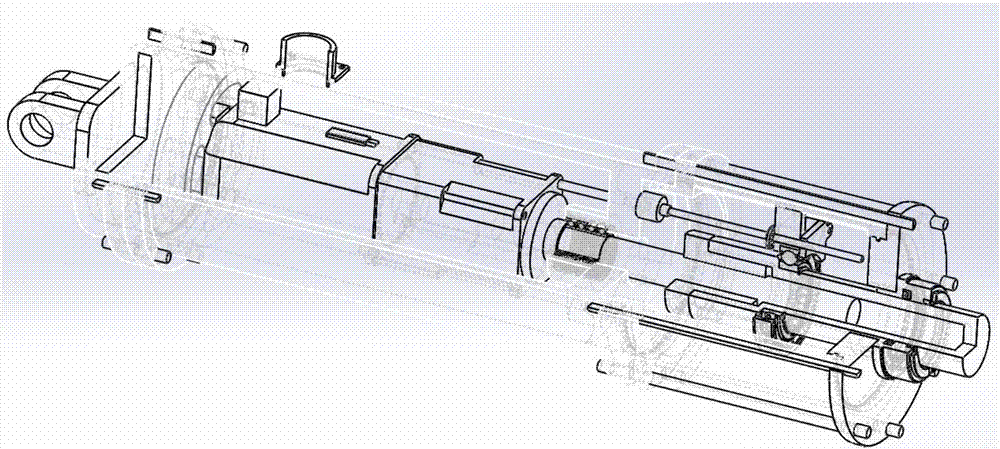

Pressure self-balance type electromechanical servo action device under high-pressure environment

InactiveCN107152506ASpeed up the flowWork lessGearingMechanical energy handlingBall bearingRoller screw

The invention discloses a pressure self-balance type electromechanical servo action device under the high-pressure environment. The pressure self-balance type electromechanical servo action device comprises a servo motor, a planet pin roller screw pair, a piston, a speed reducer, a sensor, a shell and other matched devices. The shell is internally fully filled with oil liquid, and the piston can freely move in a piston cylinder. An oil passing hole is reserved in a main shell, and it is guaranteed that oil liquid in the main shell and a front shell flows smoothly. The rotation movement of a screw is converted into the linear movement through a nut, and an output rod is pushed to output the linear movement. A linear displacement sensor is arranged on the main shell, and a magnetic ring is arranged on a guiding block and does the linear reciprocating movement along with a deep groove ball bearing. A high-low lip seal is adopted as a dynamic seal at the position of a copper sleeve, static seals are adopted at other shell connecting parts, and inner and outer liquid mixing is prevented. The pressure self-balance type electromechanical servo action device solves the problems that an existing electromechanical action device is weak in voltage endurance capability, low in efficiency and the like, the power to weight ratio, the voltage endurance capability and the load capability of the electromechanical action device are improved, and a technology guarantee is provided for promoting the development of submarines and underwater devices under the high-pressure environment.

Owner:BEIHANG UNIV

Propeller shaft sealing structure of ship propeller

InactiveCN104806736AAvoid enteringAvoid emulsificationGear lubrication/coolingWater acting propulsive elementsInterference fitThermal spraying

The invention relates to a shaft sealing structure of a ship propeller. A race is fixedly connected with a conical ring; the conical ring is arranged on a gearbox body; a thermal spraying bushing sleeves a propeller shaft in an interference way; four rotary skeleton oil seals are arranged on a ceramic area of the thermal spraying bushing; the outer diameter of each rotary skeleton oil seal is in interference fit with an inner hole of the race; a sealing lip of the inner diameter is in contact with the ceramic area of the thermal spraying bushing; the sealing lip of the outermost rotary skeleton oil seal faces outwards, the sealing lip of the innermost rotary skeleton oil seal faces inwards, a space ring is arranged between the two middle rotary skeleton oil seals, and the space ring, the two middle rotary skeleton oil seals and the thermal spraying bushing form a cavity; a communicated gravity oil passage is arranged in the gearbox body, the conical ring, the race and the space ring, and is communicated with the cavity; a sealing part sleeves the thermal spraying bushing; a sealing lip of the sealing part is in contact with the vertical end surface of a cover plate. The propeller shaft sealing structure has the advantage that gravity oil is filled into the gravity oil cavity through the oil passage, so the seawater is prevented from entering the gearbox, and the emulsifying of lubricating oil is avoided.

Owner:SMMC MARINE DRIVE SYST SUZHOU

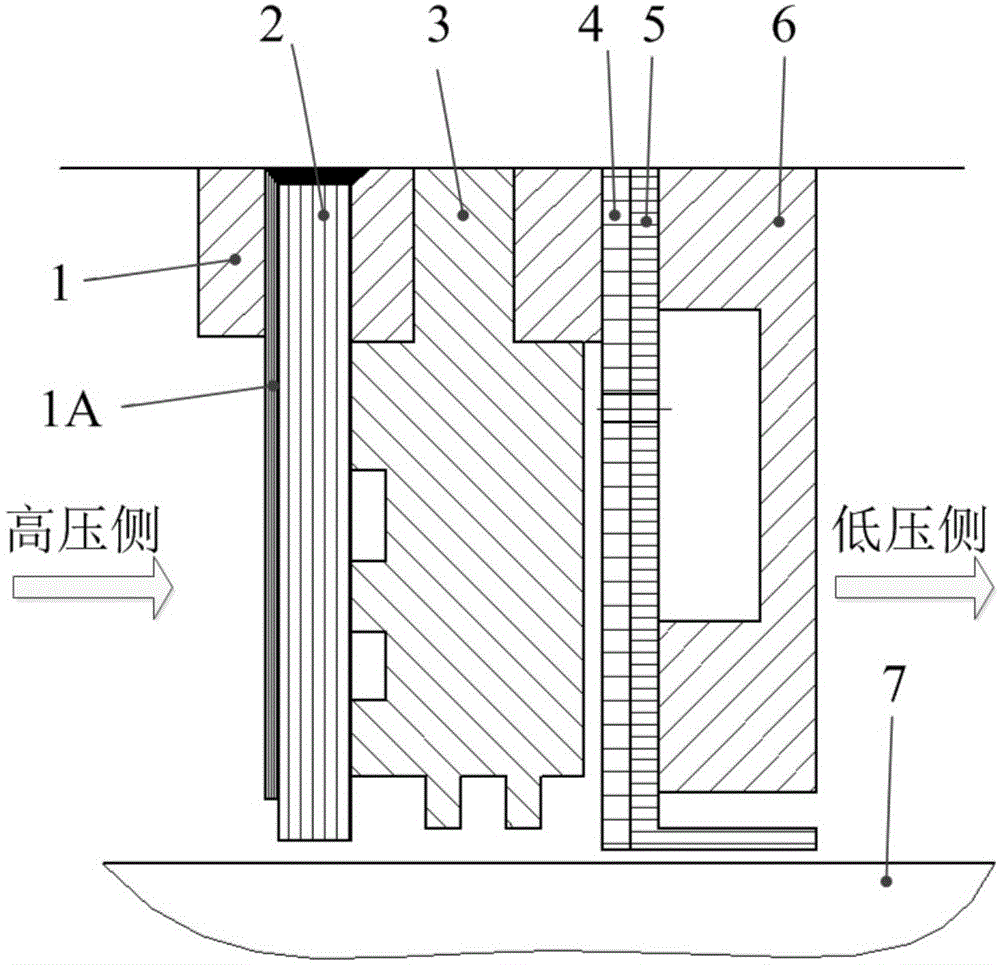

Non-contact fingertip-labyrinth-brush type combined sealer

ActiveCN104806301AGood dynamic sealing effectOvercoming the disadvantages of sealingLeakage preventionMachines/enginesEngineeringHigh pressure

The invention discloses a non-contact fingertip-labyrinth-brush type combined sealer. The combined sealer comprises labyrinth teeth, which are connected with a rotor in a matching way, in a labyrinth sealing area, the high pressure sides of the labyrinth teeth are connected with a brush type sealing area consisting of brush wires and a composite front baffle plate, and the low pressure side of the labyrinth teeth is connected with a non-contact fingertip sealing area consisting of a high pressure fingertip piece, a low pressure fingertip piece and a rear baffle; the labyrinth teeth are served as the rear baffle of the brush wire sealing and can be served as the front baffle in the non-contact fingertip sealing area, the pressure can be greatly reduced after the upstream high pressure side pressure passes through the brush type sealing area and the labyrinth sealing area, and the pressure on the non-contact fingertip sealing area can be greatly reduced, and the sealing differential difference resistance can be greatly improved; furthermore, a leak-proof structure is of a non-contact way, the dynamic sealing performance can be improved, and the stability of a rotor-sealing system can be greatly improved.

