Patents

Literature

55results about How to "Reduce tension differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

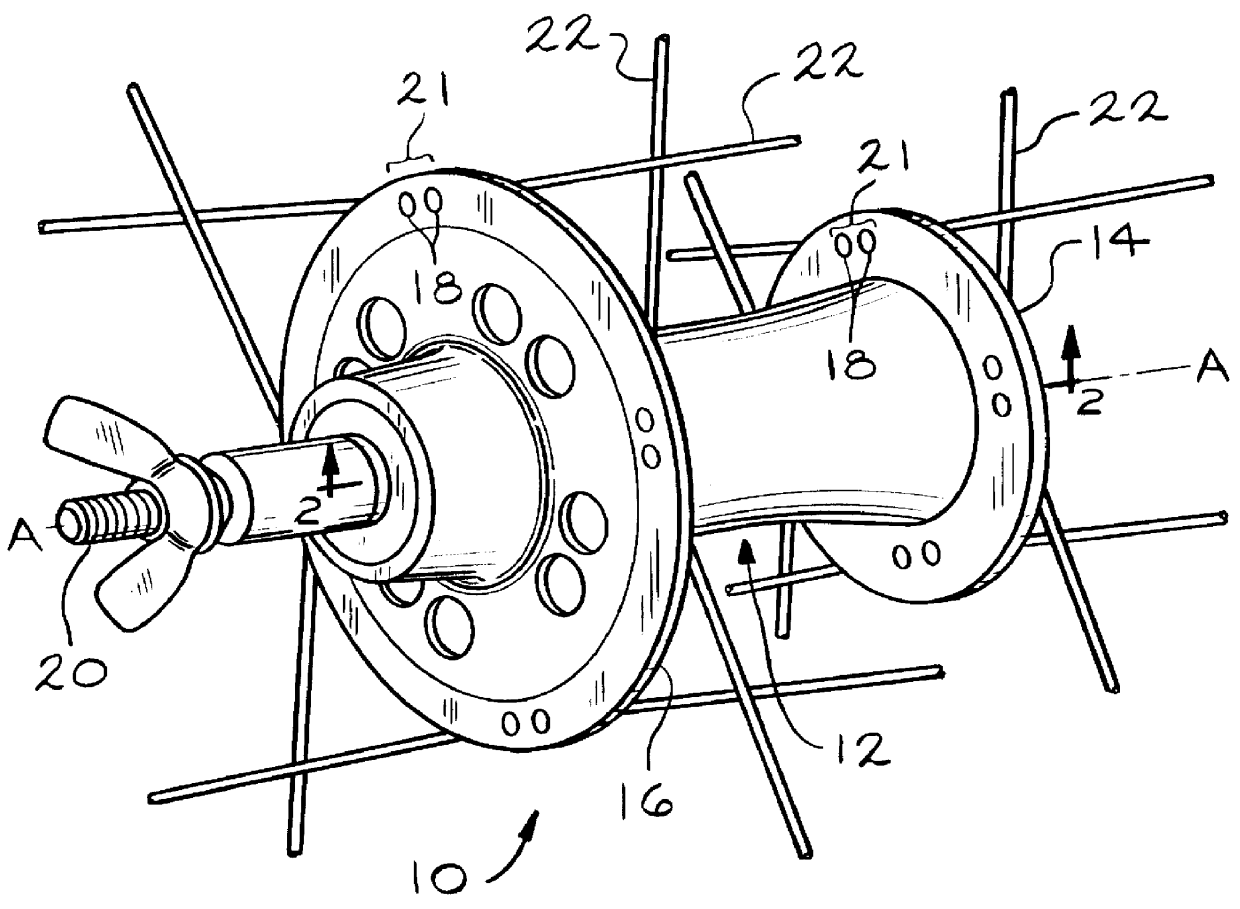

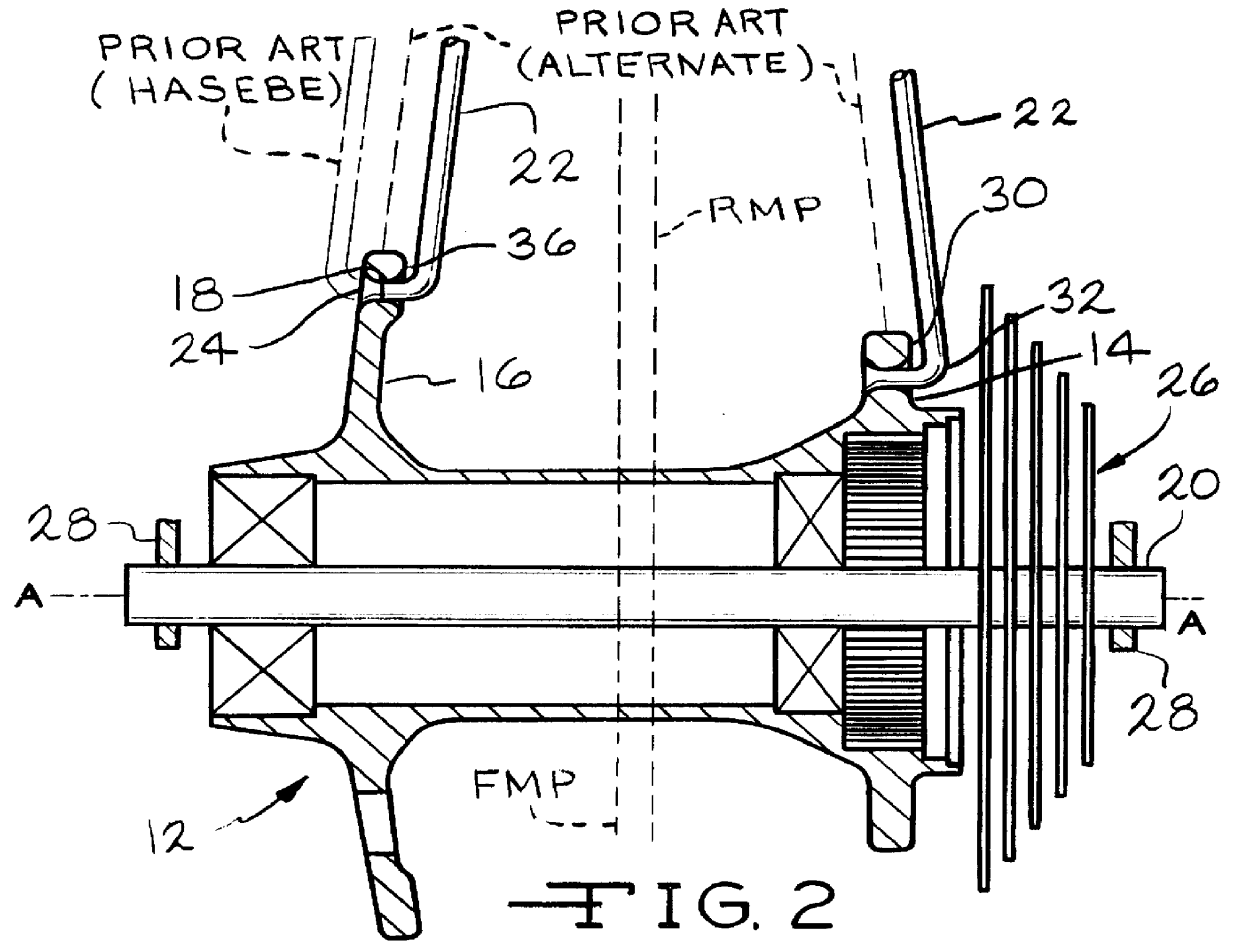

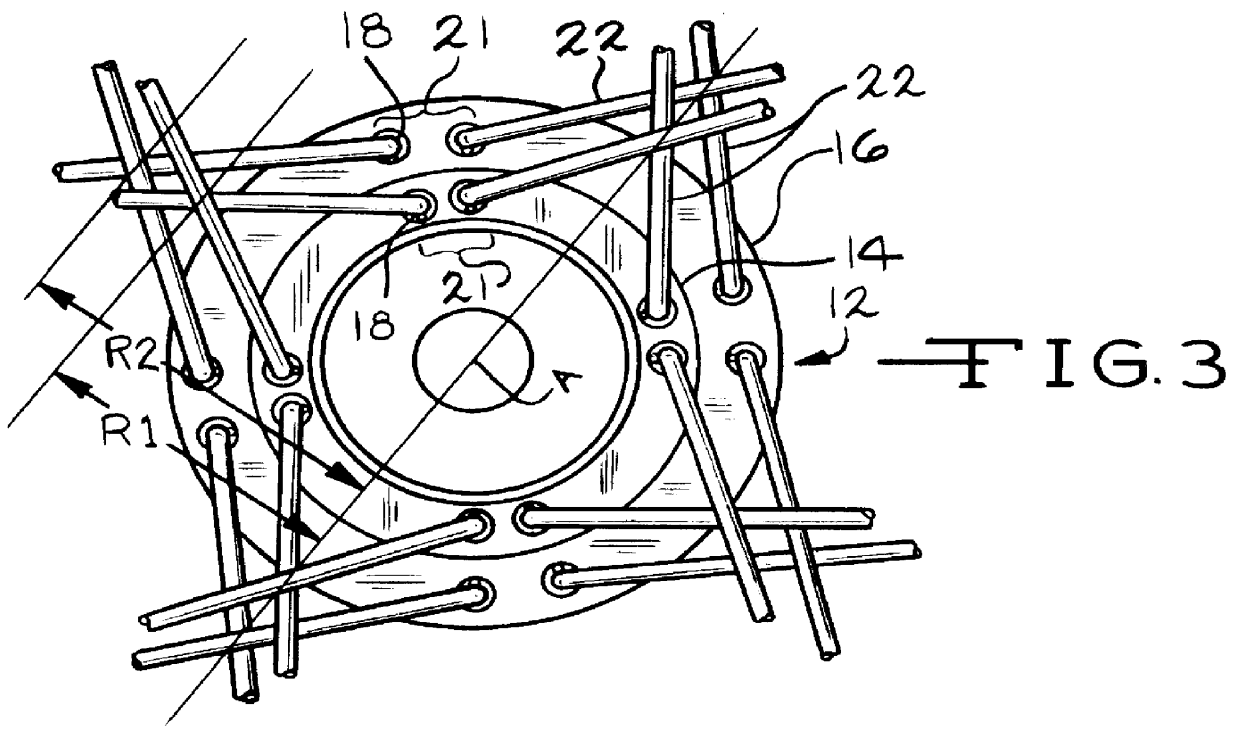

Tensioned spoked bicycle wheel assembly and hub therefor

An improved bicycle wheel is disclosed which has reduced dish by comparison with a conventionally laced wheel. The wheel is one which, when laced conventionally, would be dished such as a rear wheel with at least one sprocket or a front wheel with a brake disk. In a rear wheel embodiment, the spokes extend from inside to outside, through a proximate hub flange and along the outside or sprocket surface of the proximate hub flange and from outside to inside through the opposed hub flange and along the inside or sprocket surface of the opposed hub flange. In a front wheel embodiment, the spokes extend from inside to outside through the proximate hub flange along an inside or disk surface thereof and from outside to inside through the opposite hub flange and along the inside or disk surface thereof. The spokes in a given flange of a hub according to the present invention are all secured to the hub flange at substantially the same axial location relative to the axis of rotation of the hub or have spoke elbows which are all at substantially the same axial location relative to the axis of rotation of the hub. As a consequence of the reduced dish there is a reduction in the tension differential between the proximate spokes and the opposed spokes. According to another aspect of the invention, spoke bores in each of the hub flanges are grouped into pairs and the circumferential distance between adjacent pairs is greater than the distance between bores in a given pair.

Owner:RPA CYCLING INC

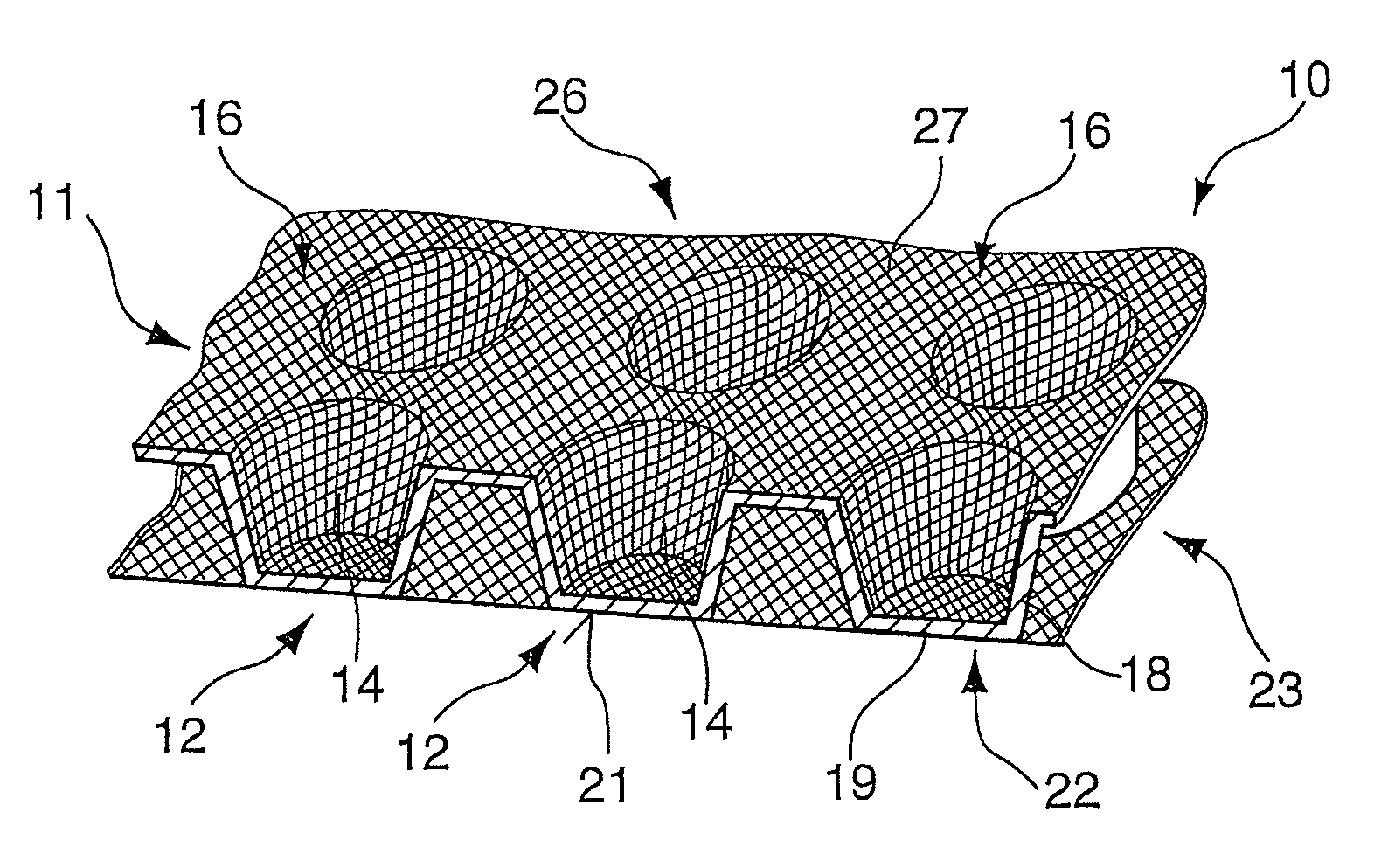

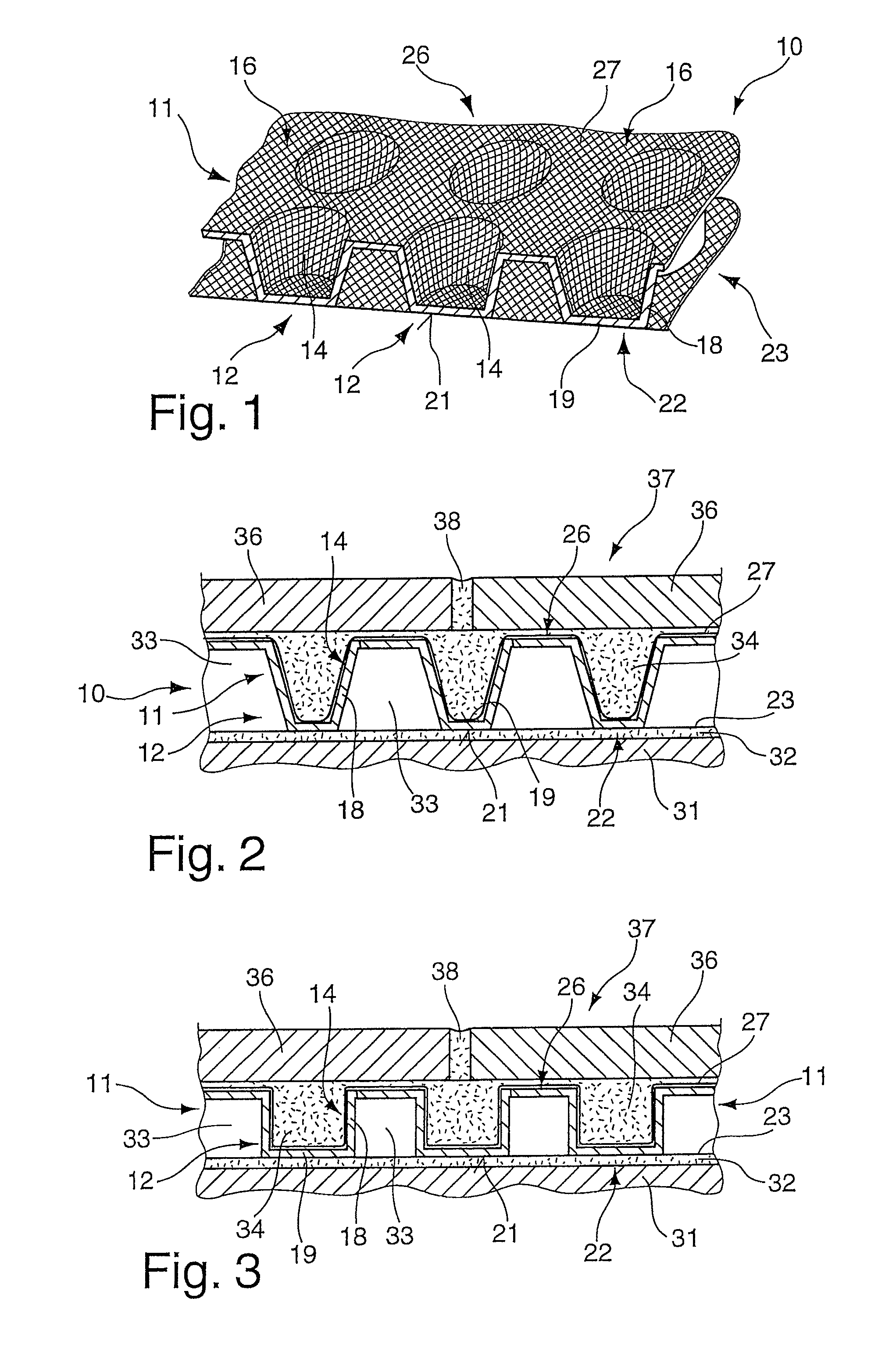

Support plate and method for producing such a support plate

ActiveUS8695300B2Strong mechanical bondEasy to manufactureCovering/liningsFloorsPlastic materialsEngineering

A support plate for a slab-lined wall, ceiling, or floor construction for achieving decoupling between a ground and a surface lining to be affixed to the support plate. The support plate comprises a foil-like plate made of plastic material and provided with a plurality of chambers constituted by recesses with respect to a plane of the foil-like plate, outer end faces which form a first plate side and on an opposite side a second plate side, the recesses being configured for receiving a hardening contact means for providing a contact layer for the surface lining to be applied, a woven or non-woven fabric disposed on the first plate side, and an adhesion-strengthening layer made of a web-like material being applied to at least one of the first or second plate sides for lining at least the recesses of the chambers.

