Guide roller water-cooling circulating device for continuous cast rolling

A technology of water-cooling circulation and guide rollers, applied in workpiece cooling devices, guiding/positioning/alignment devices, metal rolling, etc. , casting and rolling coil uncoiling adhesion and other problems, to achieve the effect of reducing the risk of sticking, ensuring quality and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

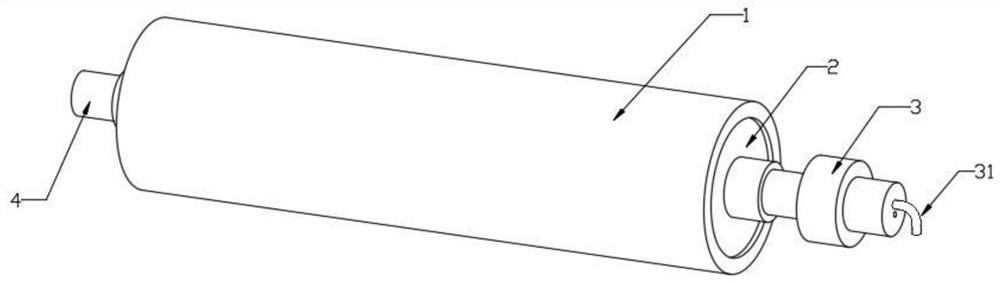

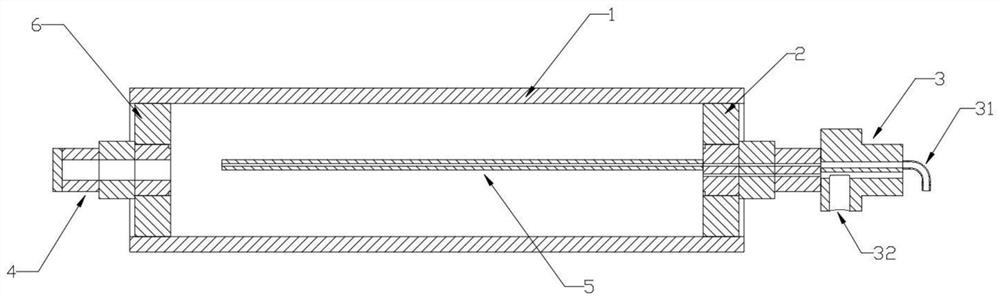

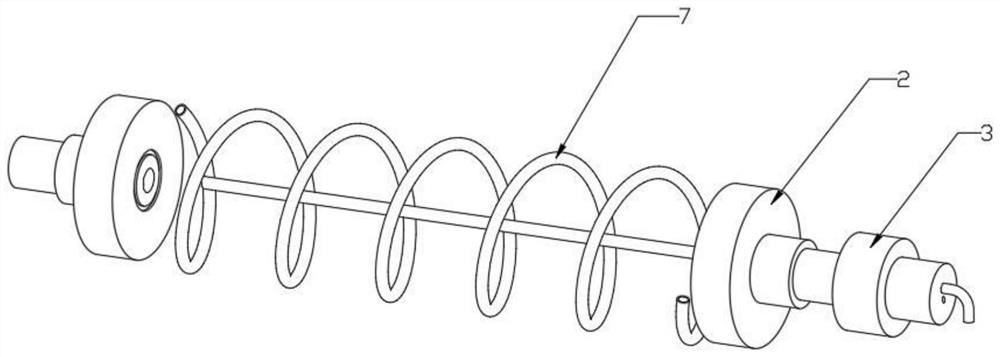

[0021] Such as Figure 1-3 As shown, a guide roll water cooling circulation device for continuous casting and rolling comprises a hollow roll 1, the two ends of the hollow roll 1 are respectively provided with a right end shaft head 2 and a left end shaft head 6, and the inside of the right end shaft head 2 is provided with There is a water inlet pipeline and a water return pipeline, and the right end of the shaft head 2 at the right end is connected with a two-way rotary joint 3, and the two-way rotary joint 3 is provided with a water inlet 31 and a water return mouth 32, and the water inlet 31 and the water inlet pipeline The inlet is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com