Owner:TSINGHUA UNIV

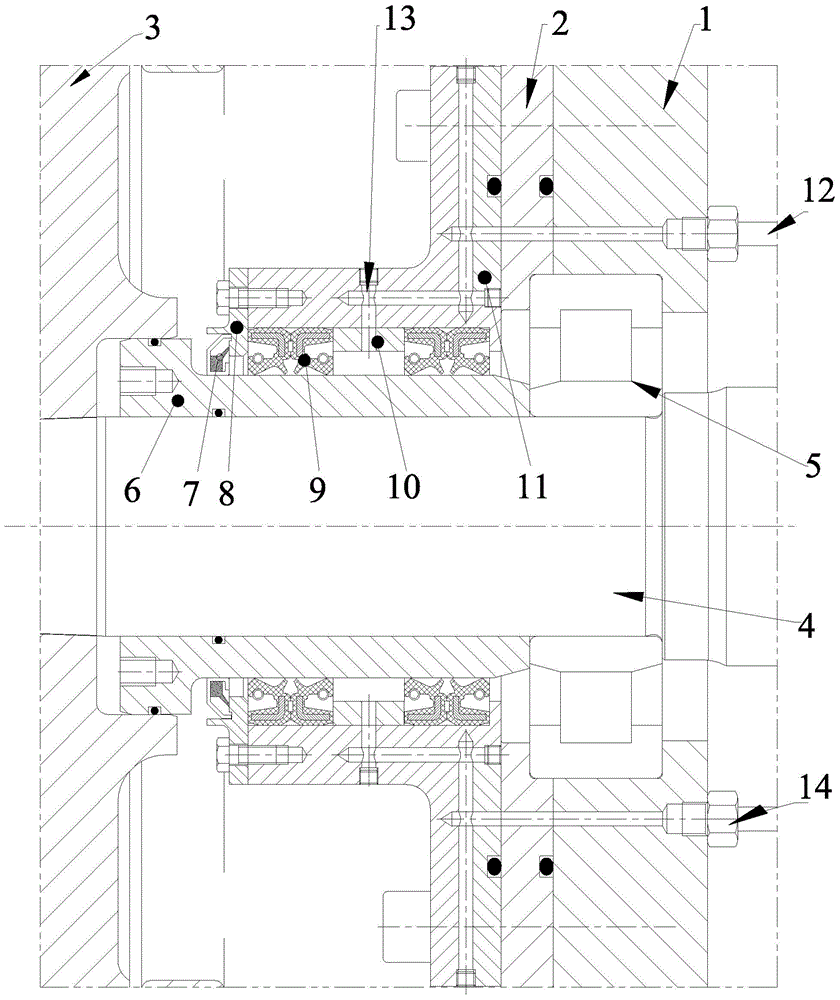

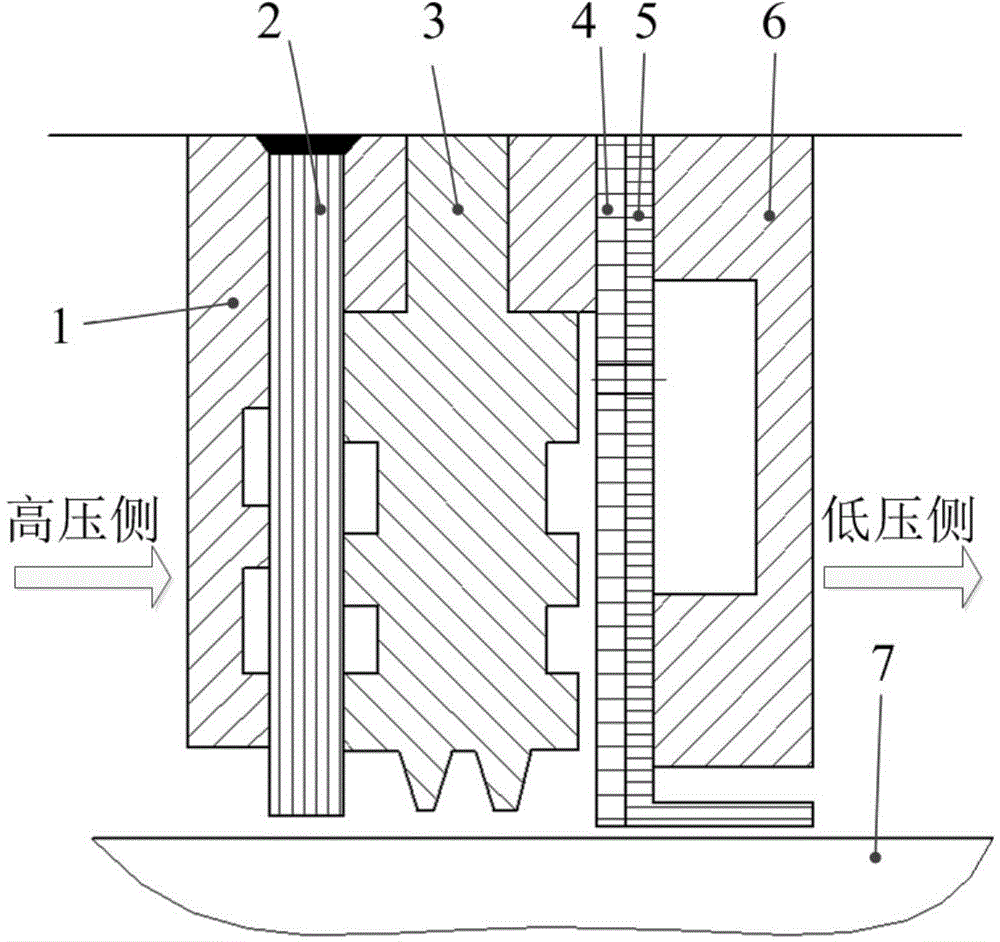

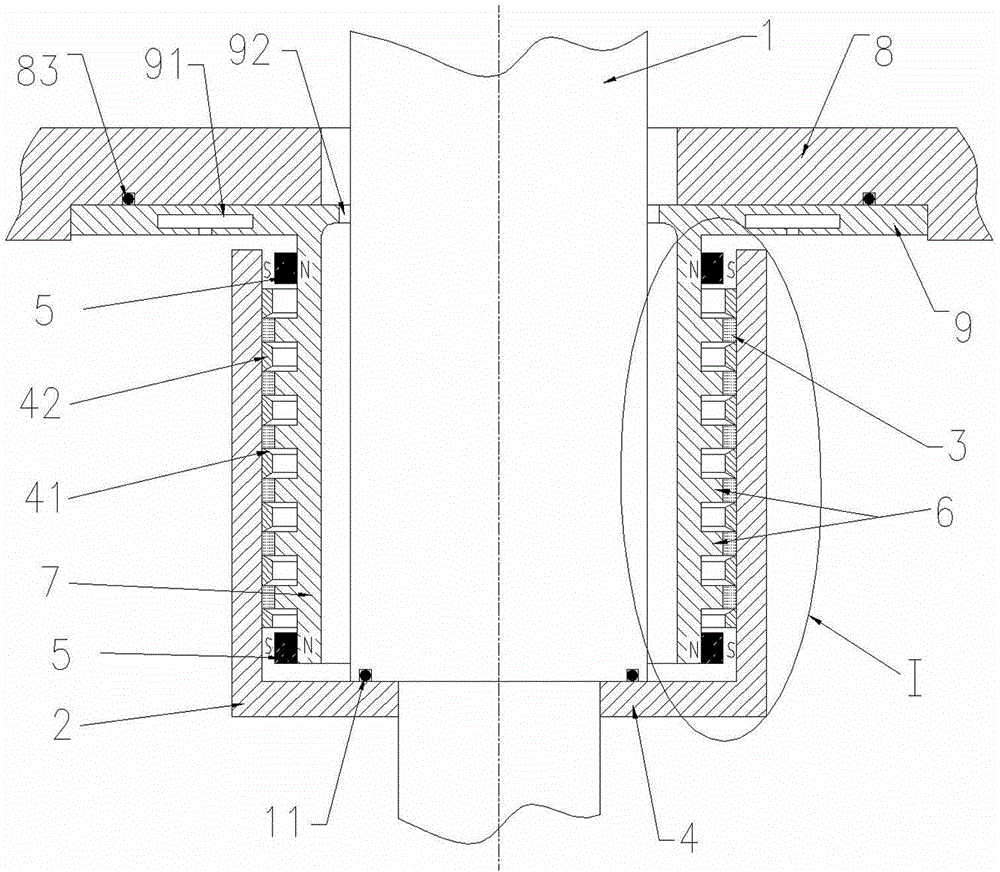

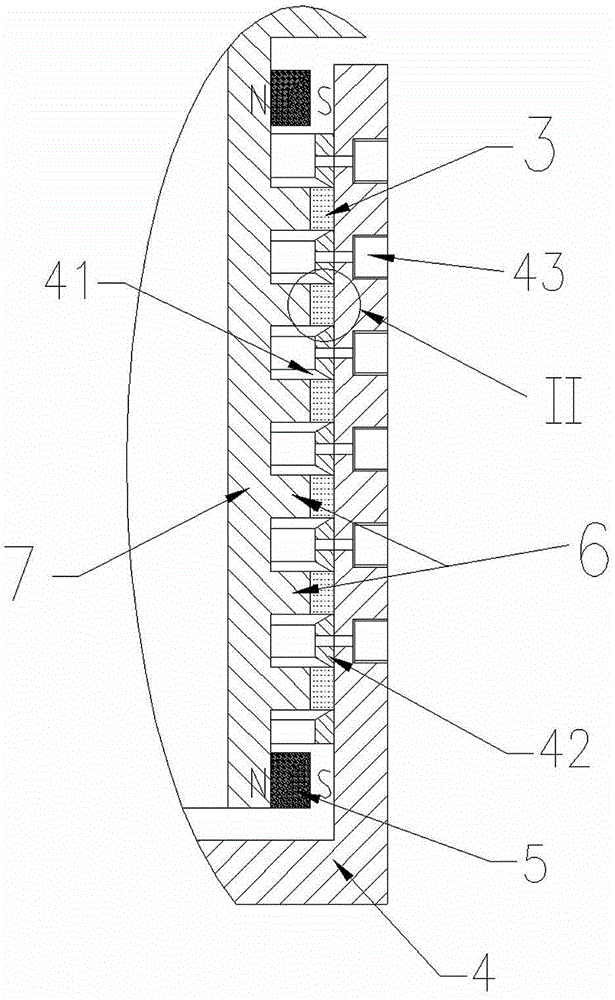

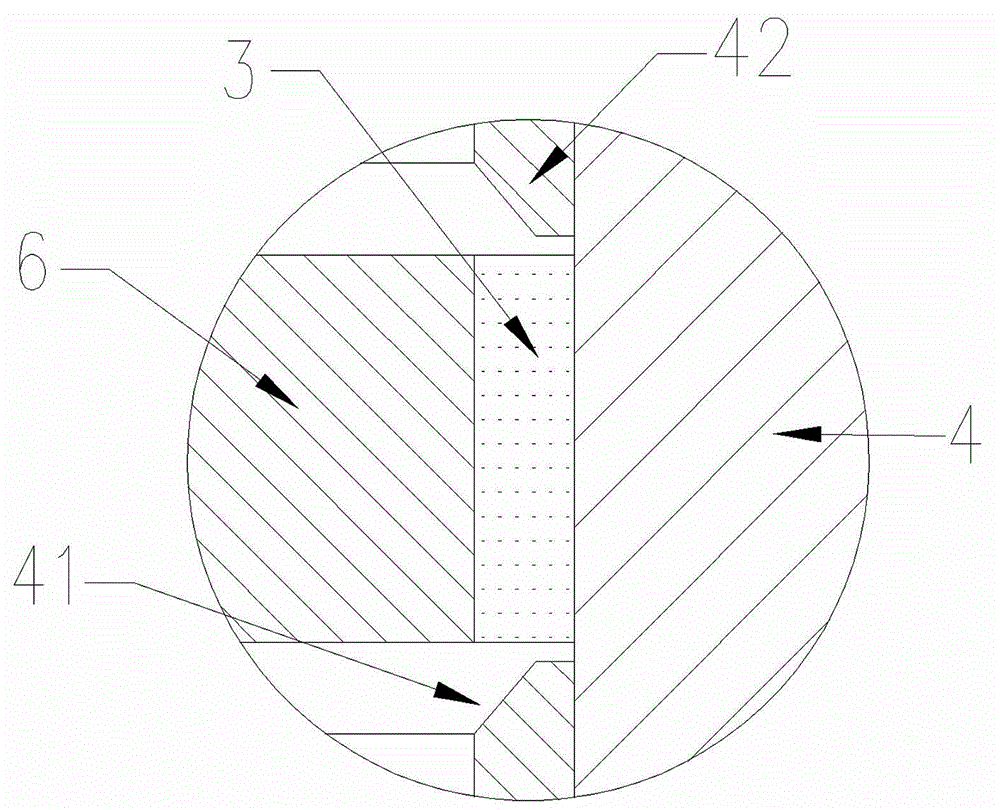

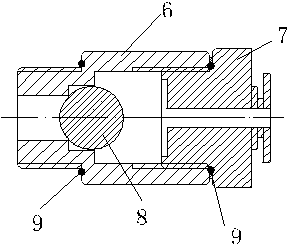

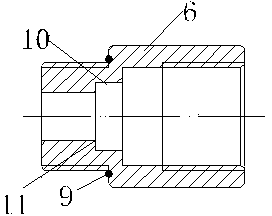

Magnetofluid motive sealing structure suitable for high rotation speed

InactiveCN103343821AGood dynamic sealing effectGood sealing effectEngine sealsPhysicsRotational axis

A magnetofluid motive sealing structure suitable for high rotation speed mainly solves the technical problem that an existing magnetofluid motive sealing structure cannot bear the high rotation speed because the existing magnetofluid motive sealing structure cannot overcome the centrifugal force of magnetofluid. The magnetofluid motive sealing structure suitable for the high rotation speed comprises a cylindrical static magnetic pole (7) and a cylindrical rotation magnetic pole (4) which is sleeved outside the static magnetic pole (7) coaxially. One end of the static magnetic pole (7) is fixed on a machine shell (8), and more than two protruding sealing rings (6) are arranged on the outer surface of a cylinder of the static magnetic pole (7). A rotating shaft (1) penetrates through an axis hole of the static magnetic pole (7) and is fixedly connected with the rotation magnetic pole (4) into a whole. The magnetofluid (3) is arranged in a radial clearance between the sealing rings (6) and the magnetic inner surface of the rotation magnetic pole (4), so that the static magnetic pole (7) is in magnetofluid motive sealing fit with the rotation magnetic pole (4). The magnetofluid motive sealing structure suitable for the high rotation speed has the advantages of being good in sealing effect and heat dissipation performance, and the linear velocity of more than 20meter per second can be borne.

