Water lubricating dynamic sealing rubber alloy bearing

A sliding seal and rubber alloy technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as lubricating oil leakage and pollute water areas, achieve high cost performance, optimize shafting structure, and good dynamic sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

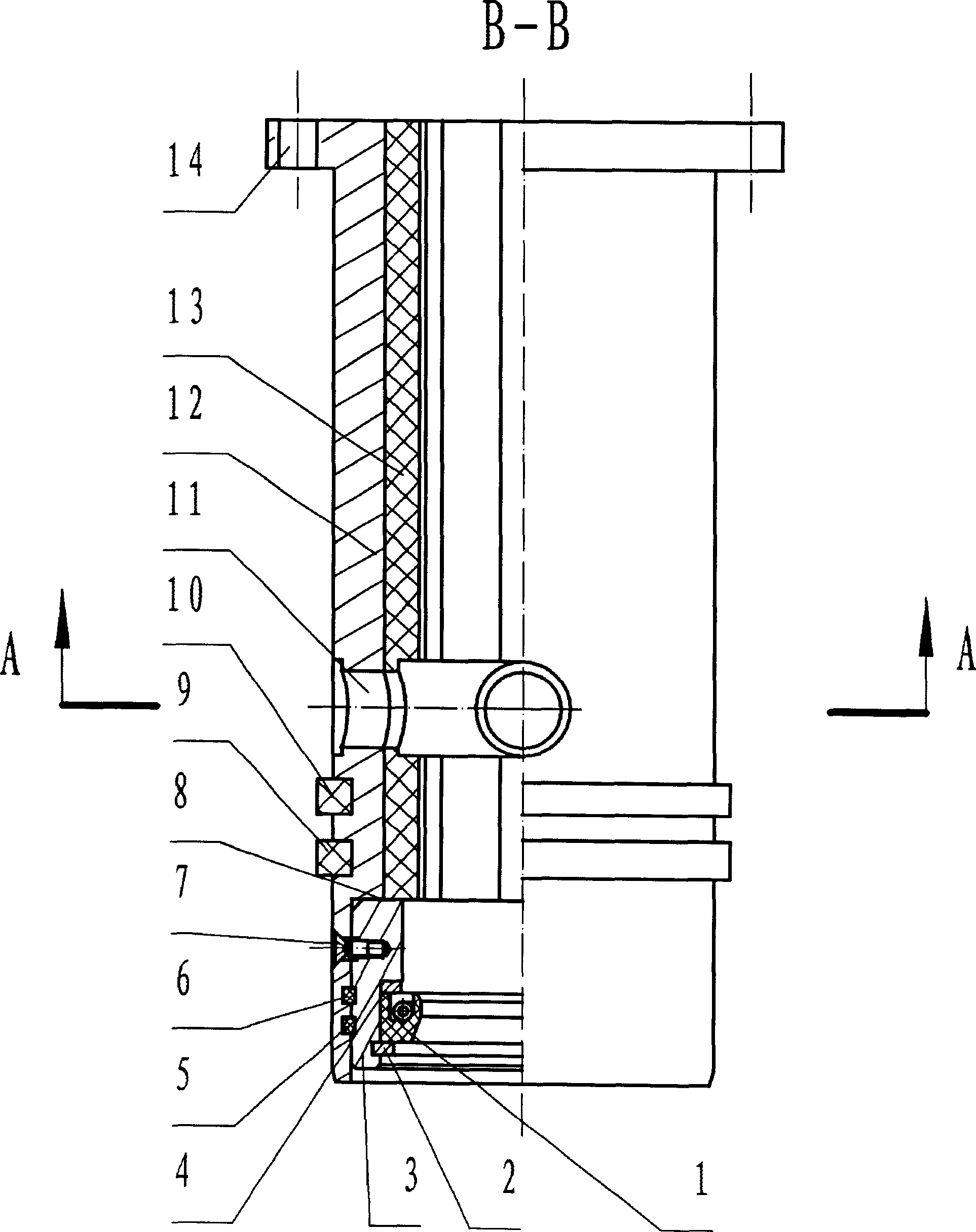

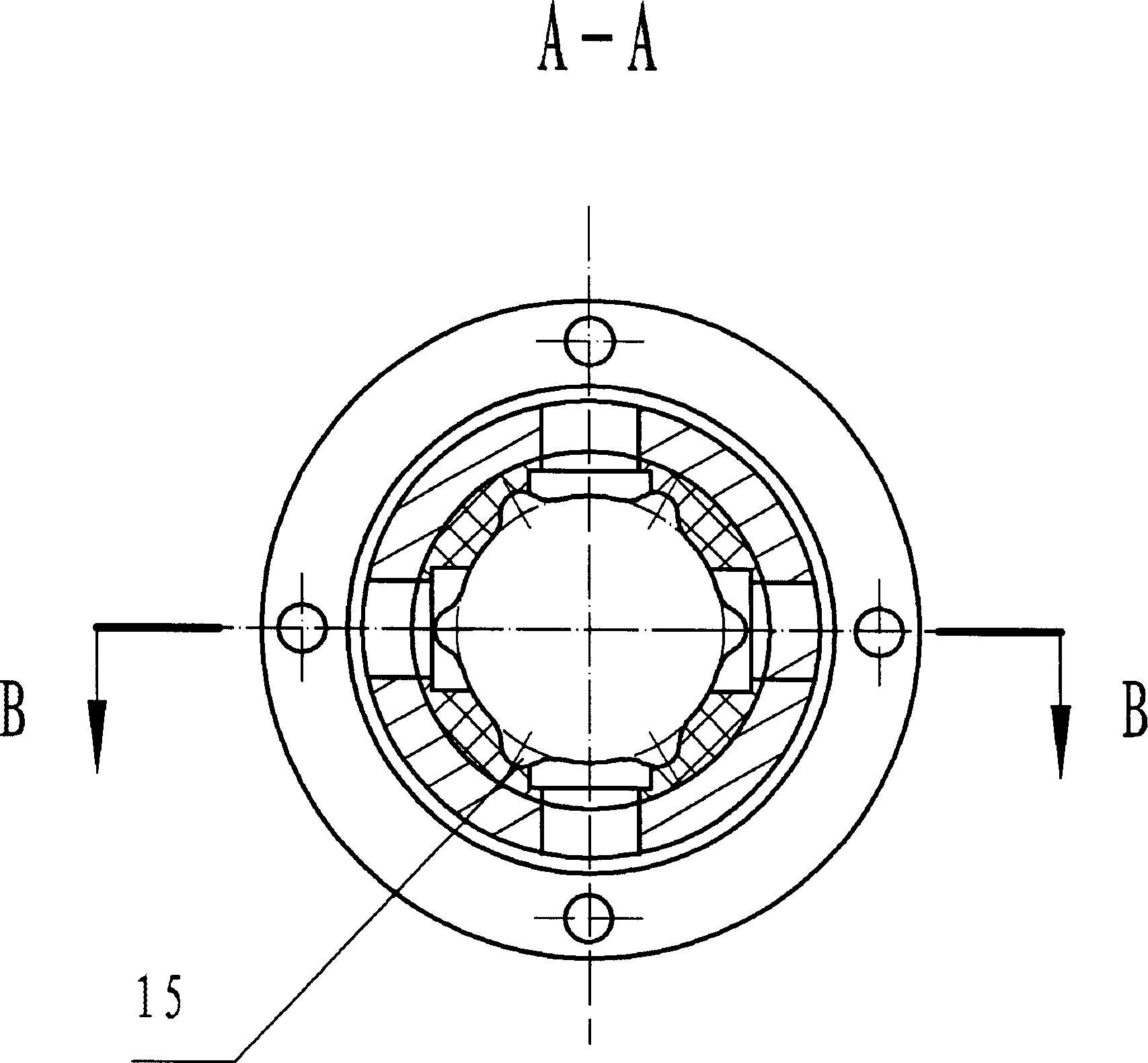

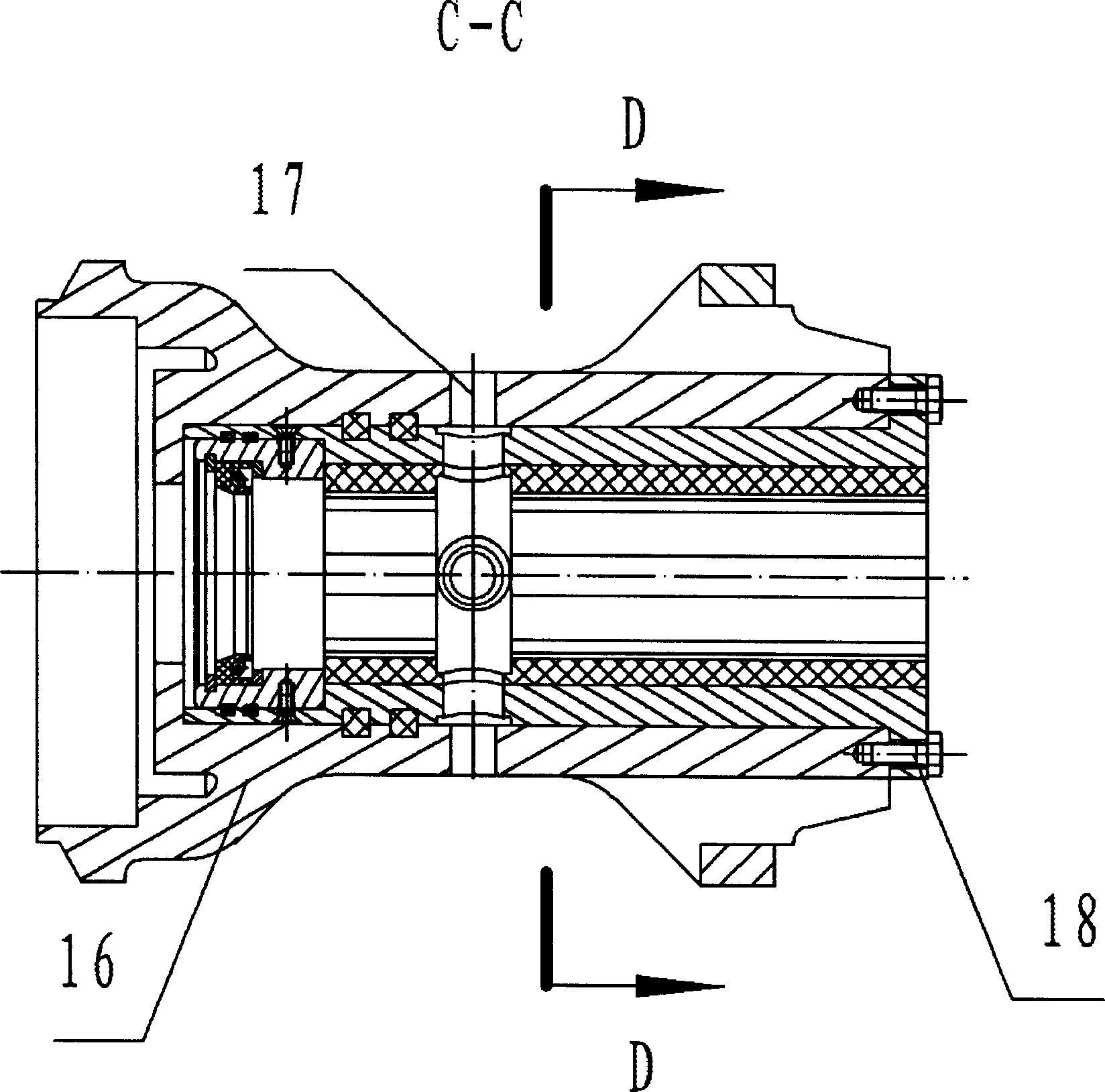

[0022] A water-lubricated dynamic-seal rubber alloy bearing for ship propulsion system

[0023] Such as image 3 As shown, the water-lubricated dynamic-sealed rubber alloy bearing is installed in the bearing seat 16, and is fixed on the bearing seat 16 by four screws 18 evenly distributed on the end surface. Two static sealing rings 9 and 10 are used to prevent the entry