Automatic cooker

A cooking machine and automatic technology, which is applied in the direction of timing control of ignition mechanism, heating device, cooking utensils, etc., can solve the problems of inability to stir-fry ingredients, ingredients sticking to the pan, uneven heating of ingredients, etc., achieve uniform and sufficient heating, and improve Quality, the effect of reducing the risk of sticking to the pan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

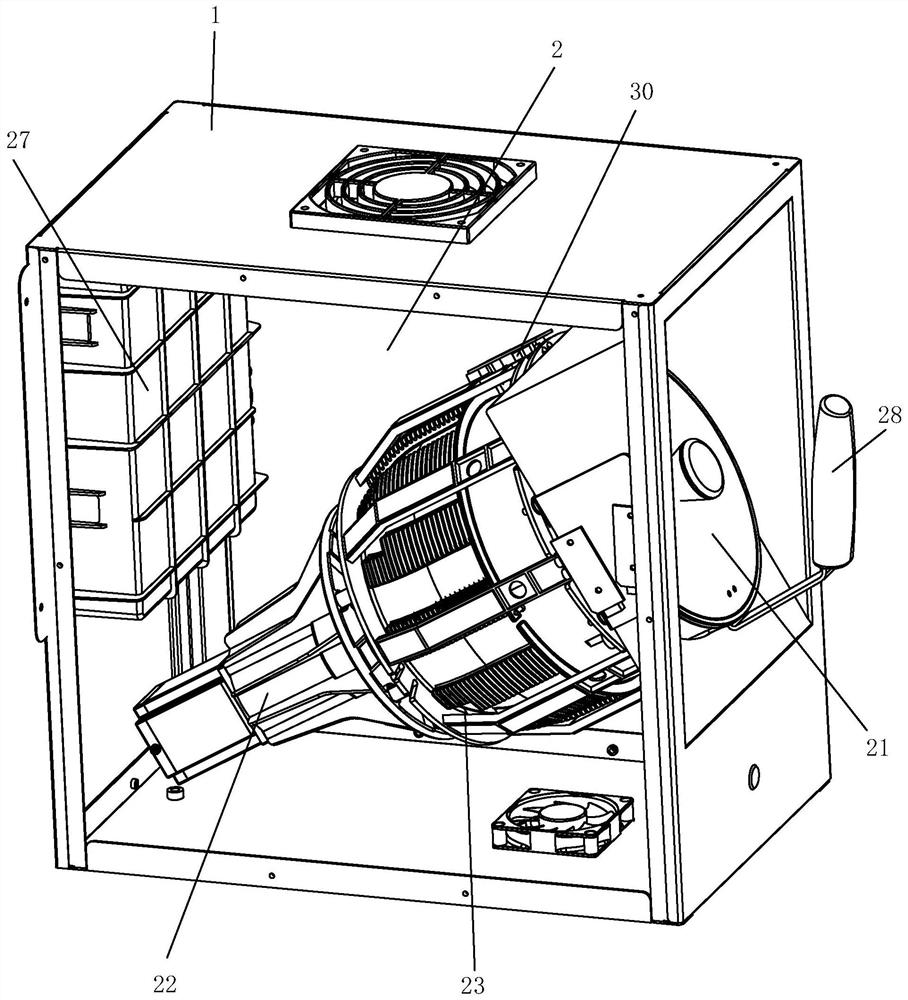

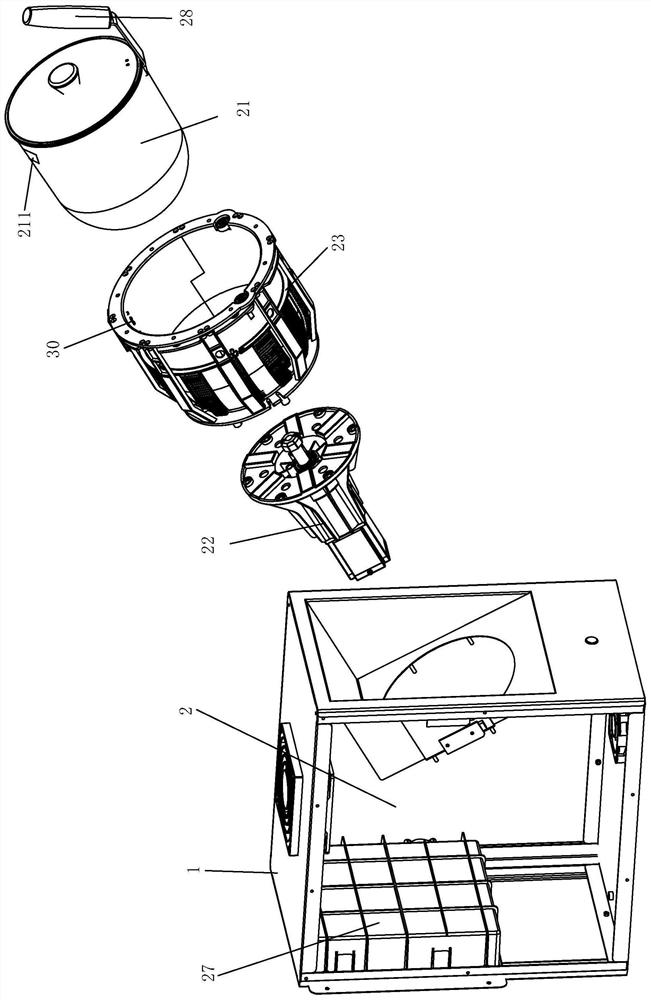

[0030] Such as Figure 1 to Figure 8 As shown, an automatic cooking machine of this embodiment includes a frame 1, and the frame 1 is provided with an accommodating cavity 2, and the accommodating cavity 2 is provided with a frying pan 21 for cooking ingredients, for The heating mechanism 23 for heating the frying pan 21 and the driving mechanism 22 for driving the frying pan 21 to turn upside down, the frying pan 21 is obliquely arranged in the accommodation chamber 2; The forward and reverse driving mechanism, when the automatic cooking machine is