Owner:南京旋妙机械设备有限公司

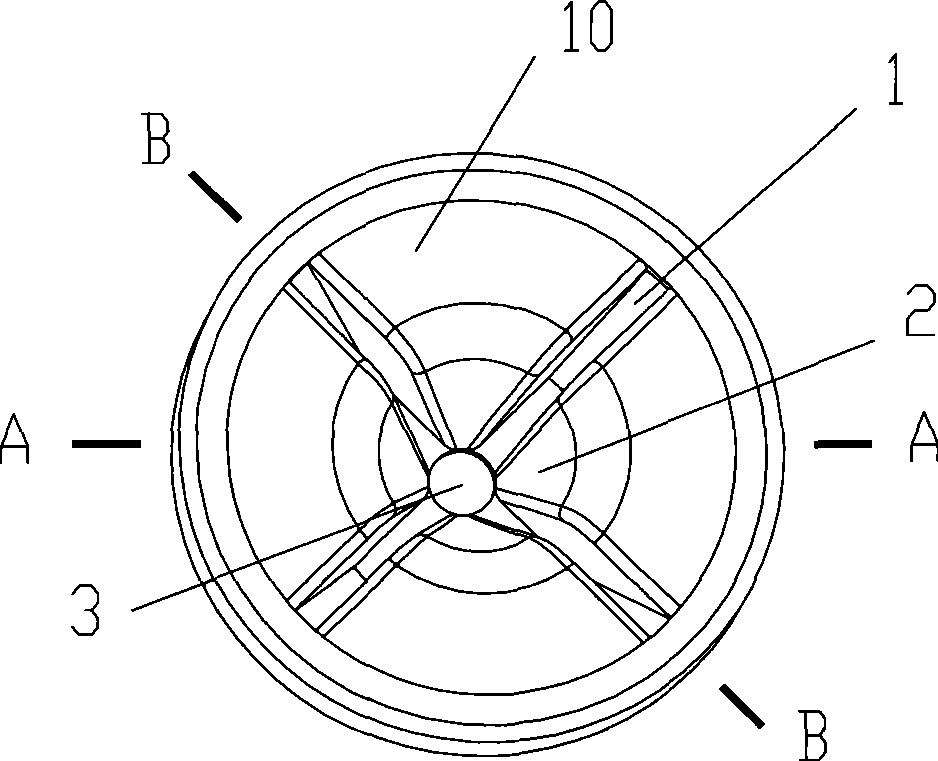

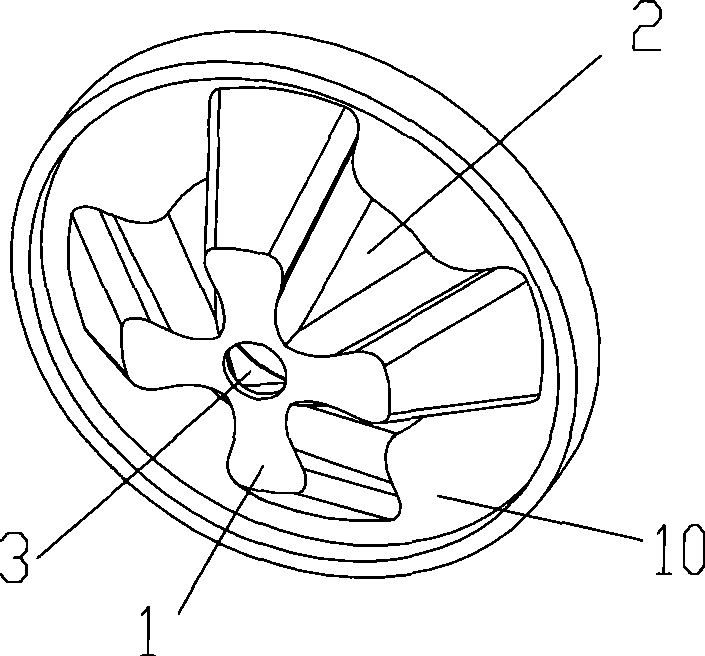

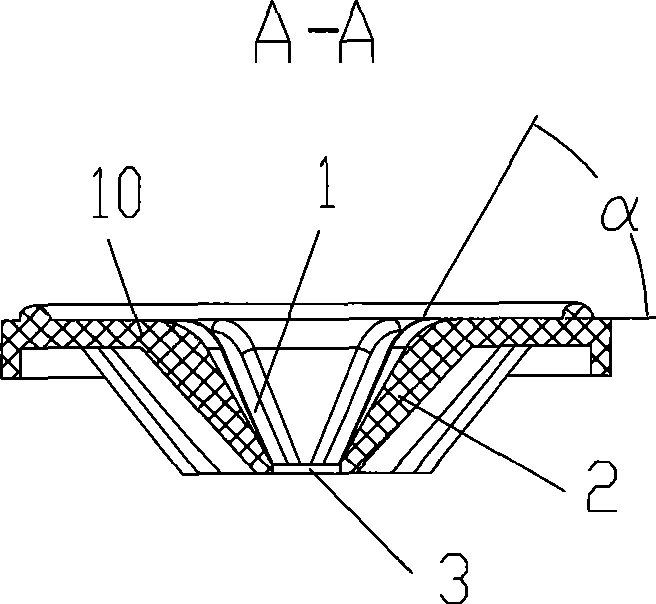

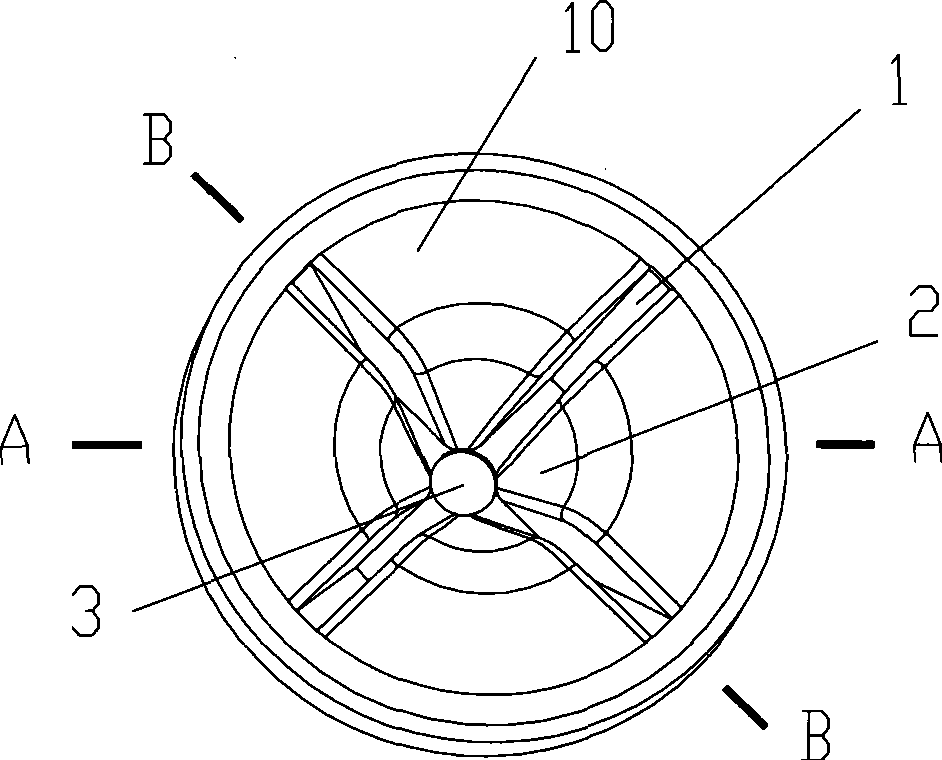

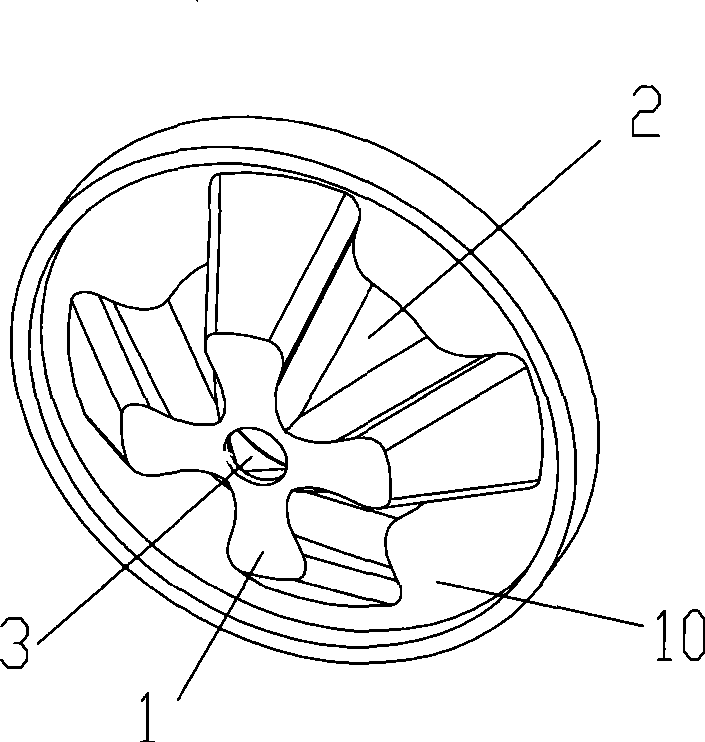

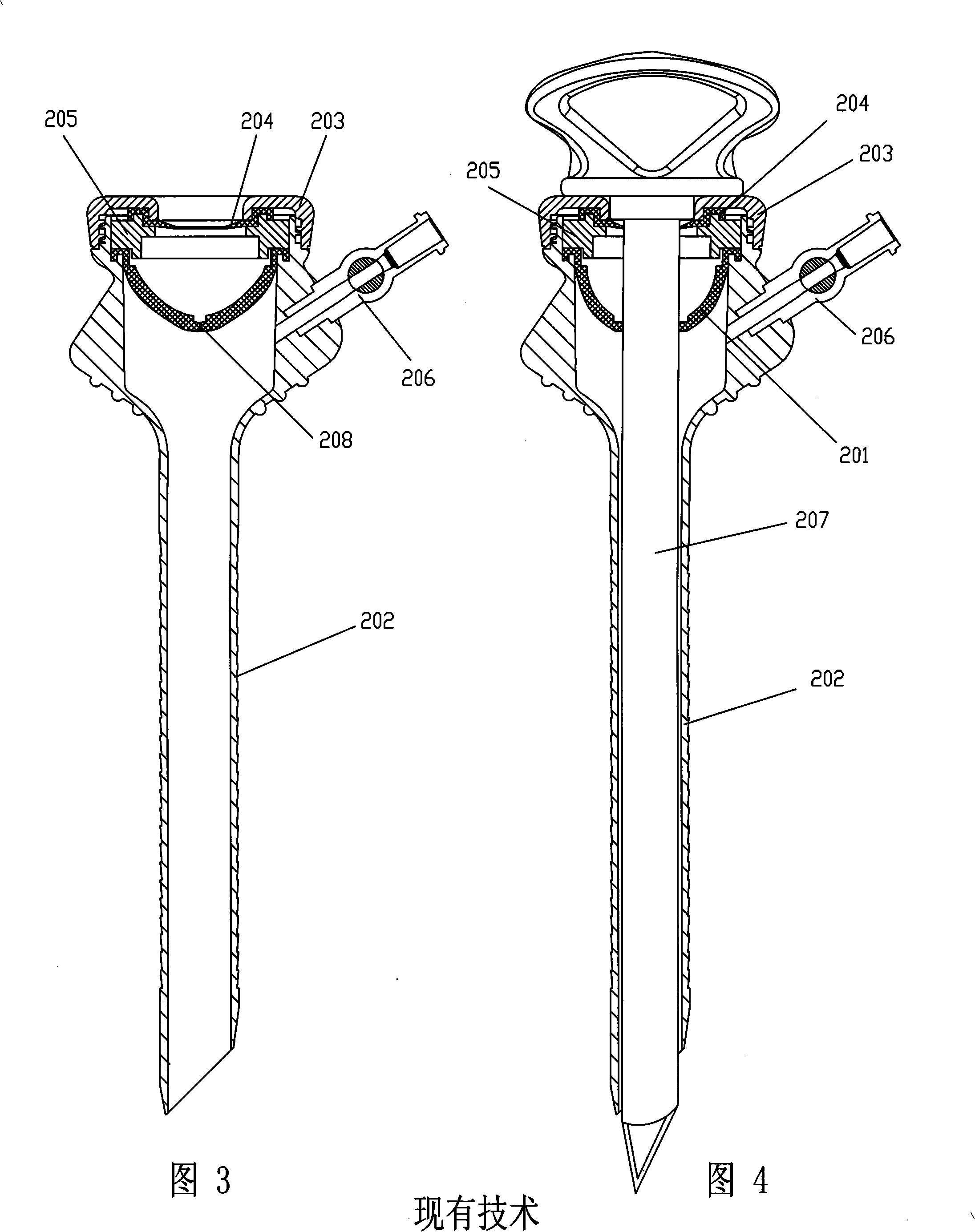

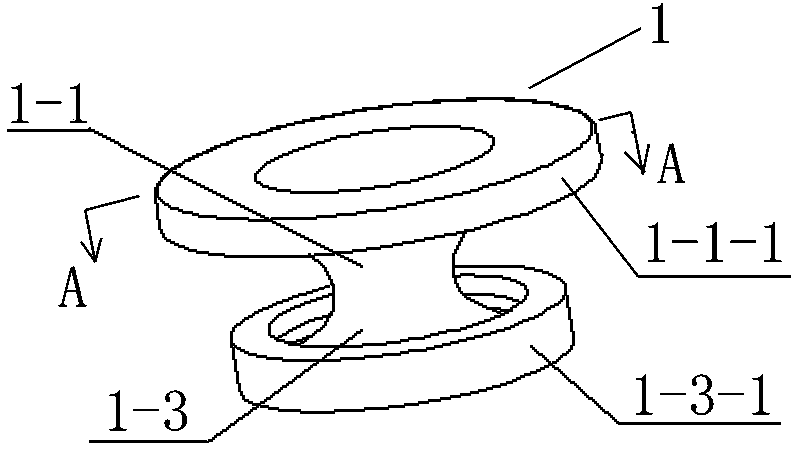

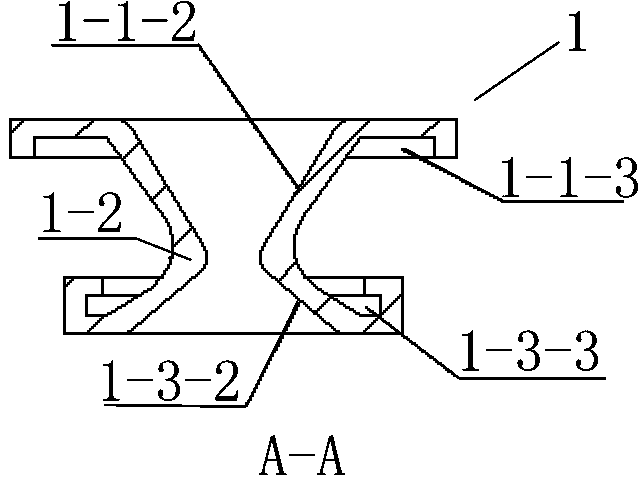

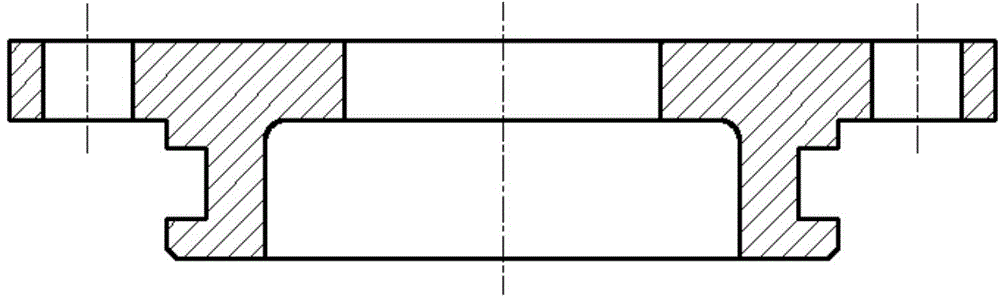

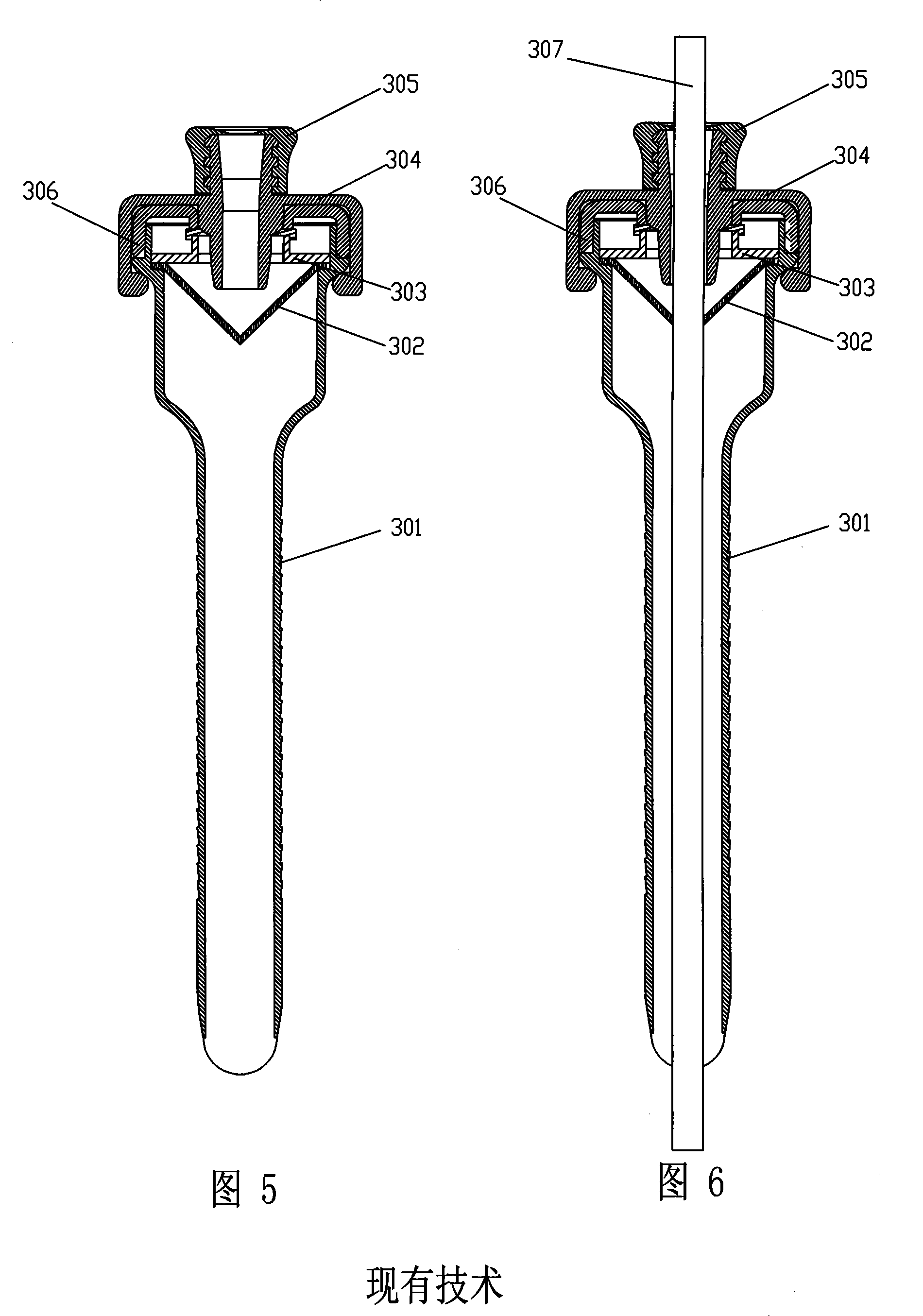

Puncture device general purpose type radial direction seal ring and puncture device

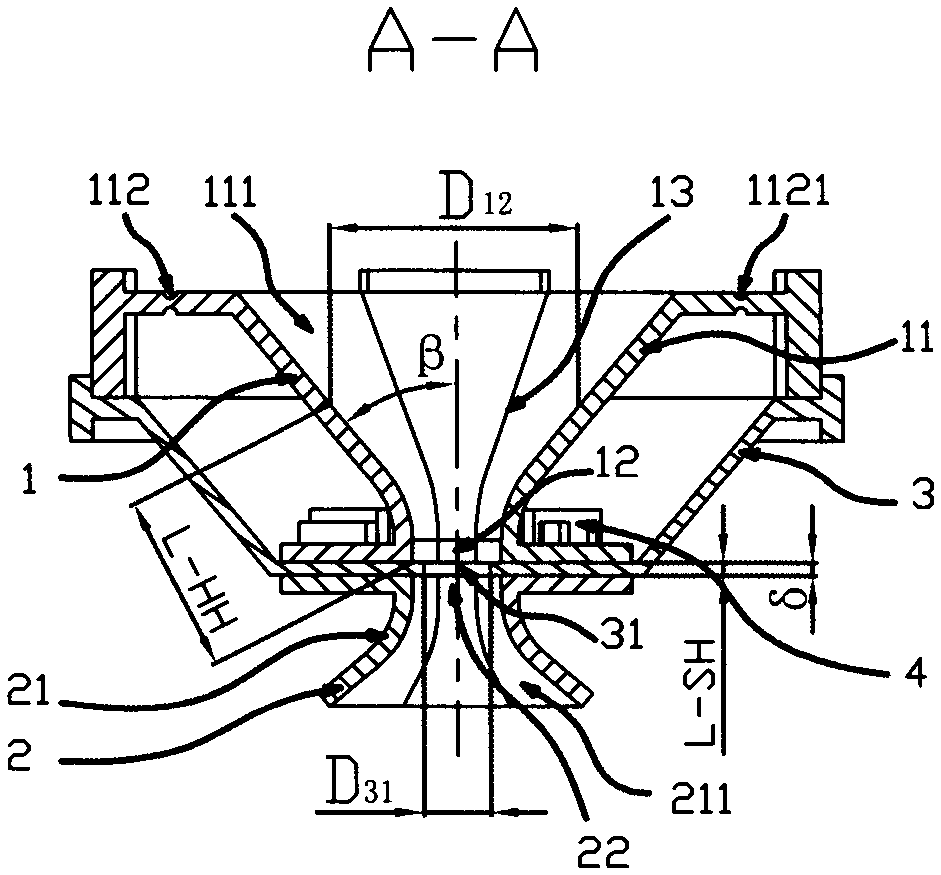

ActiveCN101259030AAny replacementGood dynamic sealSuture equipmentsInternal osteosythesisSurgical operationGeneral purpose

The invention relates to a universal radial sealing ring for a puncture machine. The edge of an inner hole of the sealing ring is provided with a high intensity section and a low intensity section is arranged between the outer edge of the sealing ring and the high intensity section. When a surgical instrument is inserted into the inner hole of the high intensity section, the high intensity section can be closely attached to the surgical instrument; when the surgical instrument is moved or shaken, the low intensity section is transformed, but the high intensity section can be closely attached to the surgical instrument and not transformed, thereby maintaining better dynamic sealing. The structure has the advantage that a random replacing among the surgical instruments with a diameter of 12mm, 10mm and 5mm is realized; surgical operations are convenient.

