Cutting platform and cutting system

A cutting platform and cutting system technology, applied in the direction of welding/cutting auxiliary equipment, auxiliary devices, laser welding equipment, etc., can solve the problem of sticking to the surface of the workpiece 12 to be cut and the surface of the abutment body 11, platform damage, increased maintenance costs, etc. problem, achieve the effect of reducing the risk of adhesion, avoiding damage and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

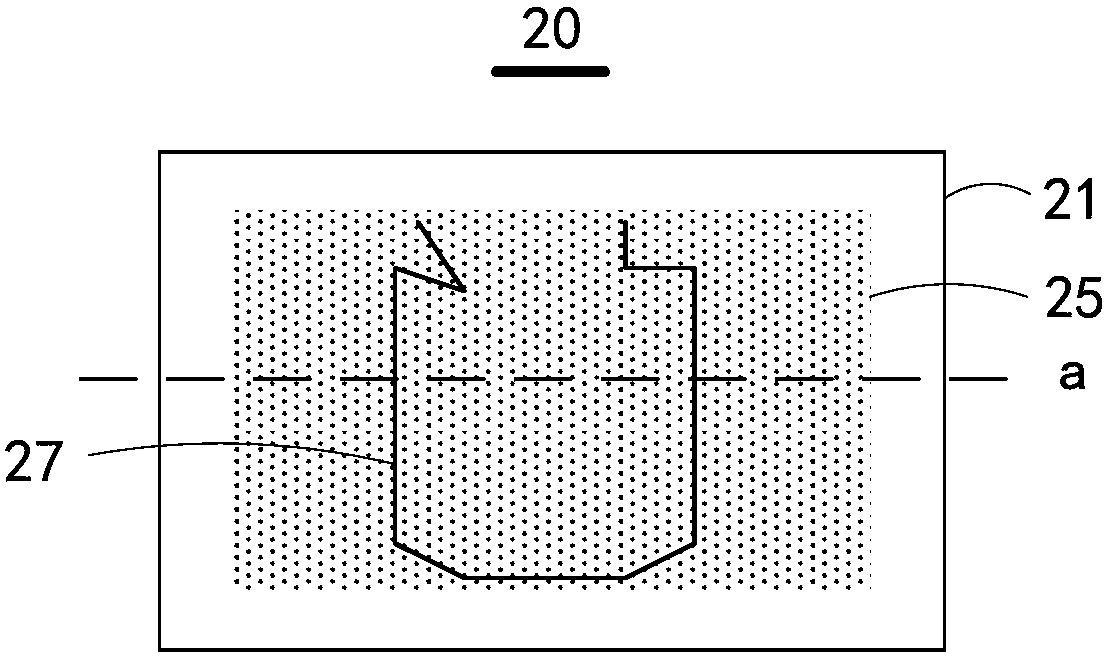

[0020] see figure 2 , is a top view structural diagram of the cutting platform of the present invention. The cutting platform 20 includes:

[0021] The platform body 21, the platform body 21 includes a first surface 211 for fixing the workpiece 22 to be cut;

[0022] The cutting groove 27 is arranged on the first surface 211 of the platform body 21, and the cutting groove 27 corresponds to the cutting line 23 issued by the cutting device (not shown in the figure);

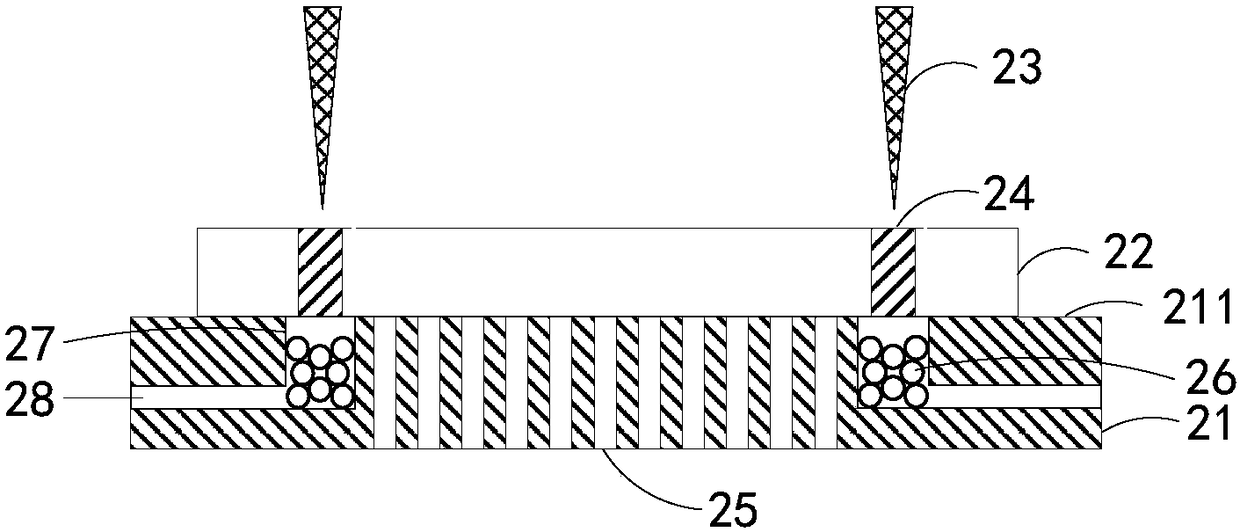

[0023] combine image 3 , image 3 It is a schematic diagram of the cross-sectional structure of the cutting platform of the present invention.

[0024] along figure 2 The middle dotted line a cuts off the cutting platform 20, and the platform body 21 includes at least one dust removal channel 28, one end of the dust removal channel 28 communicates with the cutting groove 27, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com