Owner:INFINEX HLDG

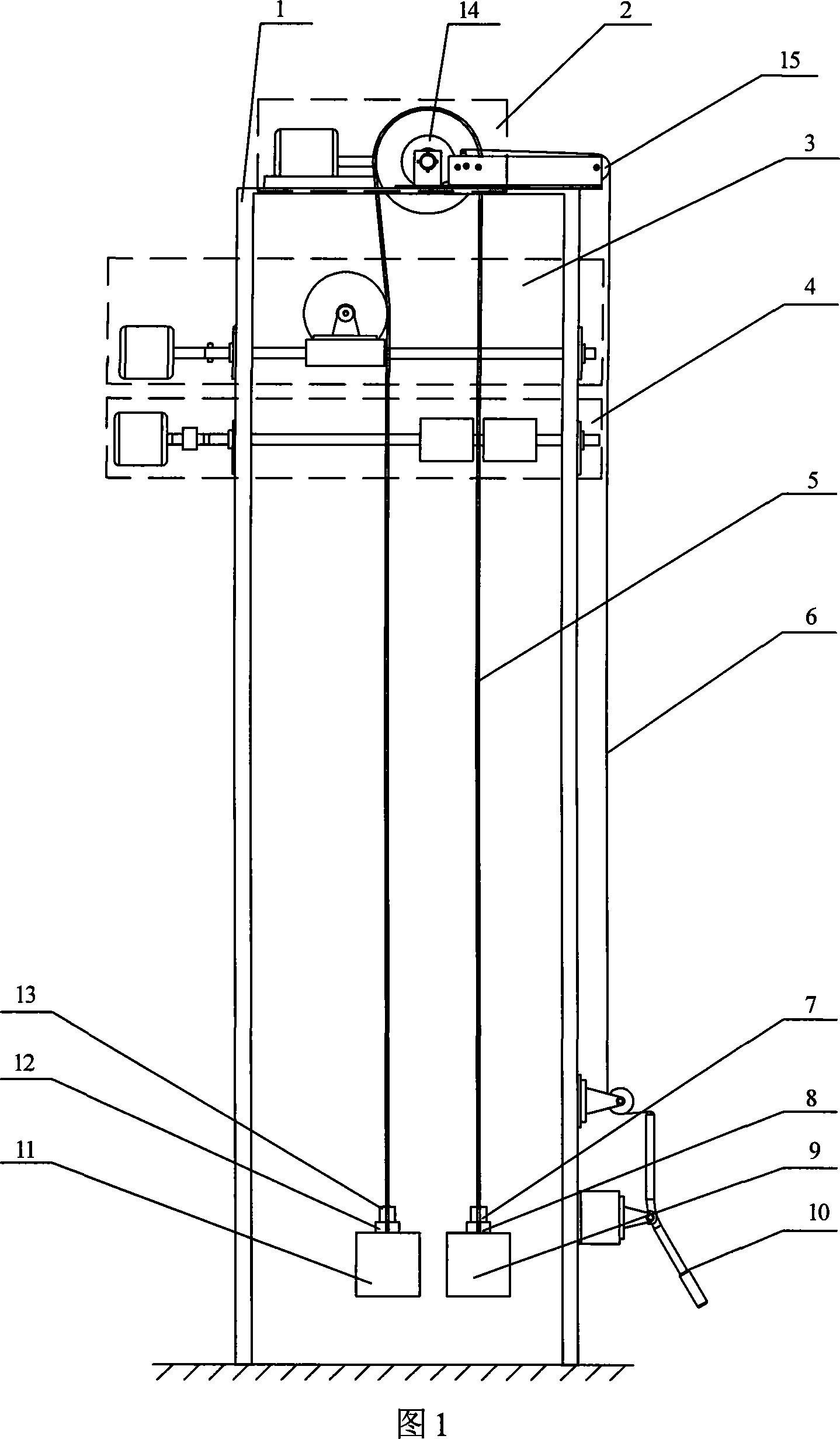

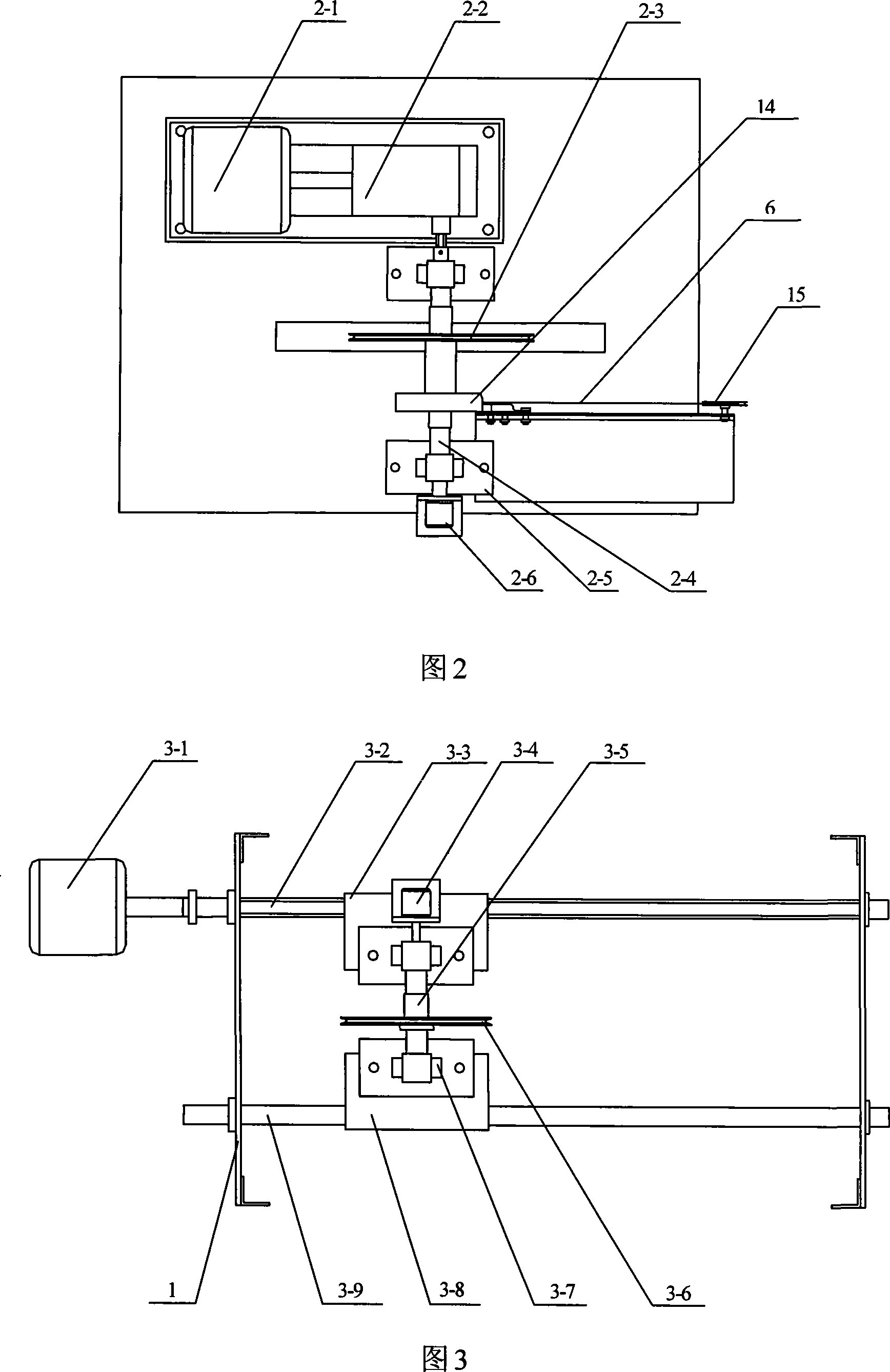

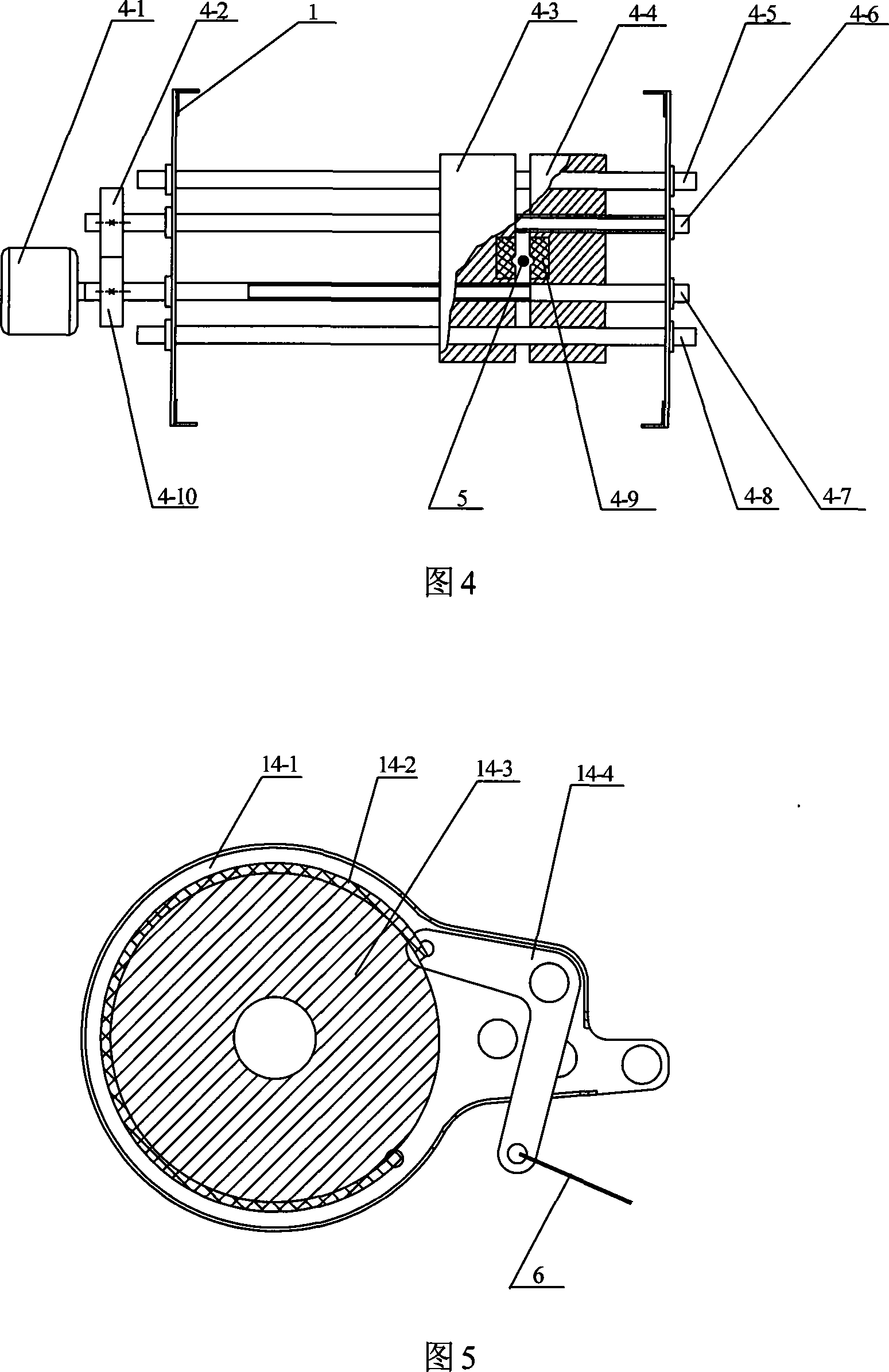

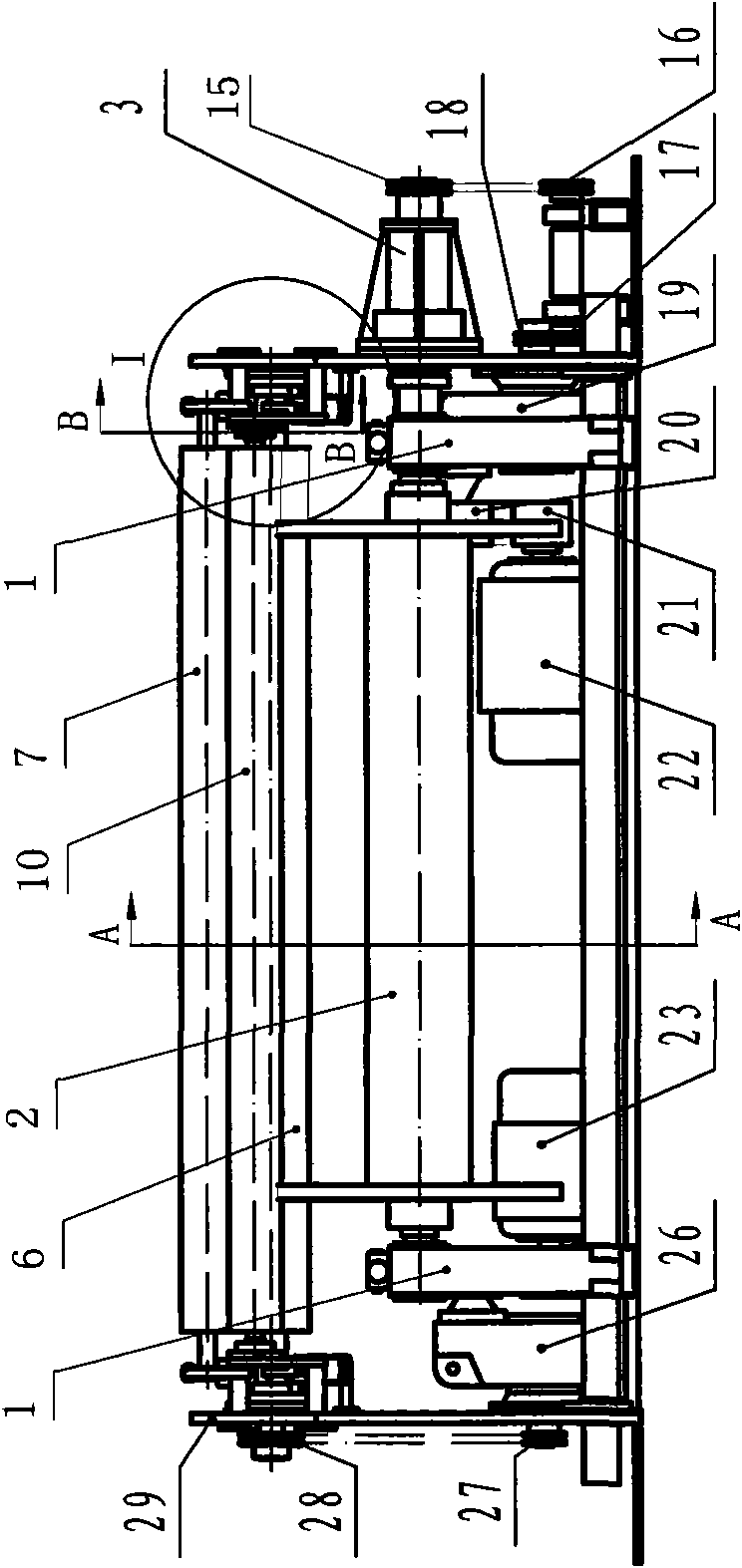

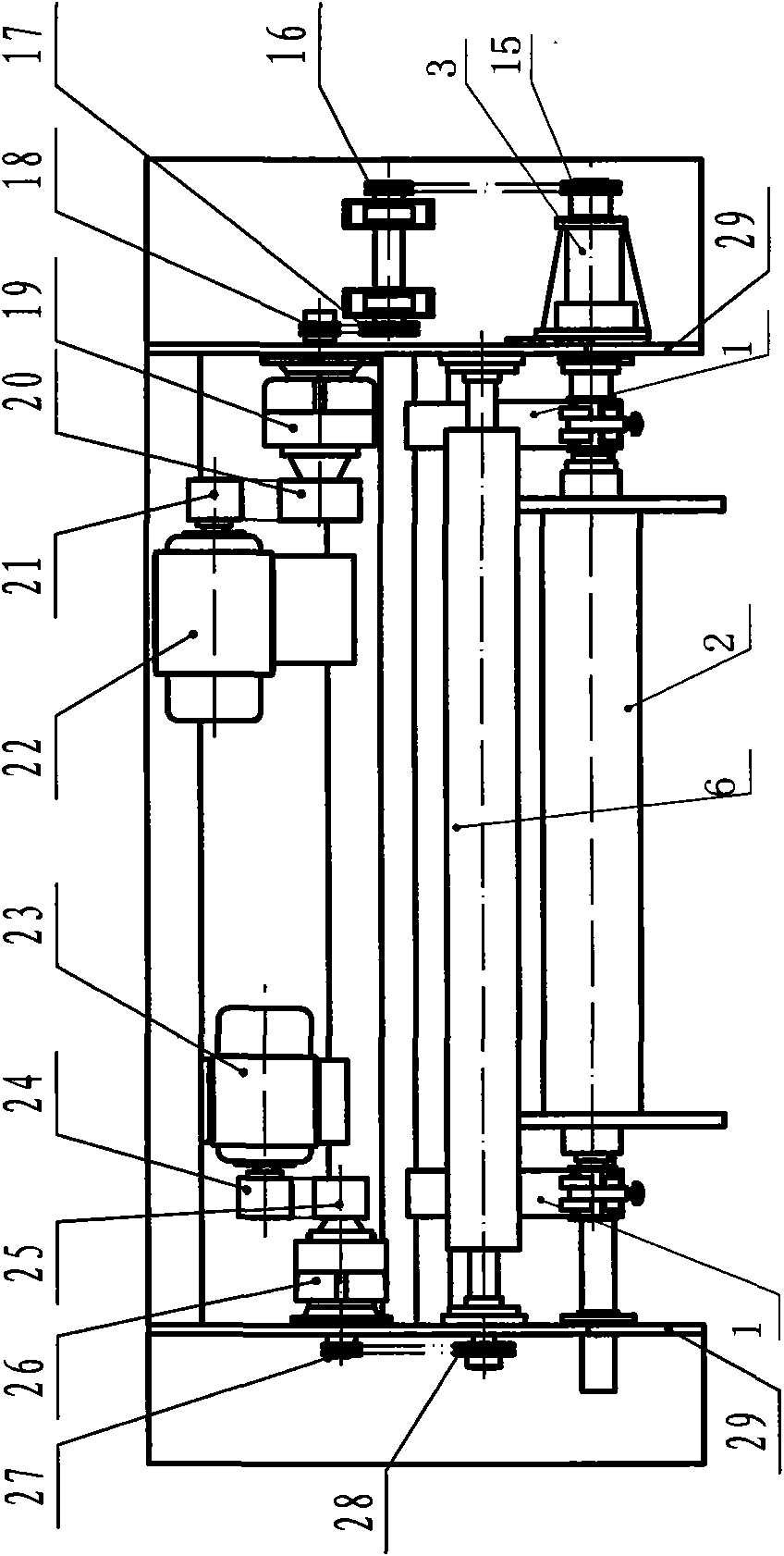

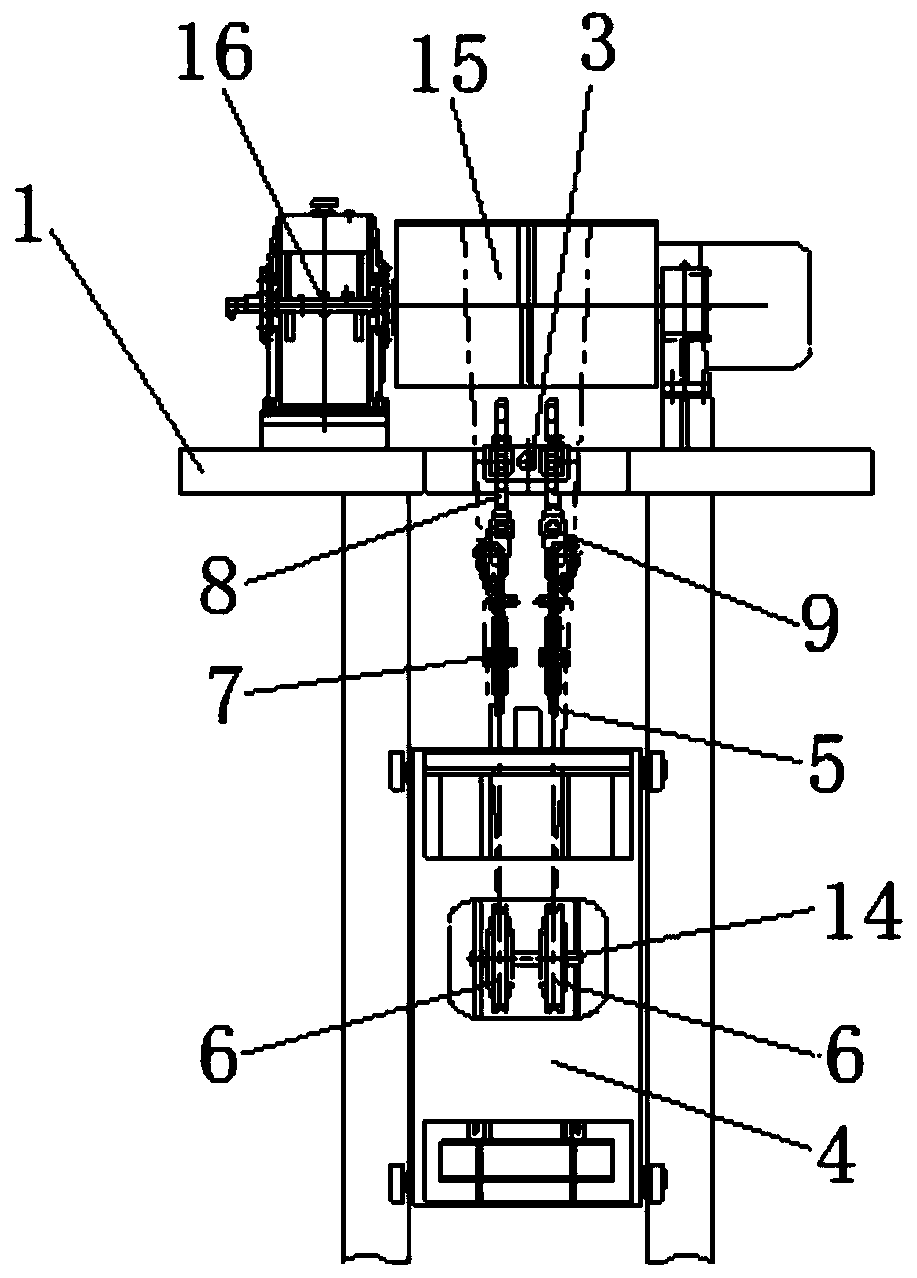

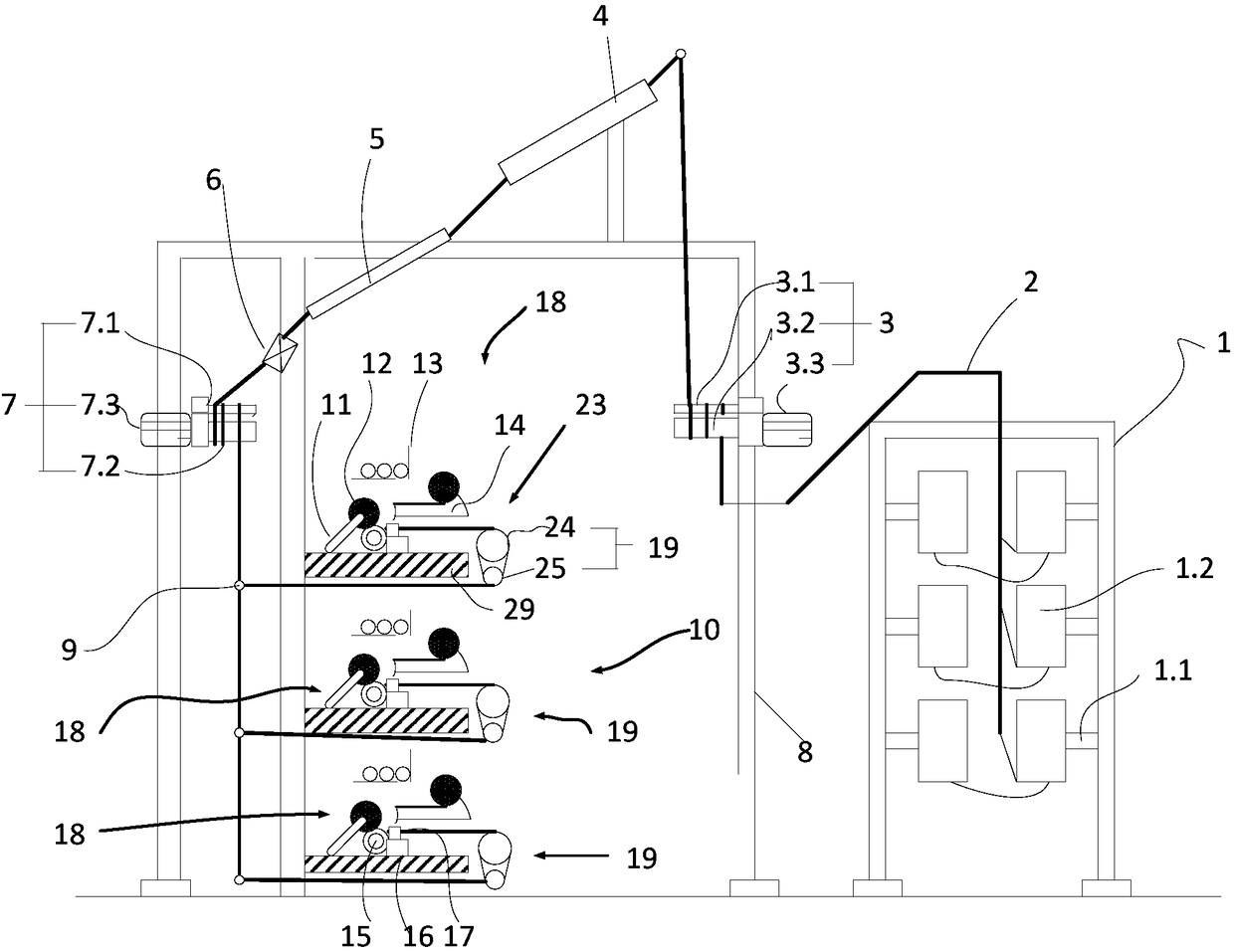

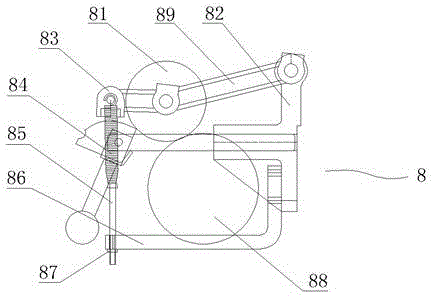

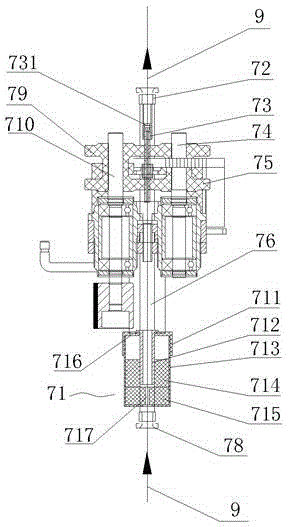

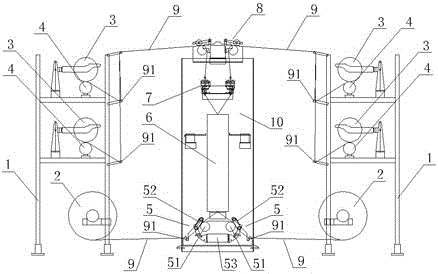

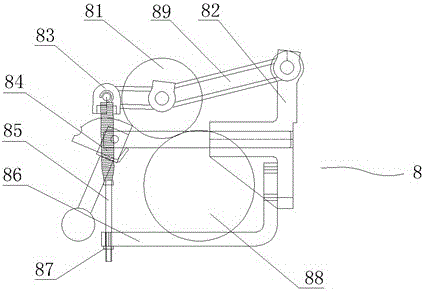

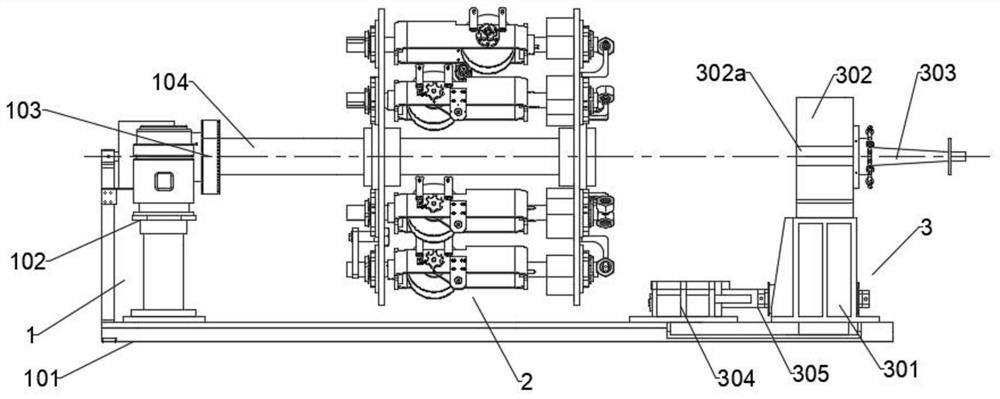

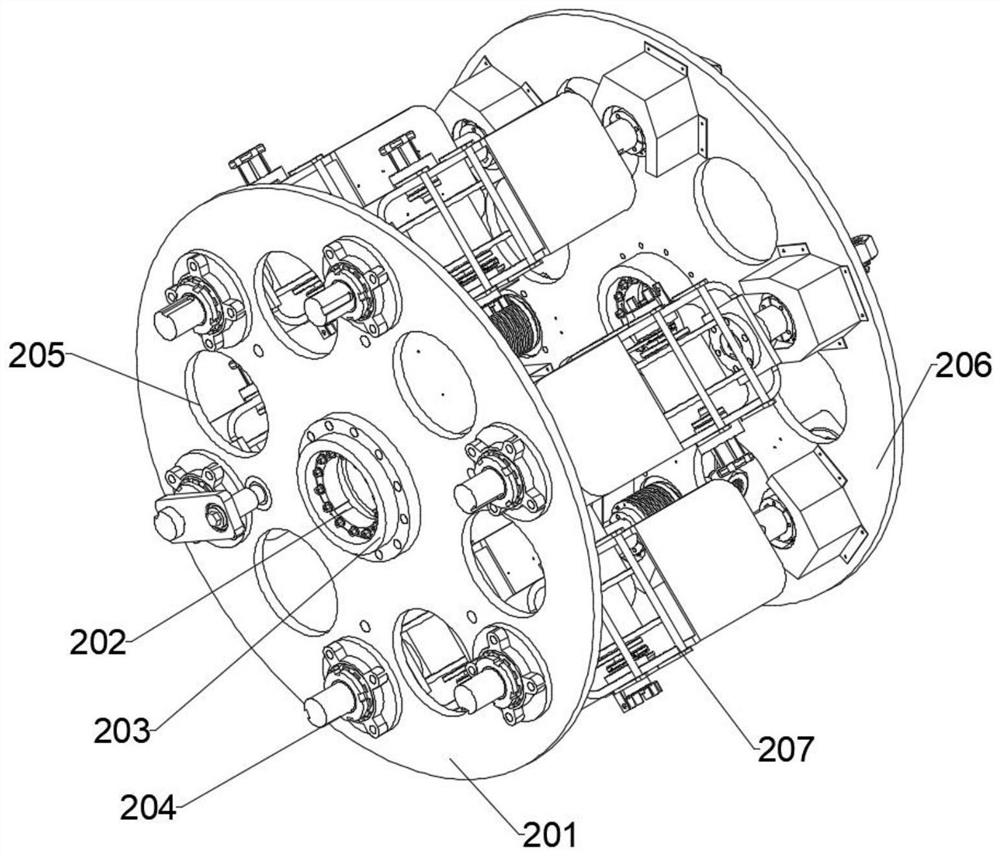

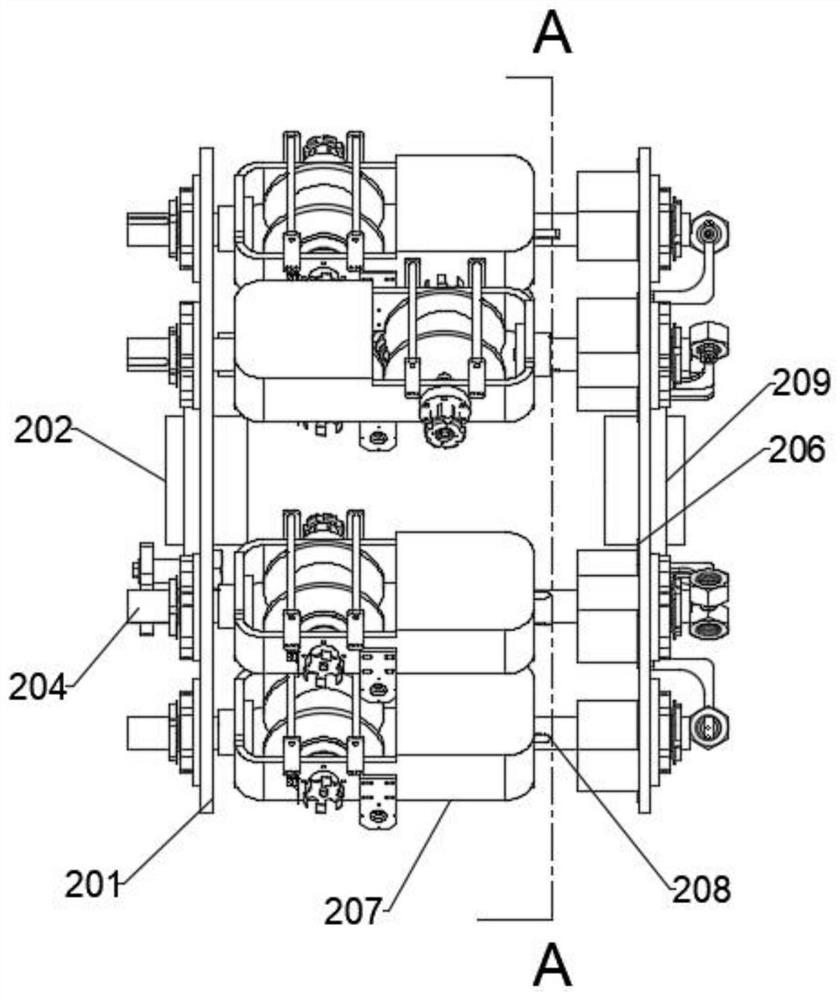

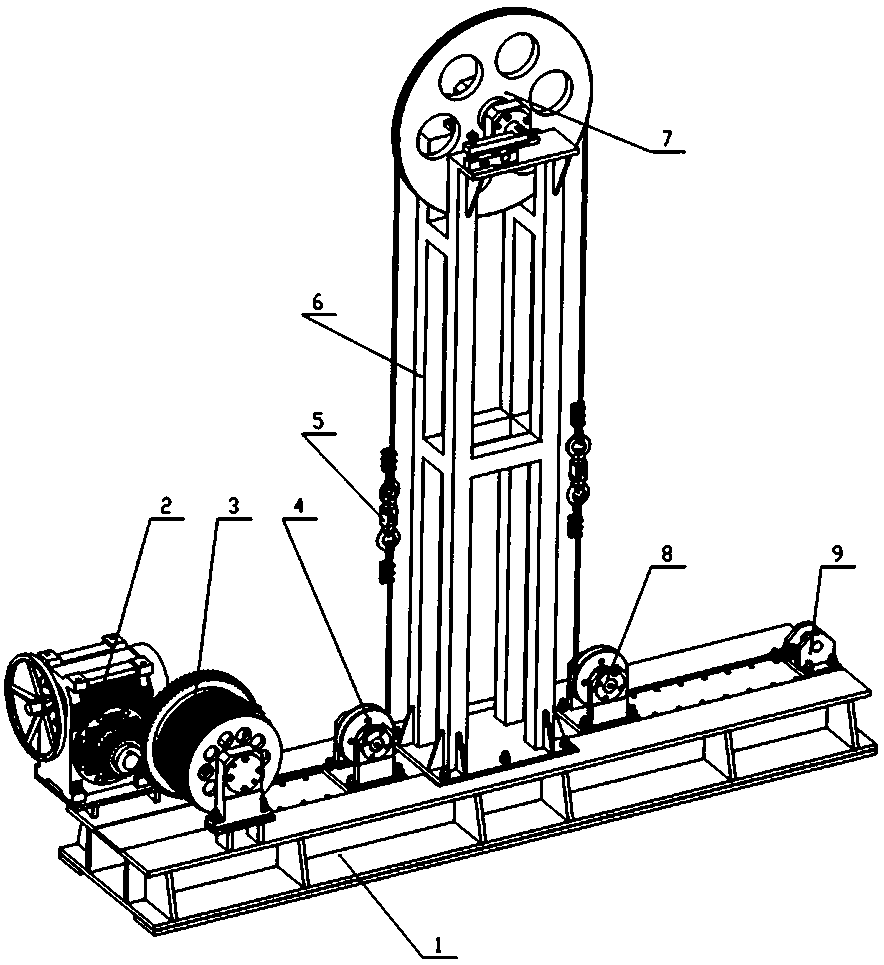

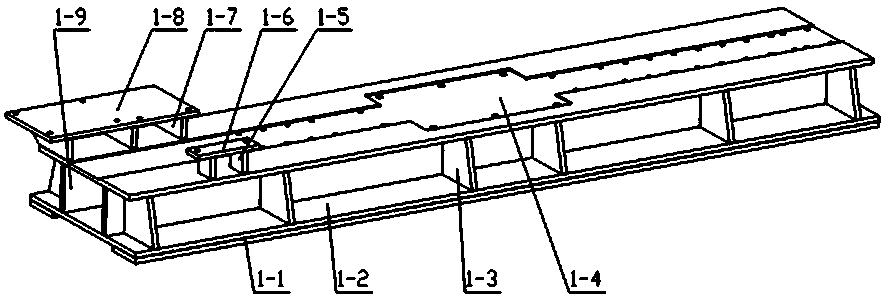

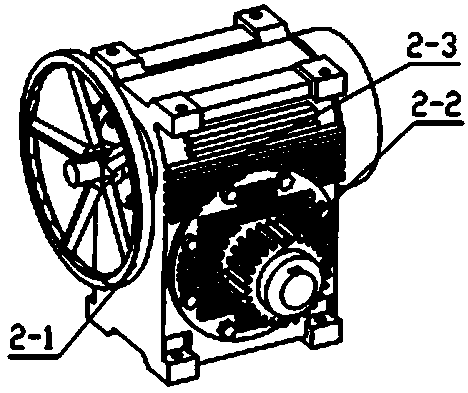

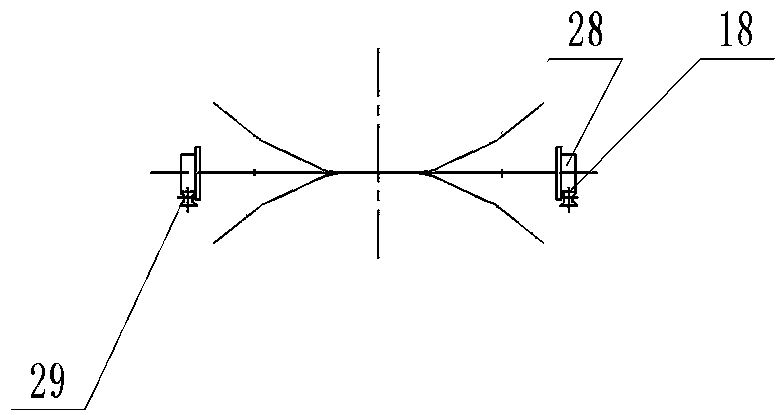

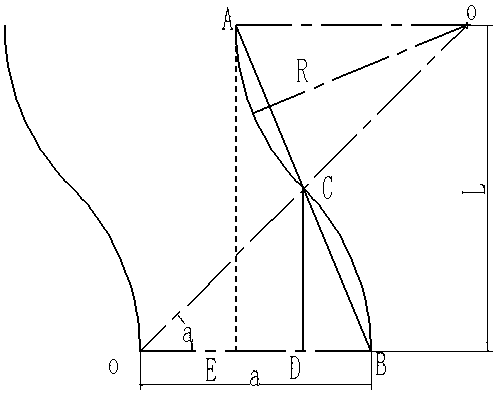

Multifunctional friction hoisting antiskid experimental device and method

InactiveCN101216381APrevent and eliminate sliding failuresCompact structureStructural/machines measurementArresting gearAcceleration Unit

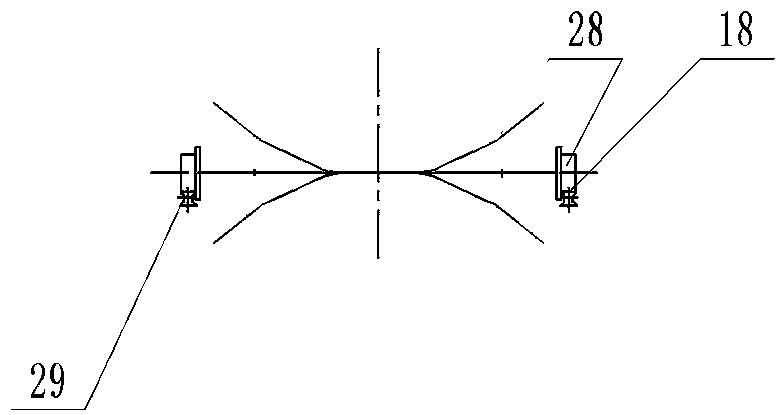

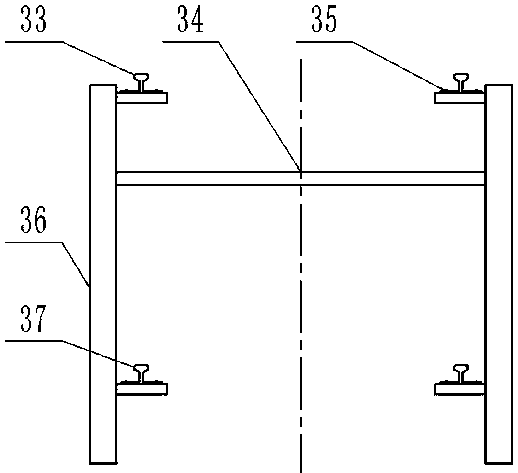

The invention provides a multifunctional friction lifting anti-slip experimental device and a method. The experimental device is composed of a frame, a drive device, a guide device, a tension adjusting device, a brake device, a loading device and a detection and control device. The drive device can drive the loading device to make lifting and lowering movement through a wire rope, thus simulating the friction lifting operation condition of mines. The brake device is disposed on the same shaft with the drive device for braking the drive device. The guide device can change the magnitude of a wrap angle of a friction wheel in the drive device. The tension adjusting device is used for clamping the wire rope to reduce the tension difference of wire ropes on both sides of the friction wheel in the drive device. A shaft coder is provided on the drive device and the guide device, a tension sensor and an acceleration sensor are provided on the loading device, and the detection and control device is used for determining the lifting state by receiving the values of the sensors to predict sliding rope and for controlling the drive device, the guide device and the tension adjusting device to act once a sliding sign occurs, thus preventing and eliminating slippage.