Owner:周星

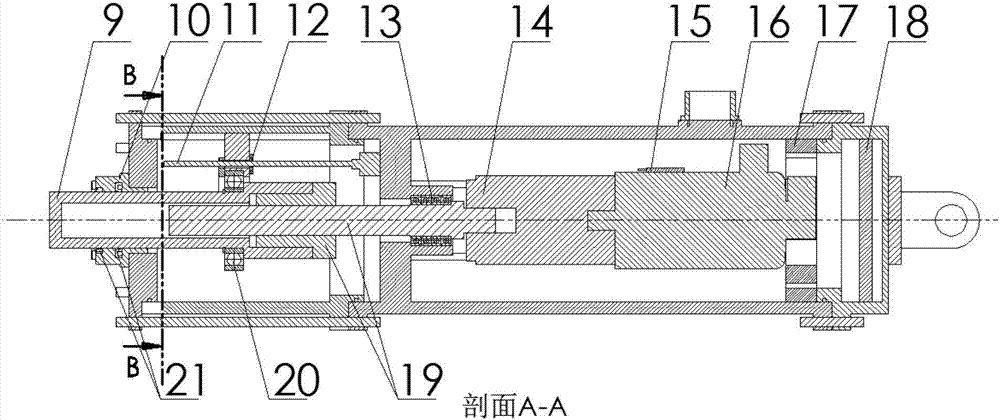

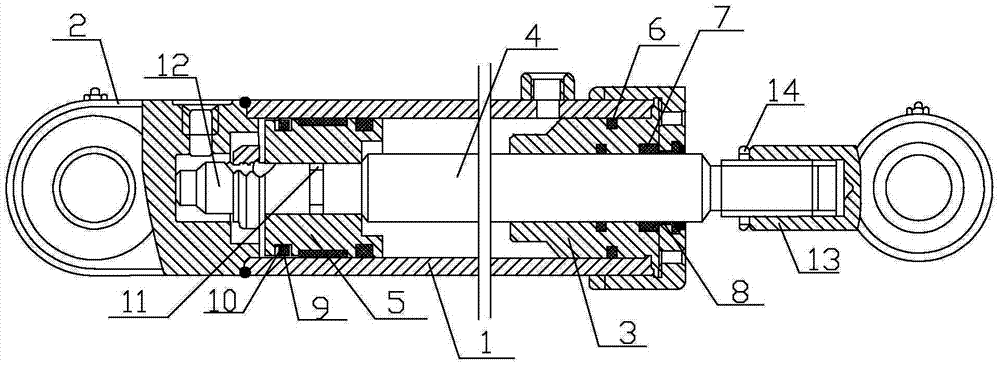

Hydraulic oil cylinder

InactiveCN104747528AGood dynamic sealing effectEasy to flow outFluid-pressure actuatorsElastomerMechanical engineering

The invention relates to engineering machinery common equipment, in particular to a hydraulic oil cylinder. The hydraulic oil cylinder comprises a cylinder barrel, a cylinder bottom, a guide sleeve, a piston rod and a piston, wherein a first seal ring is arranged between the guide sleeve and the cylinder barrel, a first movable seal structure is arranged between the piston rod and the guide sleeve, the first movable seal structure comprises an O-shaped elastomer and a YX-shaped seal ring located behind the O-shaped elastomer, a sealing piece installing groove is formed between the piston and the cylinder barrel, the installing groove is internally provided with a second seal ring and a baffle, and a through hole is formed in the baffle. According to the hydraulic oil cylinder, the first movable sealing structure comprises the O-shaped elastomer and the YX-shaped seal ring located behind the O-shaped elastomer, the seal effect between the piston rod and the guide sleeve is more evident, fluid is easy to flow out by the arrangement of the through hole formed in the baffle of the second seal ring, and the phenomenon that the sealing piece is squeezed out from the installing groove caused by fluid accumulation is prevented.

