Magnetofluid motive sealing structure suitable for high rotation speed

A magnetic fluid dynamic sealing, high-speed technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., to achieve good heat dissipation performance, good sealing effect, and good dynamic sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

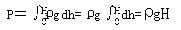

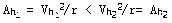

[0029] Example 1, A ferrohydrodynamic seal structure suitable for high speed, such as figure 1 , figure 2 and image 3 shown. Installed on the casing (8), it includes a cylindrical stationary magnetic pole 7 and a cylindrical rotating magnetic pole 4 coaxially sleeved outside the stationary magnetic pole 7. The stationary magnetic pole 7 is formed by a radial ring at its end. 9 is fixed with casing 8. Specifically, the stationary magnetic pole 7 is rigidly connected to the casing 8 by a radial ring 9 arranged at its end, the radial ring 9 is fixedly mounted on the casing 8 and sealed with a sealing ring 83, and the rotating magnetic pole 4 is installed in a non-vacuum environment , the radial ring 9 of the stationary pole 7 is provided with a cooling medium circulation channel 91 .

[0030] The outer surface of the cylinder of the stationary magnetic pole 7 is provided with more than two protruding cylindrical sealing rings 6, and the number of cylindrical sealing ring...

Embodiment 2

[0081] Example 2, Same as Embodiment 1, the difference is that: the inner hole of the casing 8 is provided with an annular casing protection ring 82 for limiting the radial runout range of the rotating shaft 1, and the casing 8 is provided with a cooling medium circulation Channel 81.

[0082] like Figure 7 As shown, the protection ring 82 is used to prevent the rotating shaft 1 from causing the rotating magnetic pole 4 to rub against the sealing ring 6 on the stationary magnetic pole 7 when the radial runout of the rotating shaft 1 is large, thereby damaging the magnetic fluid sealing structure.

Embodiment 3

[0083] Example 3, The rotating magnetic pole 4 is installed in a vacuum to meet the needs of special working conditions. like Figure 8 As shown, the rotating magnetic pole 4 is placed in a vacuum environment enclosed by a flange and a casing 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com