Three-dimensional dynamic water cooling system of spray belt device

A water-cooling system, dynamic technology, applied in household refrigeration devices, cooling fluid circulation devices, lighting and heating equipment, etc. Fouling and fouling, chips and other problems, to achieve the effect of scientific and reasonable setting structure and matching operation mode, improve production quality and efficiency, and avoid secondary aggregation and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

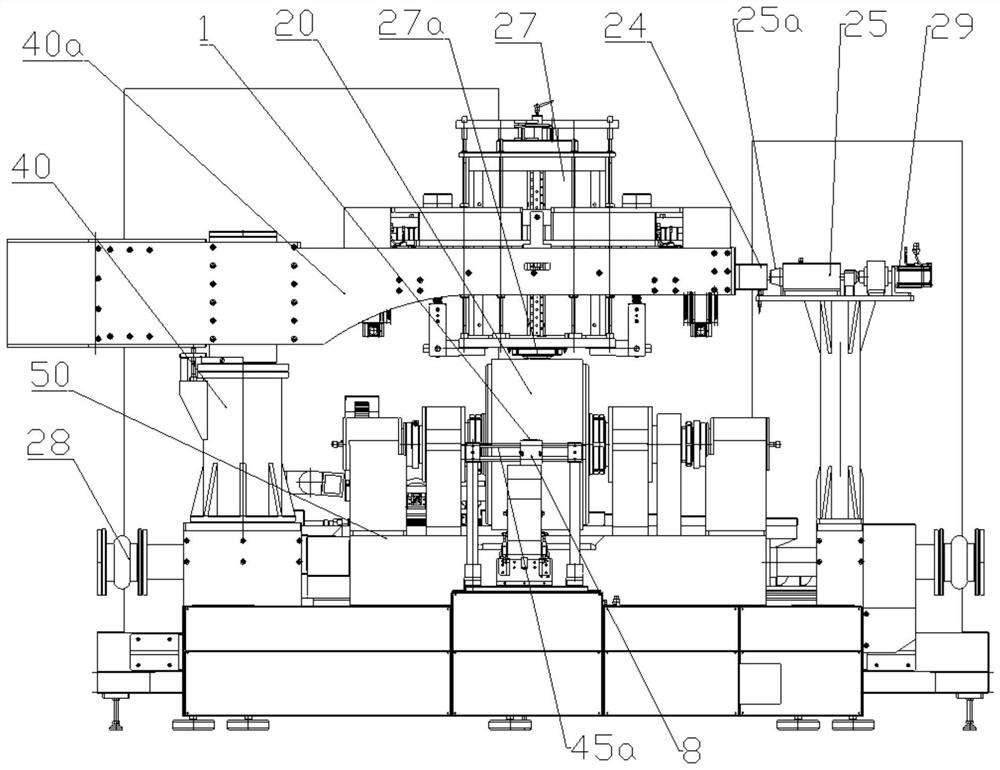

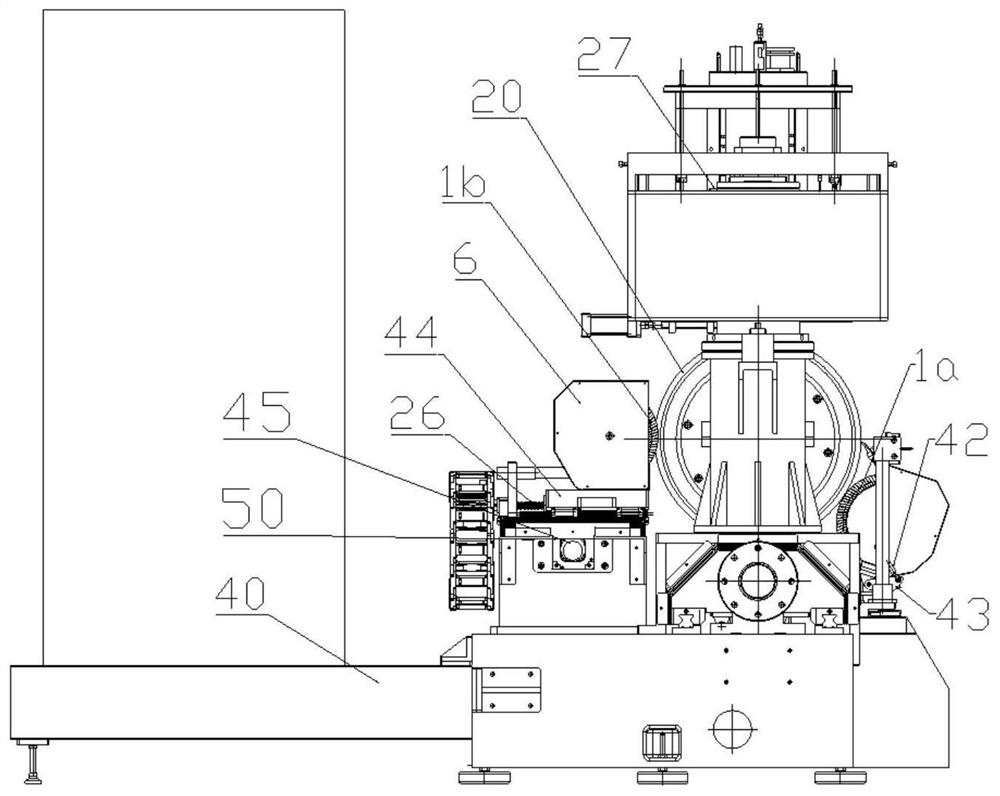

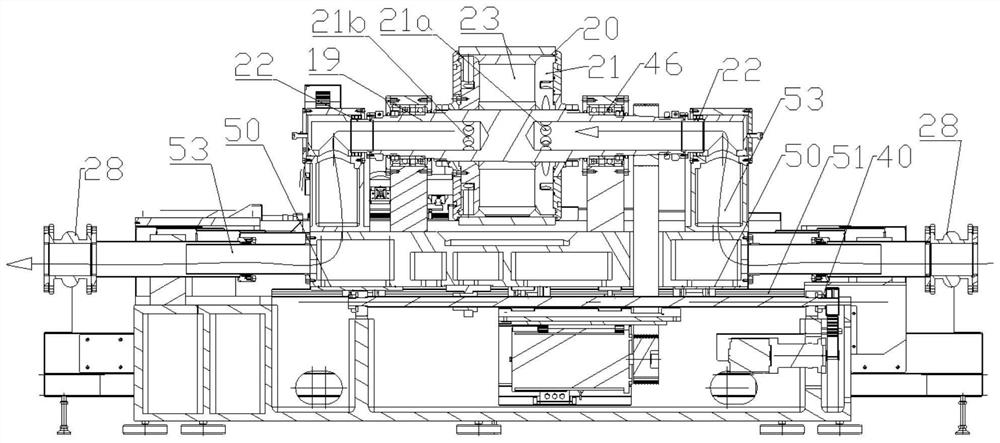

[0011] In order to better understand the technical solutions of the present invention, the present invention is now clearly and completely described through embodiments in conjunction with the accompanying drawings.

[0012] The tape spraying device and the tape spraying method of the present invention: implement the tape spraying and tape making in a dynamic spraying tape manner through a moving copper roller relative to the nozzle.

[0013] Such as Figure 1-3 shown. The belt spraying device of the present invention includes a frame 40, a copper roller 20 arranged on the frame 40, a copper roller polishing device, a copper roller dynamic water cooling system, and an intermediate frequency induction heating furnace 27 and its nozzle 27a fixed on the frame. The frame 40 is connected with a cantilever 40a through a column at one end, and the medium frequency induction heating furnace is arranged on the cantilever. Corresponding to the cantilever 40a, an automatic split-and-cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com