Owner:施周平

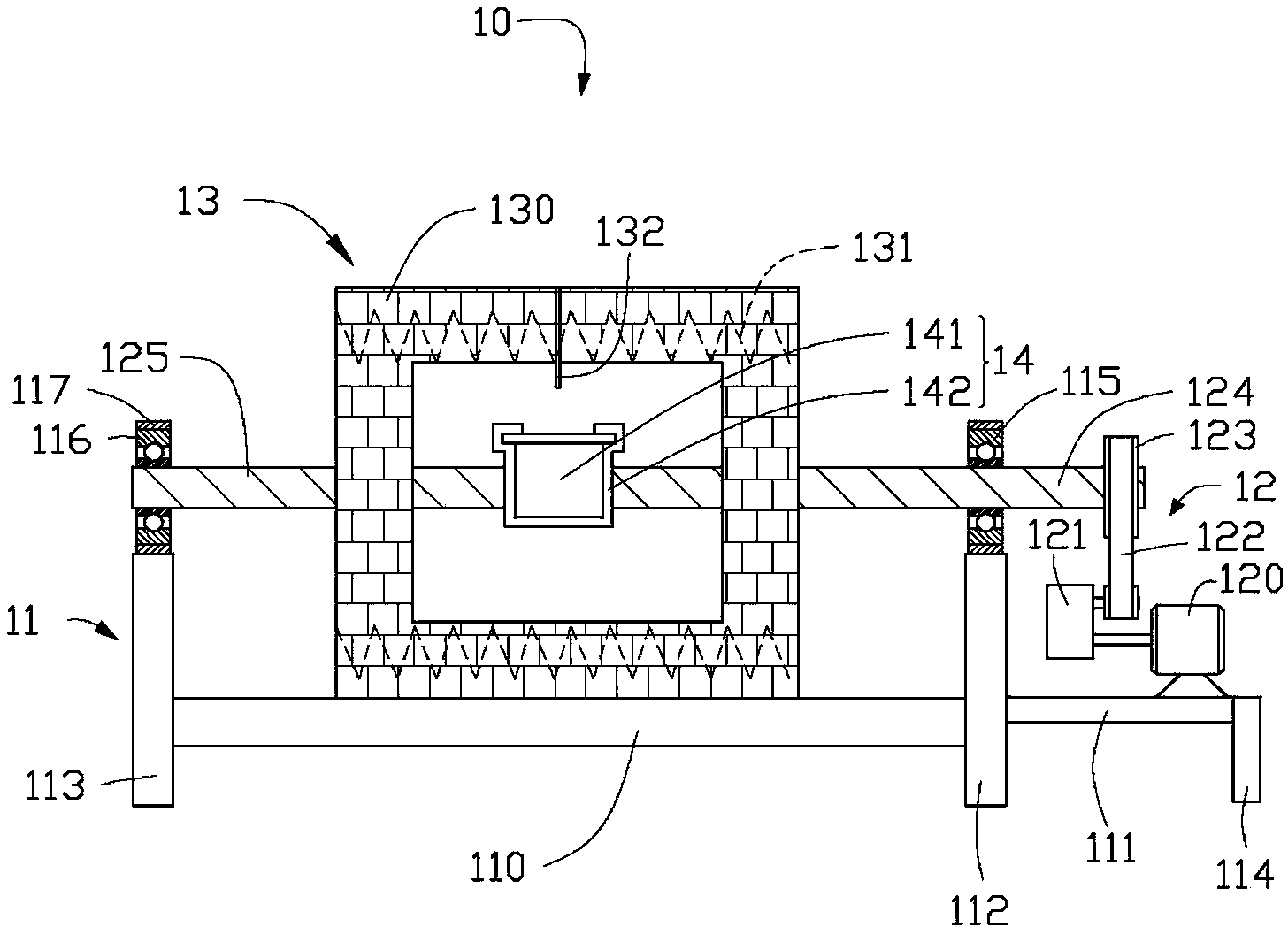

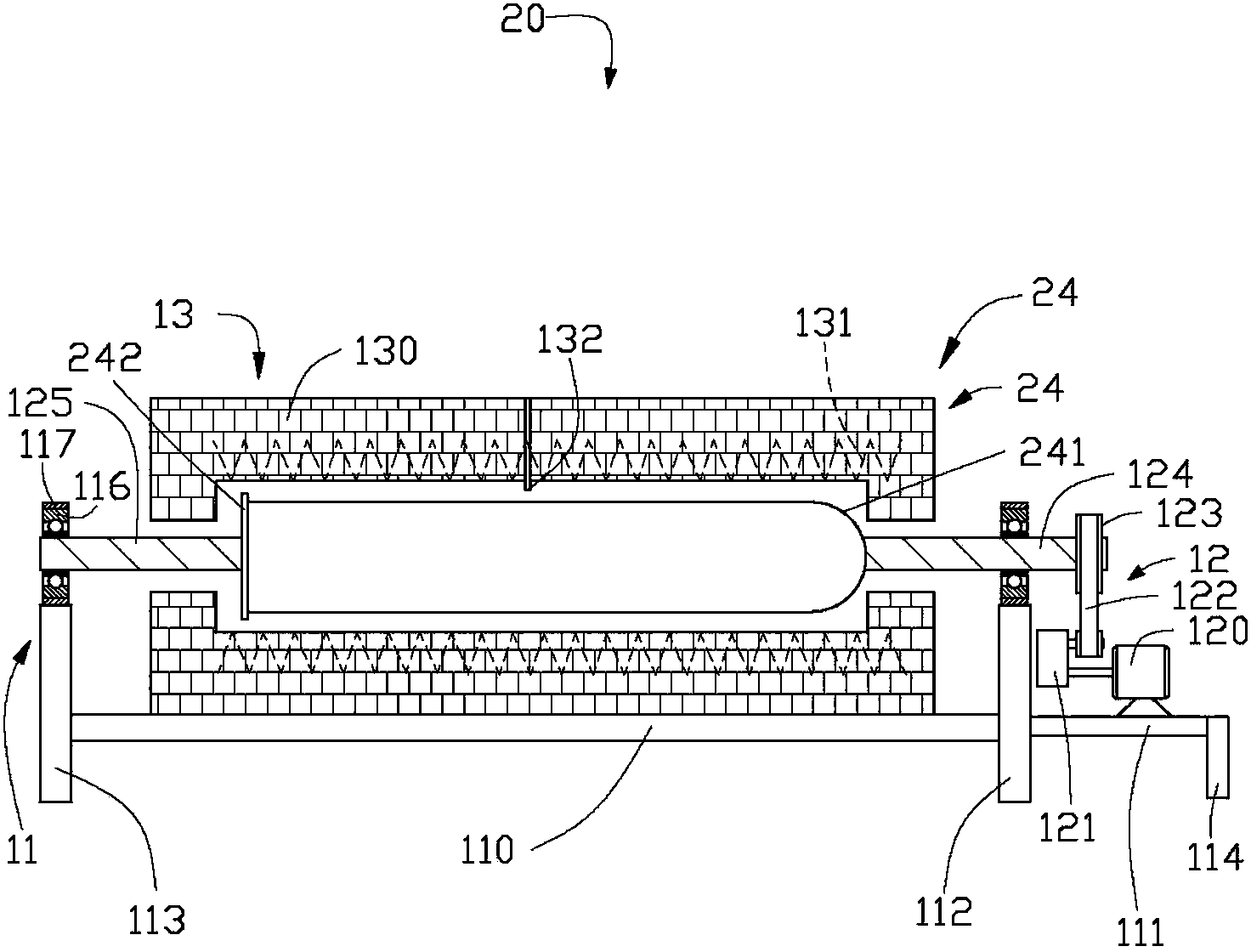

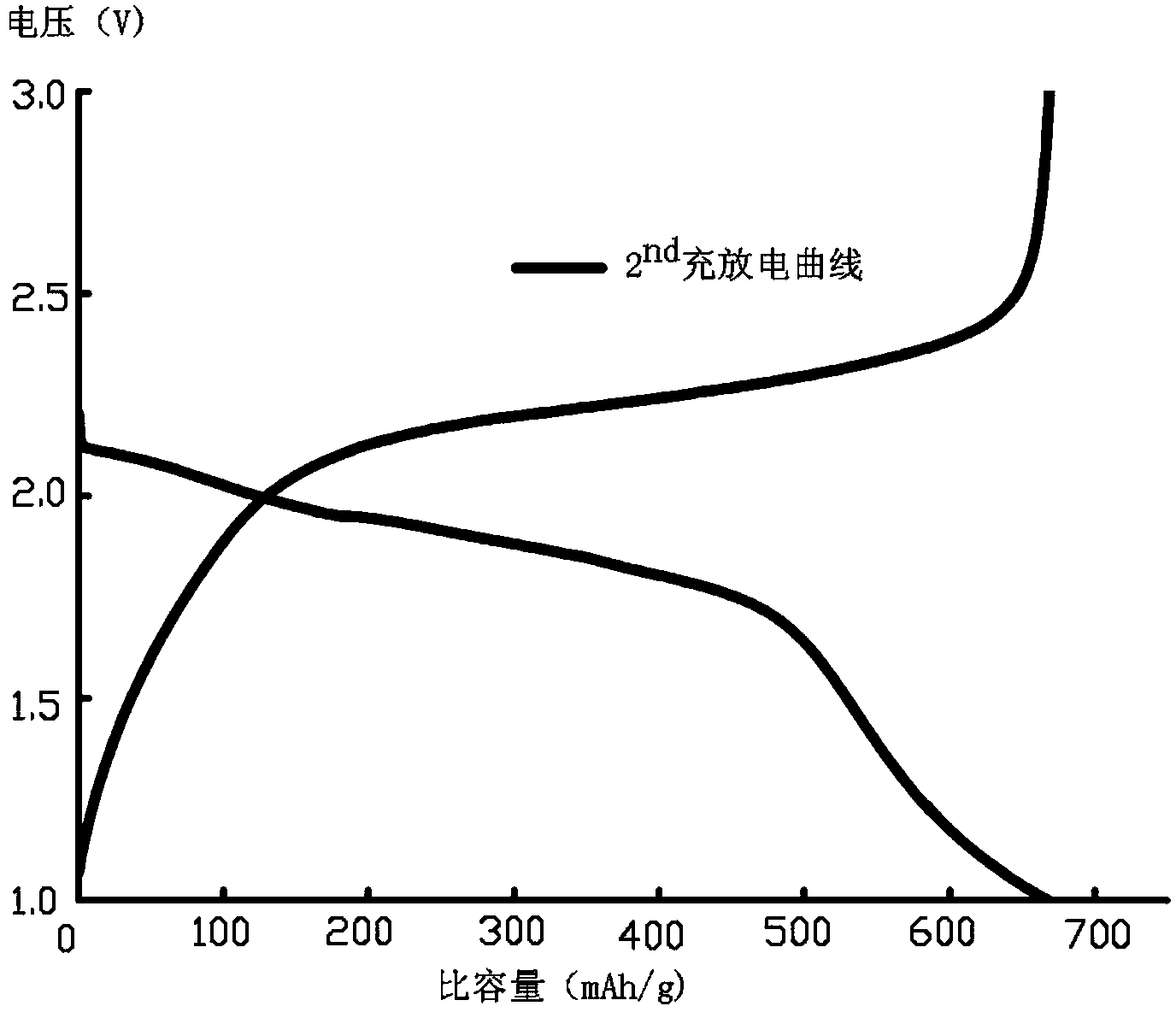

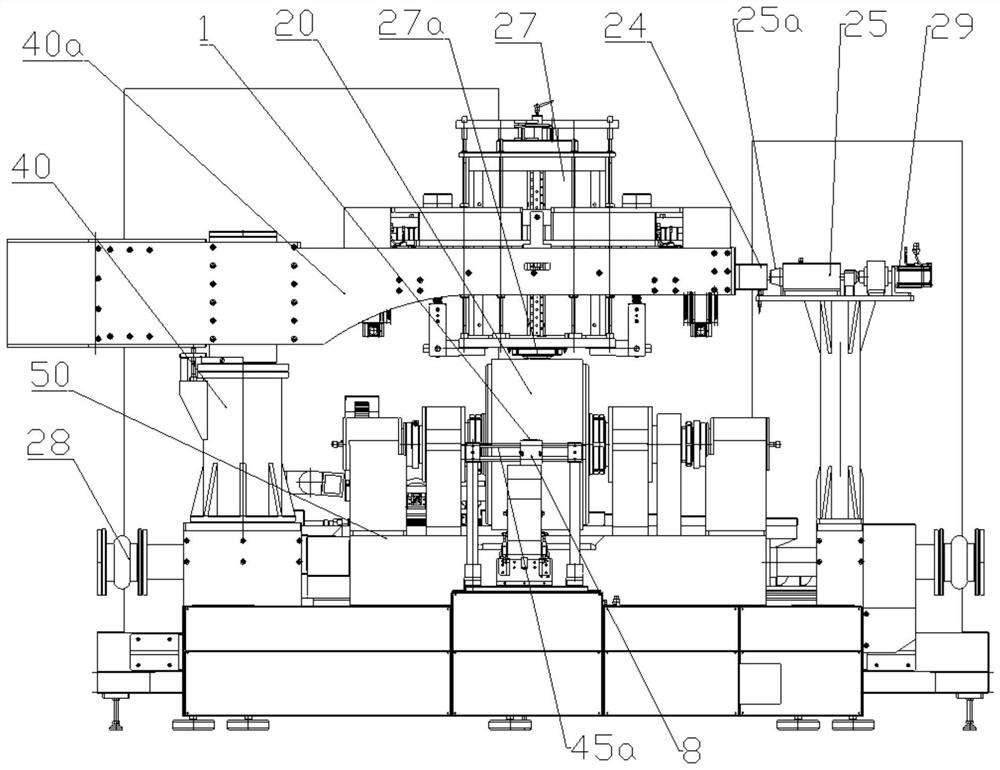

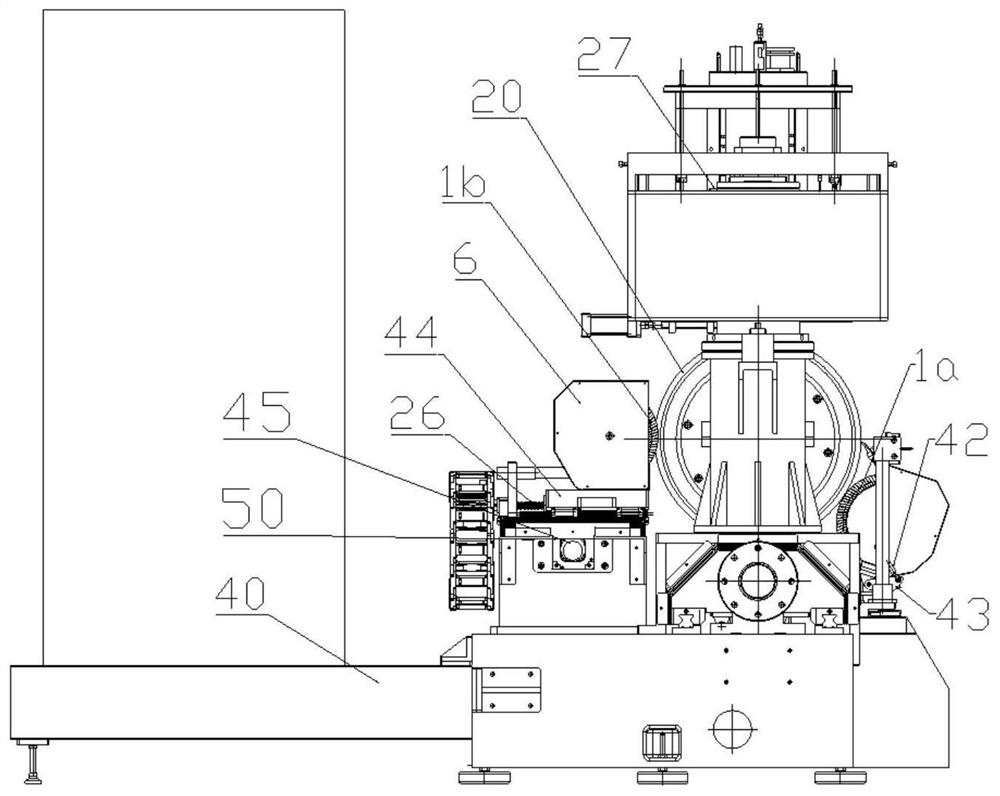

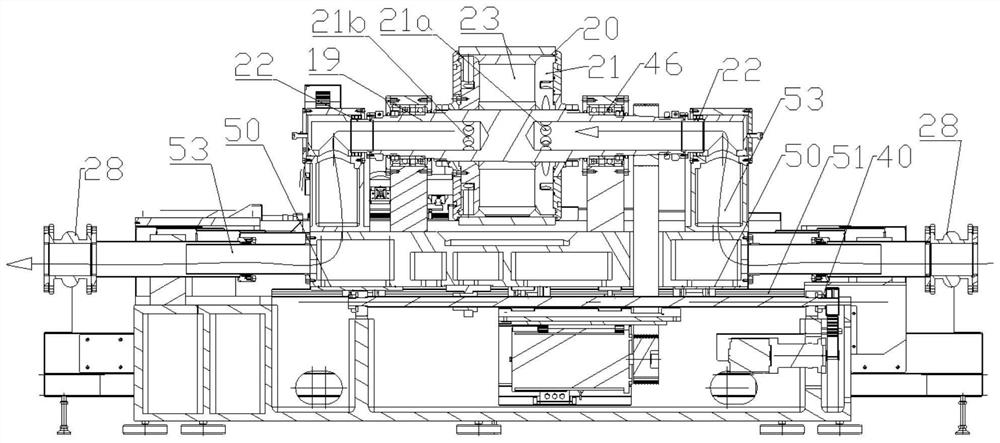

Powder sintering device

The invention relates to a powder sintering device. The powder sintering device comprises a supporting unit, a driving unit, a sintering unit and a reaction unit. The driving unit is arranged on the supporting unit; the reaction unit is arranged inside the sintering unit, can be heated through the sintering unit, is fixed in the driving unit, and can be driven by the driving unit to rotate. In addition, the invention further provides a method for preparing composite materials through the powder sintering device.

Owner:江苏合志新能源材料技术有限公司 +1

Sealing assembly for puncture device and puncture device

ActiveCN103860240AReduce frictional resistanceLow movement resistanceCannulasSurgical needlesMedical equipmentEngineering

The invention relates to medical equipment, in particular to a sealing assembly for a puncture device used in minimally invasive surgery operations such as a laparoscope and a thoracoscope and the puncture device. The sealing assembly for the puncture device comprises a dynamic sealing piece, a supporting frame and a one-way valve. The dynamic sealing piece comprises a sealing piece upper part, a sealing ring and a sealing piece lower part, and the sealing piece upper part, the sealing ring and the sealing piece lower part are integrally connected. The supporting frame is a hollow cylindrical object and is provided with a transverse support and a longitudinal support, and the transverse support and the longitudinal support are integrally connected. The one-way valve is a funnel-shaped sealing ring and is provided with a sealing nozzle, a sealing ring and a reinforcing rib. The sealing nozzle is arranged at the bottom of the one-way valve and is in a linear type, the sealing ring is arranged on the top of the one-way valve, and the reinforcing rib is arranged on the funnel face of the lower portion of the one-way valve. The dynamic sealing piece, the supporting frame and the one-way valve are matched to be connected, and the dynamic sealing piece is fixedly connected with the one-way valve through the supporting frame. The sealing assembly for the puncture device is exquisite in structure, high in reliability, low in cost, good in sealing effect and good in universality.

Owner:南京东万生物技术有限公司

Pithead steam injection anti-leakage sealing device

ActiveCN106639958AEasy to replaceThere will be no partial wearGeothermal energy generationSealing/packingEngineeringHigh pressure

The invention relates to the technical field of pithead anti-jet device, and provides a pithead steam injection anti-leakage sealing device. The device comprises a packing seal assembly, a flexible pipe and a secondary sealing assembly. The lower end of the packing sealing assembly is connected with the secondary sealing assembly through the flexible pipe. The secondary sealing assembly comprises an anti-jet cylinder and a sealing part. The lower end of the flexible pipe is fixedly installed on the upper end of the anti-jet cylinder. At least one sealing part is arranged in the anti-jet cylinder. The sealing part is a high temperature and high pressure resistant sealing part. The pithead steam injection anti-leakage sealing device is reasonable and compact in structure, and convenient to use. The anti-jet cylinder uses the flexible pipe connected with the packing sealing assembly. The camber wear situation between a pole and the sealing part is avoided. At the same time, the applied high temperature and high pressure resistant sealing ring can be used for long term in the high temperature and high pressure environment during the steam injection. The leakage is avoided. The effective sealing is guaranteed. The packing becomes simpler. The automatic lubrication is available. The downhole pressure can be predicted. The pithead steam injection anti-leakage sealing device can improve the effect of the dynamic sealing performance at the pithead packing sealing assembly.

