Non-contact fingertip-labyrinth-brush type combined sealer

A labyrinth seal, non-contact technology, applied in the direction of preventing leakage, engine components, machines/engines, etc., can solve the problems of large leakage rate, small leakage rate, low sealing pressure bearing capacity, etc., achieve high pressure difference ability, excellent dynamic sealing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

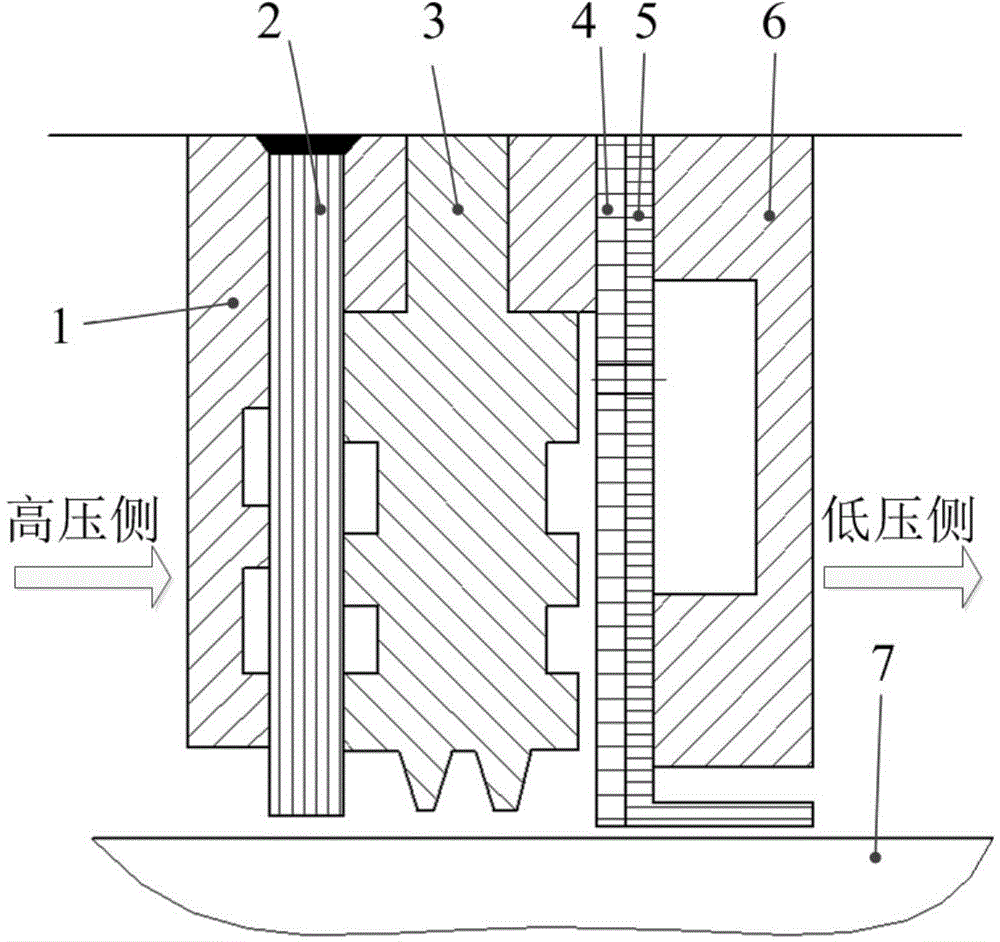

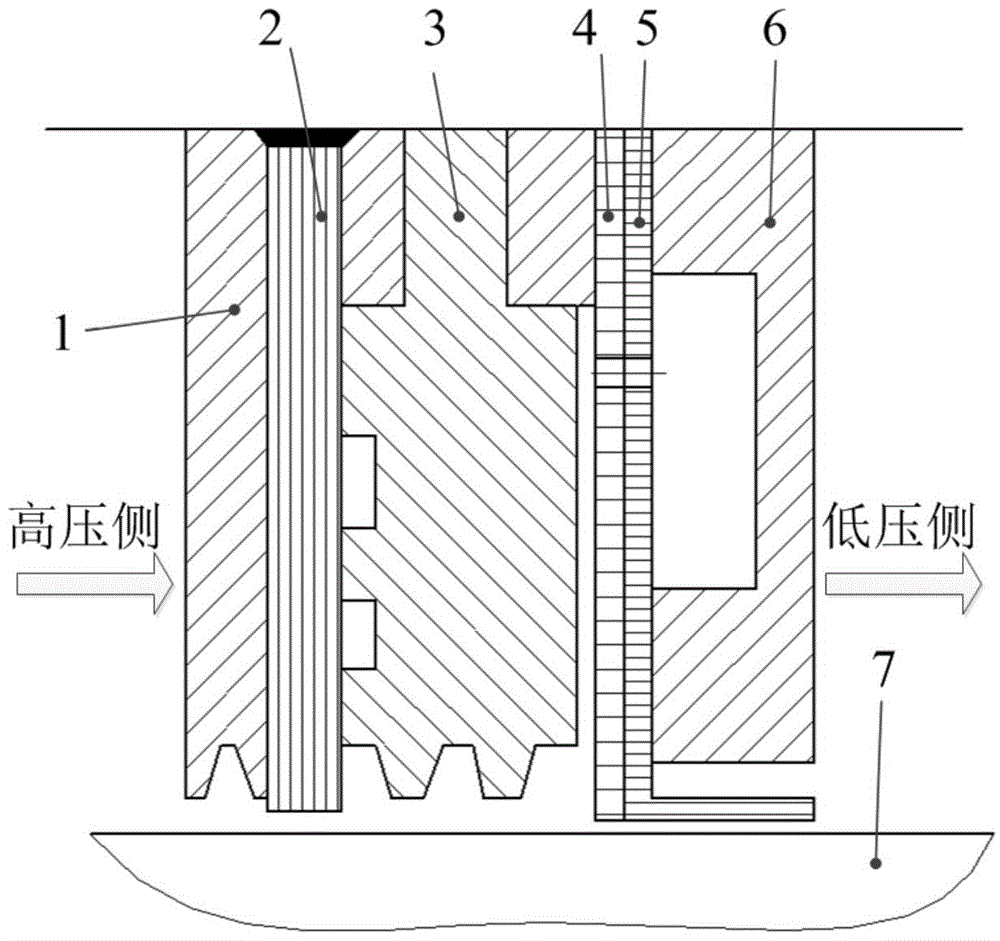

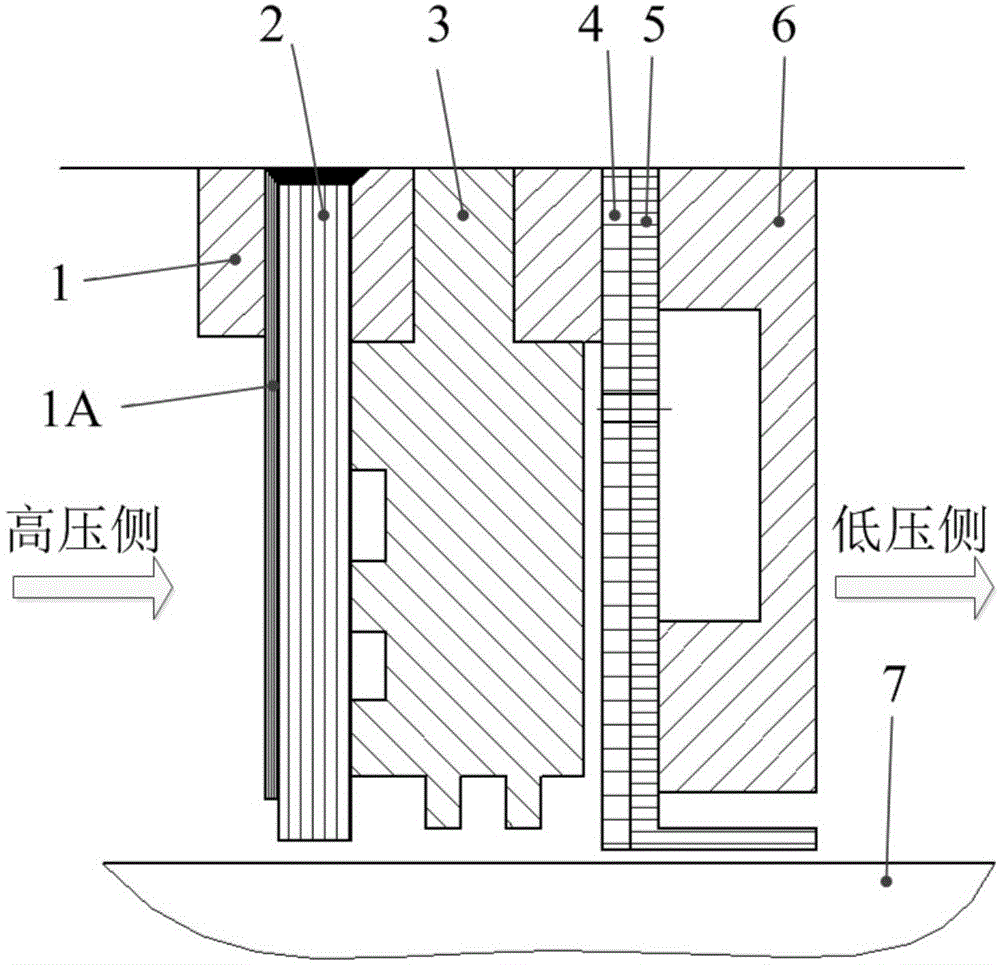

[0020] refer to figure 1 , a non-contact fingertip-labyrinth-brush composite seal, including labyrinth teeth 3 in the labyrinth seal area that are connected to the rotor 7, and the high-pressure side of the labyrinth teeth 3 is connected by a brush wire 2 and a composite front baffle 1 The brush-type sealing area composed of labyrinth teeth 3 is connected to the non-contact fingertip sealing area composed of high-pressure fingertip piece 4, low-voltage fingertip piece 5 and rear baffle plate 6. Labyrinth tooth 3 is used as a brush seal The rear baffle in the area is also used as the front baffle in the non-contact fingertip sealing area. The labyrinth teeth 3 are close to the brush filament 2 and there is an axial gap between the high-voltage fingertip sheet 4.

[0021] There is a gap between the brush filament 2, the labyrinth teeth 3, the high-voltage fingertip sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com