Slurry pulsator

A mud pulse and pulse technology, used in surveying, wellbore/well components, earth-moving drilling, etc., can solve the problems of difficult configuration change, increase drilling cost, leakage of mud, etc., to improve the quality of pulse signal, processing and use Low cost and good dynamic sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

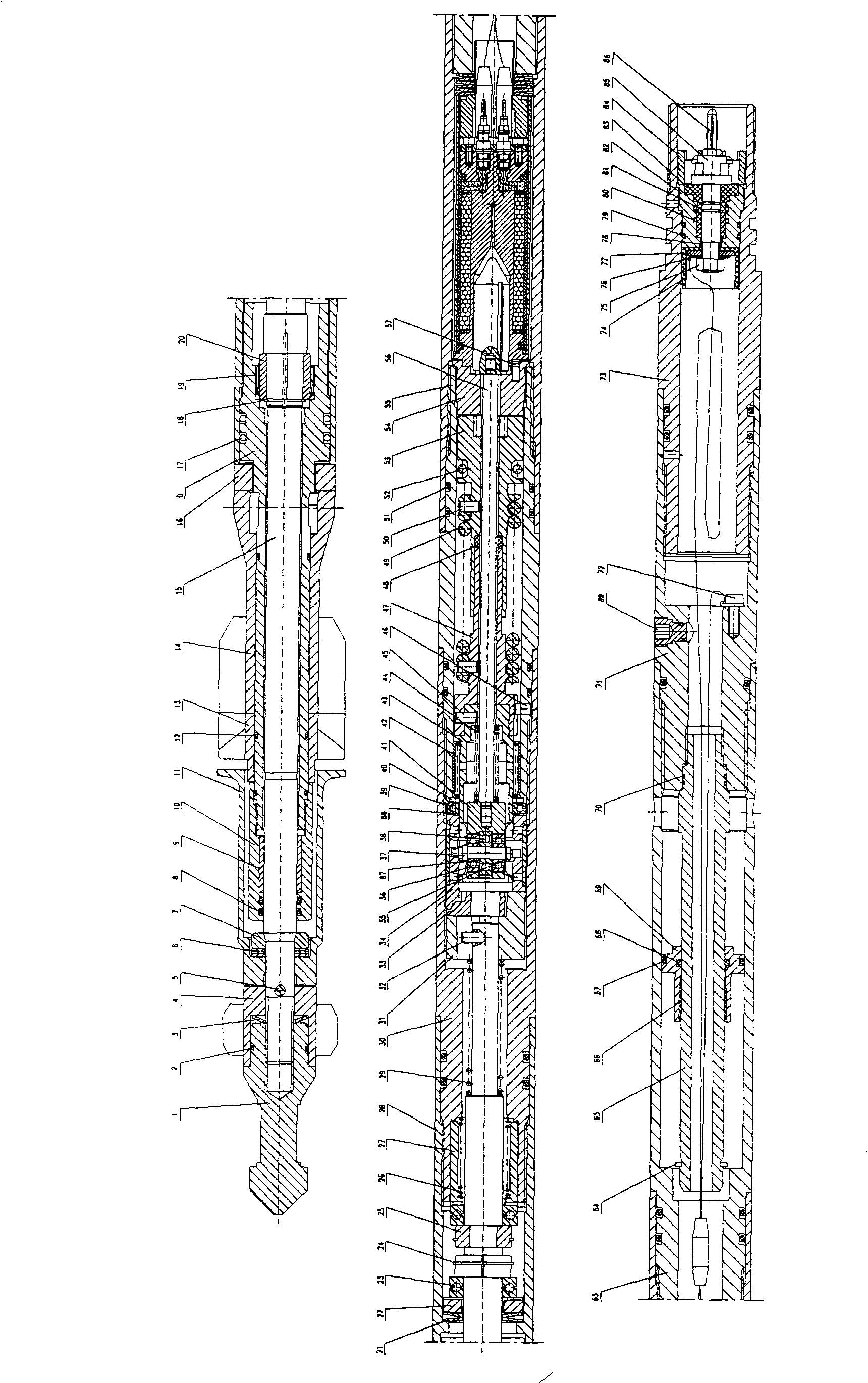

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012]The invention is mainly composed of a rotating pulse head, a pulse head support seat, a main shaft support mechanism, a main shaft assembly, a control and buffer mechanism, a solenoid valve assembly, a balance piston mechanism, a pulser housing and a pressure-bearing electrode assembly. Head 1, impeller 4, stop ring 7, and rotor 11 constitute a rotary pulse head, and impeller 4 is set on the outer surface of fishing head 1; by sliding bearing nut 10, stator 13, rectifying support frame 14, backup ring 16, 0 No. body shell 0 constitutes the pulse head supporting seat; it consists of main shaft 15, main shaft copper sleeve 9, upper shaft pin 5, needle roller bearing sleeve 20, coupling pin 32, compression damping spring 26, backstop bearing upper seat 22, main shaft Backstop bearing 23, main shaft half tile (pair) 25, backstop bearing lower seat 27, coupling 31 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com