Owner:KARAMAY SHENGLI PLATEAU MACHINERY CO LTD

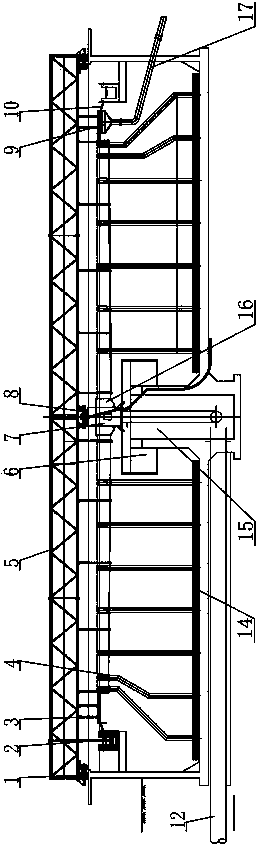

Width-depth range ocean current multi-parameter measuring device

The invention provides a width-depth range ocean current multi-parameter measuring device. The width-depth range ocean current multi-parameter measuring device comprises four functional modules for measuring the flowing direction, the flowing speed, the temperature and the seawater pressure intensity of an ocean current. The flow-direction measuring module is mainly composed of a cross-fluid-shaped guide empennage, a hollow rotating shaft and a rotating transformer. The flow-speed measuring module comprises an impeller, an impeller sensing piece and a proximity switch, and the impeller is driven by the ocean current to rotate. By means of the width-depth range ocean current multi-parameter measuring device, the problems of the pressure intensity at different depths, seawater corrosion and the like can be well solved. Hardware of a lower computer of a monitoring system can collect and process information including the flowing speed, the flowing direction, the temperature and the pressure intensity of the ocean current through a sensor, a high-speed single-chip microcomputer and a signal collecting and processing circuit in real time; changes in parameters are monitored and displayed through a monitoring interface of an upper computer of the monitoring system in real time, and the parameter information is stored. The parameters of the flowing direction, the flowing speed, the temperature, the seawater pressure intensity and the like of the ocean current from shallow sea to deep sea are monitored by the monitoring system in real time, and the importance information is provided for exploring the ocean environment.

Owner:HARBIN ENG UNIV

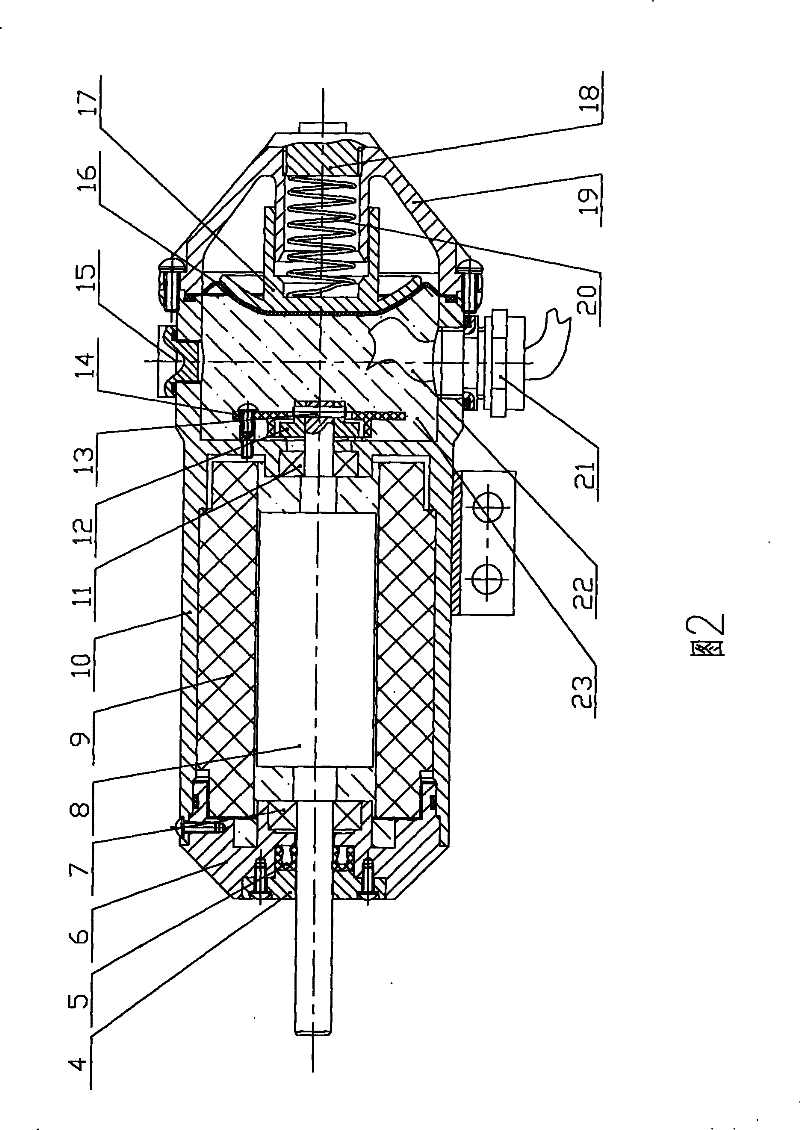

Three-dimensional dynamic water cooling system of spray belt device

PendingCN113587541AImprove product qualityIncrease productivityLighting and heating apparatusCooling fluid circulationCooling effectMechanical engineering

The invention discloses a three-dimensional dynamic water cooling system of a spray belt device. The three-dimensional dynamic water cooling system comprises a cooling inner cavity arranged in a copper roller, dynamic seal connecting devices and hollow shafts which communicate and are connected between the cooling inner cavity of the copper roller and the corresponding dynamic seal connecting devices and fixedly connected with the copper roller; the dynamic seal connecting devices are arranged on a sliding frame, and the hollow shafts are arranged on the sliding frame through corresponding bearing devices; and the sliding frame is arranged on a rack slidably. The three-dimensional dynamic water cooling system of the spray belt device is simple and reasonable in structure, excellent in overall structural performance and good in cooling effect.

Owner:宜春市龙腾机械电气有限公司

Puncture device general purpose type radial direction seal ring and puncture device

ActiveCN101259030BAny replacementGood dynamic sealSuture equipmentsInternal osteosythesisSurgical operationGeneral purpose

The invention relates to a universal radial sealing ring for a puncture machine. The edge of an inner hole of the sealing ring is provided with a high intensity section and a low intensity section is arranged between the outer edge of the sealing ring and the high intensity section. When a surgical instrument is inserted into the inner hole of the high intensity section, the high intensity section can be closely attached to the surgical instrument; when the surgical instrument is moved or shaken, the low intensity section is transformed, but the high intensity section can be closely attached to the surgical instrument and not transformed, thereby maintaining better dynamic sealing. The structure has the advantage that a random replacing among the surgical instruments with a diameter of 12mm, 10mm and 5mm is realized; surgical operations are convenient.

