Waste gas recirculation valve

A technology for exhaust gas recirculation valves and air passages, which is applied in the direction of exhaust gas recirculation, engine components, machines/engines, etc., and can solve the problems of valve and housing air passage jamming, excessive air leakage, and inability to block housing air. To eliminate the leakage of exhaust gas out of tolerance and reduce the risk of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

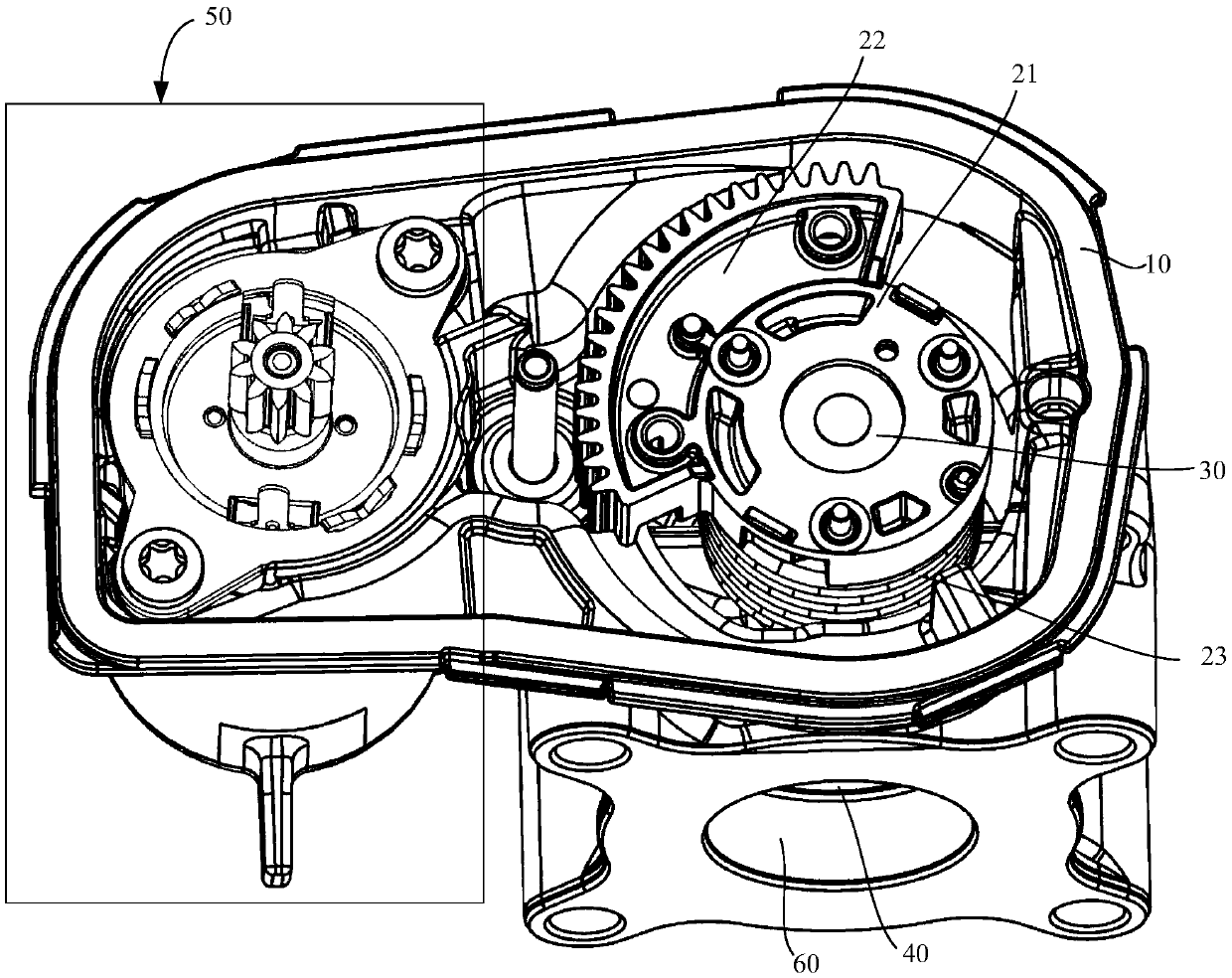

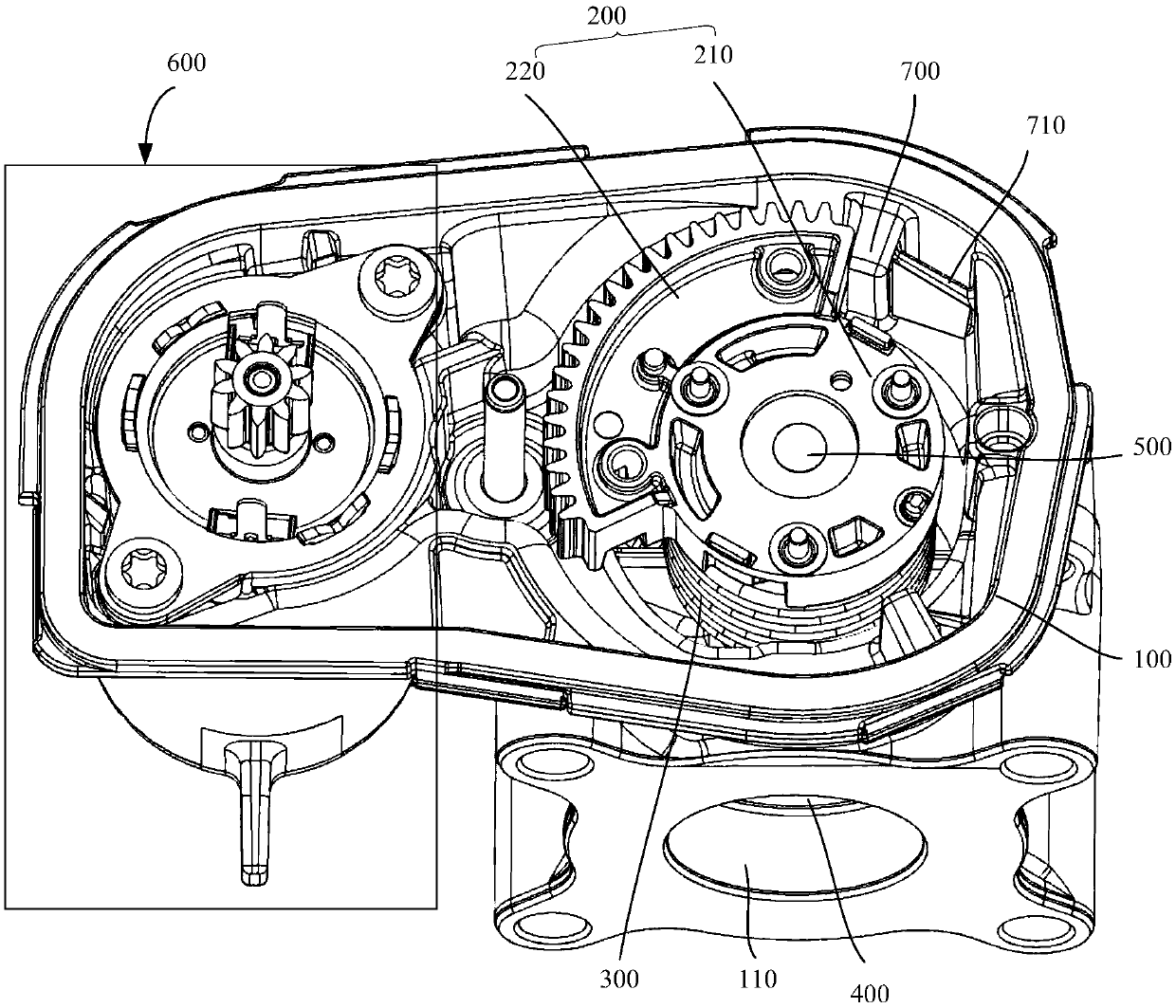

[0029] figure 1 It is a structural schematic diagram of an exhaust gas recirculation valve. like figure 1 As mentioned above, the traditional EGR valve includes a housing 10, a transmission wheel 21 and a torsion spring 23 arranged in the housing 10, a housing air passage 60 arranged on the housing 10, and the housing The air channel 60 is provided with a valve 40, the transmission wheel 21 is connected with a gear 22, the valve 40 is connected with the gear 22 through the valve shaft 30, and a driving device 50 is provided on one side of the housing 10. The driving device 50 drives the gear 22 to drive the transmission wheel 21 to rotate in the first direction, and drives the gear 22 to drive the valve to rotate in the housing air passage 60 in the first direction. The torsion spring 23 is helically wound on the transmission wheel 21 along the axial direction of the transmission wheel 21 and is located on one side of the gear. On the two convex ribs of the housing, the tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com