Bellows clamp valve with splittable tube body and dynamic sealing

A dynamic sealing and bellows technology, applied in the direction of pipes/pipe joints/fittings, valve details, diaphragm valves, etc., can solve the problems of short service life, affecting operation, insufficient heat resistance and fatigue resistance, and improve service life. , Easy disassembly and assembly, good anti-fatigue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

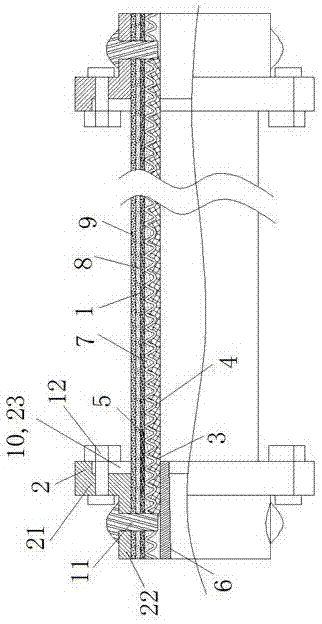

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0016] Such as figure 1 As shown, the corrugated pipe pinch valve with detachable pipe body and dynamic seal includes a composite pipe body 1 and pipe joint flanges 2 connected at both ends, wherein the composite pipe body 1 includes reinforcing fiber layers 3 arranged in sequence from the inside to the outside , stainless steel bellows layer 4 and anti-aging rubber outer layer 5, and each pipe joint flange 2 includes a flange portion 21 and a connecting cylinder portion 22, wherein the side of the flange portion 21 facing the composite pipe body 1 is also provided There is an annular groove 23, and an extrusion gasket 10 is arranged on the outside of the composite pipe body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com