Owner:周星

Magnetic fluid dynamic seal structure suitable for high speed

Owner:南京旋妙机械设备有限公司

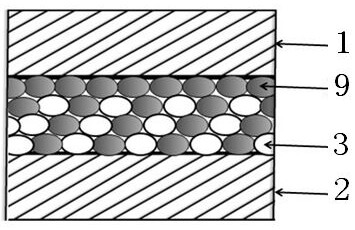

Water lubricating dynamic sealing rubber alloy bearing

InactiveCN1719058AExtended service lifeSimple structureBearing componentsSliding contact bearingsAlloyLubrication

The present invention relates to a water lubrication slip-sealing rubber alloy bearing. It is formed from external shell made of metal or non-metal material and interior structure formed from special rubber alloy internal liner bushing and slip-sealing body which are combined into one body. Said invention also provides the concrete interior structure of said liner bushing and said shell body.

Owner:重庆奔腾科技发展有限公司

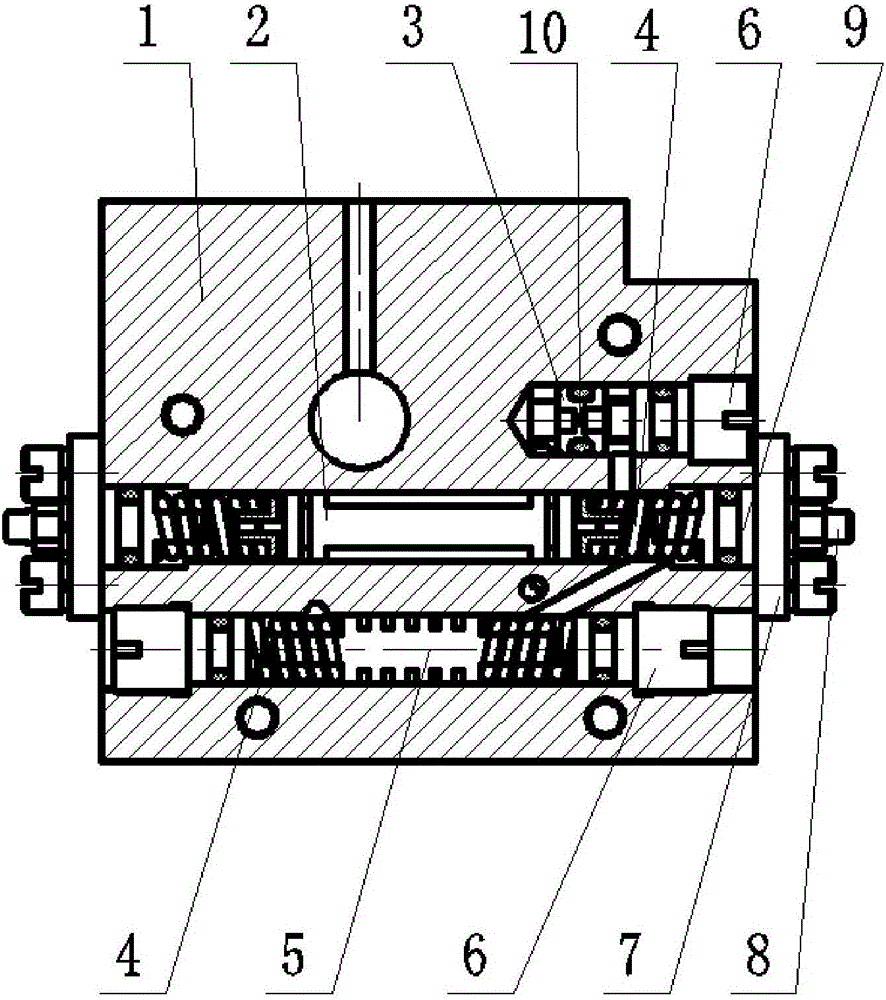

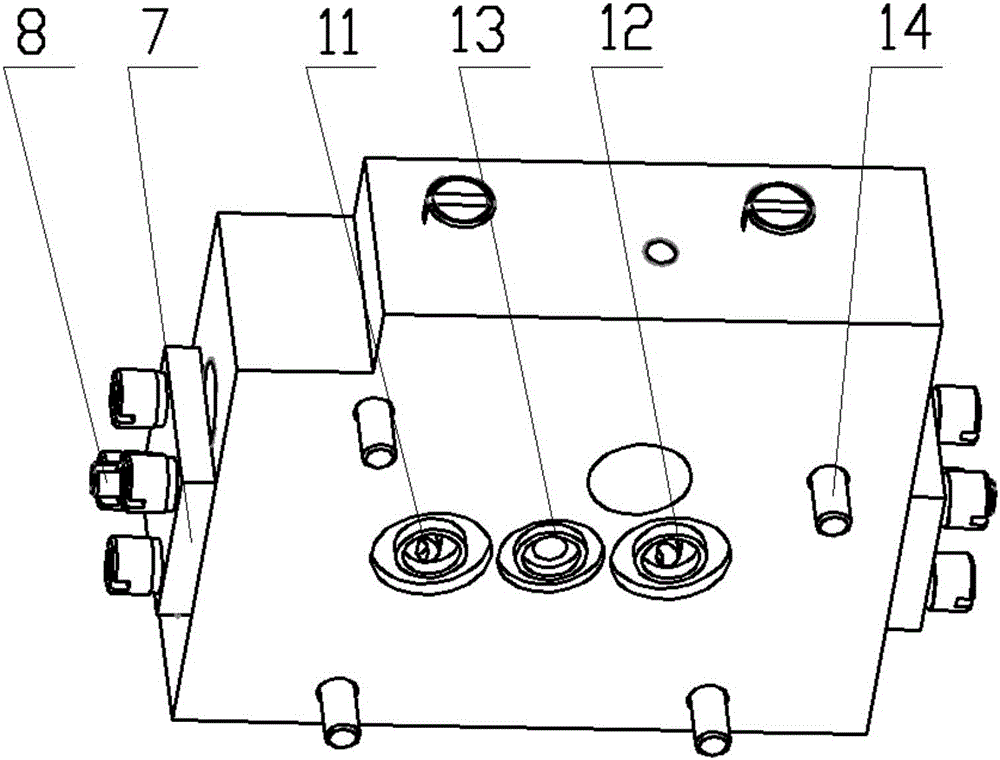

Hydraulic system dynamic correction device capable of effectively inhibiting load resonance

ActiveCN105156404AResonant Peak Suppression FunctionEasy dockingFluid-pressure actuator testingServomotor componentsHydraulic cylinderResonance

The invention relates to a hydraulic system dynamic correction device capable of effectively inhibiting load resonance, which comprises a shell, a throttling valve core, a damping hole, a spring, a pressure storage valve core, a plug, a cover plate, an adjusting bolt and the like. The hydraulic system dynamic correction device is used in a hydraulic control system, and increases the system damping under high frequency by the matching design of the spring stiffness, damping hole, pressure storage valve core and throttling valve core, thereby inhibiting the load resonance. As an independent functional block, the hydraulic system dynamic correction device can effectively inhibit the high-frequency resonance on the premise of ensuring the low-frequency phase to be basically unchanged, has the advantages of compact structure and simple interface, and can be conveniently installed on the hydraulic cylinder.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Novel drum brake wheel cylinder structure

InactiveCN109027065AExtended service lifeGuaranteed OrientationBrake actuating mechanismsActuatorsWheel cylinderMechanical engineering

The invention relates to a novel drum brake wheel cylinder structure, and belongs to the technical field of automobile braking. A first wheel cylinder piston and a second wheel cylinder piston are assembled on the two sides of a wheel cylinder hole respectively, and a wheel cylinder is in clearance fit with the first wheel cylinder piston and the second wheel cylinder piston. A first sealing function piece is connected with the first wheel cylinder piston and the wheel cylinder separately, and a second sealing function piece is connected with the second wheel cylinder piston and the wheel cylinder separately. Two leather cup mounting grooves are formed in an inner hole of the wheel cylinder, the first leather cup and the second leather cup are arranged in the leather cup mounting grooves of the wheel cylinder respectively, and a wheel cylinder spring is installed between the first wheel cylinder piston and the second wheel cylinder piston. The first wheel cylinder piston and the secondwheel cylinder piston are provided with outer cylindrical surfaces. The novel drum brake wheel cylinder structure has the advantages that the structure is novel, the axial matching length of the wheel cylinder pistons and the wheel cylinder hole is increased, the guide performance of the wheel cylinder hole to the wheel cylinder pistons is kept, and the eccentric abrasion phenomenon of the wheelcylinder pistons in the braking process is relieved, so that the higher the roughness grade of the outer surfaces of the wheel cylinder pistons is, the better the dynamic sealing performance of the wheel cylinder pistons is.

Owner:JILIN DONGGUANG AOWEI AUTOMOBILE BRAKE SYST

Bellows clamp valve with splittable tube body and dynamic sealing

PendingCN107300022AHigh thermal conductivityImprove fatigue resistanceDiaphragm valvesFlanged jointsFiberWasher

The invention discloses a bellows clamp valve with a splittable tube body and dynamic sealing, comprising a composite tube body and tube joint flanges connected to the two ends of the composite tube body, wherein the composite tube body includes a reinforcing fiber layer, a stainless steel bellows layer and an outer anti-aging rubber layer which are arranged sequentially from inside to outside, and each tube joint flange includes a flange disc portion and a connection barrel portion, wherein the side of the flange disc portion facing the composite tube body is also provided with a circular groove, and an extrusion washer is arranged in the circular groove; the inner wall of the composite tube body is compressed to the inner wall of the connection barrel portion of each tube joint flange through a compressive bushing; the extrusion washers and the flange disc portions of the tube joint flanges are fixedly connected through a plurality of matched bolt and self-locking nut sets; the connection barrel portions of the tube joint flanges are fixedly connected to the composite tube body and the compressive bushings through a plurality of ball-head screws. The bellows clamp valve of the invention provides improved heat conductivity, fatigue resistance, improved disassembly performance for maintenance and corrosion resistance for a bellows clamp.

Owner:NANTONG YANGZI RUBBER & PLASTIC

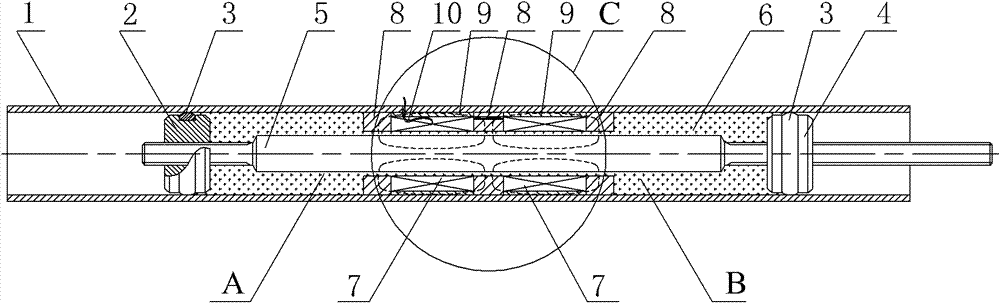

Compact light-weight double-piston magnetorheological damper

InactiveCN102425638BSimple structureReduce the total massNon-rotating vibration suppressionSemi activeVibration control

The invention discloses a compact light-weight double-piston magnetorheological damper, which relates to a magnetorheological damper and is used for solving the problems of large structural size and large weight of the conventional magnetorheological damper. In a scheme I, a first dynamic seal piston, three magnetic loop rings and a second dynamic seal piston are arranged in an outer bushing in sequence from left to right; the two dynamic seal pistons are connected with each other through a connecting rod; an excitation coil is arranged between the two magnetic loop rings, and is fixed between the two magnetic loop rings through an outer ring sleeve; a magnetorheological cavity is formed among the outer bushing, the first dynamic seal piston and the second dynamic seal piston, and is filled with a magnetorheological fluid; and an annular throttling channel is formed between the inner end faces of the magnetic loop rings and the excitation coil and the outer cylindrical surface of the connecting rod. The difference between a scheme II and the scheme I is that: an annular throttling channel is formed between the outer cylindrical surface of the connecting rod and the inner end face of a U-shaped annular groove bottom plate. The magnetorheological damper is particularly suitable for small-load mass vibration isolation and semi-active vibration control over a light structure.

Owner:HARBIN INST OF TECH

Vertically-mounted food discharging valve

InactiveCN104235389APrevent jumpingAvoid drippingOperating means/releasing devices for valvesFrozen sweetsEngineeringValve seat

The invention discloses a vertically-mounted food discharging valve which comprises a valve seat (6), a quick-plug connector (7) and a valve ball (8). The quick-plug connector is connected to the position of a discharging hole at the upper end of the valve seat, the valve ball is mounted in a guide hole (10) in the valve seat, and the guide hole is arranged between a feeding hole and the discharging hole in the valve seat. The valve ball is closed and sealed and can be vertically assembled on a valve assembly of a feeding cart, a plurality of discharging valves are totally identical in discharging weight, product quality in production is greatly improved, filling accuracy is quite high with + / -0.1g error, and yield of products reaches up to more than 98%. Production cost is lowered, connection is fast, great convenience is brought to users, and production efficiency is effectively improved.

