Vertically-mounted food discharging valve

A discharge valve, vertical installation technology, applied in the field of vertical installation food discharge valve, can solve the problems of increasing labor intensity and production cost, yield of less than 60%, high filling volume requirements, etc., to avoid slurry Drip, consistent slurry quality, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

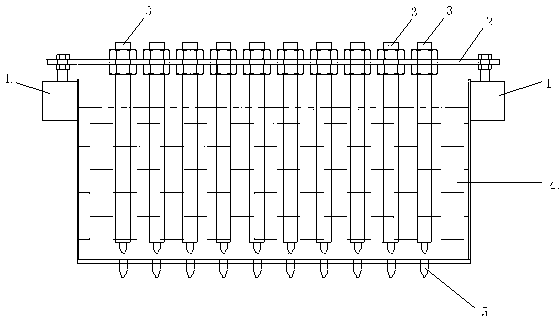

[0017] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

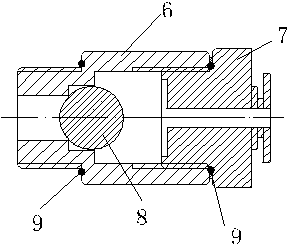

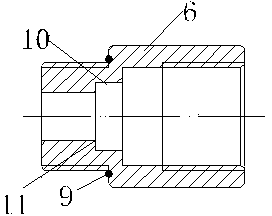

[0018] Such as figure 2 As shown: the food vertically installed discharge valve 14 described in this embodiment includes a valve seat 6 , a push-in joint 7 , a valve ball 8 and a sealing ring 9 . Such as Figure 3-4 As shown, the valve seat 6 is made of 304 stainless steel, which has good high temperature resistance and corrosion resistance. The upper end of the valve seat 6 is threadedly connected to the lower end of the push-in joint 7, and a connecting piece is connected to the upper end of the quick-inserting joint 7. The connecting piece is made of metal or plastic, and has excellent resistance to high pressure, vibration, and corrosion. Abrasion-resistant, twist-resistant performance. The lower end of the connector is embedded in the push-in connector 7, and the upper end is connected with a pressure plate. The lower end of the pressure plate is tubular and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com