Owner:CHINA UNIV OF MINING & TECH

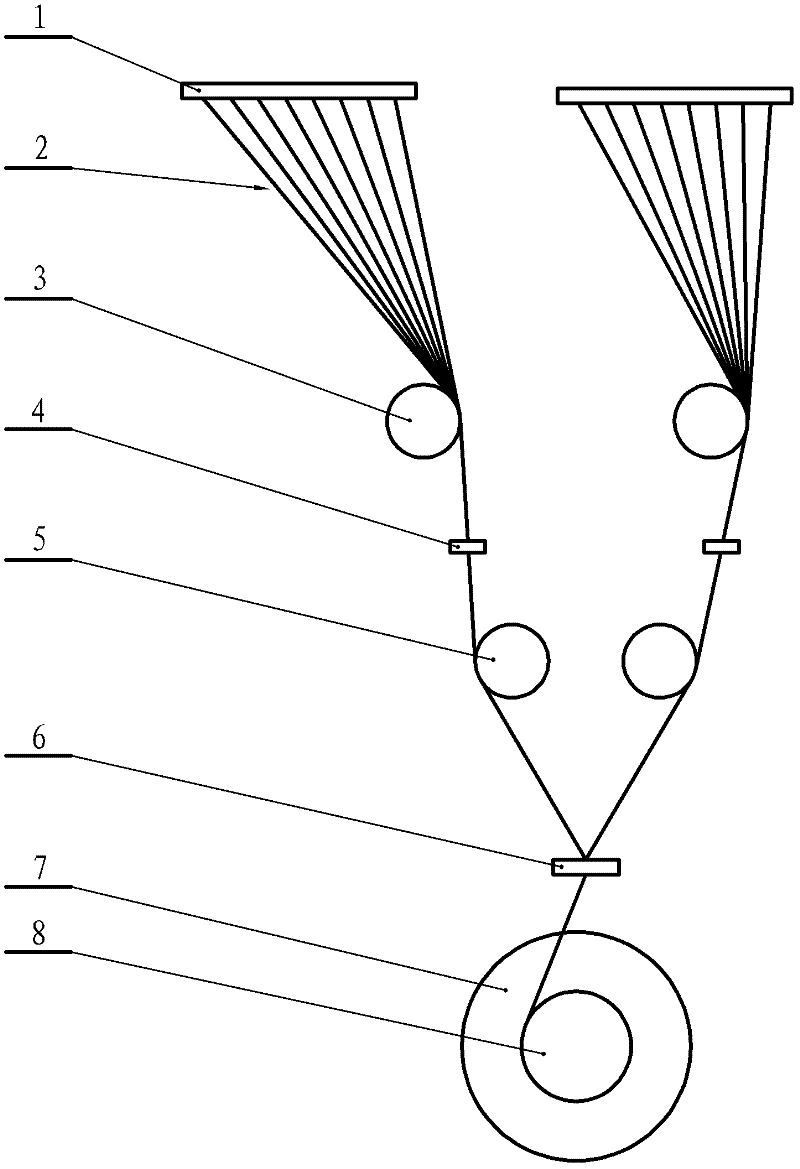

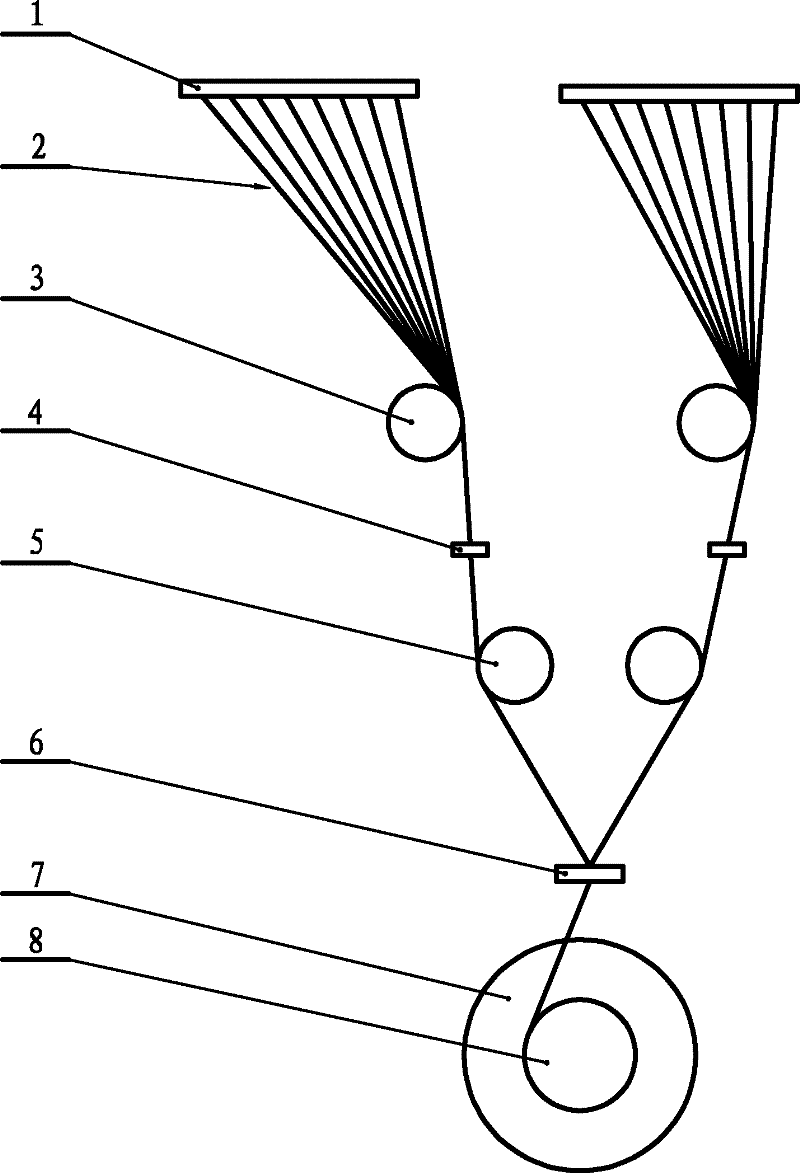

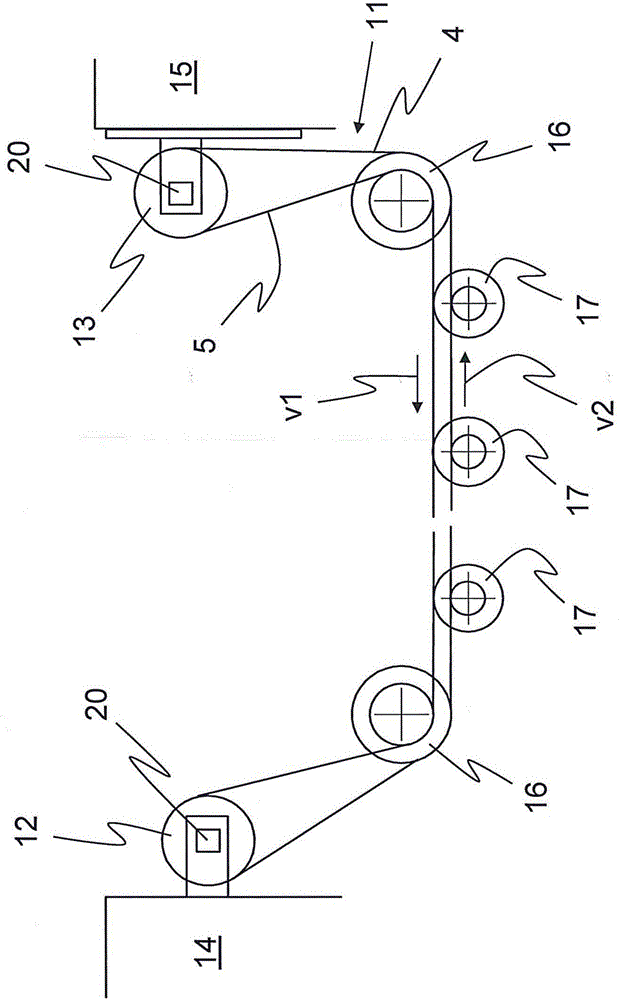

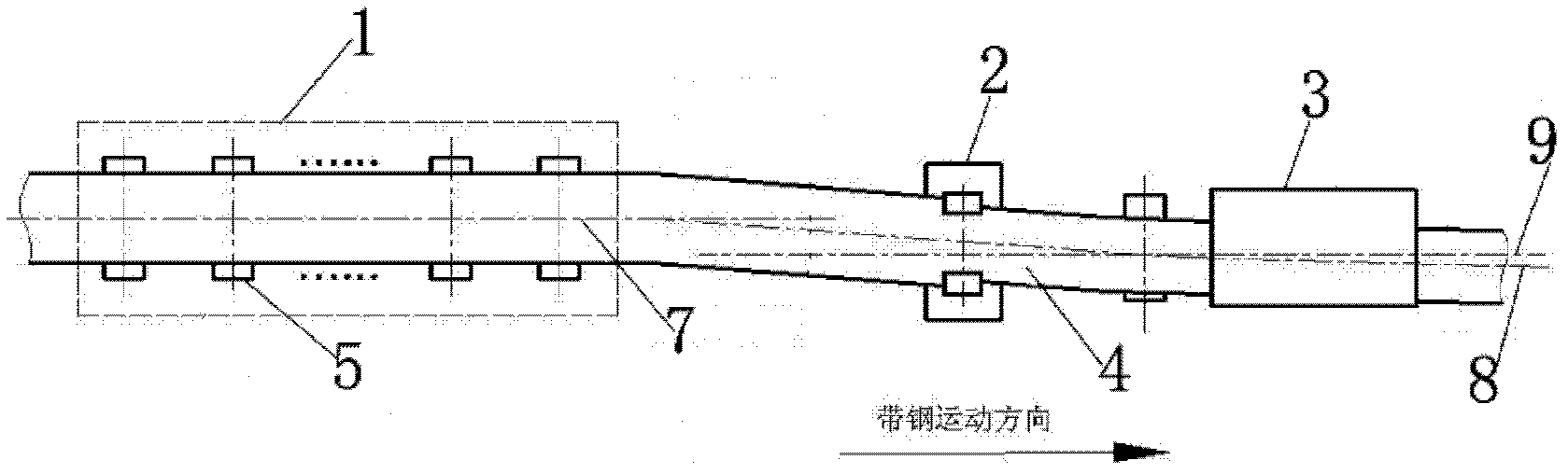

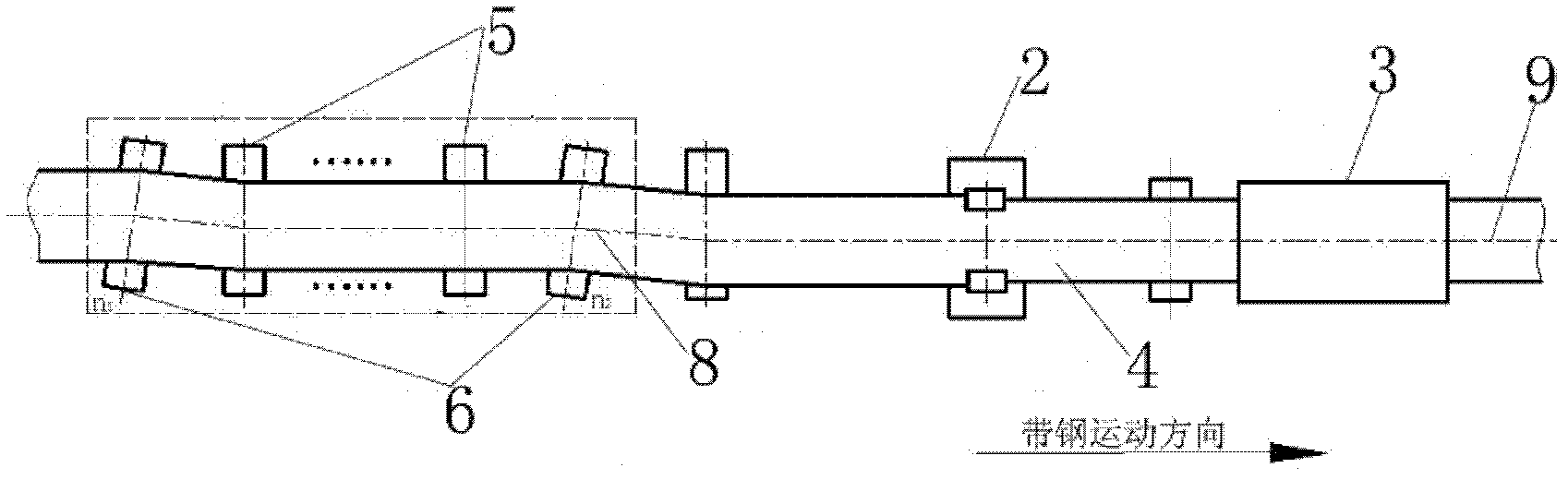

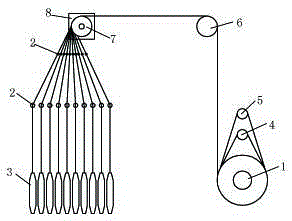

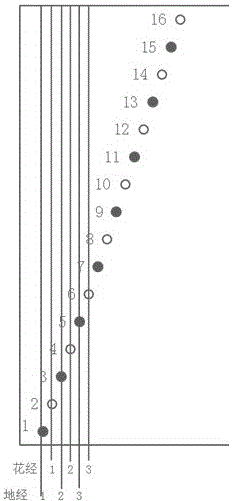

Multi-bushing plate merging wiredrawing technology and multi-bushing plate wiredrawing device employing it

ActiveCN102515504ASimplify temperature controlReduce manufacturing costGlass making apparatusGlass fiberEngineering

The invention provides a multi-bushing plate merging wiredrawing technology. Specifically, 2 or more bushing plates are employed, and each bushing plate is provided with a plurality of leaks. Molten glass flows through each leak of each bushing plate and is cooled, and then a plurality of glass fibers can be obtained through wiredrawing molding respectively. Pulled by a wiredrawing machine driven wire cylinder, the glass fibers respectively pass through multiple upper bunchers and are neatened and gathered into glass fiber bundles, which are then neatened and gathered by a gathering buncher into a complete glass fiber bundle that is then wound on the wire cylinder into a finished glass fiber bundle. A multi-bushing plate wiredrawing device is provided with 2 or more bushing plates, each of which is equipped with a plurality of leaks. An upper buncher is installed behind each bushing plate respectively, a gathering buncher is arranged behind each upper buncher, the wiredrawing machine is disposed behind the gathering buncher, the wire cylinder is positioned on the gathering buncher, and the wire cylinder and the wiredrawing machine are in driving rotary connection. With the technology and device provided in the invention, the manufacturing cost of a bushing plate for a glass fiber bundle with a great weight of per unit length can be reduced, the band forming property of the glass fiber bundle can be improved, and the effect can be obvious.

