Compensated underwater brushless DC motor structure and assembly method thereof

A brushed DC motor and compensation type technology, applied in the field of compensation type underwater brushless DC motor structure and its assembly, can solve the problems of motor debugging, assembly difficulty, complex compensation form, cumbersome structure, etc., and achieve scientific installation and fixation. problems, easy access and maintenance, and the effect of streamlining the motor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

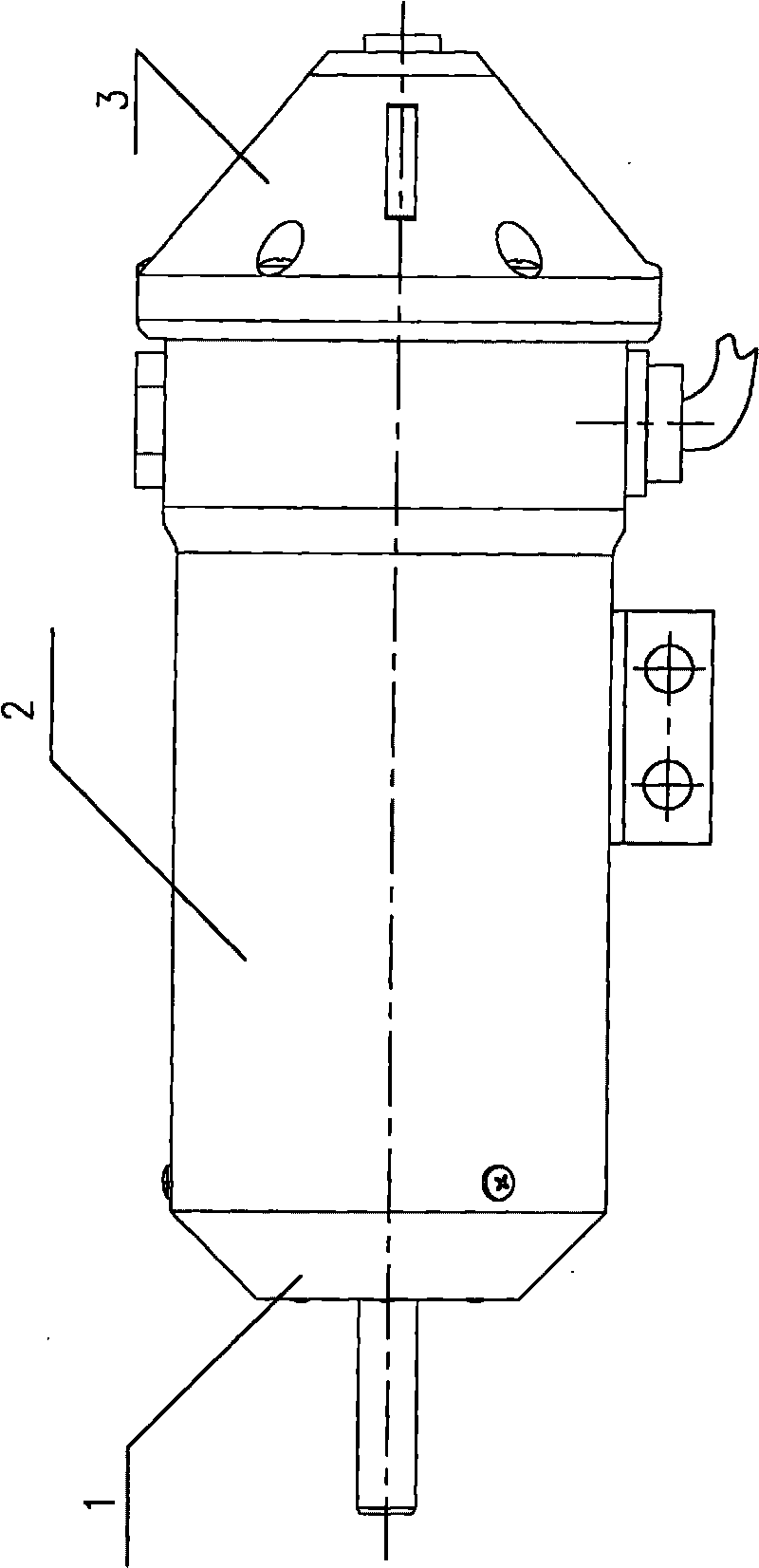

[0025] Embodiment 1: Motor structure

[0026] The structure of the motor adopts a modular design, and the main modules include a motor end cover assembly 1 , a motor body 2 and a compensator device 3 . Among them: the motor end cover assembly 1 is located at the front end of the motor, and is fixedly connected to the motor body 2 through the radial screws of the motor, and the interface position is radially statically sealed with an O-ring; the compensator device 3 is located at the tail of the motor, and is The axial screw is fixedly connected with the motor main body 2, and the interface position is statically sealed by compressing the sealing ring of the compensator bladder in the axial direction.

