Method and device for lubricating false-twisted yarns with oil

A false-twisted silk and oil-lubricated technology, used in textiles and papermaking, can solve problems such as high friction, single chemical fiber breakage, single fiber chemical fiber breakage, etc., to improve consistency, prevent fluff or yarn breakage, and improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

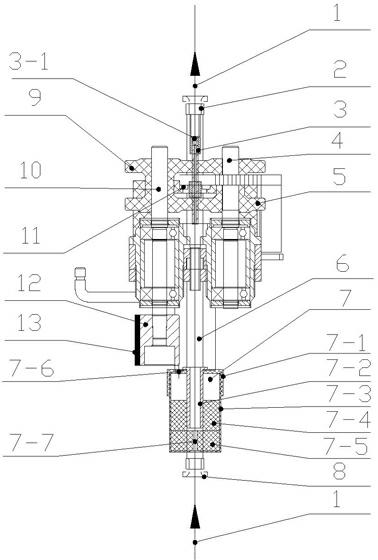

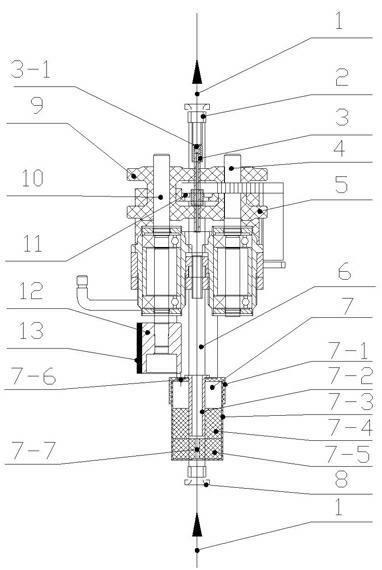

[0024] Such as figure 1 A false twist silk oil lubricating device shown is installed below the false twister. In this embodiment, the oil lubricating device adopts an oiler 7, and the oiler 7 is installed on the lower column 6 of the false twister to be connected with the false twister. into one.

[0025] The false twister includes a yarn guide 2, a false twist rotor 3, a driven shaft 4, a driven wheel 5, a lower column 6, a lower yarn guide 8, a driving wheel 9, and a driving shaft 10, in which: a pulley 12 and a dragon belt 13 linkage connection, driving shaft 10 is linked with pulley 12, driving wheel 9 is linked with driving shaft 10, false twist rotor 3 is adsorbed and positioned between driving wheel 9 and driven wheel 5 by magnet 11, false twist rotor 3 and driving wheel 9 linkage connection, the driven wheel 5 is linked with the false twist rotor 3, the driven wheel 5 is installed on the driven shaft 4, the oiler 7 is installed on the lower column 6, the lower yarn gu...

Embodiment 2

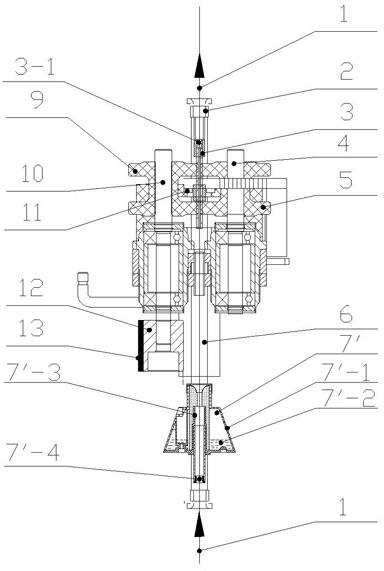

[0029] figure 2 Another embodiment of the present invention is shown, and its oil lubrication structure and method are the same as those in Embodiment 1, the difference is that the oiler 7' having a different structure from the oiler 7 in Embodiment 1 is used, specifically as figure 2 As shown, the oiler 7' is installed on the lower column 6, including a closed oiler housing 7'-1, in which the lubricating oil 7'-2 is filled in the oiler housing 7'-1, and the oil seepage channel 7'-3 is set In the middle of the oiler casing 7'-1, the axis of the oil seepage channel 7'-3 is consistent with the running track of the wire, the ceramic part 7'-4 is arranged below the oil seepage channel 7'-3, and the oil seepage channel 7'-3 '-3 adopts a honeycomb structure, through the honeycomb micropores on the oil seepage channel 7'-3, the lubricating oil 7'-2 in the oiler shell 7'-1 seeps out, so that the oil from the lower wire guide 8 The incoming false twisted yarn 1 enters the oil seepag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com