Method for producing woven fabric

A technology of multi-layer fabrics and airbag fabrics, applied in fabrics, multi-strand fabrics, looms, etc., can solve problems such as weaving and quality loss, and achieve the effects of improving uniformity, reducing differences, and balancing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

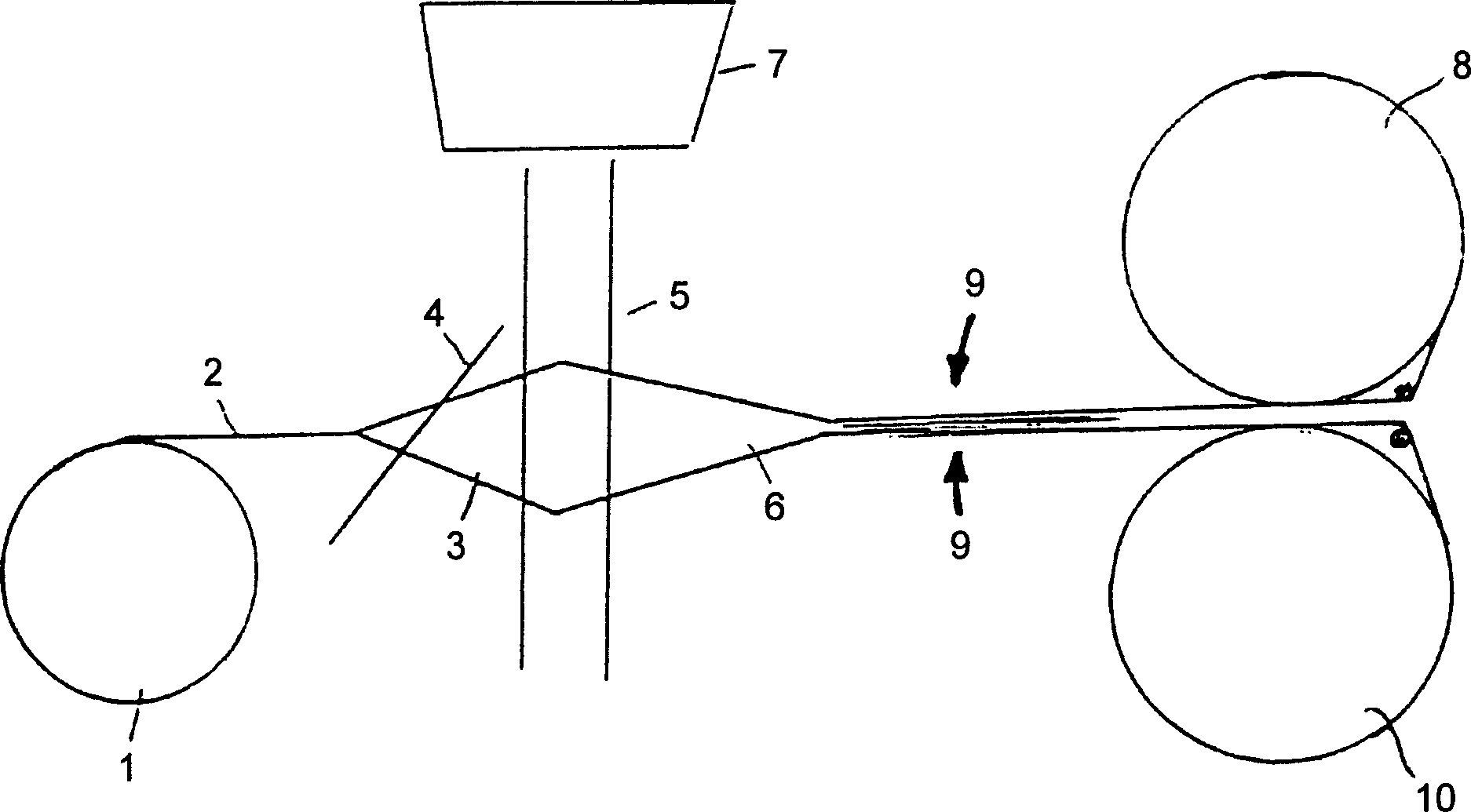

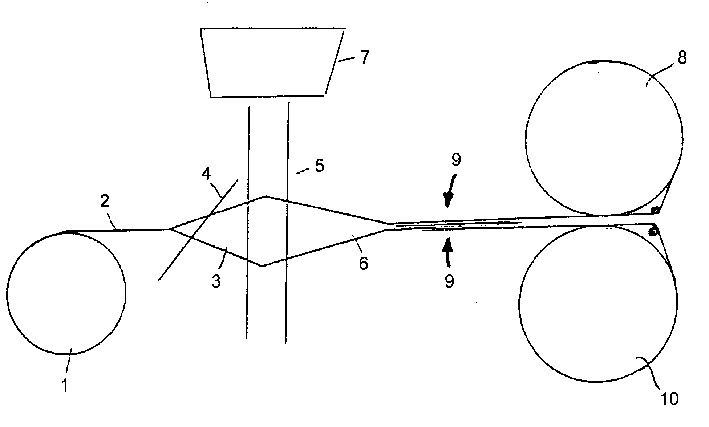

[0011] The method of the invention will now be described by way of example with reference to the accompanying drawings.

[0012] Reference is now made to the sole accompanying drawing, which schematically shows the arrangement of the loom seen from the side. Warp beams 8 and 10 weaving positions provide warp tape 9 . In the area of the harness packet 5 of the jacquard machine 7 (shown in fixed format), the reciprocating movement of the individual warp threads forms the rear shed 6 and the weaving shed 3 . In the region of the left-hand end of the shed 3 , a reed 4 can be seen from which the single- and / or multi-layer fabric 2 is wound up by the product winding drum 1 .

[0013] The use of two or more warp beams in interlacing single-layer and / or multi-layer fabrics according to the invention also enables considerable cost savings, since the frequency and time required to change warp threads is reduced by using multiple warp beams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com