Owner:CHONGQING POLYCOMP INT

Pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and production technology thereof

The invention discloses pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and a production technology thereof. The pure aloe fiber warp and weft double-elasticity yarn-dyed fabric comprises a warp yarn, a weft yarn and an elastic yarn, wherein 60S aloe fiber yarns are adopted as the warp yarn and the weft yarn; aloe 50S / 20D is adopted as the elastic yarn; a plain fancy cellular structure is adopted as a fabric structure; a bottom structure formed by plain as main material and triple fancy cellular structures in the transverse direction and longitudinal direction; an edge structure is the plain; and a jacquard part is formed by the fancy cellular structure as main part in transverse direction and horizontal direction matched with the shrinkage action of an aloe fiber spandex core-spun yarn. The production technology comprises a spooling step, a warping step, a slashing step, a drafting step and a weaving step. The fabric is reasonable in color match, light and thin in texture and slight in wrinkle, and gives a casual feeling to a consumer. Meanwhile, the pattern is relatively large in cycle, and is matched with unique plain fancy cellular structure, so that the fabric is high in third dimension and good in breathability. The weaving efficiency reaches 91%; and the first grade percentage put in storage reaches 99%.

Owner:IANGSU COLLEGE OF ENG & TECH

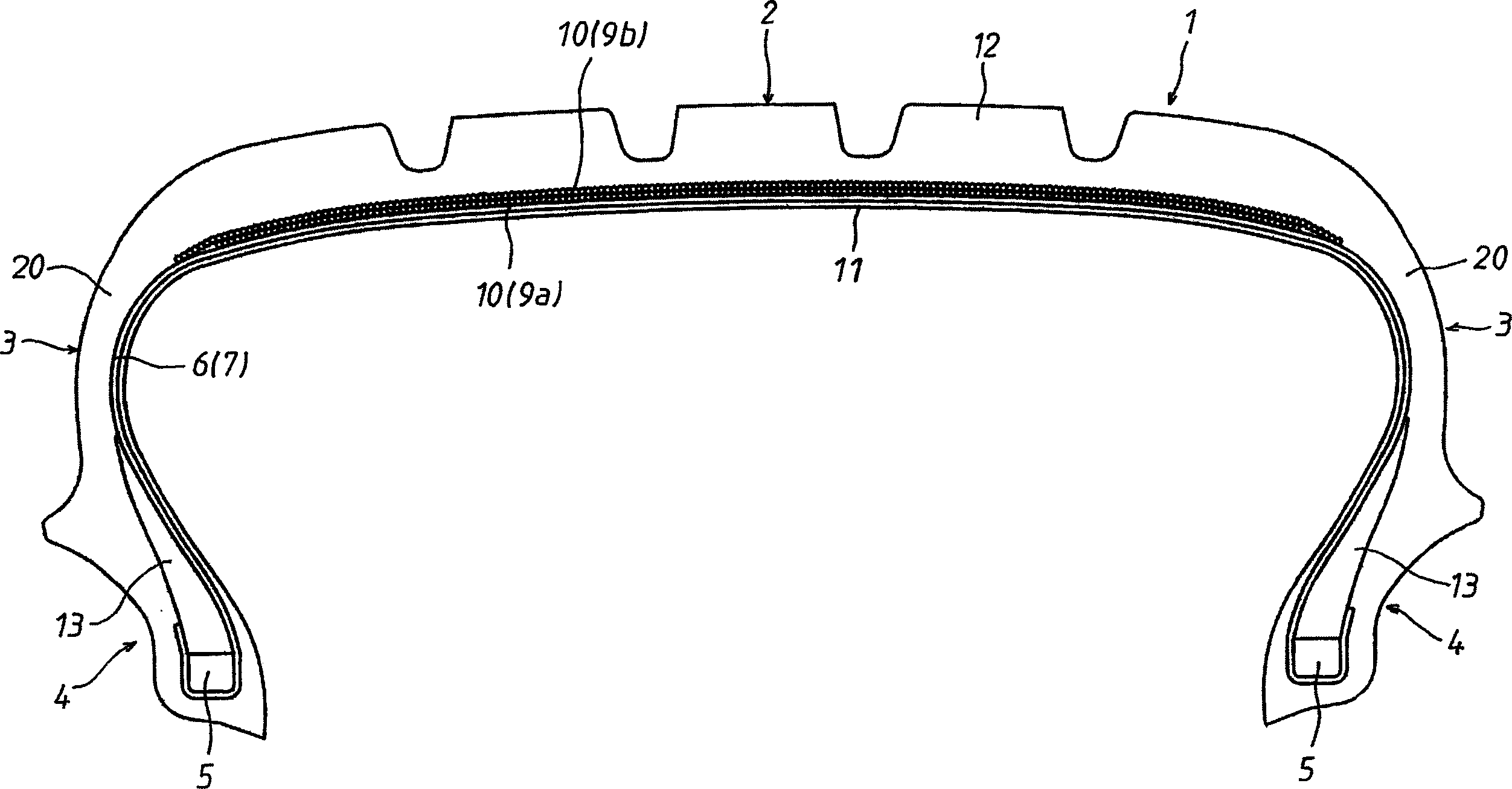

Radial tire with circumferential spirally wound belt layer

InactiveCN1708415AImprove braking effectImprove handling stabilityPneumatic tyre reinforcementsYarnEngineeringMechanical engineering

A belt layer in which one or more belt cords covered with rubber are arranged spirally wound substantially in parallel in the tire circumferential direction, and at least one layer is arranged on the outer periphery of the main body ply. The belt cord has a small increase ratio of the tensile load with respect to an increase in the elongation at a predetermined elongation or less, and a large increase ratio of the tensile load when the elongation exceeds the predetermined elongation. Therefore, since the belt cords expand together with the unvulcanized compound rubber with a small tensile load during vulcanization molding, and the expansion of the main body ply cords is not prevented, the normal shape of the raw tire is maintained and expanded, Reliably fit and vulcanize each part.

Owner:FUJISEIKO

Production process of copper ammonia and spun silk twill fabric

InactiveCN108060492ASmall beating resistanceEasy to tightenArtificial filaments from cellulose solutionsGrip property fibresCuprammonium rayonFiber

The invention discloses a production process of a copper ammonia and spun silk twill fabric. The process includes the following steps of key point designing, spooling, warping, sizing, drafting and weaving. The four-in-one product formed by blending and interweaving copper ammonia fiber, spun silk, jute fibers and tencel fibers has the inherent advantages of a real silk fabric of being comfortable, soft, elegant and cool, is good in drapability, stiff and smooth, free of creases, not prone to ageing after sunburn, free of yellowing after sweat absorption and better in performance compared withthe real silk fabric and is a high-grade summer clothes fabric.

Owner:IANGSU COLLEGE OF ENG & TECH

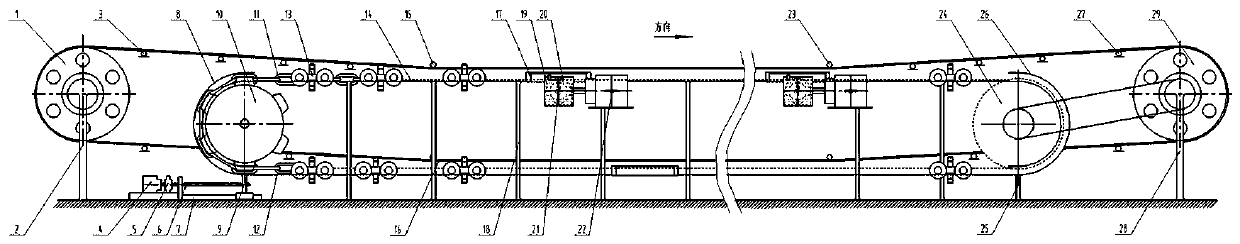

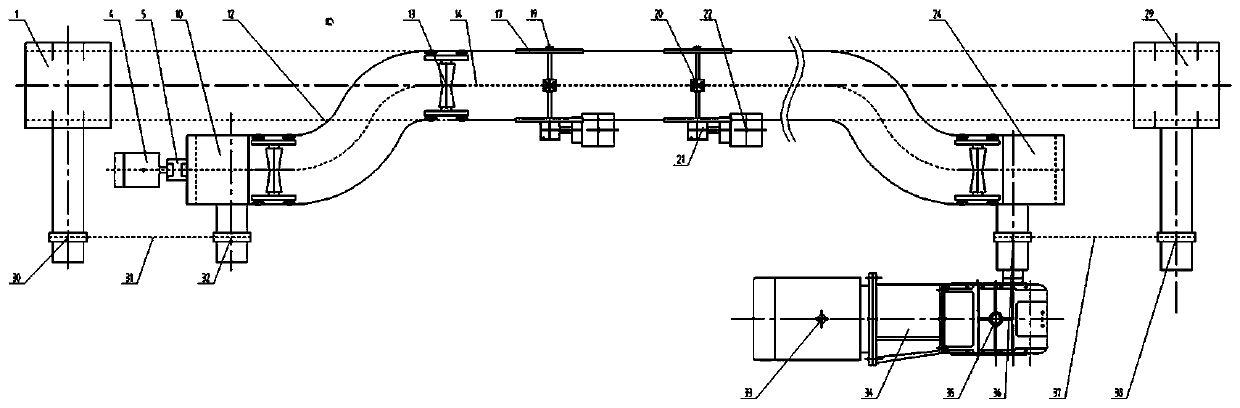

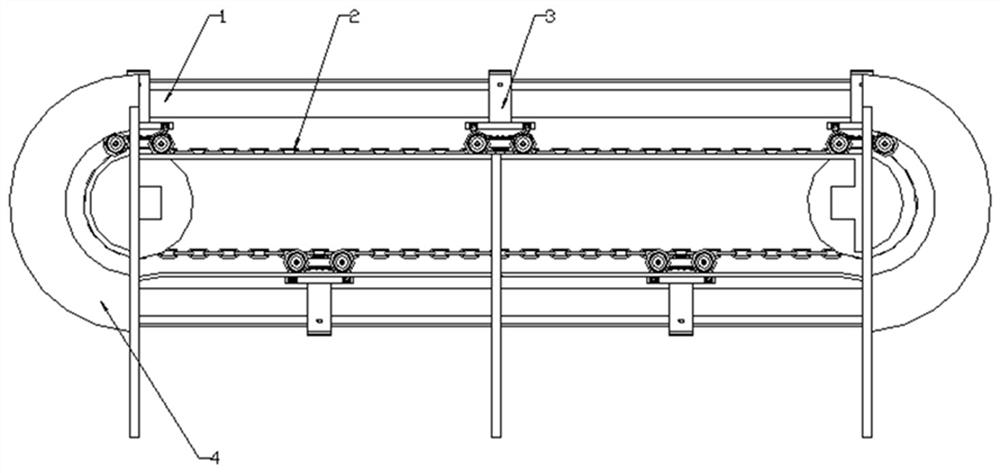

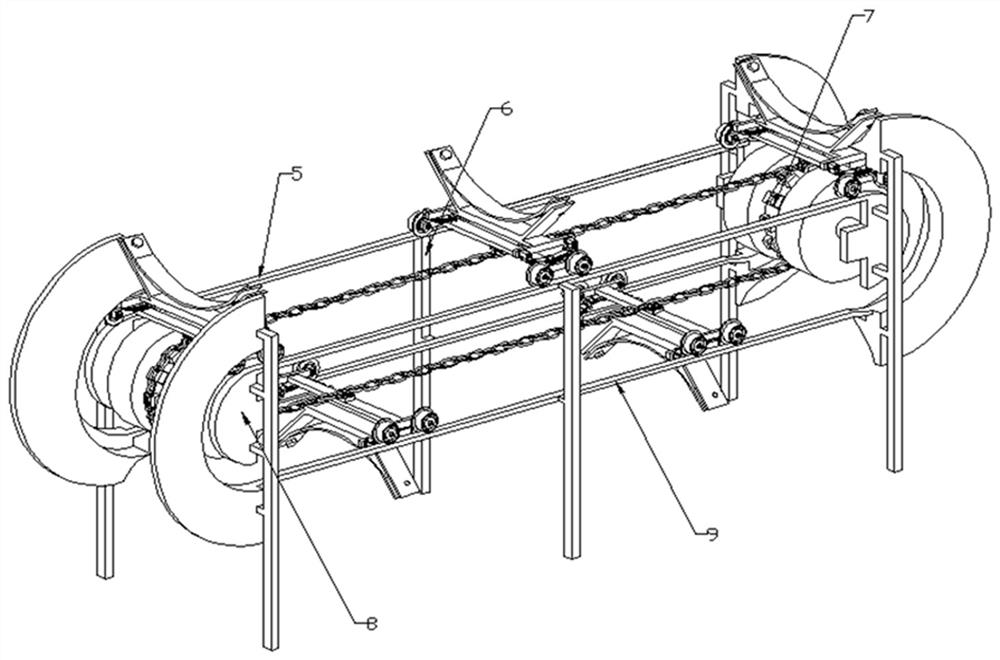

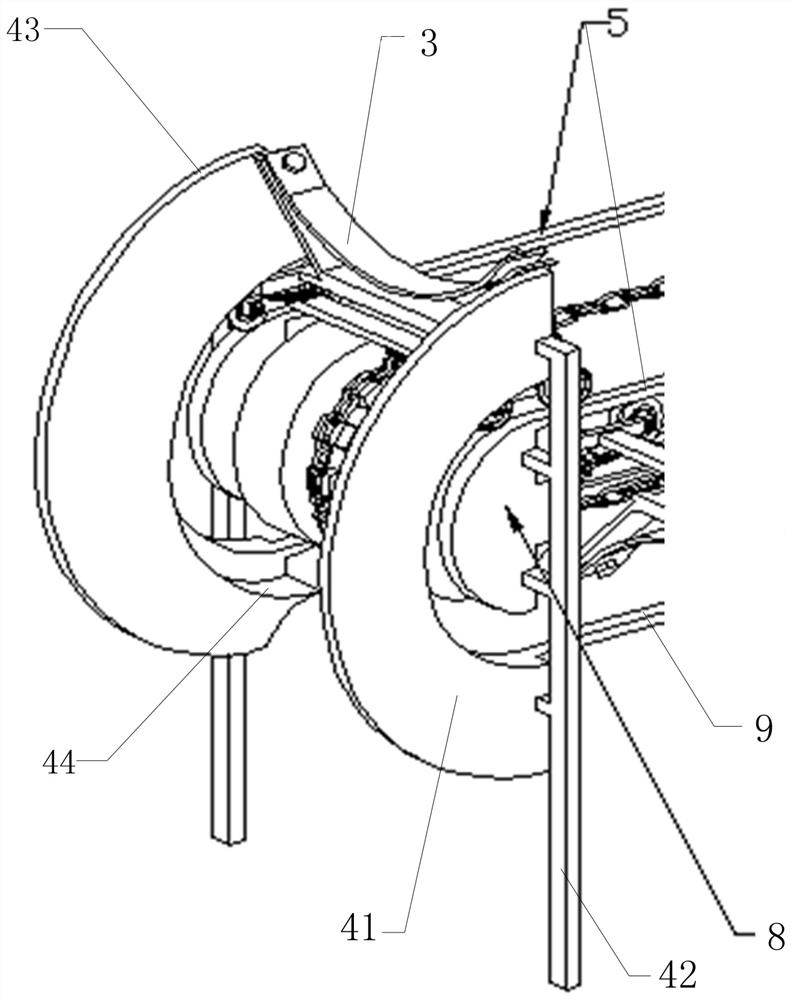

Trolley group towed type adhesive tape conveyor

ActiveCN109230261AImprove contact stiffnessLow coefficient of rolling frictionConveyorsSprocketAdhesive

The invention belongs to the technical field of bulk material transport equipment and particularly relates to a trolley group towed type adhesive tape conveyor. The problems are solved that existing adhesive tape conveyors have a large difference in tension of adhesive tapes, the running adhesive tapes deviate and are unsafe, the running resistance is large, and the energy consumption is high. Theadhesive tape conveyor comprises a fixed bearing rack, a driving device, a traction mechanism and a guiding mechanism, wherein the driving device, the traction mechanism and the guiding mechanism aredisposed on the fixed bearing rack; the traction mechanism pulls a trolley group sprocket chain to move horizontally on the rack when a machine head guide rail sprocket wheel rotates so that trolleygroup sprocket trolleys can move along a guide rail, and the adhesive tapes are moved forward simultaneously, so that transport of materials is achieved. The adhesive tapes are in fraction with trolley supports to transmit a traction force, and the adhesive tapes run along with a belt conveyor body under the action of the traction force of the trolleys; since the trolleys are distributed at intervals, segmental traction is achieved, and the difference in the tension of the adhesive tapes is small. The low-strength adhesive tapes can be selected, and the investment cost of the adhesive tapes isreduced.

