Drain valve sealed by pressure-equalizing water film

A drainage valve and water film technology, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, radial flow pumps, etc., can solve the problem of increased motor power, increased friction, failure, etc. Problems, achieve good dynamic sealing effect, reduce exhaust volume, and high air density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

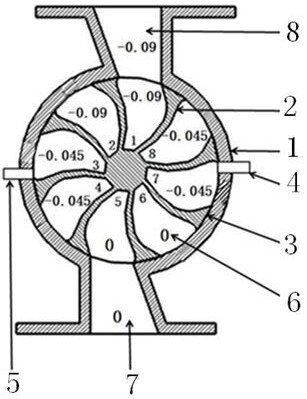

[0037] like figure 1 The shown drain valve sealed with a pressure-equalizing water film includes a valve body 1, an impeller 2, a porous material 3, and a conduit.

[0038] The valve body 1 has a water inlet 8 and a water outlet 7 on it.

[0039] The number of water bins 6 of the impeller 2 is eight.

[0040] Said porous material 3 is a sponge.

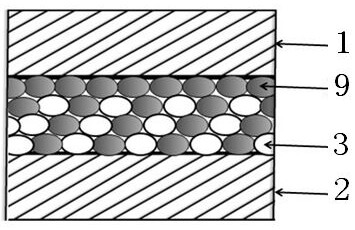

[0041] like figure 1 , figure 2 One side of the shown porous material 3 is fixed on the surface of the impeller 2 , and the other side is attached to the valve body 1 .

[0042] The thickness of the porous material 3 is 5 mm.

[0043] The impeller 2 is in the inner cavity of the valve body 1 , and the water film seal between the impeller 2 and the valve body 1 is performed by the water 9 in the porous material 3 .

[0044] The intake valve 5 and the exhaust valve 4 of the valve body 1 are communicated by a conduit.

[0045] The present invention adopts a drain valve sealed by a pressure-equalizing water film for water discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com