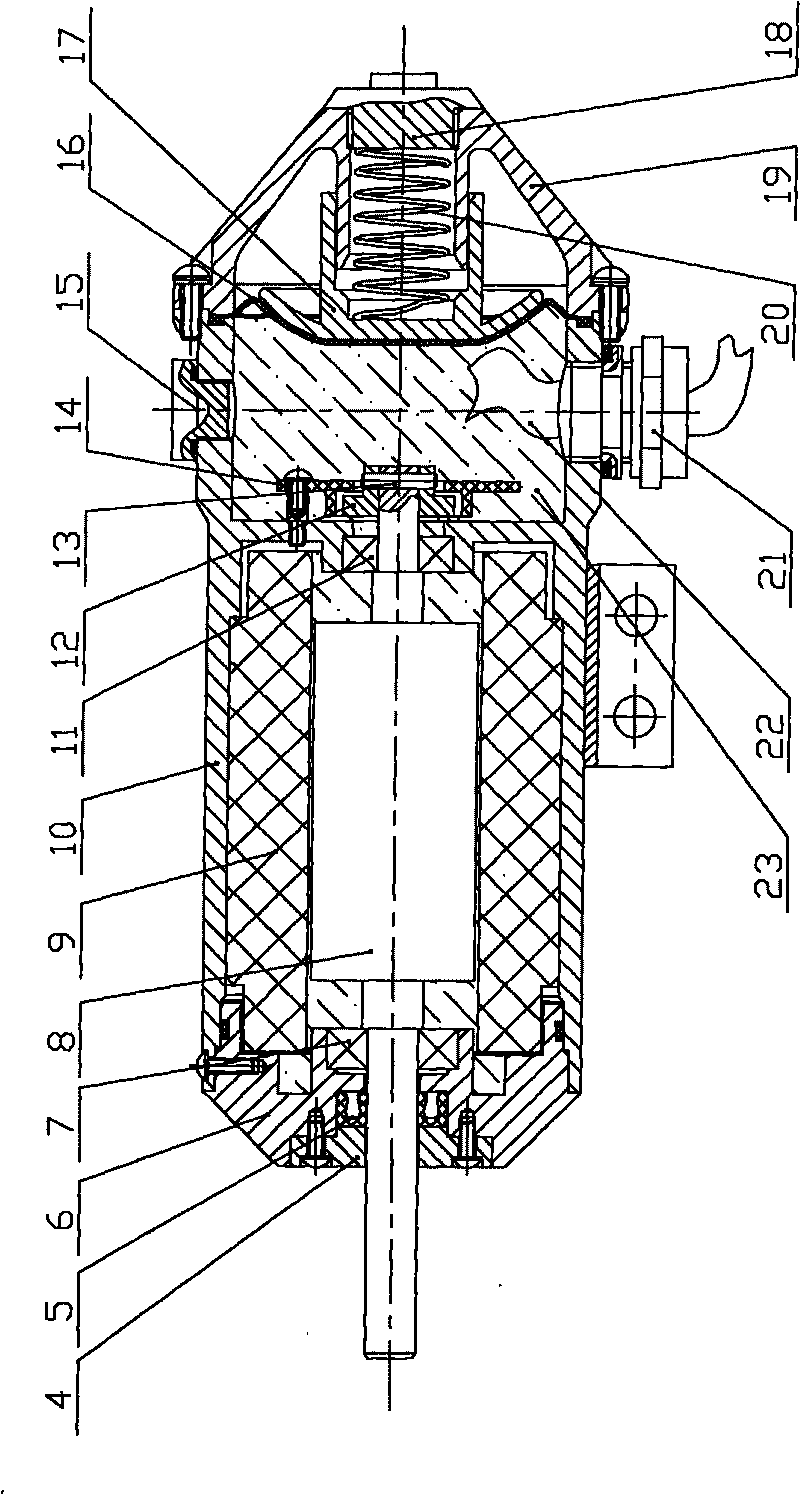

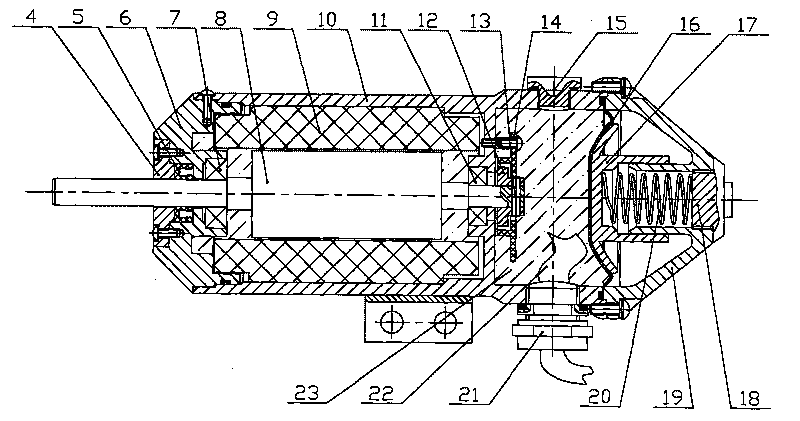

[0027] The motor end cover assembly 1 includes a motor end cover gland 4, a rotating seal body 5, a motor rotor front end bearing 7 and a motor end cover 6, wherein the motor rotor front end bearing 7 is positioned on the motor end cover 6 through the shoulder of the motor rotor...

Embodiment 2

[0030] Embodiment 2: assembly method

[0031] like figure 2 As shown, the motor stator 9 and the motor casing 10 are assembled into one body in a hot melt state; the motor rotor rear end bearing 11 is embedded in the bearing groove in the cavity of the motor casing 10; the motor rotor 8 is put into the inner cavity of the motor stator 9 , wherein the bottom end is embedded in the motor rotor rear end bearing 11; the magnetic ring 12 is fixedly connected to the motor rotor 8 through radial positioning rivets 13; the motor rotor front end bearing 7 is positioned in the bearing groove of the motor end cover 6; the rotating sealing body 5 is fixed in the sealing groove of the motor end cover 6 through the motor end cover gland 4 in such a way that the lip opening of 5 faces the inner side of the motor; the motor end cover gland 4 is fixedly connected to the motor end cover 6 with axial connecting screws; Under the guidance of the rotor 8 and the bearing 7 at the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com