Owner:TAIYUAN UNIV OF TECH

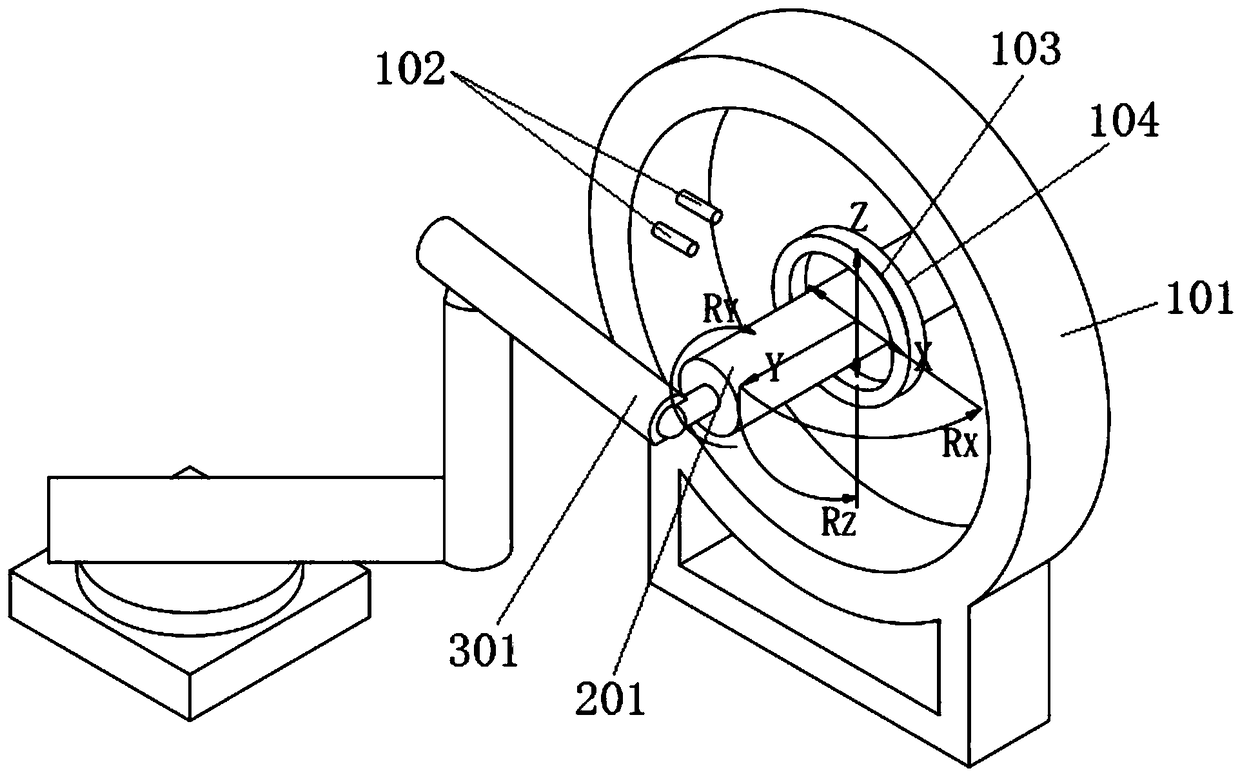

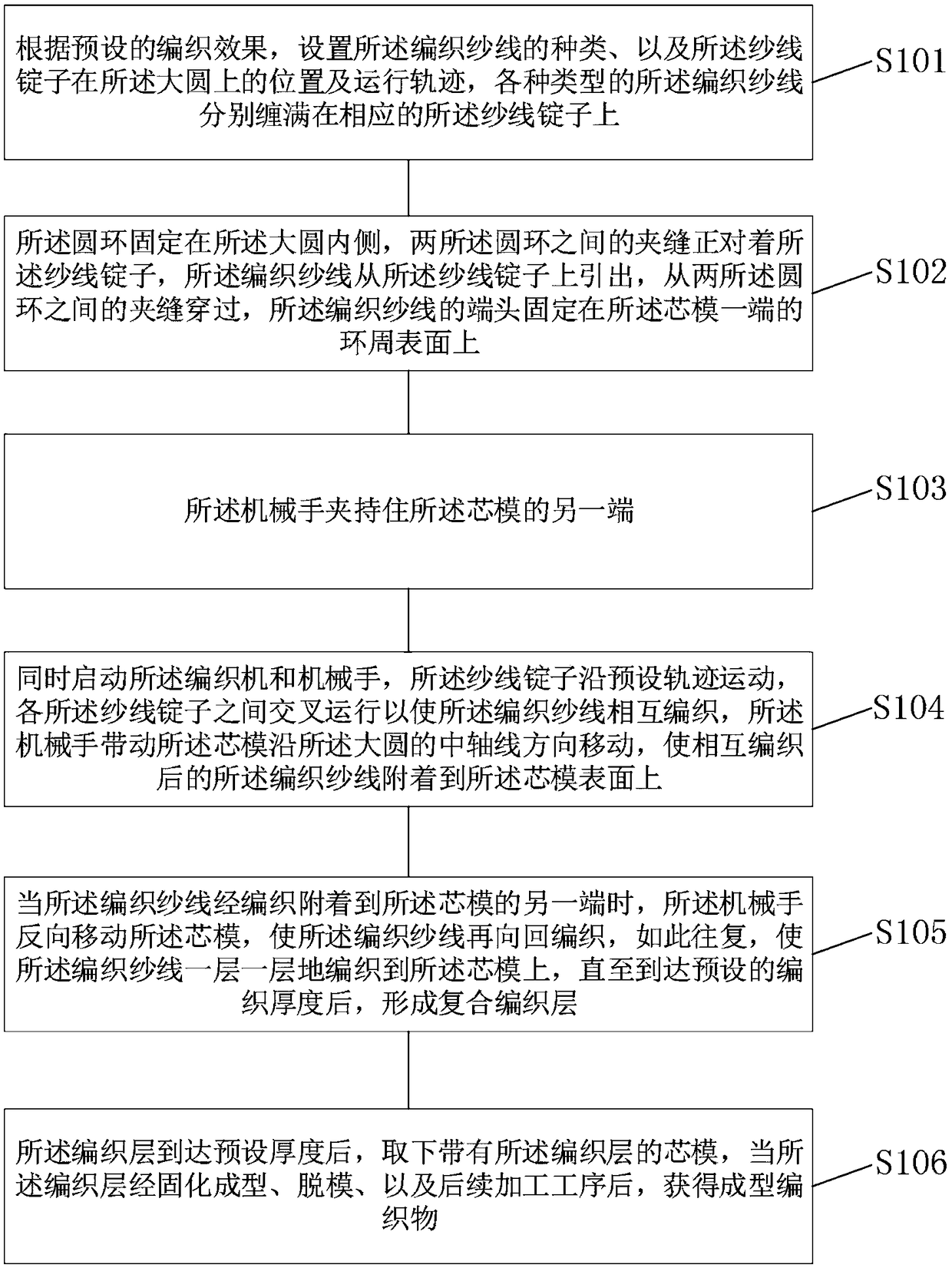

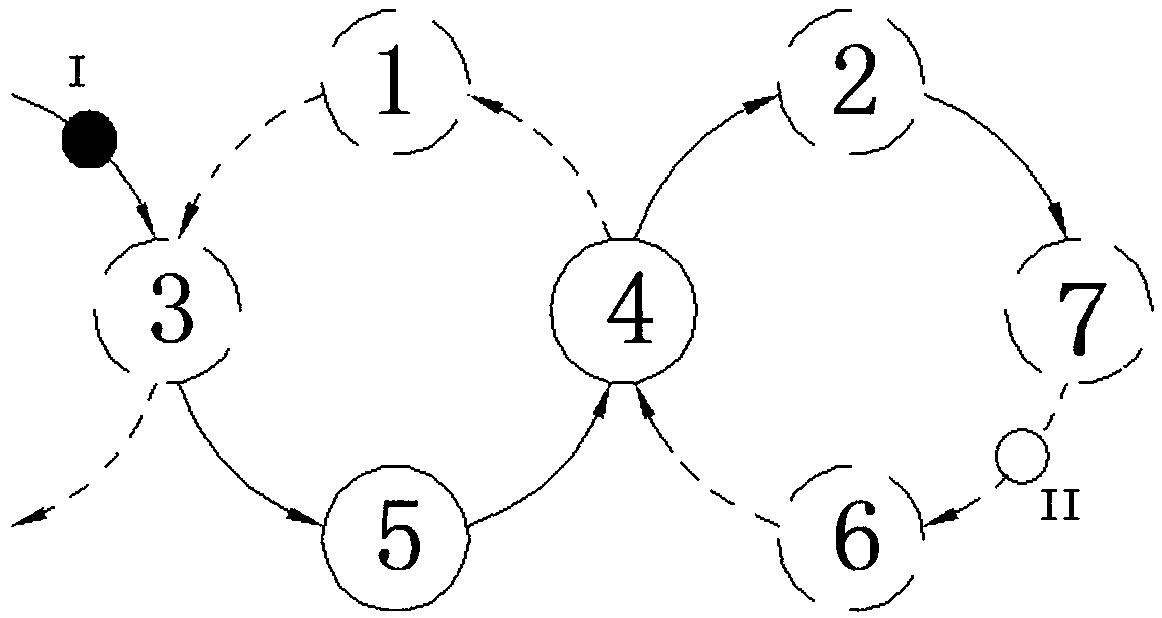

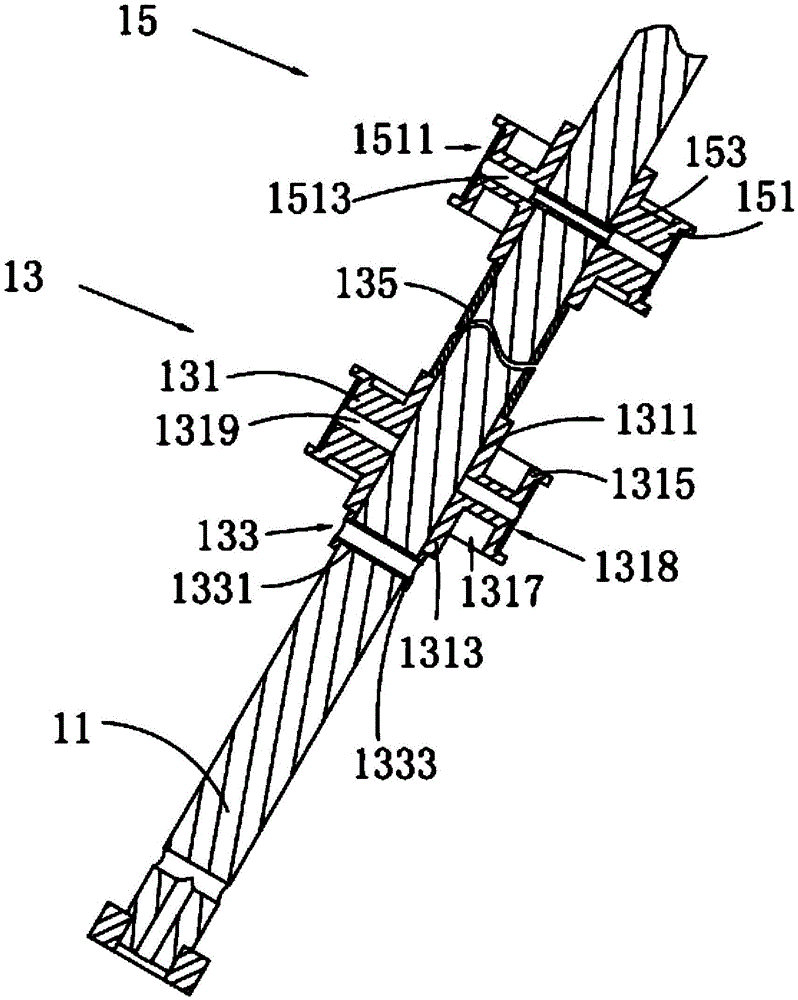

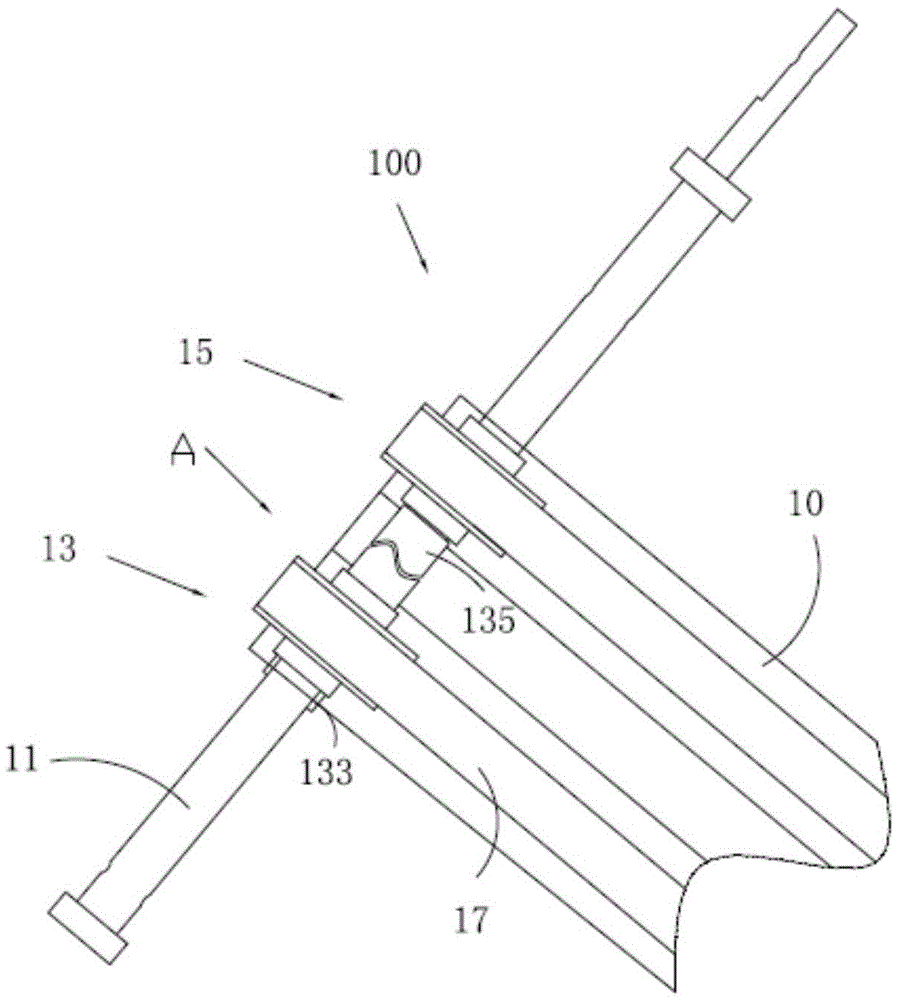

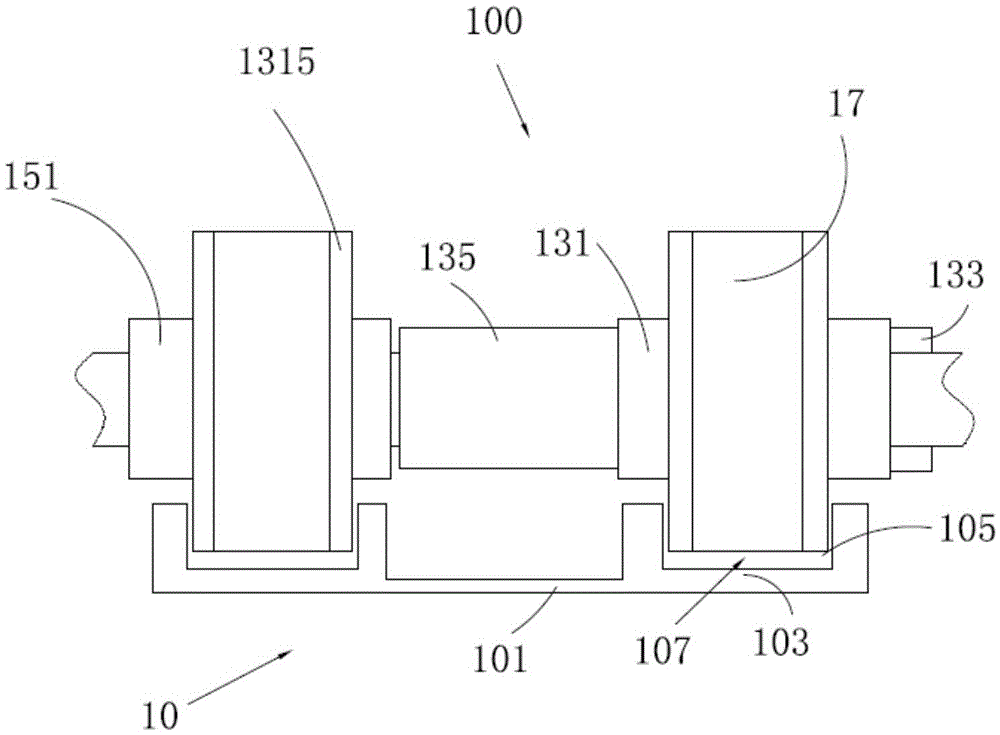

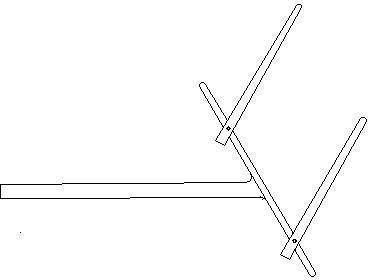

Equipment and process for weaving composite material

The invention provides equipment and a process for weaving a composite materials; the equipment comprises a knitting machine and a mechanical arm, the knitting machine comprises a large circle, yarn spindles, two circular rings and a core mould; the yarn spindles are arranged on the inner side wall of the large circle, and are uniformly arranged along the circumferential direction of the inner side wall of the large circle; the two circular rings are arranged side by side, the two circular rings coincide with the central axis of the large circle, and a preset distance is reserved between the two circular rings, so that woven yarns can pass through the preset distance; the core mould is arranged in the circular rings in a penetrating mode, one end of the core mould is connected with the mechanical arm, and the mechanical arm is used for driving the core mould to do reciprocating motion along the central axis direction of the large circle; the type of the yarn spindles is at least two, the yarn spindles of all types rotate synchronously with the large circle, and the large circle revolves according to a preset trajectory. An insulation operating rod produced by the weaving process and the equipment is higher in fiber density compared with other insulating rod formed by other processes, internal air bubbles are fewer, the insulation operating rod has the advantages of being lighter in weight, better in mechanical and insulating performance and capable of being applied to overhauling work of extra-high voltage electric power engineering.

Owner:STATE GRID CORP OF CHINA +3

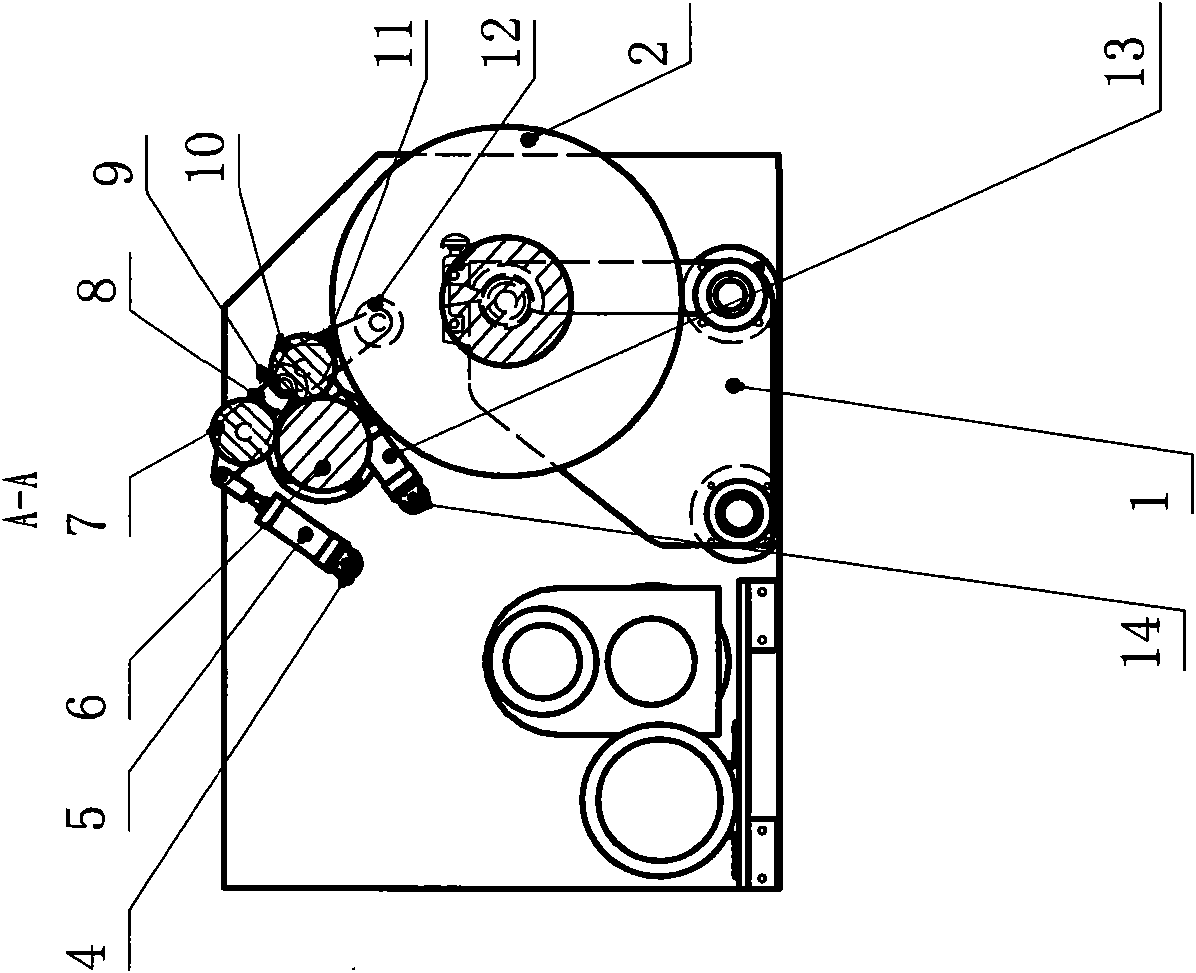

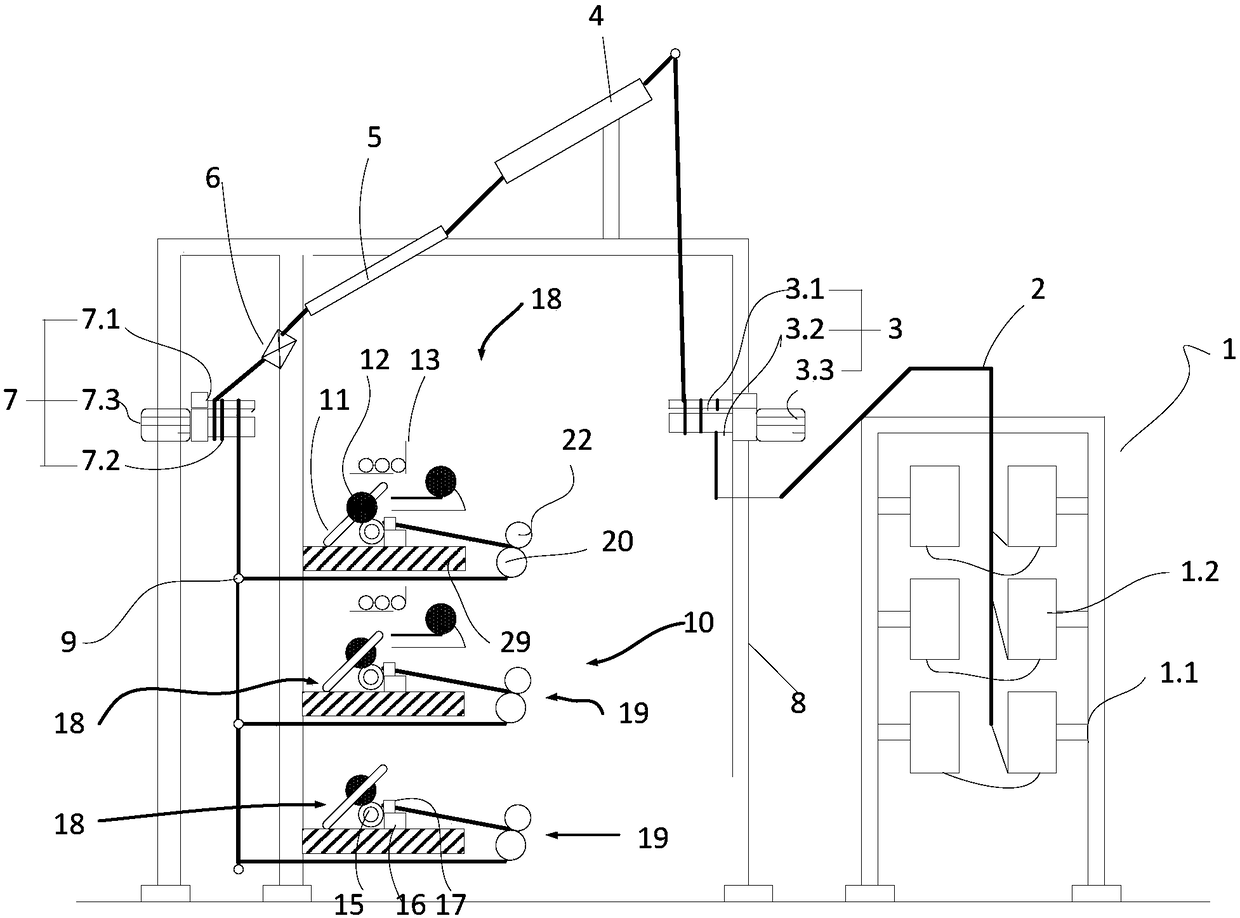

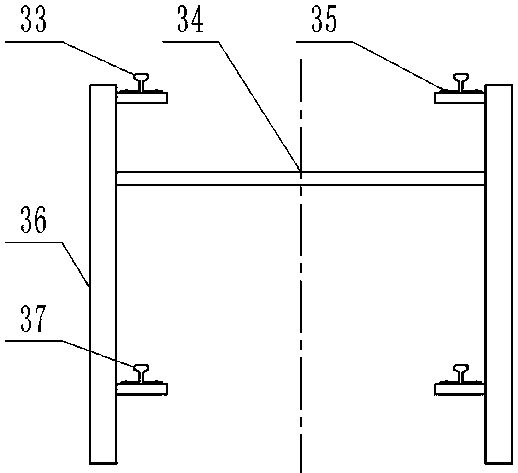

Bi-motor yarn tension control device of disposable warping machine

InactiveCN101555644AHigh control precisionConstant speedOther manufacturing equipments/toolsTextiles and paperElectric machineDrive shaft

