Engine oil returning structure

An engine and oil technology, applied in the installation/connection of lubricant purification devices, lubricating parts, lubrication indicating devices, etc., can solve the problem of unfavorable disassembly and maintenance of the arrangement position, inconvenient installation of oil filters, and unfavorable cleaning of expired oil, etc. problems, to avoid oil leakage to pollute the environment, reduce the risk of sticking, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

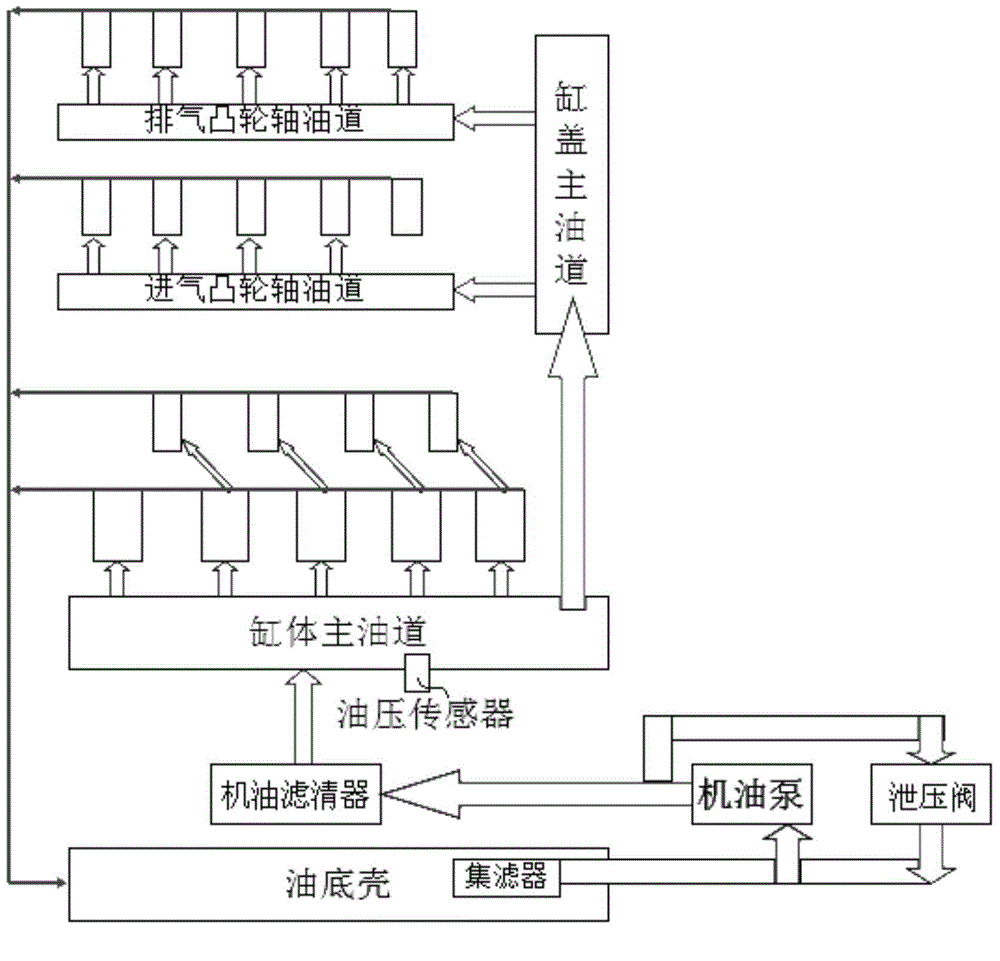

[0039] reference Figure 4 The engine oil return structure in the embodiment of the present invention also includes an oil pan, a filter, an oil pump, an oil filter, an oil pressure sensor, etc. In this embodiment, a solenoid valve is used as a pressure relief valve for practical use, and Figure 7 It can be seen that the solenoid valve is connected to an ECU (Electronic Control Unit, electronic control unit) and is controlled by the ECU. The oil in the oil pan passes through the filter, the oil pump and the oil filter in sequence, and then enters the main oil passage of the cylinder block, and then enters the branch oil such as the main oil passage of the cylinder head, the exhaust camshaft oil passage and the intake camshaft oil passage. Road, and finally return to the oil pan. The solenoid valve in this embodiment is connected to the oil filter and the oil pan. The oil pressure sensor measures the oil pressure of the oil entering the main oil passage of the cylinder in the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com