Owner:LUOYANG ZHIZHEN COLD FOOD MASCH FACTORY

Underwater seal device

The invention discloses an underwater sealing device, which is characterized in that it comprises: a housing, a first end cover (7) and a first sealing ring (8); the housing has an assembly cavity, and the first end The cover (7) is connected to the housing; the first end cover (7) has a first matching hole, and the first end cover (7) is installed on the The fitting (9) in the first fitting hole constitutes a dynamic seal. The beneficial effects achieved by the present invention are: better dynamic sealing effect can be provided, and at the same time, medium intrusion can be prevented through static sealing when the dynamic sealing fails.

Owner:南京恒兴达机电设备制造有限公司

Compensated underwater brushless DC motor structure and assembly method thereof

InactiveCN101752937BImprove reconfigurabilityEasy maintenanceStructural associationSupports/enclosures/casingsUnderwaterEngineering

The invention relates to a compensated underwater brushless DC motor structure and an assembly method thereof. The motor structure comprises a motor end cover subassembly (1), a motor main body (2) and a compensator device (3), wherein the motor end cover subassembly (1) is positioned at the front end of the motor main body (2) and is fixedly connected with the motor main body (2) via bolts, the compensator device (3) is positioned at the tail of the motor main body (2) and connected with the motor main body (2) via bolts, and the compensator device (3) comprises a compensator skin (16), a compensator gland bush (17), a motor tail hood (19), a compensator spring (20) and a compensator screw cap (18). The motor structure has modularized design characteristic, the compensator device and themotor main body can be separated, and different compensator devices can be correspondingly adjusted or replaced for meeting different work environmental requirements so that the motor structure has the advantages of simple and compact structure, convenient assembly and debugging, and safe and reliable working and easy maintenance.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

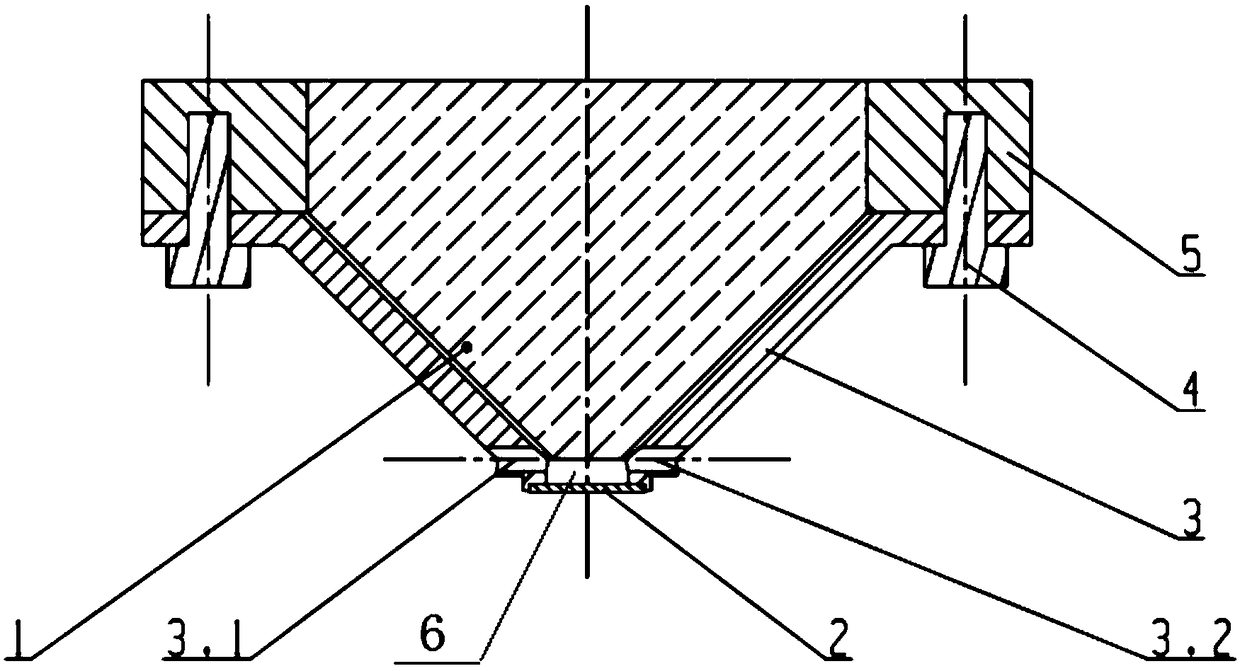

Immersion head with protective glass

PendingCN109407474AAvoid corrosionCause corrosionPhotomechanical exposure apparatusMicrolithography exposure apparatusImage resolutionProtective glasses

The invention relates to an immersion head with protective glass. The immersion head comprises an immersion head base and the protective glass. The upper edge of the immersion head base is fixedly connected with a lens barrel. The bottom end of the immersion head base is provided with a through hole. The protective glass is bonded at the bottom end of the through hole in the sealing mode. A gap between the bottom of a last objective lens and the protective glass serves as a liquid receiving cavity, and an injection hole is processed in the immersion head base at the position corresponding to the liquid receiving cavity. The immersion head can prevent an immersion solution from causing corrosion to the objective lens, and can effectively protect the objective lens while increasing the resolution of the objective lens.

Owner:CHANNGCHUN CHANGGUANG ADVANCED OPTICS TECH CO LTD

Sealing structure for sludge collecting cylinder and central post of sludge scraping suction dredger

ActiveCN102743904BPrevent leakageExtend your lifeSettling tanks feed/dischargeSedimentation settling tanksAbnormal tissue growthRubber ring

The invention discloses a sealing structure between a mud collection cylinder and a center column of a scraper and suction mud machine. A rubber ring is fixed on the outer peripheral surface of the center column through flanges and fasteners, and the bottom wall of the mud collection cylinder is directly placed on the rubber ring. On the upper surface, the two are compressed by internal and external pressure to realize dynamic sealing during rotation. The present invention utilizes the bottom surface of the bottom wall of the mud collecting cylinder and the upper surface of the rubber ring to be frictionally and rotationally sealed, the contact surface is relatively large, and the water level in the pool and the mud level difference of the mud collecting tank are used to compress and seal, so a good dynamic sealing effect can be obtained to prevent Leakage of clean water. And it is not easy to wear, which effectively improves the life of the seal. The joints of the upper and lower layers of rubber rings in the present invention are staggered, which not only prevents sludge from leaking from the joints, but also facilitates maintenance, greatly reduces the consumption of manpower and material resources, and has significant economic value.

Owner:江苏通用环境工程有限公司

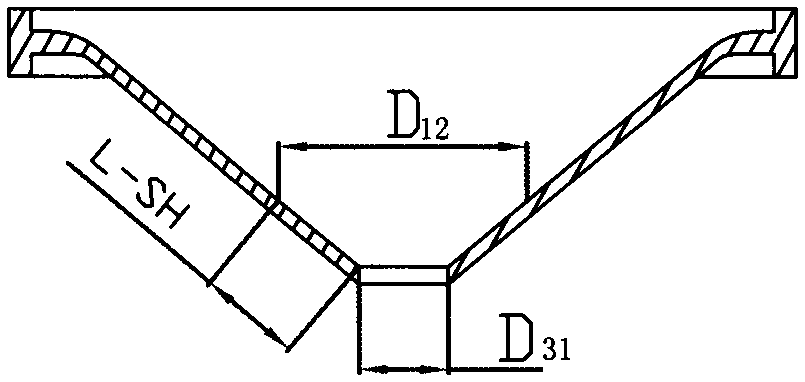

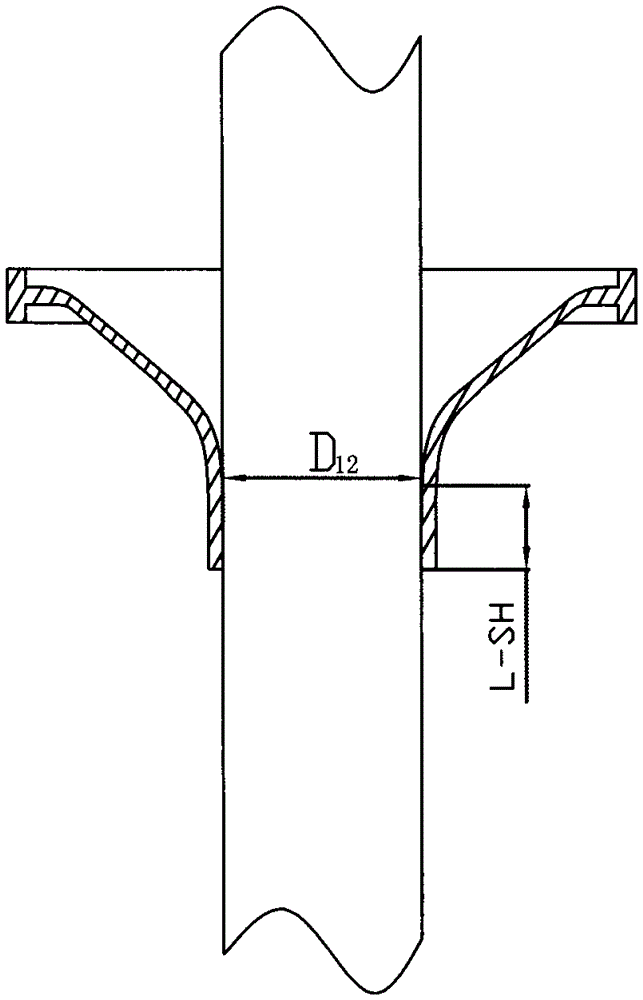

Low resistance universal seal and trocar for trocar

ActiveCN102525600BReduce contact areaLow movement resistanceCannulasSurgical needlesEngineeringSurgical device

The low-resistance general-purpose sealing device and trocar used for the trocar, because the sealing ring is compressed between the upper guide mechanism and the lower guide mechanism, through the smooth transition between the upper guide mechanism and the lower guide mechanism, the maximum The structure that reduces the contact area between the sealing ring and the surgical instrument not only has a guiding function when the surgical instrument enters or exits, it is suitable for the insertion and withdrawal of surgical instruments of various shapes; The soft-hard friction zone can be transformed into the "hard-hard" friction zone between the plastic of the upper and lower guide surfaces and the metal sheath of the surgical instrument to the greatest extent, which greatly reduces the movement resistance and has a good sealing effect. At the same time, the sealing device and the puncture device of the present invention can use instruments with any diameter between 5 mm and 12 mm to achieve its versatility.

Owner:GUANGZHOU T K MEDICAL INSTR

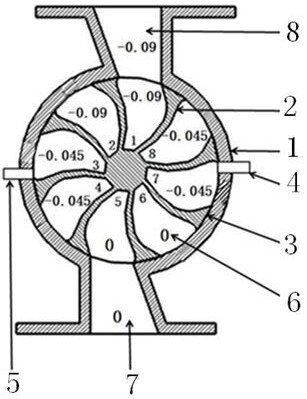

High air tightness type air closer

The invention discloses a high air tightness type air closer. The high air tightness type air closer comprises a valve body, a rotating impeller and a motor, wherein the motor is fixed on a rear sidecover of the valve body; the rotating impeller is installed inside the valve body; a transmission shaft, extending out of the rear side cover of the valve body, of the rotating impeller is fixed on amotor shaft of the motor; a storage bin, consists of partition plates, a side plate and a sealing plate, positioned on the rotating impeller is provided with a small opening and a large middle part; and the aperture of the storage bin opening on the rotating impeller is reduced by the upper ends of the arc-shaped sectors of the partition plates and the sealing plate. The partition plates of the rotating impeller and a sealing device on the sealing plate are attached to a shell in the valve body, the attachment sealing area among the partition plates of the high-speed rotating impeller, the sealing device on the sealing plate and the shell in the valve body is large, the motor drives the transmission shaft of the rotating impeller to rotate, the better dynamic sealing effect of the sealingdevice can be achieved through the pressure buffering support of rubber and the sealing of hard materials, and the sealing air tightness of the dynamic sealing is high when the rotating impeller rotates; and the air closer is strong in practicability and wide in application range.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Drain valve sealed by pressure-equalizing water film

PendingCN114763793AEvenly dispersedGood capillary actionPump componentsRadial flow pumpsImpellerExhaust valve

The drain valve sealed by the pressure-equalizing water film comprises a valve body, an impeller, a porous material and a guide pipe. One side of the porous material is fixed on the surface of the impeller, and the other side is attached to the inner wall of the valve body. The motor drives the impeller to rotate and work, a water film adheres to the inner wall of the valve body, water film sealing is conducted between the impeller and the inner wall of the valve body through water in the porous material, and the air density of surface tension sealing is high. An intake valve and an exhaust valve on the valve body are communicated through a guide pipe, and different pressures in two water cabins, corresponding to the guide pipe, in the impeller are equalized; the pressure difference between the pressures in the adjacent water cabins above and below the impeller is small, the water film on the valve body also plays a role in lubrication, the friction force between the impeller and the valve body is reduced, and the power of a motor driving the impeller to rotate is also reduced. Impurities on the surface of the porous material are cleaned under the scouring action of water. Adjustment can be carried out according to the working requirements of vacuum equipment, the external condition limitation is few, and the application range is wide.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com