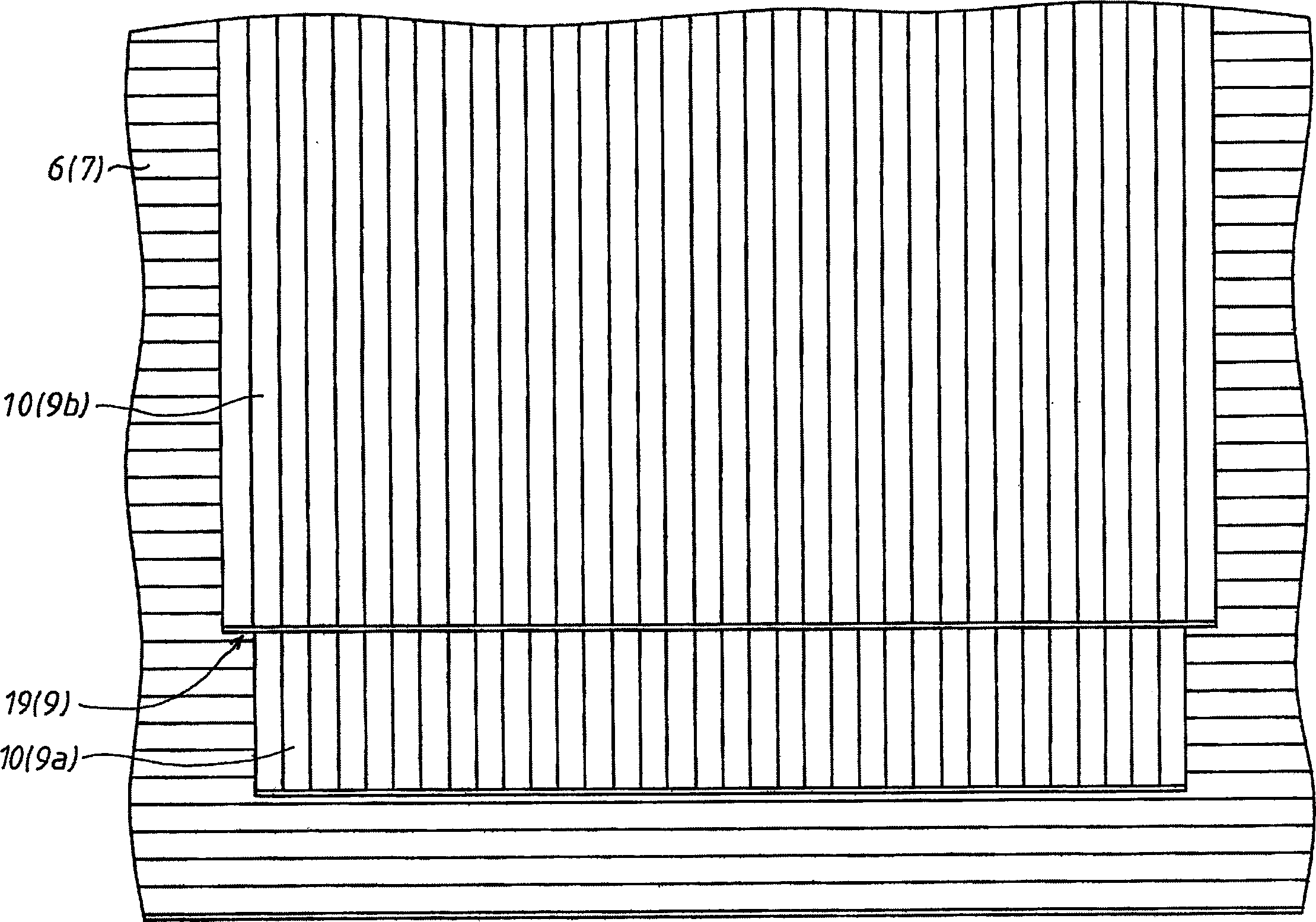

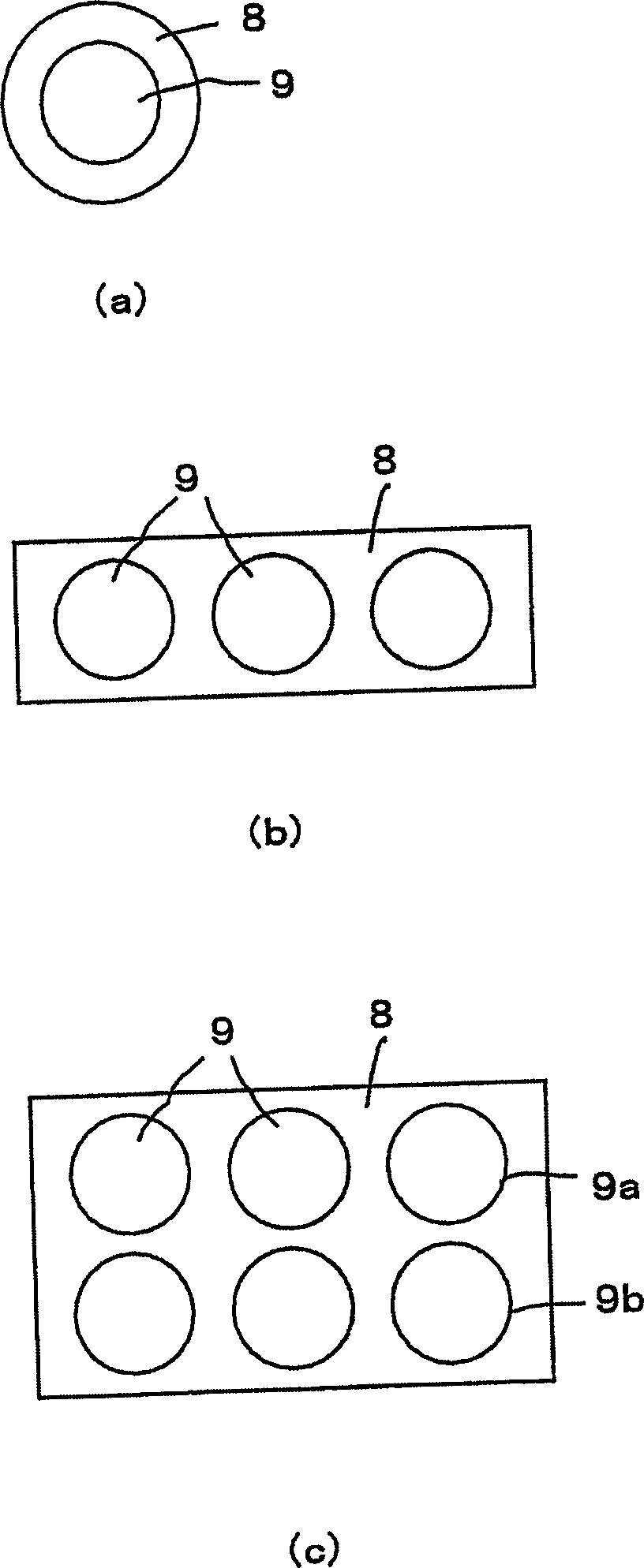

The invention relates to a bi-motor yarn tension control device of a disposable warping machine, which is characterized in that a driving shaft (2) and a wrapping roller (6) are respectively driven by a motor; a three-roller delivery device is arranged above the front of the driving shaft (2), two ends of the wrapping roller (6) in the three rollers are respectively arranged in bearing blocks on a wallboard (29), and an upper pressing roller (7) and a side pressing roller (10) in the three rollers can be pressed or loosened on the periphery of the wrapping roller (6). The invention respectively controls the winding of the driving shaft and the yarn delivery of the three-roller delivery device through two motors because of controlling the yarn tension at a machine head, and the driving shaft controls the winding moment through the regulation of a transducer by utilizing the moment control principle so as to lead the driving shaft to realize the constant tension winding; and a three-roller drive motor realizes constant yarn winding speed through the regulation of the transducer by utilizing the speed control principle. The cooperation of the two control methods of the two motors accurately controls the yarn tension.

Owner:射阳东翔纺织机械有限公司

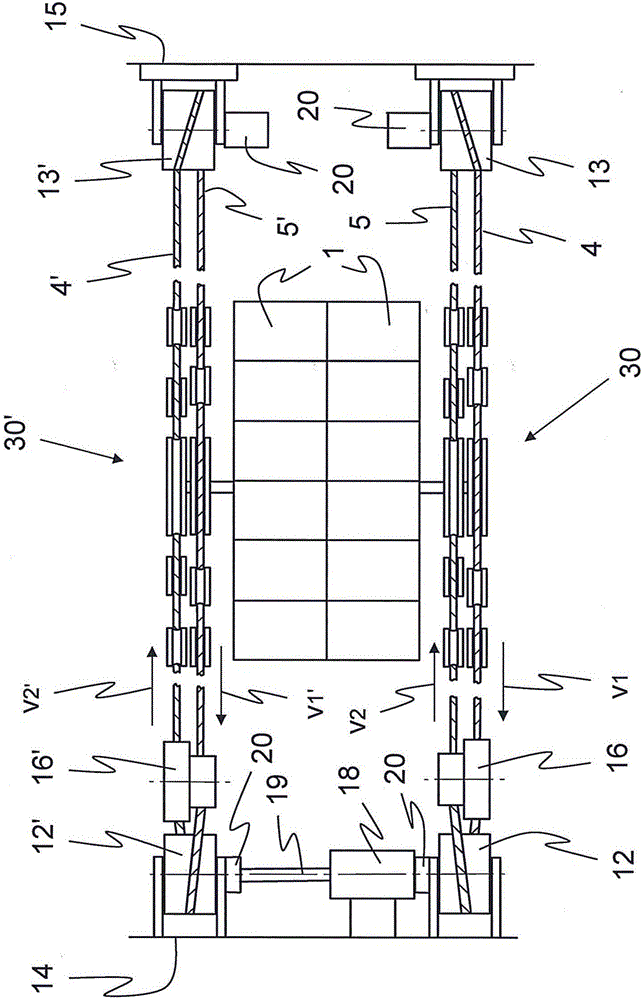

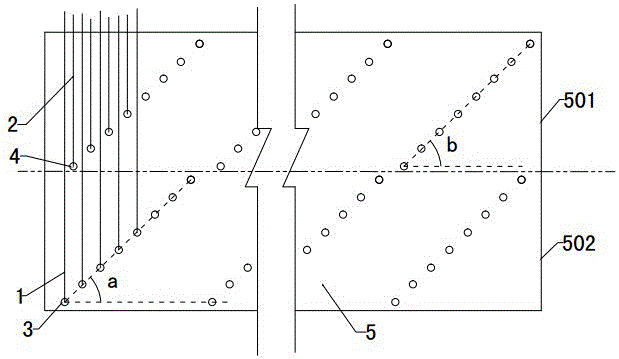

Electrodeless car unit chain multi-point driving belt type conveyor and chain tensioning method

ActiveCN110239894AReduce maximum tensionIncrease carrying capacityConveyorsCarrying capacitySprocket

The invention discloses an electrodeless car unit chain multi-point driving belt type conveyor and a chain tensioning method. The conveyor comprises a bearing machine frame, a machine head driving device, a multi-point driving transmission mechanism and a bearing rail used for bearing the operation of the multi-point driving transmission mechanism; the bearing rail, the machine head driving device and the multi-point driving transmission mechanism are arranged on the bearing machine frame; a conveyor belt of the conveyor is driven by an electrodeless closed annular car unit chain; and the car unit chain is driven by a multi-point chain wheel, so that the maximum tension of the chain is reduced, and the tension of each chain segment of the car unit chain is ensured by adopting a segmented tensioning mode. The maximum tension of the chain is effectively reduced by the drive of the multi-point chain wheel, so that the stress of the machine frame during turning is improved, the carrying capacity of the chain and the conveying distance of the conveyor are improved, and the method is suitable for the development direction of large transport capacity and long transport distance of the conveyor; and the segmented tensioning method is adopted, so that the required tension of the car unit chain can be obtained, the tensioning adjusting amount of a machine tail is small, and the method is suitable for installing, adjusting and testing and maintaining of the long-distance conveyor.

Owner:TAIYUAN UNIV OF TECH

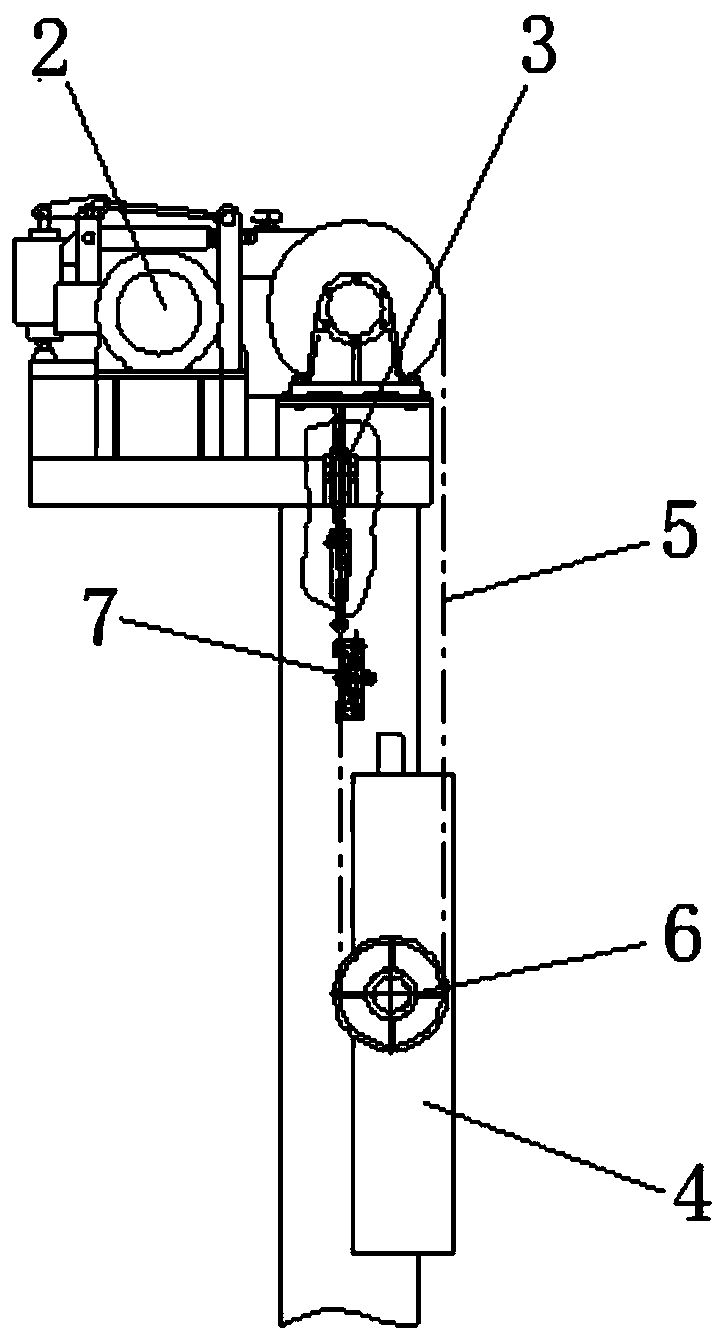

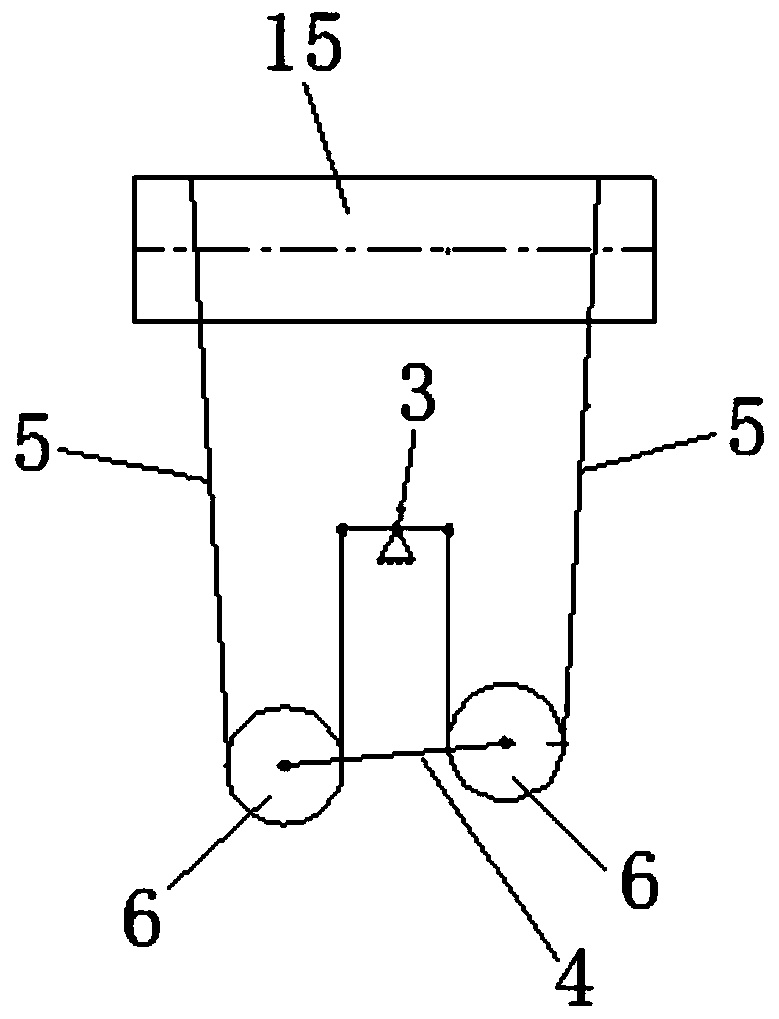

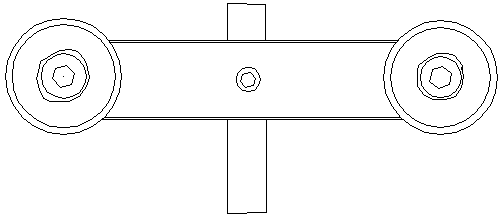

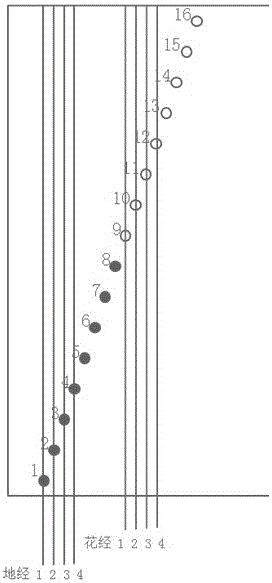

Double-pulley lifting device with balancer and oxygen lance device with balancer

ActiveCN110951936AReduce tension differencesAvoid uneven wearManufacturing convertersControl engineeringWinch

The invention belongs to the field of lifting equipment, and relates to a double-pulley lifting device with a balancer. The double-pulley lifting device comprises a winch, a balancing pole, a liftingtrolley and two traction ropes, wherein the winch is fixedly arranged on a rigid support, and the midpoint of the balancing pole is rotatably arranged on the rigid support; the lifting trolley is provided with double pulleys, the two pulleys are arranged on the two corresponding sides of the lifting trolley respectively, and the two traction ropes are connected with the two ends of the balancing pole after being wound across the two pulleys. The invention further relates to a double-pulley lifting oxygen lance device with a balancer. The double-pulley lifting oxygen lance device with the balancer comprises a winch platform and an oxygen lance, and further comprises the double-pulley lifting device with the balancer. The balancing pole can automatically and sensitively reduce the tension difference value between the two traction ropes in the double-pulley lifting device in the working process, traction rope uneven abrasion caused by the excessive tension difference value of the tractionropes is prevented, the service life of equipment is prolonged, maintenance frequency is reduced, and the production efficiency is improved.

Owner:CISDI ENG CO LTD

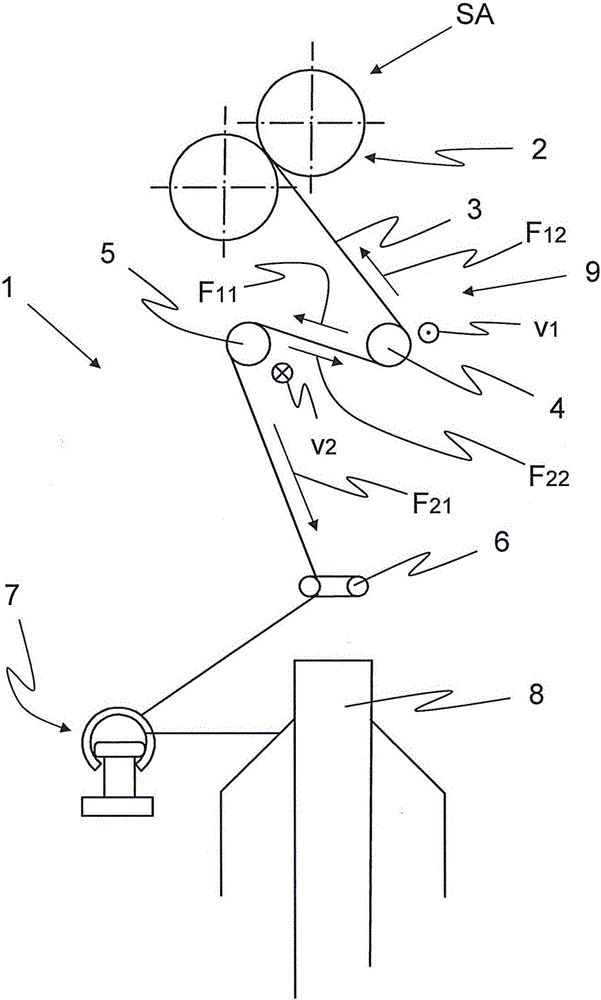

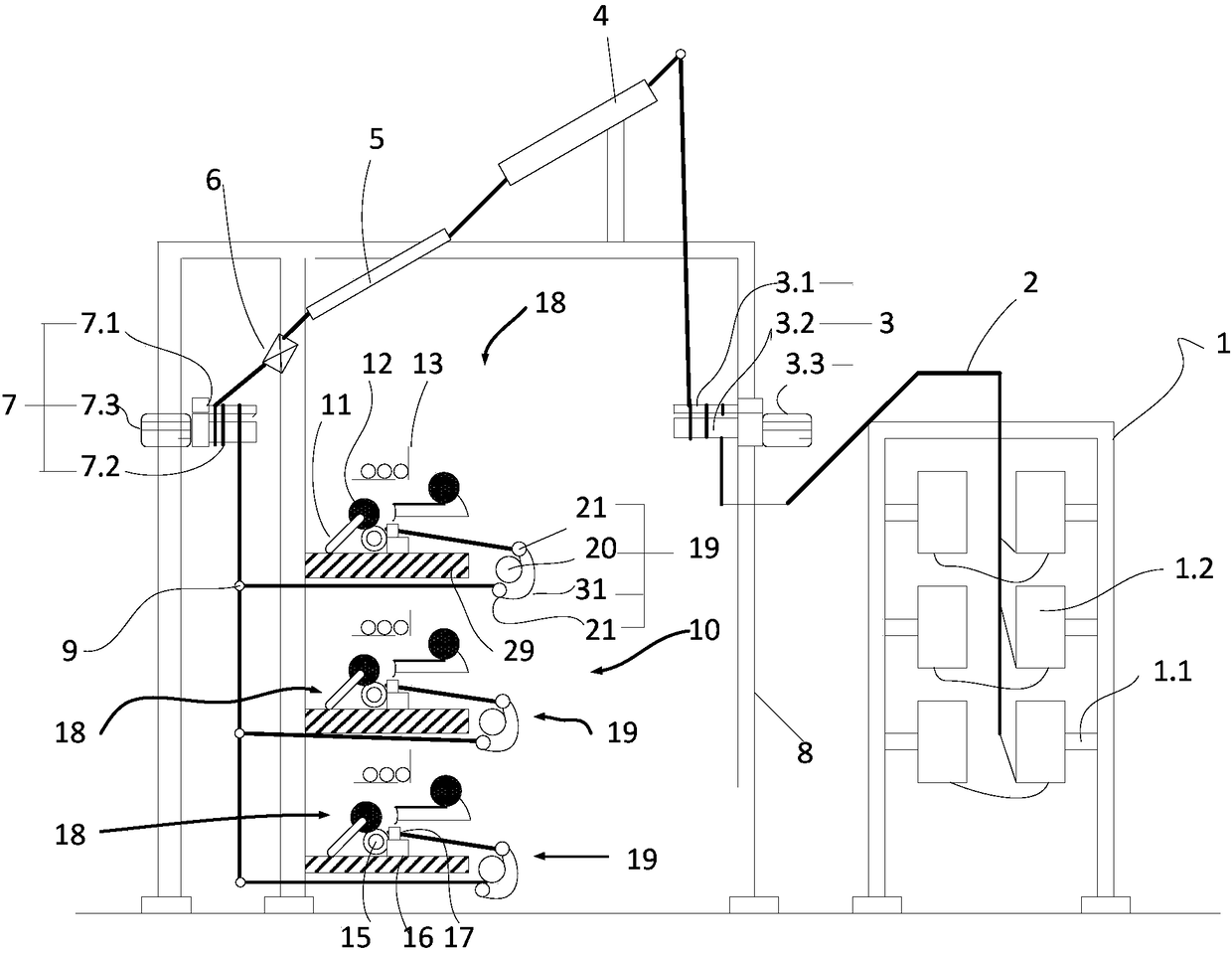

Spinning machine and false twist unit

InactiveCN106835400AReduce tension differenceTo achieve different adjustmentsTextiles and paperEngineeringFiber

A spinning machine, in particular a ring-spindle spinning machine is provided with a plurality of units (1) arranged side by side. Each unit (1) is provided with a traction mechanism moving a fiber belt, a spinning device twisting the moving fiber belts into a twine (3), and a false twist unit (9) arranged between the traction mechanism and the spinning device; the false twisting device (9) is provided with at least one belt (11) driven by a driving device; the belt basically extends along the twine (3) in a transverse direction; the twine (3) particularly winds two return sections (4,5) opposite to each other of the belt (11) in a Z shape or an S shape; and the at least one belt (11) extends between the at least one driving device and the steering device along a plurality of units (1) of a spinning machine (10). According to the invention, at least one assisting device (30) is arranged between the at least one driving device and the steering device to cooperatively guide and / or drive the at least one belt (11).

Owner:MASCHINENFABRIK RIETER AG

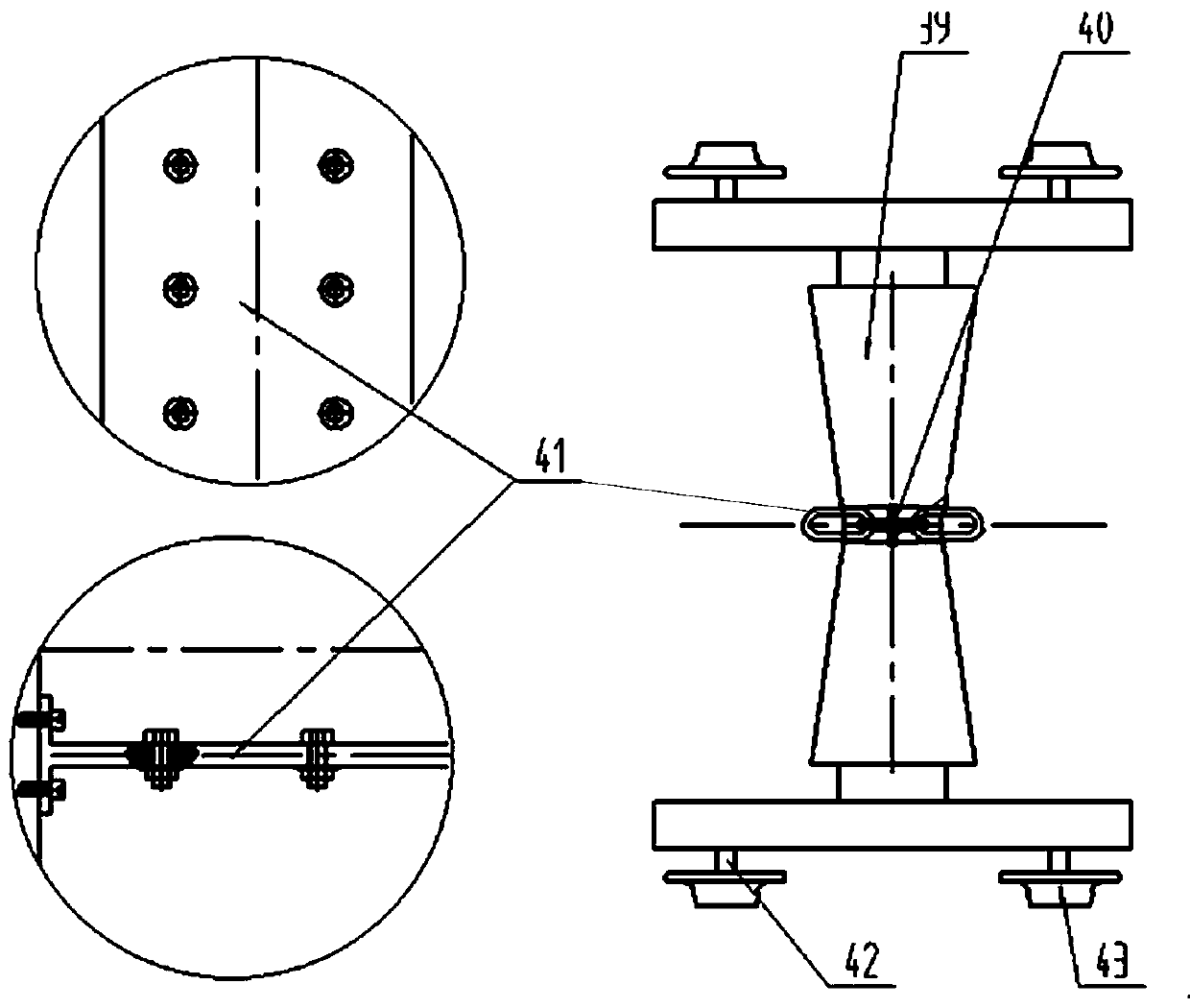

isochronous transfer structure

ActiveCN103910254BReduce tension differencesNot easy to jumpArticle feedersArticle deliveryDrive wheelTransmission belt

A synchronous conveying structure comprises a driven shaft, a first transmission wheel, a second transmission wheel, two transmission belts, a conveying seat, a retaining piece and a retaining ring, wherein the first transmission wheel and the second transmission wheel sleeve the driven shaft at interval, the second transmission wheel fixedly sleeves the driven shaft, and the first transmission wheel rotatably sleeves the driven shaft; the conveying seat is provided with at least two conveying units at interval and in parallel; the driven shaft is arranged on the conveying seat at interval; the retaining piece and the retaining ring are mounted on the driven shaft and abuts against both sides of the first transmission wheel to clamp the first driven wheel, so that the axial position of the first transmission wheel relative to the driven shaft can maintain constant; one sides of the transmission belts are accommodated inside the corresponding conveying units to form a conveying passage between the conveying units and the transmission belts. According to the synchronous conveying structure, the two transmission belts can maintain the relative identity in position relatively easily, have small tension difference and avoid fluctuation. Meanwhile, the synchronous conveying structure is simpler in structure.