of water and the leakage of oil in the gap between the outer surface of the water-lubricated dynamic seal rubber alloy bearing and the inner surface of the bearing seat 16. Four water injection holes 17 are evenly distributed on the circumference of the bearing seat, and these four water injection holes 17 correspond to the four water injection holes 11 of the water-lubricated dynamic sealing rubber alloy bearing, and the axis lines thereof coincide with each other. The left side of the bearing seat 16 is the power plant of the ship's propulsion system, and the right side of the bearing seat 16 is the power o...

Embodiment 2

[0027] A water-lubricated, dynamic-sealed rubber alloy bearing used in the stirring drive system of a washing machine

[0028] Drive the drive shaft of the agitator in the washing machine to realize the washing function, pass through the water-lubricated dynamic-sealed rubber alloy bearing and connect with the power system. When the washing machine is in working condition, the water in the washing machine will flow into the water-lubricated dynamic seal rubber alloy bearing along the transmission shaft. At this time, the dynamic seal body of the water-lubricated dynamic seal rubber alloy bearing can prevent water from entering the washing machine through the dynamic seal body The power system of the water-lubricated dynamic-seal rubber alloy bearing is connected to the drainage system of the washing machine simultaneously, so the water flowing into the water-lubricated dynamic-seal rubber alloy bearing can flow out through the water injection hole 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com