Immersion head with protective glass

A technology for protecting glass and head base, applied in the field of imaging optics, can solve problems such as inability to achieve, and achieve the effect of increasing the resolution of the objective lens and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

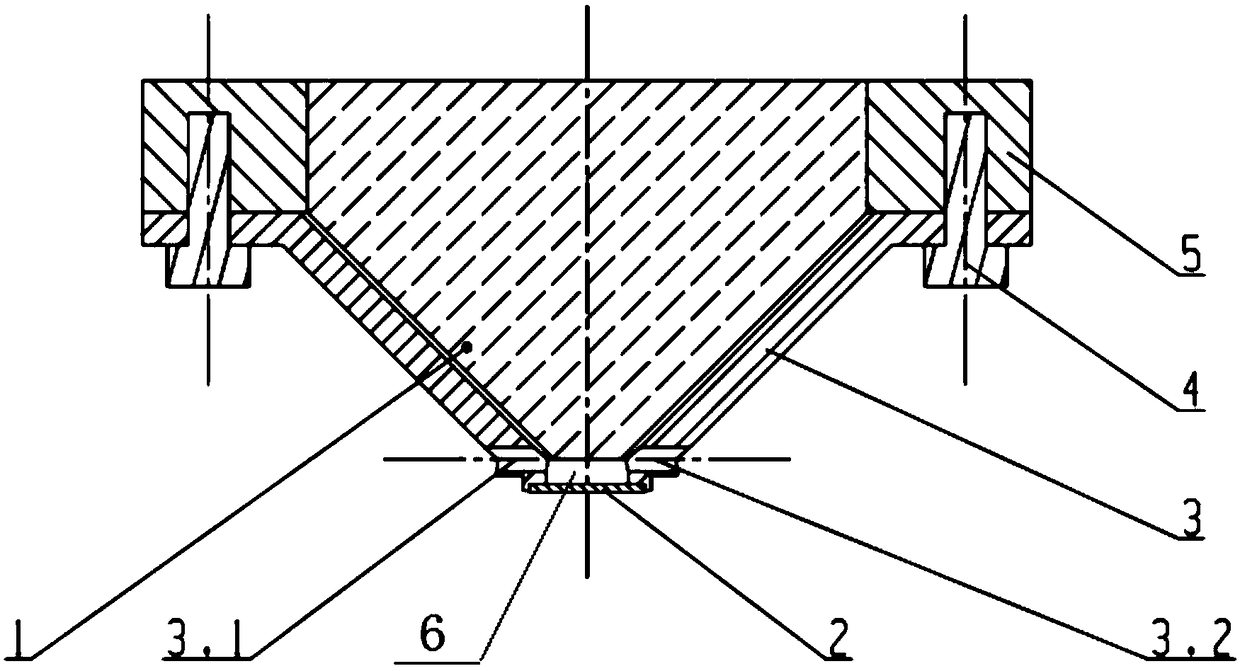

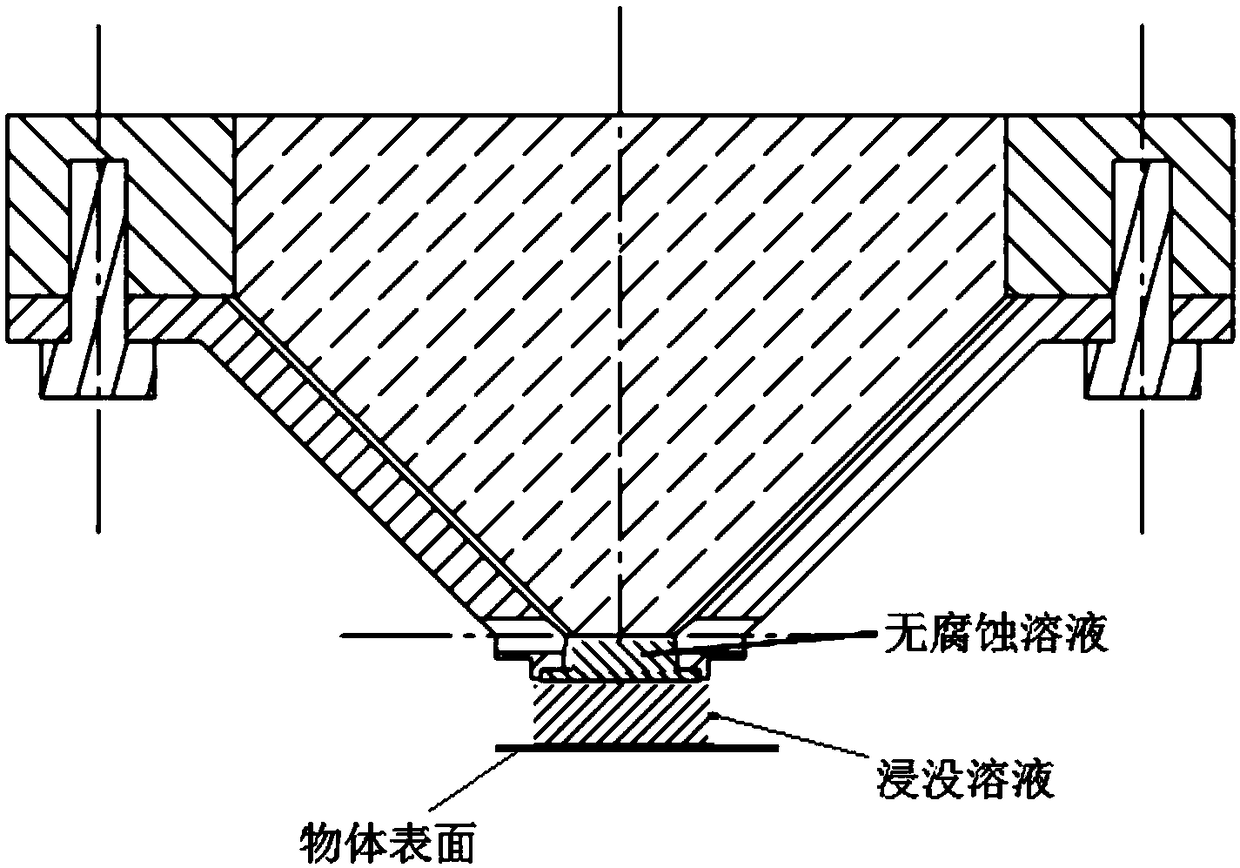

[0018] Such as figure 1 As shown, the immersion head with cover glass of the present invention comprises immersion head base 3 and cover glass 2; The last sheet glass 1 of objective lens is installed in lens barrel 5; The upper edge of immersion head base 3 is connected with mirror by four screws 4. The cylinder 5 is connected; the bottom of the immersion head base 3 has a through hole, and the protective glass 2 is bonded and sealed at the bottom of the through hole with an anti-corrosion glue; the gap between the bottom of the lens 1 and the protective glass 2 is used as a liquid chamber 6. A coaxial liquid injection hole 3.1 and a liquid discharge hole 3.2 are processed at the position of the immersion head base 3 corresponding to the liquid chamber 6; the non-corrosive solution can be injected into the liquid chamber 6 through the liquid injection hole 3.1, and the non-corrosive solution is simultaneously The liquid chamber 6 is drained through the drain hole 3.2.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com