Owner:SHENZHEN YIHUA COMP +2

False twisting machine with winding equipment

ActiveCN108657869AConsistency of hardnessReduce tension differencesFilament handlingTextiles and paperYarnBobbin

The invention discloses a false twisting machine with winding equipment. The winding equipment is provided with a plurality of winding devices, wherein the winding devices are distributed in a plurality of layers in the longitudinal direction and sequentially distributed side by side in the transverse direction; each winding device comprises a cradle, a friction roller and a transverse yarn guiding device, the cradle is used for clamping a winding bobbin and can be rotated, the friction roller can be driven to rotate and can make contact with the winding bobbin during winding, and the transverse yarn guiding device is provided with a yarn guiding machine which can be used for guiding the yarn to move transversely; each winding device is provided with an inlet side for receiving the yarn, each winding device is provided with a conveying device which is arranged on the upstream side of the yarn guiding machine in the advancing direction of the yarn so that the speed of the yarn can be controlled, and the conveying devices are arranged in a multi-layer mode. According to the arrangement of the false twisting machine, the consistency of the hardness of the winding bobbin can be improved.

Owner:OERLIKON TEXTILE GMBH & CO KG

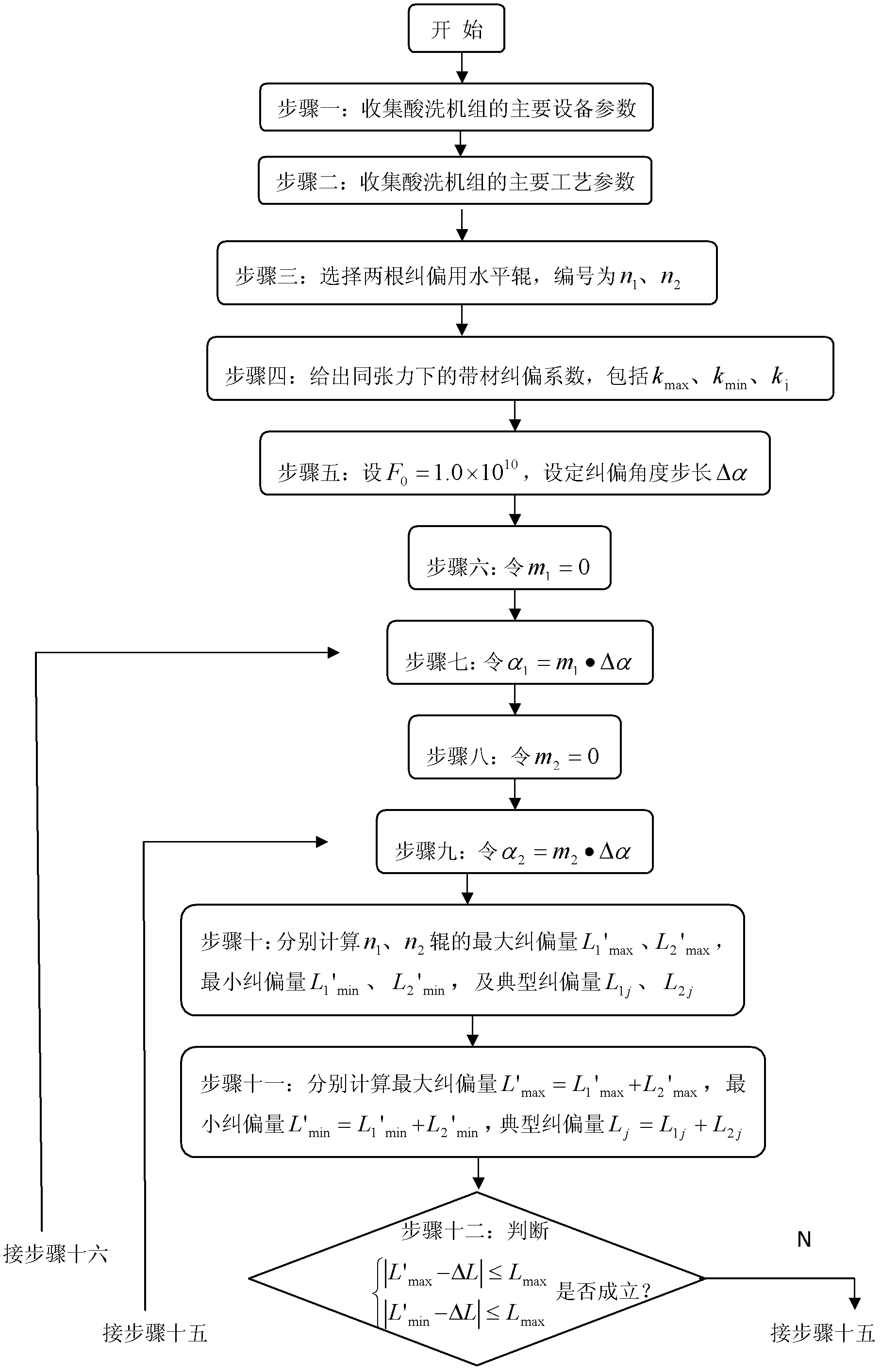

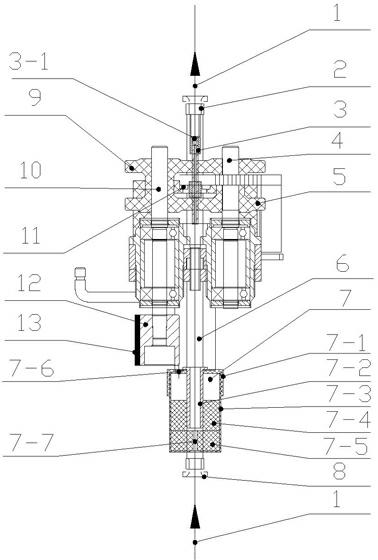

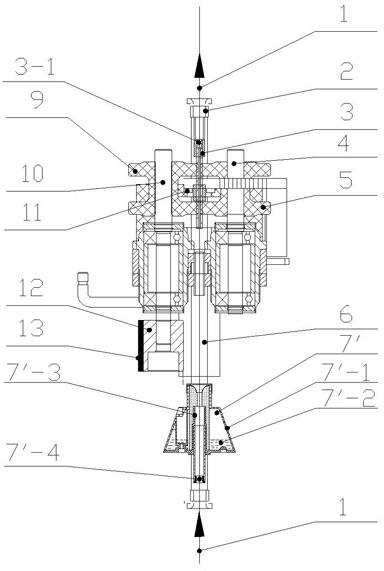

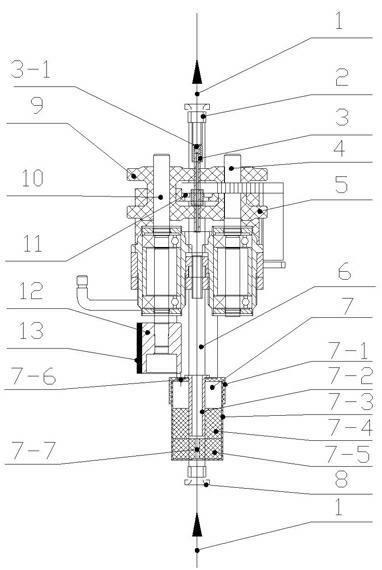

Strip deviation correction control method for cold rolling pickling unit

ActiveCN103203373AReduce tension differencesReduce incidenceWork treatment devicesRoll mill control devicesGeneration rateEngineering

The invention relates to a strip deviation correction control method for a cold rolling pickling unit, which is characterized in that operation of optimally setting the horizontal deviation of relevant rollers in a pickling section is taken as a basis, the minimal deviation of a strip in front of a circle shear is used as a target, and the horizontal deviation of a special roller in the pickling section is quantitatively and precisely set, so the deviation of the steel strip caused by the installation error of equipment can be effectively compensated, the tension difference at two sides of the circle shear can be reduced, the burr generation rate can be reduced, and the quality of a finished product steel strip can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Method and device for lubricating false-twisted yarns with oil

The invention discloses a method and device for lubricating false-twisted yarns with oil, belonging to the textile technical field. The device is characterized by comprising an oil feeder, wherein the oil feeder is installed below a false twister and is used for lubricating false-twisted yarns with oil before the false-twisted yarns enter into a false-twist rotor. After being lubricated by the device with oil, the false-twisted yarns enter into the false-twist rotor to be false-twisted. The friction of the false-twisted yarns is reduced in the false-twist process so as to achieve uniform and full false twist degree of the false-twisted yarns and effectively reduce the end breakage rate in the yarn false-twist process. The invention provides a new method and process device for production of the false-twisted yarns.

Owner:绍兴华裕纺机有限公司

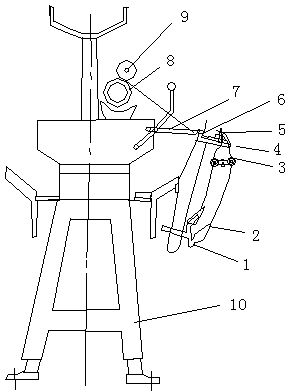

Reversely-rotating pre-filament-separation system device for mother filaments

InactiveCN105386186AReduce end break rateReduce tension differencesTextiles and paperEngineeringMechanical engineering

The invention belongs to the technical field of FDY mother filament tools and particularly relates to a reversely-rotating pre-filament-separation system device for mother filaments. The reversely-rotating pre-filament-separation system device for the mother filaments comprises an FDY mother filament frame, filament guiding hooks and monofilament cakes, a lower filament guiding rod and an upper filament guiding rod are arranged above the FDY mother filament frame, thereby the mother filaments can be naturally dispersed and arranged on a reversely-rotating godet wheel side by side, monofilaments are separated naturally when the mother filaments leave the reversely-rotating godet wheel, and filament separating points are fixed to points, from which the mother filaments leave, of the reversely-rotating godet wheel. The reversely-rotating pre-filament-separation system device has the advantages that the filament separating point positions are fixed, so that tension tightness is avoided; the filament separating point positions are raised, so that tension differences among all spindles are decreased; in the FDY mother filament separating process, tension is maintained stable, monofilament rupture is avoided, and the monofilaments are maintained being shaped up in a good condition.

Owner:ZHEJIANG WELONG NEW MATERIAL

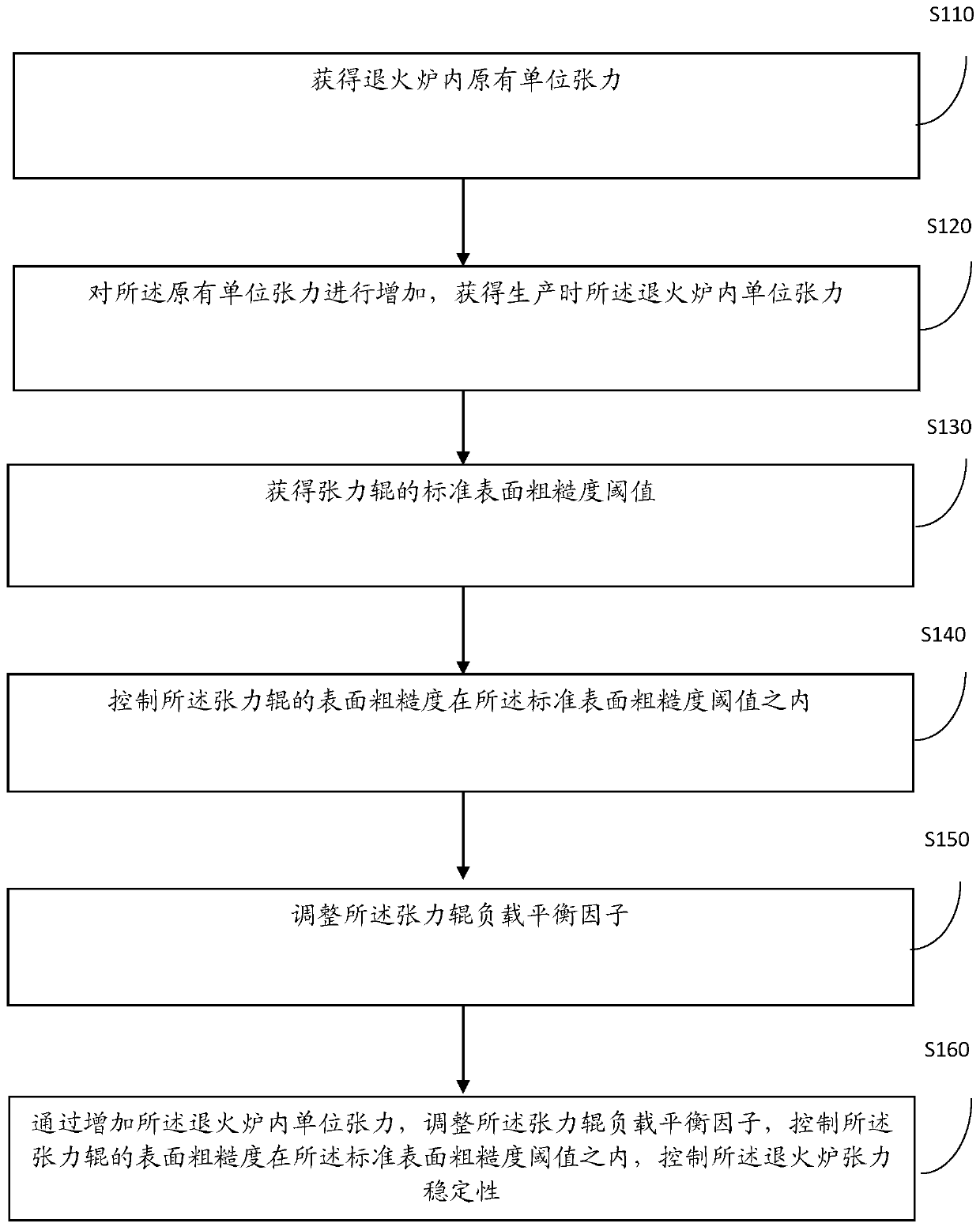

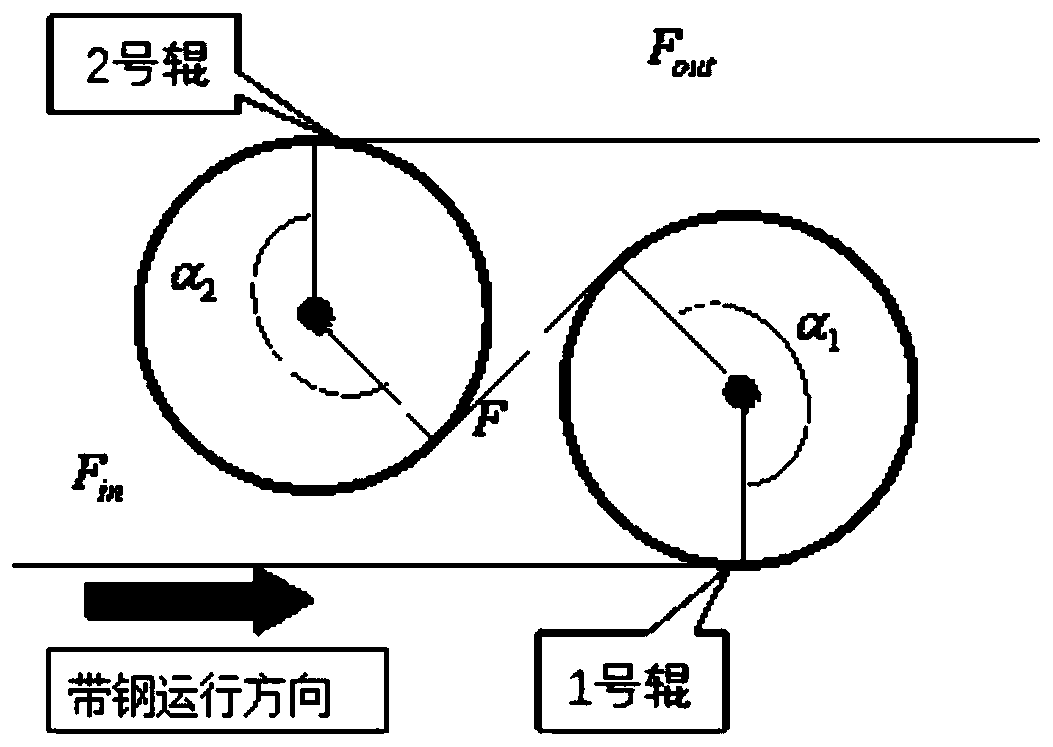

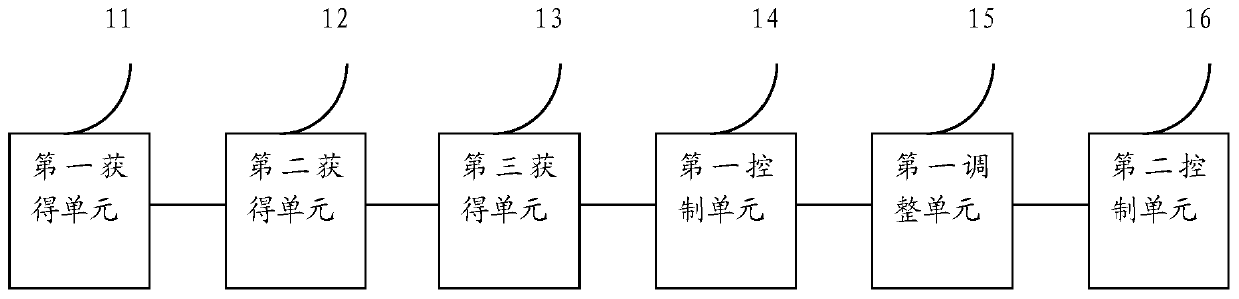

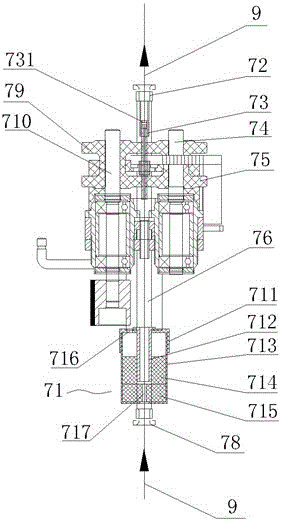

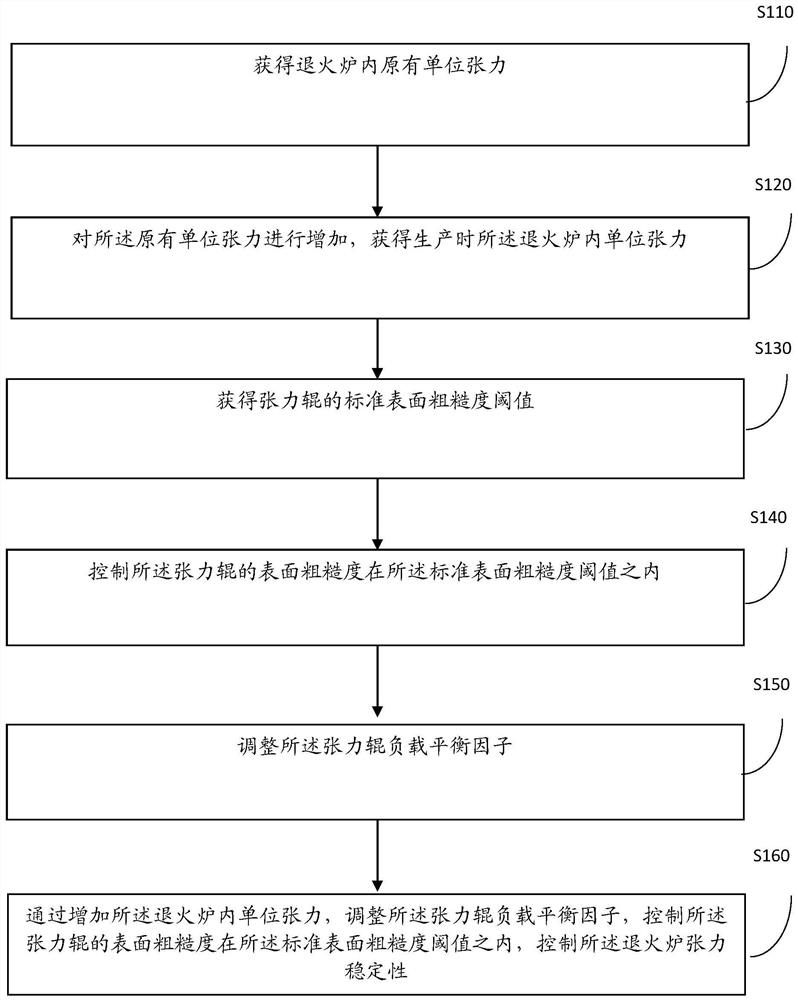

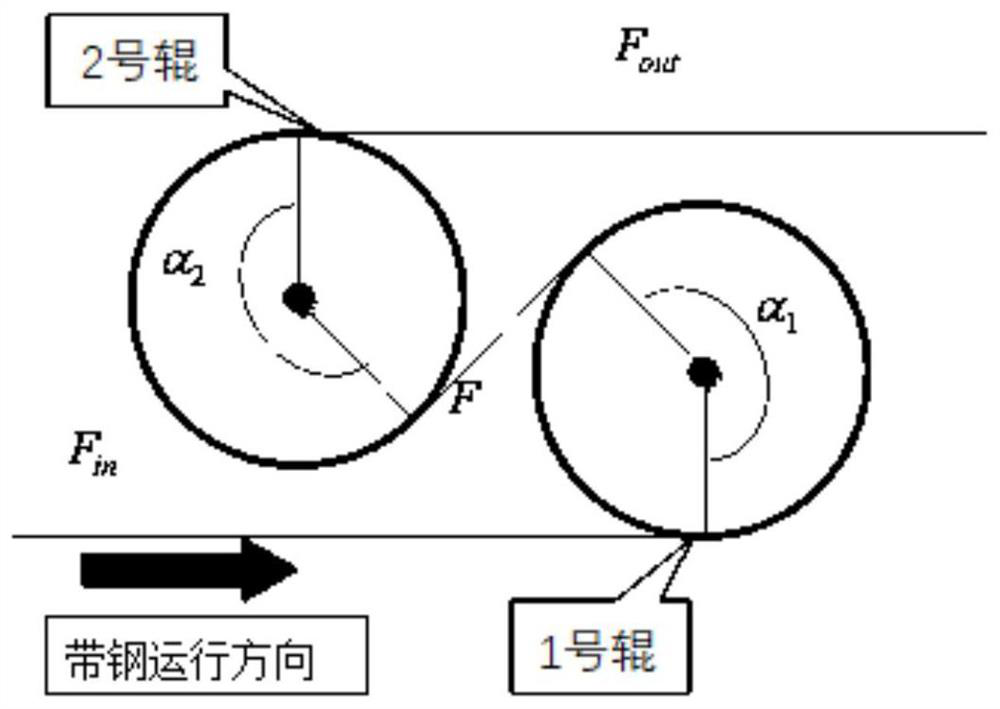

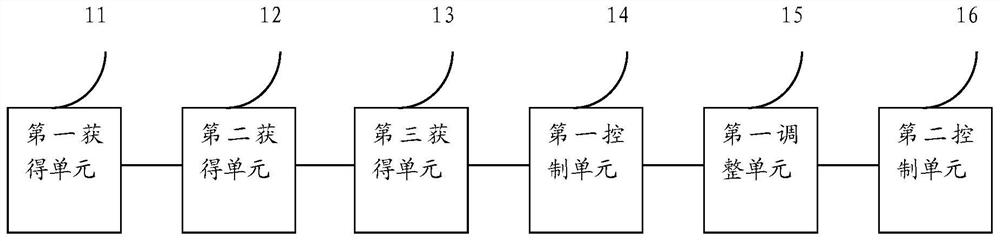

Method and device for improving tension control stability of annealing furnace

ActiveCN110129545AImprove stabilityImprove balanceFurnace typesHeat treatment furnacesSurface roughnessStrip steel