cooking ingredients, the driving mechanism drives the frying pan to perform forward and reverse flipping actions according to the preset conditions, so that the ingredients in the frying pan are turned forward and backward accordingly, and will not only be heated One side of the food makes the food evenly heated, and the wok is placed obliquely in the accommodating cavity, so that when the food is turned upside down in the wok to a...

Embodiment 2

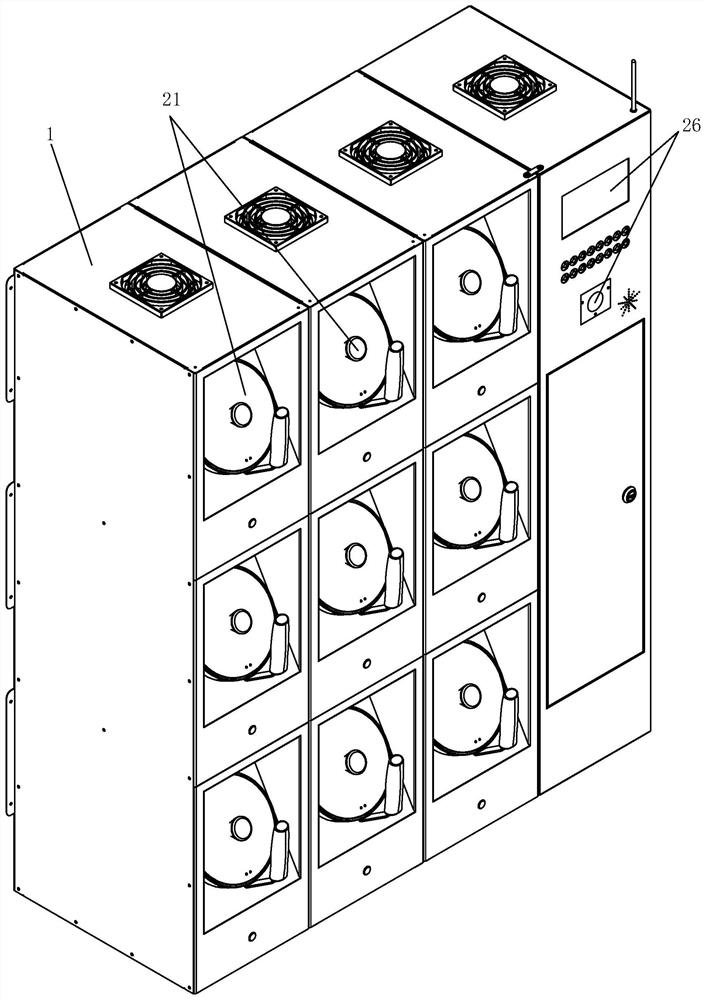

[0042] Such as Figure 9 As shown, the difference between this embodiment and embodiment 1 is that in this embodiment, the number of combinations of cooking stations on the automatic cooking machine is 18, and the structure and operation mode of the device on the automatic cooking machine are the same as in embodiment 1.

Embodiment 3

[0044] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the number of combinations of cooking stations on the automatic cooking machine is 3, and the structure and operation mode of the device on the automatic cooking machine are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com