The invention provides a method and device for improving tension control stability of an annealing furnace. By increasing the original unit tension, the unit tension of the interior of the annealing furnace during production is obtained; the standard surface roughness threshold value of a tension roller is obtained; the surface roughness of the tension roller is controlled to be within the standard surface roughness threshold value; a tension roller load balancing factor is adjusted; and by increasing the unit tension of the interior of the annealing furnace, the tension roller load balancingfactor is adjusted, the surface roughness of the tension roller is controlled to be within the standard surface roughness threshold value, and the tension stability of the annealing furnace is controlled. The technical problem that in the prior art, a tension roller cannot provide the sufficient balance force, and thus, stable operation of strip steel cannot be ensured is solved. The technical effects that control over the tension of the annealing furnace is achieved, the tension balancing capacity of the tension roller is improved, it is ensured that the tension roller can provide enough balance force, the risk of slipping of the tension roller is avoided, the control stability of tension of the interior of the annealing furnace is greatly improved compared with the original design, and the production requirements are completely met are achieved.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

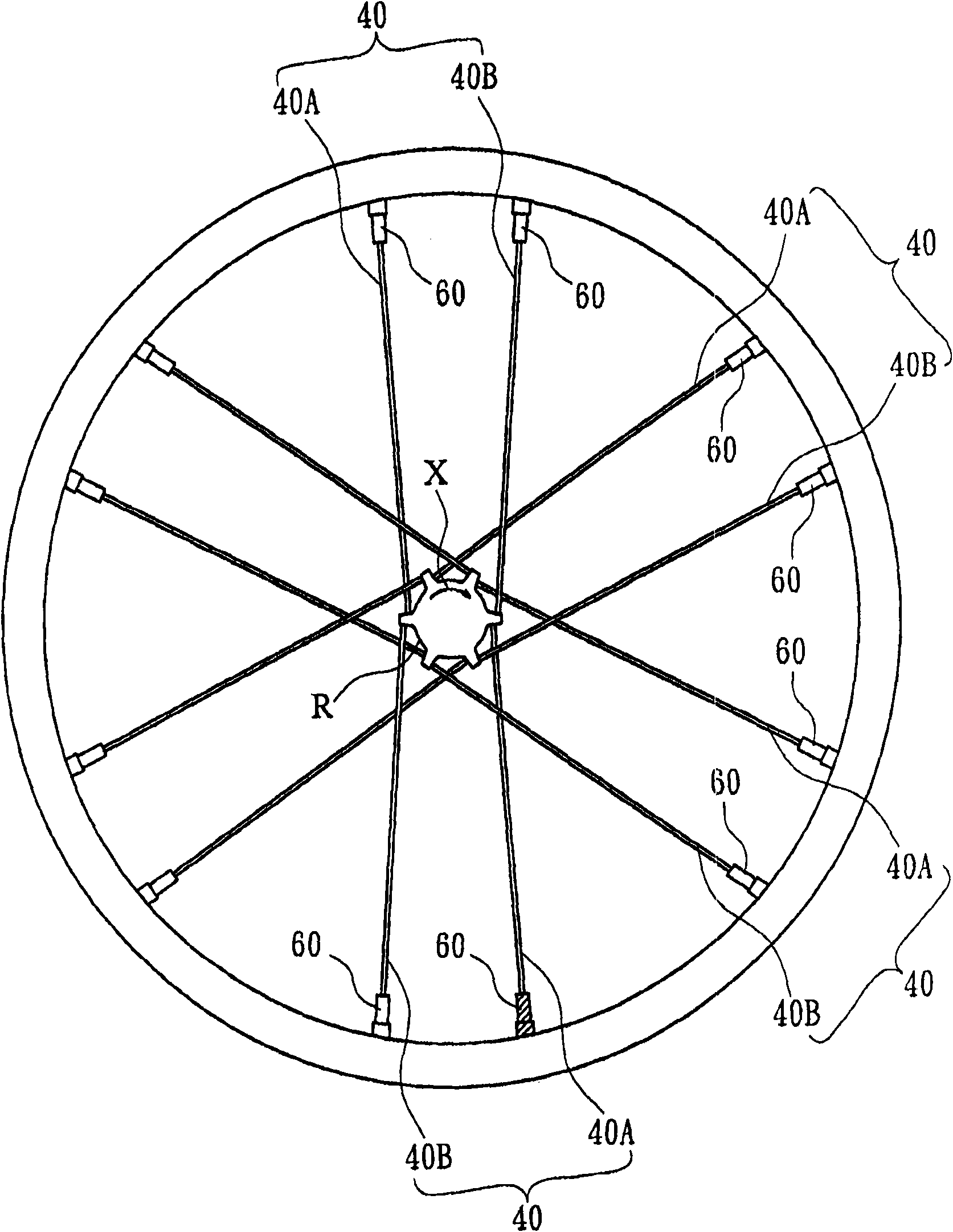

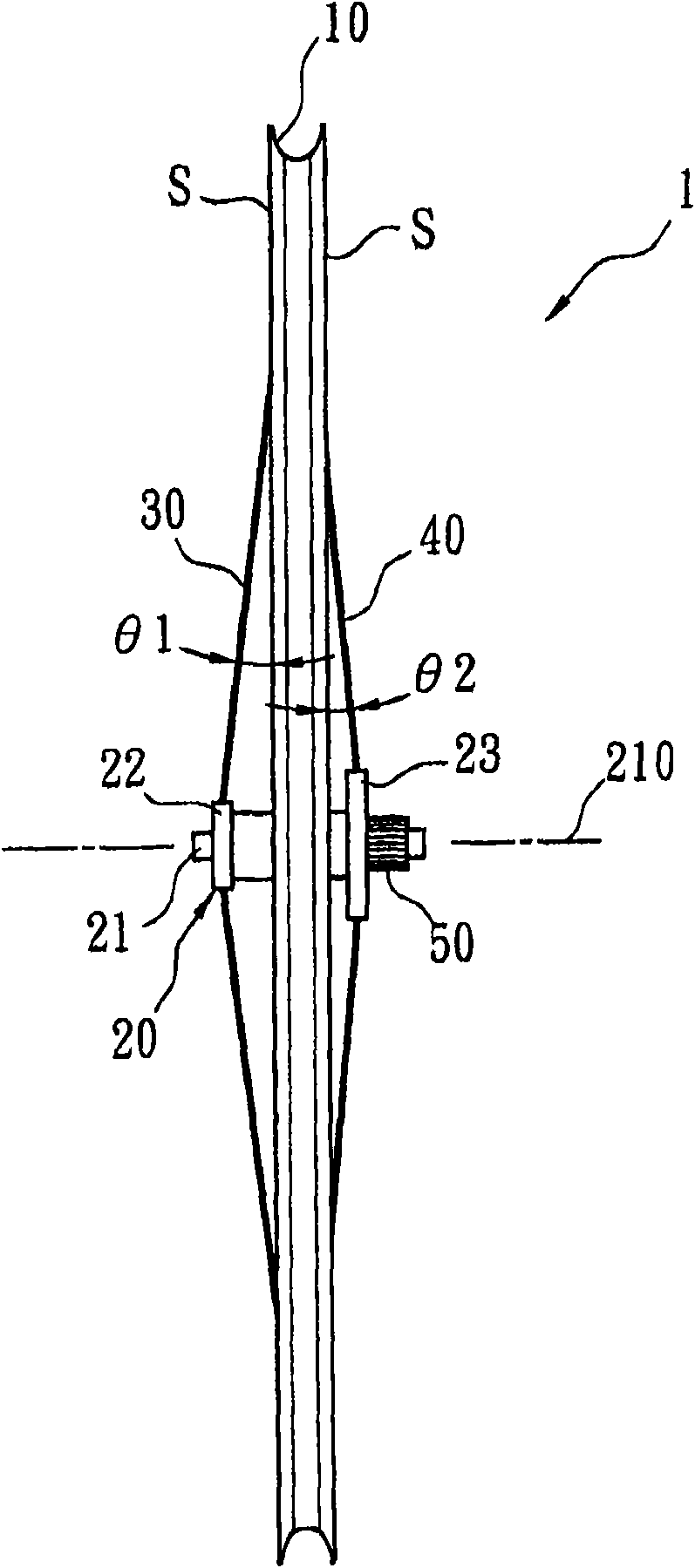

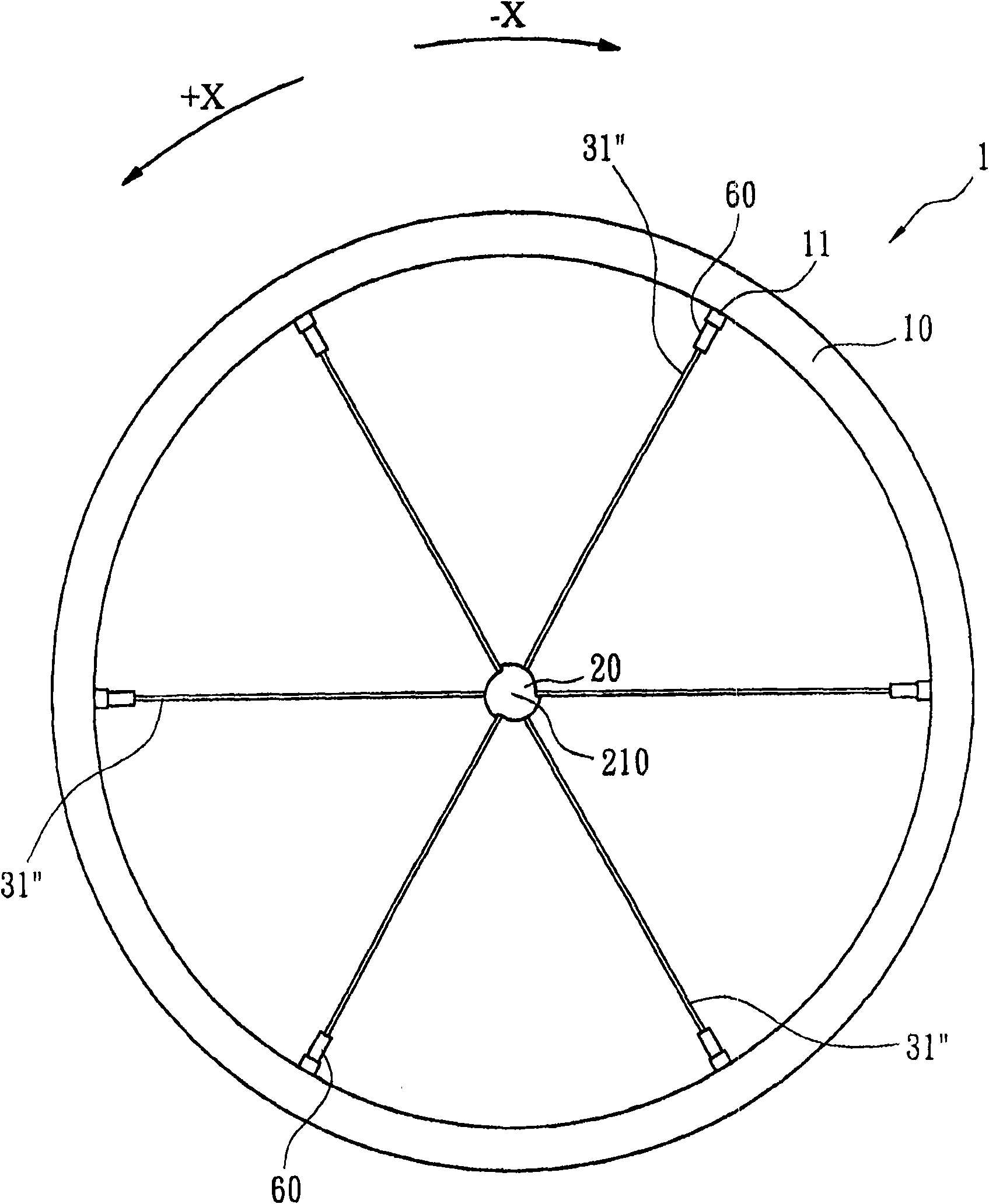

Rear wheel spoke rim for bicycle

ActiveCN101659178AImprove rigidityReduce stretch deformationRimsSpoked wheelsEngineeringMechanical engineering

The invention provides a rear wheel spoke rim for a bicycle, which can enhance the rigidity of the rim in the state that the weight increase of a spoke is inhibited as much as possible. The rear wheelspoke rim comprises a rim, a hub, a first spoke group and a second spoke group, wherein the hub is provided with a hub shaft, first spoke connecting parts and second spoke connecting parts alternately formed with the first spoke connecting parts; the first spoke group is used for connecting the rim and the first spoke connecting parts; the second spoke group is used for connecting the rim and thesecond spoke connecting parts; the first spoke group is provided with a second sectional area spoke and a first sectional area spoke; the second sectional area spoke comprises a rim side end, a hub side end and a second central part; the rim side end is connected to the rim, the hub side end is connected to the first spoke connecting parts, and the second central part is connected to the two endsand comprises a first central part with a first sectional area which is larger than the second sectional area.

Owner:SHIMANO INC

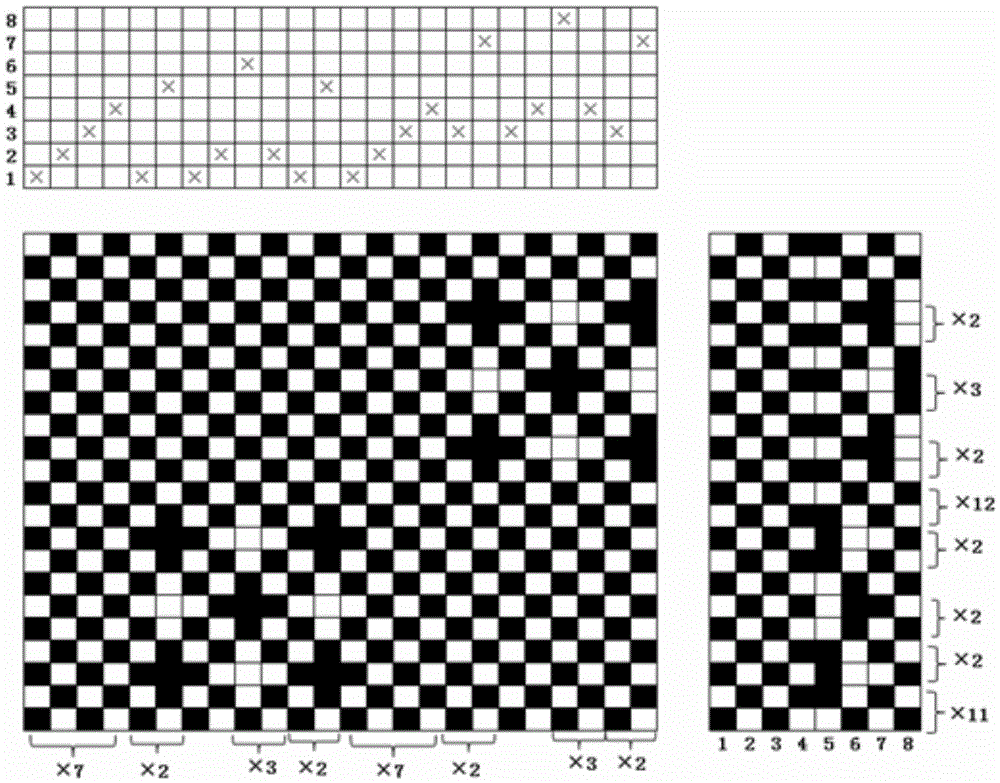

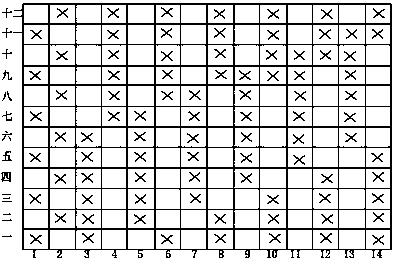

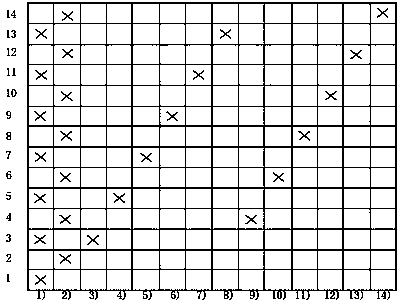

Technical method for eliminating defects of sparse and dense ways of textile temple

ActiveCN109137221AReduce tension differencesIncrease heightJacquardsAuxillary apparatusComputer scienceWoven fabric

The invention, which belongs to the technical field of weaving of twill-weaving textiles, relates to a technical method for eliminating defects of sparse and dense ways of a textile temple. When 6 / 6 twill-weaving fabric is woven, a used heald frame includes 14 pages of heald frame units and has 12 fells during the movement of the heald frame. The method is characterized in that the lifting rule ofheald pieces is as follows: every two heald pieces carry out heald lifting in an up-down manner. According to the invention, on the basis of improvement of the pattern card map and the heald threading map, the every two heald pieces carry out heald lifting in an up-down manner based on a flying threading method, so that a phenomenon that the front and rear heald frames ascend or descend simultaneously is avoided. Gaps of wefts at the two sides of the cloth surface are eliminated and the defects of sparse and dense ways are reduced, so that the product quality is improved.

Owner:山东兴国大成电子材料有限公司

One-step-method yarn doubling winder

The invention provides a one-step-method yarn doubling winder and belongs to the technical field of textile machinery. The one-step-method yarn doubling winder comprises a machine rack and a plurality of groups of yarn doubling winding mechanisms arranged on the machine rack, wherein each yarn doubling winding mechanism comprises a yarn inserting device, a yarn guiding device and a winding device which are arranged on the machine rack from bottom to top, the yarn inserting device is a novel yarn inserting spindle provided with two or more spindle bodies, the yarn guiding device is composed of a spindle split type disc spring tensioner, an S-shaped yarn guiding plate, a disc tensioner, an electronic yarn clearer and a yarn detecting rod which are arranged on the machine rack, and the winding device comprises a fixing rack and a main motor which are arranged on the machine rack. A groove drum shaft and groove drum are installed on the fixing rack and are set to be parallel in a winding mode, and the groove drum shaft is connected with and driven by the main motor by using a triangle belt. The one-step-method yarn doubling winder is simple and reasonable in structure and convenient to use. Two or more bobbin yarns can be simultaneously placed, yarns can be manufactured through multiple-bobbin combination and directly used for a twisting machine and are little in hairiness, the power consumption and labor cost can be reduced by 50%, the production efficiency is remarkably improved, and the one-step-method yarn doubling winder has good comprehensive economic benefit.

Owner:YIZHENG KING FALCON TEXTILE

Partition comber board for jacquard weaving and mounting method

Owner:ZIBO YINSHILAI TEXTILE

Setting machine with yarn dividing and false twisting function

The invention discloses a setting machine with a yarn dividing and false twisting function. The setting machine comprises a yarn rack, wherein a degradation bobbin is arranged on the lower part of the yarn rack; a plurality of groups of winding bobbins are arranged on the upper part of the yarn rack. The setting machine is characterized in that a rack is arranged on one side of the yarn rack; a lower transmission mechanism, a biphenyl heat box, a false twister and an upper transmission mechanism are sequentially arranged on the rack from bottom to top; the lower transmission mechanism comprises a lower friction roller arranged on the rack; a lower transmission leather roller group is compressed on the lower friction roller; the upper transmission mechanism is arranged on the upper part of the rack; a tension adjusting device is arranged on the upper transmission mechanism; an oil lubricating device is arranged under the false twister. According to the setting machine capable of dividing and false twisting, through the improvement of the lower transmission part, the biphenyl heat box, the false twister, the upper transmission mechanism and the like, the production efficiency and the product quality are improved, and meanwhile, the production energy consumption is reduced.

Owner:绍兴华裕纺机有限公司

Separable false twist setting machine

The invention discloses a setting machine with a yarn dividing and false twisting function. The setting machine comprises a yarn rack, wherein a degradation bobbin is arranged on the lower part of the yarn rack; a plurality of groups of winding bobbins are arranged on the upper part of the yarn rack. The setting machine is characterized in that a rack is arranged on one side of the yarn rack; a lower transmission mechanism, a biphenyl heat box, a false twister and an upper transmission mechanism are sequentially arranged on the rack from bottom to top; the lower transmission mechanism comprises a lower friction roller arranged on the rack; a lower transmission leather roller group is compressed on the lower friction roller; the upper transmission mechanism is arranged on the upper part of the rack; a tension adjusting device is arranged on the upper transmission mechanism; an oil lubricating device is arranged under the false twister. According to the setting machine capable of dividing and false twisting, through the improvement of the lower transmission part, the biphenyl heat box, the false twister, the upper transmission mechanism and the like, the production efficiency and the product quality are improved, and meanwhile, the production energy consumption is reduced.

Owner:绍兴华裕纺机有限公司

Method and device for improving tension control stability of annealing furnace

ActiveCN110129545BImprove stabilityImprove balanceFurnace typesHeat treatment furnacesSurface roughnessEngineering

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

Cart - Track Conveyor with Integral Connection Reversal

ActiveCN111573177BLow rotational resistanceReduce frictional resistanceMechanical conveyorsDrive wheelTransportation technology

Owner:TAIYUAN UNIV OF TECH

a twisting device

ActiveCN111768923BPrevent slidingReduce tensionApparatus for heat treatmentReduction of cables/conductors sizeWire rodElectric machinery

The invention relates to the technical field of cable processing, in particular to a cable stranding process and a stranding device. The stranding device includes a driving assembly and a stranding assembly. According to the moving direction of the cable, the driving assembly is located at the The moving head end of the cable; the drive assembly includes a support plate, a main drive motor, and a main shaft. It includes a front winch, a back-twist unit, a rear winch and a winch. The middle part of the front winch has a through first connecting hole, and the middle part of the rear winch has a through second connecting hole. The main shaft, the front winch and the rear winch are synchronously driven. The connecting and untwisting unit is arranged between the front winch and the rear winch. The invention is used to solve the problems in the prior art that it is not suitable for the manufacture of cable bundles with many winding wires and that if the tension of a single wire changes during the twisting process, the quality of the twisted cables will be affected.

Owner:青海鑫邦线缆有限公司

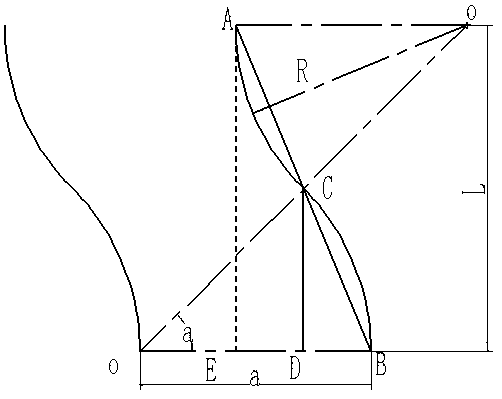

A hoisting wire rope rope tension measuring device

The invention relates to a wrap angle adjustable tension measuring device for a hoisting rope. The wrap angle adjustable tension measuring device comprises a support, wherein a head sheave for a to-be-measured hoisting rope to bypass is arranged at the top of an upright post of the support; a locating seat for being connected with the first end of the to-be-measured hoisting rope is arranged on the support; a hoist drum for applying traction acting force to the second end of the to-be-measured hoisting rope is also arranged on the support; the support is also provided with reverse wheels capable of moving towards the left side and the right side. Actual use conditions of the hoisting rope are simulated by using the hoist drum, the upright post, the head sheave and the locating seat; wrap angles formed by the to-be-measured hoisting rope and two leads of the head sheave can be adjusted by changing the positions of the reverse wheels so as to adapt to different testing conditions; during measurement, the tension of a corresponding rope wire is measured by matching a corresponding grating type optical fiber sensor; key technical parameters such as tension variations of the rope wires under the working condition that all the rope wires of the steel wire rope are bent and tensioned, total tension, friction moment of the hoisting rope and the head sheave and the like are quickly and accurately measured; the wrap angle adjustable tension measuring device has important significance for evaluating service life of the steel wire rope.

Owner:HENAN UNIV OF SCI & TECH

A car group pull type belt conveyor

ActiveCN109230261BReduce energy consumptionLow coefficient of rolling frictionConveyorsFixed bearingAdhesive belt

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com